Patents

Literature

63 results about "4-Methyl-2-pentanone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl isobutyl carbinol is an oxygenated solvent that is metabolized to methylisobutyl ketone (MIBK) and then to 4-hydroxymethyl-4-methyl-2-pentanone (HMP). Plasma levels of MIBC , MIBK and HMP were determined up to 12 hr after a single oral 5 mmol/kg dose of MIBC or MIBK to male rats.

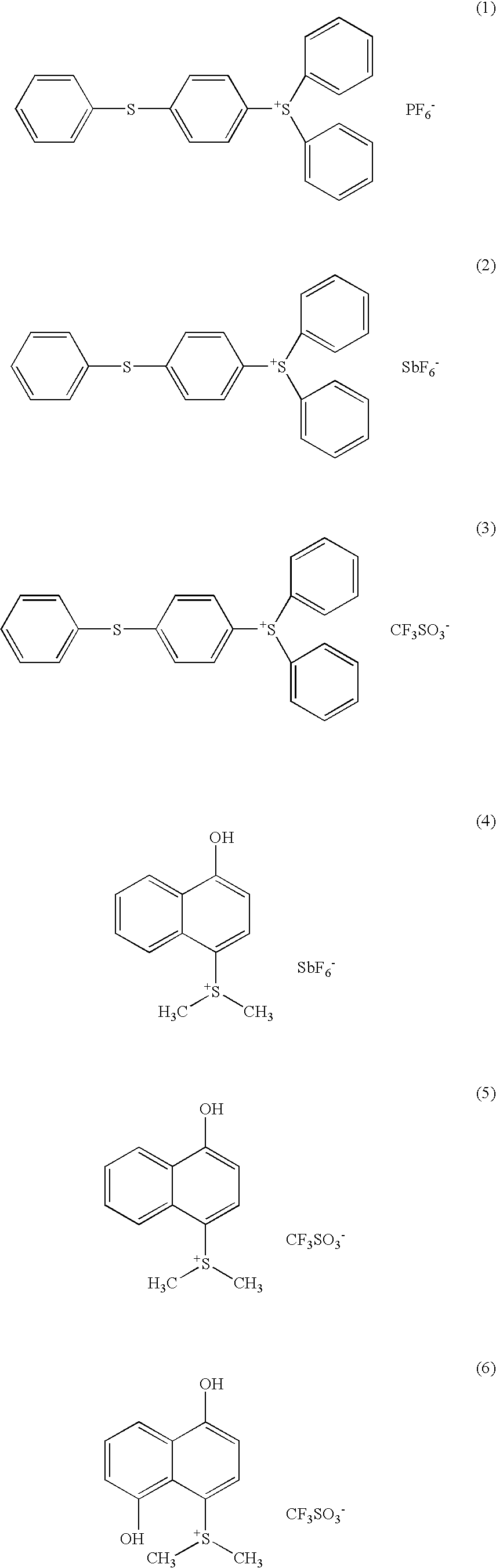

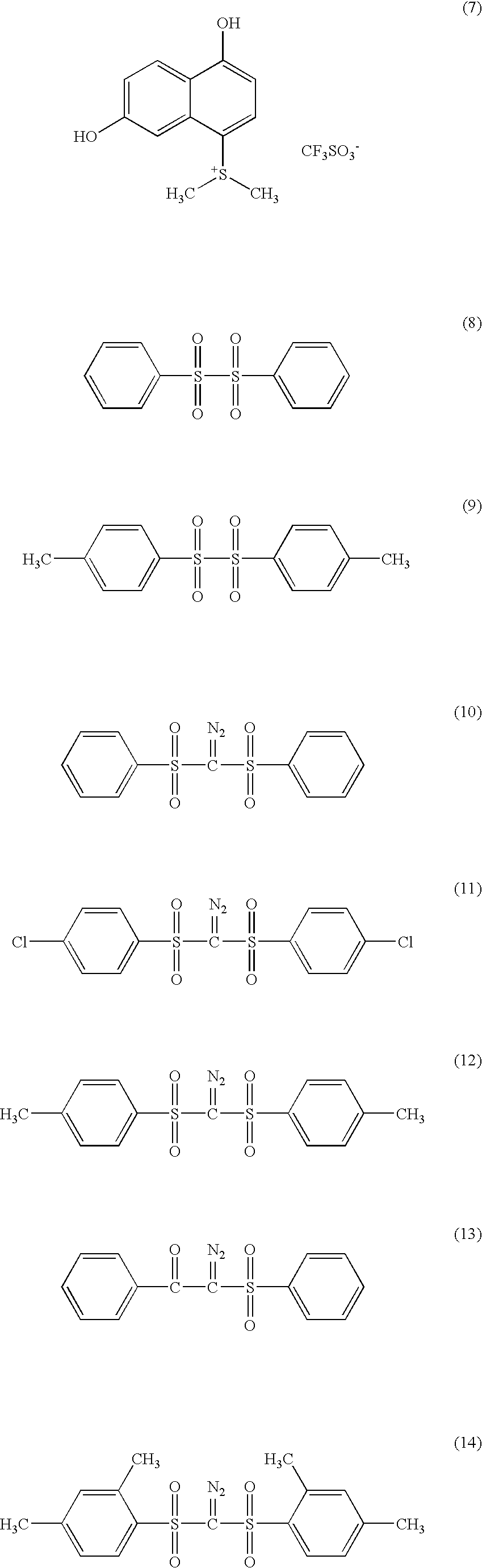

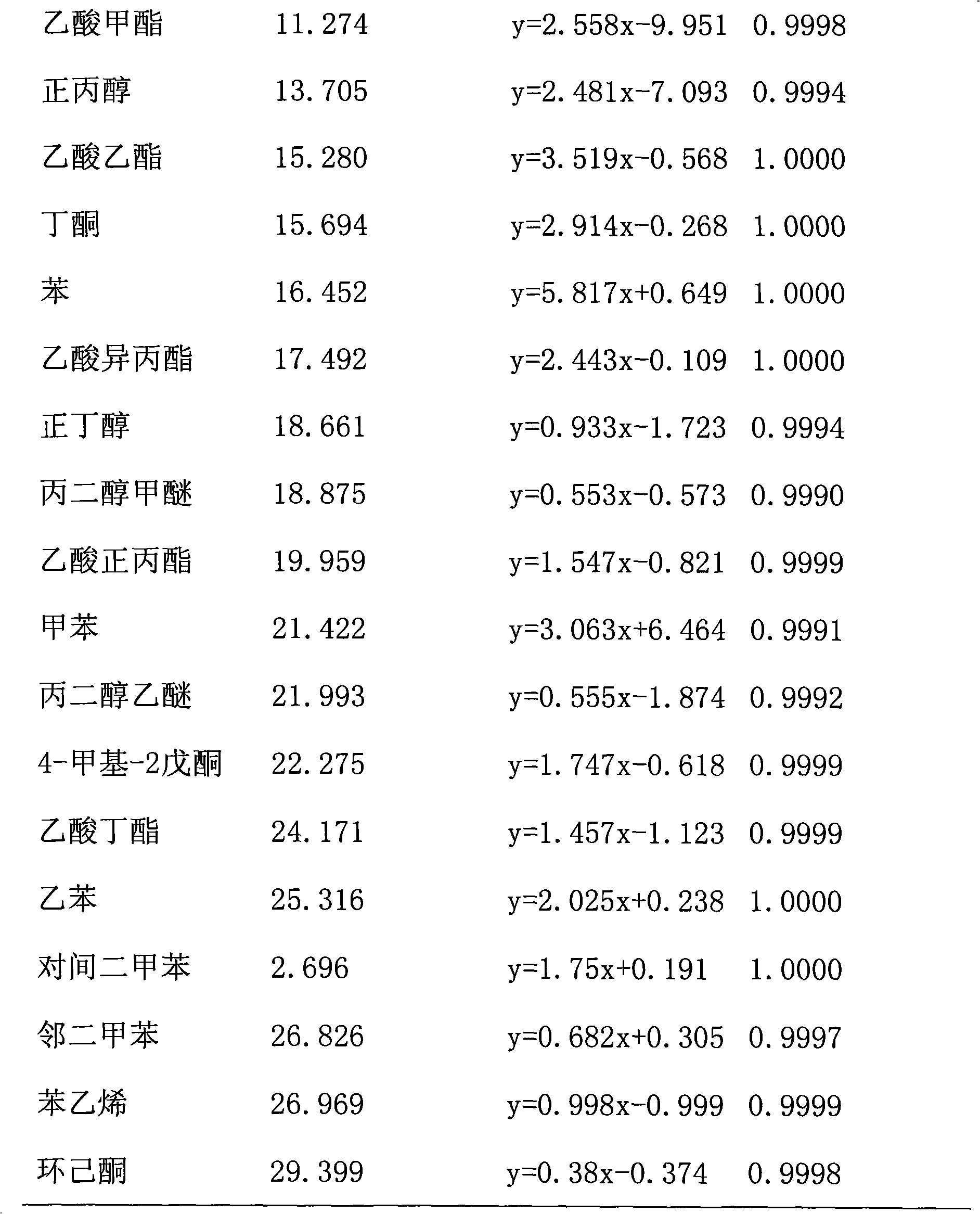

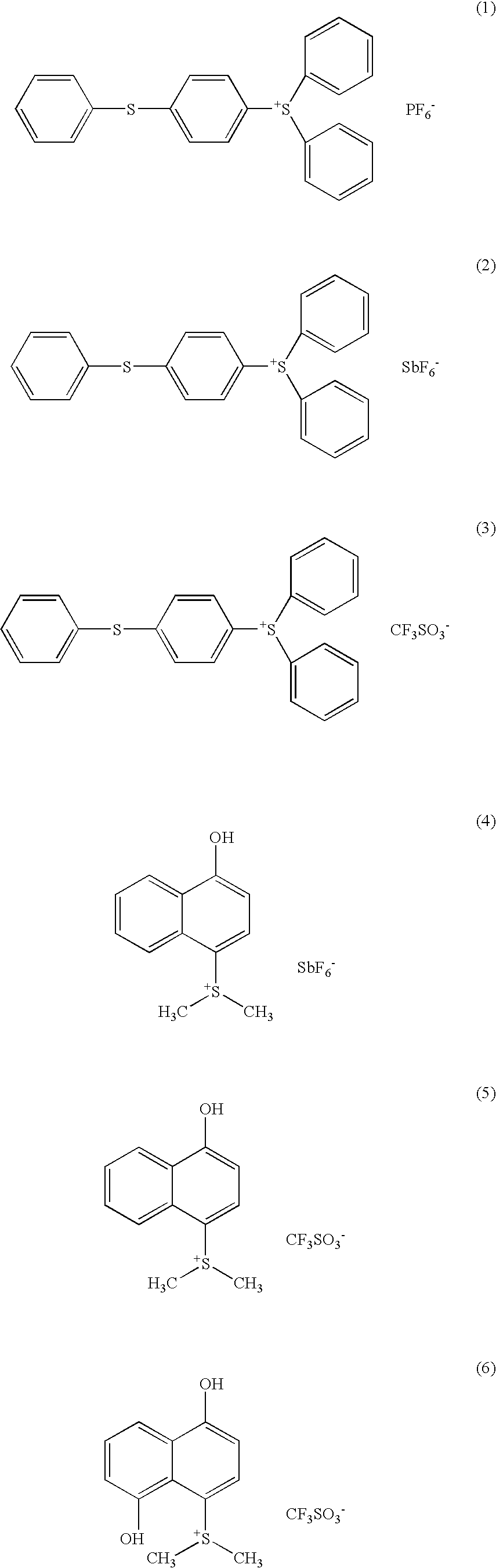

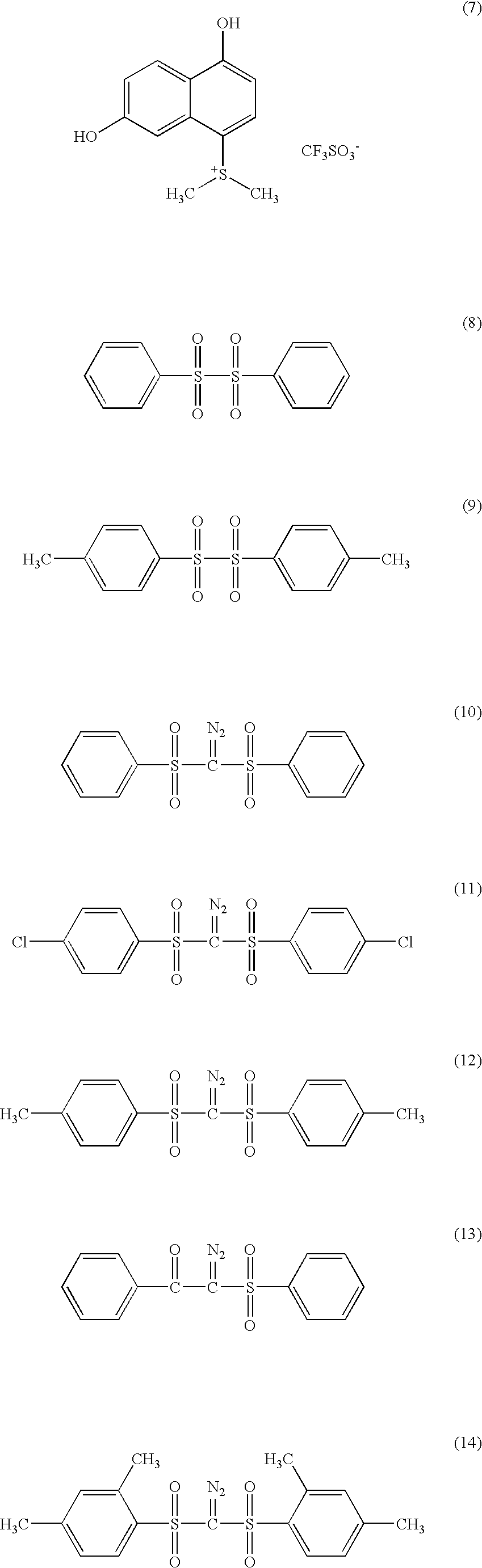

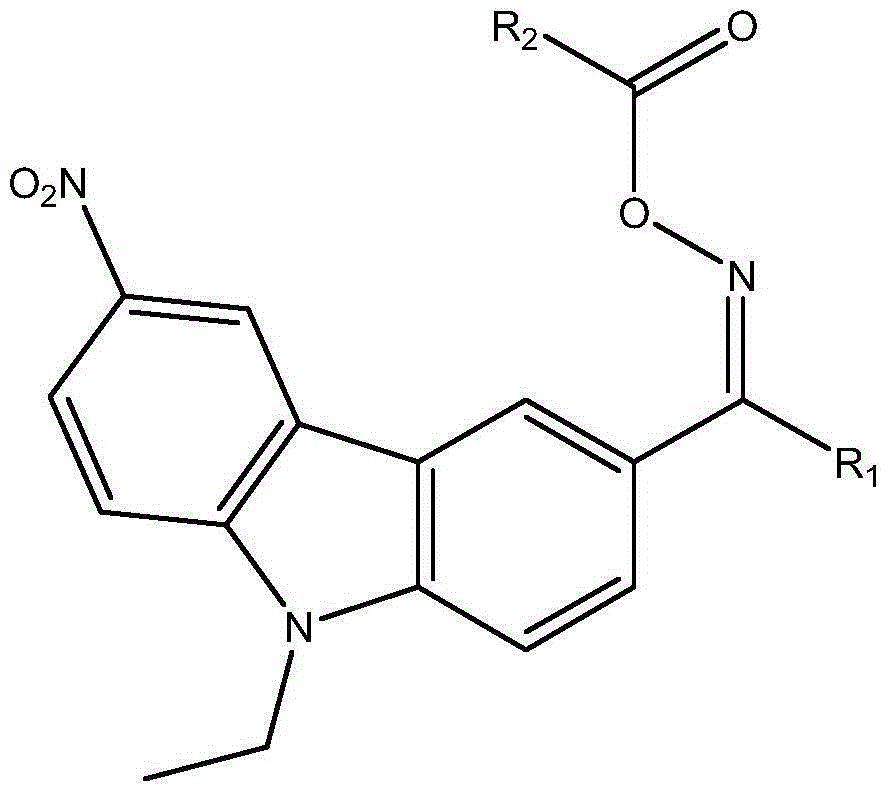

Dye-containing resist composition and color filter using same

InactiveUS20050095530A1Improve solubilityImprove stabilityDischarge tube luminescnet screensLamp detailsForeign matterNegative type

There is provided a dye-containing resist composition comprising a ketol solvent; a negative type resist composition comprising a resin, a photoacid generator or a photobase generator, a crosslinking compound, a dye and a ketol solvent; a negative type resist composition comprising a resin, a photoradical generator, a crosslinking compound, a dye and a ketol solvent; a positive type resist composition comprising a resin, a photoacid generator, a crosslinking compound, a dye and a ketol solvent. The ketol is preferably β-hydroxyketone, more preferably 4-hydroxy-4-methyl-2-pentanone. The resist composition does not occur problems such as occurrence of foreign matters (particles) even when the concentration of dye is increased, and enables the production of color filters in a shape of thinner film.

