Patents

Literature

64 results about "Hydration control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

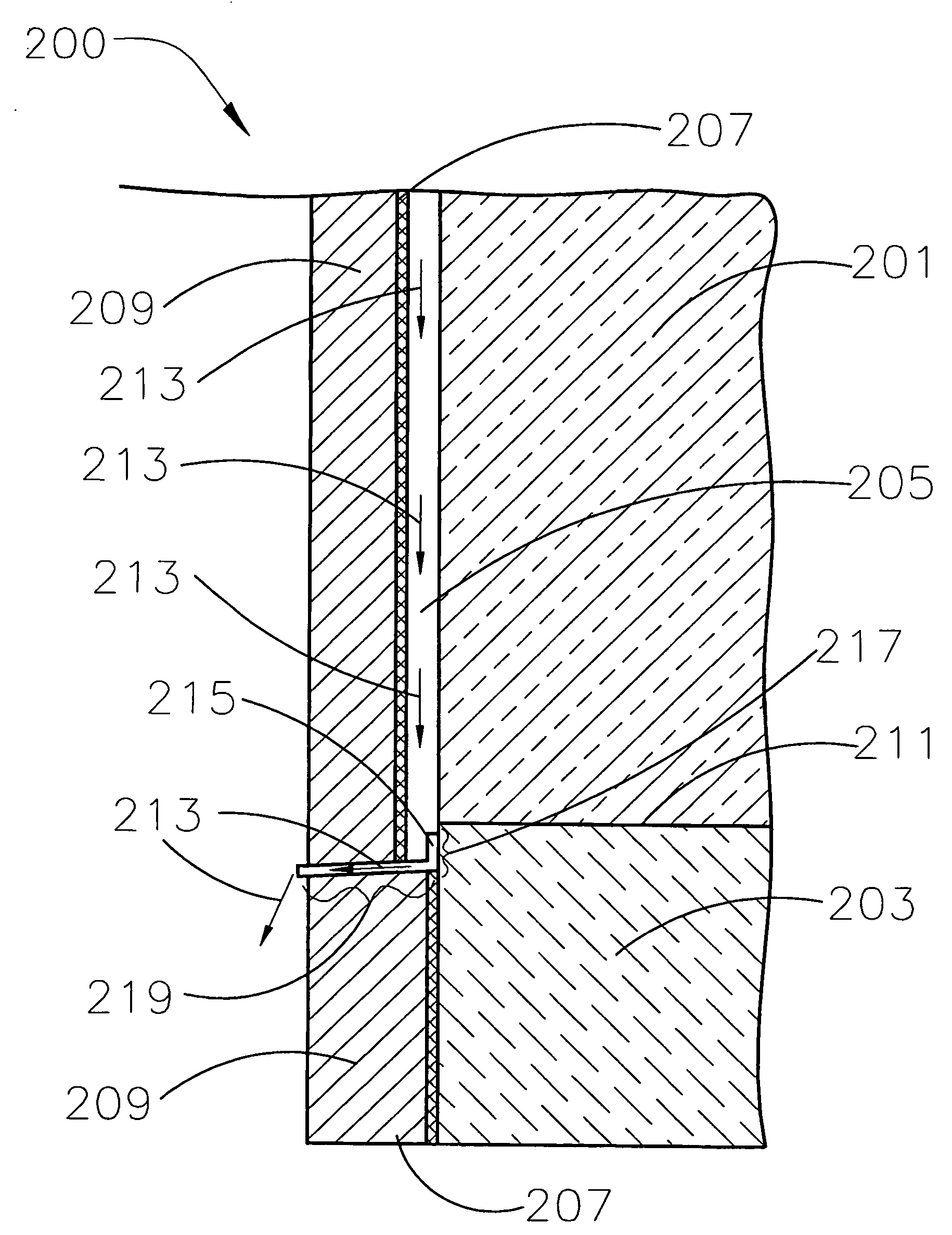

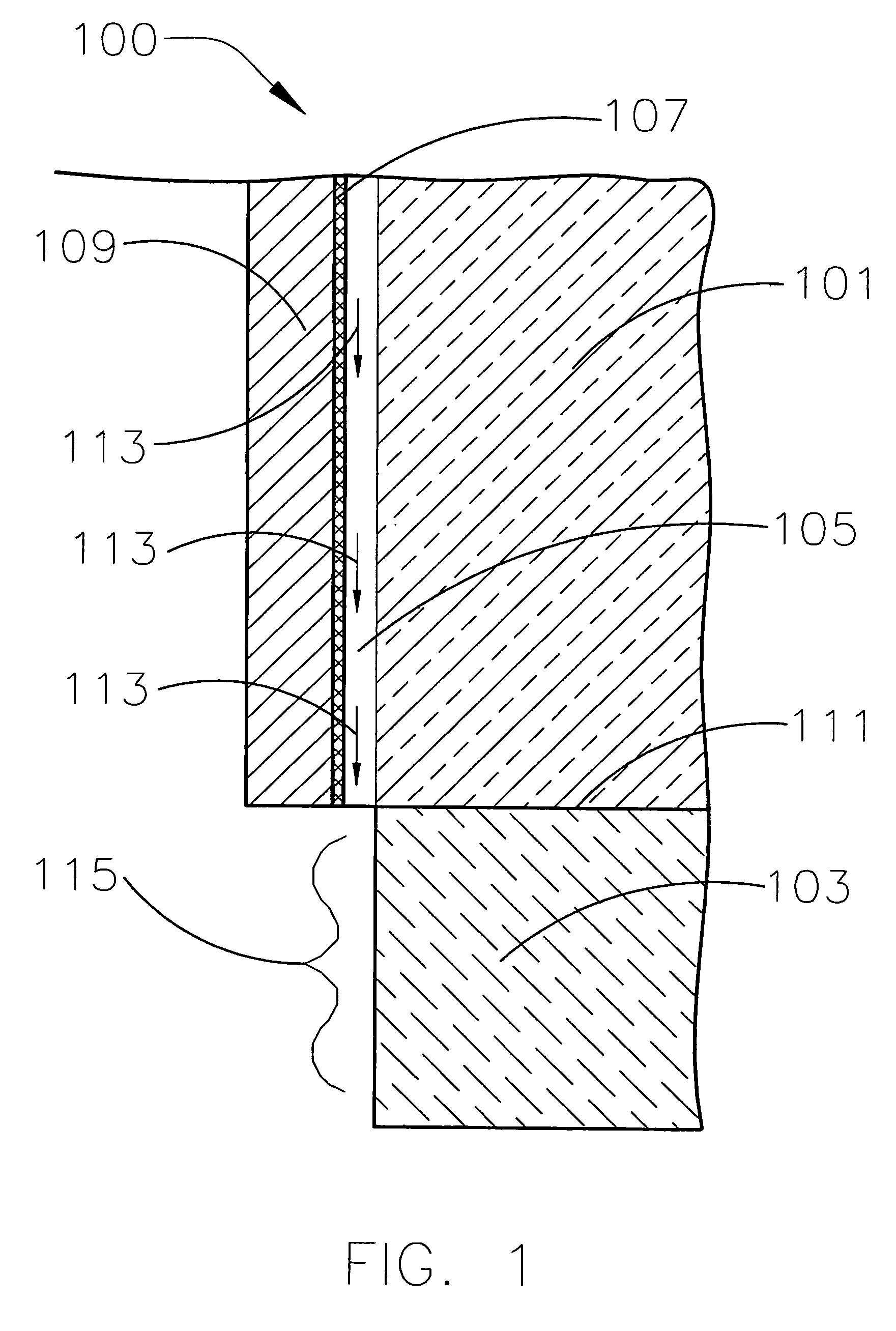

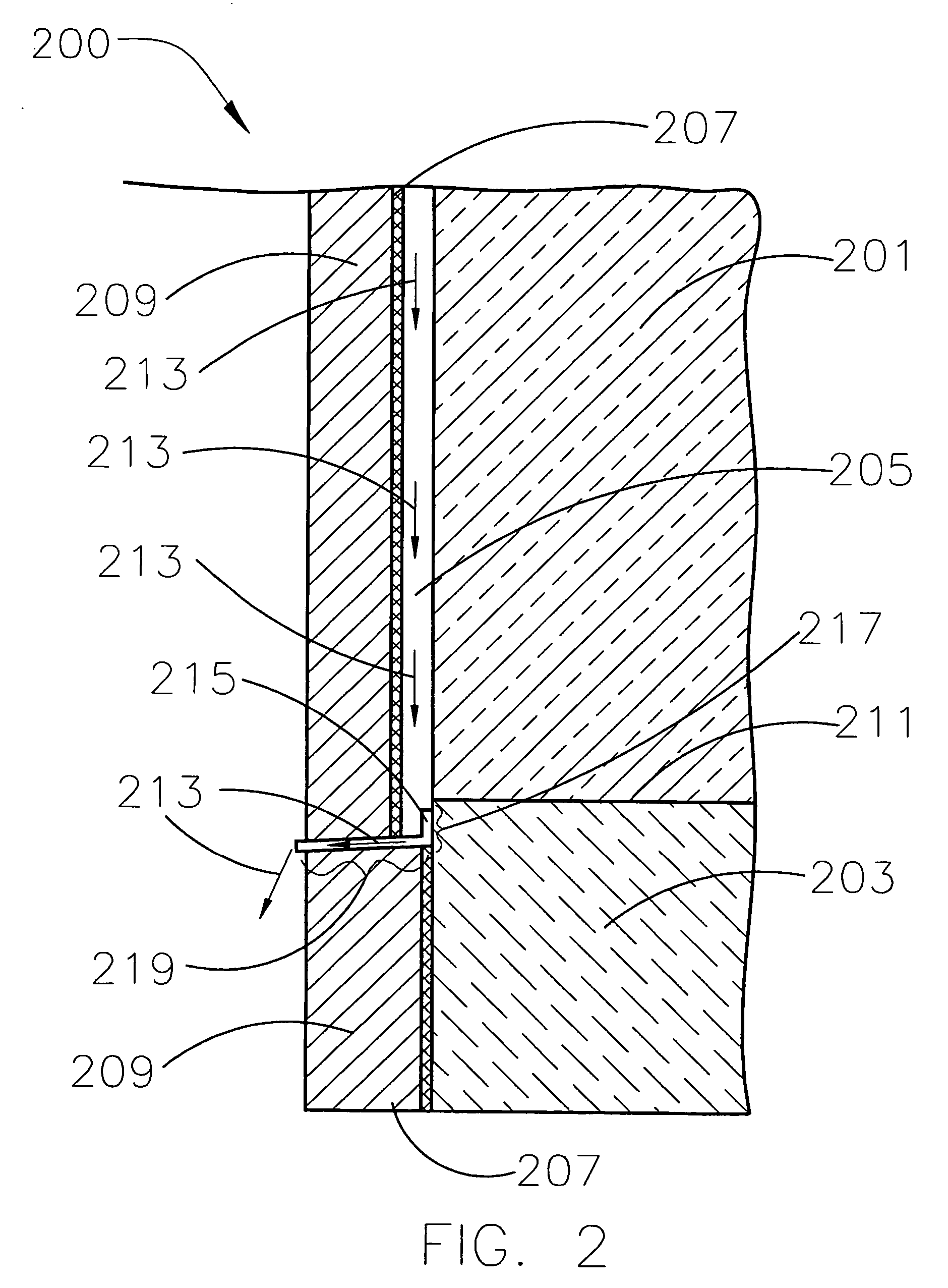

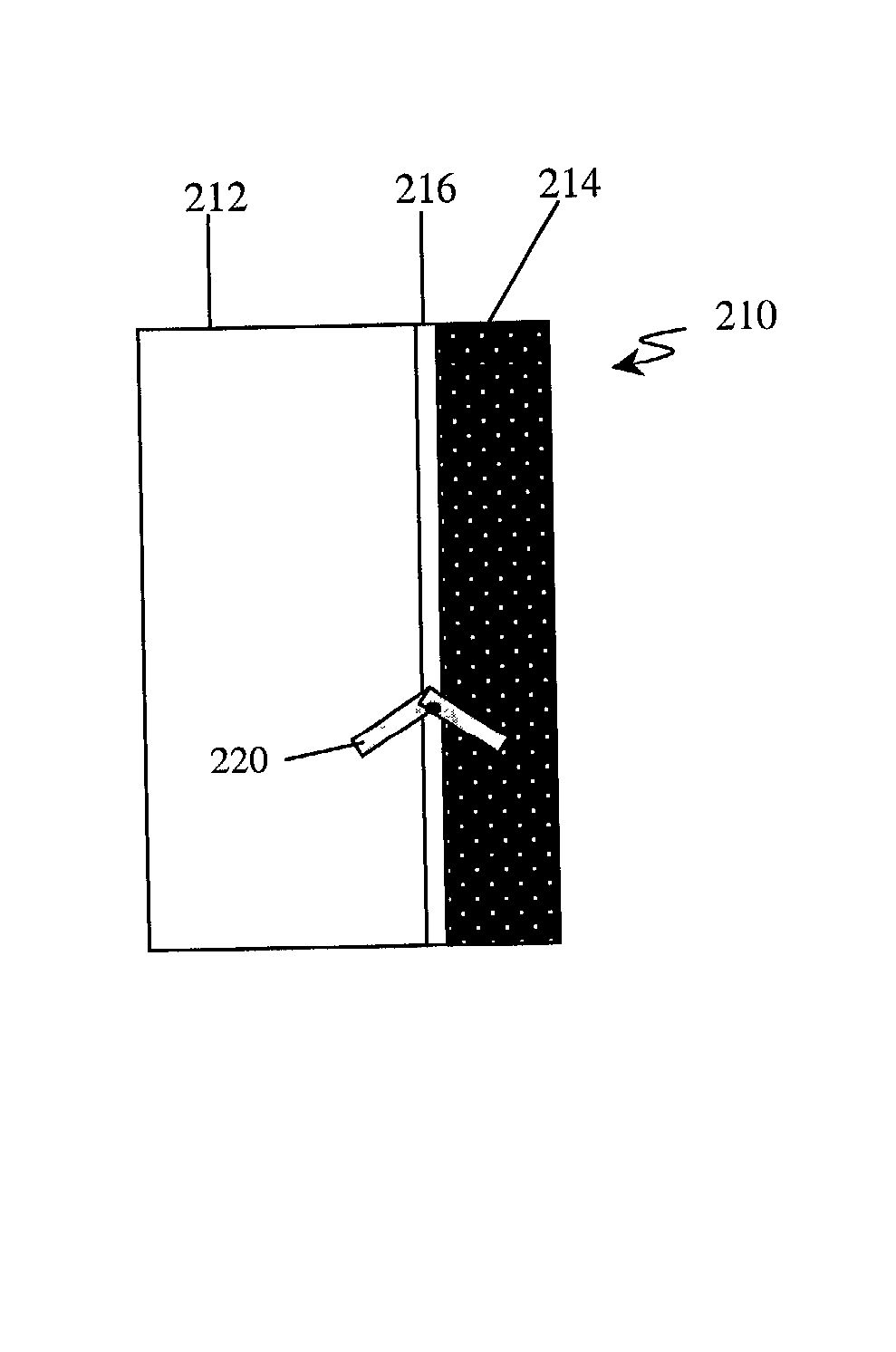

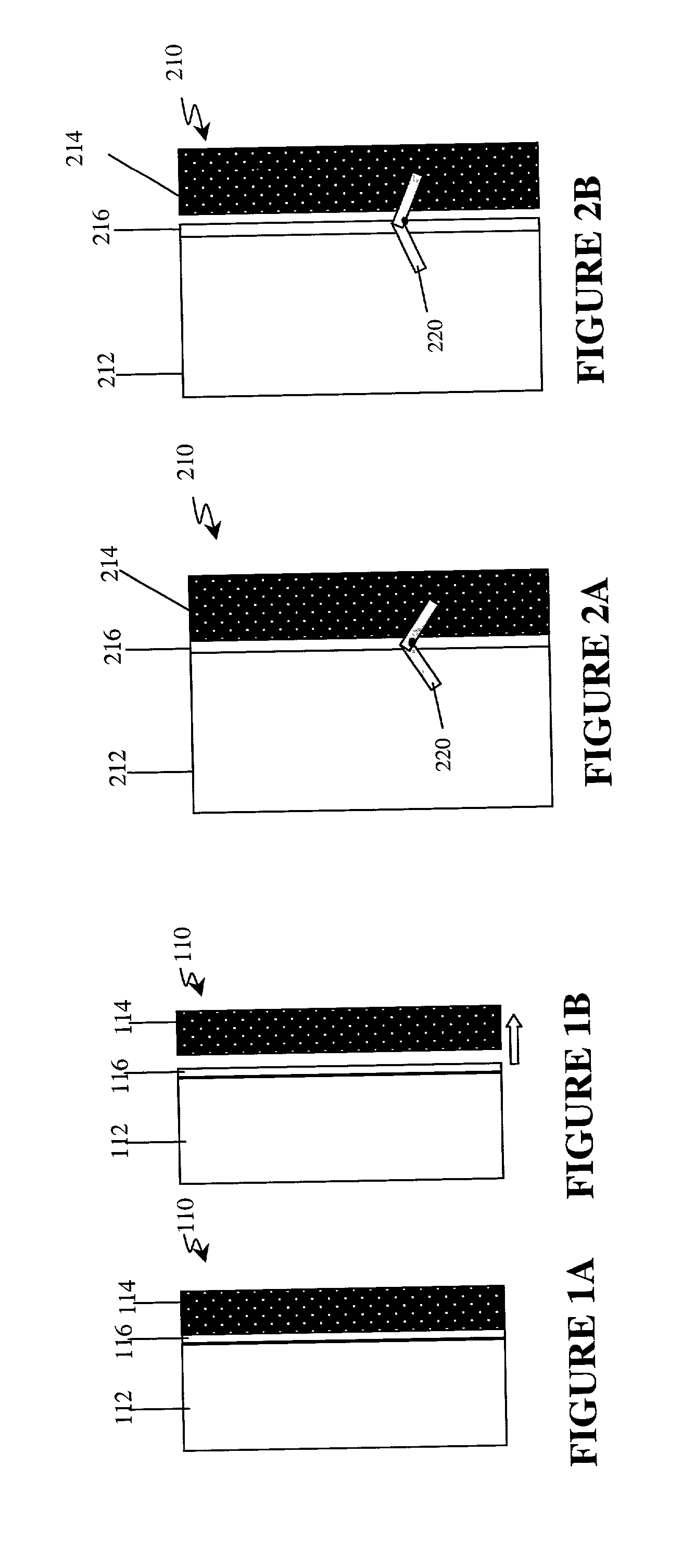

Moisture control system

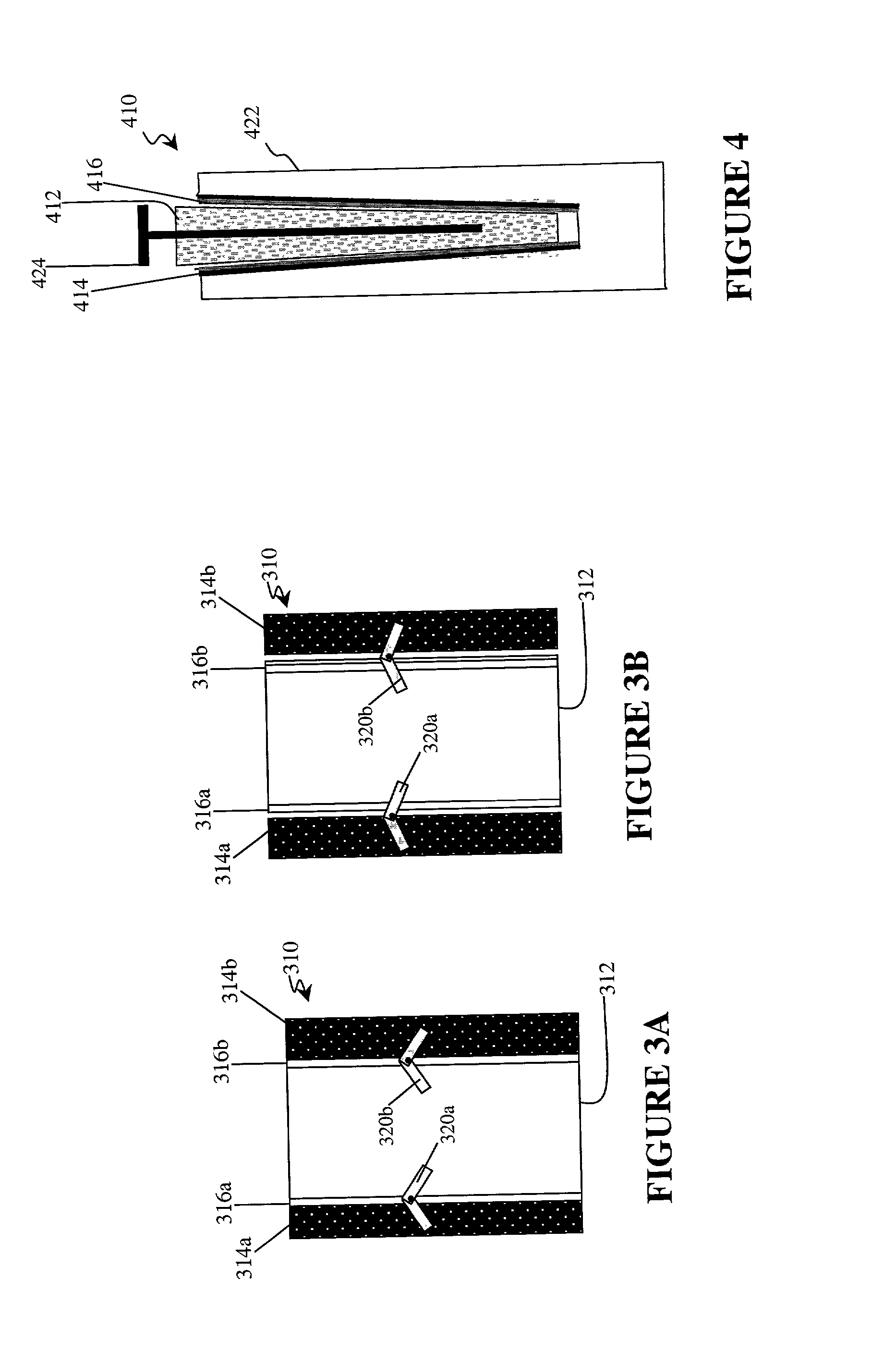

InactiveUS20070044402A1Easy to moveReduce the amount requiredVertical ductsControl systemEngineering

The present invention includes moisture channeling member for removing moisture from the interior cavity of a surface facing system. The moisture channeling member includes a channel portion having a channel with an upper end, a lower end and a surface capable of conveying liquid. The channel is inclined at an angle with respect to level sufficient to facilitate flow of liquid from the upper end to the lower end. The channel portion is in fluid communication with an interior cavity of a surface facing system. A drainage portion is in fluid communication with the channel portion. The drainage portion is capable of consolidating and diverting moisture received from the channel portion and conveying the received moisture to an exterior area of the surface facing system.

Owner:HESS JAMIE P

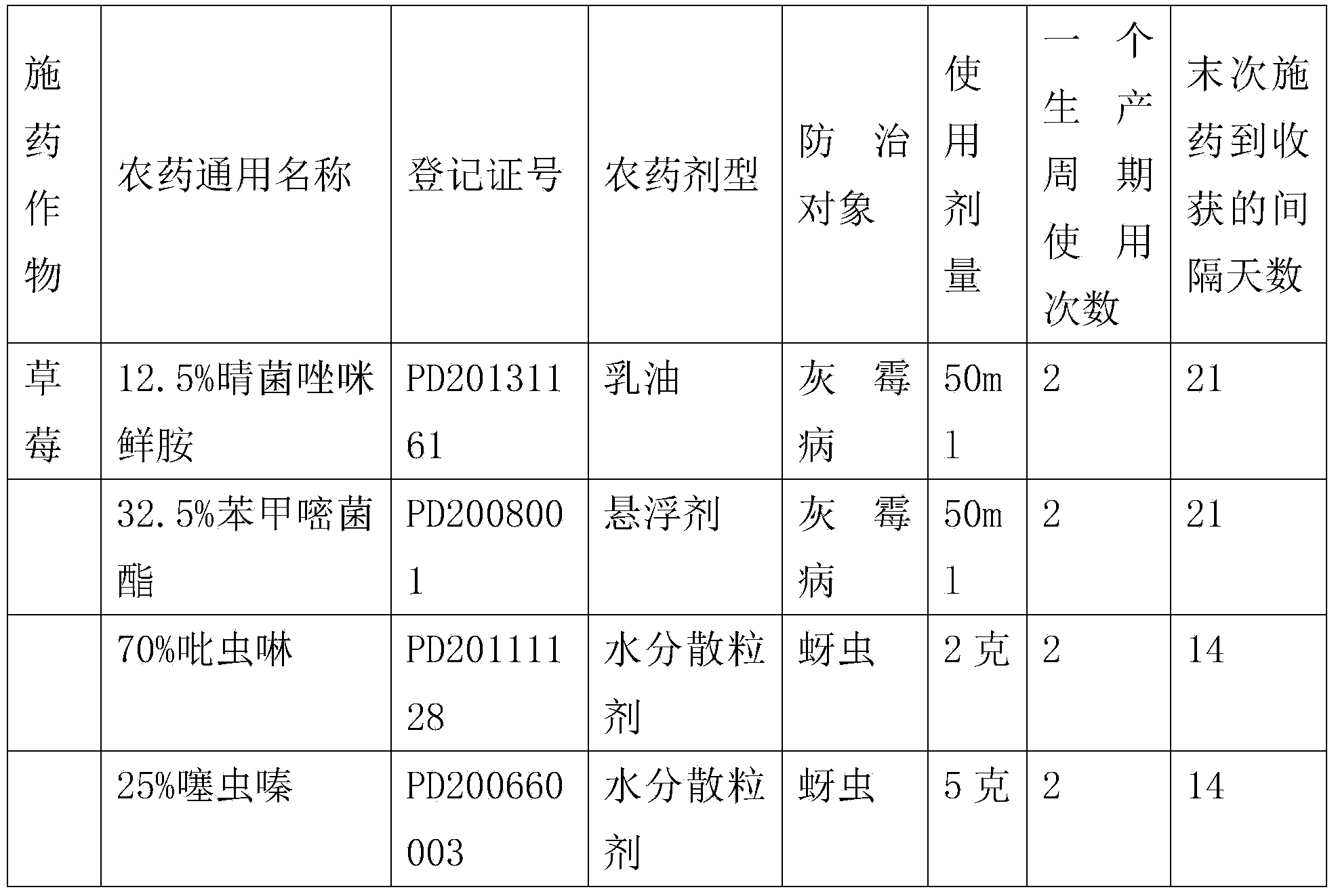

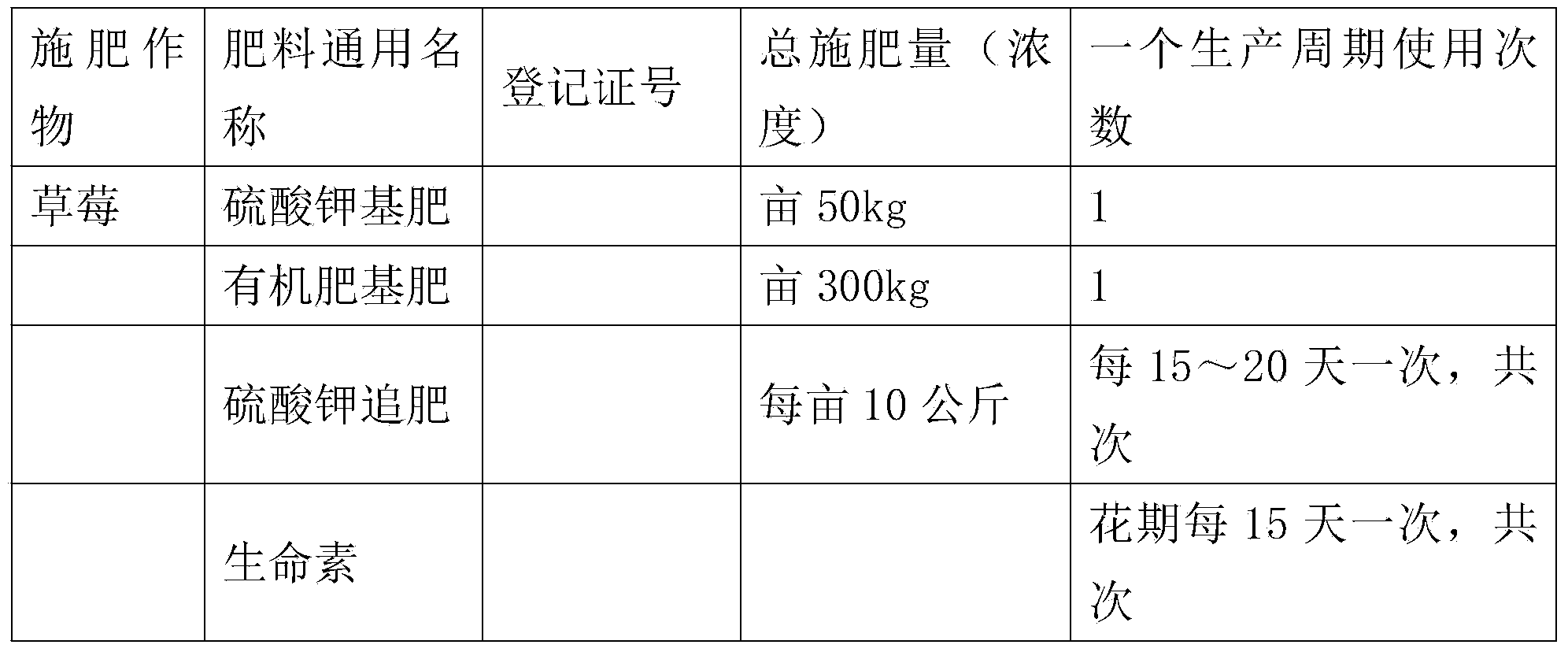

Pollution-free greenhouse strawberry cultivation method

InactiveCN104041272AImprove qualityReasonable growth environmentHorticultureDiseaseGreenhouse cultivation

