Method for producing protein feed by using apple pulps and malt roots as raw materials

A protein feed and malt root technology, applied in animal feed, animal feed, application, etc., can solve problems such as high water content and nutritional deficiencies, and achieve the effects of increasing protein content, comprehensive and balanced nutrition, and improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Mix 90kg of fresh apple pomace with 10kg of malt root, control the water content to 65% after mixing; stir evenly, ferment the mixed material, ferment it in the silage cellar at 23°C for 40 days, compact the mixed material and cover tightly ( Cause the internal anaerobic environment of the material) 3) Subpackage the fermentation product, and the obtained fermentation product can be used as protein feed.

[0017] Adding malt root mixed fermentation to apple pomace has significantly improved nutritional content and animal digestion compared with single fermentation of apple pomace

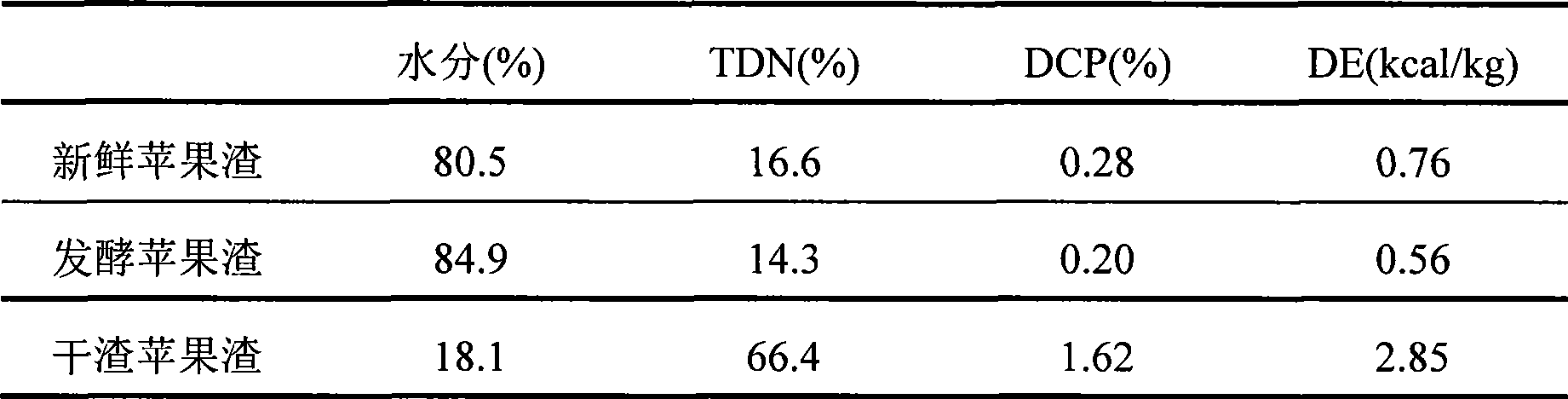

[0018] The nutritional components of fresh apple pomace, dried apple pomace and fermented apple pomace are compared, as shown in Table 1.

[0019] Table 1

[0020]

[0021] Note: TDN-total digestible matter, DCP-digestible crude protein, DE-metabolizable energy

