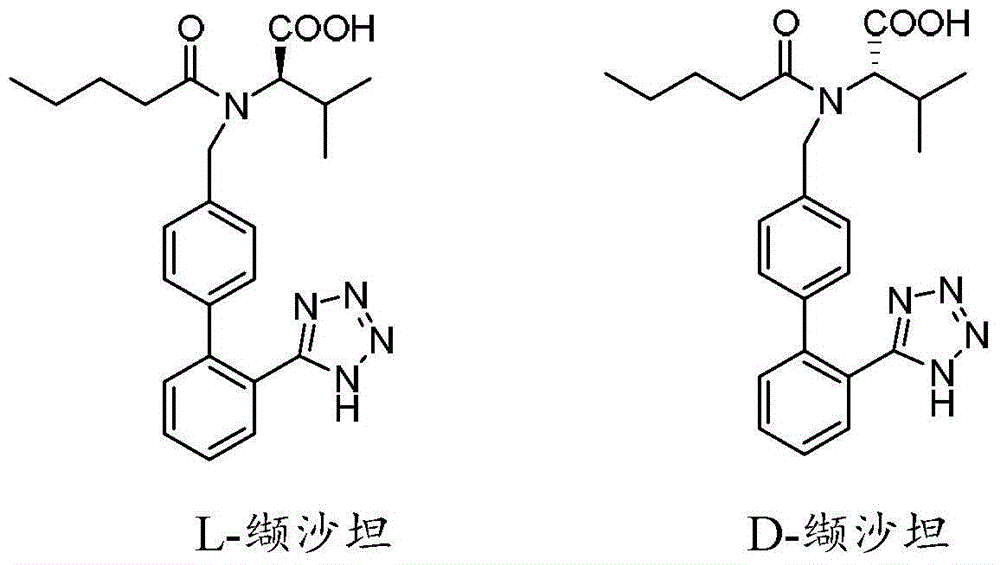

Recovery method of valsartan mother liquor

A recovery method and technology for valsartan, applied in the field of recovery of valsartan mother liquor, can solve the problems of large yield deviation, low repeatability, insignificant isomer separation effect, etc., so as to reduce the proportion and reduce energy consumption. and solvent loss, good quality of recovered product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

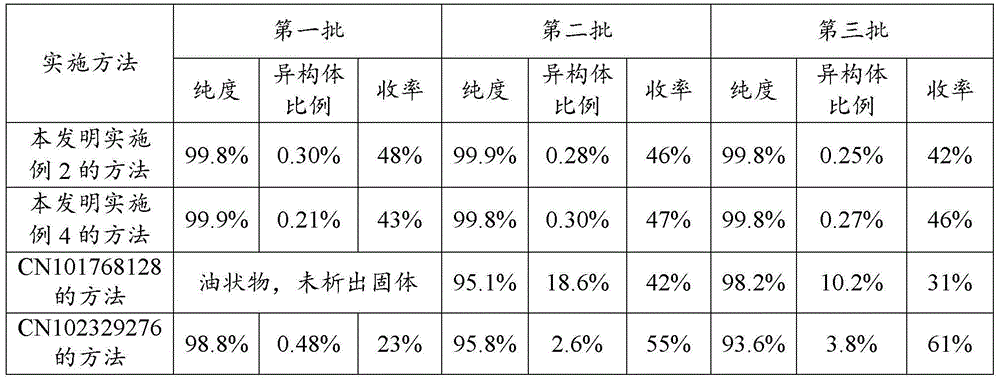

[0037] Choose the mother liquor after the valsartan recrystallization of production, concentrate to dryness, obtain the valsartan recovery crude product containing 10.0% D-type isomer (HPLC detection peak area method), its L-valsartan content is 52.2%. Add 23.0g of recovered crude product containing valsartan and 46.0g of 4-methyl-2-pentanone into a 250mL three-necked flask, heat up to 50°C and stir to dissolve, cool down to 15°C, keep warm for 2 hours, then cool to 0°C, keep warm After 10 hours, filter and dry to obtain 6.97 g of valsartan with a purity of 99.8%, a ratio of D-isomer of 0.21%, and a yield of 58%.

Embodiment 2

[0039] Choose the mother liquor after the valsartan recrystallization of production, concentrate to dryness, obtain the valsartan recovery crude product containing 20.0% D-type isomer (HPLC detection peak area method), its L-valsartan content is 46.5%. In the 500mL there-necked flask, add 23.0g containing valsartan and reclaim the crude product and the mixed solvent of 230.0g 4-methyl-2-pentanone and ethyl acetate (the mass ratio of 4-methyl-2-pentanone and ethyl acetate is 1:10), heat up to 50°C and stir to dissolve, cool down to 20°C, add 50 mg of seed crystals, keep warm for 8 hours, then cool to -5°C, keep warm for 5 hours, shake off, and dry to obtain 4.50g of valsartan, The purity is 99.8%, the proportion of D-isomer is 0.3%, and the yield is 42%.

Embodiment 3

[0041]1, choose the mother liquor after the valsartan recrystallization of production, concentrate to dryness, obtain the valsartan recovery crude product containing 18.0% D type isomer (HPLC detection peak area method), its L-valsartan content is 44.4 %. Add 23.0g of recovered crude product containing valsartan and 46.0g of 4-methyl-2-pentanone into a 250mL three-necked flask, heat up to 50°C and stir to dissolve, cool down to 20°C, keep warm for 2 hours, then cool to -5°C, Keep warm for 2 hours, shake off and filter to obtain 17.8g of wet product. After a small amount of wet product was dried and tested, the purity was 98.8%, and the ratio of D-type isomer was 0.7%.

[0042] 2. Disperse 17.8 g of the wet product obtained in 1 in 17.8 g of ethyl acetate, soak for 40 minutes at 0° C., shake off to obtain 10.6 g of the wet product, and vacuum-dry to obtain 4.70 g of the refined product of valsartan. . A small amount of wet product was taken and tested after drying. The purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com