Owner:NISSAN CHEM IND LTD

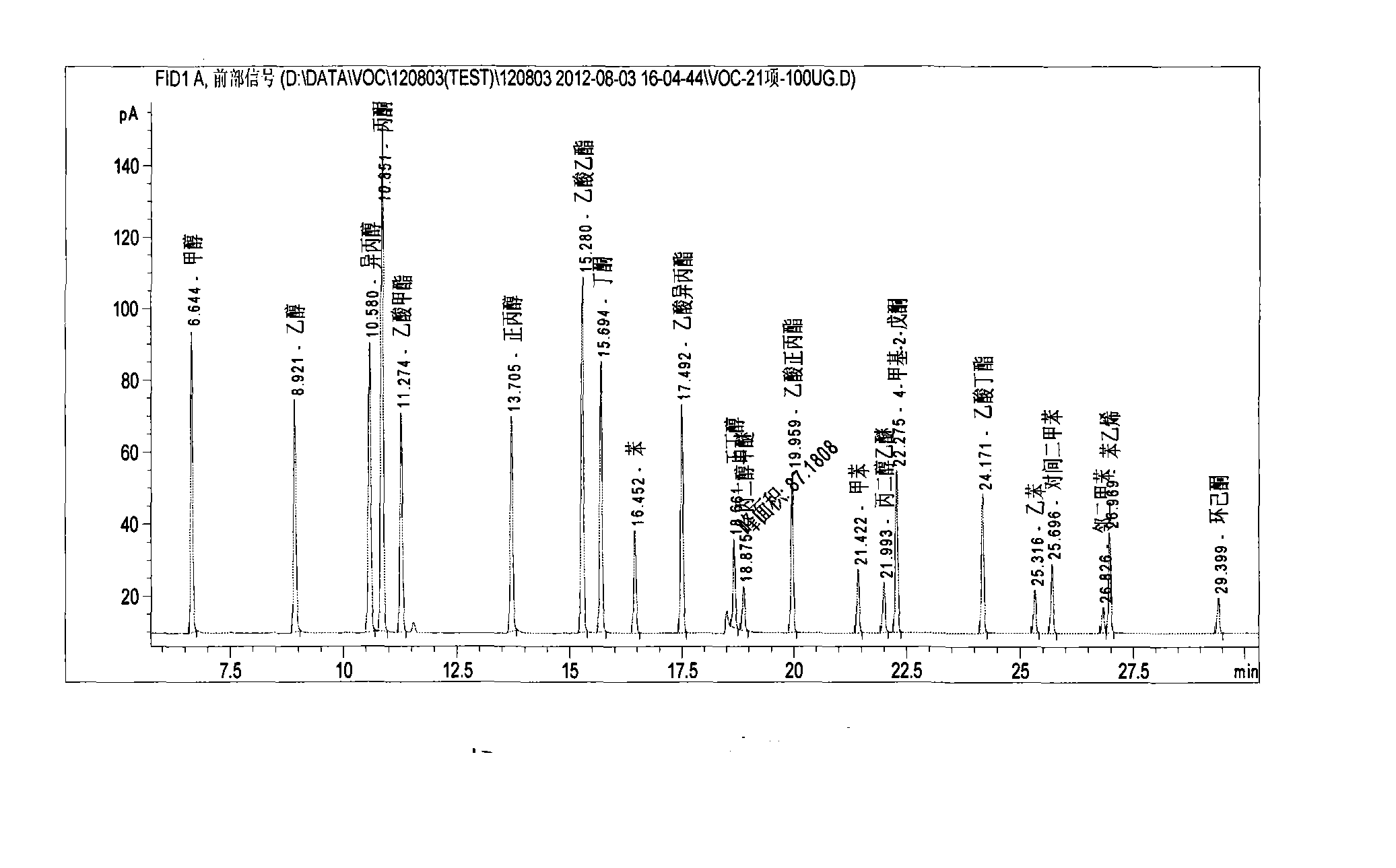

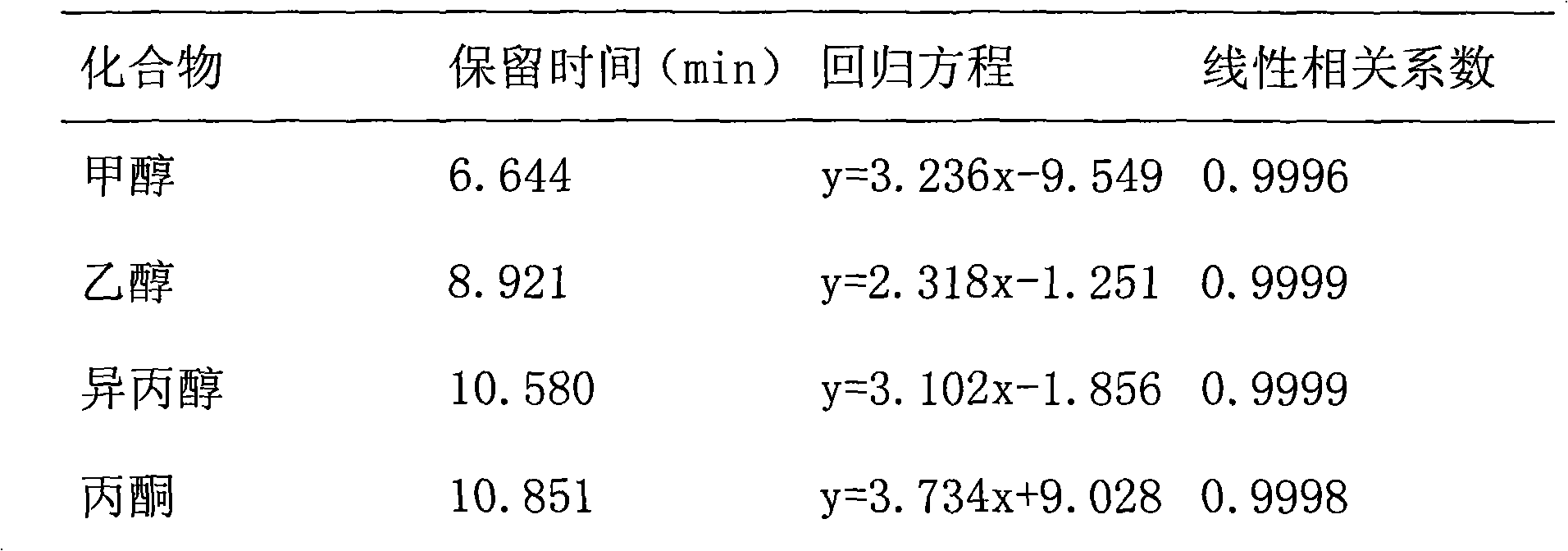

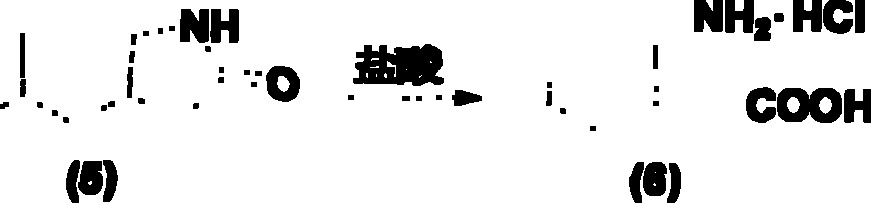

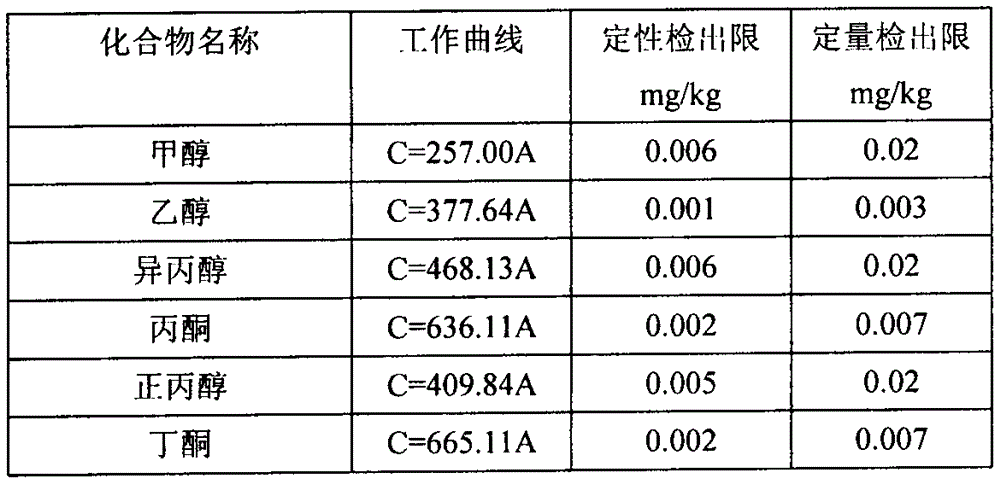

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

Dye-containing resist composition and color filter using same

InactiveUS7517619B2Improve solubilityImprove stabilityDischarge tube luminescnet screensPhotosensitive materialsForeign matterNegative type

There is provided a dye-containing resist composition comprising a ketol solvent; a negative type resist composition comprising a resin, a photoacid generator or a photobase generator, a crosslinking compound, a dye and a ketol solvent; a negative type resist composition comprising a resin, a photoradical generator, a crosslinking compound, a dye and a ketol solvent; a positive type resist composition comprising a resin, a photoacid generator, a crosslinking compound, a dye and a ketol solvent. The ketol is preferably β-hydroxyketone, more preferably 4-hydroxy-4-methyl-2-pentanone. The resist composition does not occur problems such as occurrence of foreign matters (particles) even when the concentration of dye is increased, and enables the production of color filters in a shape of thinner film.

