Patents

Literature

41results about How to "Reduce drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

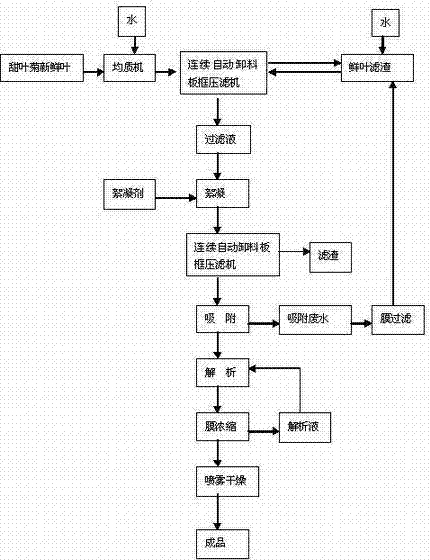

Method for extracting stevioside from fresh stevia rebaudiana leaves

InactiveCN102127129AReduce drying processLow costSugar derivativesSugar derivatives preparationFlocculationEngineering

The invention discloses a method for extracting stevioside from fresh stevia rebaudiana leaves, which comprises: crushing fresh stevia rebaudiana leaves with homogenizing crushing equipment under a condition of water, performing pressure filtration in continuous automatic discharge filtering equipment, subjecting the filtrate to flocculation by mixed flocculating agent; and absorbing by resin, analyzing, desalting and decolorizing by resin, concentrating and spray drying to obtain the stevioside product. In the invention, time and working procedures are saved, a long-distance transport process is avoided, raw material cost is lowered, discharge of waste water is reduced greatly, and clean production can be realized basically.

Owner:LIAONING QIANQIAN BIOLOGICAL TECH

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804655AReduce energy consumptionTake advantage ofLiquid surface applicatorsWood compressionSolid woodWear resistant

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: forming a solid wood flooring block, sanding the block, removing dust, coloring, coating UV putty coat I, solidifying I, sanding I, coating UV putty coat II, solidifying II, sanding II, coating wear resistant base coat, semi-solidifying I, coating transparent UV base coat, solidifying III, sanding III, coating UV finishing coat, semi-solidifying II, coating formaldehyde-removing UV wear resistant finishing coat, solidifying IV, and forming the finished product. The solid wood flooring produced by the process has the advantages of good colour and lustre, clear texture, high anti-bending static bending strength, good surface abrasion resistance, stable size, small deformation and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

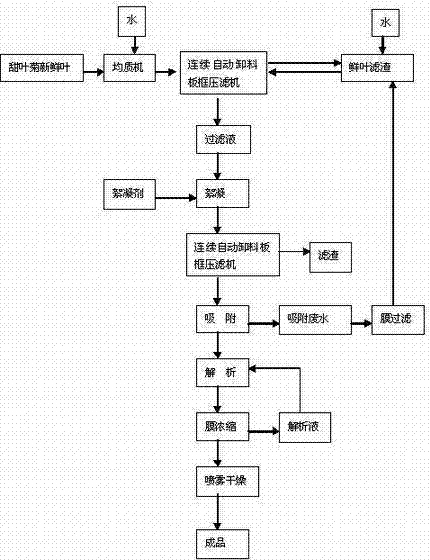

Method for manufacturing machine processed charcoal by utilizing Chinese medicinal or herbal drug to extract solid waste

InactiveCN1803981AReduce energy consumptionReduce manufacturing costBiofuelsSpecial form destructive distillationCombustion chamberThree stage

The disclosed preparation method for charcoal comprising: crushing the solid waste from extracted traditional drug or plant to extrude into bar-form; loading the product into retort for charring reaction with three stages for 10-30min at 120Deg, 200-400min at 120-350Deg and 100-300min at 350-450Deg, respectively. Wherein, firing the exhaust gas in combustion chamber to provide heat source. This invention has yield rate as 40-55% with low energy consumption and little pollution.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Method for preparing powdered Alpha-alkenyl sulphonate

InactiveCN101445472AReasonable determination of process parametersIncrease production costSulfonic acids salts preparationSodium bicarbonateGas phase

The invention relates to a method preparing powdered Alpha-alkenyl sulphonate, belonging to the technical field of organic compound synthesis. Alpha-olefin reacts with gaseous sulfur trioxide in a sulfonator so as to obtain alkenyl sulfoacid which undergoes aging and is then directly mixed with solid alkali and water, and neutralization and hydrolysis are carried out so as to obtain the powdered Alpha-alkenyl sulphonate. The range of the number of carbon atoms of the Alpha-olefin is C8-C24, mol ratio of the alkenyl sulfoacid and the solid alkali ranges from 1:1.1-5.0, and the solid alkali is any of the three components of sodium hydroxide, sodium carbonate or sodium bicarbonate or is a mixture consisting of more than one of the three components. The invention reasonably selects the solid alkali to replace liquid alkali for direct neutralization and hydrolysis, and reasonably determines technological parameters for the neutralization and hydrolysis of the alkenyl sulfoacid and the solid alkali by carrying out a great number of tests in terms of different formula ratios and different temperatures, pressures and water addition amount for aging, neutralization and hydrolysis, therefore, the investment on production apparatuses can be effectively reduced, and the energy consumption and production cost can be lowered.

Owner:JIAXING ZANYU TECH DEV CO LTD

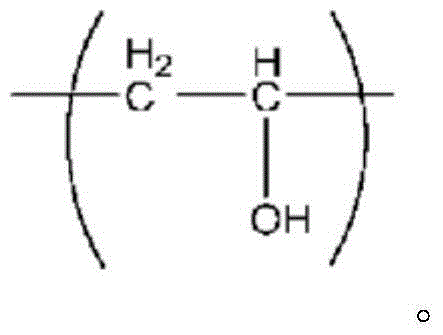

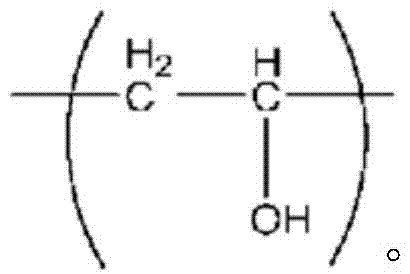

Carbon black dispersion and use thereof

ActiveCN105073915ALow viscosityIncrease concentrationPigmenting treatmentNon-aqueous electrolyte accumulator electrodesHigh concentrationPolymer science

Provided is a carbon black dispersion in which N-methyl-2-pyrrolidone that can achieve dispersibility at a lower viscosity and a higher concentration and can also achieve superior storage stability compared with conventional resin-type dispersants is used as a solvent. Also provided are: a battery electrode mix layer which is homogeneous and has good coating film properties and low surface resistance; and a lithium ion secondary battery equipped with the battery electrode mix layer. The problems can be solved by, for example, a carbon black dispersion comprising carbon black, polyvinyl alcohol (or a combination of polyvinyl alcohol with a pigment derivative) that serves as a dispersant, and N-methyl-2-pyrrolidone that serves as a solvent, said carbon black dispersion being characterized in that the degree of saponification of polyvinyl alcohol is 60 to 85 mol% and the value (a) falls within the range from 0.00017 to 0.00256 inclusive wherein X (m2 / g) represents the BET specific surface area of carbon black and aX (g) represents the addition amount of polyvinyl alcohol relative to 1 g of carbon black.