Owner:LANGXI SHENGCHUAN VEGETABLES COOP

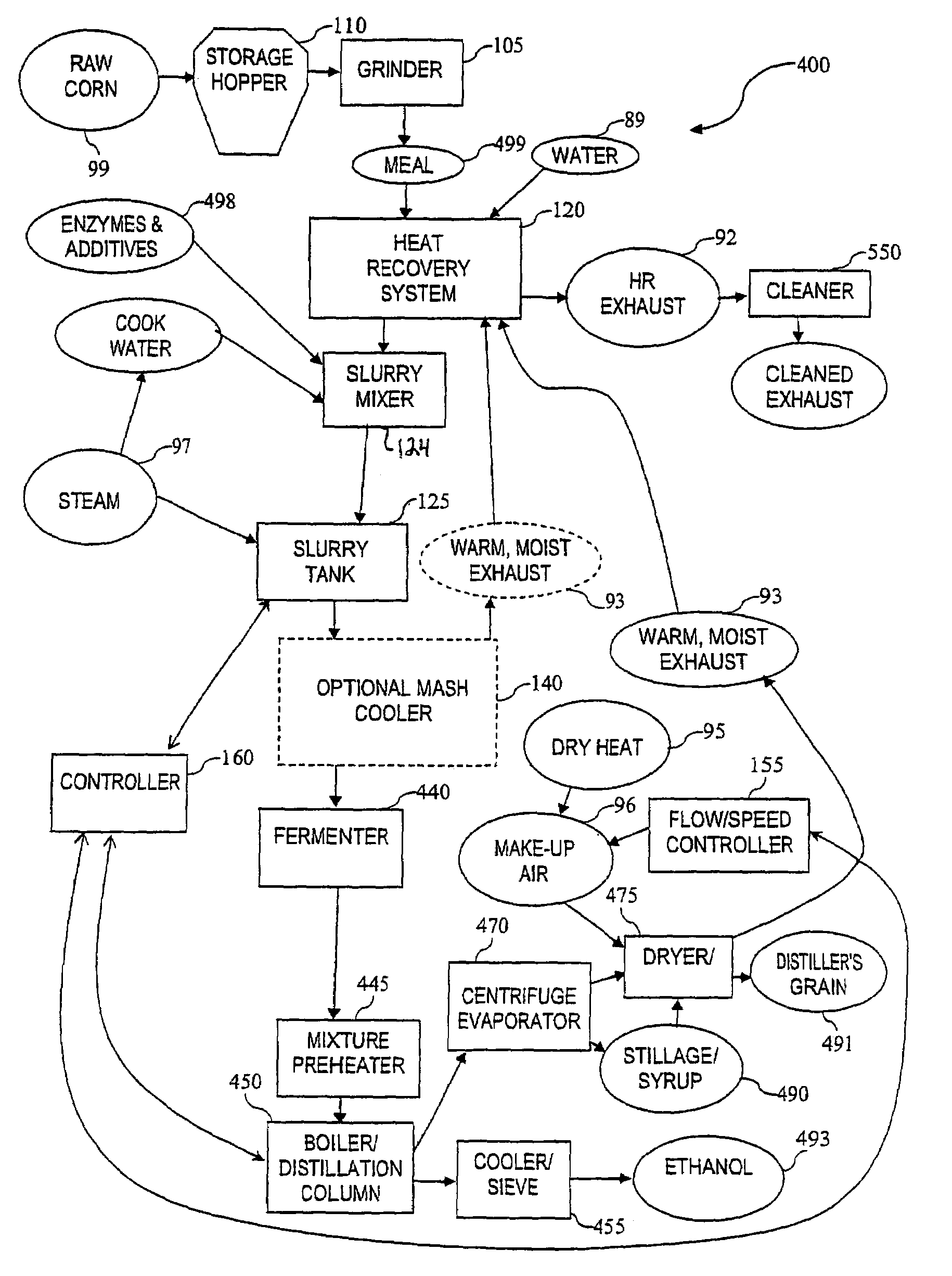

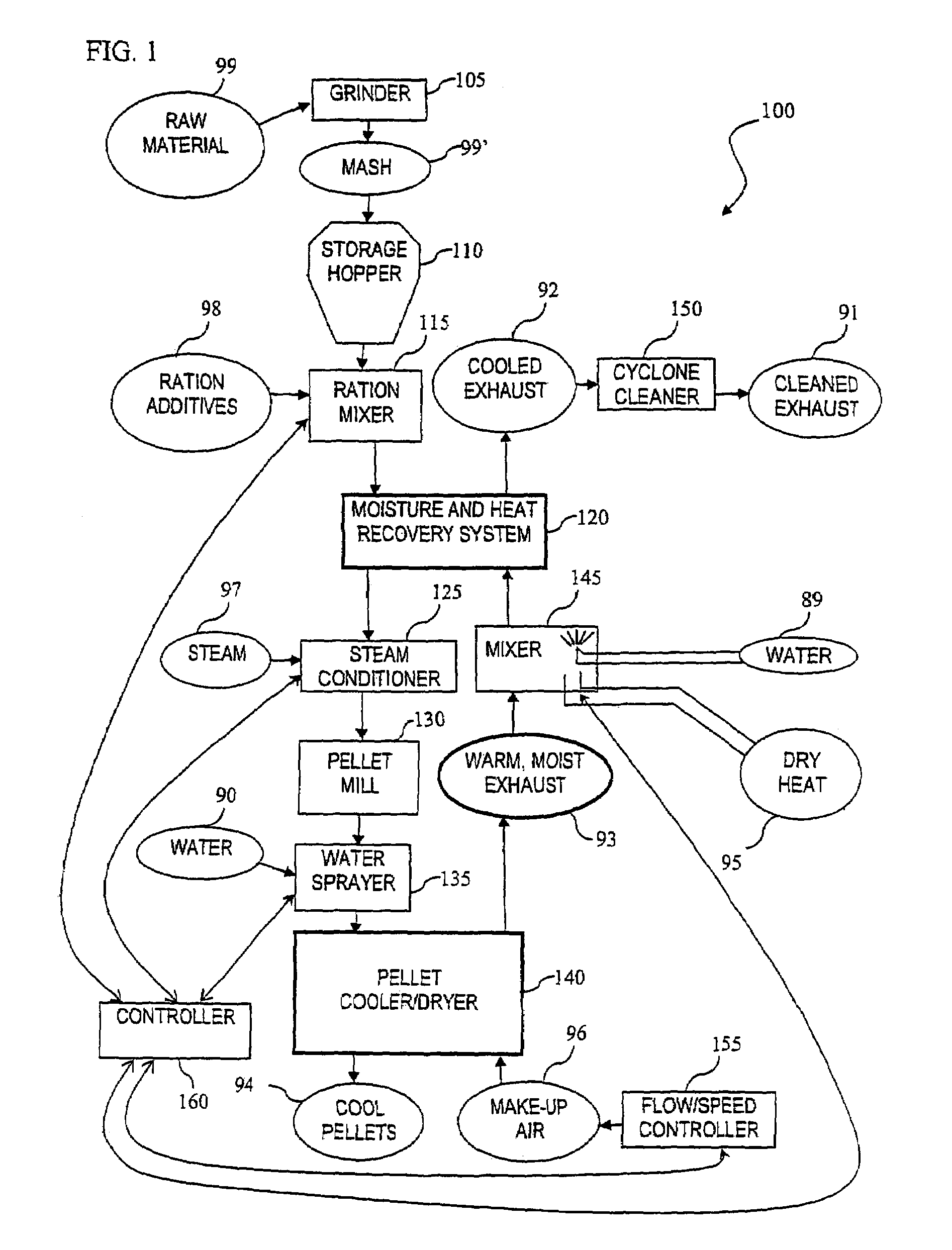

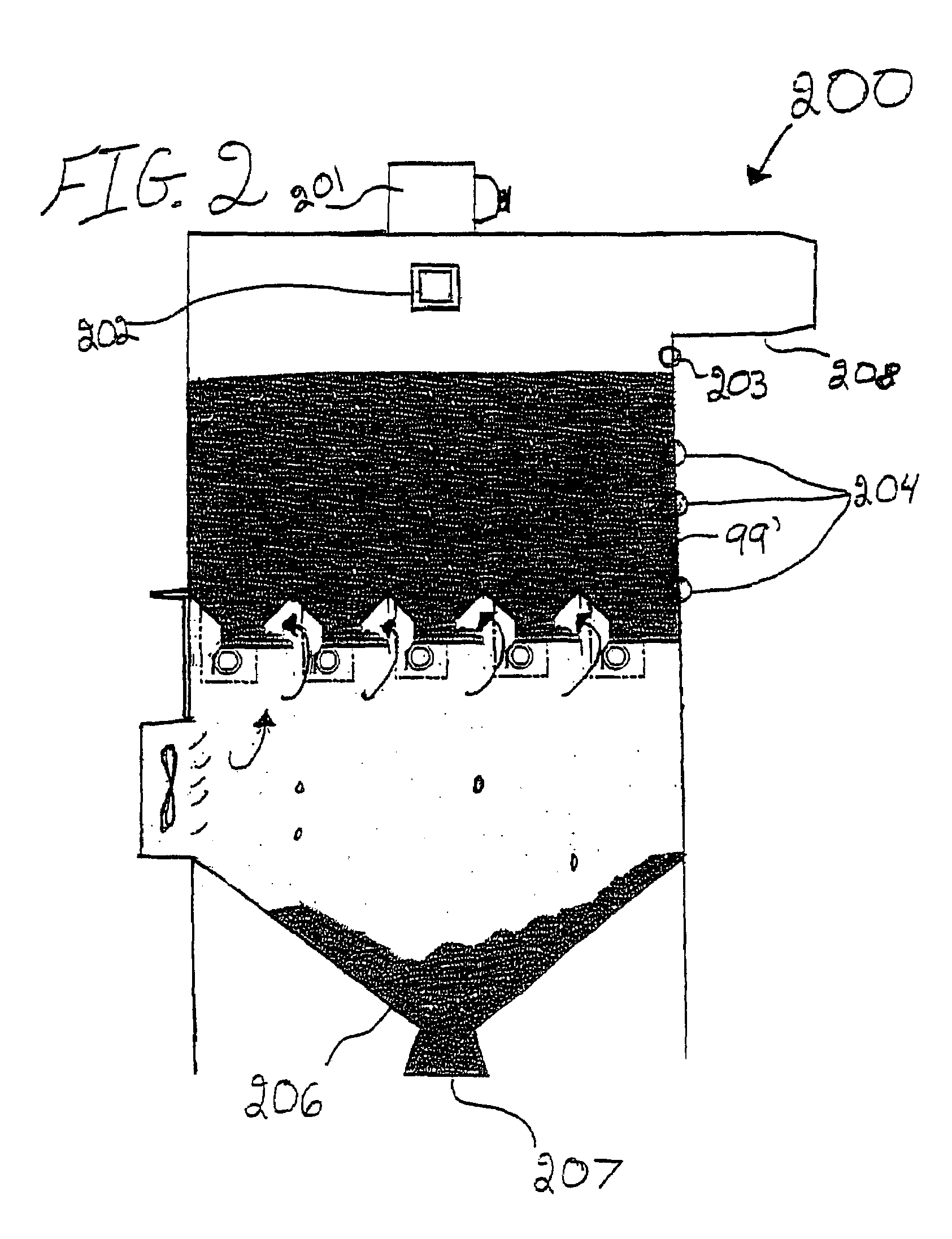

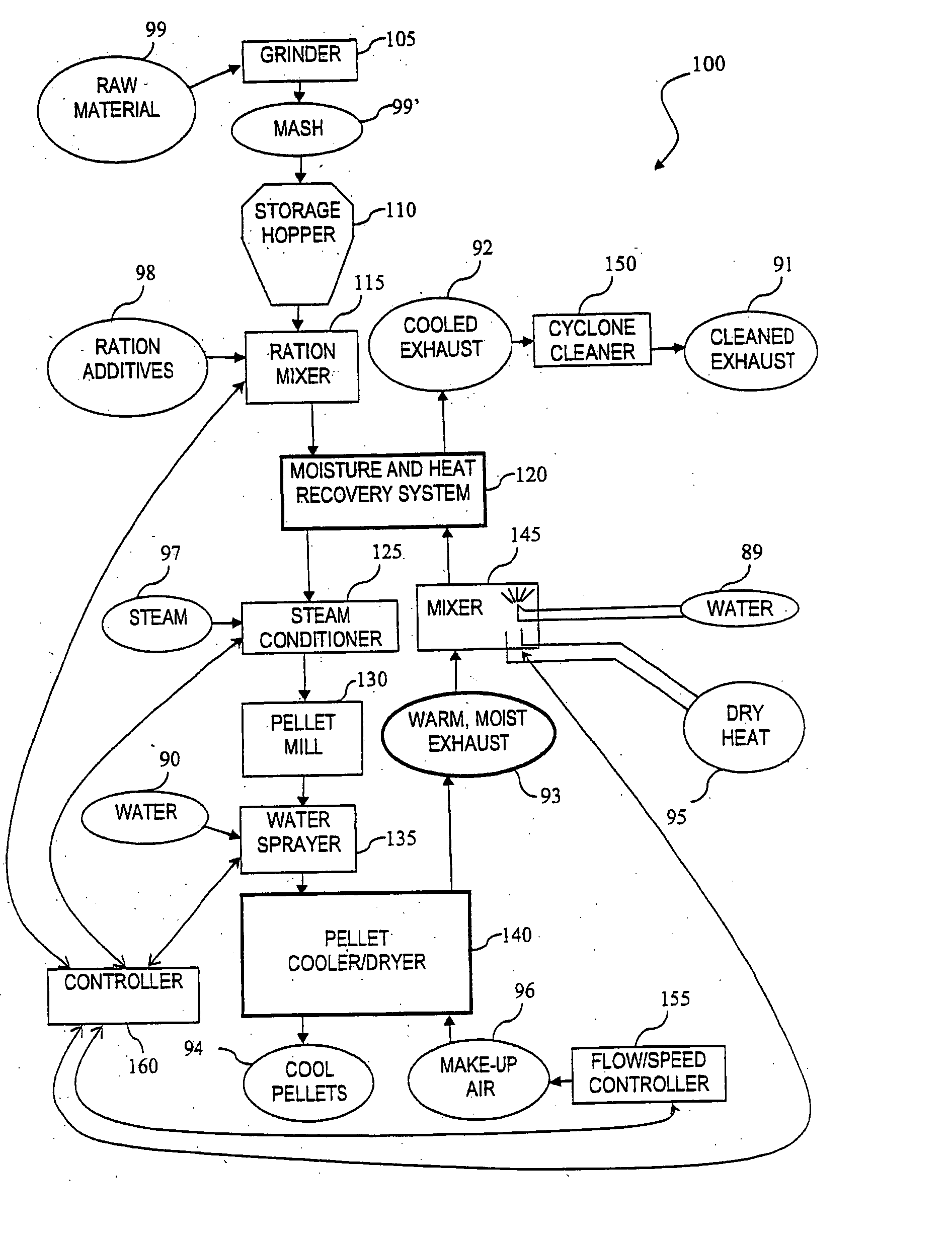

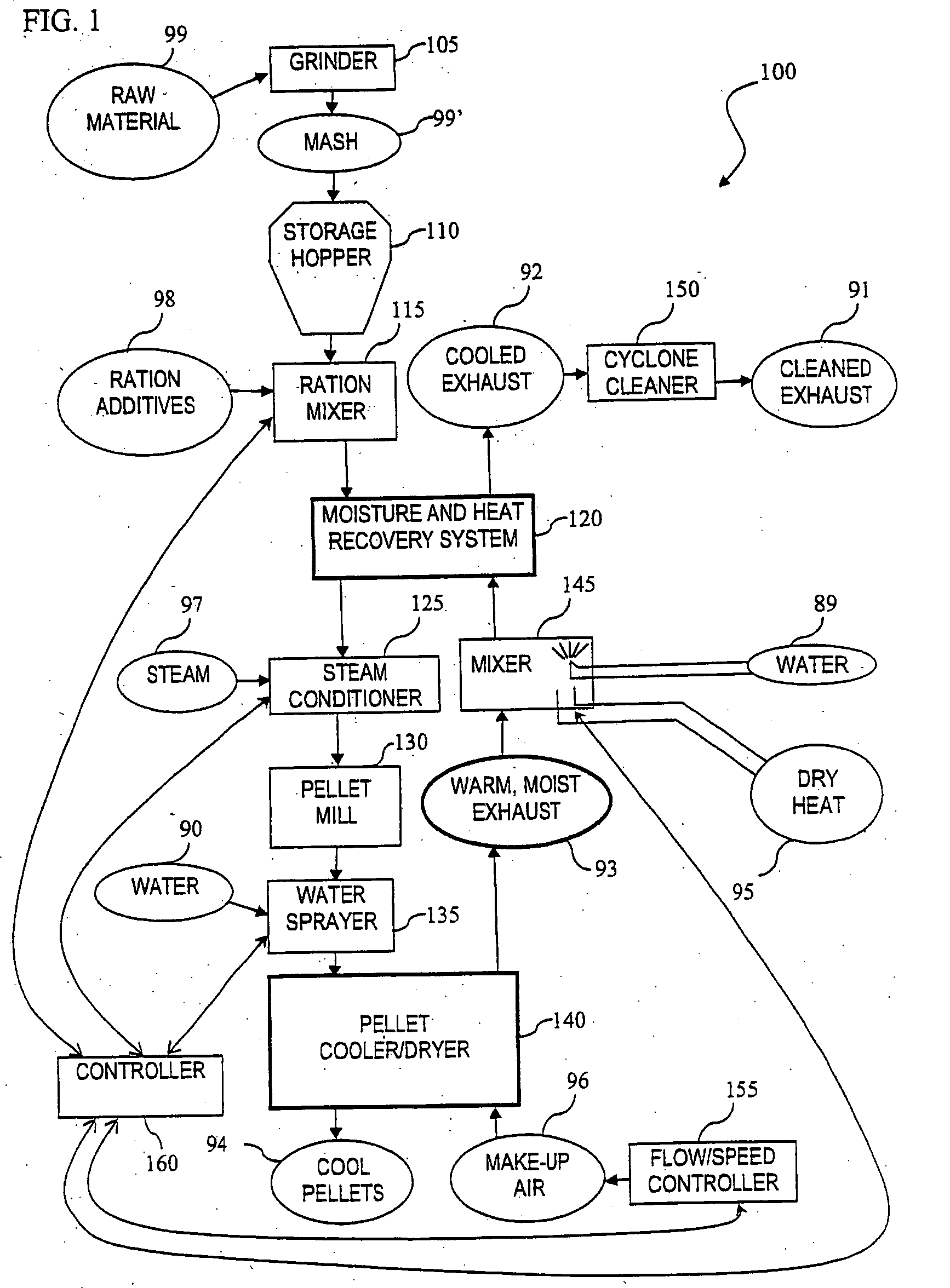

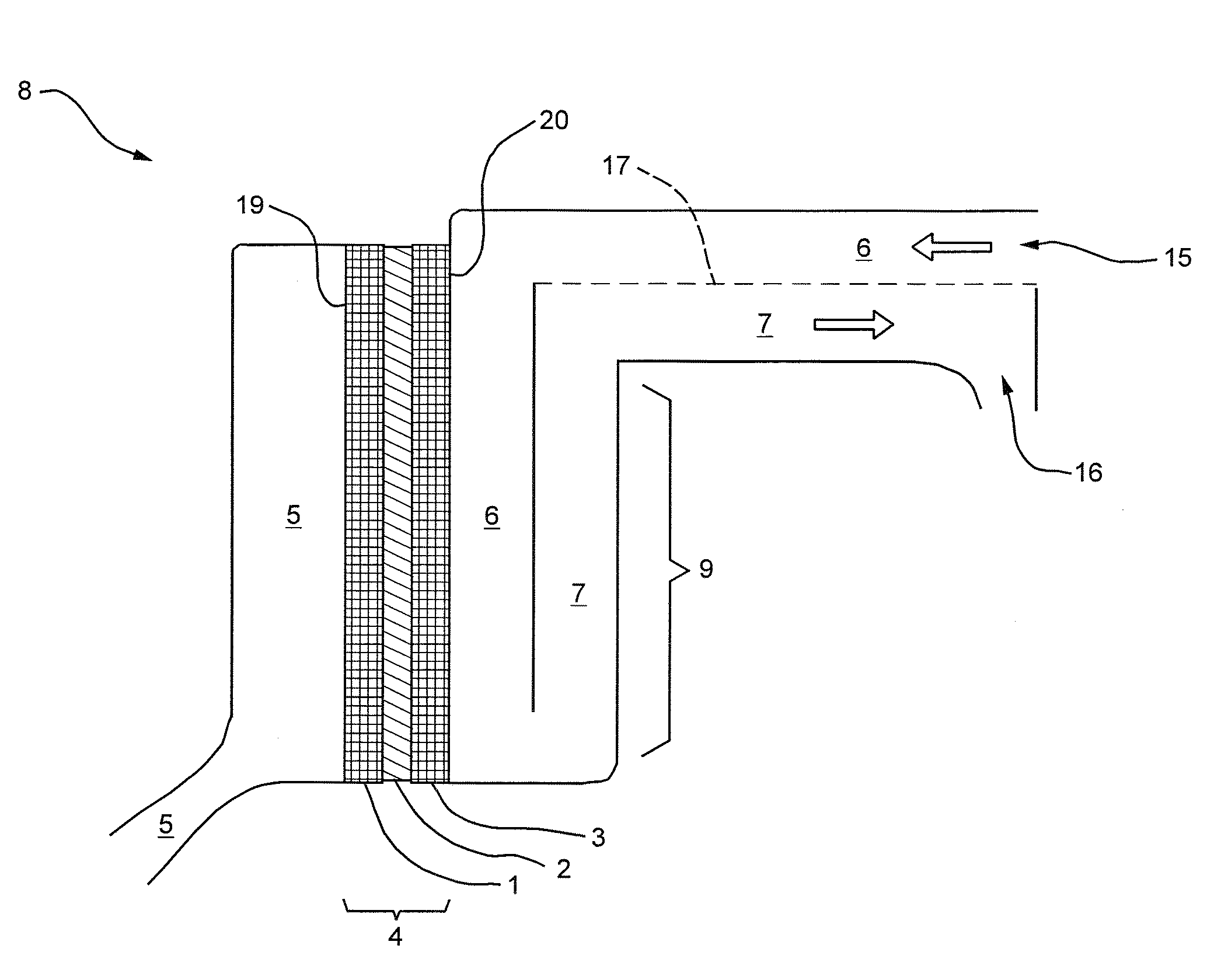

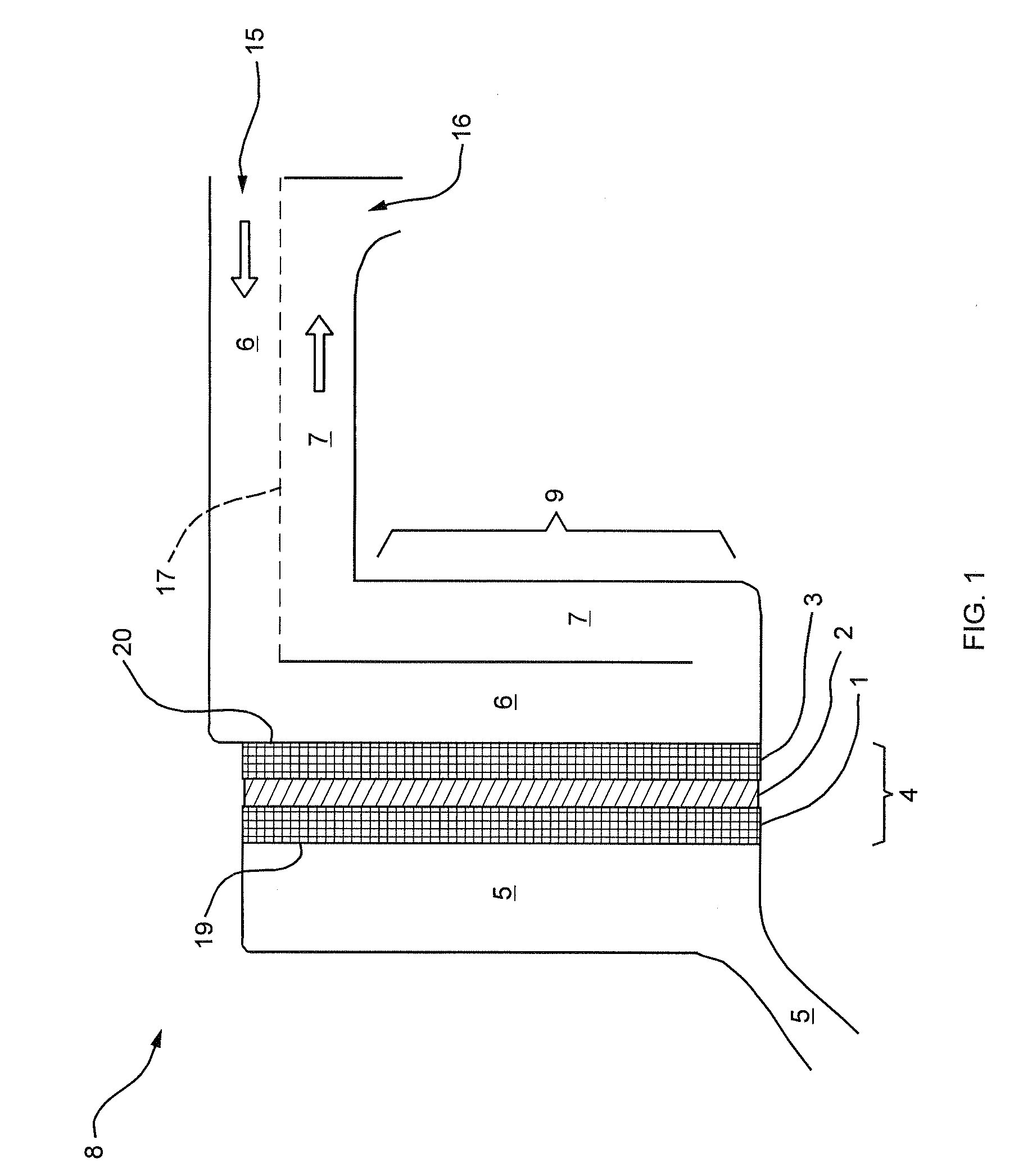

Heat-moisture control in agricultural-product production using moisture from water vapor extraction

InactiveUS7404262B2Reduce the amount requiredHigh production costDrying using combination processesMeat/fish preservation by heatingWater vaporSprayer

A method and apparatus for agricultural product production with heat and moisture control with optional heat and moisture recovery. Some embodiments transfer heat and moisture from a warm, moist exhaust air stream to incoming agricultural material, steam condition the material, pelletize the material into warm pellets, cool the warm pellets with make-up air to produce the warm, moist exhaust air used to transfer heat to the incoming material and to produce cooled pellets, wherein the cooled pellets are at a temperature lower than the warm moist air. In some embodiments, the system includes counter-flow devices to transfer heat and moisture. In some embodiments, a controller is used to adjust system devices and overall system flow. In some embodiments a water sprayer, to moisten agricultural product when the product is over dry, and an air flow controller, to slow air flow through the pellet dryer / cooler when ambient temperatures are dryer / cooler, are provided.

Owner:PESCO +1

Variable vapor barrier for humidity control

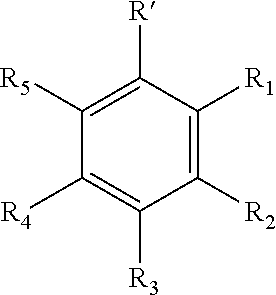

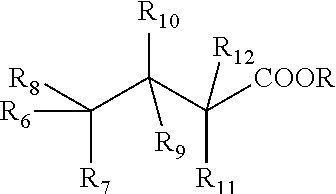

ActiveUS20070287019A1Avoid insufficient heatingSynthetic resin layered productsCellulosic plastic layered productsOrganic acidVapor barrier

Disclosed is a composition comprising a neutralized acid copolymer or ionomer thereof, an organic acid, and optionally other polymers, having a ratio of wet cup permeance to dry cup permeance greater than 10. The composition is useful as a variable vapor barrier for moisture control of buildings. Also disclosed are articles comprising the variable vapor composition and methods of their use.

Owner:DOW GLOBAL TECH LLC

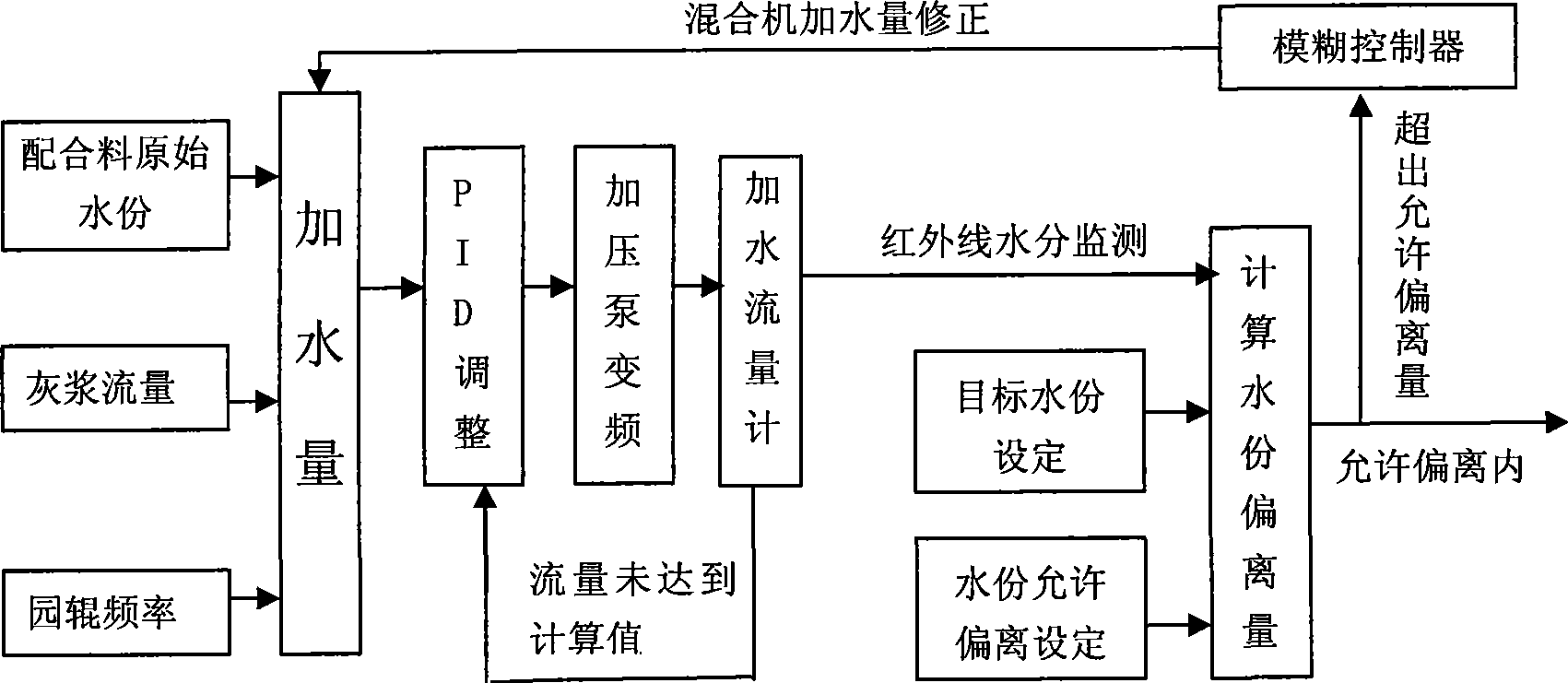

Humidity control method for mixture used in sintering production

ActiveCN101477378AReduce regulatory disturbancesMeet production requirementsControlling ratio of multiple fluid flowsAdaptive controlAutomatic controlData acquisition

The invention relates to a method for controlling moisture of a mixture for sintering production, and belongs to the technical field of automatic monitoring and intelligent control of mixture moisture. The method adopts a PLC system and a development tool. The control process comprises data acquisition, signal display, data processing, manual input of information, model operation and adjustment for fuzzy control, control quantity output, model self-adapting, and judgment and correction of manual intelligent mode. The method achieves automatic dynamic control of water adding amount of the sintered mixture to make the mixture moisture meet sintering production demand, displays data such as real-time moisture, water adding amount and the like of the material in the production process, and displays operation mode and the like. The method has the advantages that the method is suitable for control of the water adding amount in a mixing process using various sintering production process raw materials, can design an independent control system or can be realized by using the PLC control system based on automatic control of the production process, is limited little by field conditions, is suitable for new projects and reformed projects, and has low cost.