Owner:NISSAN CHEM CORP

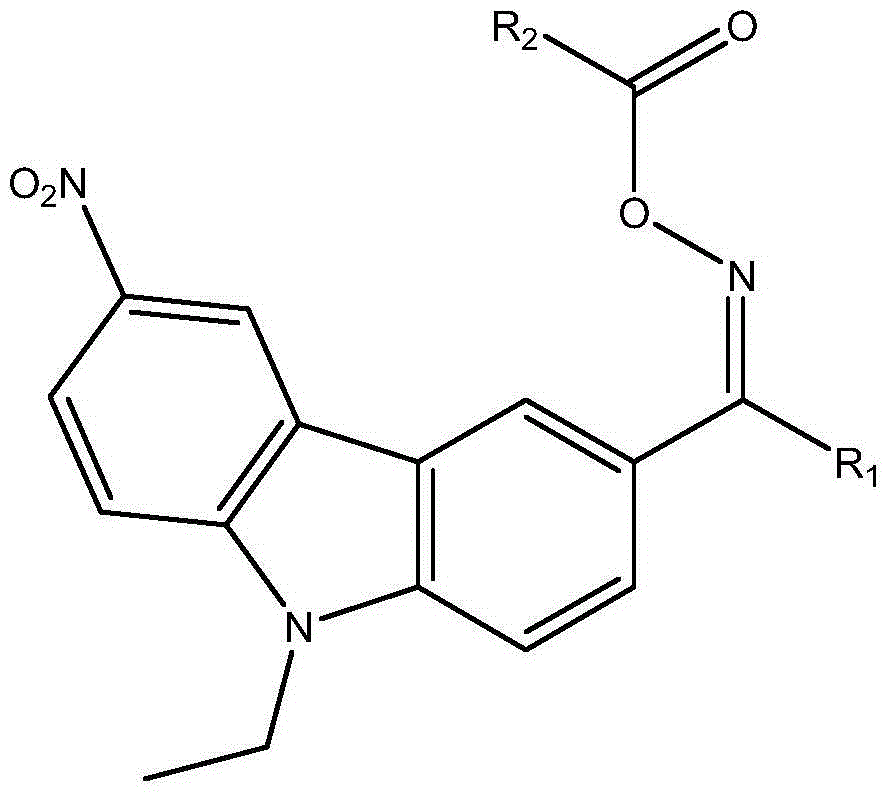

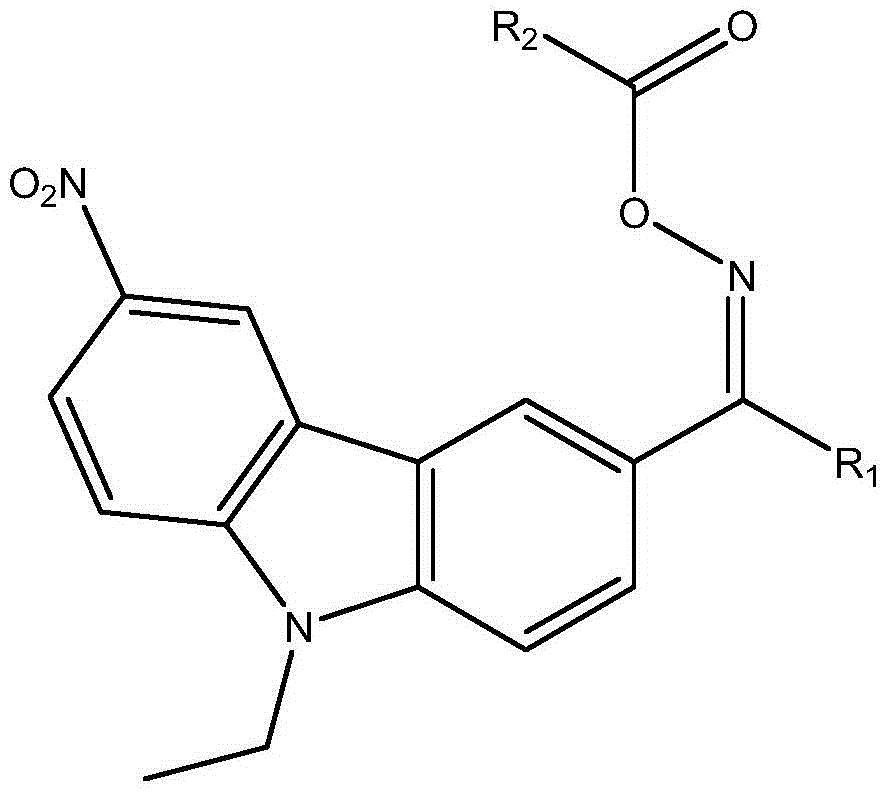

A color photosensitive resin composition, color filter and display device comprising the same

ActiveCN104423148AGood storage stabilityHigh sensitivityOptical filtersPhotosensitive materials for photomechanical apparatusDisplay deviceSolvent

The invention relates to a color photosensitive resin composition, a color filter comprising the color photosensitive resin composition, and a display device. The color photosensitive resin composition comprises a colorant, an alkali-soluble resin, a photopolymerization compound, a photopolymerization initiator and a solvent, and is characterized in that the photopolymerization initiator comprises an oxime ester compound and the solvent comprises hydroxy-4-methyl-2-pentanone.

Owner:DONGWOO FINE CHEM CO LTD

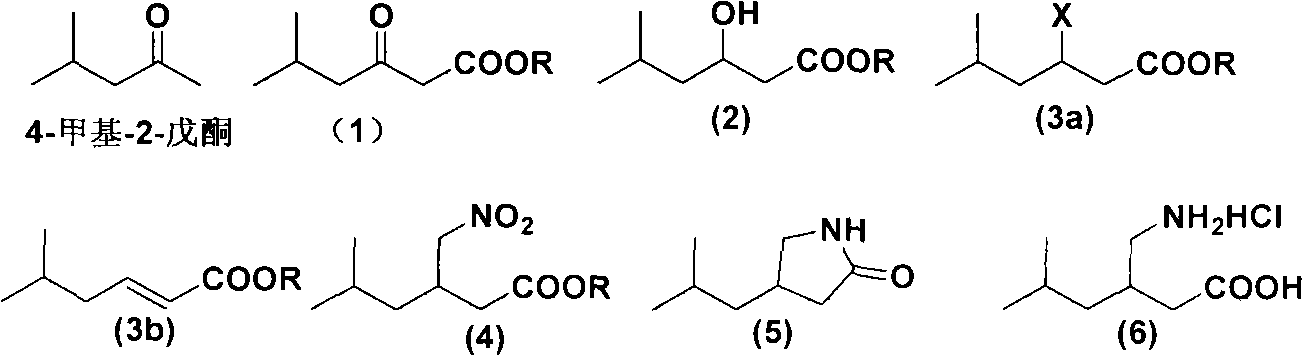

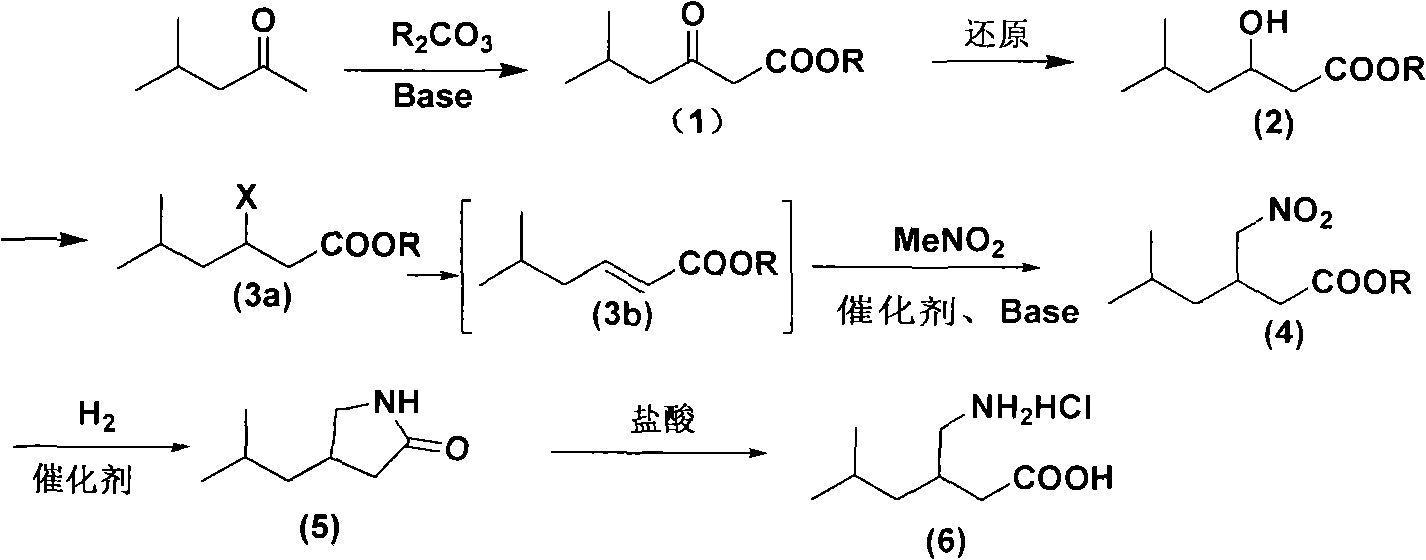

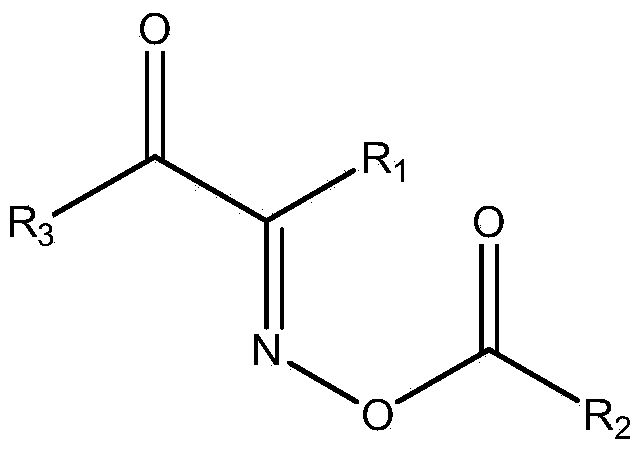

Novel method for preparing pregabalin raceme hydrochloride

ActiveCN102115449AOrganic compound preparationAmino-carboxyl compound preparationPregabalinMethyl group

The invention discloses a route and method for preparing 3-aminomethyl-5-methylhexanoic acid, namely pregabalin raceme hydrochloride. The method comprises the following steps of: performing condensation on 4-methyl-2-pentanone to obtain a compound in a formula (1), and performing reduction to obtain a compound in a formula (2); performing halogenation or esterification to obtain a compound in a formula (3a), and performing substitution to obtain a compound in a formula (4), or performing elimination on the compound in the formula (3a) to obtain a compound in a formula (3b) and performing addition to obtain a compound in the formula (4); and performing reduction and acidolysis on the compound in the formula (4) to obtain a pregabalin hydrochloride compound in a formula (6). The method is easy to operate, mild in reaction conditions, and low in cost, and is suitable for large-scale industrial production.