Owner:TOYO INK SC HOLD CO LTD +1

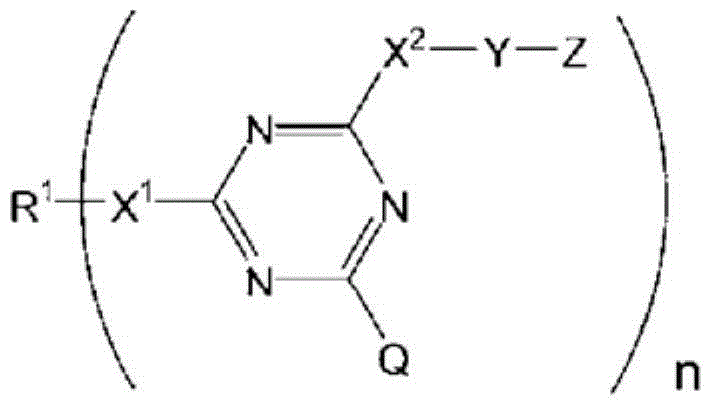

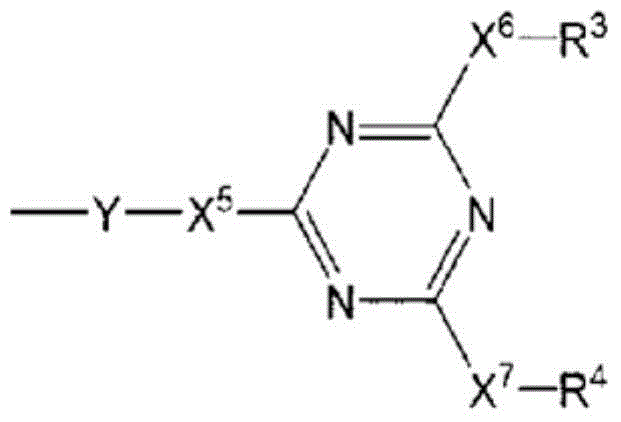

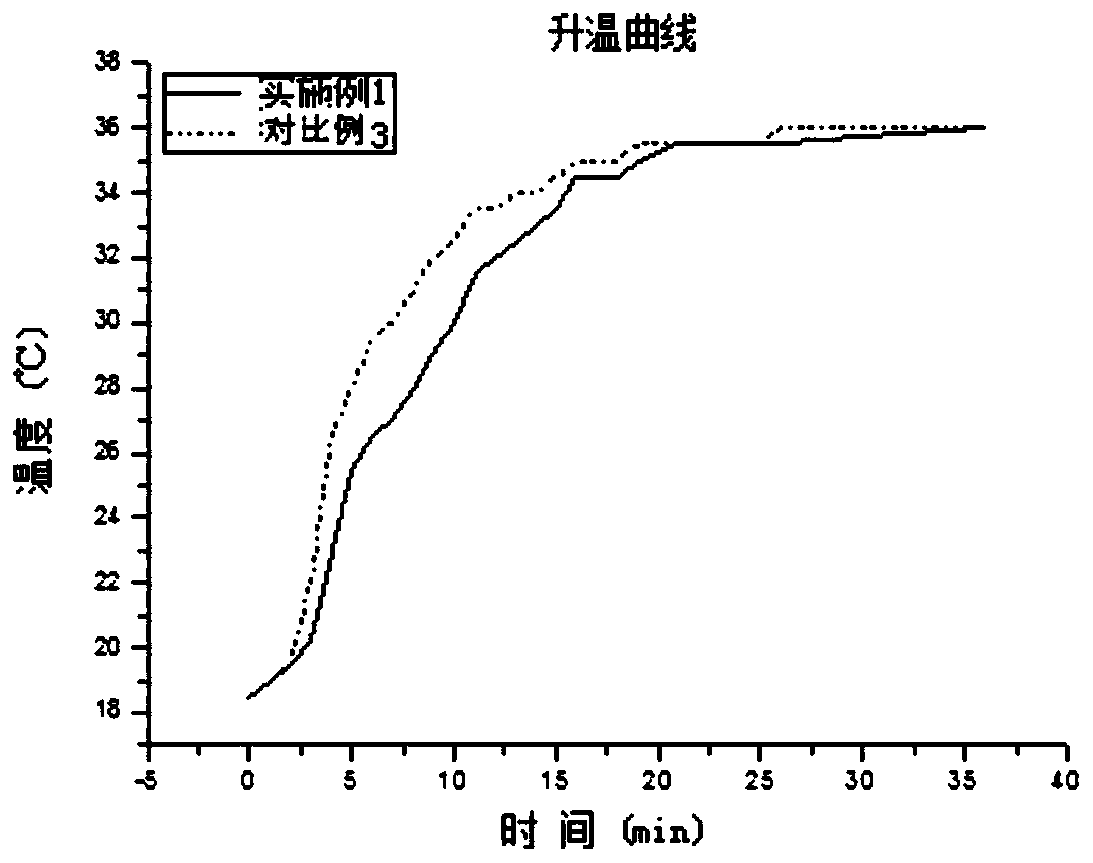

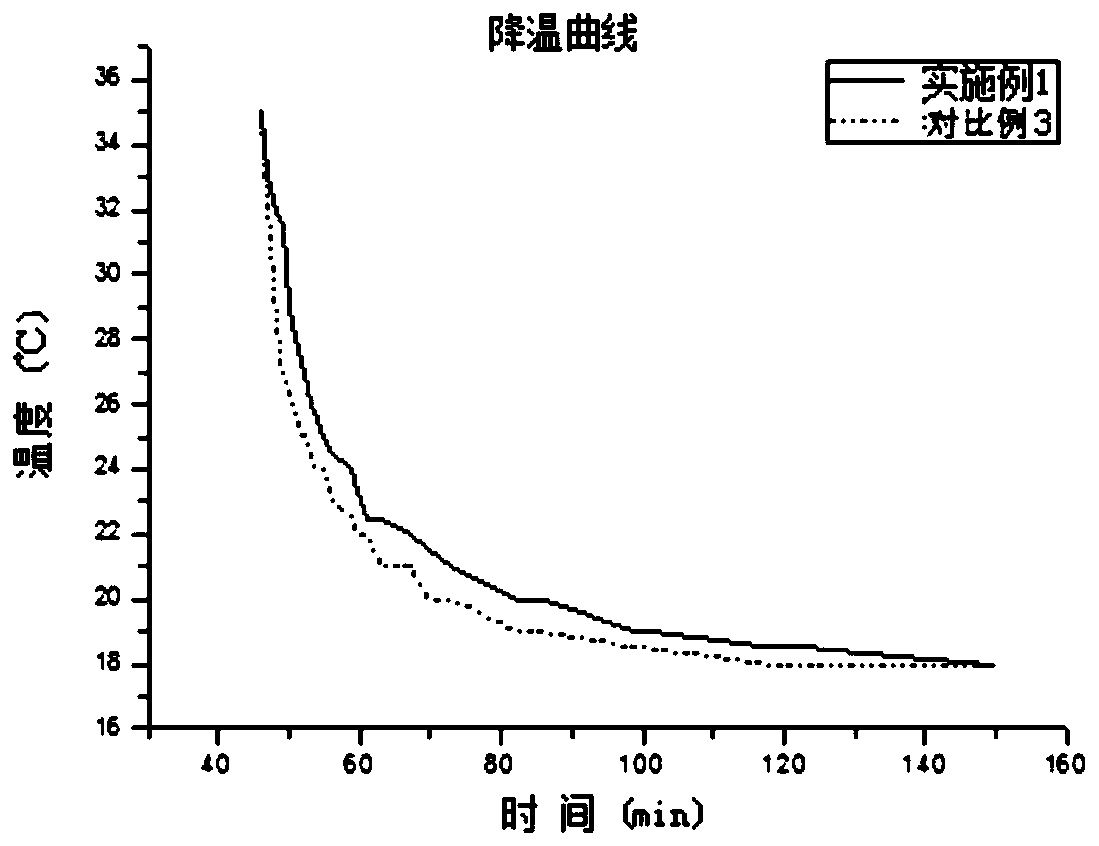

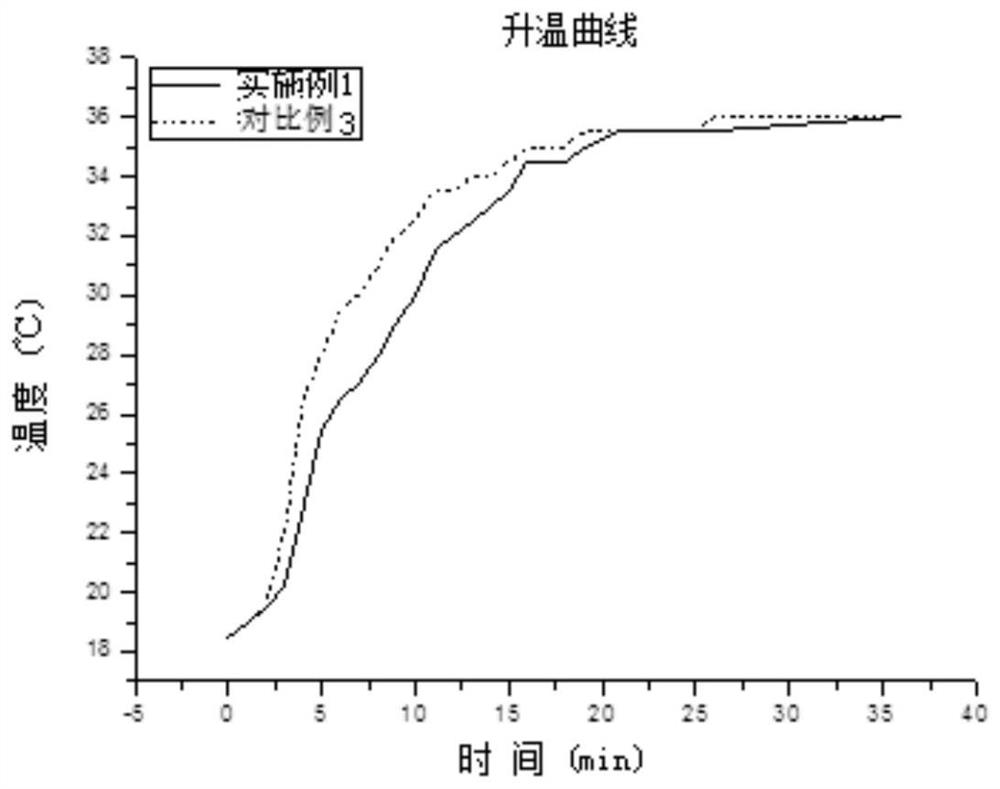

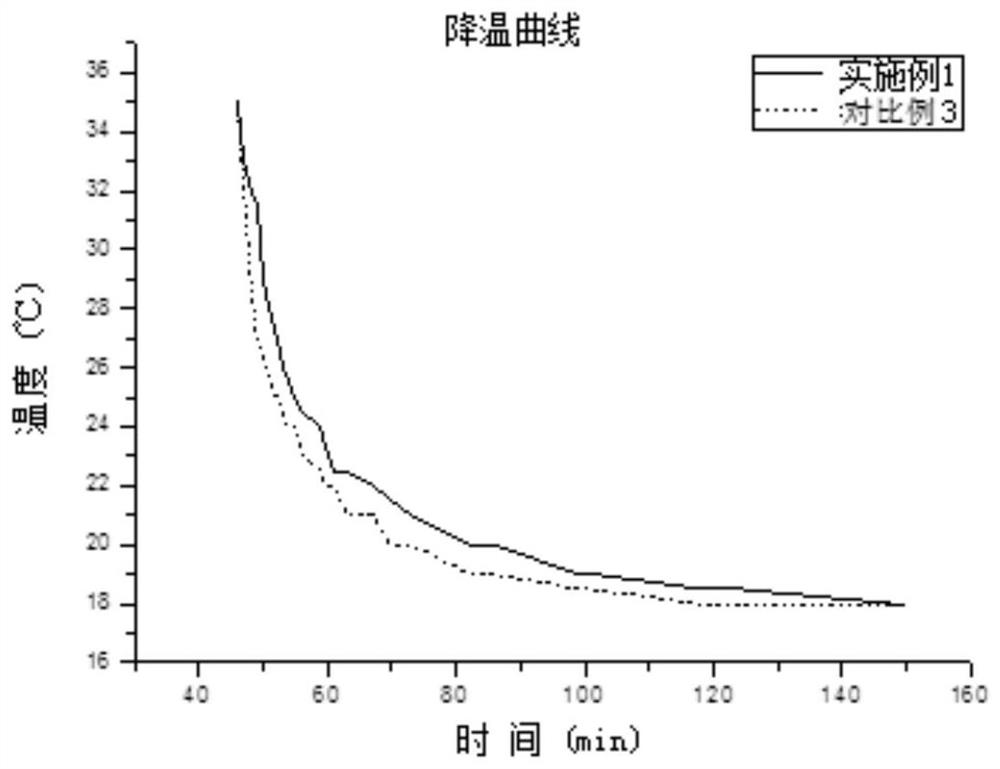

Phase change gypsum board with temperature control performance and preparation method thereof

The invention discloses a phase change gypsum board with temperature control performance. The phase change gypsum board comprises, on the basis of 100 parts by weight of calcined gypsum, 20-80 parts by weight of a phase-change microcapsule stock solution, 0.5-1.5 parts by weight of a binder, 0.05-0.5 part by weight of a reinforcing agent, 0.05-2 part by weight of a coagulant, 0.05-1 part by weightof a surfactant, 65-90 parts by weight of water and 2-10 parts by weight of surface protection paper. The invention further provides a preparation method of the gypsum board with the temperature control performance. The preparation method comprises the following steps: fully mixing the calcined gypsum, the binder, the reinforcing agent and the coagulant to form dry powder; mixing the water reducing agent, the surfactant and the water to form a wet material; fully mixing the dry powder, the phase change microcapsule solution and the wet material to form slurry; and placing the slurry at the middle part of the surface protection paper, and carrying out cutting and drying to form the phase change gypsum board. The phase change gypsum board with the temperature control performance prepared bythe invention is small in the range of temperature fluctuation along with time.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Method for preparing acetic acid activation sludge-based adsorbent

InactiveCN105817201ASimple manufacturing processEasy to operateOther chemical processesChemistryNitrogen atmosphere

The invention discloses a preparation method of an acetic acid-activated sludge-based adsorbent. The specific steps are as follows: taking an appropriate amount of sludge and glacial acetic acid to obtain a homogeneous acetic acid-activated sludge slurry; drying the homogeneous acetic acid-activated sludge slurry to obtain dry sewage Sludge and pulverize, and screen out sludge particles with a particle diameter of 1-2mm; add an activator solution compounded with zinc chloride and sulfuric acid, and perform pyrolysis reaction under nitrogen atmosphere to obtain sludge pyrolysis residue; wash with distilled water after grinding ,dry. The invention has simple manufacturing process and convenient operation. It adopts wet sludge to be directly pyrolyzed without drying treatment. The pyrolysis temperature is low, which belongs to low-temperature pyrolysis. While reducing the sludge drying process, it saves a lot of energy and is more energy-saving and environmentally friendly. The sludge adsorbent is prepared by the chemical activation method of the compound activator, and the carbon-containing compounds in the sludge are condensed into non-volatile polycondensation carbon through dehydration, condensation, moistening and expansion of chemical agents, so as to obtain adsorption with a well-developed porous structure. agent.

Owner:张能力

Manufacturing method for cold-pressed pellets for steelmaking

ActiveCN104775023ABoost Ultimate PerformanceReduce drying processMagnesium chloride hexahydratePellet Formation

A manufacturing method for cold-pressed pellets for steelmaking comprises the manufacturing technological steps that (1) steelmaking secondary fly ash, converter mud and oxide scale are mixed in advance with the weight ratio of (20-23):(55-65):(10-20), and evenly stirred into a mixture; (2) a binder is prepared through water-soluble sodium carboxymethycellulose and industrial effluent at the weight ratio of 1:(15-50) for standby application; (3) a magnesium chloride solution is prepared by magnesium chloride hexahydrate and water at the weight ratio of 1:1 for standby application; (4) 3%-5% of binder and 0.5%-1.5% of magnesium chloride solution are added in the mixture, mixing is carried out by an edge runner mill for 100-150 s, and a pellet material is made; (5) the pellet material is put into a ball press machine to achieve cold-press formation, the diameter of the pellets is 45-55 mm*30-40 mm *20-30 mm, and the pellets are naturally stacked and aired. The cold-pressed pellets manufactured through the method have the advantages that the pellet forming rate is high, the bonding strength is large, the drying time is short after pellet formation, and use for steelmaking is convenient.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

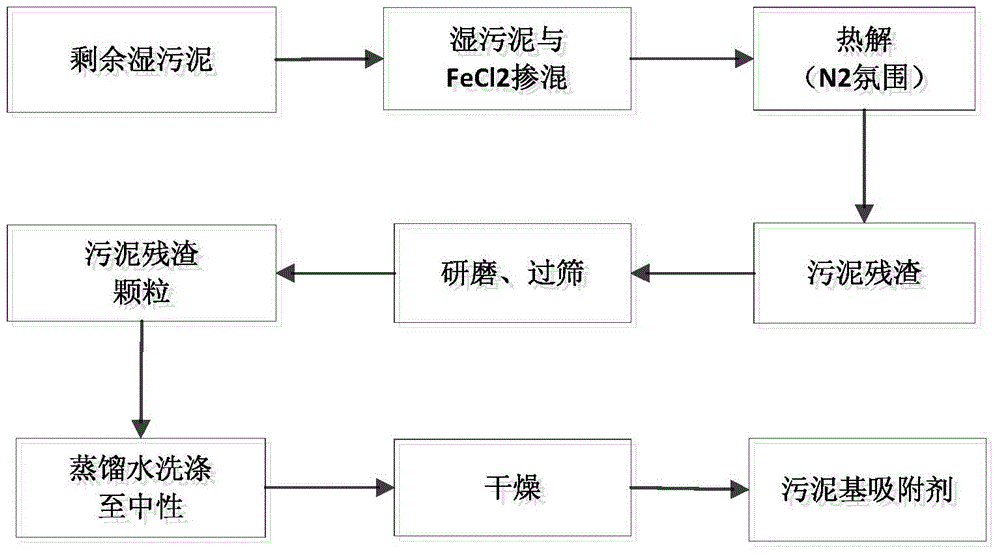

Preparation method of energy-saving sludge-based adsorbent

InactiveCN104874352AReduce drying processEmission reductionOther chemical processesSludge treatment by pyrolysisEnvironmental resistanceSludge

The invention discloses a preparation method of an energy-saving sludge-based adsorbent. The preparation method comprises the following steps: (1) placing residual wet sludge at a heating zone of a pyrolysis reactor of an external-heated tube furnace, wherein the residual wet sludge is doped with an activator FeCL2 and the content of moisture of the residual wet sludge is 60-90%, the mass part ratio of the FeCl2 to the residual wet sludge is 1 to (10-20), performing pyrolysis in a nitrogen atmosphere, wherein the temperature rising speed is 70-80 C degree per minute, the pyrolysis temperature is 550-560 C degree, the stay time is 10-15 minutes and the nitrogen blowing speed is 25-30ml per minute, switching off the tube furnace and a switch of a nitrogen tank after the reaction is completed and cooling to obtain pyrolyzed sludge residue; (2) collecting the pyrolyzed sludge residue, grinding, sieving with a 50-70 mesh screen to obtain sludge residue particles; and (3) washing the sludge residue particles with distilled water till a washing liquid is neutral and drying to obtain the sludge-based adsorbent. According to the preparation method, the energy consumption is effectively reduced and the environment friendliness is improved.

Owner:ZHEJIANG UNIV OF TECH

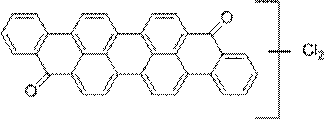

Preparation method of vat violet 1

ActiveCN108047017ASolve recycling difficultiesEasy to recycleOrganic compound preparationBenzo/naphtho/anthradianthrone dyesAlkaneReflux

A preparation method of vat violet 1 belongs to the technical field of dye preparation. The preparation method comprises: adding isoviolanthrone, water and sulfuric acid to a container in sequence, performing grinding and pulverization, adding halogenated alkane to the ground mixture, adding a chloridizing agent below the liquid level, adjusting the pH value till the obtained solution is neutral,raising the temperature of the adjusted mixture till the mixture undergoes reflux, performing filtration till halogenated alkane is totally evaporated, cleaning the filtered cake with hot water till the filtrate is colourless, taking the filtered cake out, and drying the filtered cake to obtain vat violet 1. According to the technical scheme, defects that a large amount of solvent is hard to recycle and causes pollution due to a full-solution chlorination method are overcome. The synthesized vat violet 1 is a bright-colored red purple vat dye, is more bright gorgeous than a product sold in themarket, and is high in intensity of raw powder.

