Cement hydration rate regulating material as well as preparation method and application of cement hydration rate regulating material

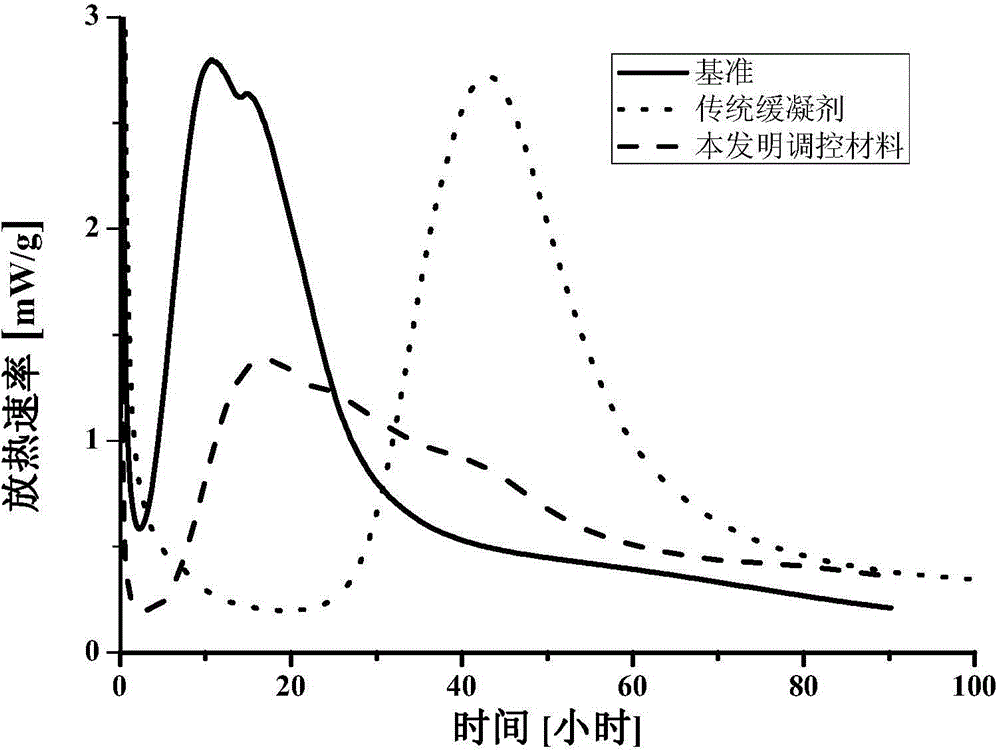

A technology for cement hydration and water-soluble polymer, applied in the field of concrete admixtures, can solve the problems of reduced strength, prolonged setting time, complicated preparation, etc., and achieve the effects of improving regulation performance, reducing hydration rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

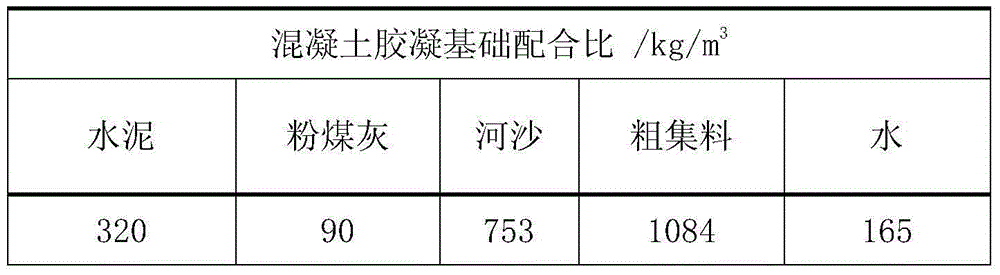

Examples

Embodiment 1

[0031] Add 100g of dextrin with a number average molecular weight of 120000g / mol to 300ml of water, then add 10g of acrylic acid and 0.05g of ammonium cerium nitrate, heat up to 50°C, react for 6h, dry and pulverize to obtain the desired hydration control material.

Embodiment 2

[0033] Add 100g of dextrin with a number average molecular weight of 60000g / mol to 300ml of water, then add 10g of acrylic acid and 0.1g of ammonium cerium nitrate, heat up to 50°C, react for 6h, dry and pulverize to obtain the desired hydration control material.

Embodiment 3

[0035] Add 100g of dextrin with a number average molecular weight of 30000g / mol to 300ml of water, then add 10g of acrylic acid and 0.2g of ammonium cerium nitrate, heat up to 50°C, react for 6h, dry and pulverize to obtain the desired hydration control material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com