Owner:首钢股份公司迁安钢铁公司

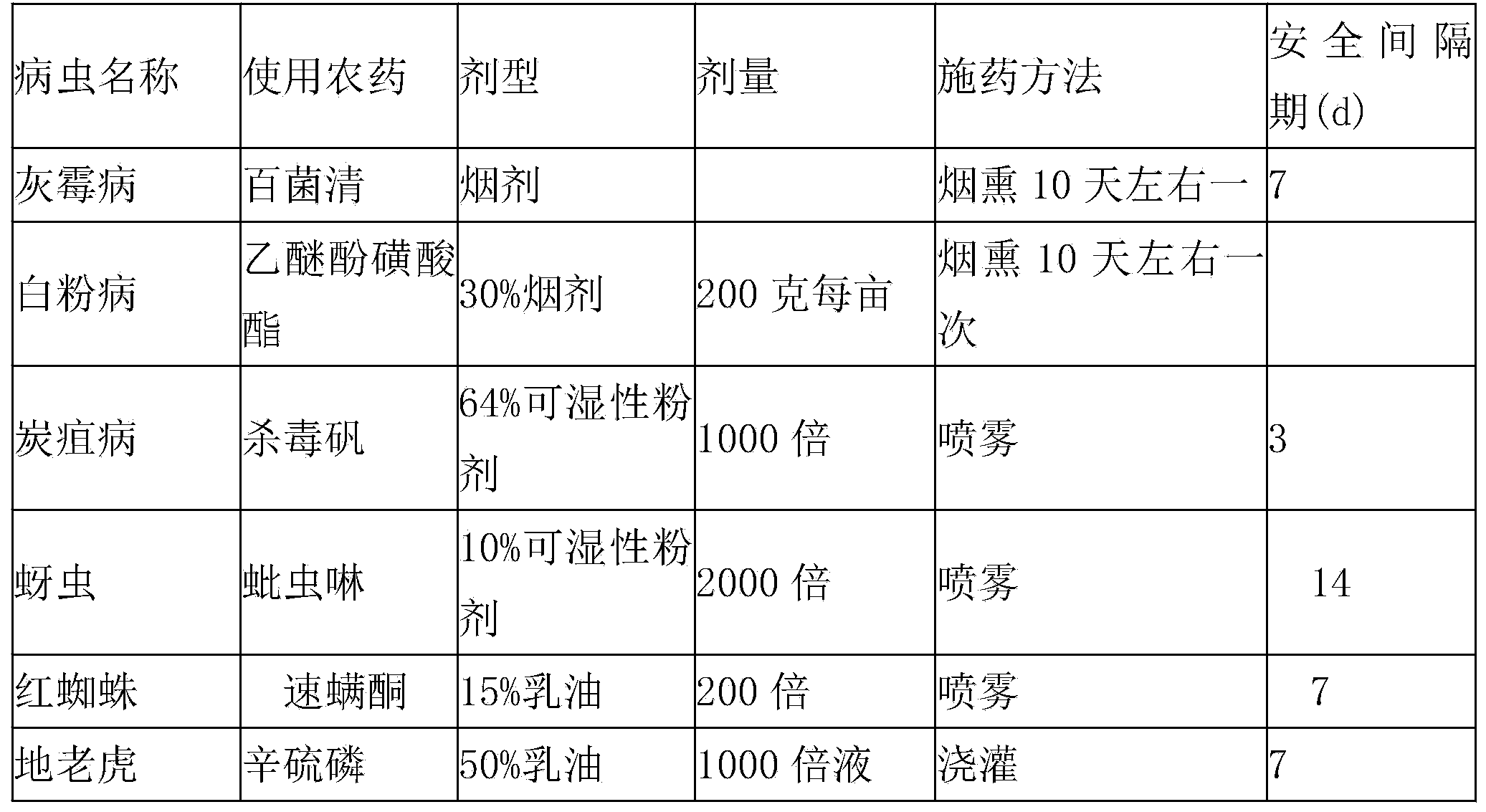

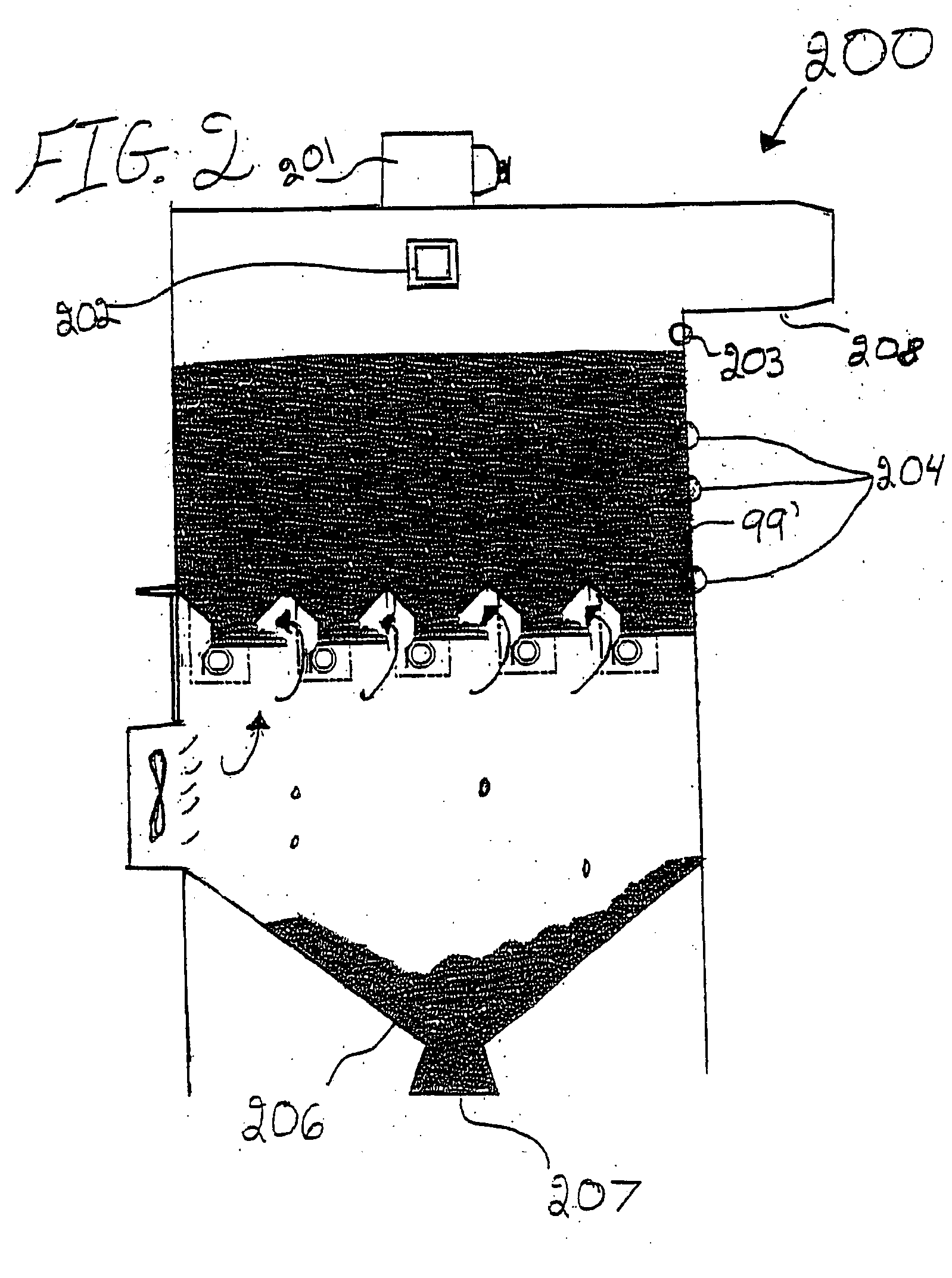

Heat and moisture control in agricultural-product production

InactiveUS20060093713A1Easy to controlReduce operating costsDrying using combination processesFeeding-stuffCounter flowSprayer

A method and apparatus for agricultural product production with heat and moisture control with optional heat and moisture recovery. Some embodiments transfer heat and moisture from a warm, moist exhaust air stream to incoming agricultural material, steam condition the material, pelletize the material into warm pellets, cool the warm pellets with make-up air to produce the warm, moist exhaust air used to transfer heat to the incoming material and to produce cooled pellets, wherein the cooled pellets are at a temperature lower than the warm moist air. In some embodiments, the system includes counter-flow devices to transfer heat and moisture. In some embodiments, a controller is used to adjust system devices and overall system flow. In some embodiments a water sprayer, to moisten agricultural product when the product is over dry, and an air flow controller, to slow air flow through the pellet dryer / cooler when ambient temperatures are dryer / cooler, are provided.

Owner:PESCO +1

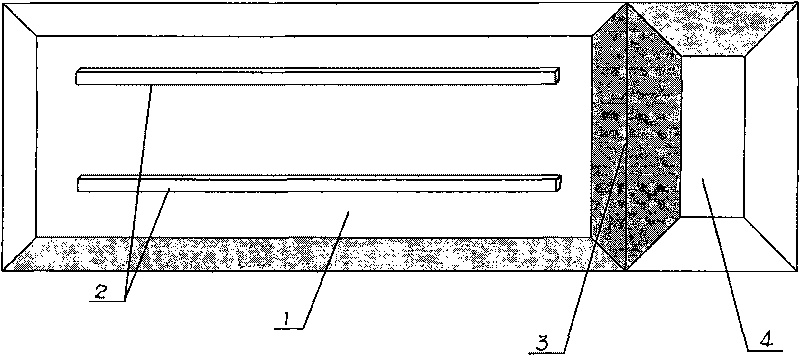

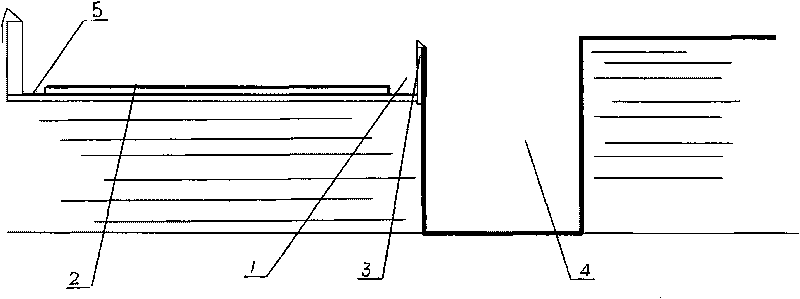

Method for controlling water of seedbed of cured tobacco seedlings by floating cultivation

InactiveCN101699985AIncrease profitPromote growthClimate change adaptationAgriculture gas emission reductionNutrient solutionWater requirement

The invention discloses a method for controlling water of a seedbed of cured tobacco seedlings by floating cultivation, relating to soilless and waterless seedlings culture of crops. The method comprises two steps of: reconstruction of a nutrition pool: removing an earth stripe at one end of a conversional nutrition pool, digging a puddle for storing nutrient fluid, sequentially arranging two columns of bamboo splints in the nutrition pool, and placing a floating plate overhead after the nutrient fluid is discharged so as to form an air layer between the bottom of the floating plate and the liquid level; and water control of cured tobacco seedlings by dry-wet alternation and discontinuous water supply: moving the nutrient fluid in due time according to the water requirement pattern of thecured tobacco seedlings so as to ensure water for the growth of the cured tobacco seedlings. The method has the advantages that: (1) the water supply time and the supplying water are based on the water requirement pattern of the cured tobacco seedlings in growing so as to be beneficial to promoting the growth of the seedlings and improving the quality of the cured tobacco seedlings; (2) the nutrient fluid is reused, the utilization ratio of water and nutrients is greatly improved, and the collected nutrients can also be used for other plants so as to reduce pollution to the environment; and (3) the plate airing process caused by overmuch water in a floating cultivation substrate during latter hardening off is reduced, the labor intensity is lowered and the manpower is saved.

Owner:GUIZHOU TOBACCO SCI INST

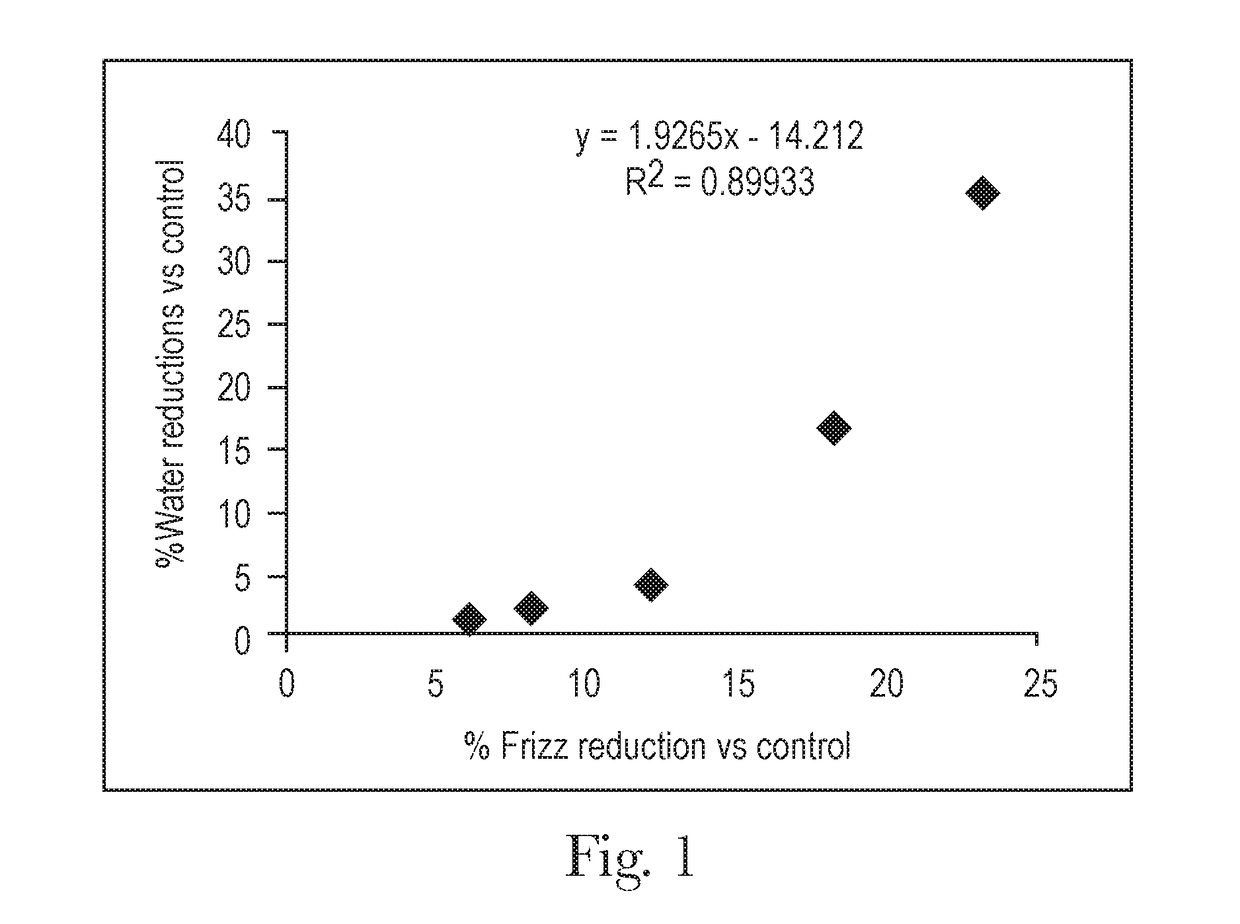

Hair care regimen using compositions comprising moisture control materials

A method is disclosed for reducing hair frizz by treating hair with a regimen comprising two or more hair care compositions wherein at least two of such compositions comprise Moisture Control Materials. Two or more of the compositions used in the method comprise from about 0.1% to about 20% of a moisture control material or mixture of moisture control materials wherein the moisture control material is selected from the group consisting of Class I and Class II.

Owner:THE PROCTER & GAMBLE COMPANY

Metal air cell incorporating ionic isolation systems

InactiveUS20020177036A1Fuel and primary cellsMoving electrode arrangementsElectrochemical cellHydration control

Electrochemical cell systems are disclosed herein that are capable of selective ionic isolation, oxidant isolation, oxidant removal, moisture control, and combinations thereof. Selective ionic isolation is generally effectuated by selectively eliminating or minimizing ionic communication between an anode and a cathode of the electrochemical cell.

Owner:REVEO

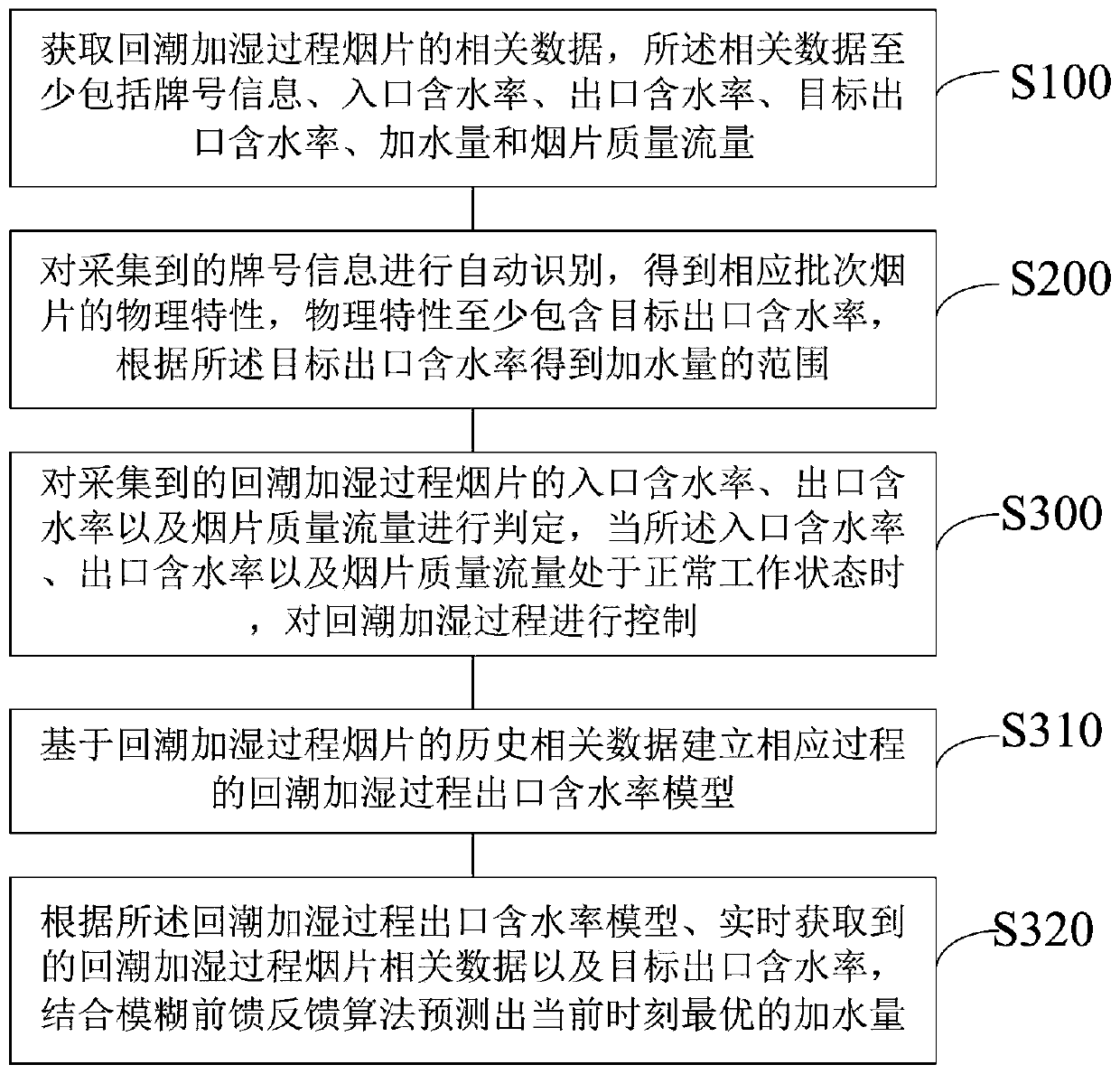

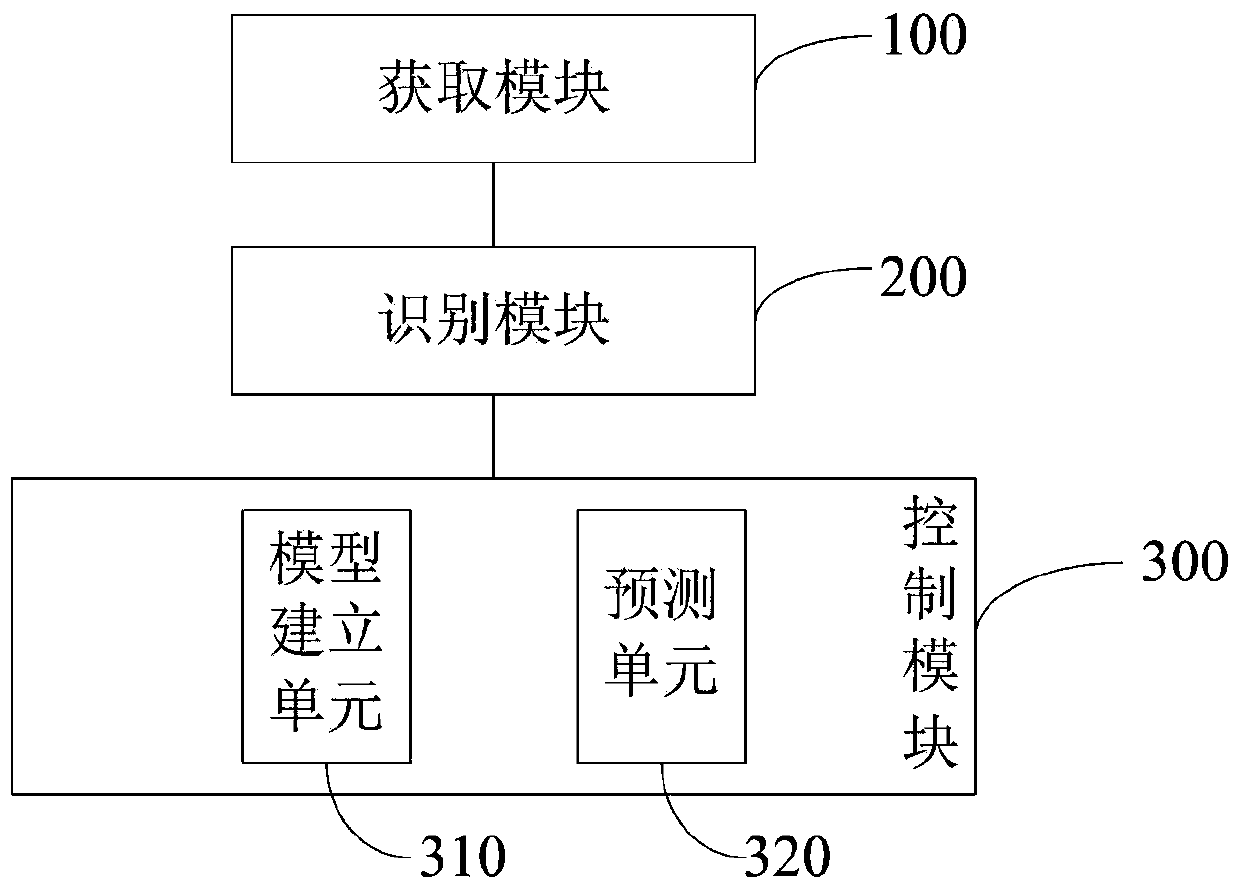

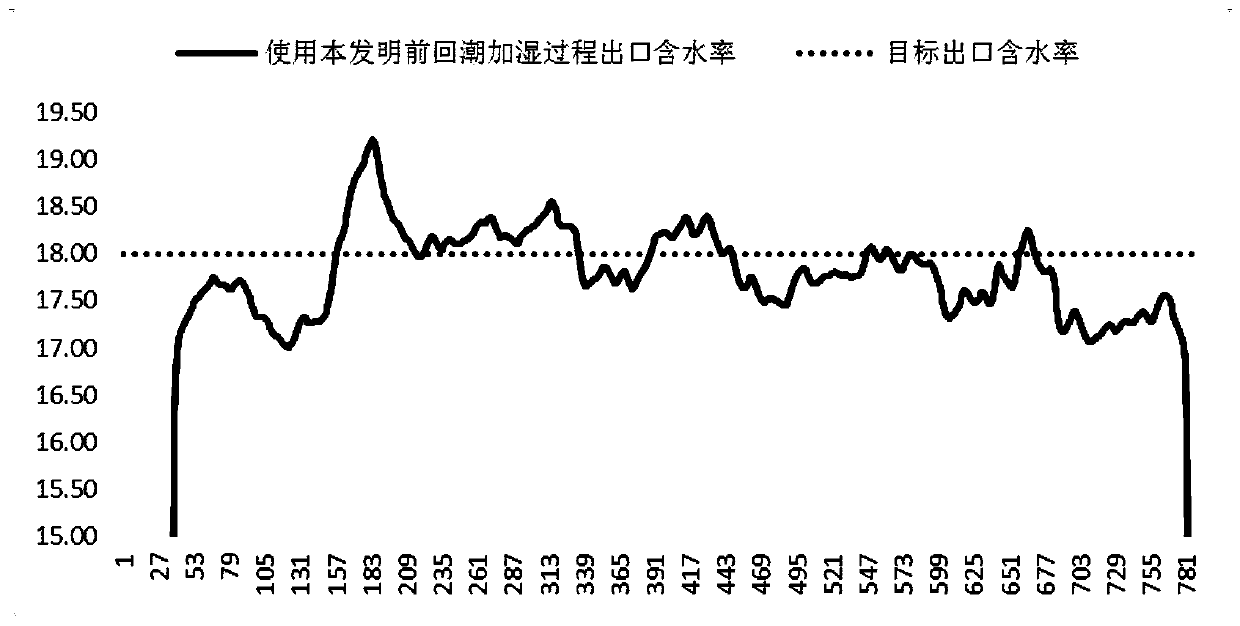

Moisture control method and system in moisture regaining and moistening process based on fuzzy feedforward feedback algorithm

ActiveCN110101106AGood technical effectStable outlet moistureTobacco preparationTobacco treatmentPass rateMoisture regain

The invention discloses a moisture control method and system in the moisture regaining and moistening process based on a fuzzy feedforward feedback algorithm. The method comprises the following stepsthat related data of tobacco sheets in the moisture regaining and moistening process is acquired; collected mark number information is automatically recognized, physical characteristics of the tobaccosheets of the corresponding batch are obtained and at least comprise target output moisture content, and according to the target output moisture content, a range of the water addition amount is obtained; the collected input moisture content, output moisture content and tobacco sheet quality flow of the tobacco sheets in the moisture regaining and moistening process are judged, and when the inputmoisture content, the output moisture content and the tobacco sheet quality flow are in the normal work state, the moisture regaining and moistening process is controlled. The moisture control methodand system finally achieves the purposes that moisture control over the moisture regaining and moistening process is conducted, the output moisture of the tobacco sheets can be stabilized, the qualification rate of the tobacco sheets is increased, and the production cost of cigarettes is reduced. Through the moisture control method and system, the robustness and control precision of the system areimproved, and the deviation caused by disturbance can be quickly eliminated.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