Owner:江苏嘉利精细化工有限公司

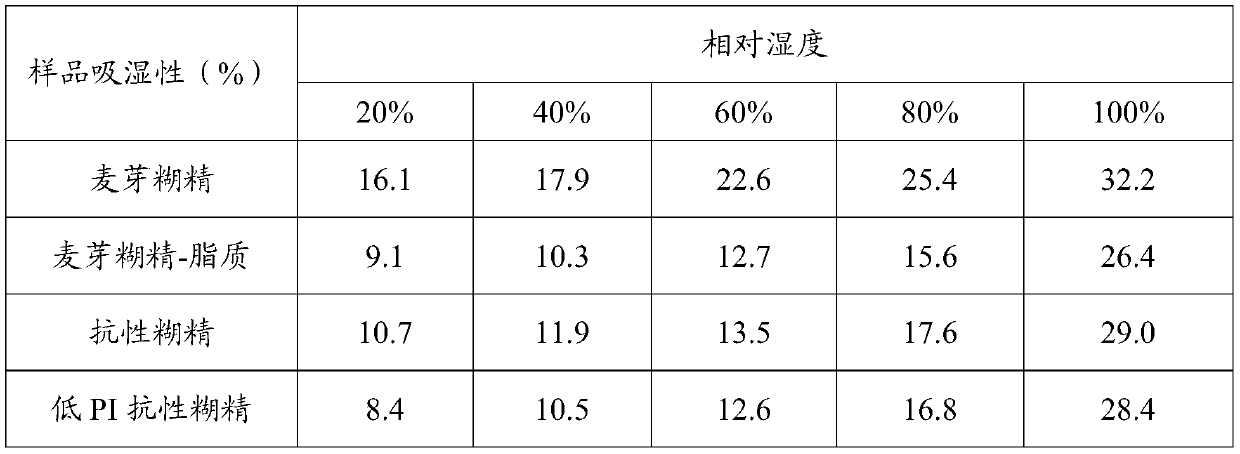

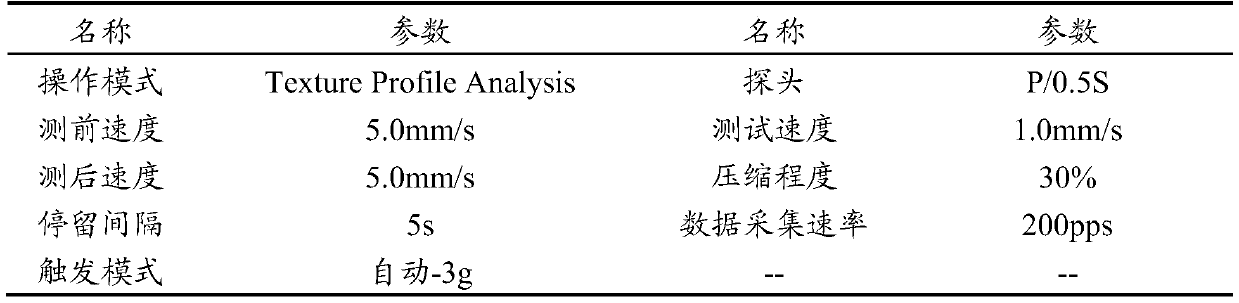

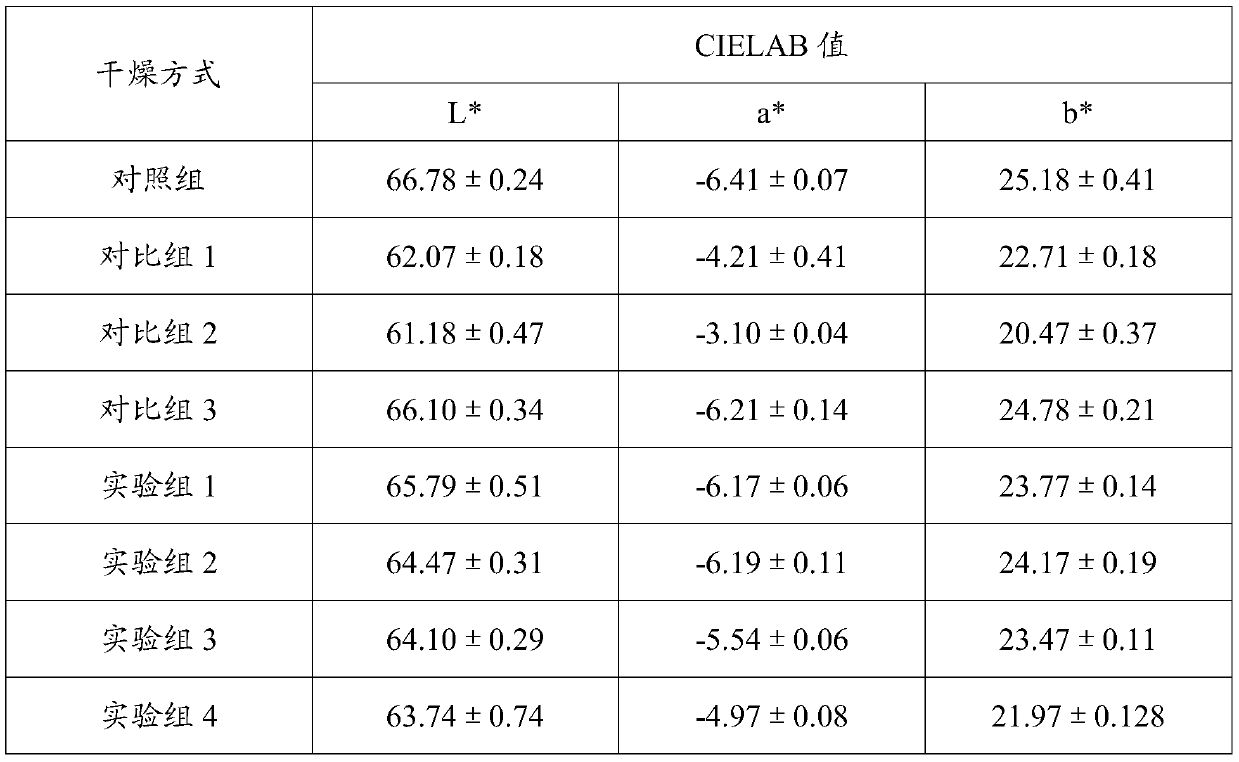

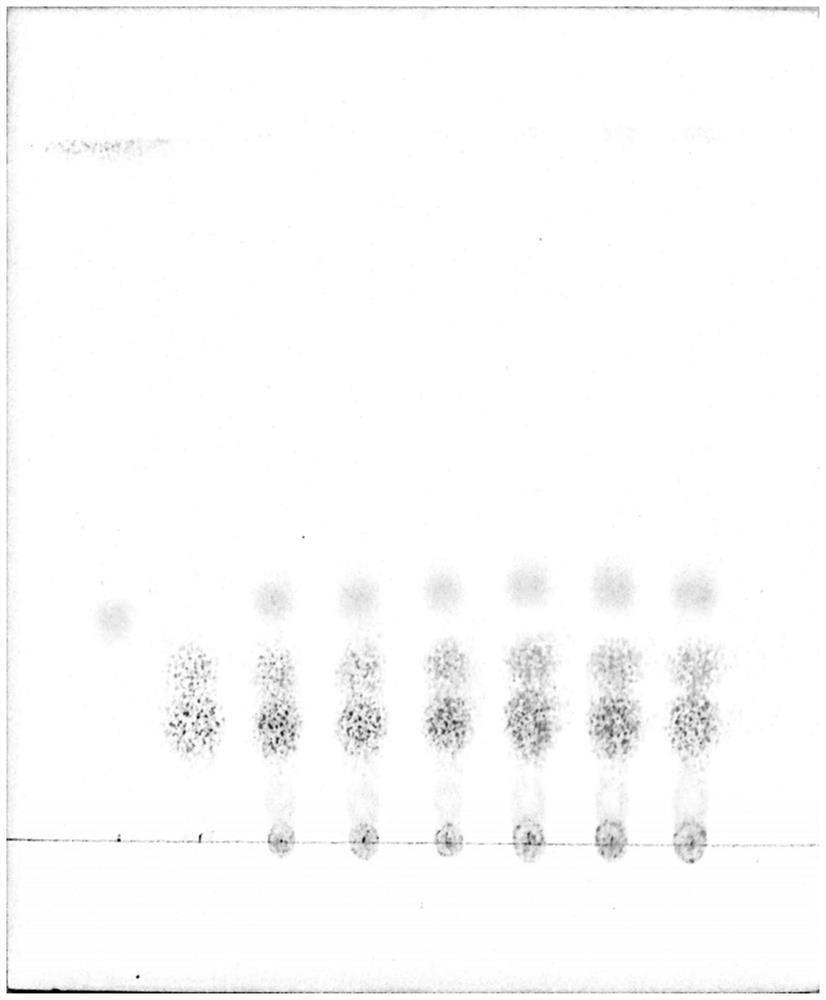

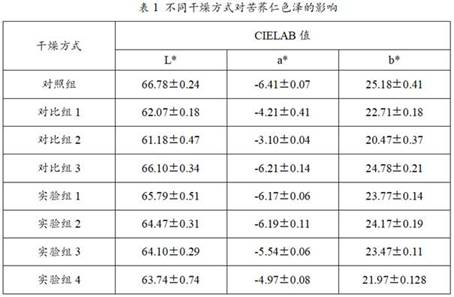

Composite embedding wall material, microcapsule tartarian buckwheat nutrient, and preparation technology

ActiveCN111150085AReduce color changeIncrease contentFood freezingFood shapingBiotechnologyStearic acid

The invention provides a composite embedding wall material. The composite embedding wall material comprises resistant dextrin / low-PI resistant dextrin and a maltodextrin-stearic acid compound. A microcapsule tartarian buckwheat nutrient comprises a tartarian buckwheat leaching solution and resistant dextrin / low-PI resistant dextrin. A preparation technology comprises the steps of S1, performing impurity removal on tartarian buckwheat, performing cleaning, performing soaking for germination, performing vacuum negative pressure freezing-hot air united drying treatment, and performing shelling toobtain tartarian buckwheat kernels and tartarian buckwheat peels; S2, leaching the tartarian buckwheat kernels and the tartarian buckwheat peels with water / ethanol, and performing filtration so as toobtain a leaching solution and leaching residues; and S3, concentrating the leaching solution, adding the embedding wall material, and performing drying so as to obtain the microcapsule tartarian buckwheat nutrient. Through the adoption of the embedding wall material disclosed by the invention, dextrin liquid is not liable to gather and coagulate to cause precipitate, and the embedding rate is high; the tartarian buckwheat nutrient is subjected to microcapsule treatment, so that the application range of the tartarian buckwheat is enlarged; and according to the preparation technology, the tartarian buckwheat is used as a raw material, extraction is performed according to solvent property differences of nutrient components of the tartarian buckwheat, and the technology is simple to operate.

Owner:西昌市正中食品有限公司

Method for directly producing non-spicy haematochrome from fresh chili pepper

The invention discloses a method for directly producing non-spicy haematochrome from fresh chili pepper. The method mainly comprises the steps of firstly, soaking the fresh chili pepper for 1-2 hours by short carbon chain fatty alcohol or acetone of which the volume concentration is 10-60% at the temperature of 40-95 DEG C, filtering to obtain shredded filtrate and shredded filter residue; soaking the shredded filter residue for 1-2 hours by short carbon chain fatty alcohol or acetone or ethyl acetate of which the volume concentration is 80-100% at the temperature of 40-95 DEG C, filtering to obtain coarse extract filtrate; recovering the short carbon chain fatty alcohol or acetone or ethyl acetate in the coarse extract filtrate to obtain a haematochrome crude product; finally extracting the haematochrome in the haematochrome crude product by short carbon chain fatty alcohol or acetone or ethyl acetate of which the volume concentration is 90-100%, and recovering the short carbon chain fatty alcohol or acetone or ethyl acetate to obtain the refined product. The existing production line is applied by the method, so that high-quality natural chili pepper haematochrome which is free of peppery taste, free of 6# solvent residue, high in yield, bright-colored in color and luster and high in color value can be obtained.

Owner:HUNAN AGRICULTURAL UNIV

Processing method of sour bamboo shoots with special-flavor

PendingCN112205596AReduce cookingReduce drying processClimate change adaptationFood scienceEngineeringInstant noodle

The invention discloses a processing method of sour bamboo shoots with a special flavor. The method comprises the following steps: step 1. conducting cleaning; step 2. conducting finishing and cutting; step 3. conducting primary fermentation; step 4. conducting secondary fermentation; and 5. mixing the fermented bamboo shoots in southern stinky tofu brine fermentation liquor, or dehydrating, seasoning and sterilizing the stinky bamboo shoots according to edible requirements to obtain leisure foods, or to apply the bamboo shoots as seasonings of Liuzhou river snails rice noodles, instant rice noodles and instant noodles. Fresh bamboo shoots are directly soaked in water, the procedures of cooking and sun-curing in the general processing process are reduced, energy is saved, and the labor cost is reduced; Under the condition that salt is not added, the product contains high moisture, is convenient to store and long in period, and is a resource-saving product preservation method. The product is wide in application range and can be used as an auxiliary material for seasonings, ingredients and dietary fiber suppliers. The product is unique in flavor and is a special cold processing method.

Owner:柳州市美申园食品科技有限公司

Compound salvia miltiorrhiza concentrated pills and preparation method thereof

InactiveCN112402488AExcellent dissolution timeReduce churnNervous disorderHydroxy compound active ingredientsSalvia miltiorrhizaMedicinal herbs

The invention discloses compound salvia miltiorrhiza concentrated pills and a preparation method thereof, and relates to the technical field of traditional Chinese medicines. The compound salvia miltiorrhiza concentrated pills are prepared from the following raw materials in parts by weight: 130-140 parts of salvia miltiorrhiza, 40-45 parts of pseudo-ginseng and 2-3 parts of borneol. The preparation method of the compound salvia miltiorrhiza concentrated pills comprises the following steps: weighing the raw materials for later use; extracting the salviae miltiorrhizae by adopting an ethanol extraction method, and concentrating to obtain salviae miltiorrhizae thick paste; crushing cleaned and dried pseudo-ginseng medicinal material into fine powder, and uniformly mixing the fine powder withthe salvia miltiorrhiza thick paste; and grinding the borneol, dissolving the borneol with ethanol, uniformly mixing with the pseudo-ginseng fine powder and the salvia miltiorrhiza thick paste, pelleting, drying at low temperature, and coating with films to obtain the compound salvia miltiorrhiza concentrated pills. According to the preparation method of the compound salvia miltiorrhiza concentrated pills, a drying process is reduced in the mixing stage of the raw materials, the process is reduced, the loss of effective components is reduced, and the efficacy is better.