Owner:ZHEJIANG HUAHAI PHARMA CO LTD +1

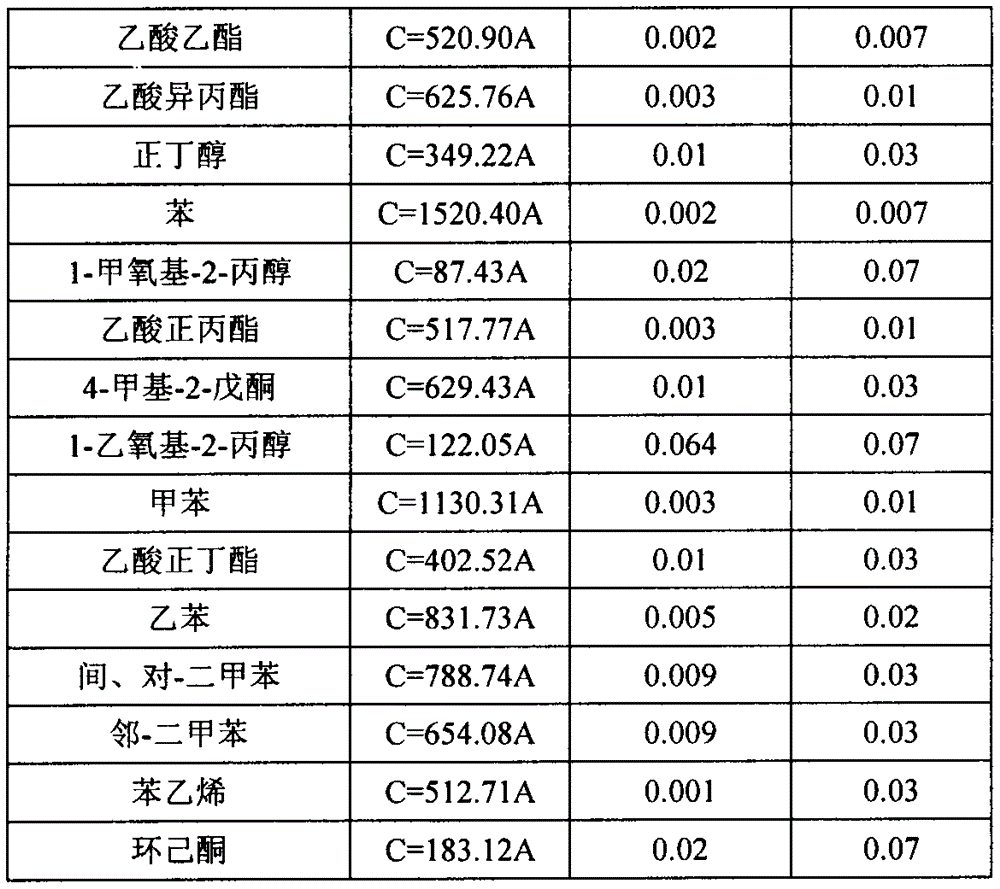

Method for detecting volatile organic compounds in cigarette tipping paper printing ink

InactiveCN104597166AEasy to handleAchieving Simultaneous DetectionComponent separationCyclohexanoneN-Propyl alcohol

The invention relates to a method for detecting the contents of 22 kinds of volatile organic compounds in cigarette tipping paper printing ink, including benzene, toluene, ethylbenzene, ortho / meta / para-xylene, phenethylene, methanol, ethanol, isopropyl alcohol, n-propyl alcohol, n-butanol, acetone, 4-methyl-2-pentanone, butanone, cyclohexanone, ethyl acetate, n-propyl acetate, n-butyl acetate, isopropyl acetate, 1-methoxy-2-propyl alcohol and 1-ethoxy-2-propyl alcohol. Detection is performed by headspace gas chromatography by taking glyceryl triacetate as a matrix rectifier. According to the method provided by the invention, a sample pretreatment process is simple, the automation degree of the whole operation is high, the simultaneous detection of various volatile organic compounds can be realized, and the detection sensitivity, the recovery rate and the result precision are high.

Owner:GUANGXI ZHENLONG IND

Purification method for Tylosin

ActiveCN101565438AFor the purpose of purificationSugar derivativesSugar derivatives preparationPurification methodsPhosphoric acid

The invention relates to a purification method for tylosin. The invention describes the post treatment of the extraction liquid of tylosin when chloroform is used for extracting the tylosin from fermentation filter liquid, i.e. a purification method. The essential of the method is as follows: the extraction liquid is concentrated into a condition that chloroform is basically removed; a condensateis dissolved by acid water; butyl acetate or toluene or 4-methyl-2-pentanone is added; the pH value is adjusted to 7.5-9.5 by alkali liquid, and extraction and phase splitting are sequentially performed; and a tartaric acid aqueous solution or a phosphoric acid aqueous solution is added to an ester phase for performing back extraction, back extraction liquid is obtained and is sprayed and dried, or the pH value of the back extraction liquid is adjusted to 7.5-10.5, and the back extraction liquid is pressed and filtered or centrifugated to obtain the tylosin.

Owner:河北威远药业有限公司

Improved extraction method for tylosin

The invention relates to an improved extraction method for tylosin. The invention describes the process of using a cosolvent to extract the tylosin from tylosin fermentation filter liquid. The cosolvent comprises chloroform or methylene dichloride and ethyl acetate or butyl acetate or amyl acetic ester or isoamyl acetate or 4-methyl-2-pentanone or toluene. The method using the cosolvent to extract the the tylosin from the fermentation filter liquid has the advantages that the use quantity of the cosolvent is only 1-8% of the quantity of the fermentation filter liquid; the extraction rate is high and can reach 98.8%; and the cosolvent has a selective extraction function, the impurity content of extraction liquid is very little, product purification is convenient and the product purity is improved.

Owner:荷本(北京)大药厂有限公司

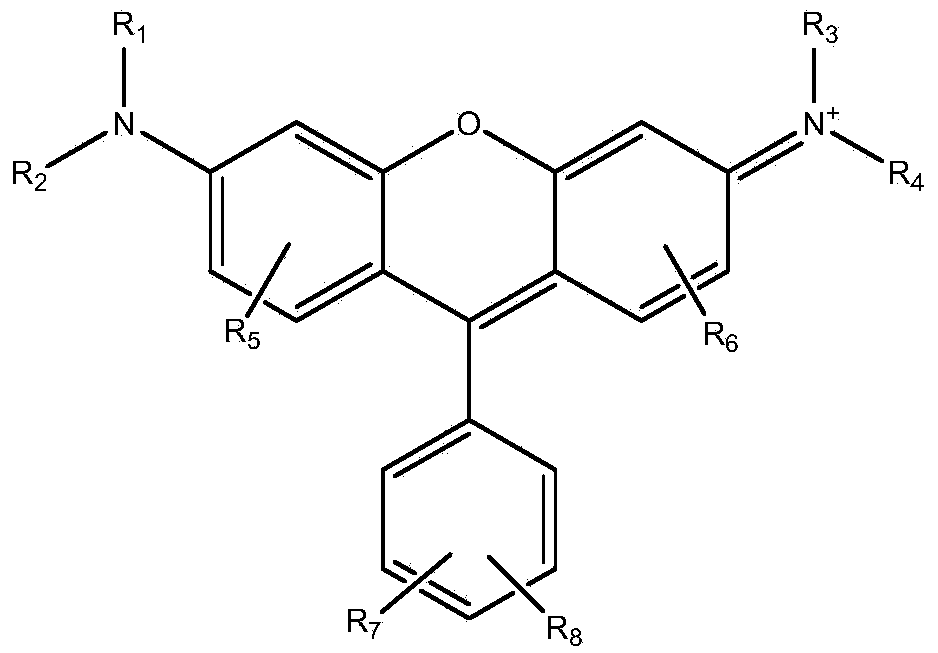

Colored Photosensitive Resin Composition

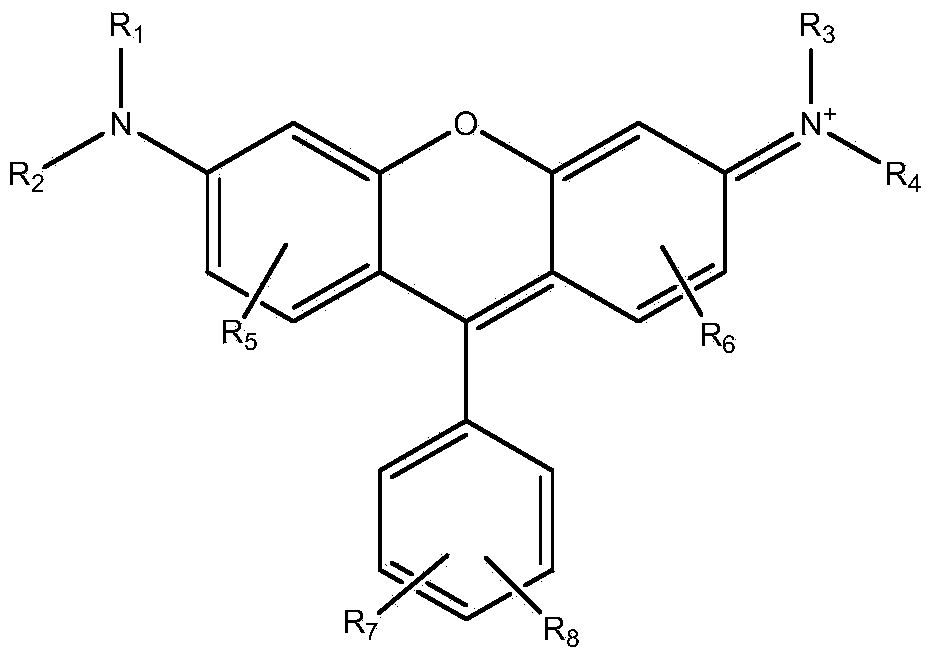

ActiveCN103969953AAvoid stratificationFast developing speedOptical filtersPhotomechanical exposure apparatusStructural formulaSolvent

The invention discloses a colored photosensitive resin composition including a red coloring agent, an alkali soluble resin, photopolymerisable compound, a polymerization trigger and a solvent. The red coloring agent includes red pigment and xanthene dye indicated by structural formula 1. The alkaili soluble resin has an acid value of 30mg KOH / g to 170mg KOH / g. The photopolymerisable compound includes a compound indicated by structural formula 2. Besides, the solvent includes propylene glycol monomethyl ether and 4-hydroxy-4-methyl-2-pentanone. Thus, the composition has high developing rate and excellent inhibition of photosensitivity and adherence of pattern in a developing period and has storage stability with no decrease in photosensitivity and no increase in adherence. Therefore, a color filter made from the photopolymerisable compound can have extremely high comparison and light transmittence.