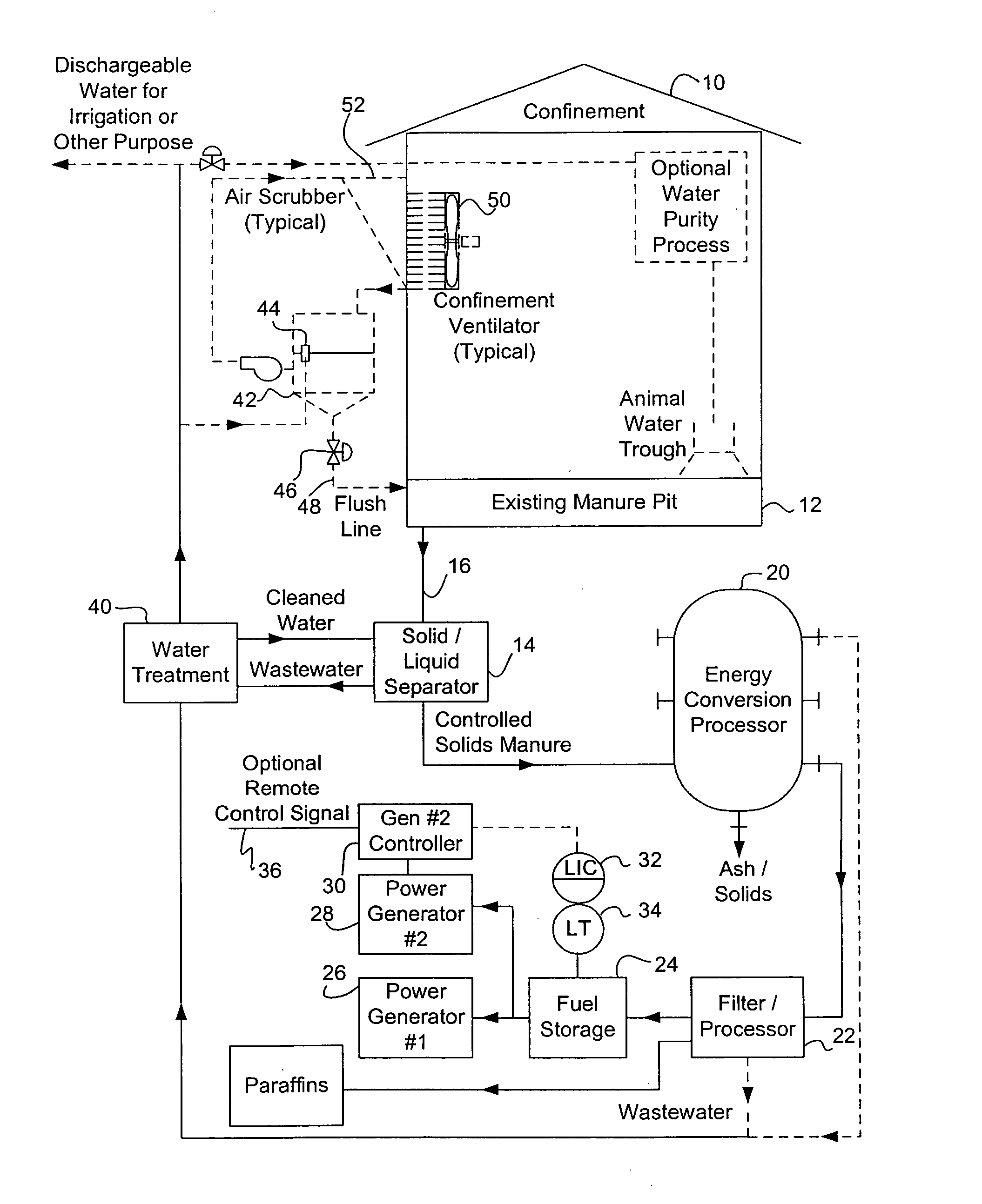

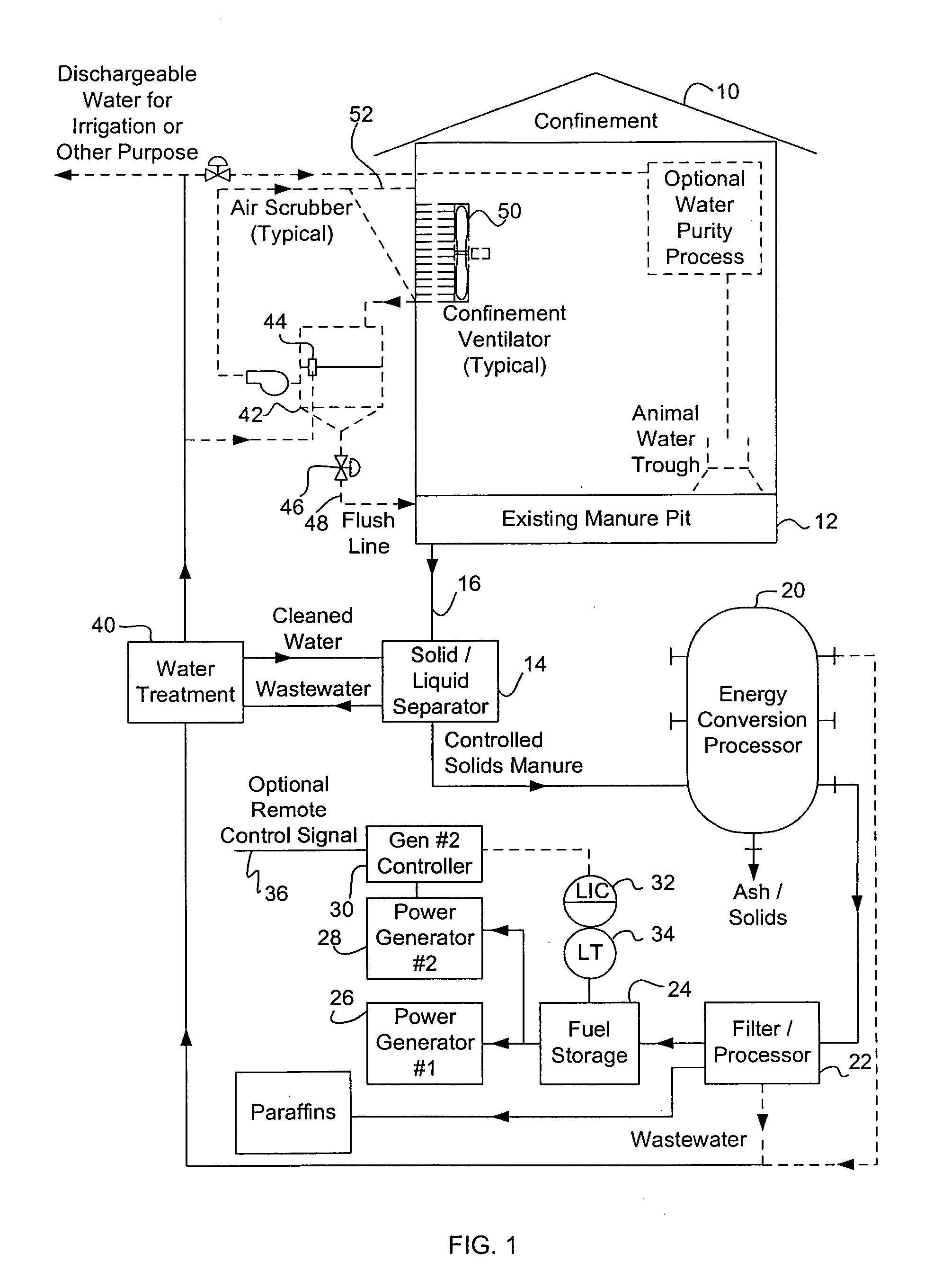

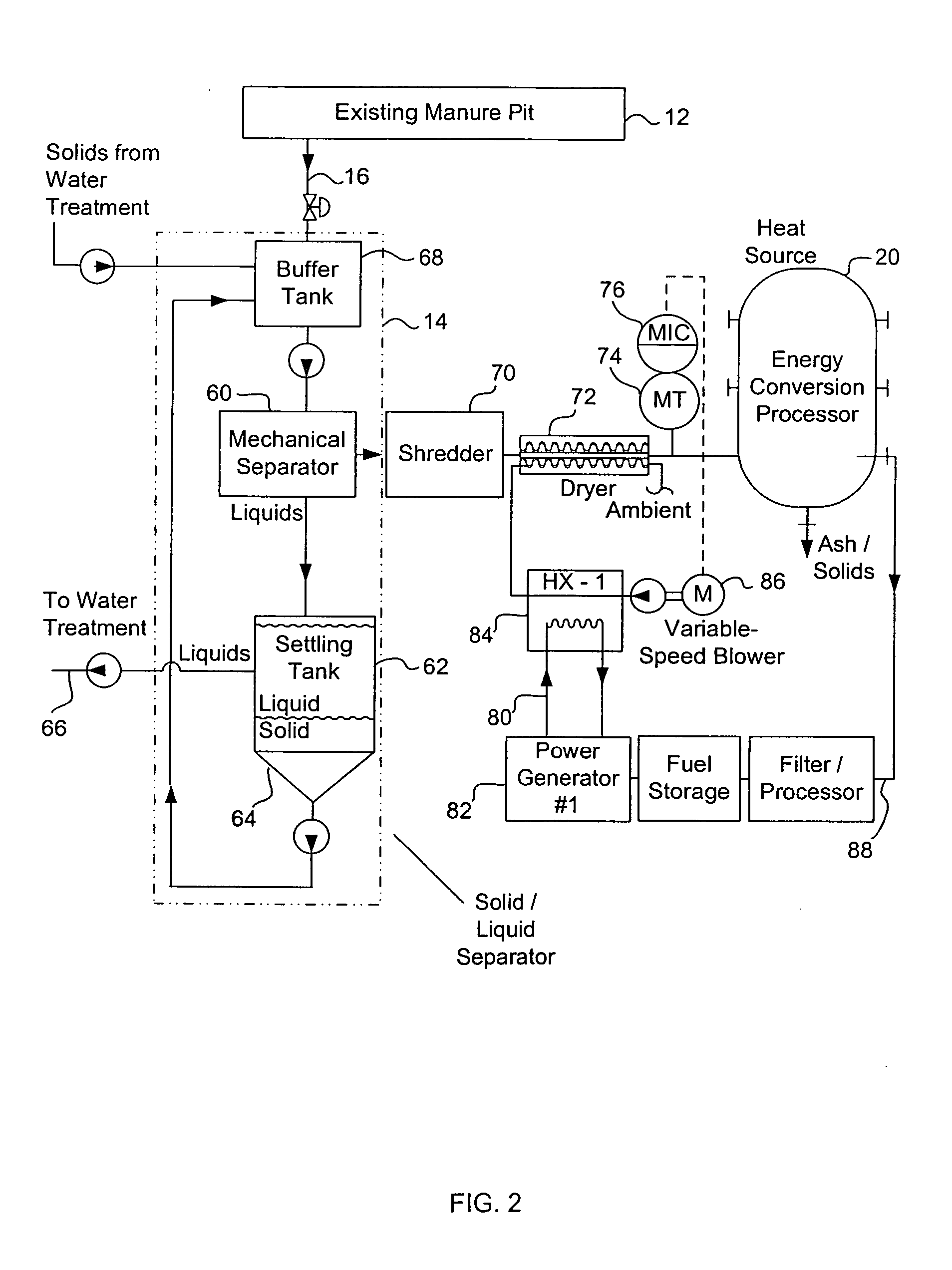

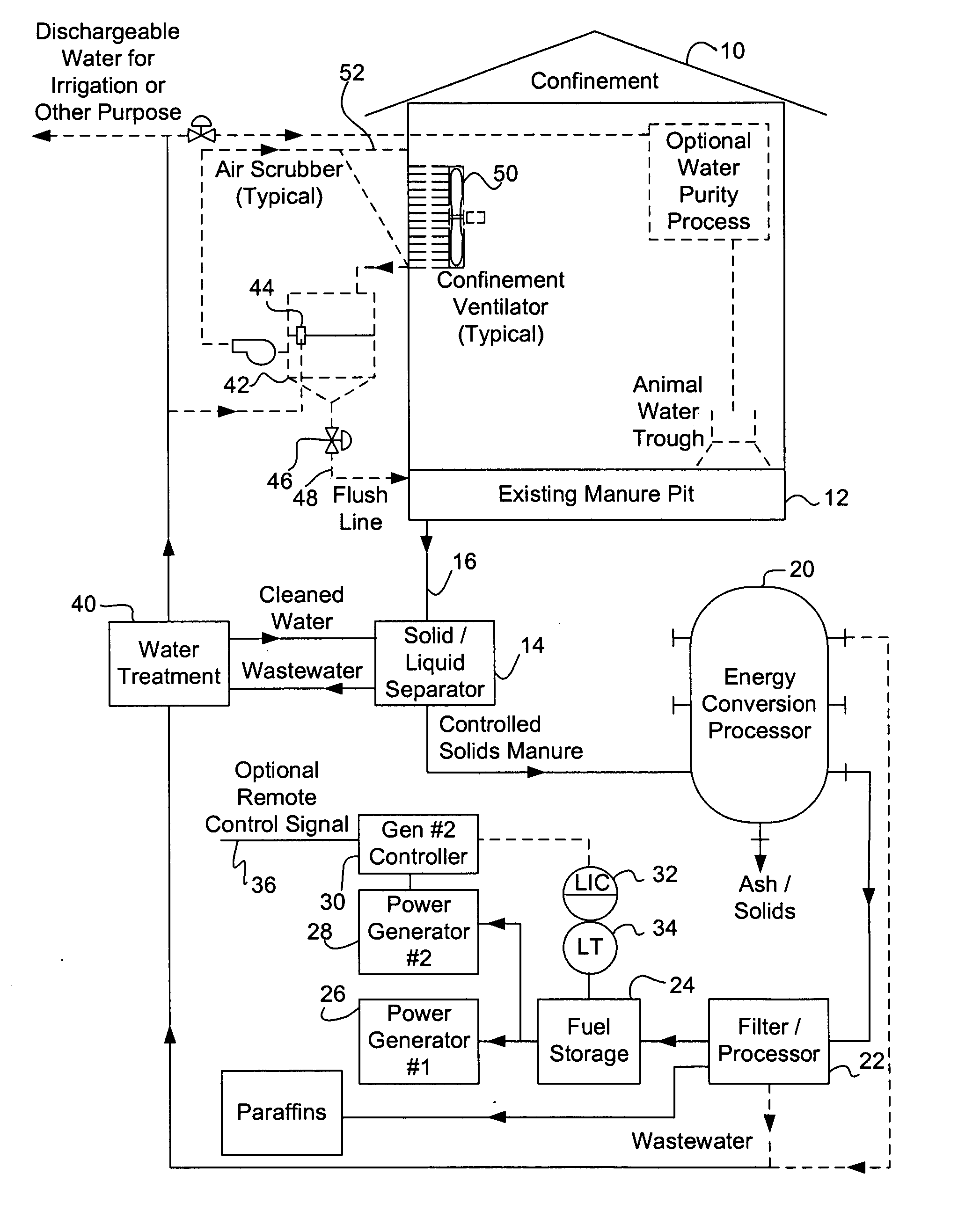

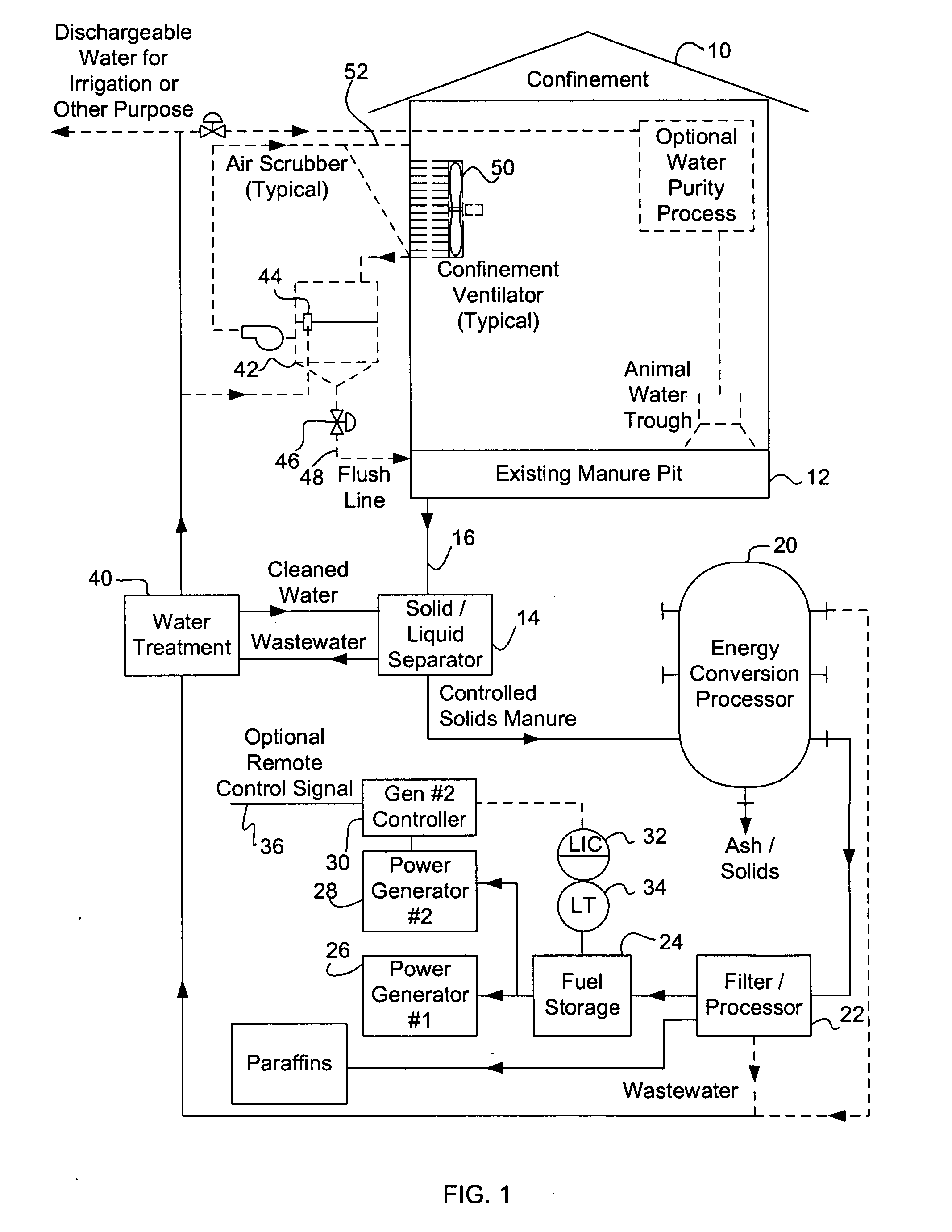

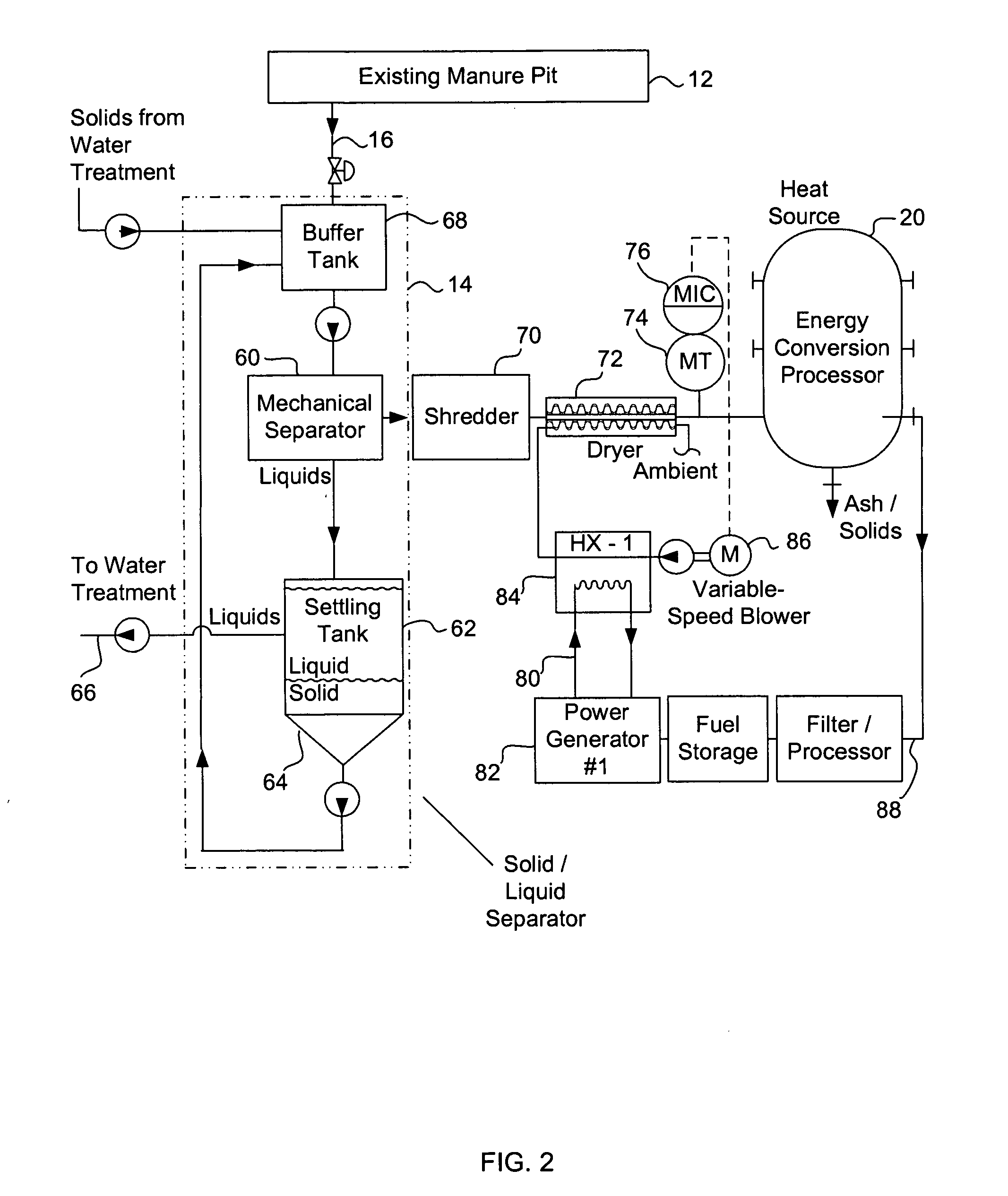

Methods and systems for converting waste into energy

ActiveUS20060278587A1Liquid separation auxillary apparatusGasifier feeding meansWaste streamMoisture

A method for receiving animal waste from animal confinements or other concentrated animal waste sources and for converting the waste into a usable form is described. The waste contains both liquids and solids. The method includes separating the liquids and solids into separate waste streams, controlling an amount of moisture in the solids waste stream such that the amount of moisture in the solid waste stream is compatible with a selected energy conversion process, and feeding the moisture controlled solid waste into the energy conversion process.

Owner:SNAPSHOT ENERGY LLC

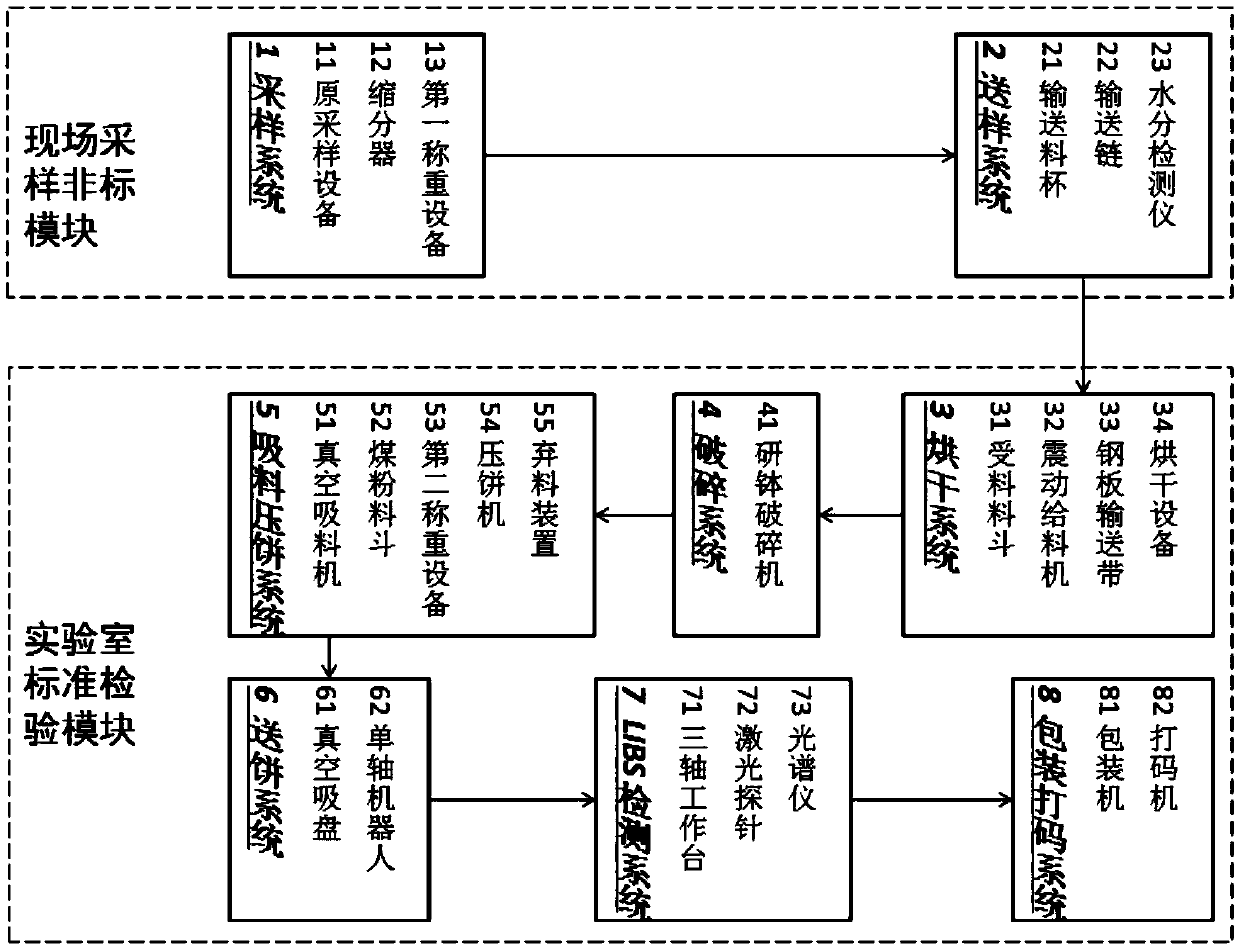

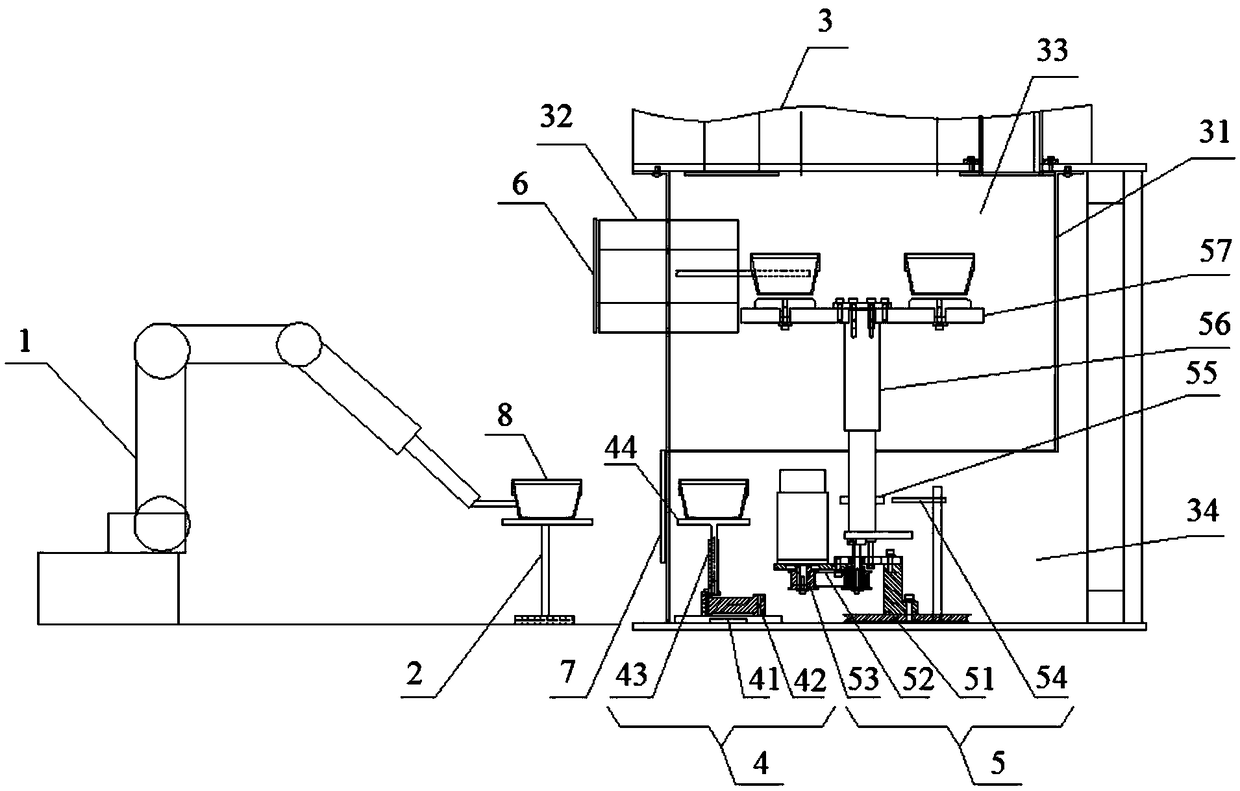

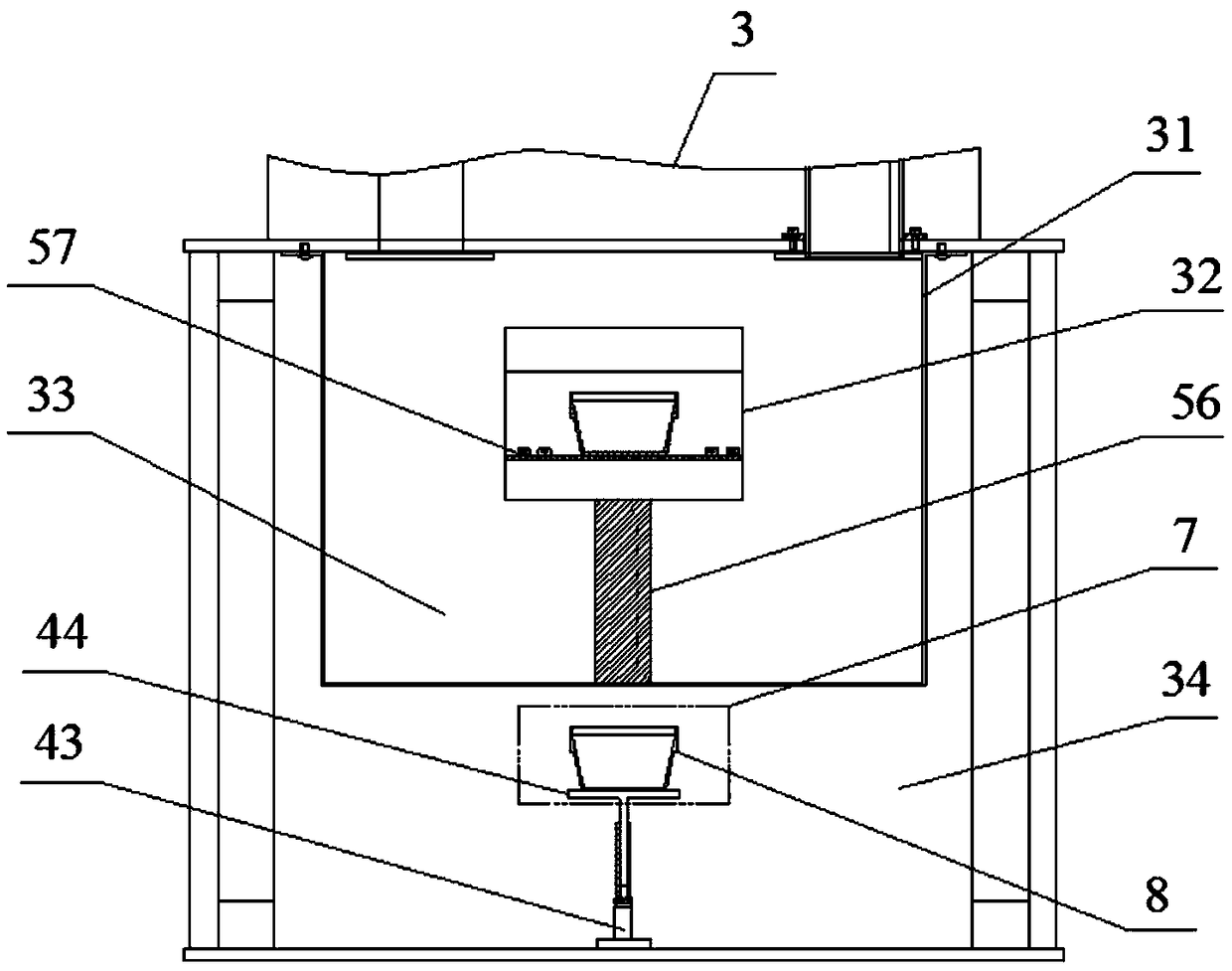

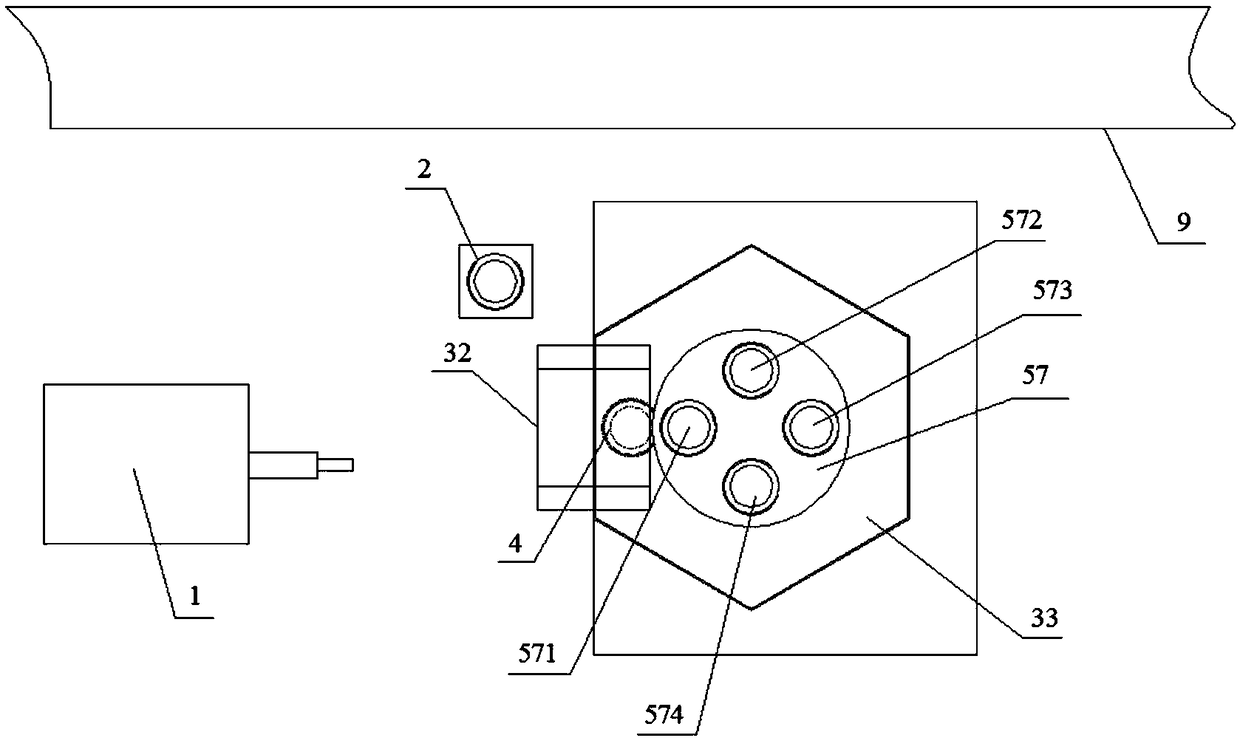

LIBS (Laser-induced Breakdown Spectroscopy) intelligent online rapid detection system for coal quality

PendingCN109557278ASolve the problem of long coal quality analysisSolve the problem of long analysis timePreparing sample for investigationFuel testingBiochemical engineeringModular design

An LIBS (Laser-induced Breakdown Spectroscopy) intelligent online rapid detection system for coal quality comprises eight modules of a sampling system, a sample delivery system, a drying system, a crushing system, a material-sucking and cake-pressing system, a cake delivery system, an LIBS detection system and a packaging and coding system, wherein the sampling system is used for acquiring a total-moisture coal sample and sending the total-moisture coal sample to the sample delivery system; the sample delivery system delivers the coal sample to the drying system; the drying system controls themoisture of the total-moisture coal sample within a certain range; the crushing system is used for grinding the coal sample subjected to the drying system to obtain pulverized coal; the cake-pressingsystem is used for completing pressing of coal cakes; the cake delivery system sends the two pressed coal cakes to the LIBS detection system and the packaging and coding system, respectively; the LIBS detection system is used for detecting one of the coal cakes; and the packaging and coding system is used for completing automatic packaging and code spraying of the two coal cakes. According to theLIBS intelligent online rapid detection system for the coal quality provided by the invention, the effect that the charging coal quality of a coal-fired power plant is analyzed and detected timely, rapidly and accurately is implemented; the modular design is adopted; and the intelligent online rapid detection system is suitable for use of different combinations under various working conditions and is convenient to install and maintain.