Owner:爱民药业集团股份有限公司

Filling equipment for liquor

PendingCN108862171AGuaranteed qualitySimplify the cleaning processSynchronising machinesArchitectural engineeringThreaded rod

The invention discloses a filling equipment for liquor. The filling equipment for the liquor comprises a stand; the stand is vertically provided with limiting groove and a threaded hole; a threaded rod is in threaded connection to the interior of the threaded hole; the side wall of the stand is provided with a side hole; the side wall of the threaded rod is provided with a side rod which penetrates through the side hole and is used for driving the threaded rod to rotate; the top of the threaded rod is provided with a disc; a first spring is arranged between the disc and the limiting groove; the positions on the stand and on the two sides of the threaded rod are provided with tensioning mechanism used for limiting a winebottle respectively; the stand is provided with a pipeline into which awinebottle mouth is put; a vertical plate is vertically connected to the middle part of the pipeline in a sliding manner and is provided with a transverse plate and an L-shaped bottom hole; the bottom hole is communicated with the pipeline; the bottom of the pipeline is provided with an auxiliary pipe; the auxiliary pipe is provided with a first one-way valve which enters the pipeline through theexternal; and the stand is provided with a reciprocating mechanism used for driving the vertical plate to perform reciprocating movement in a vertical direction. The technical scheme of the inventionmainly solves the problem that the winebottle is adhered with dusts, and the quality of the liquor is influenced after the liquor is filled at present.

Owner:重庆技嘉模具有限公司

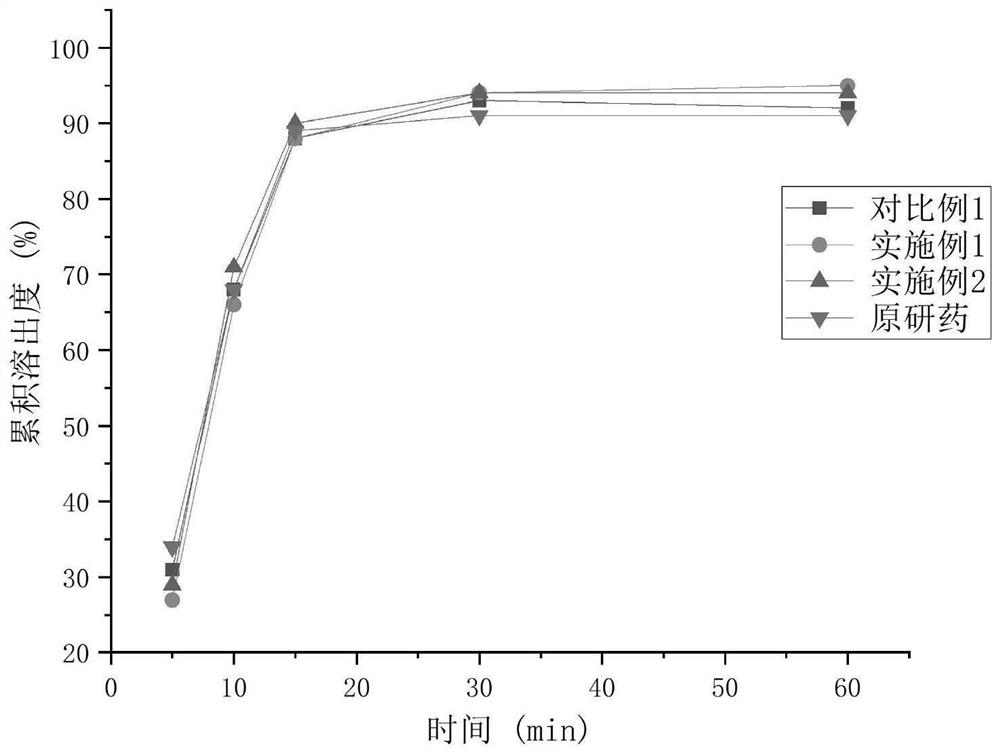

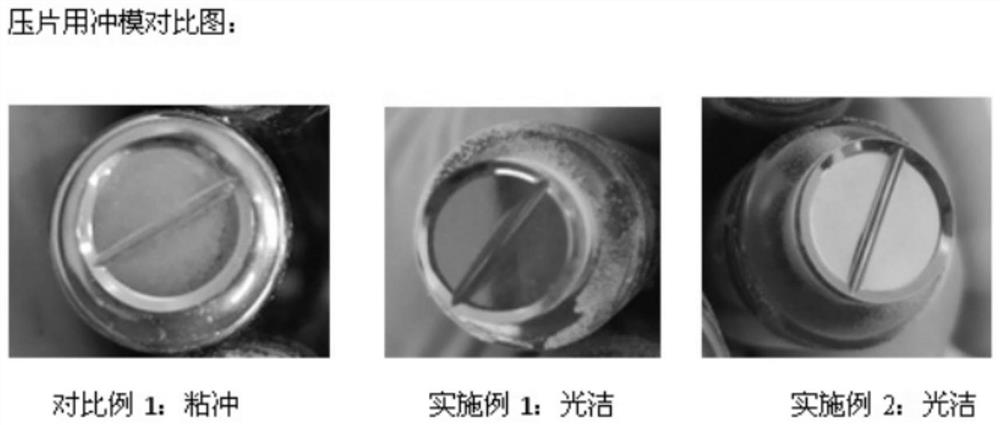

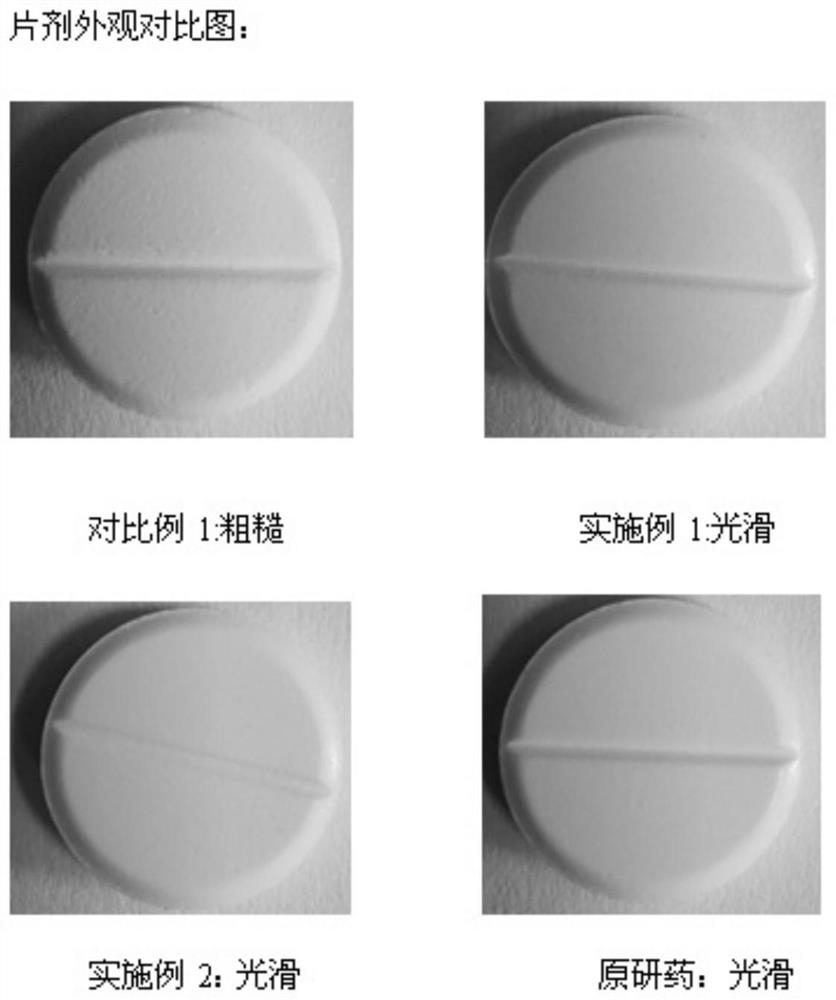

Amisulpride tablet and preparation method thereof

InactiveCN111728947AReduce exposed areaAct as a glueNervous disorderOrganic non-active ingredientsEngineeringMedicinal chemistry

The invention belongs to the technical field of medicine preparation, and particularly relates to an amisulpride tablet and a preparation method thereof. The amisulpride tablet comprises the followingingredients: amisulpride, adhesives, filling agents, disintegrating agents, lubricating agents and auxiliary lubricating agents. According to the amisulpride tablet prepared by the invention, the problem that the amisulpride tablet is likely to be subjected to sticking is solved, in addition, the amisulpride tablet has a good similarity with the dissolution curve of an original drug, has a good product appearance, has good stability and preparation technology tolerance and is suitable for industrial mass production.

Owner:YANGTAI PHARMA SHANDONG

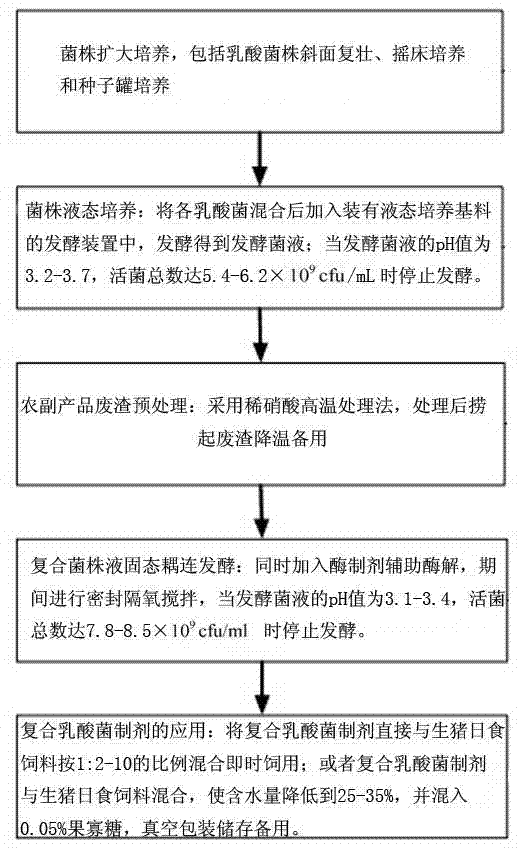

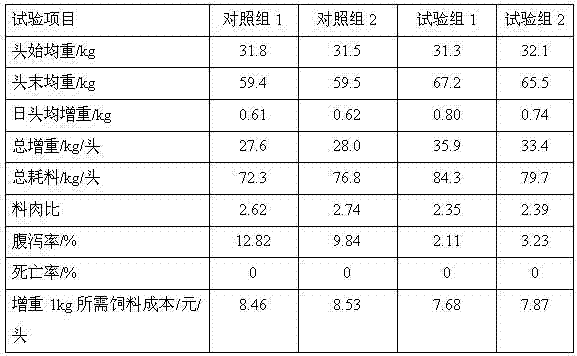

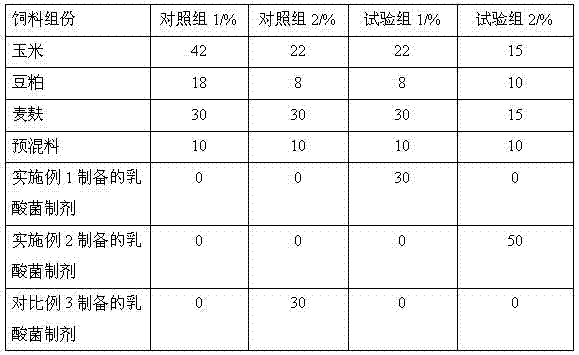

A kind of method and application of preparing compound lactic acid bacteria preparation

ActiveCN103146616BImprove performanceColonization rateBacteriaAnimal feeding stuffCouplingColonization rate

The invention belongs to the technical field of animal feeds and in particular discloses a method for preparing a compound lactobacillus preparation and the application of the compound lactobacillus preparation. The method comprises the steps of: expanded culturing of strains, liquid culturing of compound strain, waste residue pretreating of agricultural and sideline products and liquid-solid coupling fermentation of compound strain. According to the method for preparing compound lactobacillus preparation, the problem that the existing probiotic feed additives are poor in performance stability and high in production cost is overcome, the competitiveness of the strain in compound lactobacillus preparation product is increased, the host colonization rate is improved, the cost is greatly reduced, and the waste residue resource of agricultural and sideline products can be effectively utilized to serve as an important component of the feed additive, so that the prominent problems of wasting of resources and environmental pollution can be partly solved; and therefore, the compound lactobacillus preparation can be successfully applied to the aspect of feeds.

Owner:GUANGDONG YIHAO FOOD

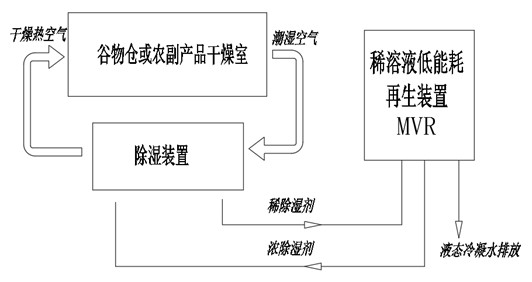

Low-cost drying technology for grains and agricultural and sideline products

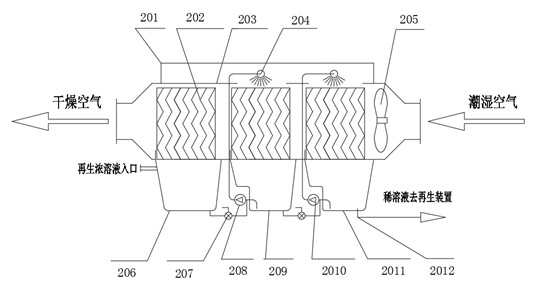

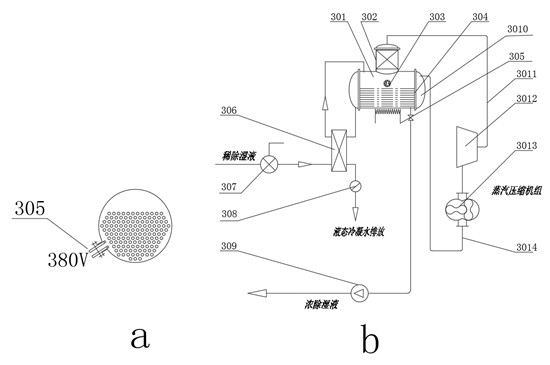

InactiveCN114576944ALow costLow running costDispersed particle separationDrying gas arrangementsLiquid waterDesiccant

The invention discloses a low-cost drying technology for grains and agricultural and sideline products. The low-cost drying technology comprises an air dehumidification technology and a low-energy-consumption concentration and regeneration technology of a dehumidizer. According to the air dehumidification technology, a concentrated solution with hygroscopicity is adopted as a drying agent to be in contact with wet air, and dry air and a diluted dehumidizer solution are obtained; the dry air is used for drying and dehydrating grains and agricultural and sideline products. According to the low-energy-consumption concentration and regeneration technology of the dehumidizer, a diluted dehumidizer solution is subjected to concentration and regeneration treatment, water vapor is pumped out of a dilute solution through combination of a single-stage or two-stage vapor compressor and compressed for heating, the obtained compressed vapor is used for heating the dilute dehumidizer, concentration and regeneration of the dilute dehumidizer are achieved, and water leaves a system in a liquid water form. Gasification latent heat is recycled in the dehumidification process and the regeneration process, energy input of traditional drying is omitted, the system is suitable for drying treatment of large-scale grains and agricultural and sideline products, all-weather starting can be achieved, operation conditions are extensive, and engineering application is easy.

