Processing system and method for providing a heated etching solution

a technology of processing system and etching solution, which is applied in the direction of electrical programme control, instruments, program control, etc., can solve the problems of poor stability of the etching process, the position or region where the boiling occurs can shift within the tool with detrimental effects, and the etching process can be difficult to achieve the effect of improving the etching uniformity, improving the etching rate, and low hydration level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

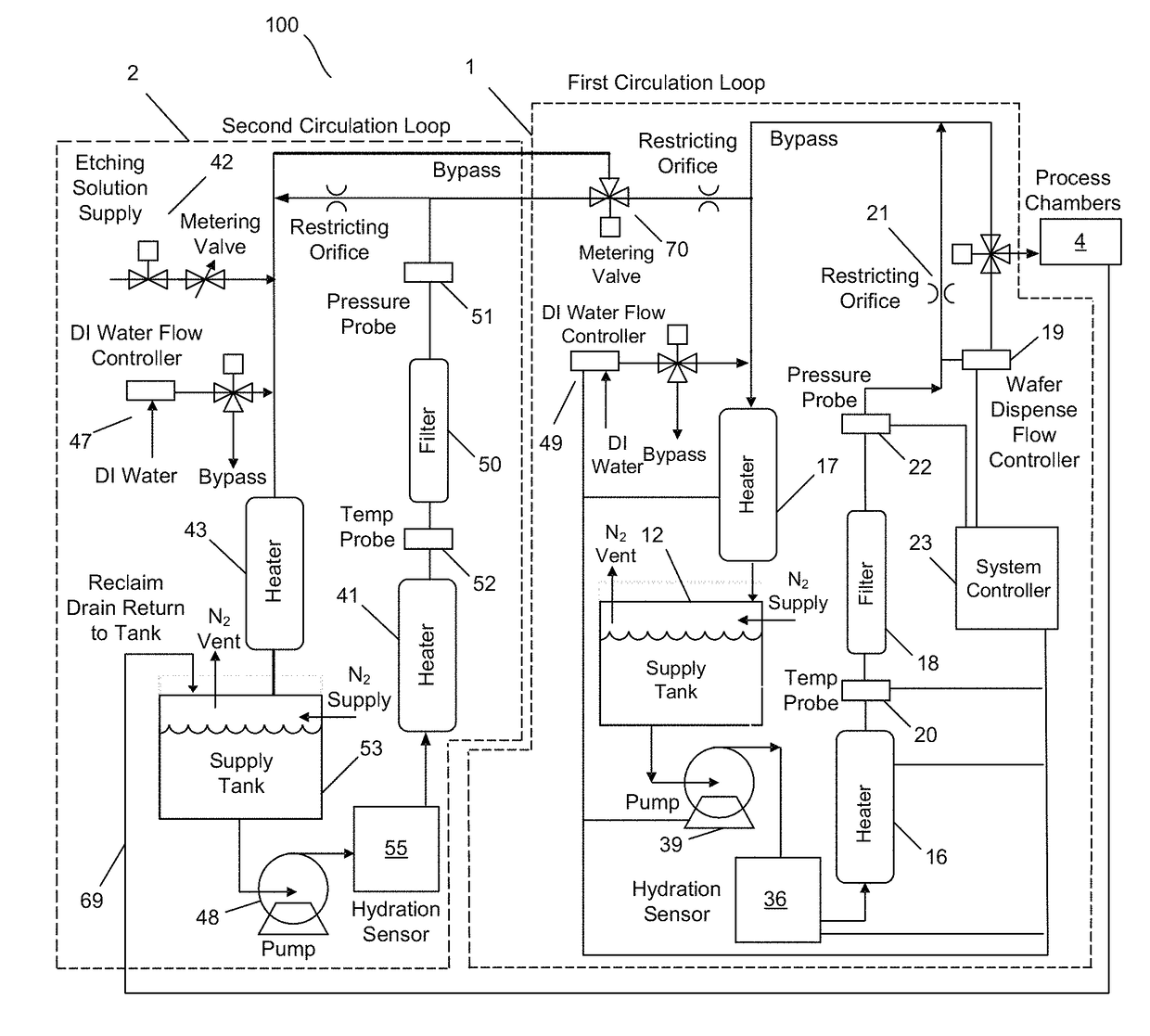

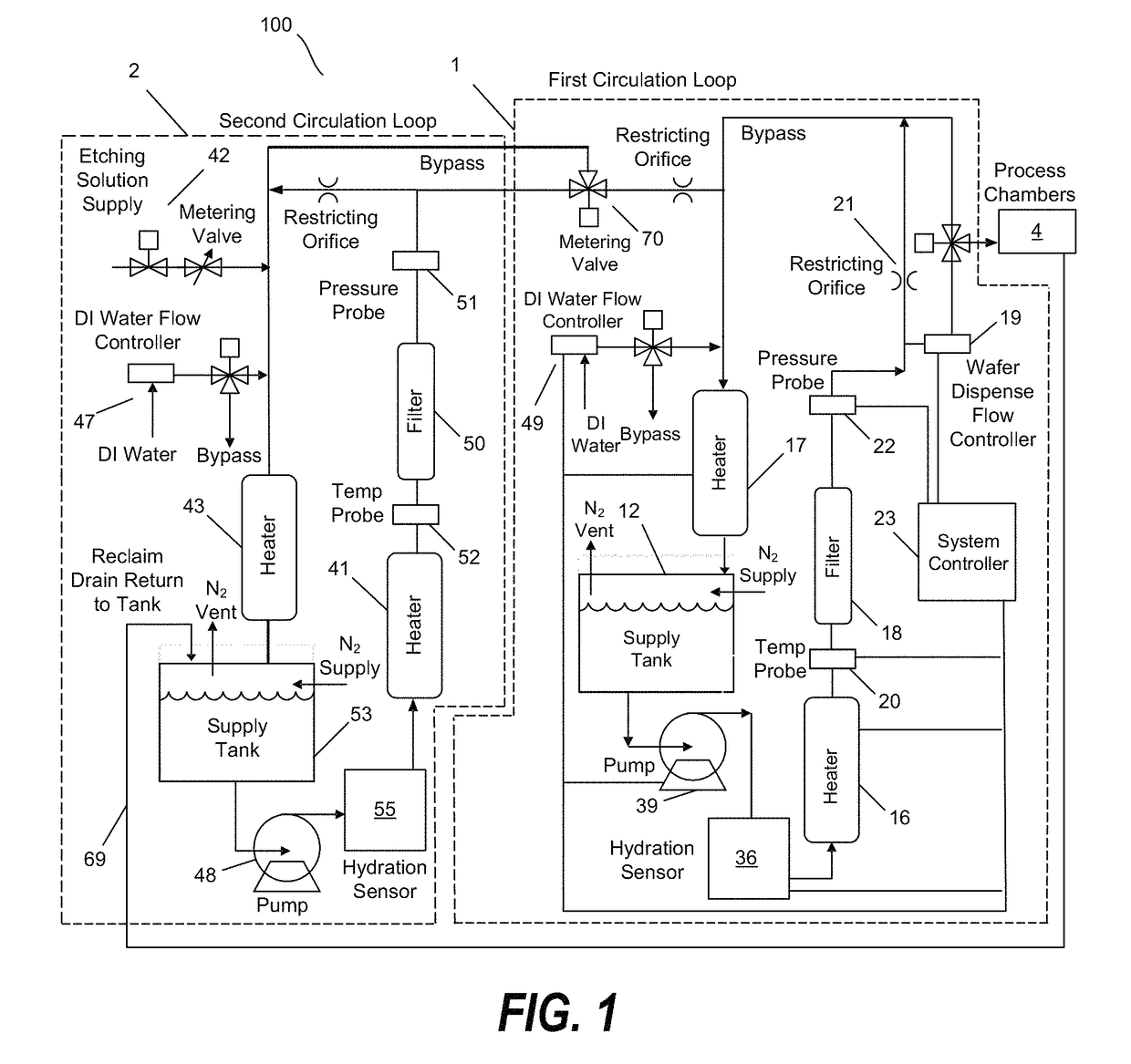

[0016]Embodiments of the invention relate to a processing system and a method for improving temperature and hydration level control of a heated etching solution. According to one embodiment, the etching solution can contain phosphoric acid, but embodiments of the invention may be applied to other etching solutions and mixtures.