Owner:湖北凯瑞知行智能装备有限公司

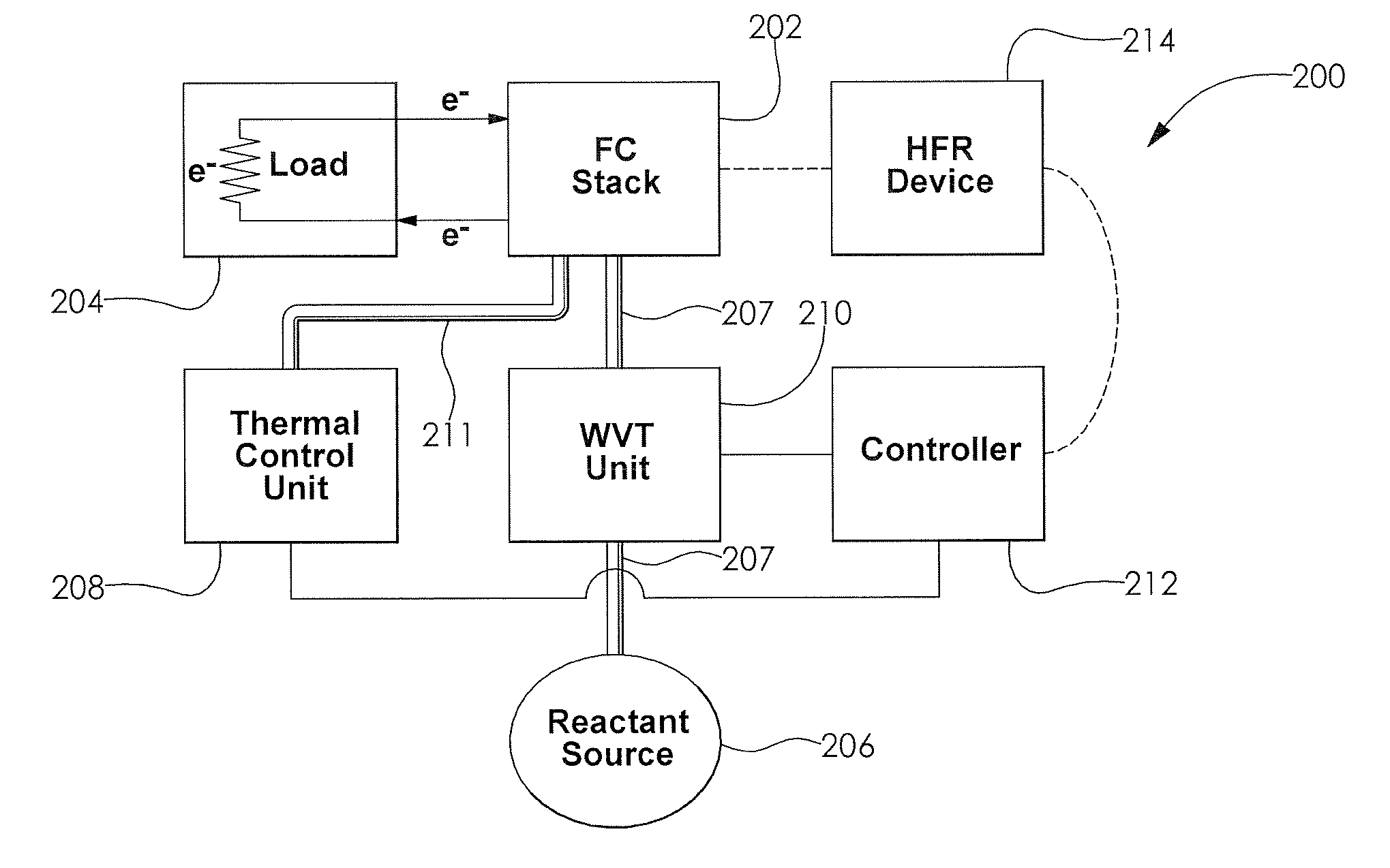

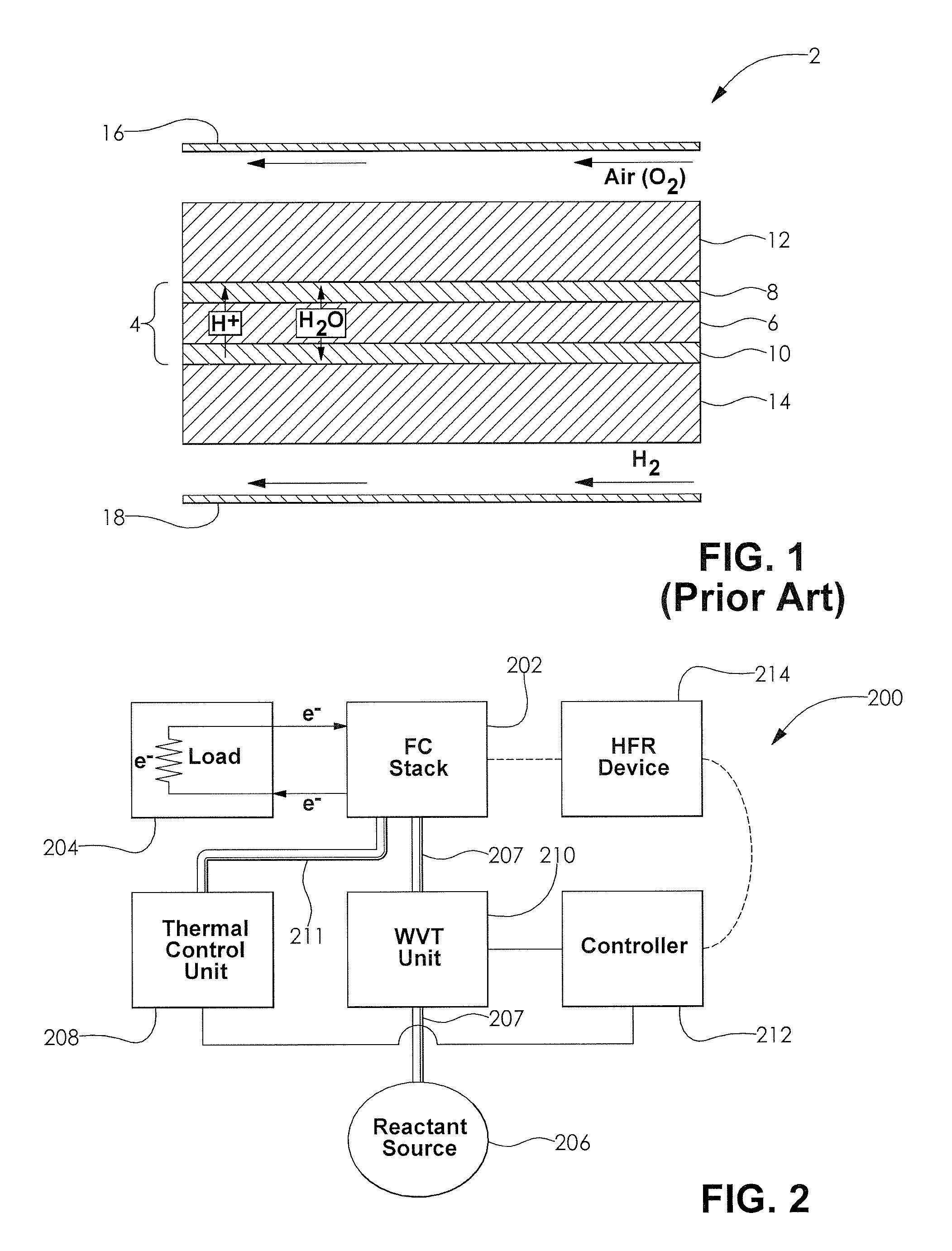

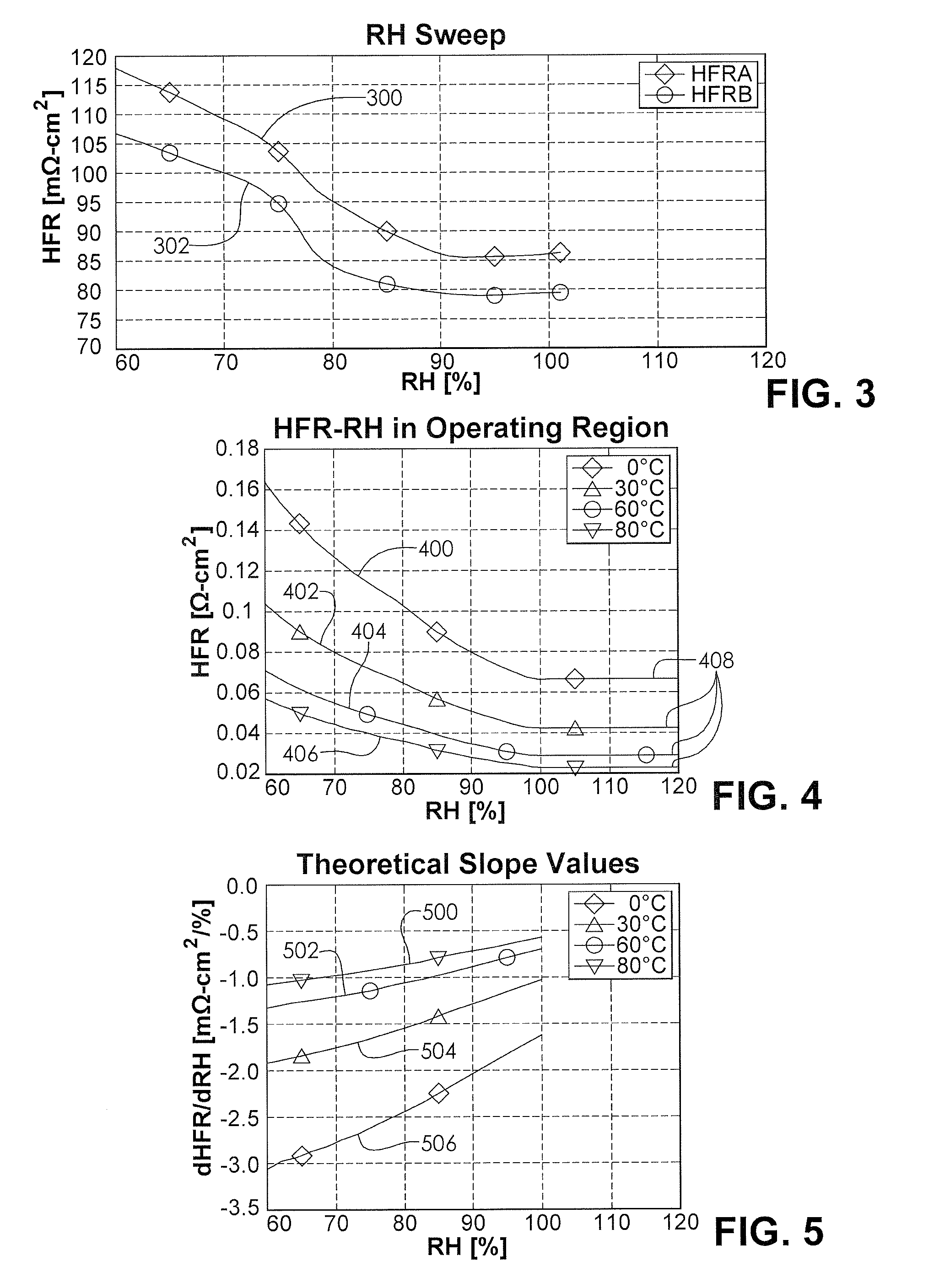

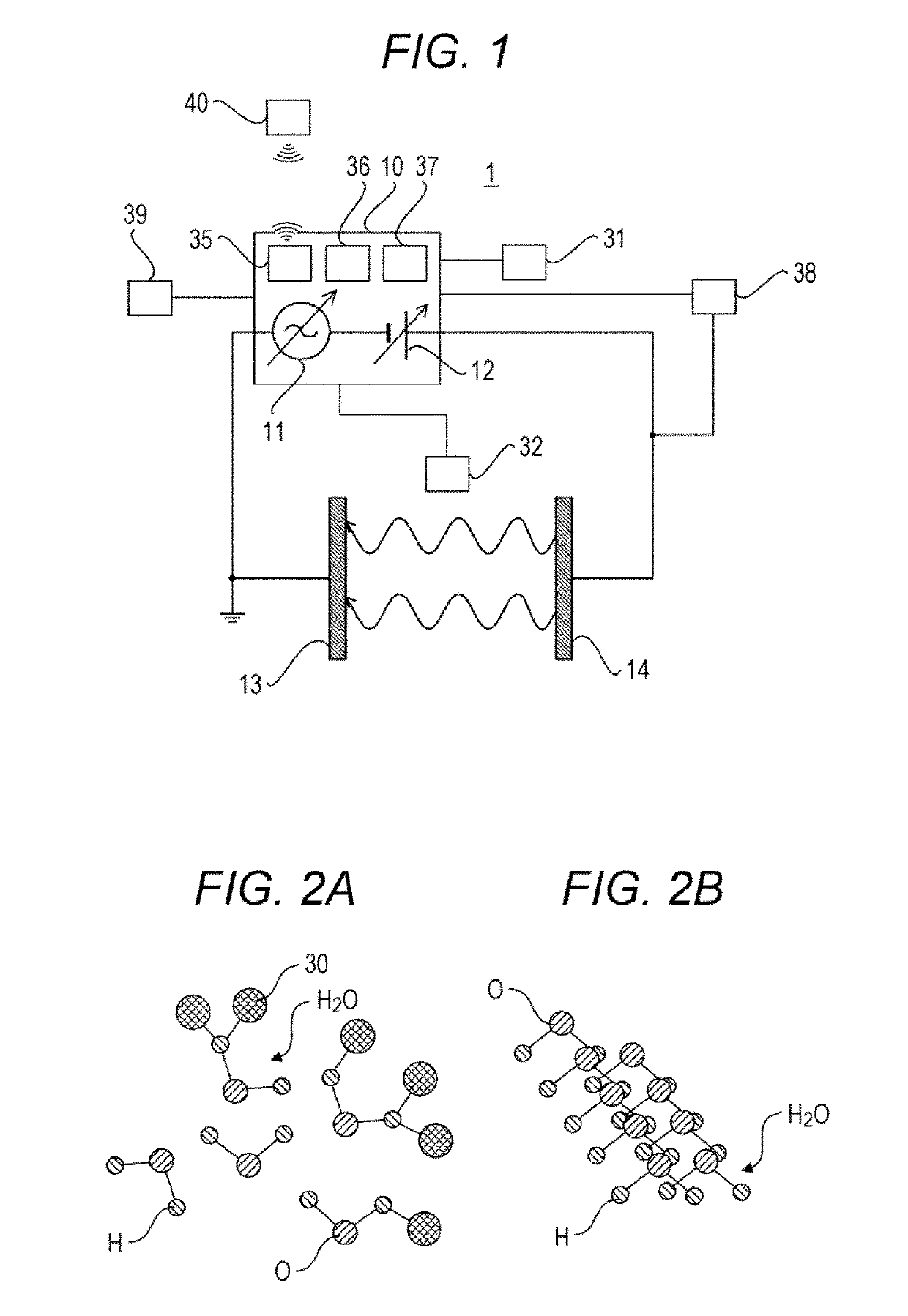

On-line system identification and control of fuel cell humidification via HFR measurements

A fuel cell system is provided, including an HFR measurement device in electrical communication with a fuel cell stack. The HFR measurement is used online to measure an HFR of the fuel cell stack suitable for calculation of a d(HFR) / d(RH) ratio. A humidity regulator is provided in fluid communication with the fuel cell stack. A controller periodically changes stack operating conditions to perturb an RH of the fuel cell stack, process the HFR response, and compute the d(HFR) / d(RH) ratio. A method for online identification and control of the fuel cell stack humidification is also provided. The d(HFR) / d(RH) ratio is an auxiliary measurement of membrane hydration which is used as a feedback for hydration control.

Owner:GM GLOBAL TECH OPERATIONS LLC

Powered activated carbon physical method regeneration technology

InactiveCN105289489ALow costLow efficiencyOther chemical processesCombustible gas purificationActivated carbonMass ratio

The invention discloses a powdered activated carbon physical method regeneration technology. The powdered activated carbon physical method regeneration technology comprises the following specific steps: (A) mixing used waste powered activated carbon (over dry), an organic bonding agent and pitch or strong cohesive coal powder according to the mass ratio of 100 to (1-3) to (5-10) to (35-50), adding water, and then mixing and kneading evenly into paste; (B) extruding the paste on a banded extruder into charcoal sticks with the diameters of 3-6mm; (C) putting the dried charcoal sticks in an activating furnace, and introducing vapor at the temperature of 700-850 DEG C to activate; and (E) crushing the activated charcoal sticks so as to obtain powdered activated carbon regeneration products. The powdered activated carbon physical method regeneration technology can be realized industrially and conveniently, and has the advantages of energy conservation, environmental friendliness, high efficiency and low cost.

Owner:CHINA UNIV OF MINING & TECH

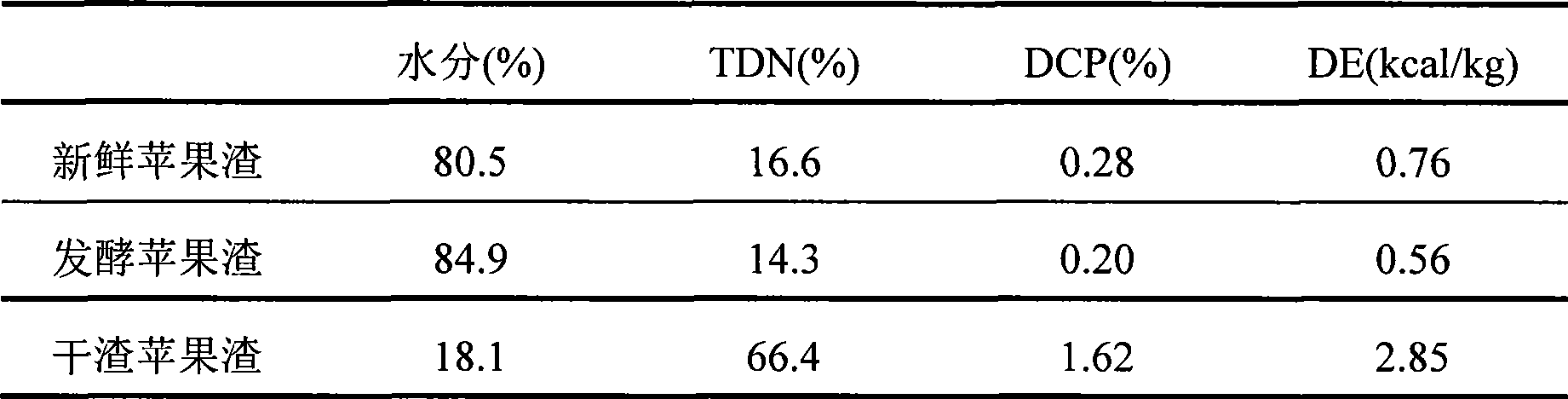

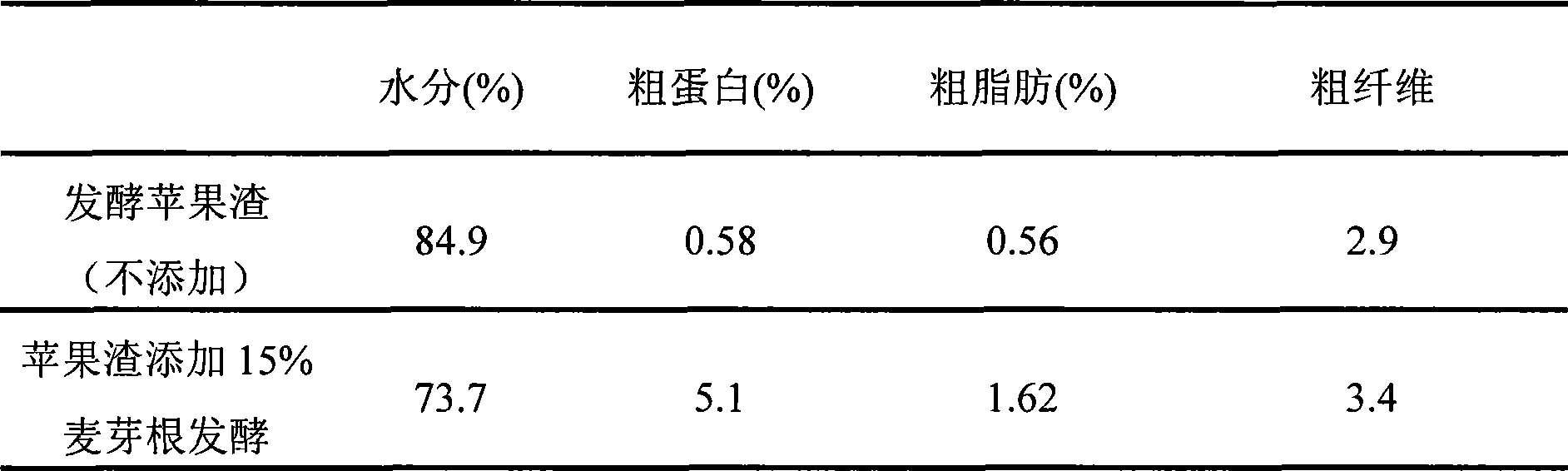

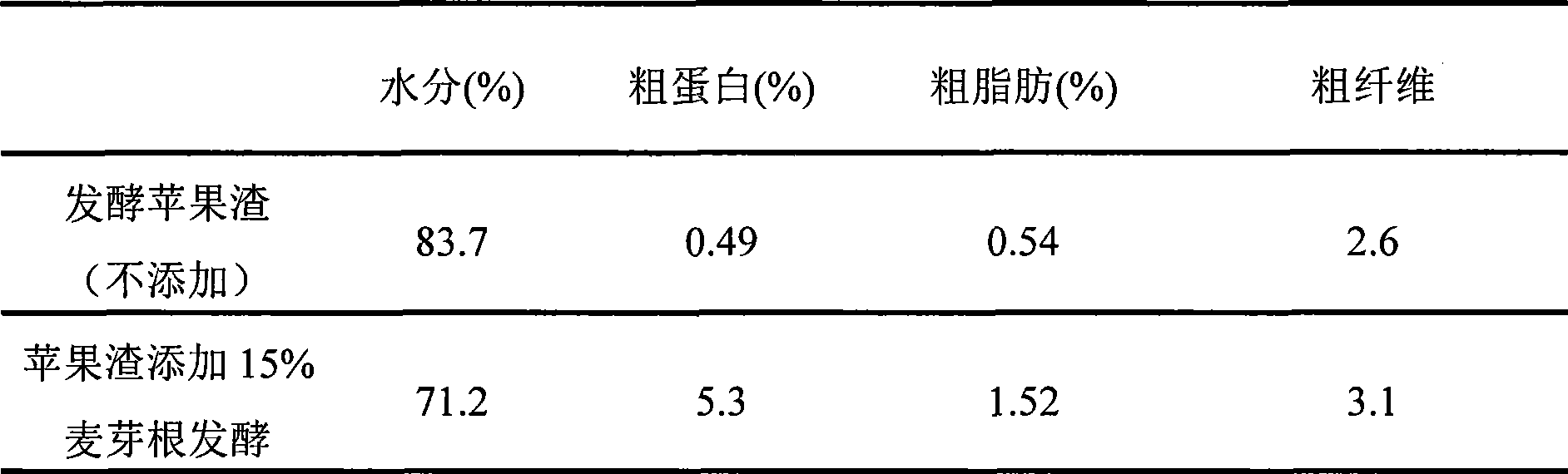

Method for producing protein feed by using apple pulps and malt roots as raw materials

InactiveCN101530154AFermentation function does not affectAnimal feeding stuffBiotechnologyAdditive ingredient

The invention relates to the feed field, in particular to a method for producing a protein feed by using apple pulps and malt roots as raw materials. The method comprises the following steps: 1) mixing the fresh apple pulps and malt roots based on the mass ratio of 9:1-8:2 and controlling the moisture content between 65-75% after mixing; 2) stirring the mixture uniformly and fermenting the mixed materials; 3) sub-packing the fermentation product which can be used as a protein feed. The apple pulps and malt roots are mixed and fermented based on certain proportion; the nutrient contents and characteristics of the two raw materials have strong complementarity; the two raw materials have high output in China and are feasible in production.