Owner:孙聪

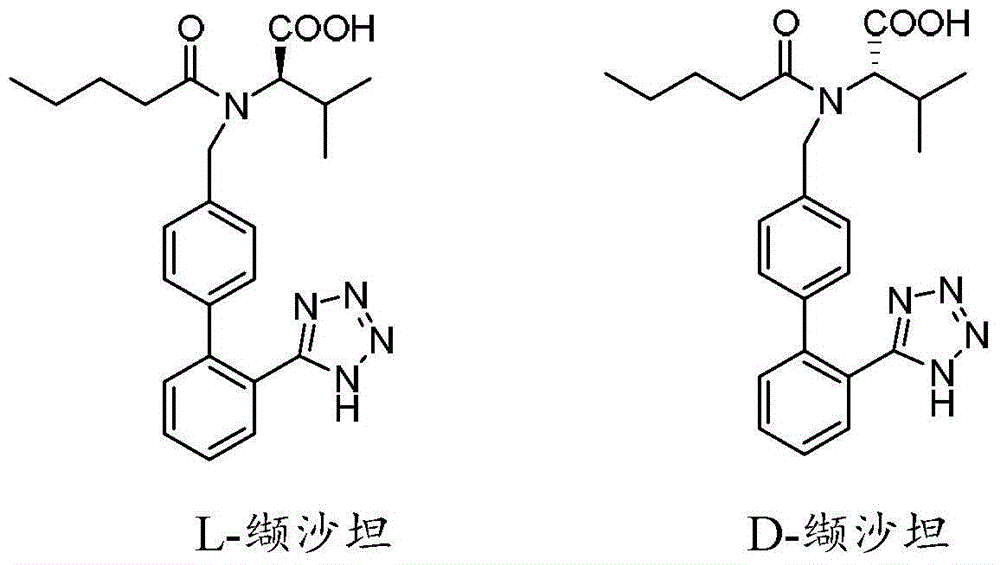

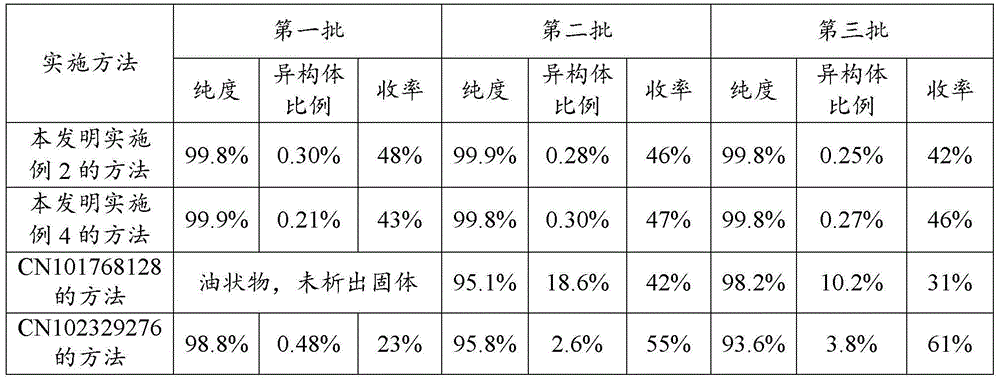

Recovery method of valsartan mother liquor

The invention relates to a recovery method of a valsartan mother liquor and belongs to the technical field of medical chemistry. The recovery method comprises the steps of dissolving the valsartan coarse product into a solvent containing 4-methyl-2-pentanone, heating till completely dissolving, cooling in stages for crystallization, and filtering to obtain valsartan solid. The purity of the valsartan mother liquor is greater than 99.8%, and the total recovery rate of the valsartan mother liquor is greater than or equal to 42%. For the valsartan coarse product having the isomer D-valsartan proportion within the range of 10% to 35%, the recovery method is capable of effectively reducing the isomer proportion, increasing the utilization rate of the valsartan and reducing the cost.

Owner:SOLIPHARMA

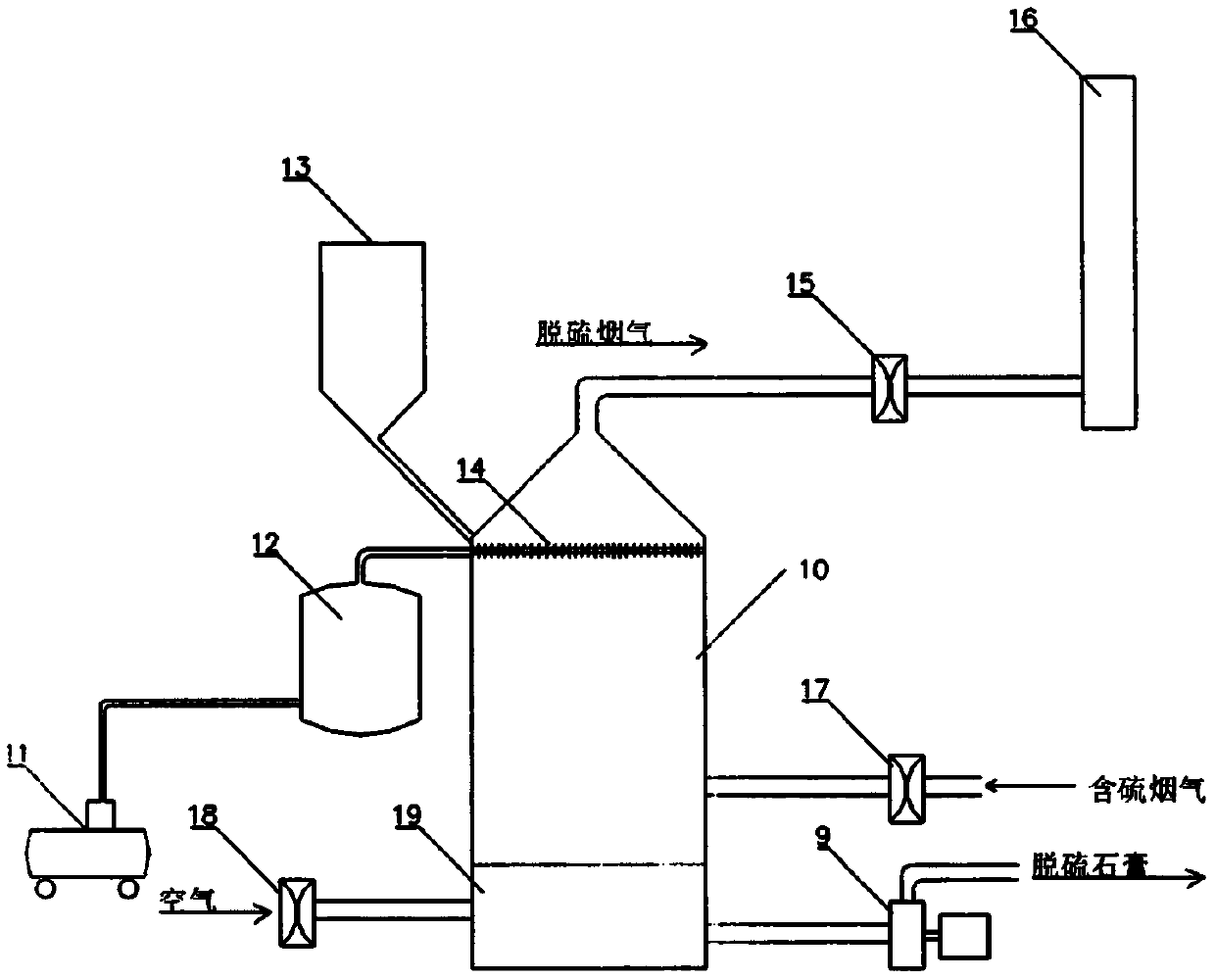

Marble desulfurizing agent desulfurization method and byproduct cyclic utilization method thereof

InactiveCN111359421AReduce moisture contentReduce recycling costsGas treatmentSolid waste managementFlue gasPhysical chemistry

The invention relates to a marble desulfurizing agent desulfurization method and a byproduct cyclic utilization method thereof. A marble desulfurizing agent is prepared by the following steps: precipitating into a slurry through a precipitation tank, squeezing into a mud cake by a filter press, and grinding into sand powder by a grinding machine. The marble desulfurizing agent is mixed with water,and dispersing is performed by using a high-speed liquid dispersing machine to prepare an absorption slurry with the solid content of 20-35%; in an absorption tower, flue gas containing sulfur dioxide is in spray contact with an absorbent slurry for physical and chemical reaction, and finally byproducts CaSO3 and CaSO4.2H2O crystals for curing sulfur dioxide are generated and fall into an absorption slurry circulating pool arranged at the bottom of the absorption tower. A large amount of air is blown in to forcibly oxidize CaSO3 to generate CaSO4.2H2O. The desulfurizing agent is premixed withmarble dry powder, so that the problems that the desulfurized gypsum is high in water content and high in viscosity, accumulated materials are blocked, the grading is poor, and the rheological property is poor after water is added are solved. The mixture is mixed with other raw materials to prepare putty powder and self-leveling mortar, and the putty powder and the self-leveling mortar are addedinto concrete as a filling early strength agent.

Owner:林铭昭

A kind of composite embedding wall material and microencapsulated tartary buckwheat nutrient and preparation process

ActiveCN111150085BReduce color changeIncrease contentFood freezingFood shapingBiotechnologyNutrition

The invention provides a composite embedding wall material, which comprises resistant dextrin and maltodextrin-stearic acid compound. Microencapsulated buckwheat nutrients, including tartary buckwheat extract and resistant dextrin. Its preparation process includes: S1 removing impurities and cleaning tartary buckwheat, soaking and germination, vacuum negative pressure freezing-hot air combined drying, and then shelling to obtain tartary buckwheat kernels and tartary buckwheat skin; S2 making tartary buckwheat kernels and tartary buckwheat skin with water / ethanol Leaching and filtering to obtain the extract and extract residue; S3 Concentrate the extract, add composite embedding wall material, and dry to obtain microencapsulated tartary buckwheat nutrients. The composite embedding wall material of the present invention makes the dextrin liquid not easy to gather and coagulate to cause precipitation, and the embedding rate is high; by microencapsulating the tartary buckwheat nutrients, the application range of tartary buckwheat is expanded; its preparation process uses tartary buckwheat The raw material is extracted according to the solvent difference of nutritional components of tartary buckwheat, and the process operation is simple.