Owner:DONGWOO FINE CHEM CO LTD +1

Graphene-containing vegetable lubricant and preparation method thereof

InactiveCN106350167AReduce friction lossGood friction and lubrication propertiesLubricant compositionSucrosePolymethyl methacrylate

The invention discloses a graphene-containing vegetable lubricant. The graphene-containing vegetable lubricant is prepared from the following raw materials: castor oil, modified castor oil, liquid graphene, trimethyl citrate, N,N-dimethylacetamide, modified nano cerium vanadium oxide, modified sodium carboxymethylcellulose, sucrose ester, an organic molybdenum compound, dodecyl selenium, 4-hydroxy-4-methyl-2-pentanone, benzotriazole, polymethyl methacrylate, 1-butyl-3-vinyl imidazole hexafluoroantimonate, polyurethane, cyclohexane and an organic anti-aging agent. The graphene-containing vegetable lubricant disclosed by the invention has the advantages that the castor oil and other additives are combined, an environment-friendly vegetable lubricant is prepared, the balance of properties is achieved by controlling the types and quantity of the additives, the vegetable lubricant has better oxidation resistance and self-cleaning capability and also has good lubricating property, viscosity-temperature characteristic, low temperature fluidity, low volatility, corrosion resistance, anti-foam property and anti-emulsifying property, and the overall performance is good.

Owner:梁海东

UV hardening liquid for PET electronic membrane as well as preparation method and application thereof

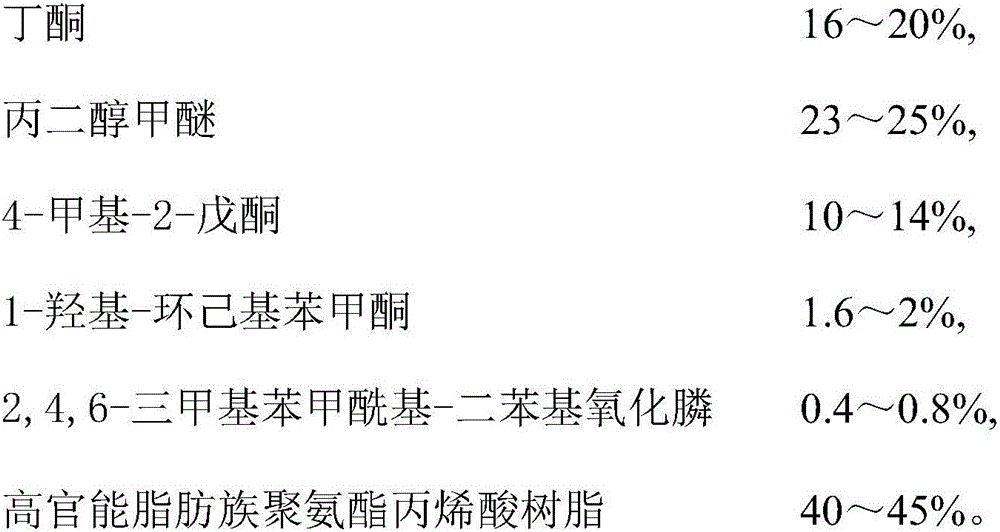

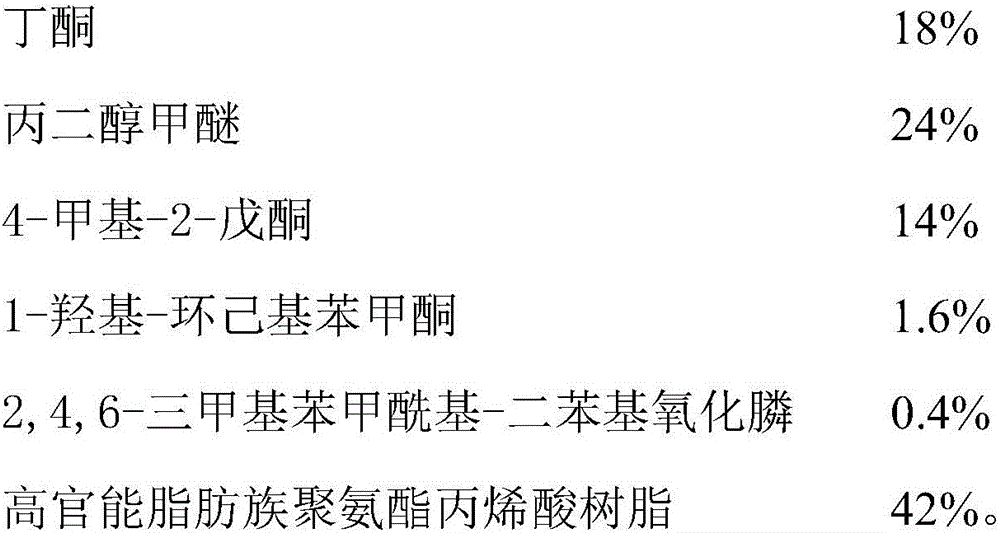

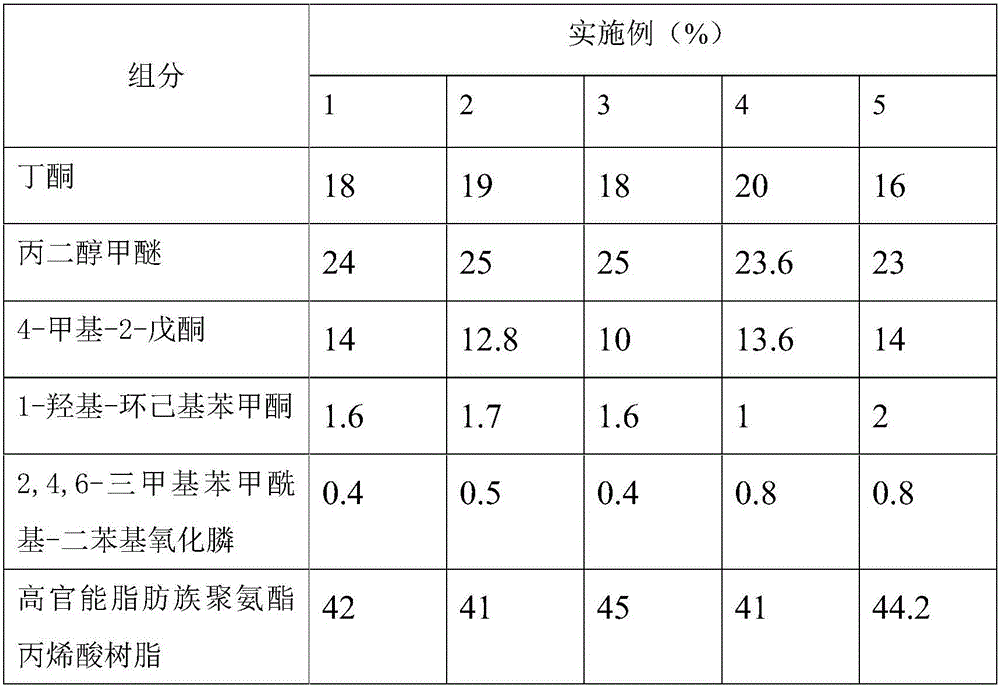

InactiveCN106833356ALow viscosityImprove adaptabilityPolyurea/polyurethane coatingsAcrylic resinDiphenylphosphine oxide

The invention discloses UV hardening liquid for a PET electronic membrane. According to the key points of the technical scheme, the UV hardening liquid for the PET electronic membrane comprises the following components by weight percent: 16-20% of butanone, 23-25% of propylene glycol monomethyl ether, 10-14% of 4-methyl-2-pentanone, 1.6-2% of 1-hydroxyl- phenylcyclohexyl ketone, 0.4-0.8% of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide and 40-45% of highly functionalized aliphatic polyurethane acrylic resin. The invention aims at overcoming the defects of existing solvent type UV hardening paint and providing economic applicable UV hardening liquid which is used for the PET electronic membrane, simple in preparation technology and convenient and efficient to use and has excellent optical and physical properties after film formation. The invention provides a preparation method of the UV hardening liquid. The invention also provides application of the UV hardening liquid.