Owner:赵欣 +2

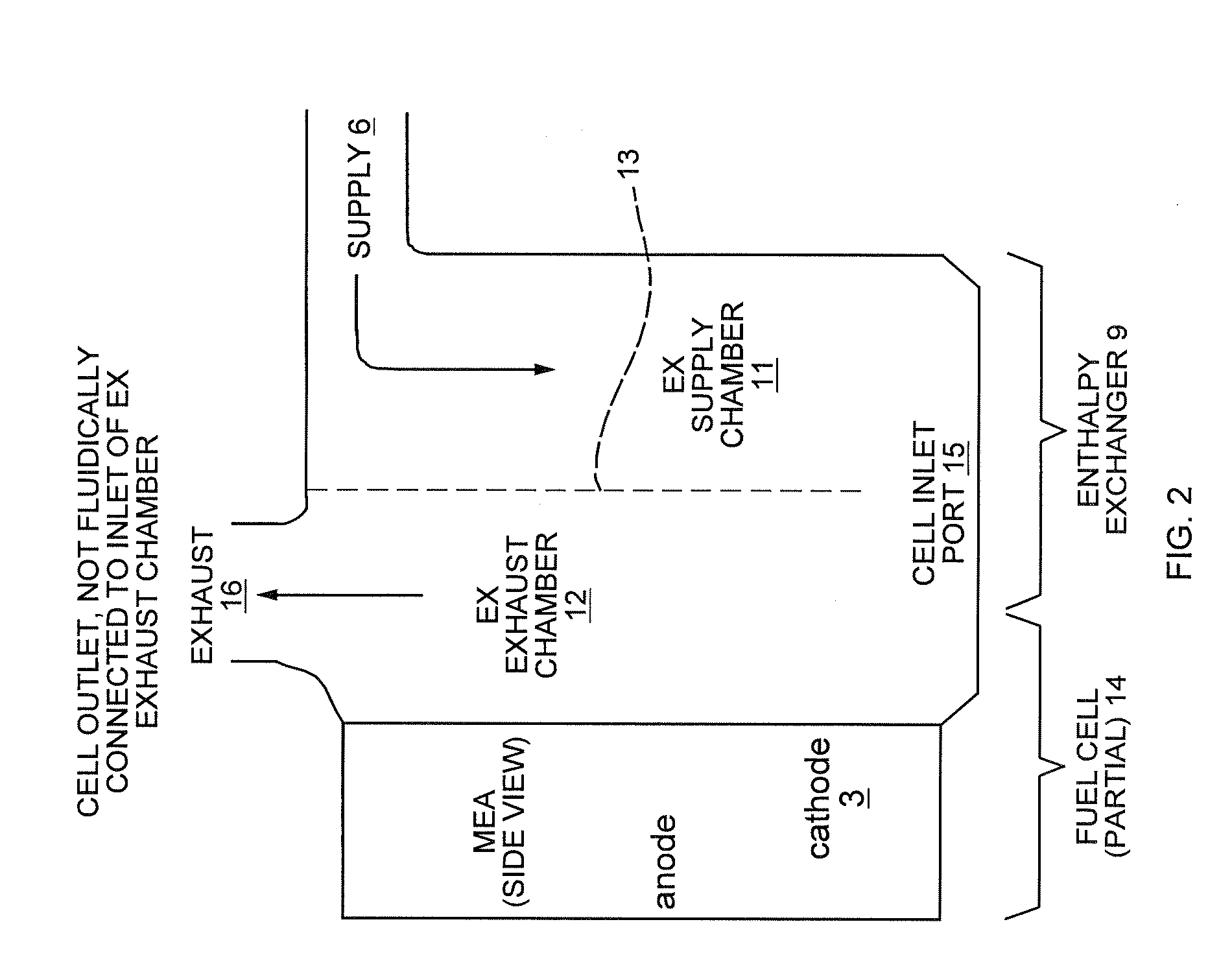

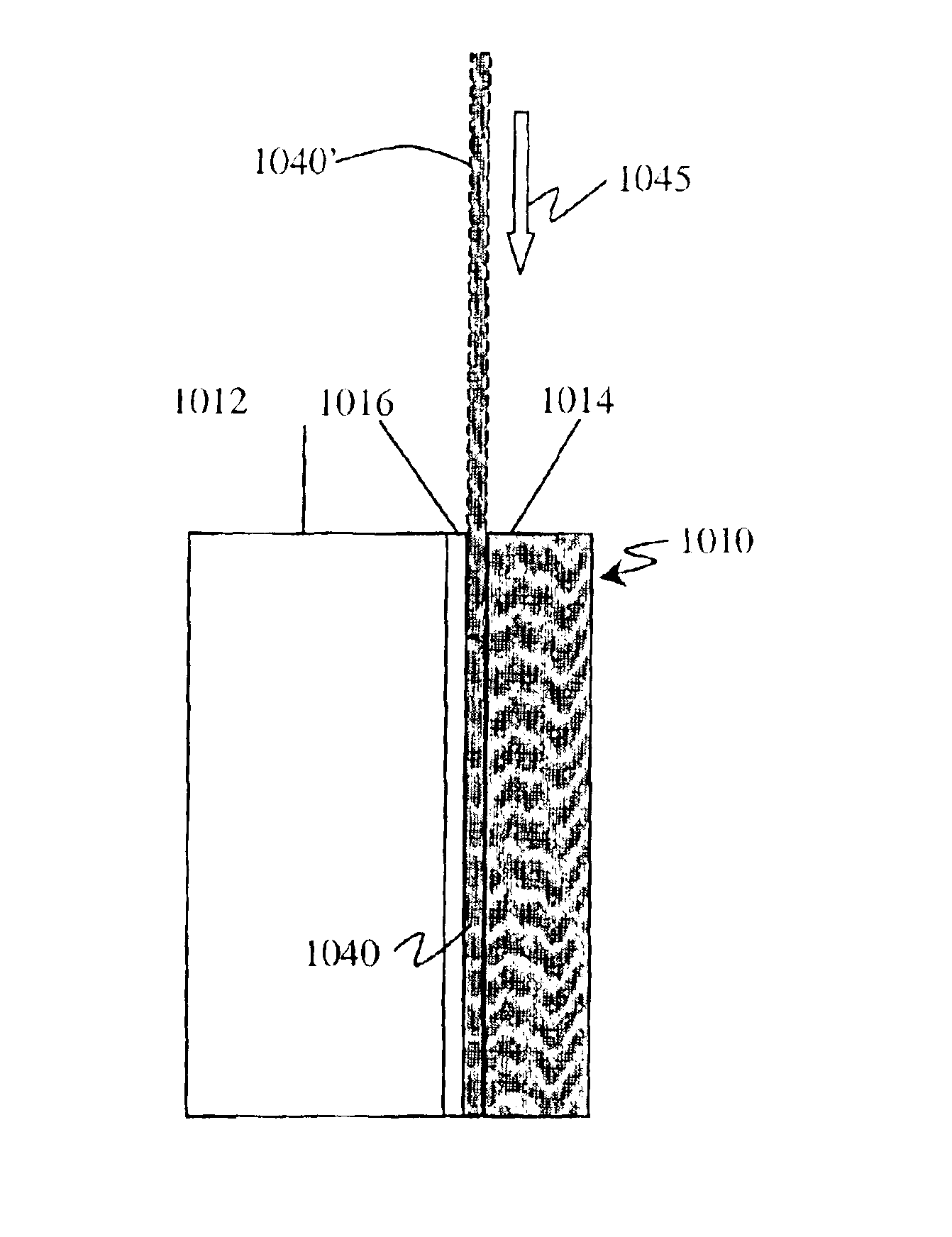

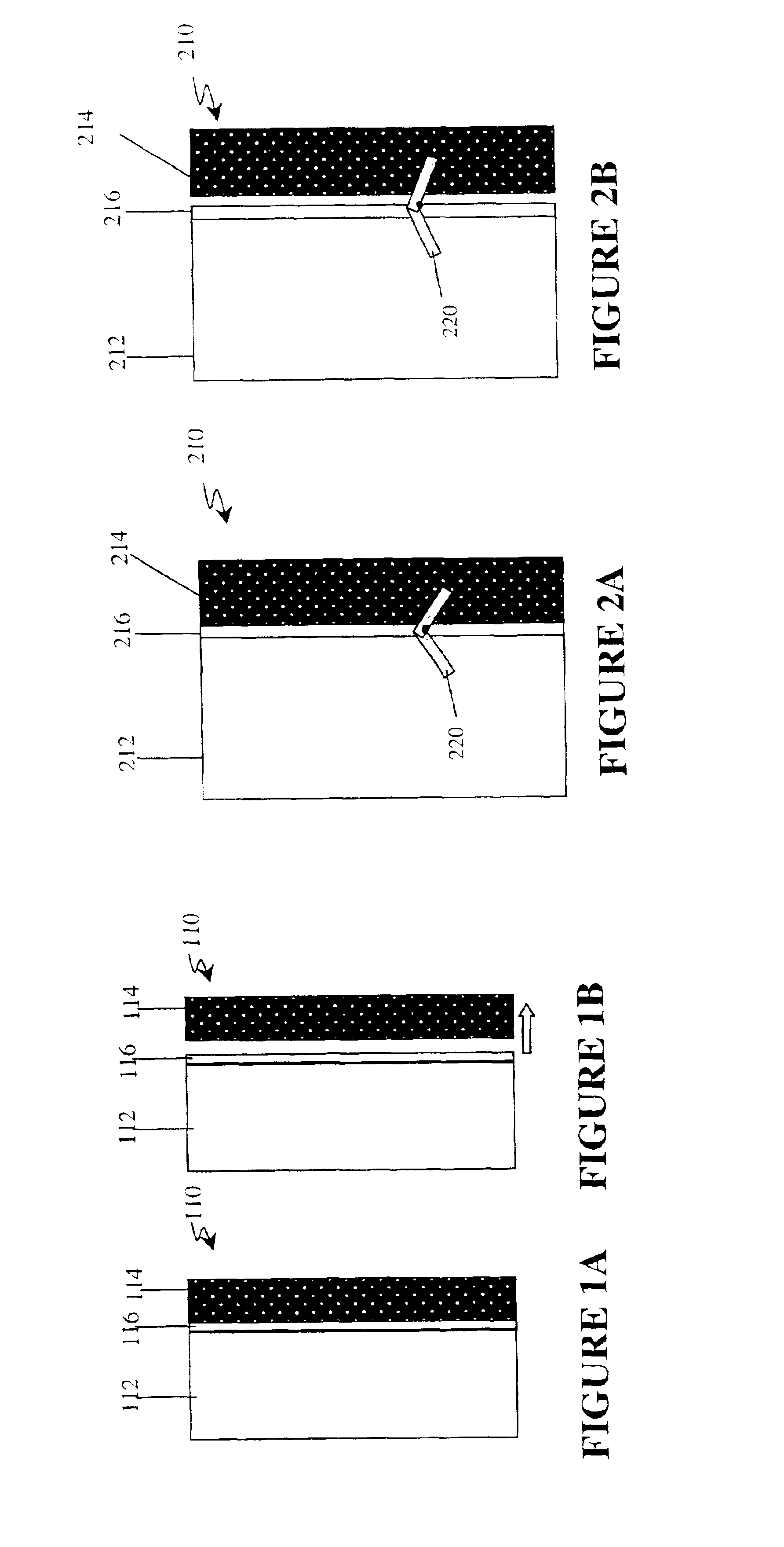

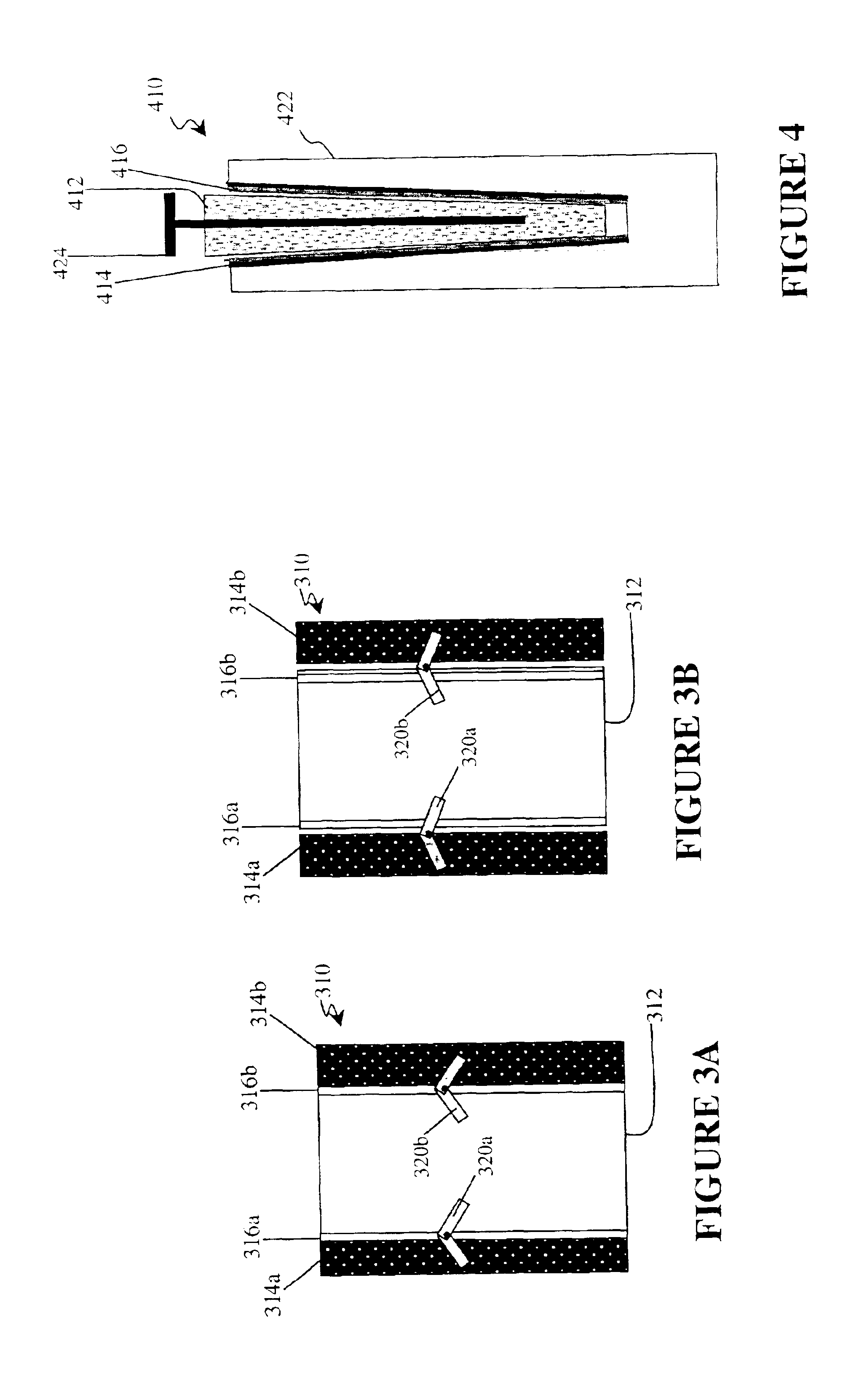

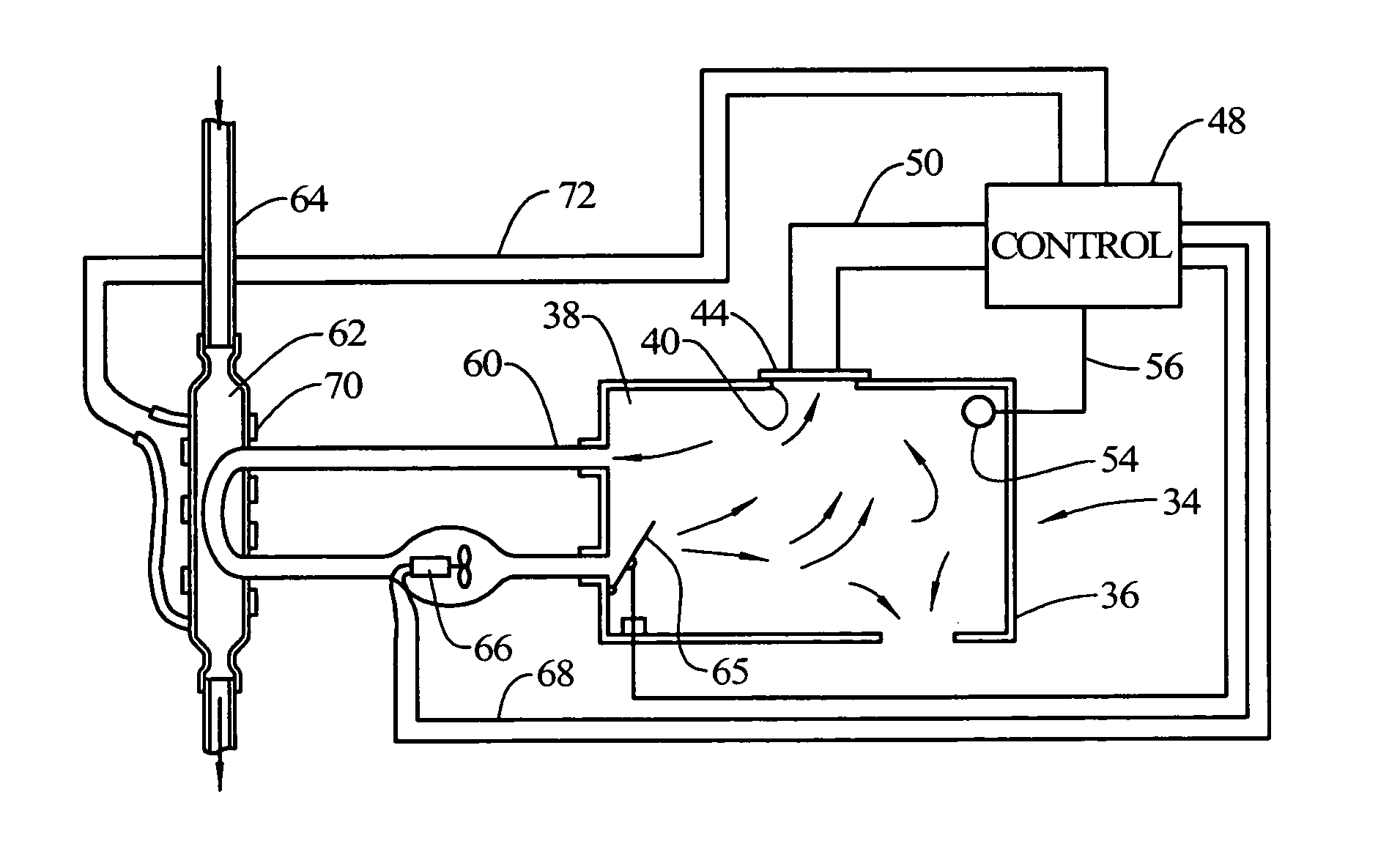

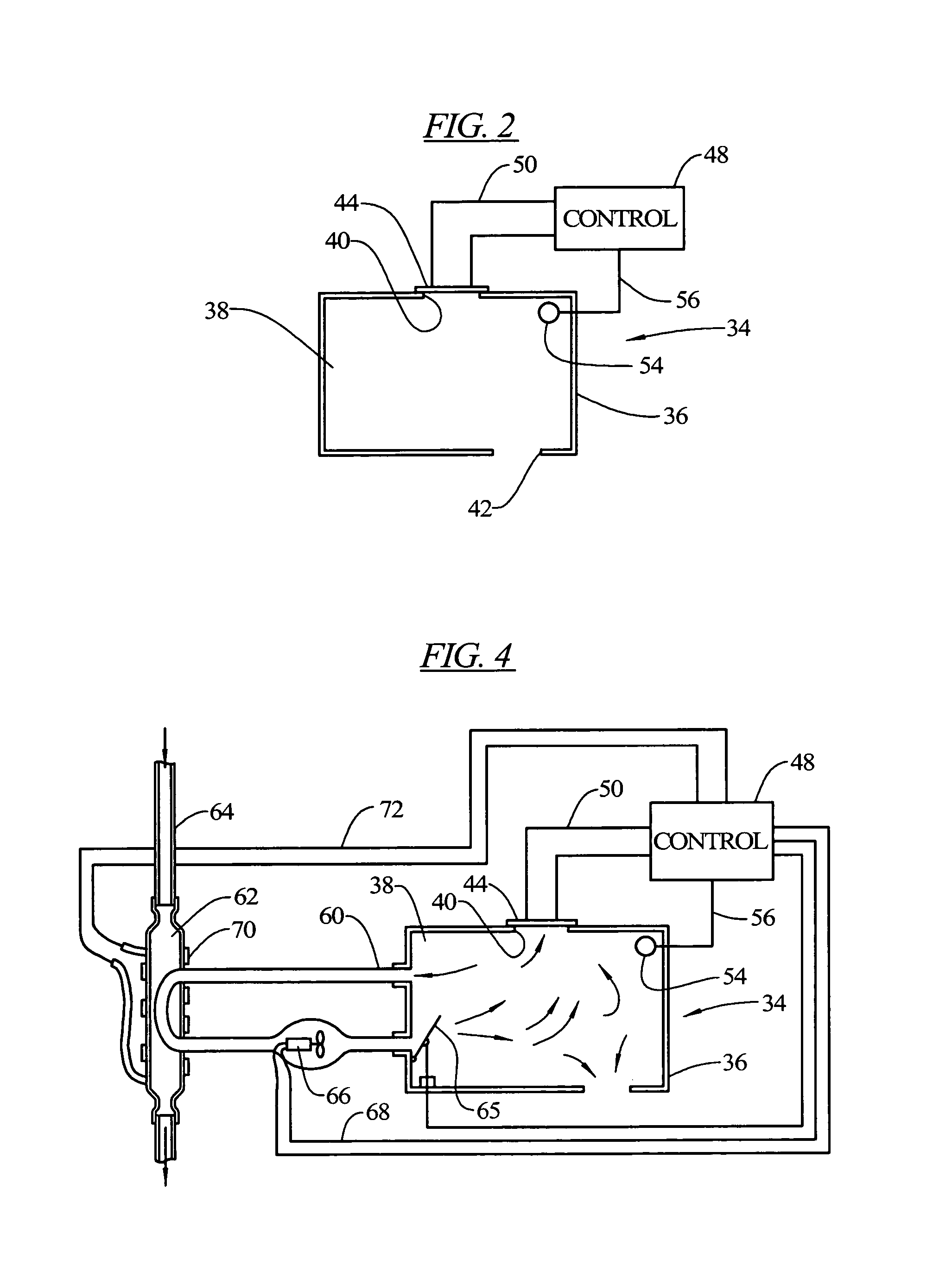

Method and apparatus for internal hydration of a fuel cell system

InactiveUS20080220305A1Overcome disadvantagesGood effectFuel cell heat exchangeWater management in fuel cellsFuel cellsEngineering

A fuel cell system having internal pushback of water, with a compact, thermally integrated enthalpy exchanger enabling effective hydration control in a small fuel cell system is provided. The enthalpy exchanger provides for the moisture in the fuel cell effluent to by used to humidify the incoming air stream to allow the fuel cell to be operated at higher temperatures while avoiding dry out. The enthalpy exchanger includes a moisture permeable membrane which collects moisture from the exhaust flow and makes this moisture available to an incoming air stream, thus humidifying the incoming air stream. In addition, the waste heat from the fuel cell reactions is transferred to the incoming air stream. The exhaust stream from the anode can also be used to provide additional moisture and heat to the enthalpy exchanger to be added to the incoming air stream. A water separator is also provided in one embodiment.

Owner:MTI MICROFUEL CELLS

Metal air cell incorporating ionic isolation systems

Electrochemical cell systems are disclosed herein that are capable of selective ionic isolation, oxidant isolation, oxidant removal, moisture control, and combinations thereof. Selective ionic isolation is generally effectuated by selectively eliminating or minimizing ionic communication between an anode and a cathode of the electrochemical cell.

Owner:REVEO

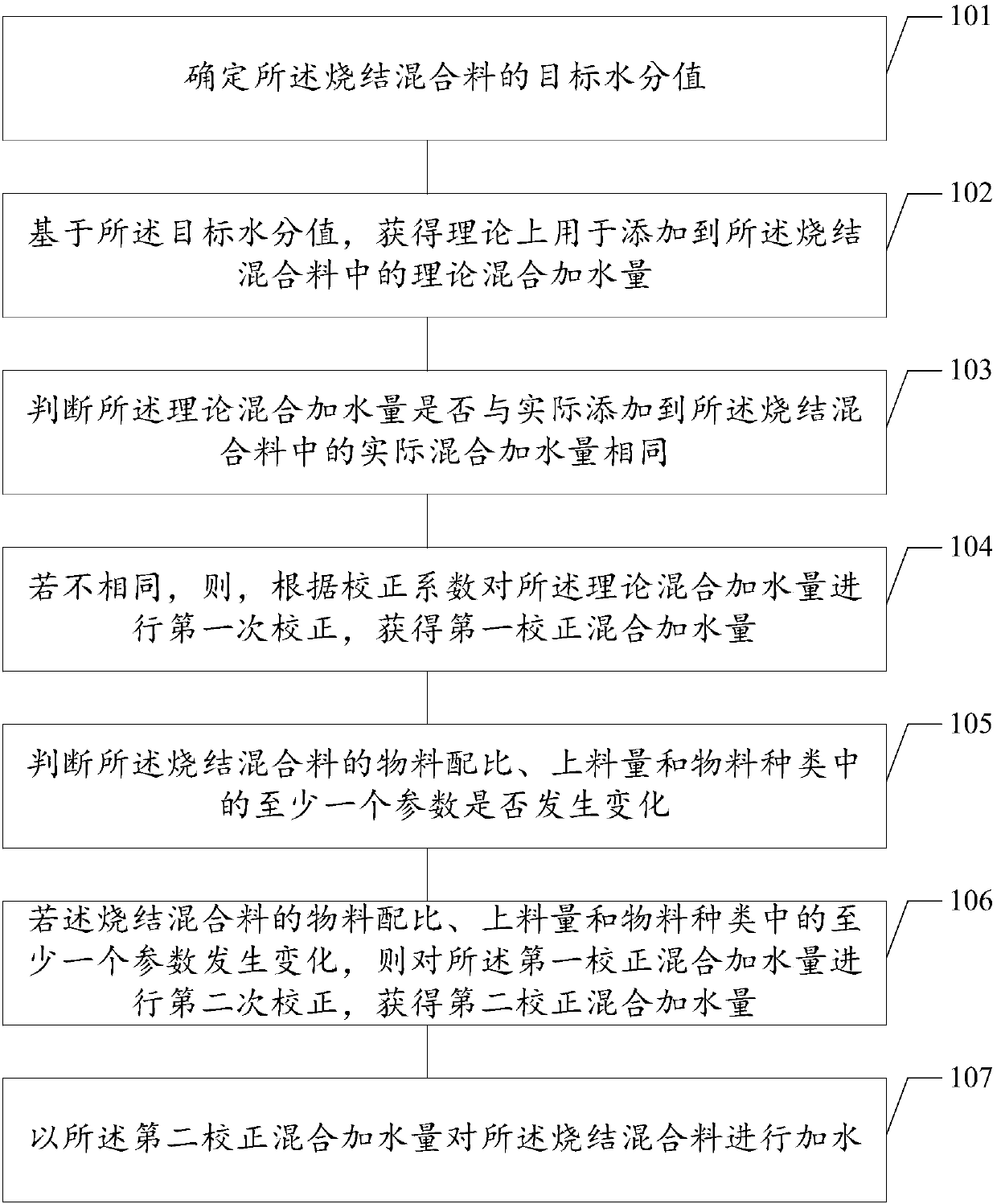

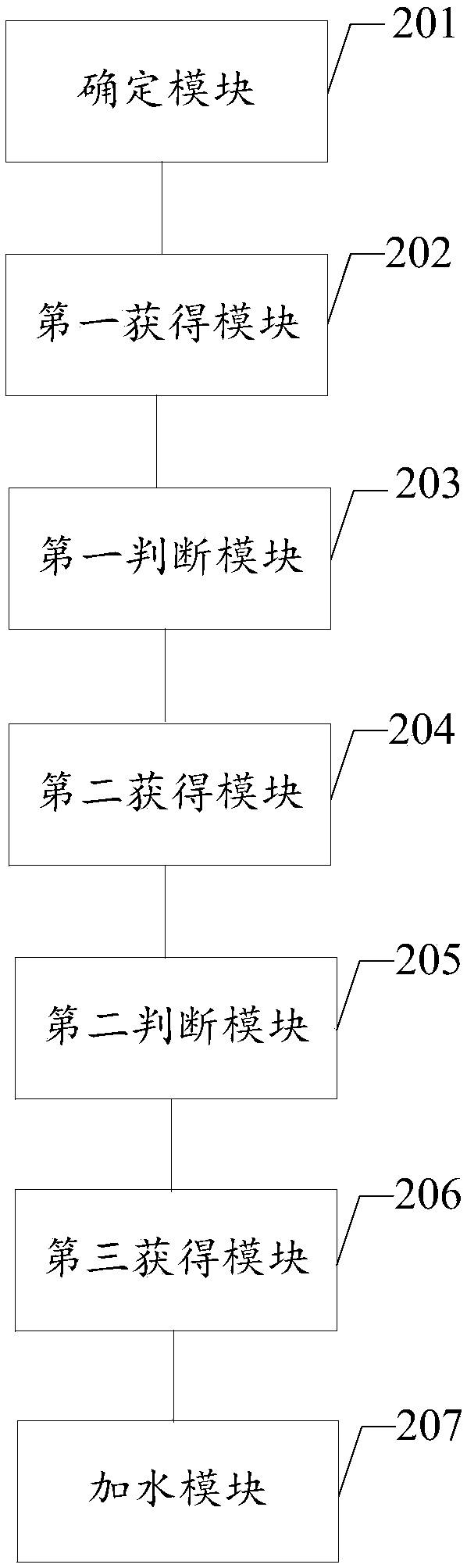

Sinter mixture moisture control method and device, computer storage medium and equipment

The invention relates to the technical field of sintering, in particular to a sinter mixture moisture control method, a sinter mixture moisture control device, a computer storage medium and equipment.The sinter mixture moisture control method comprises the steps of: determining a target moisture value of a sinter mixture; acquiring a theoretical mixed water addition amount to be added into the sinter mixture theoretically based on the target moisture value; judging whether the theoretical mixed water addition amount is the same as an actual mixed water addition amount actually added into thesinter mixture; if not, performing first correction on the theoretical mixed water addition amount according to a correction coefficient to obtain a first correction mixed water addition amount; judging whether at least one parameters of materiel proportion, a material loading amount and material types of the sinter mixture changes; if the at least one parameters of materiel proportion, the material loading amount and the material types of the sinter mixture changes, performing second correction on the first correction mixed water addition amount to obtain a second correction mixed water addition amount; and adding water into the sinter mixture according to the second correction mixed water addition amount.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +2

Methods and systems for converting waste into energy

A method for receiving animal waste from animal confinements or other concentrated animal waste sources and for converting the waste into a usable form is described. The waste contains both liquids and solids. The method includes separating the liquids and solids into separate waste streams, controlling an amount of moisture in the solids waste stream such that the amount of moisture in the solid waste stream is compatible with a selected energy conversion process, and feeding the moisture controlled solid waste into the energy conversion process.

Owner:SNAPSHOT ENERGY LLC

Method for enhancing survival rate of seedling after cutting

ActiveCN101919334AImprove the survival rate after cuttingHorticultureTemperature controlReproduction speed

The invention relates to a method for enhancing the survival rate of a seedling after cutting, comprising the following steps of moisture control, sterilization, fertilizer supplementation and temperature control. The method can enhance the growth and reproduction speed of the seedling after cutting, promote root development and has the cutting survival rate above 95 percent.