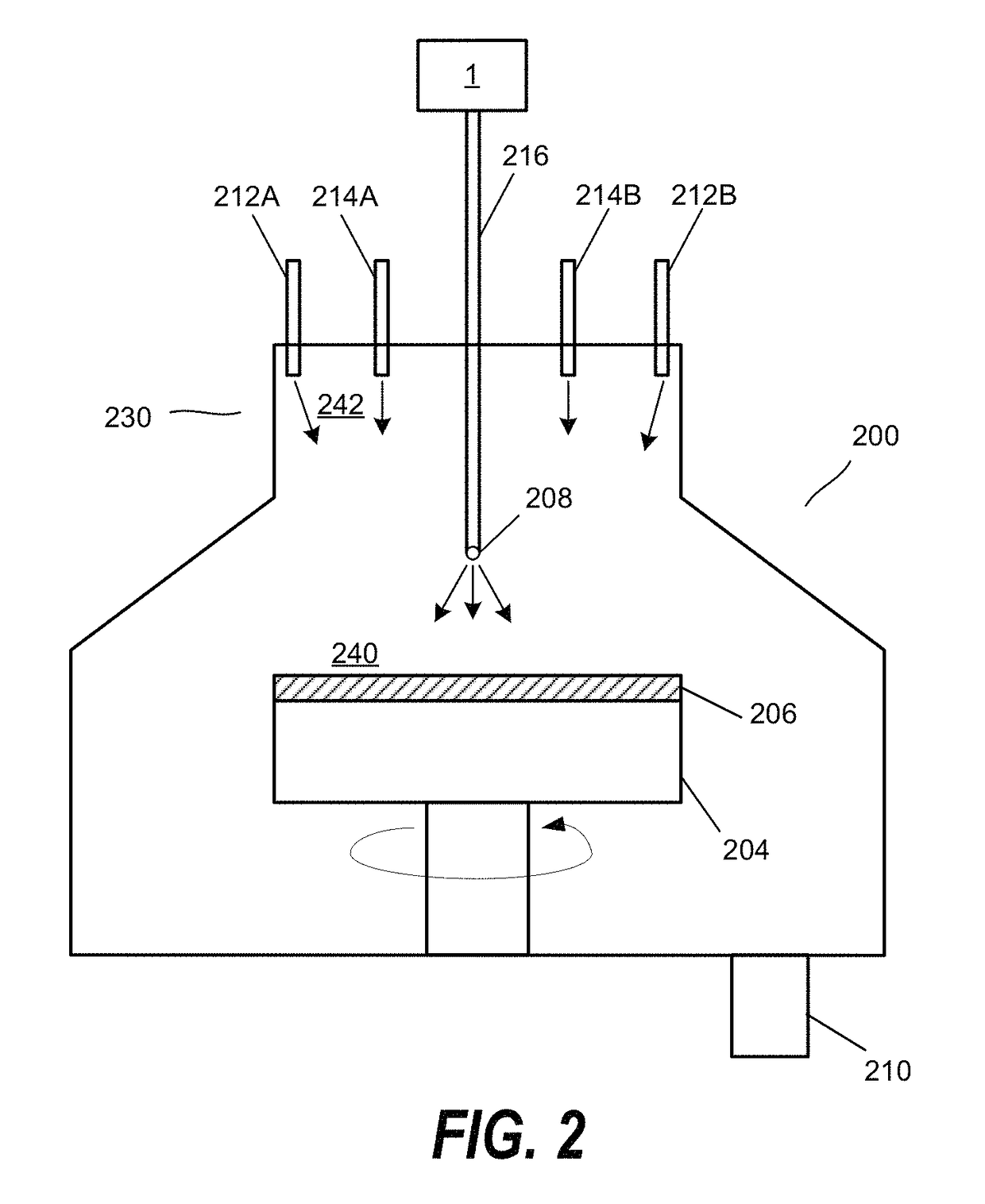

[0017]In one non-limiting example, a method is described for improving temperature and hydration level control of a hot phosphoric acid etching solution. As described in the Background section, in a single wafer spin cleaning tool, boiling of the heated etching solution can occur in various positions or regions of the circulation loop, including downstream of the heater, where the pressure in the circulation loop is reduced. Boiling can occur on the downstream side of a wafer dispense flow controller for dispensing the heated etching solution from the circulation loop to the process chamber, or inside a nozzle or spray bar that delivers the heated etching solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com