Owner:ZHONGSHAN BOHAI SPECIAL CHEM CO LTD

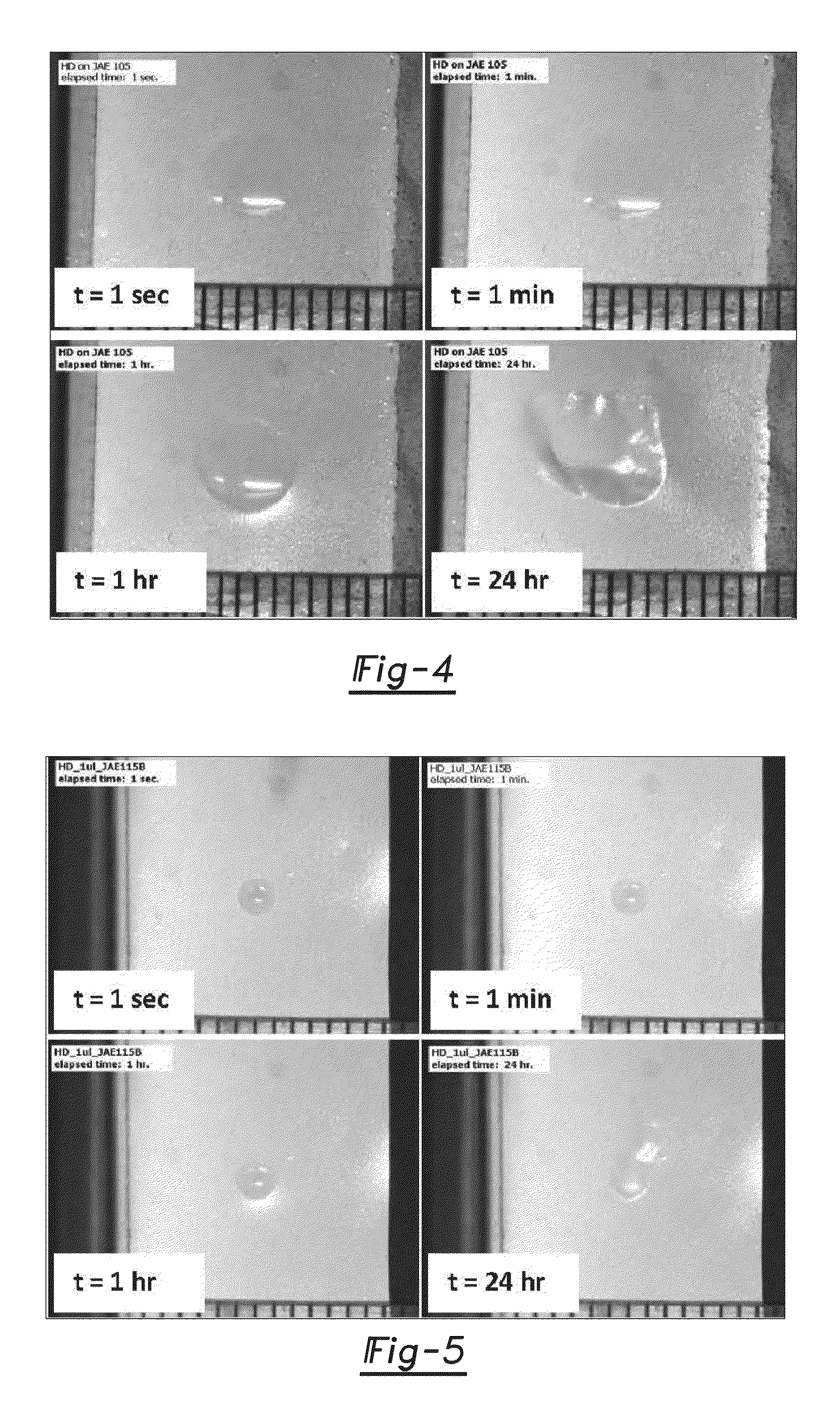

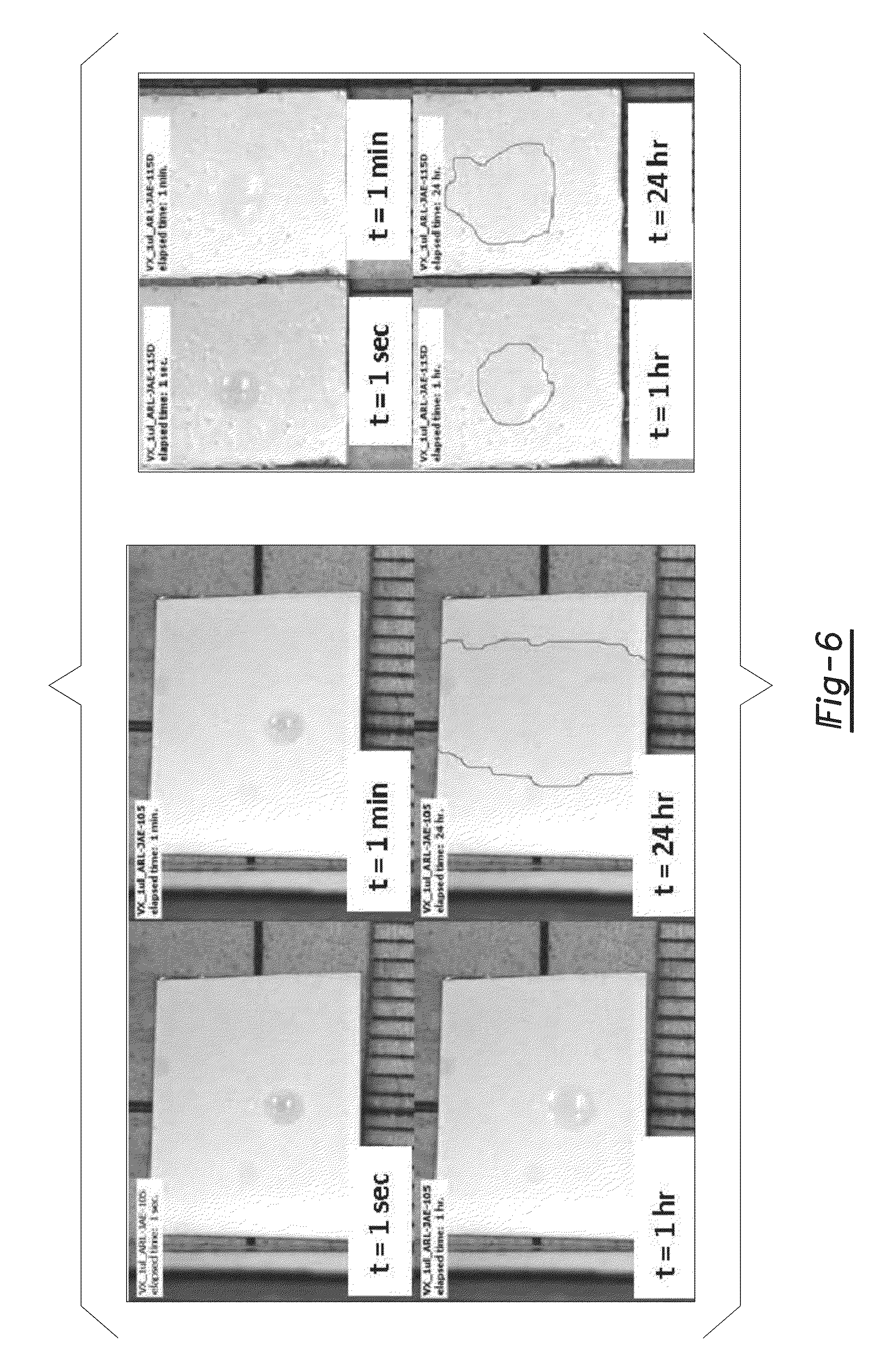

Surface segregating additives for