Method for controlling water of seedbed of cured tobacco seedlings by floating cultivation

A floating seedling raising and watering technology, which is applied in the fields of botany equipment and methods, climate change adaptation, soilless cultivation, etc., can solve the problems of no flue-cured tobacco floating seedling bed moisture control technology, time-consuming cost, and difficult promotion, so as to reduce water Excessive, reduce environmental pollution, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

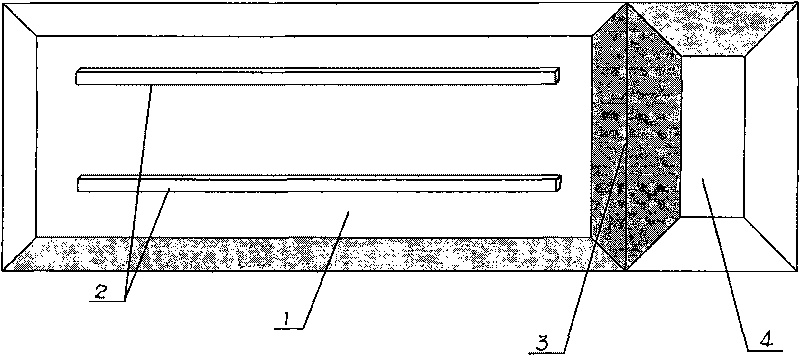

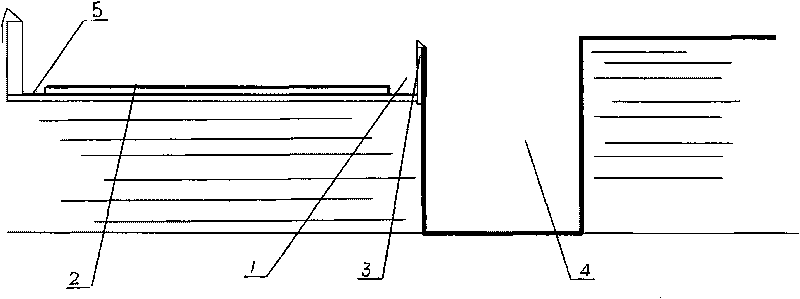

[0019] Embodiment: be that length 11.5m, width are one end of the conventional floating seedling raising nutrient pool 1 of 1.6m, remove ridge, dig a long 1.6m, the square puddle 4 of wide 1m, its volume is slightly larger than the liquid amount that nutrient pool discharges Lay a bottom film 5 in the nutrition pool 1; put a plank 3 under the bottom film between the nutrition pool 1 and the puddle 4, and simultaneously put two rows of bamboo strips 2 in the nutrition pool 1 along the direction of the nutrition pool 1; After the nutrient solution was released, the seedling raising tray was overhead to form an air layer between the bottom of the seedling raising tray and the nutrient solution surface in the pond; the water pit 4 was mainly used to store the nutrient solution, and when the moisture in the flue-cured tobacco matrix was too much and the water supply needed to be adjusted, the The plank 3 between the nutrient pool 1 and the water pit 4 is laid flat, and the nutrient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com