Owner:西昌市正中食品有限公司

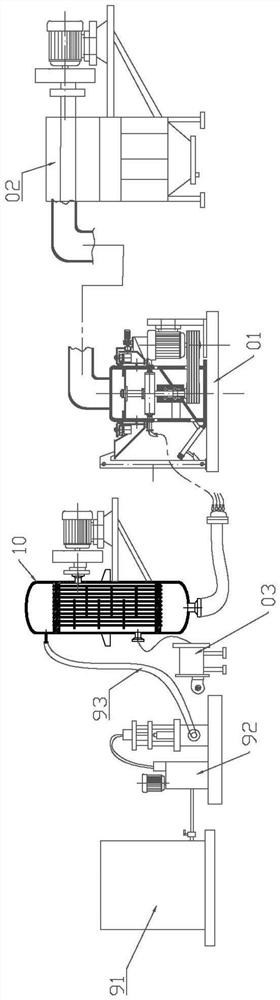

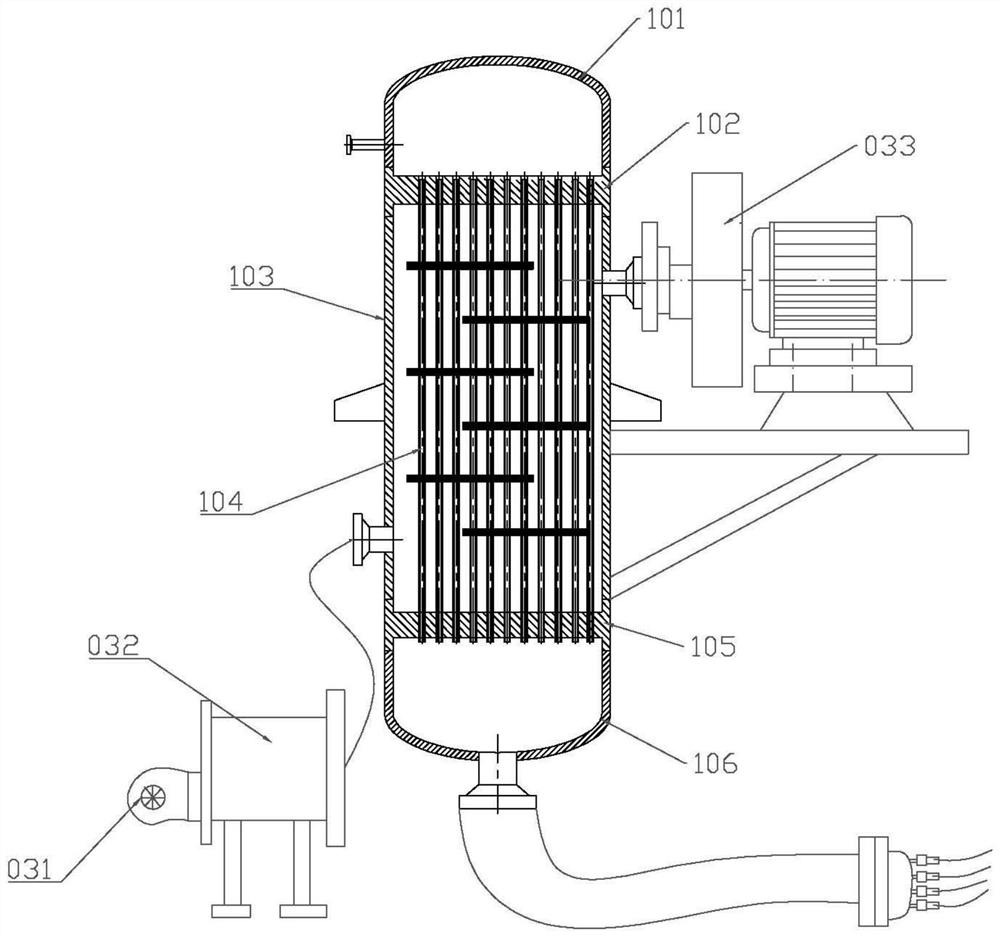

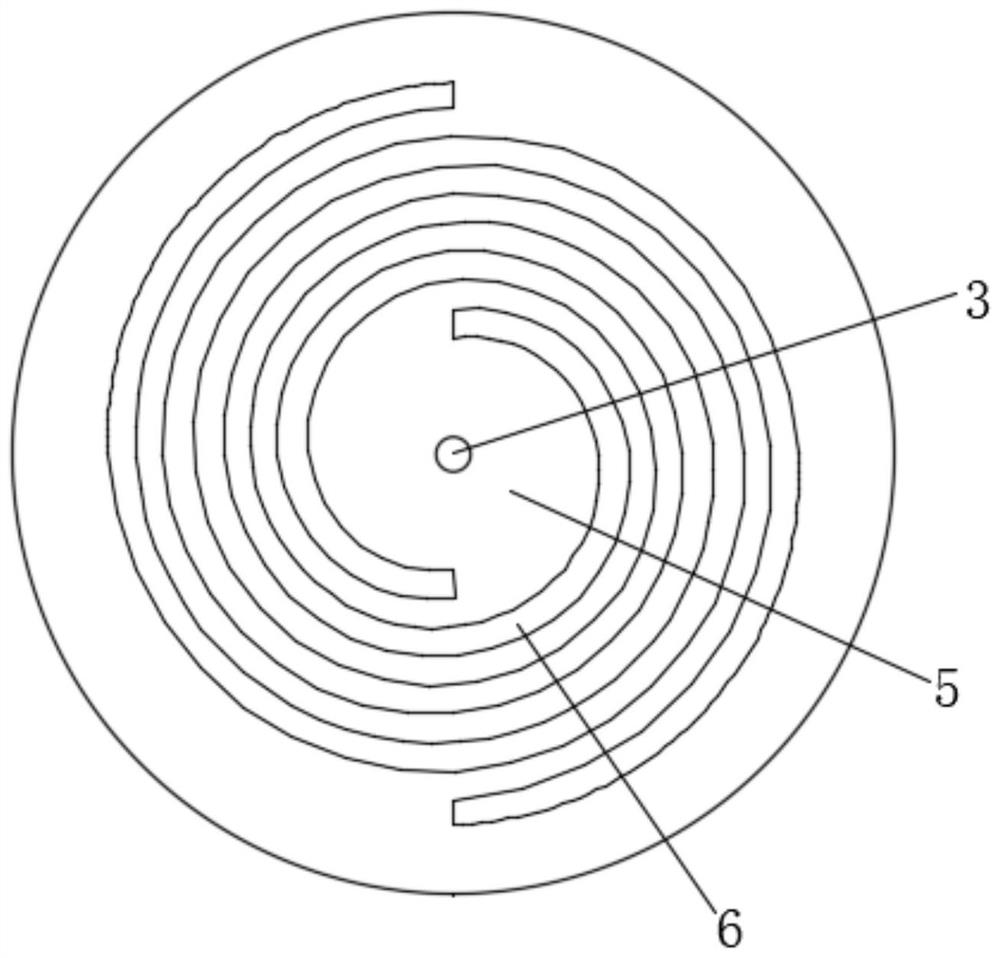

Pulpifying steam flow crushing and drying machine

PendingCN114453117AReduce drying processLow costDrying gas arrangementsGrain treatmentsProcess engineeringMechanical engineering

The invention relates to the technical field of material crushing and drying, in particular to a slurrying steam flow crushing and drying machine which comprises a slurry storage cylinder, a heater, an air mill and a drying and collecting machine which are sequentially communicated, the slurry storage cylinder is connected with a slurry inlet pump and a slurry inlet pipe, and the slurry inlet pump is connected with the slurry storage cylinder and the heater through the slurry inlet pipe; materials in the slurry storage cylinder are conveyed into the heater to be heated; the air mill comprises a machine shell, a main shaft, a rotating target, a plurality of Laval nozzles, a classifying screen and a first driving mechanism used for driving the main shaft to rotate, the main shaft is rotatably and longitudinally arranged in the machine shell, the main shaft penetrates through and fixes the rotating target and the classifying screen, the classifying screen is located above the rotating target, and the Laval nozzles are arranged around the circumferential side of the rotating target. Each Laval nozzle is communicated with an outlet of the heater through a steam slurry pipe; a discharging port is formed in the position, located above the classifying screen, of the machine shell and connected with a drying and collecting machine through a discharging pipe, and the drying and collecting machine is provided with an exhaust mechanism for conducting air draft on the discharging pipe. And the cost is low, and the crushing efficiency is high.

Owner:林焕

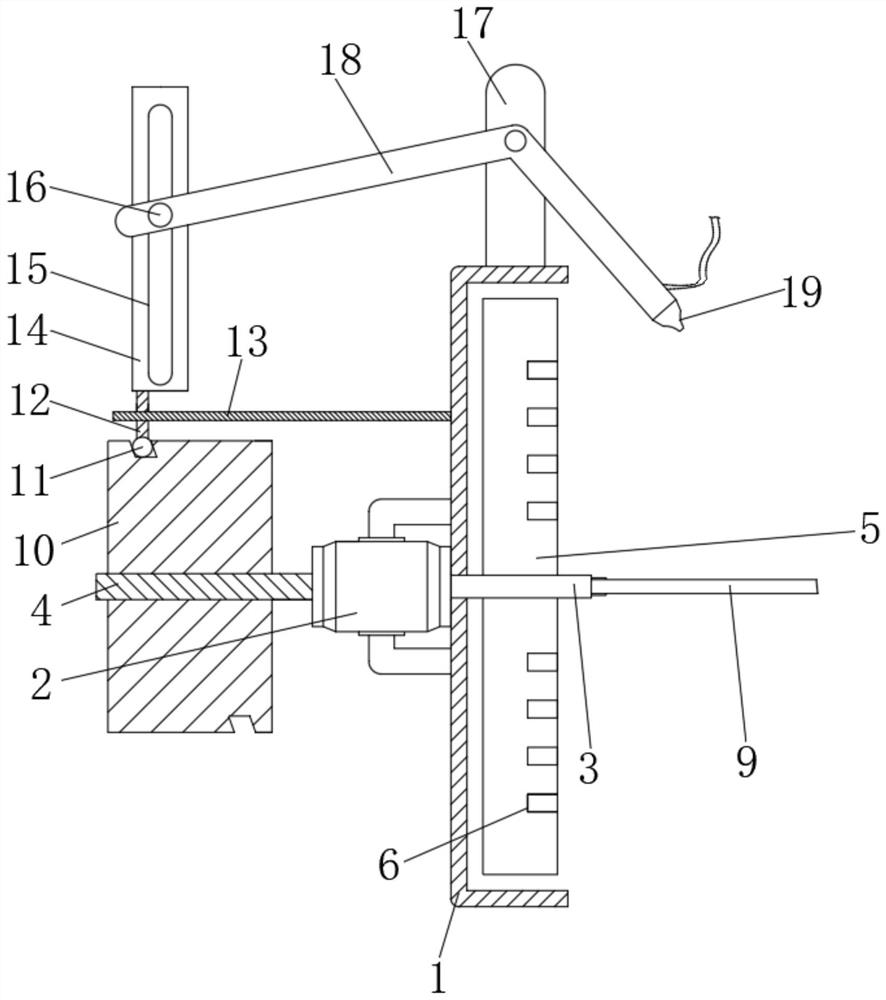

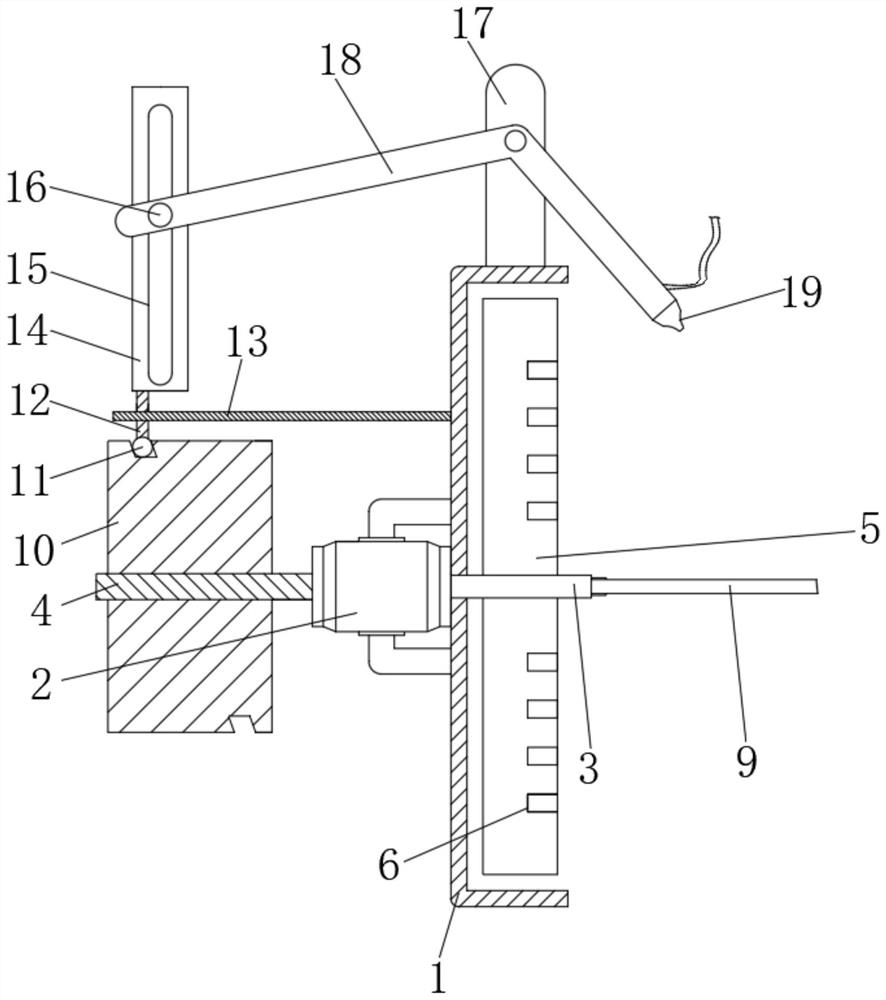

A high-efficiency finishing device for frame yarn

ActiveCN110844700BAchieve tensionAchieve relaxationFilament handlingFibre cleaning/openingYarnStructural engineering

The invention discloses a high-efficiency finishing device for framed yarn, which includes a fixed seat and a framed yarn arm, and also includes a movable blowing mechanism and a tensioning mechanism that controls the relative movement of the framed yarn arm. The movable blowing mechanism and the tensioning mechanism pass through the driving mechanism drive movement. The movable blowing mechanism includes a moving plate that reciprocates left and right, the surface of the moving plate is provided with a guiding channel, and a sliding bar is slidably connected in the guiding channel, and the sliding bar is connected to one end of the swing arm. A support seat is fixedly connected to the fixed seat, the swing arm is hinged to the support seat through pins, and the other end of the swing arm is fixedly connected to a hair dryer. In the present invention, it will continuously eject high-speed airflow, and guide and comb the yarn through high-speed airflow acceleration; and the reciprocating swing improves the injection range of the high-speed airflow on it, that is, airflow carding is performed on more yarns, and the work efficiency is improved. efficiency.

Owner:YUHUAN DEGU NEW MATERIAL TECH CO LTD

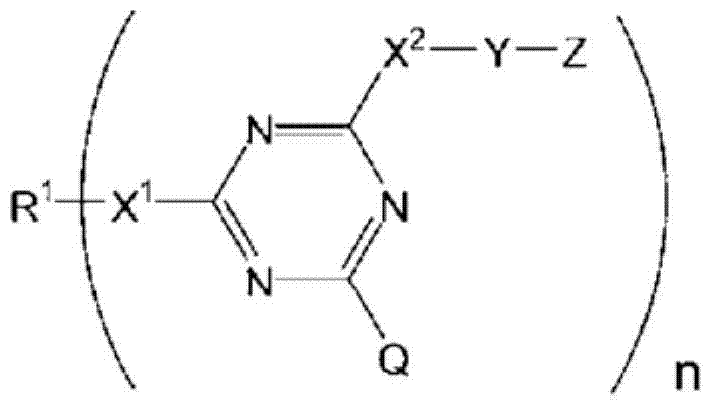

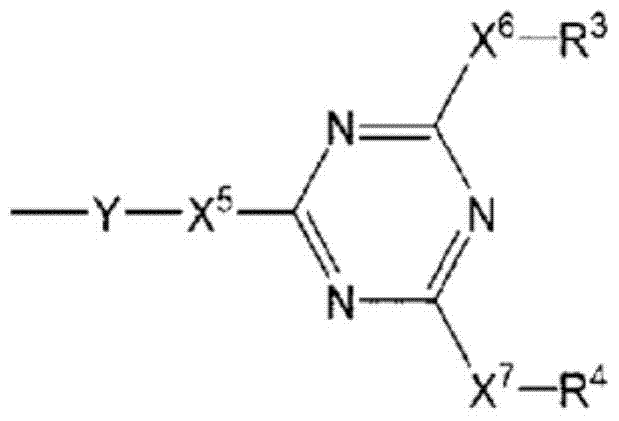

Preparation method of diazo photosensitizer

PendingCN112279986AShorten the synthesis processReduce drying processPhotomechanical apparatusPolyoxymethyleneO-Phosphoric Acid

The invention discloses a preparation method of a diazonium photosensitizer, which comprises the following steps: 1) mixing concentrated sulfuric acid and phosphoric acid according to a proper ratio to obtain a mixed acid, cooling, and slowly adding a proper amount of p-aminodiphenylamine diazonium sulfate (VRT) which is a wet product; wherein the temperature is controlled to be 20-40 DEG C when the p-aminodiphenylamine diazonium sulfate is added; 2) slowly adding a proper amount of paraformaldehyde after the dissolution in the step 1) is finished, and reacting at the temperature of below 40 DEG C until the reaction is complete; 3) dissolving a reaction solution completely reacted in the step 2) in water, adding a proper amount of a chlorine salt, and separating out a yellow precipitate; and 4) filtering, and drying the yellow precipitate to obtain the product. According to the preparation method disclosed by the invention, reaction with paraformaldehyde is carried out in the mixed acid, the reaction temperature can be effectively increased, the direct damage effect of the concentrated sulfuric acid on the raw materials is reduced, the reaction can be carried out at a relatively high temperature which is easier to control, the weight of the synthesized photosensitizer required for photoresist mixing is reduced to 90%, and the cost is saved.