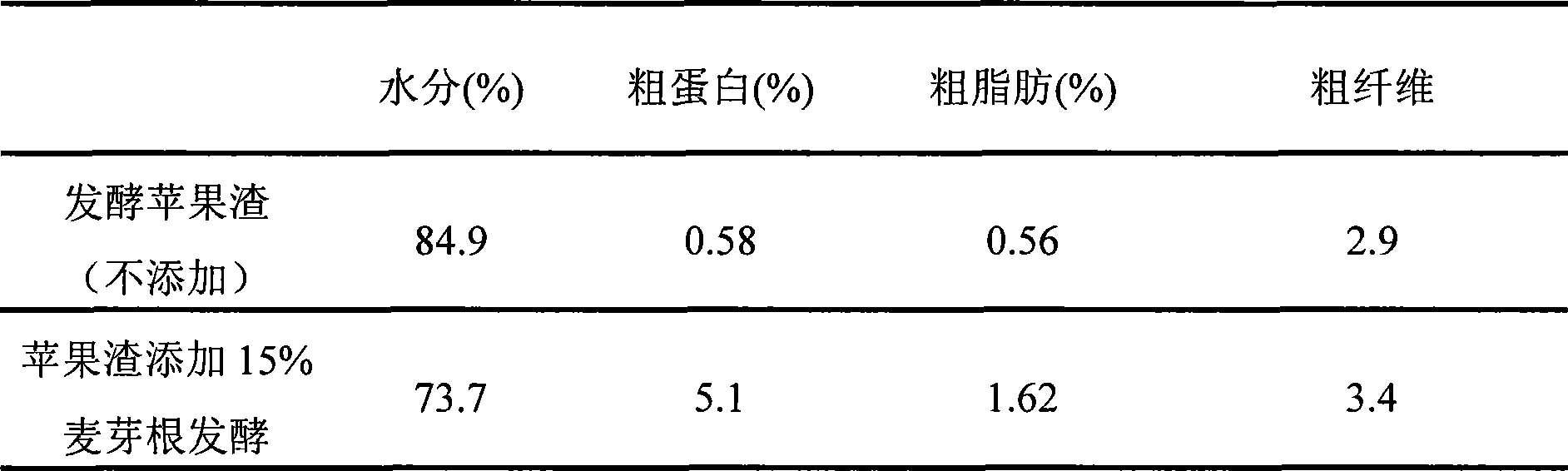

[0022] Table 2 compares the nutritional components of apple pomace fermented with 10% malt root.

[0023] Table 2

[0024] ...

Embodiment 2

[0026] 85kg of fresh apple pomace is mixed with 15kg of malt root, and the moisture after mixing is controlled to be 70%. Stir evenly, add the mixed material into a silage bag with a volume of 1 cubic meter, inoculate yeast, vacuumize and ferment after bagging, and ferment at 24°C for 43 days. The fermented product is packaged separately, and the obtained fermented product can be used as protein feed.

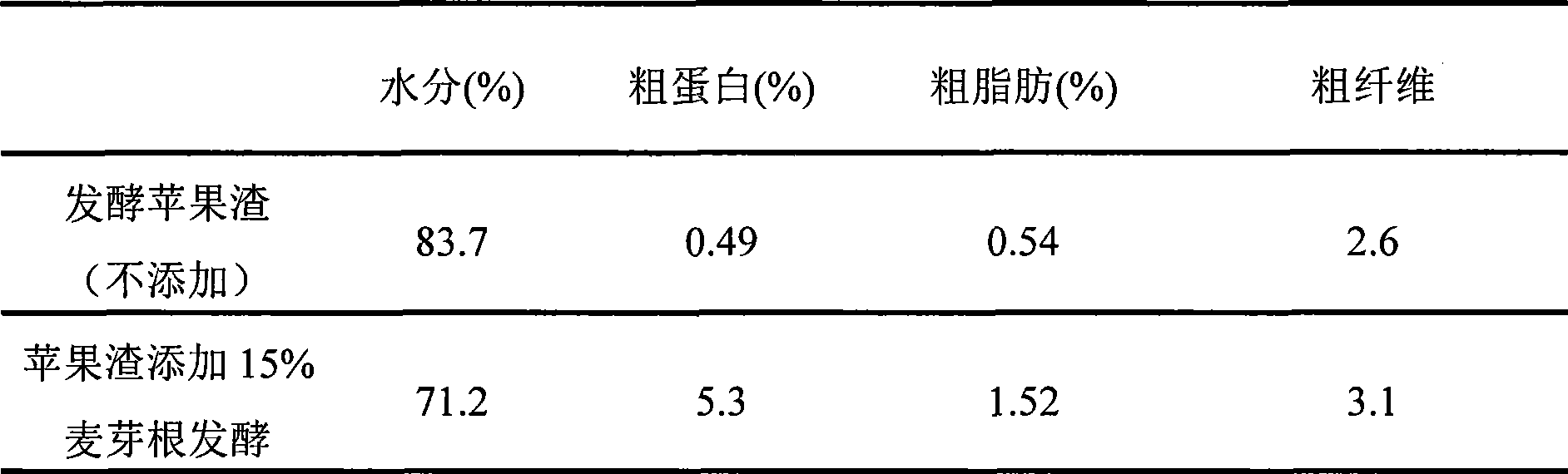

[0027] Table 3 compares the nutritional components of apple pomace fermented with 15% malt root.

[0028] table 3

[0029]

Embodiment 3

[0031] 80kg of fresh apple pomace is mixed with 20kg of malt root, and the moisture after mixing is controlled to be 75%. Stir evenly, add the mixed material into a silage bag with a volume of 1 cubic meter, inoculate Lactobacillus plantarum, vacuumize and ferment after bagging, and ferment at 25°C for 45 days. The fermented product is packaged separately, and the obtained fermented product can be used as protein feed.

[0032] Table 4 compares the nutritional components of apple pomace fermented with 20% malt root.

[0033] Table 4

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com