Owner:SUZHOU FULLCOLUR ECOLOGICAL AGRI SCI & TECH GRP CO LTD

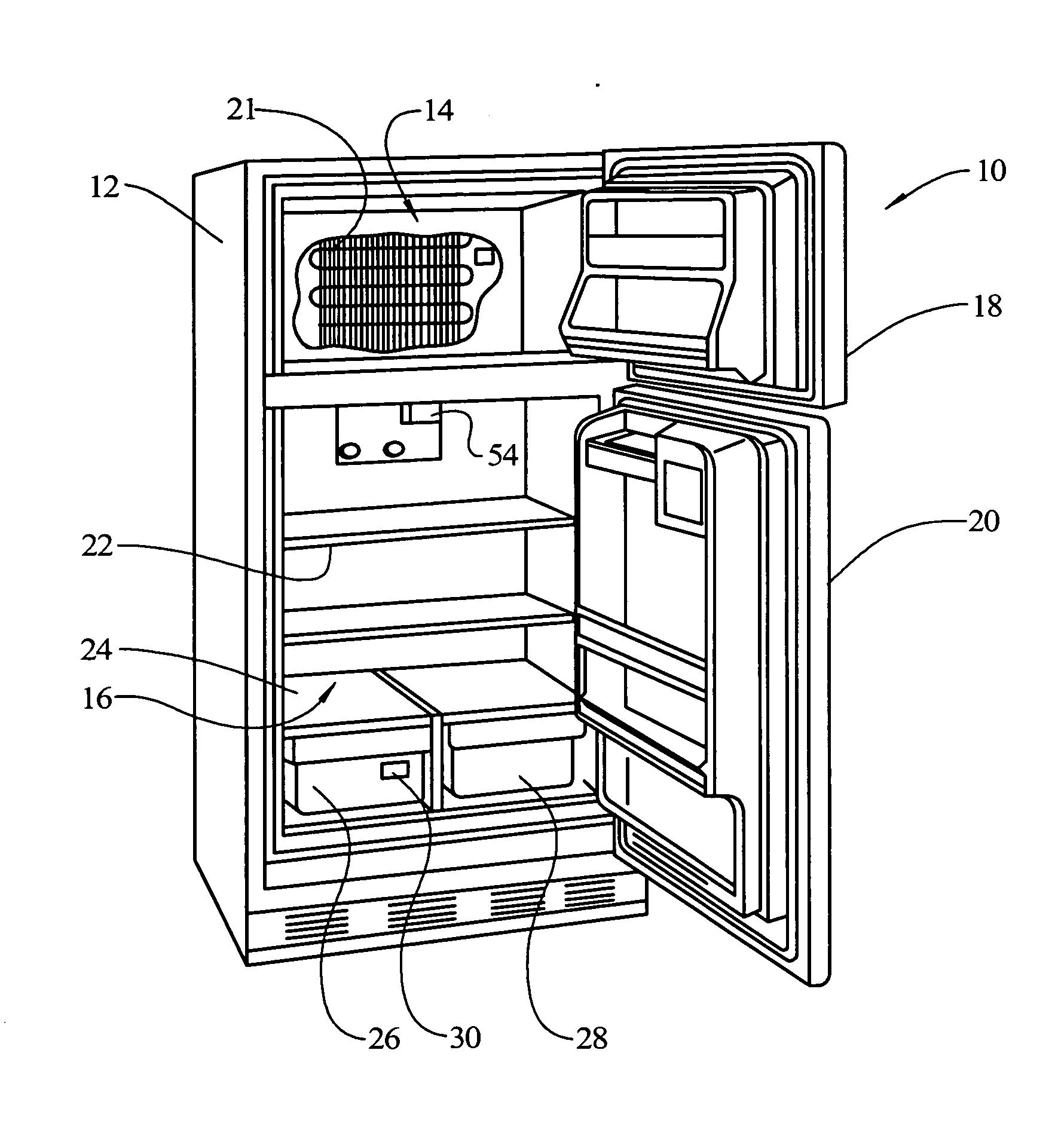

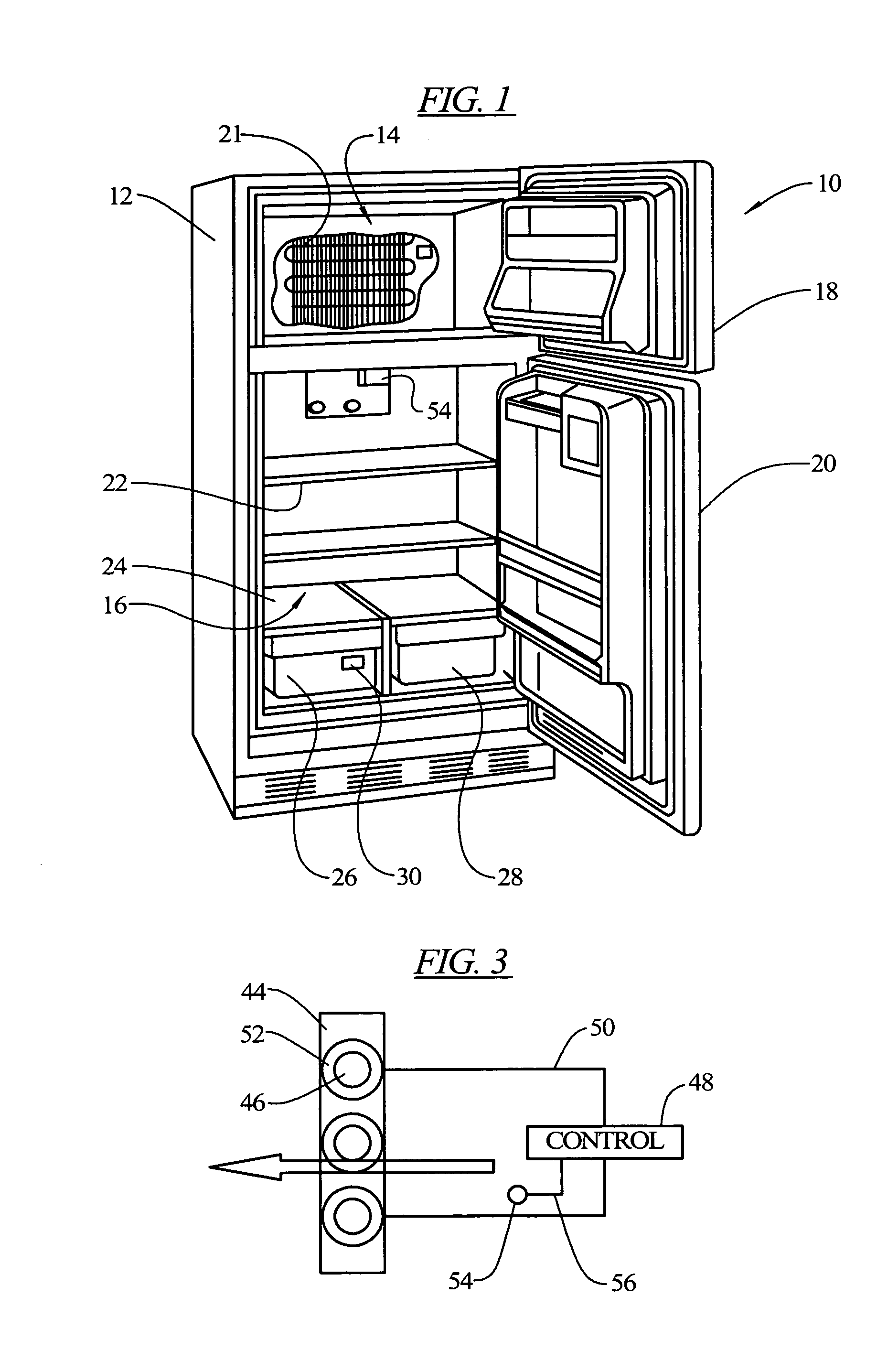

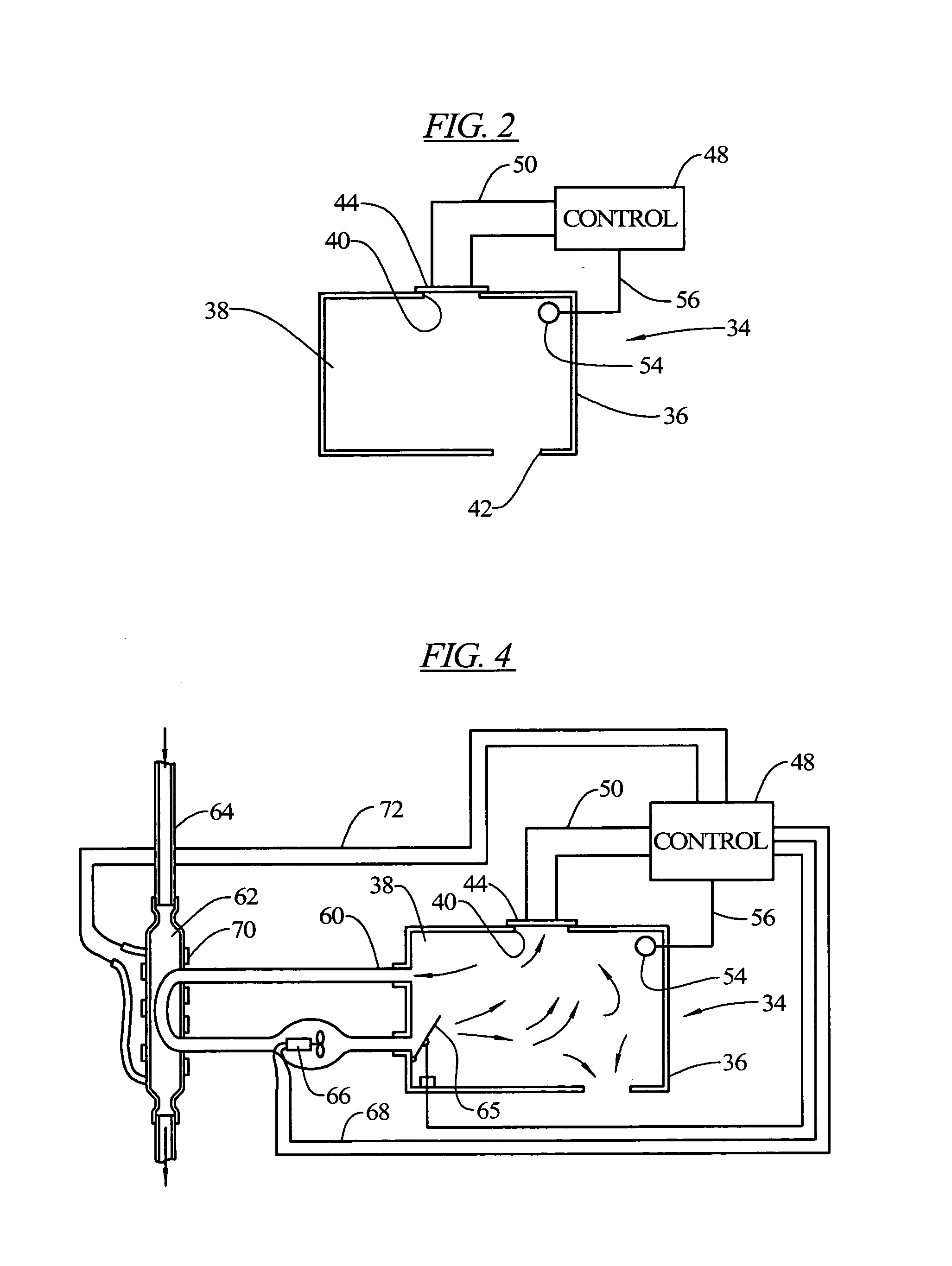

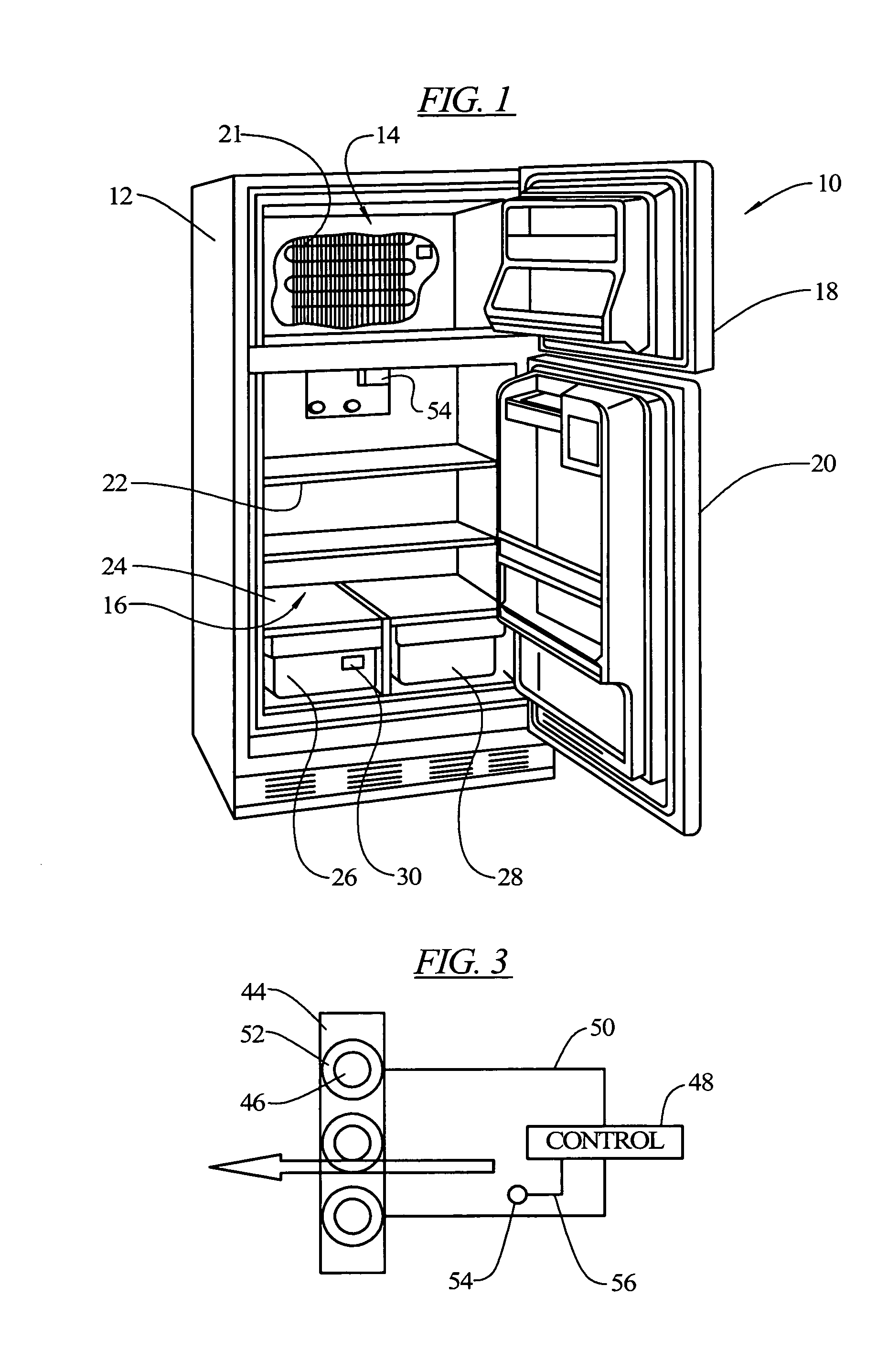

Active moisture control barrier and active humidity controlled space

InactiveUS20070113565A1Domestic refrigeratorsRefrigeration safety arrangementEngineeringControl space

An active moisture control barrier is provided which comprises a layer of shape memory polymer and a heating arrangement associated with the layer of shape memory polymer. The barrier may be used to provide an active humidity controlled space having an enclosure with walls to separate an interior of the enclosure from an environment surrounding the enclosure. An opening in one of the walls allows communication between the interior of the enclosure with the environment. A layer of shape memory polymer is provided at the opening to isolate the interior of the enclosure from the environment. A control may be provided for the heating arrangement to allow for a heating of the layer to a level as controlled or set by a user. An air passage conduit may extend from the interior of the enclosure through a zone of relatively higher water vapor pressure. The air passage conduit may be formed, at least in part, of shape memory polymer to allow water vapor to migrate from the zone of relatively higher water vapor pressure into the interior of the enclosure thereby adding moisture into the enclosure.

Owner:WHIRLPOOL CORP

Active moisture control barrier and active humidity controlled space

Owner:WHIRLPOOL CORP

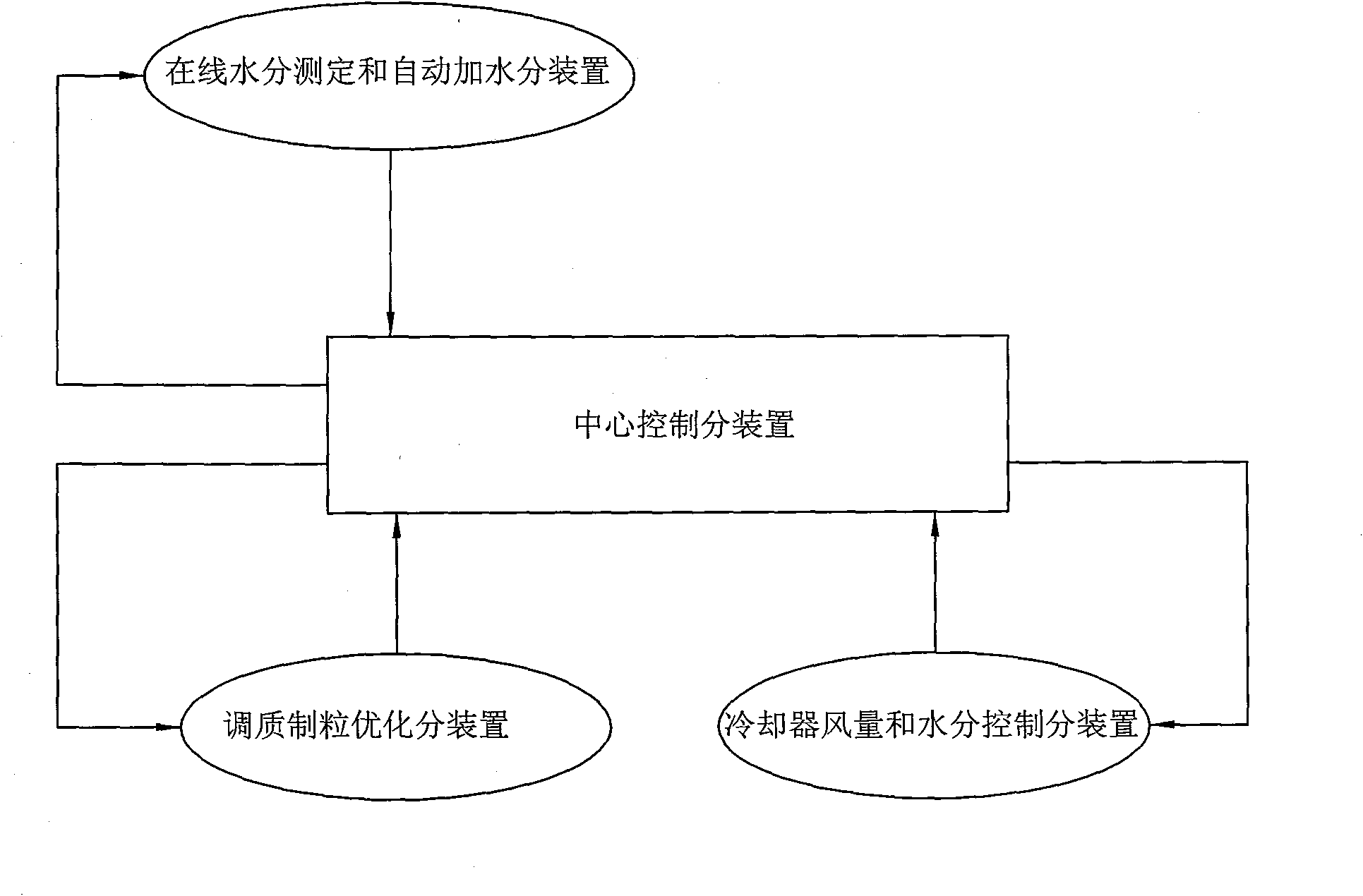

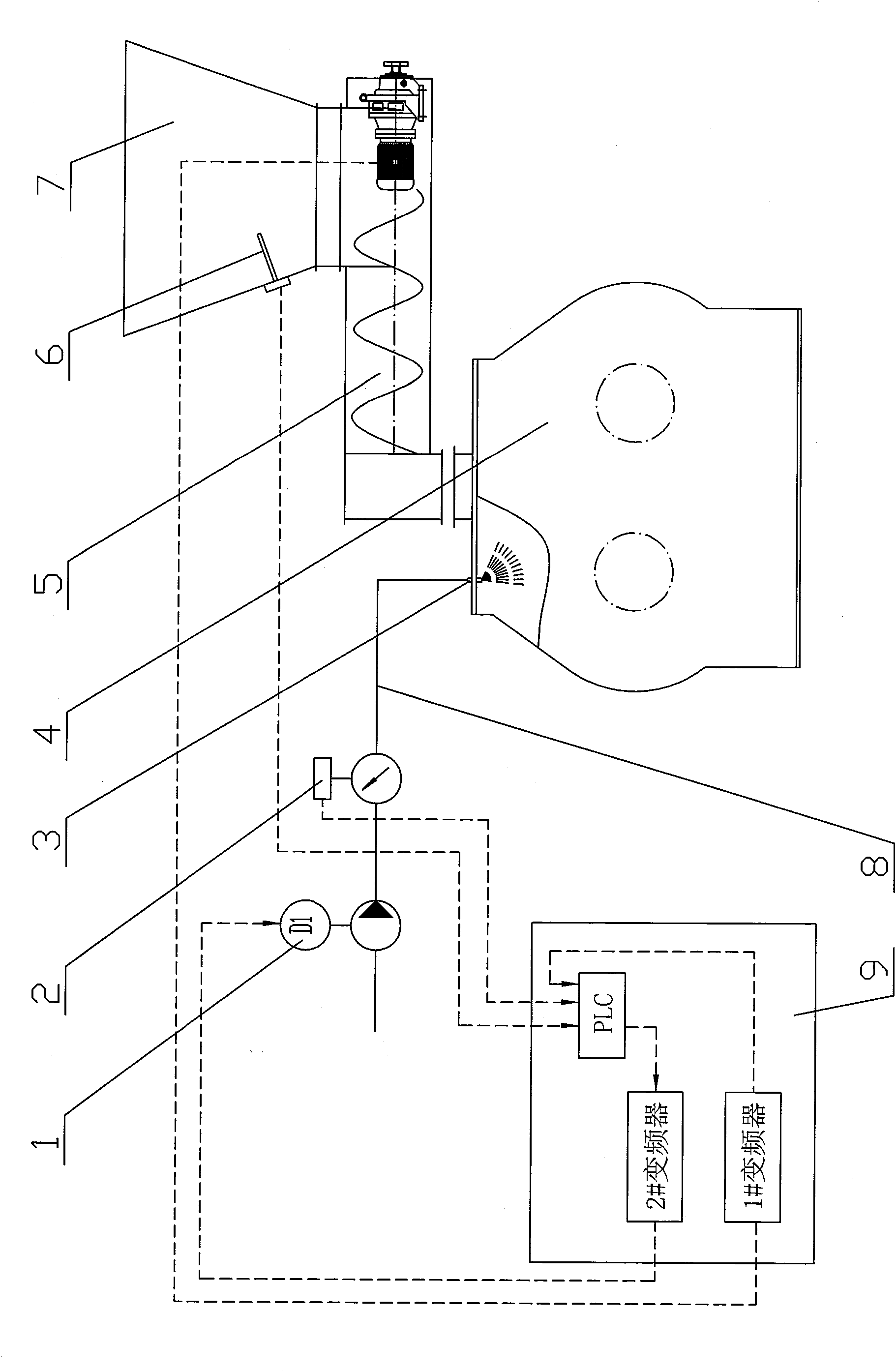

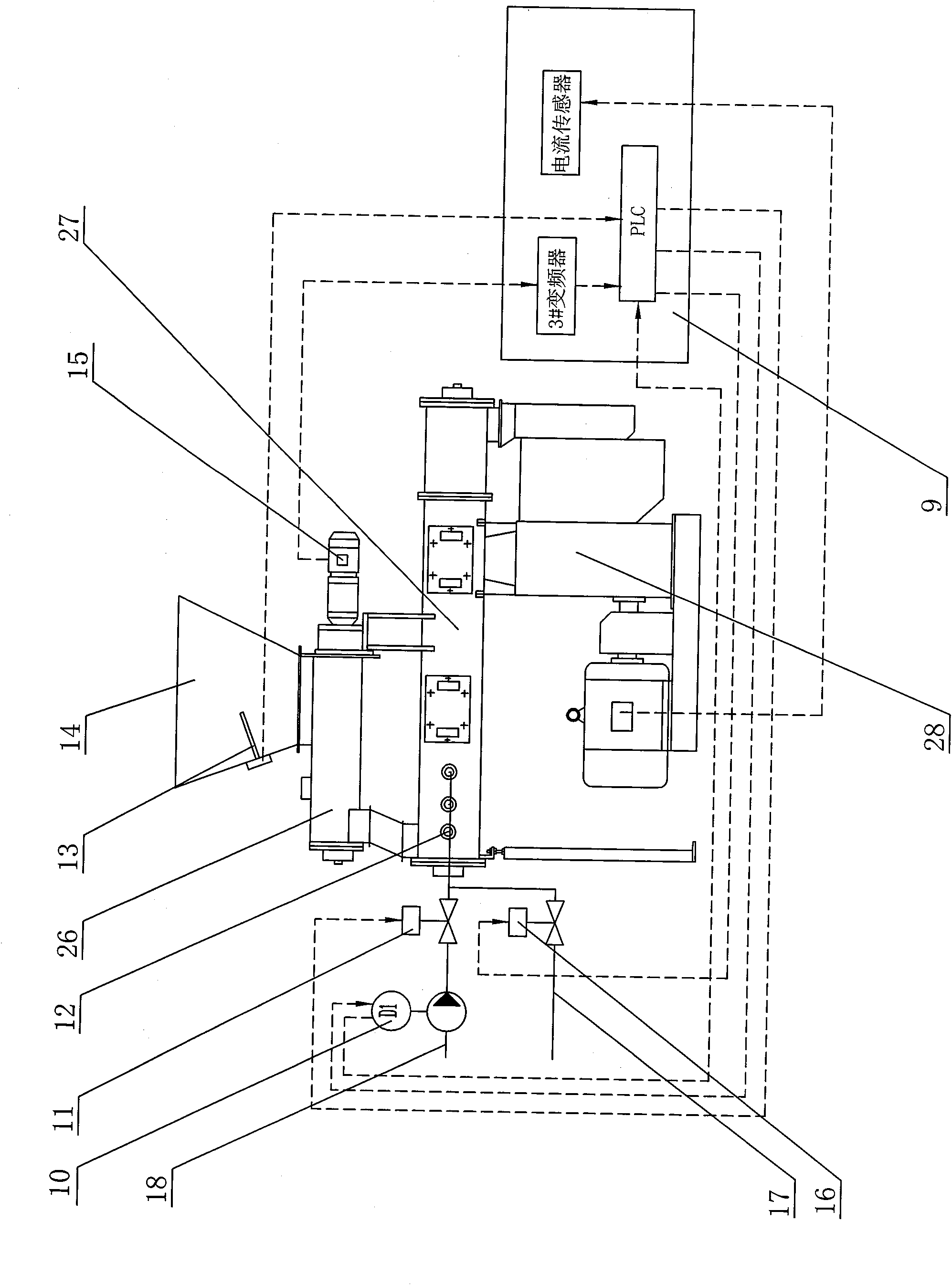

On-line water detection and pellet-fodder optimization device

ActiveCN101782564AAvoid failing moisture content indicatorsEnsure consistencyFeeding-stuffTotal factory controlAir volumeEngineering

The invention discloses an on-line water detection and pellet-fodder optimization device which comprises a powdery material buffer storehouse, a screw feeder, a granulator, a conditioner and a cooler, and is characterized in that the whole set of granulating equipment comprises an on-line water determination and automatic water feeding device, a conditioning, granulating and optimizing separated device, a cooler air volume and water control separated device and a central control separated device; and the central control separated device is respectively connected with the on-line water determination and automatic water feeding device, the conditioning, granulating and optimizing separated device, and the cooler air volume and water control separated device. The on-line water detection and pellet-fodder optimization device has the advantages of timely and precise control and convenient use operation, prevents the problem that the water content index of a large amount of finished productmaterial is unqualified because the water control is not timely, can keep the consistency of water in finished fodder and improve the fodder quality, saves time and labor, and improves the working efficiency and reduces the energy consumption; and in addition, the device prolongs the service life of a granulator circular mold through the on-line precise control of water when in fodder processing.

Owner:JIANGSU GUOLIANG STORAGE ENG CO LTD

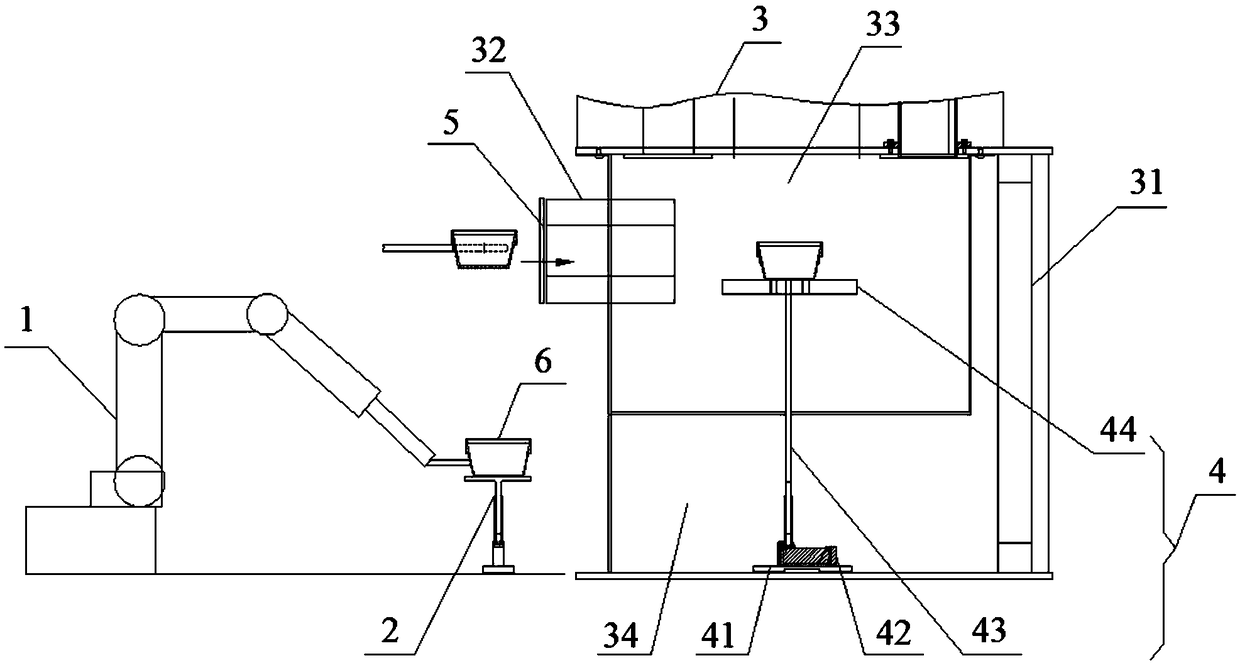

Material moisture online detection device and control method and control system thereof

ActiveCN108800761ATimely online moisture detectionAccurate dataWeighing by removing componentDrying solid materials with heatMicrowaveControl signal

The invention discloses a material moisture online detection device and a control method and control system thereof. A material moisture control system and a mechanical arm control system conduct interaction of a control signal, so that the mechanical arm control system controls a mechanical arm device to carry out corresponding operation. The mechanical arm device moves an empty material cup anda material storing cup onto a weighting tray inside a microwave drying device from the initial stations successively according to the control signal, and the weight of the empty material cup and the dry initial weight of the material storing cup are obtained through a weighing sensor. After the microwave drying process is finished, the dry ending weight of the material storing cup is obtained. According to the weight of the empty material cup, the drying initial weight of the material storing cup and the drying ending weight of the material storing cup, the content of moisture in to-be-detected materials is obtained through a weight loss method. According to the material moisture online detection device and the control method and control system thereof, the content of moisture in the materials is detected in the drying process, that is, timely online moisture detection is achieved, data are more accurate, and the working efficiency is improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

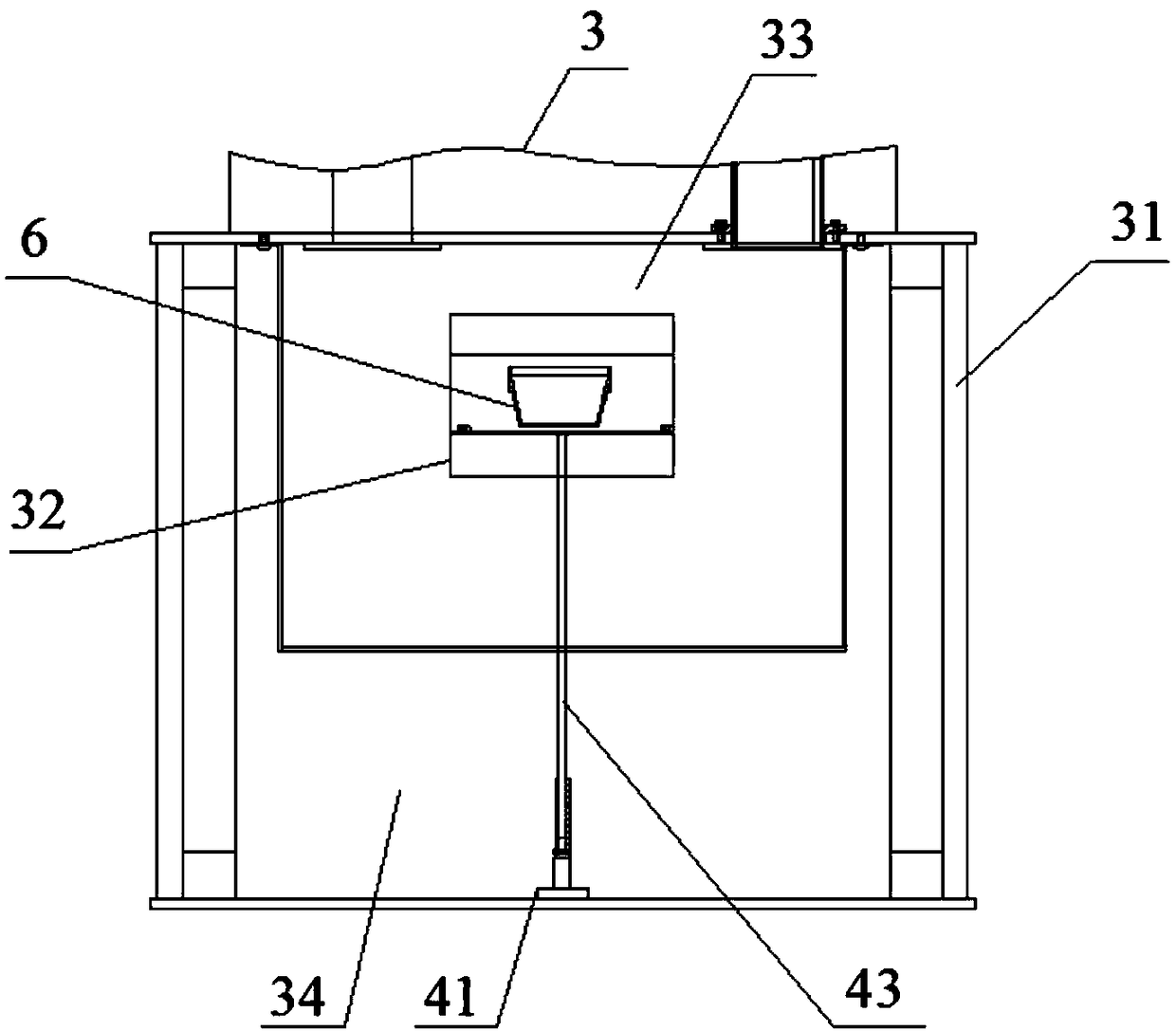

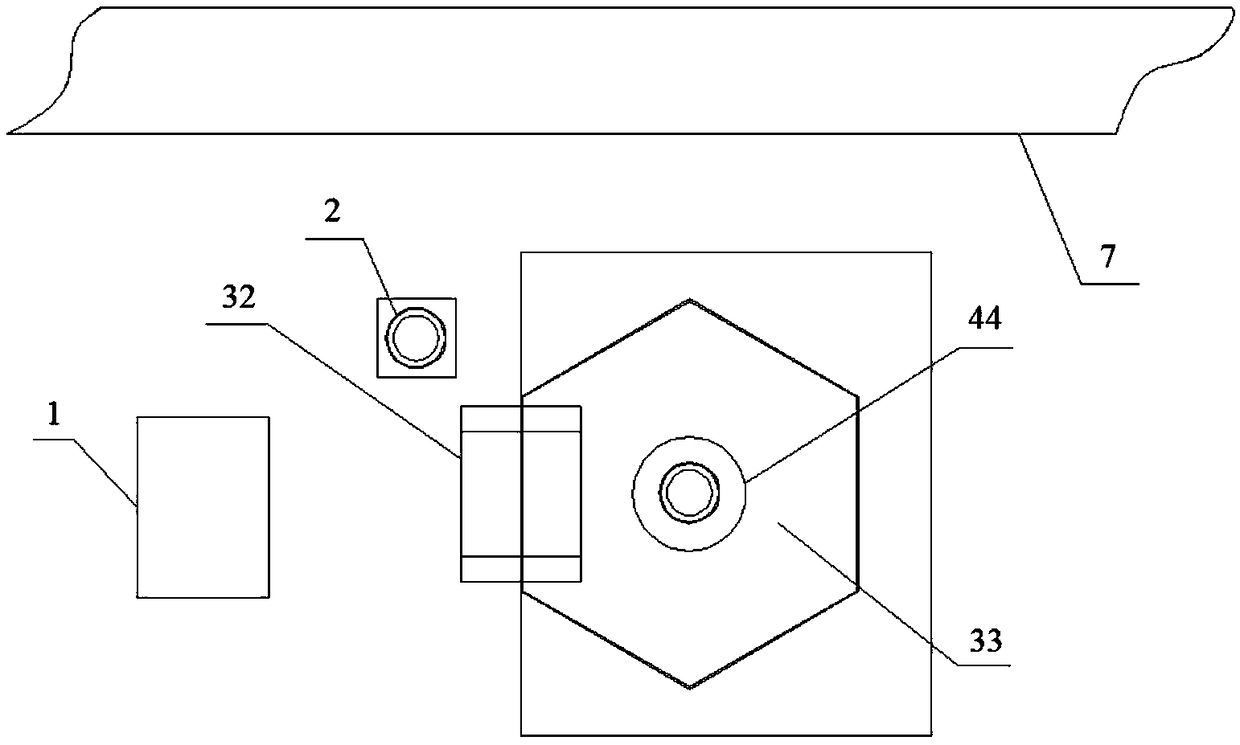

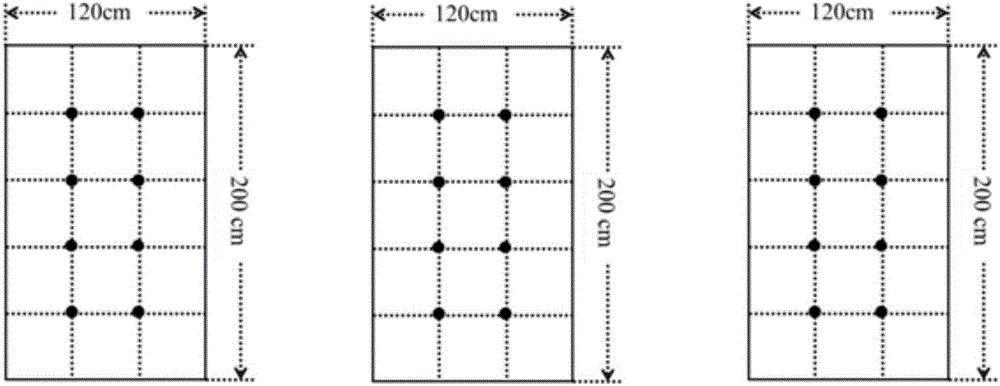

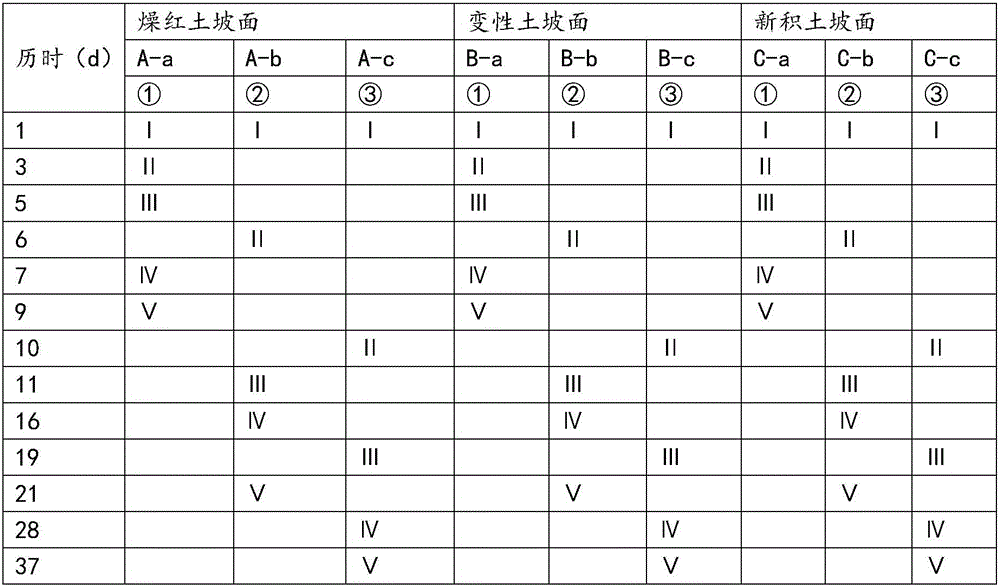

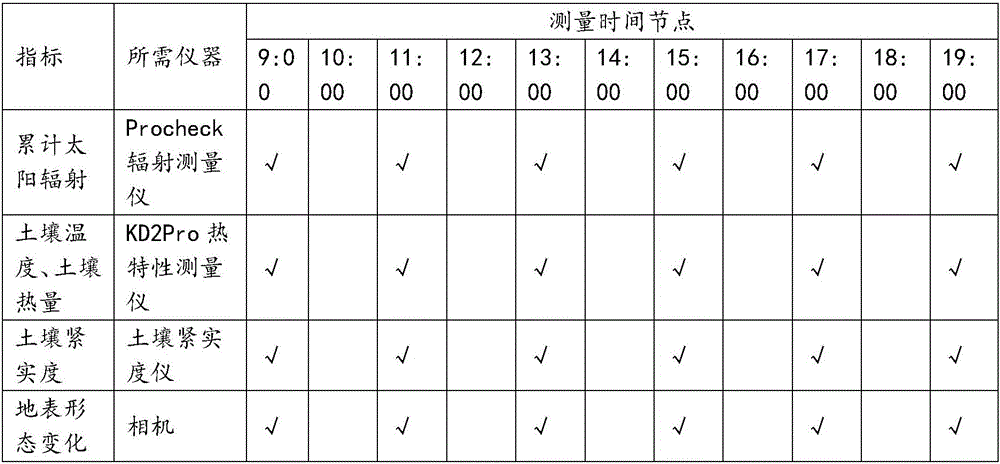

Test method for determining property changes and erosion effect of topsoil

InactiveCN106644919AReasonable designThe result is accurateWeather/light/corrosion resistanceEarth material testingProcess mechanismMoisture