Owner:浙江荣生科技有限公司

Carbon Black Dispersion and Its Utilization

ActiveCN105073915BLow viscosityIncrease concentrationPigmenting treatmentNon-aqueous electrolyte accumulator electrodesHigh concentrationLithium

Provided is a carbon black dispersion in which N-methyl-2-pyrrolidone that can achieve dispersibility at a lower viscosity and a higher concentration and can also achieve superior storage stability compared with conventional resin-type dispersants is used as a solvent. Also provided are: a battery electrode mix layer which is homogeneous and has good coating film properties and low surface resistance; and a lithium ion secondary battery equipped with the battery electrode mix layer. The problems can be solved by, for example, a carbon black dispersion comprising carbon black, polyvinyl alcohol (or a combination of polyvinyl alcohol with a pigment derivative) that serves as a dispersant, and N-methyl-2-pyrrolidone that serves as a solvent, said carbon black dispersion being characterized in that the degree of saponification of polyvinyl alcohol is 60 to 85 mol% and the value (a) falls within the range from 0.00017 to 0.00256 inclusive wherein X (m2 / g) represents the BET specific surface area of carbon black and aX (g) represents the addition amount of polyvinyl alcohol relative to 1 g of carbon black.

Owner:TOYO INK SC HOLD CO LTD +1

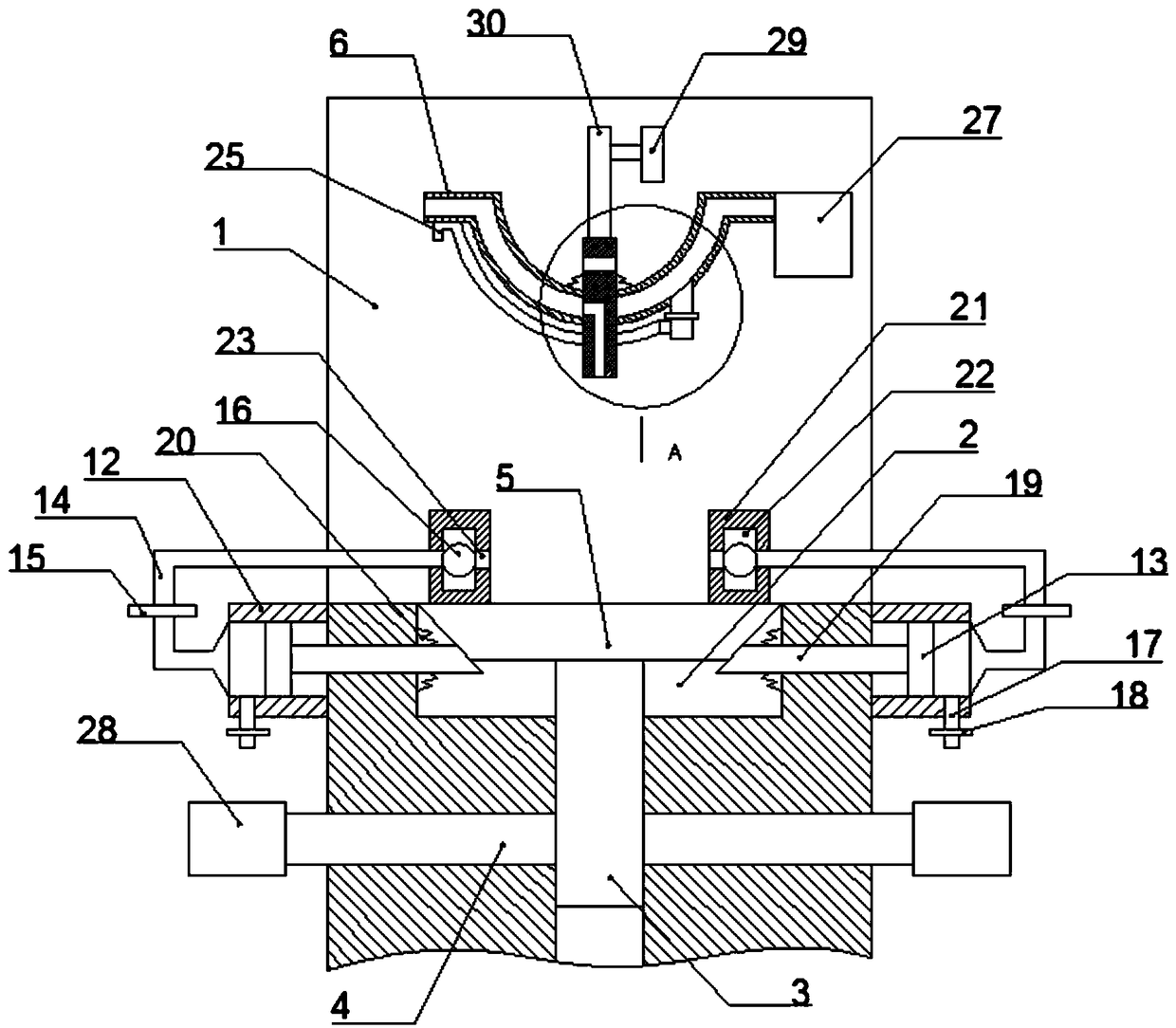

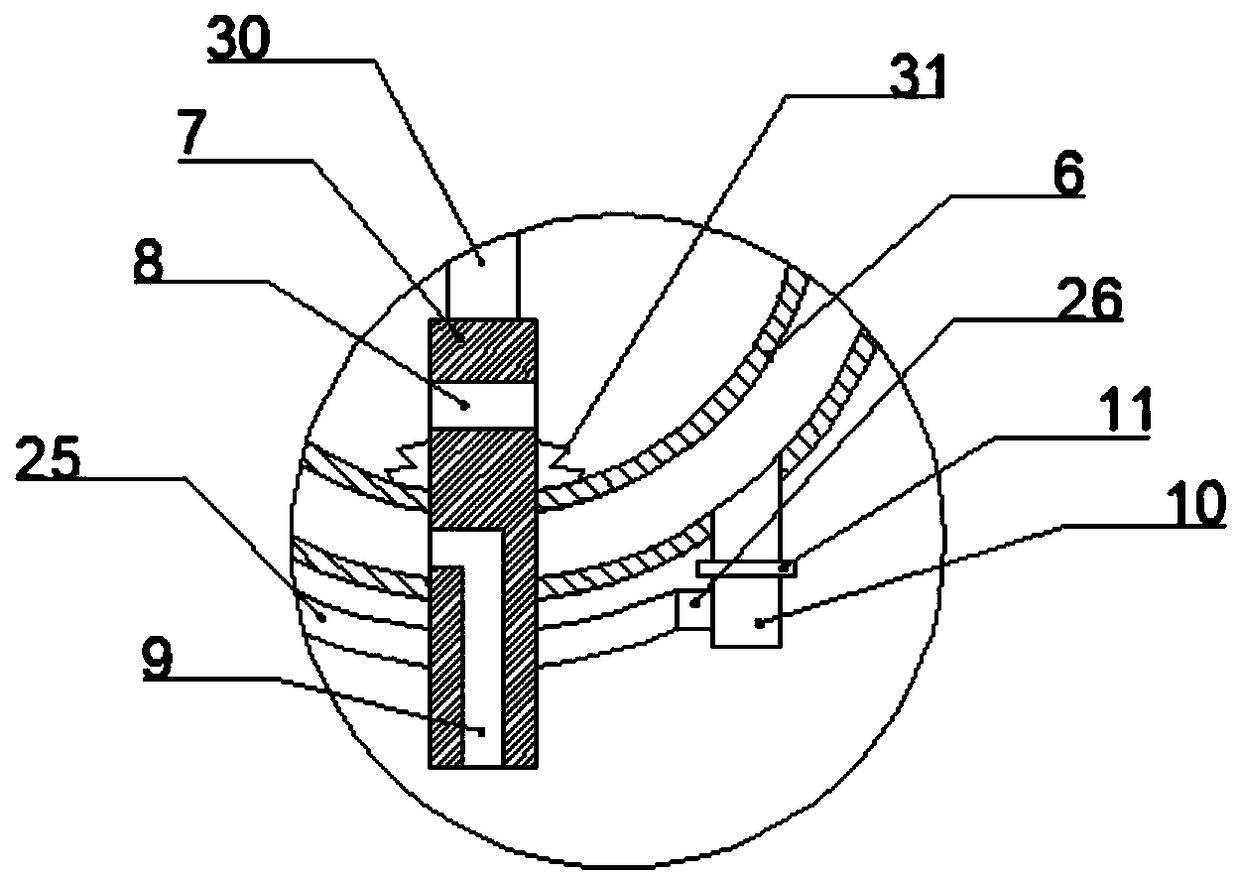

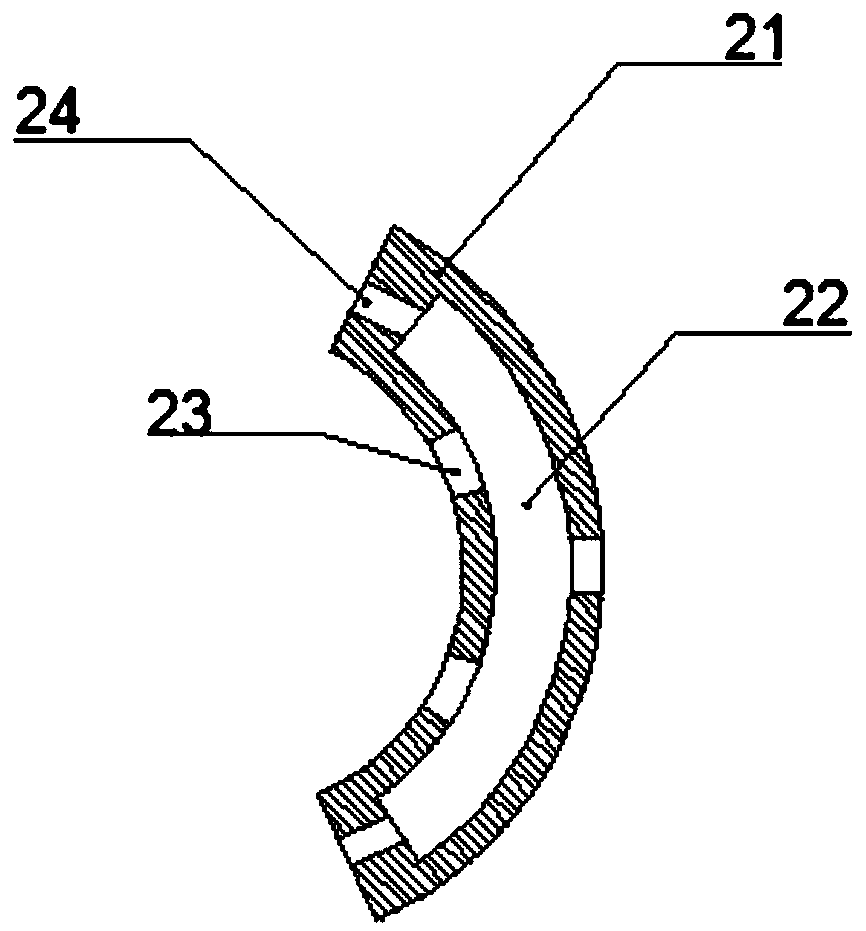

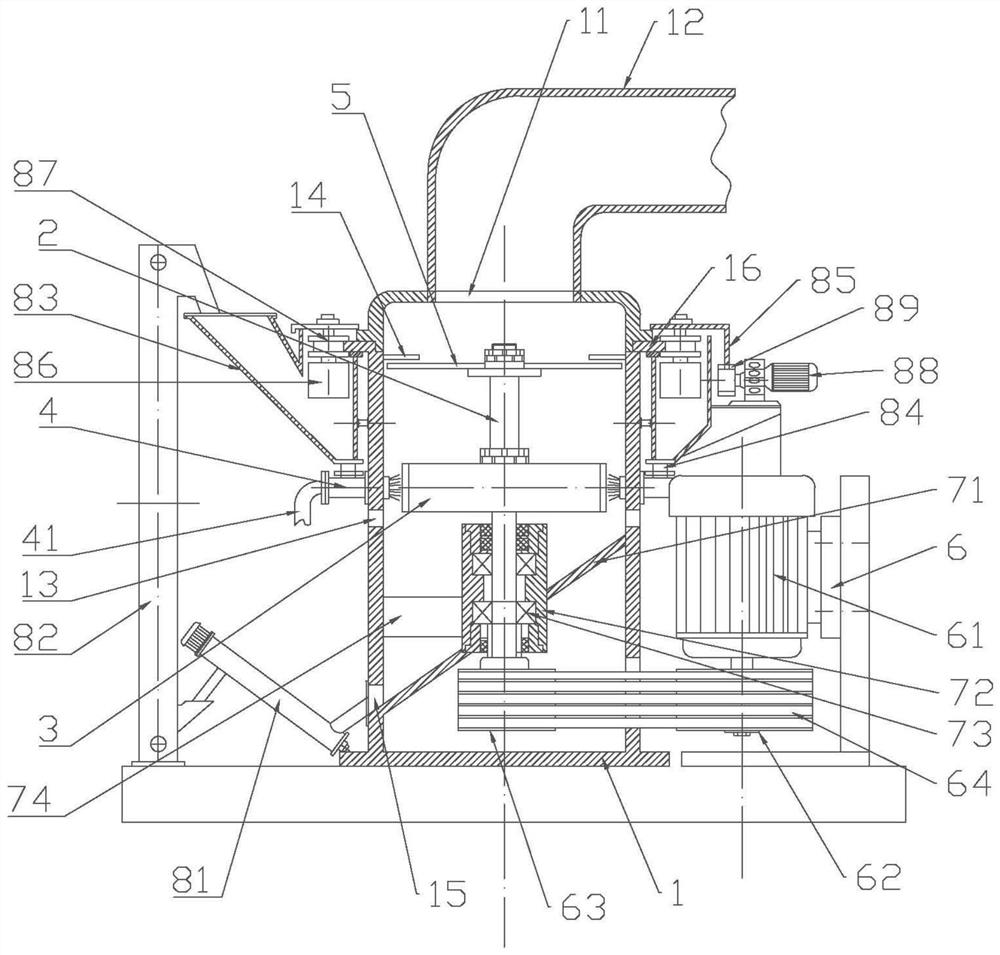

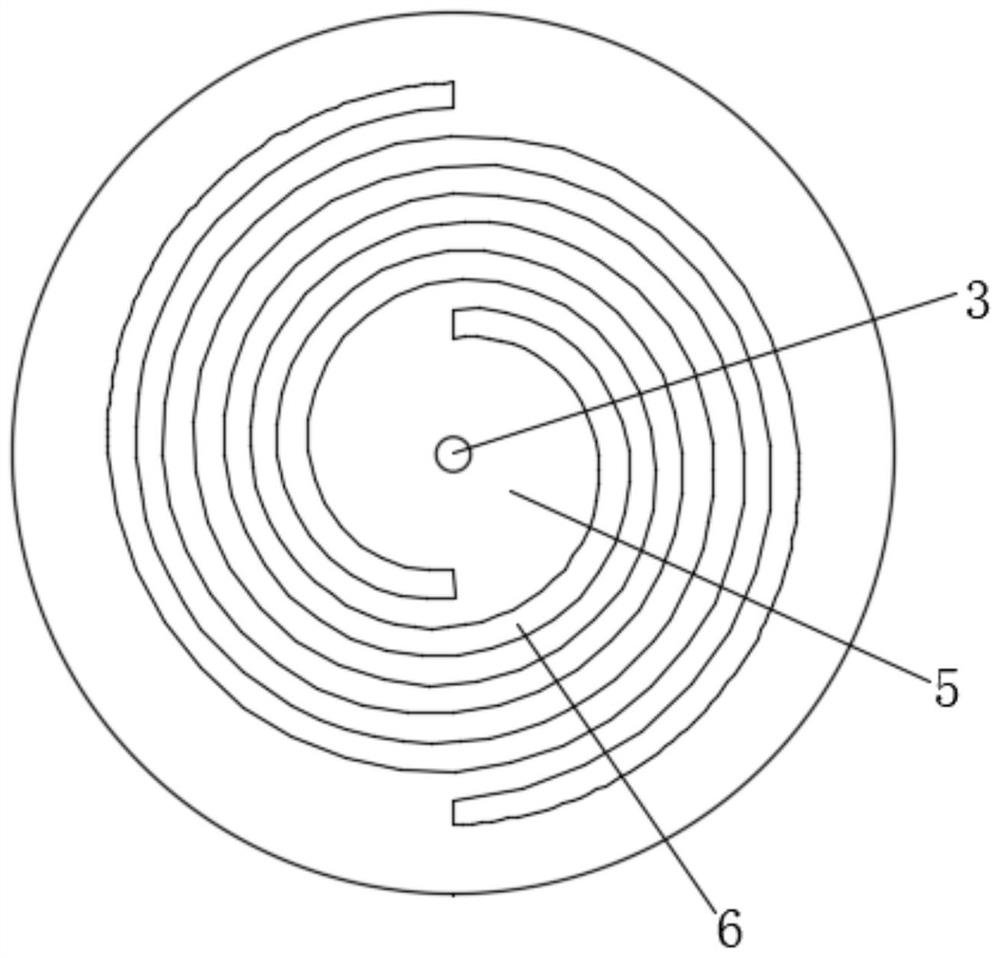

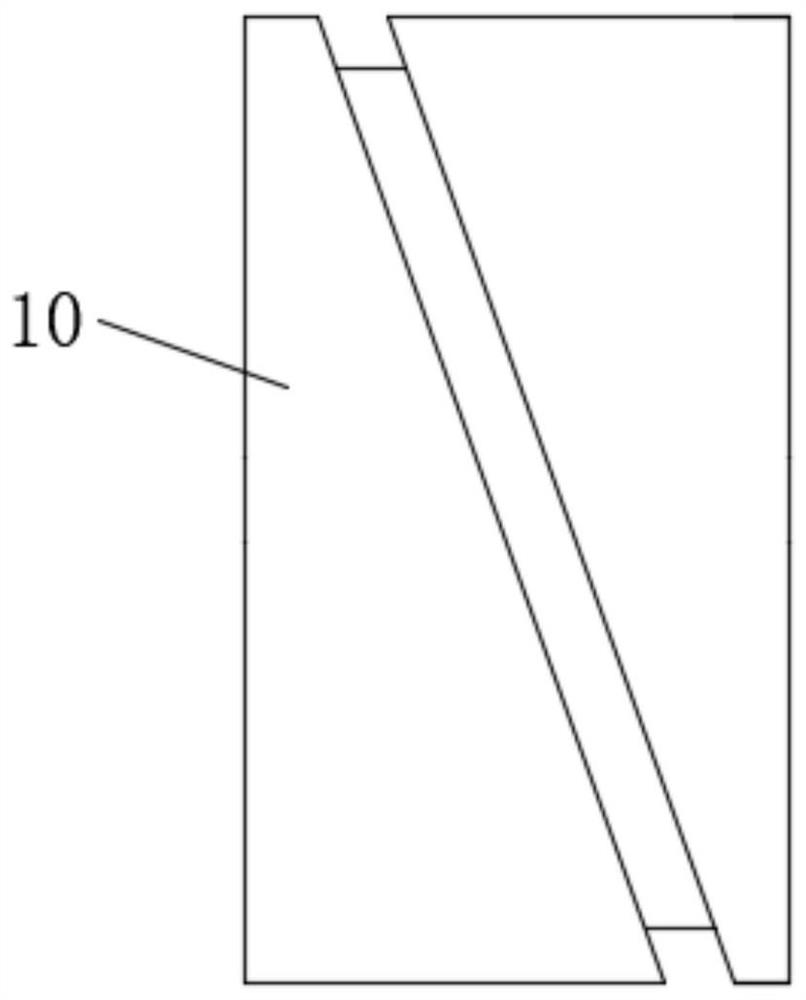

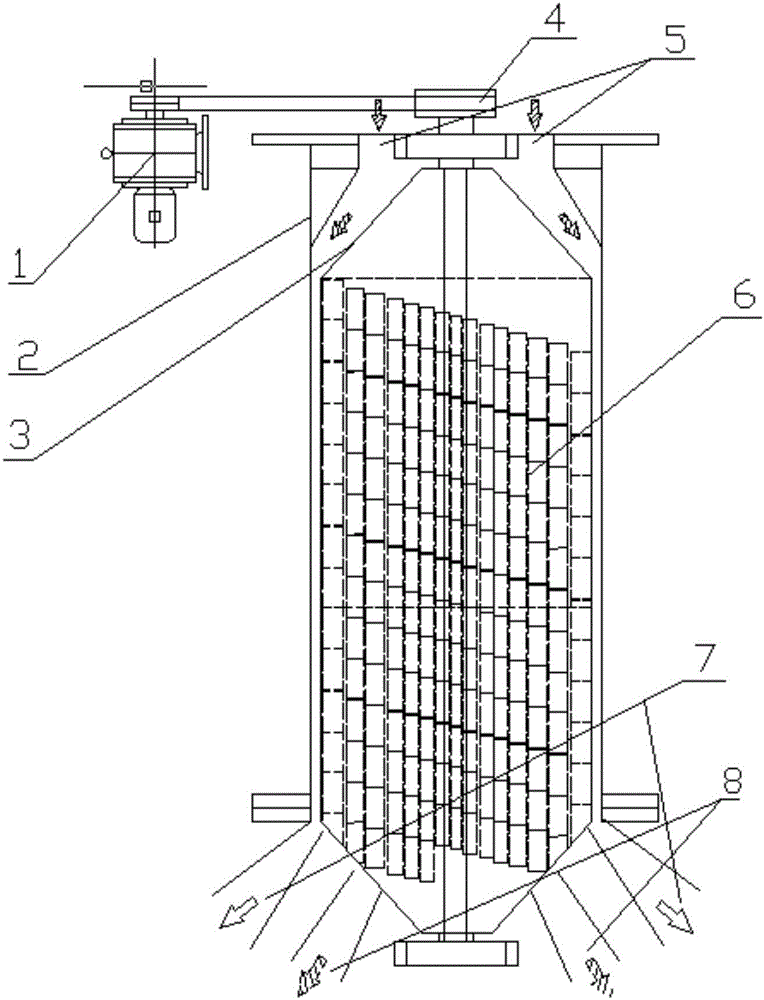

Spiral magnetic field type micro powder magnetic separator

ActiveCN106513170AIncrease profitReduce drying processMagnetic separationMagnetic separatorEngineering

The invention discloses a spiral magnetic field type micro powder magnetic separator. The spiral magnetic field type micro powder magnetic separator comprises a rotating cylinder (3), an outer cover (2) externally sleeving the rotating cylinder (3), spiral magnetic rolls (6) fixed in the rotating cylinder (3) and a driving device driving the rotating cylinder (3) to rotate; gaps exist between the rotating cylinder (3) and the outer cover (2) and between the rotating cylinder (3) and each of the spiral magnetic rolls (6); feed inlets (5), from which materials enter a cavity between the spiral rotating cylinder (3) and the outer cover (2), are formed in the upper ends of the outer cover (2); finished product outlets (7) are formed in the lower end of the cavity; iron material outlets (8) are formed in the lower end, corresponding to the spiral magnetic rolls (6), of the rotating cylinder (3); the magnetic field directions of the spiral magnetic rolls (6) incline downward and form a set angle with the horizontal plane; and the spiral magnetic rolls (6) extend to the upper portions of the iron material outlets (8). The spiral magnetic field type micro powder magnetic separator effectively solves the problems that materials and magnetic substance in micropowder, the granularity of which is smaller than 320-meshes, are hard to separate and the like.

Owner:河南特耐高温材料有限公司

A working method of a frame yarn high-efficiency finishing device

The invention discloses a working method of an efficient frame yarn finishing device. The finishing device comprises a fixed seat, a frame yarn arm, a movable blowing mechanism and a tension mechanism, the tension mechanism control the frame yarn arm to oppositely and separately move, and a driving mechanism drives the movable blowing mechanism and the tension mechanism to move. The movable blowing mechanism comprises a bilateral reciprocating plate, a guide through groove is formed in the surface of the reciprocating plate, a sliding rod is slidably connected in the guide through groove and connected with one end of a swinging arm, a supporting seat is fixedly connected on the fixed seat, the swinging arm is hinged to the supporting seat through a pin, and the other end of the swinging arm is fixedly connected with a blowing head. According to the working method, the device can continually spray high-speed air flow, yarns are guided and carded by the high-speed air flow in an accelerated manner, the ejecting range of the high-speed air flow is widened in a reciprocating swing manner, namely, more yarns are carded by the air flow, and working efficiency is improved.

Owner:江西祥力纺织有限公司

Method for classifying and treating wet crimped spinning cakes

InactiveCN101736544BImprove product added valueSimple processLiquid/gas/vapor removalLiquid/gas/vapor yarns/filaments treatmentBobbinEconomic benefits

The invention discloses a method for classifying and treating wet crimped spinning cakes, which comprises the following process steps: classifying the wet crimped spinning cakes according to crimping degree in a covering silk collecting process; after performing pressure washing, dehydration and baking on mild wet crimped spinning cakes, making the mild wet crimped spinning cakes into cheeses on a bobbin winder; and after performing pressure washing and dehydration on heavy wet crimped spinning cakes, making the heavy wet crimped spinning cakes into three-element cheeses on a silk winder. Themethod classifies and treats the crimped spinning cakes, directly makes the mild wet crimped spinning cakes into the cheeses, eliminates a process of baking the heavy wet crimped spinning cakes, unwinds the heavy wet crimped spinning cakes into three-element cheeses on the silk winder, increases yield, added value of products of the heavy wet crimped spinning cakes and the economic benefit, and reduces energy consumption because the baking treatment is not needed in a heavy wet crimped spinning cake treating process.

Owner:YIBIN HIEST FIBER +1

Method for controlling water of seedbed of cured tobacco seedlings by floating cultivation

InactiveCN101699985BIncrease profitPromote growthClimate change adaptationAgriculture gas emission reductionNutrient solutionWater requirement

The invention discloses a method for controlling water of a seedbed of cured tobacco seedlings by floating cultivation, relating to soilless and waterless seedlings culture of crops. The method comprises two steps of: reconstruction of a nutrition pool: removing an earth stripe at one end of a conversional nutrition pool, digging a puddle for storing nutrient fluid, sequentially arranging two columns of bamboo splints in the nutrition pool, and placing a floating plate overhead after the nutrient fluid is discharged so as to form an air layer between the bottom of the floating plate and the liquid level; and water control of cured tobacco seedlings by dry-wet alternation and discontinuous water supply: moving the nutrient fluid in due time according to the water requirement pattern of thecured tobacco seedlings so as to ensure water for the growth of the cured tobacco seedlings. The method has the advantages that: (1) the water supply time and the supplying water are based on the water requirement pattern of the cured tobacco seedlings in growing so as to be beneficial to promoting the growth of the seedlings and improving the quality of the cured tobacco seedlings; (2) the nutrient fluid is reused, the utilization ratio of water and nutrients is greatly improved, and the collected nutrients can also be used for other plants so as to reduce pollution to the environment; and (3) the plate airing process caused by overmuch water in a floating cultivation substrate during latter hardening off is reduced, the labor intensity is lowered and the manpower is saved.

Owner:GUIZHOU TOBACCO SCI INST

A phase-change gypsum board with temperature control performance and its preparation method

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com