The invention relates to a test method for determining property changes and an erosion effect of topsoil. A typical soil type test slope surface in a research area is selected, drying treatment and wetting treatment are alternatively conducted on test soil the same times, physicochemical property indexes of the soil are measured after drying treatment is conducted on the test soil each time, and then wetting treatment is conducted at once to measure the erosion amount of the soil; the test slop surface is an in-situ area of which surface vegetation is pruned, and the moisture content of the initial test soil reaches the highest field capacity; drying treatment and wetting treatment are alternatively conducted on the in-situ area not less than three times; manual water filling is adopted in wetting treatment to reach the highest field capacity; in drying treatment, the soil is naturally exposed in the sun under the temperature threshold condition of 25 DEG C to 35 DEG C, and the moisture content of the soil is made to reach a wilting coefficient by combining a soil temperature and moisture control system air cooler and a vertical air duct part. The test method is reasonable in design, the property changes and the erosion effect of the slop surface topsoil under the drying and wetting alternation condition can be determined, and the important significance on verification of the water and soil imbalance process mechanism under the influences of a changing environment is achieved.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

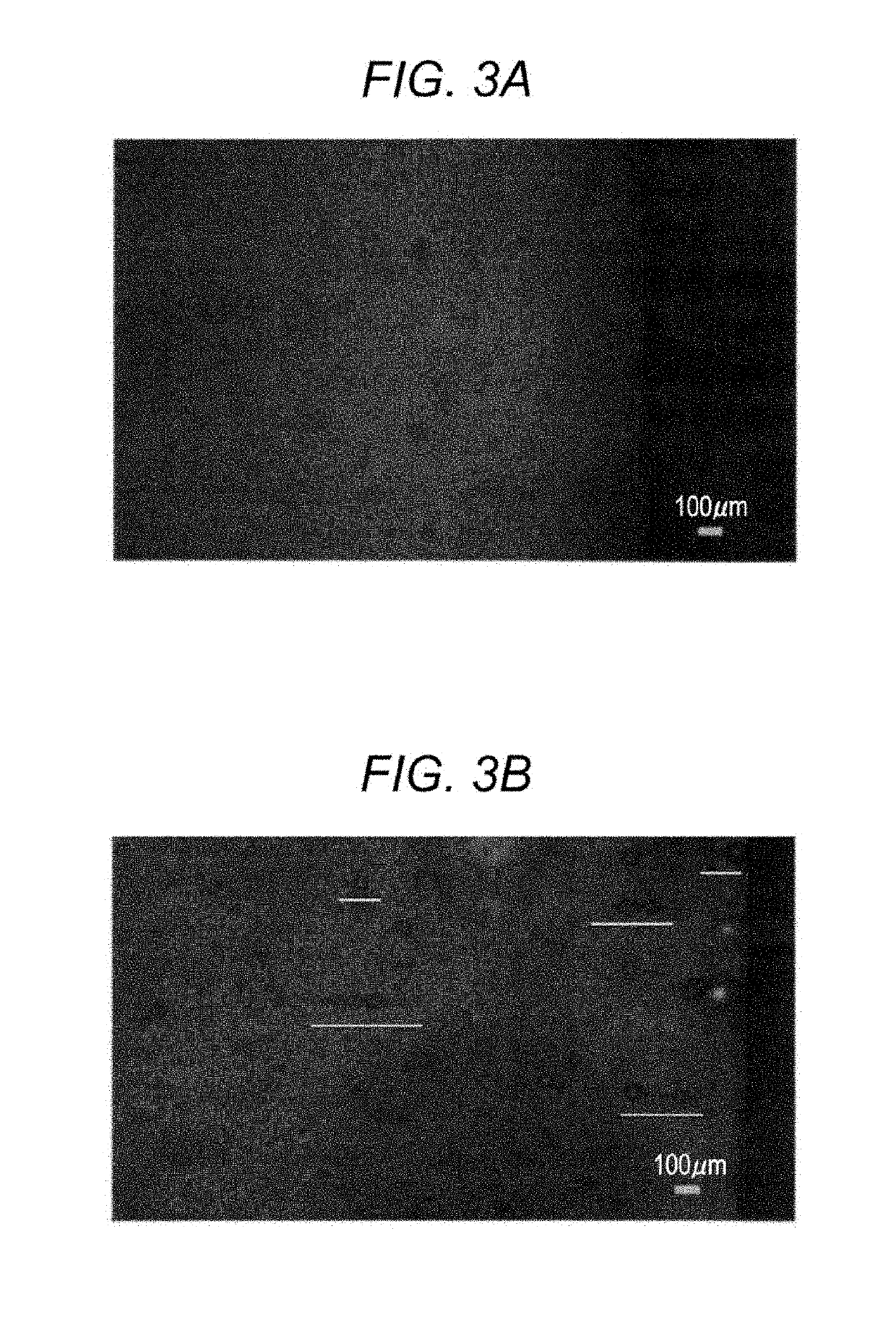

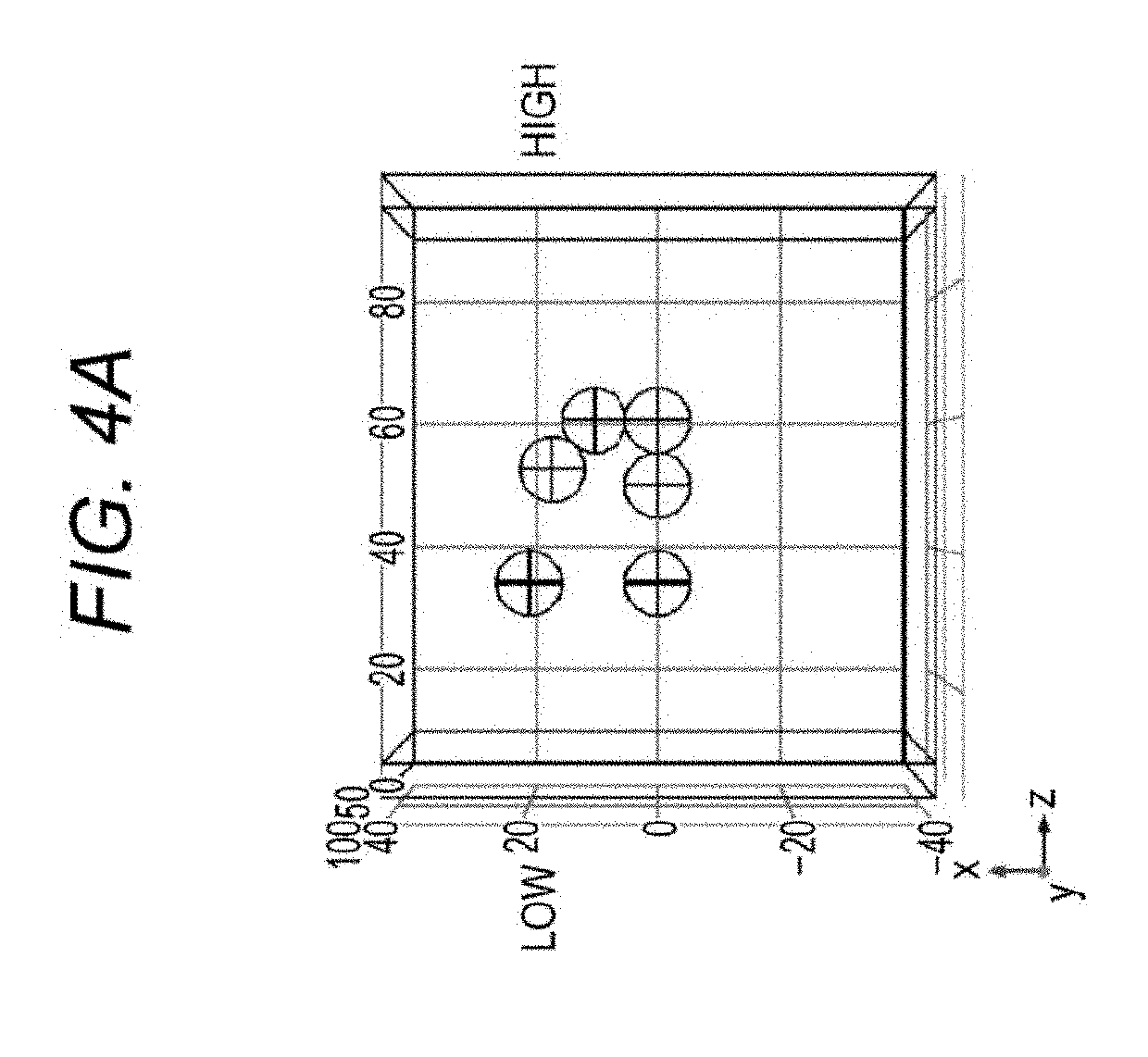

Moisture control apparatus and moisture control method

ActiveUS20190200649A1Improve featuresDrying solid materials without heatFood preservationEngineeringAlternating current

A moisture control apparatus includes at least one electrode configured to receive at least one of an alternating current or a direct current, and to direct at least one of an electric field, a magnetic field, an electromagnetic field, an electromagnetic wave, a sonic wave, or a supersonic wave toward a substance. The moisture control apparatus further includes a controller configured to communicate with the at least one electrode, wherein the controller is configured to control a voltage applied to the at least one electrode to induce a bonded state between water molecules of moisture present in the substance.

Owner:EVERTRON HLDG

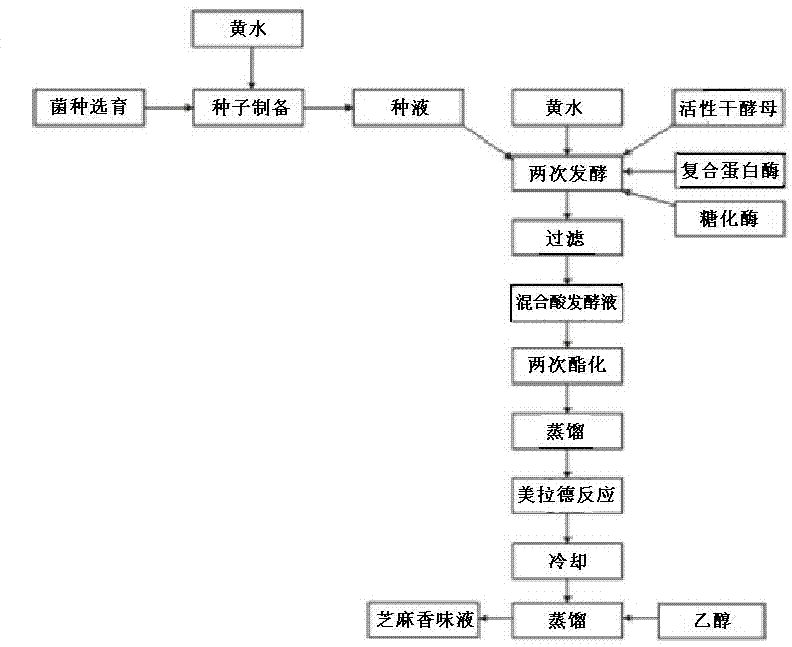

Technology for preparing sesame flavor liquid through yellow water

The invention discloses a technology for preparing sesame flavor liquid through yellow water. The technology includes the steps that strains are selected and the selected strains are used for preparing seeds. In the seed preparing step, the yellow water is used as culture mediums, the seeds are prepared into seed liquid, and the yellow water, activated dry yeast, compound protease and saccharifying enzyme are added in the seed liquid for secondary fermentation, wherein the proportion of the seed liquid is 15%, and mixed acid fermentation liquid can be formed after fermentation of the seed liquid; three-effect distilling is performed on the mixed acid fermentation liquid, secondary esterification is performed on remaining liquid formed after three-effect distilling, three-effect distilling is performed on esterified liquid obtained after secondary esterification, and a Maillard reaction is performed on remaining liquid obtained after distilling, wherein water in the remaining liquid is controlled to be 60% to 80%, pH is controlled to be 5-7, the Maillard reaction lasts for 3-5 h, reaction temperature is controlled to be 110-130 DEG C, and the sesame flavor liquid is formed after the Maillard reaction. According to the technology, the yellow water is recycled. Due to the technology, the sesame flavor liquid is produced through the yellow water.

Owner:SICHUAN YINFAN BIOTECH LTD

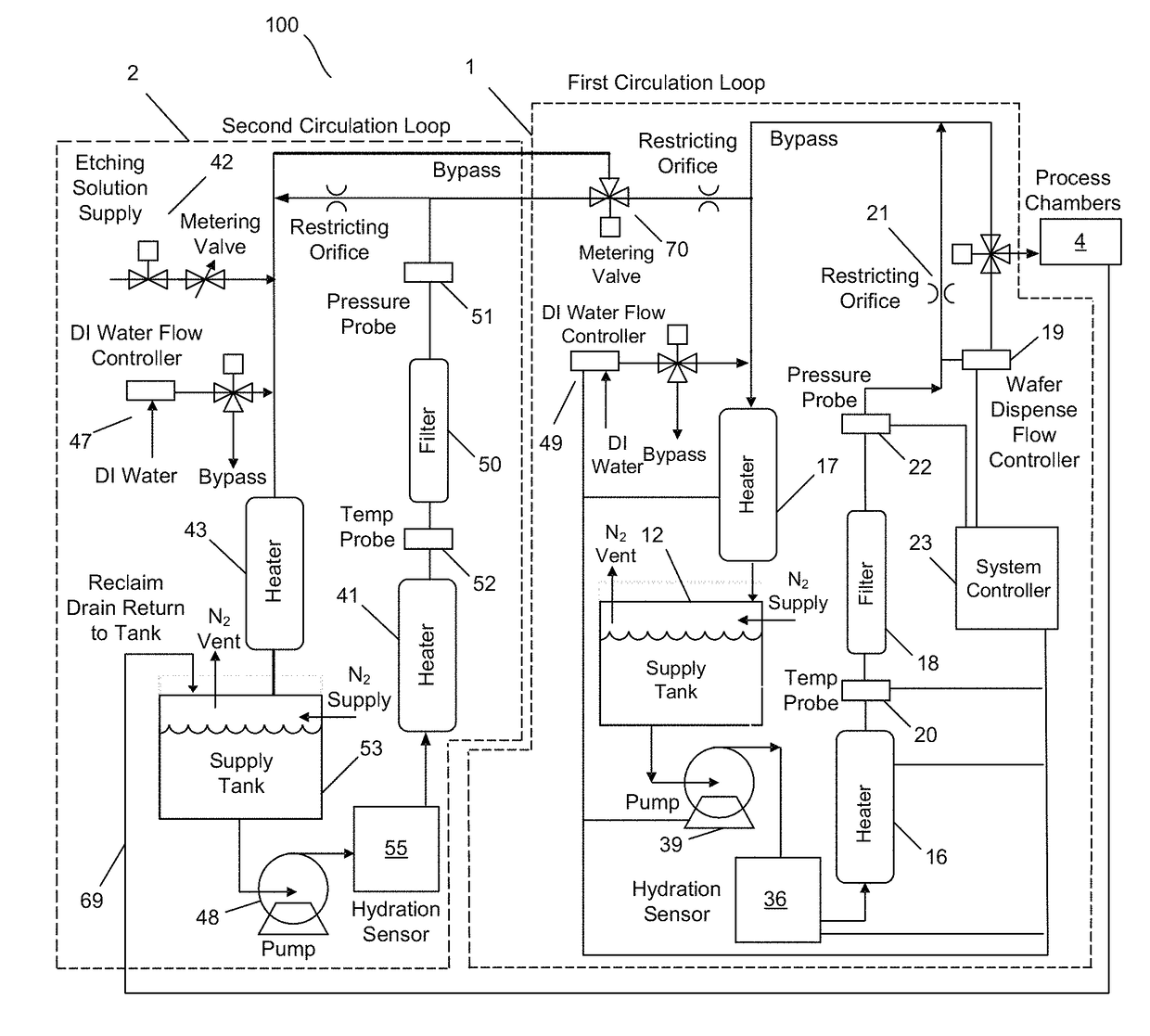

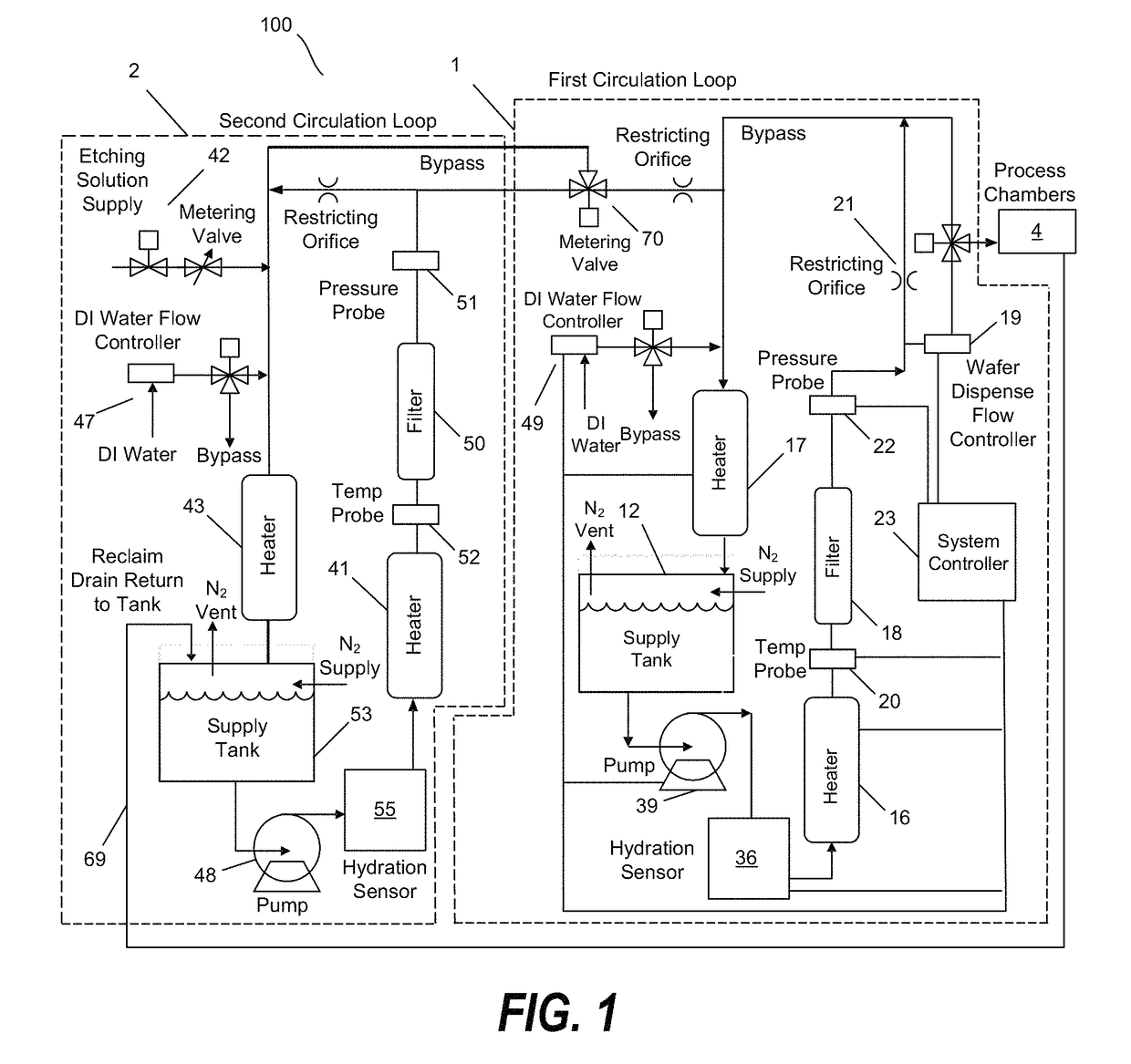

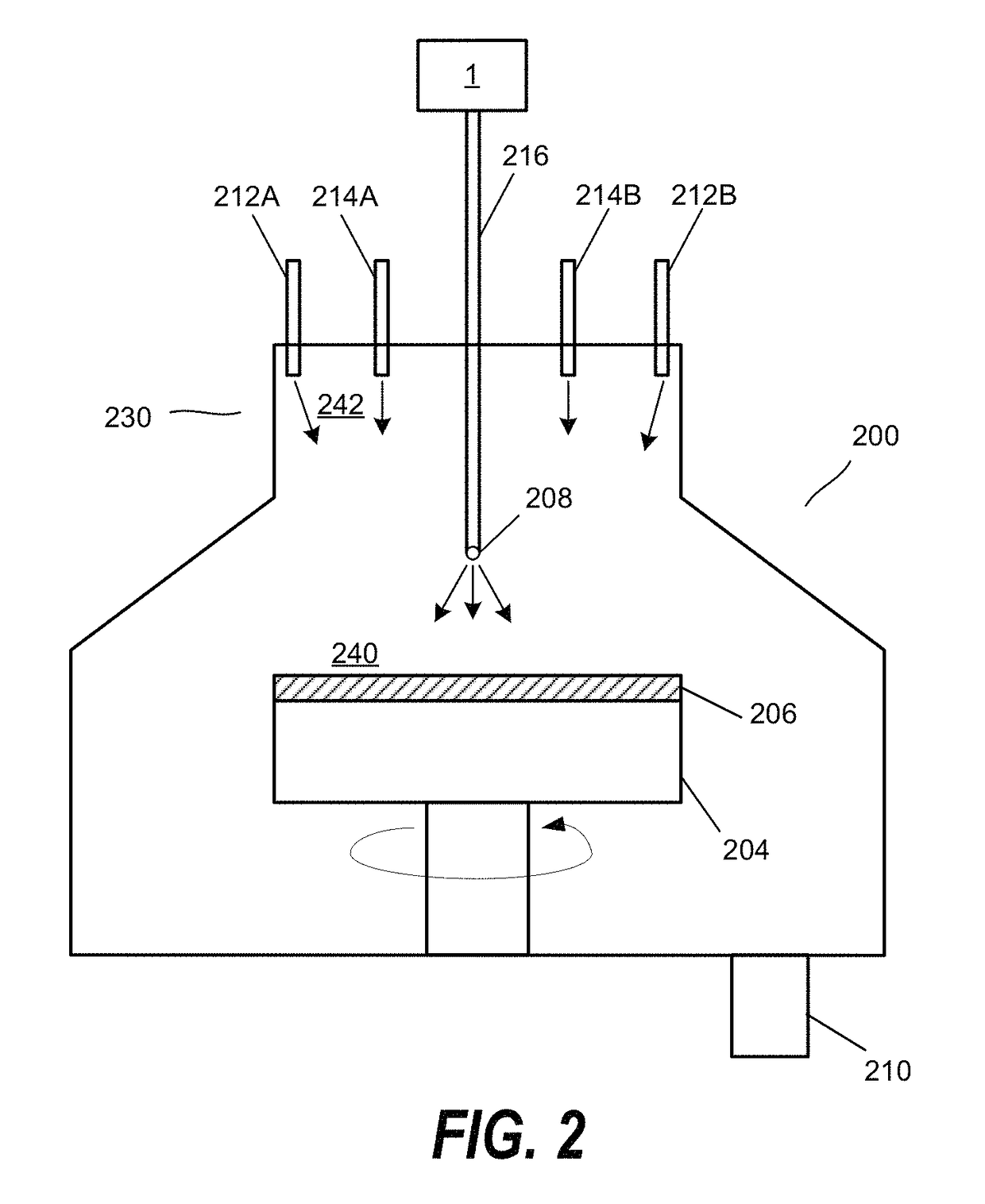

Processing system and method for providing a heated etching solution

A method and processing system are provided for independent temperature and hydration control for an etching solution used for treating a wafer in process chamber. The method includes circulating the etching solution in a circulation loop, maintaining the etching solution at a hydration setpoint by adding or removing water from the etching solution, maintaining the etching solution at a temperature setpoint that is below the boiling point of the etching solution in the circulation loop, and dispensing the etching solution into the process chamber for treating the wafer. In one embodiment, the dispensing includes dispensing the etching solution into a processing region proximate the wafer in the process chamber, introducing steam into an exterior region that is removed from the wafer in the process chamber, and treating the wafer with the etching solution and the steam.

Owner:TEL EPION

Material moisture detection device and control method and control system thereof

ActiveCN108800762AImprove work efficiencyTimely online moisture detectionWeighing by removing componentDrying solid materials with heatMicrowaveControl system

The invention discloses a material moisture detection device and a control method and control system thereof. A material moisture control system and a mechanical arm control system conduct interactionof a control signal, so that the mechanical arm control system controls a mechanical arm device to carry out corresponding operation. The mechanical arm device moves an empty material cup onto a weighting tray for weighing according to the control signal, and the weight of the empty material cup is obtained. Then to-be-detected materials are added into the empty material cup to obtain a materialstoring cup, the material storing cup is weighed again, and the drying initial weight of the material storing cup is obtained; and then the material storing cup is taken out to be put into a microwavecavity to be subjected to microwave drying. After the microwave drying is finished, the dry ending weight of the material storing cup is obtained. According to the weight of the empty material cup, the drying initial weight of the material storing cup and the drying ending weight of the material storing cup, the content of moisture in the to-be-detected materials is obtained through a weight lossmethod. According to the material moisture detection device and the control method and control system thereof, the content of moisture in the materials is detected in the drying process, that is, timely online moisture detection is achieved, data are more accurate, and the working efficiency is improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

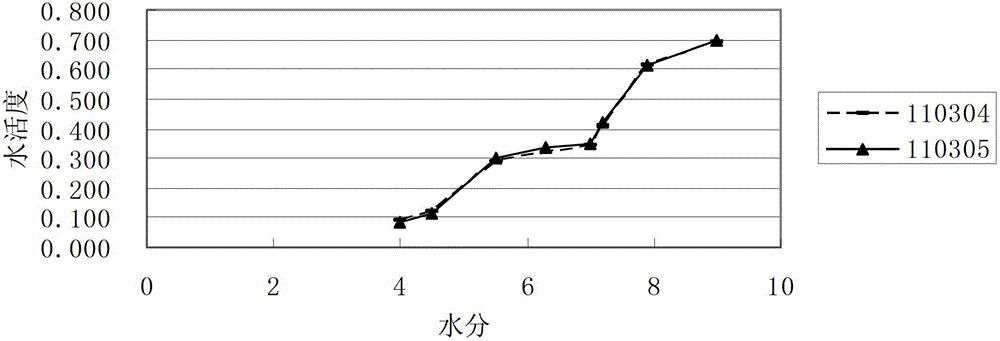

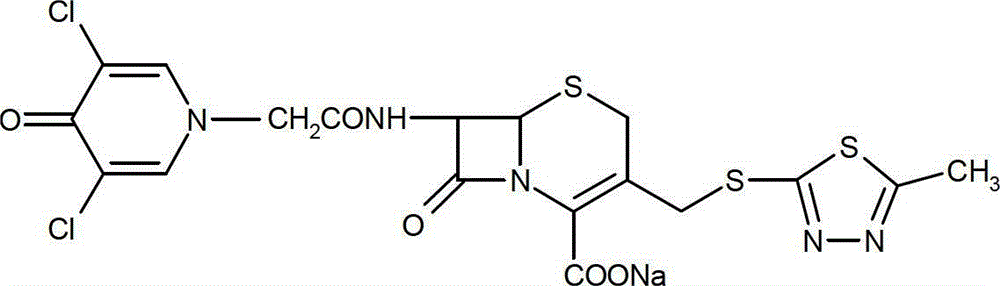

Method for determining moisture limit of cefazedone sodium sterile

InactiveCN102914626AEfficient determination of moisture limit valuesGuaranteed stabilityTesting medicinal preparationsWater activityCefazedone sodium

The invention relates to a method for determining a moisture limit of cefazedone sodium sterile. The method comprises the steps of: (1) measuring water activity of a cefazedone sodium sterile sample; (2) measuring a moisture content of the cefazedone sodium sterile sample; and (3) drawing a correlation curve of the water activity and the moisture content through the two values and finally determining the moisture control limit of the cefazedone sodium sterile. By measuring the moisture content in the cefazedone sodium sterile solid and the water activity thereof, drawing an isothermal adsorption curve of the cefazedone sodium sterile sample and determining the moisture control limit of the cefazedone sodium sterile based on the relationship between the two indexes, the invention provides a method for determining the moisture limit more simply and more directly.

Owner:天津新丰制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com