enhanced chemical agent resistant topcoats

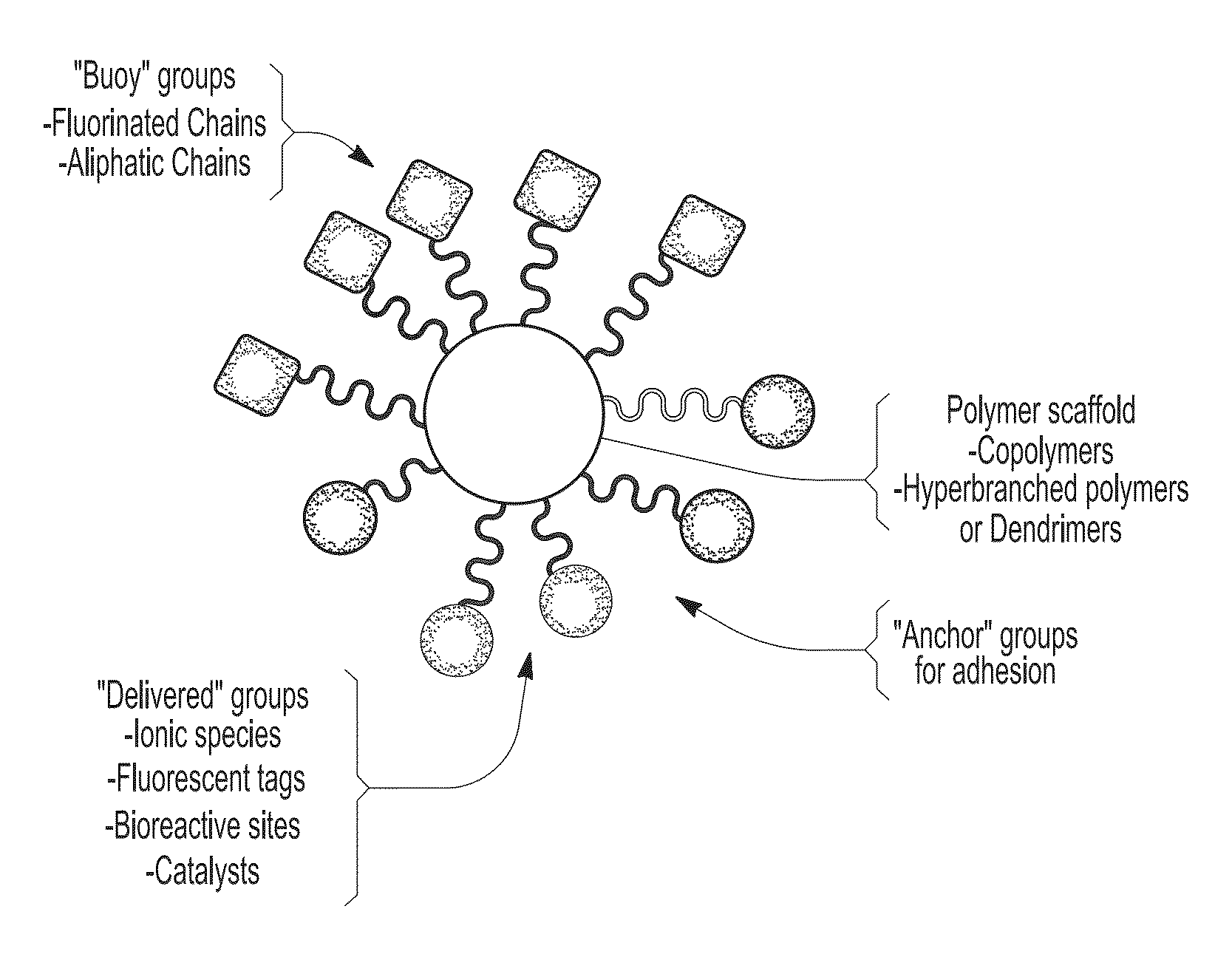

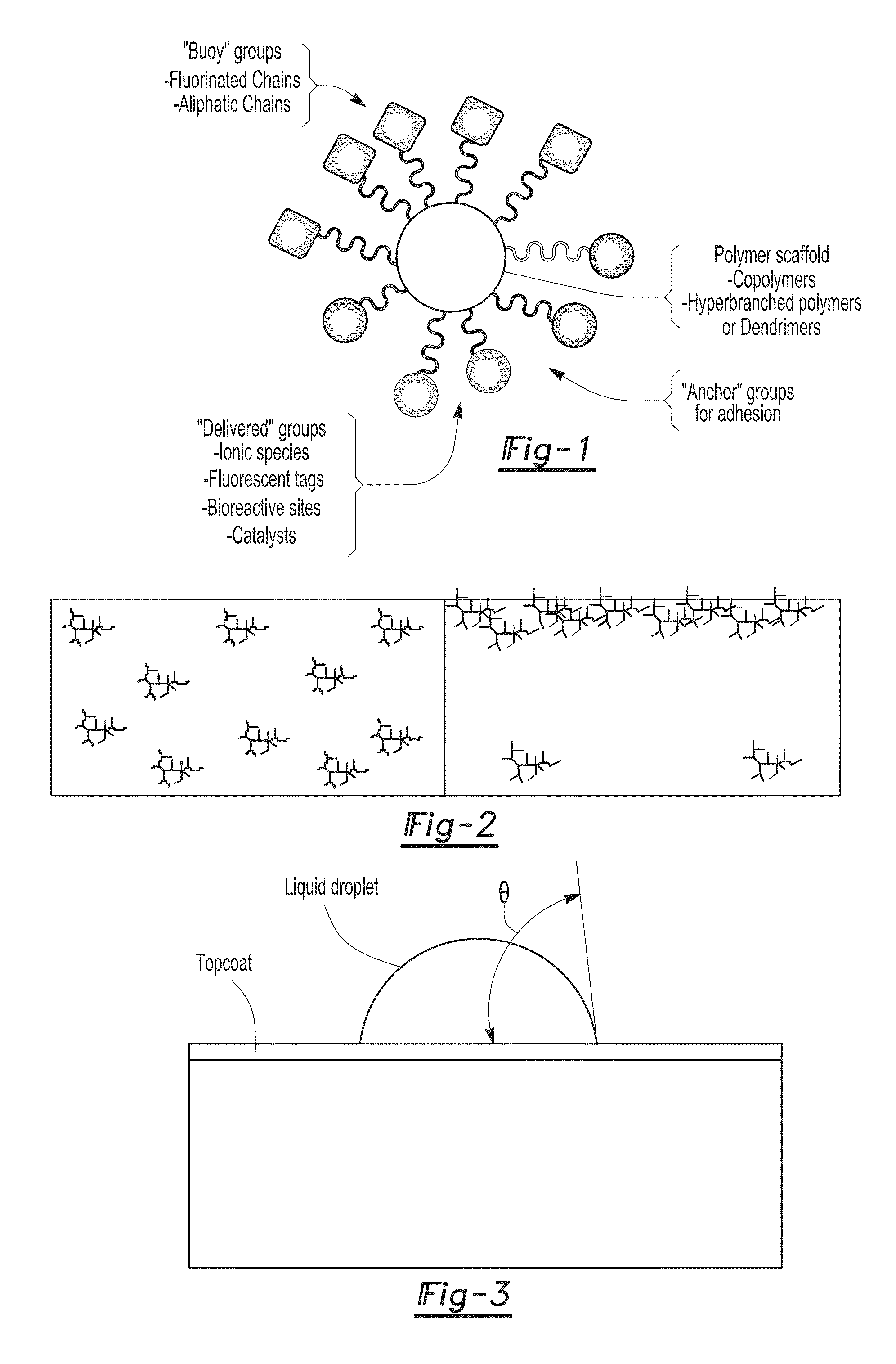

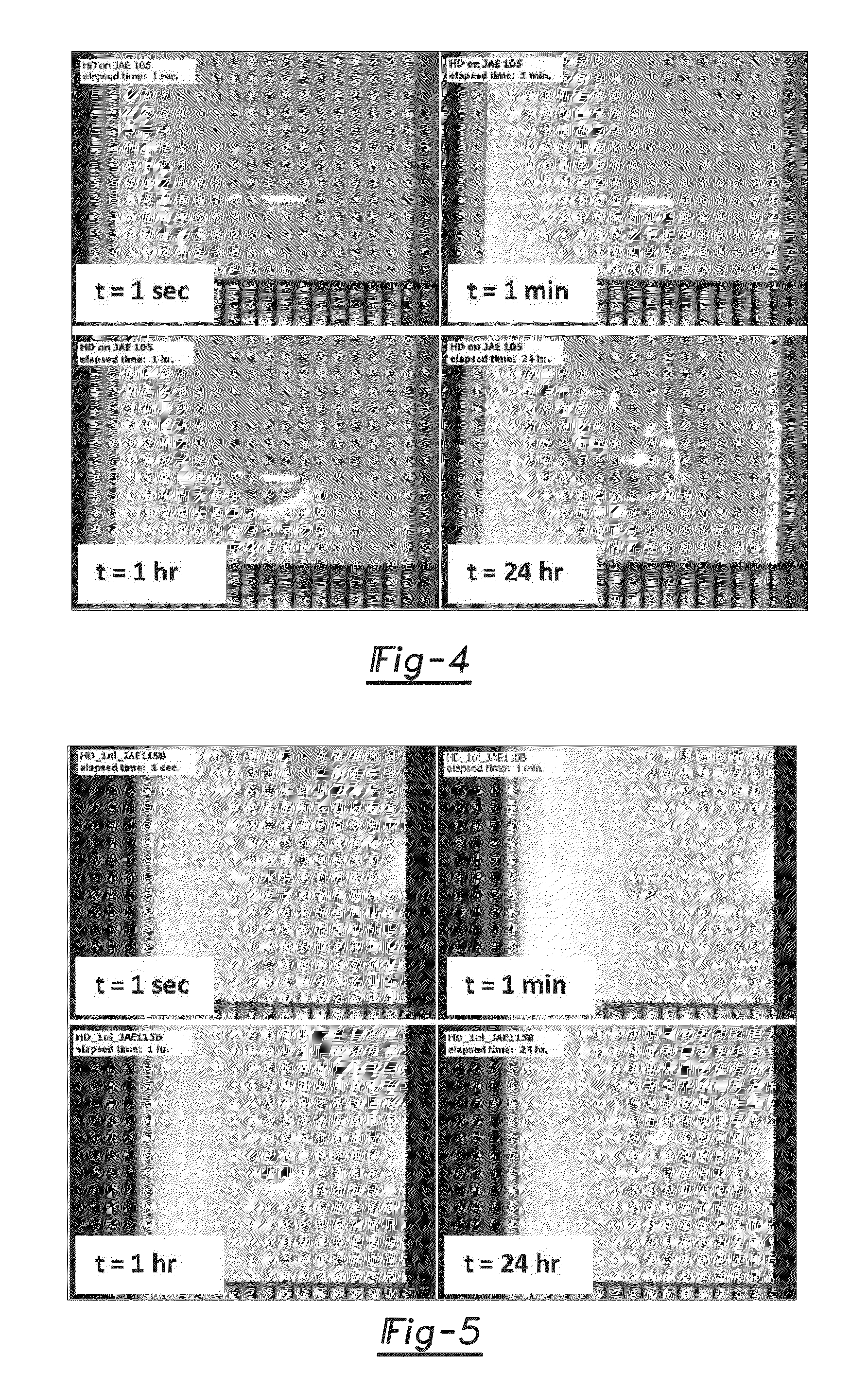

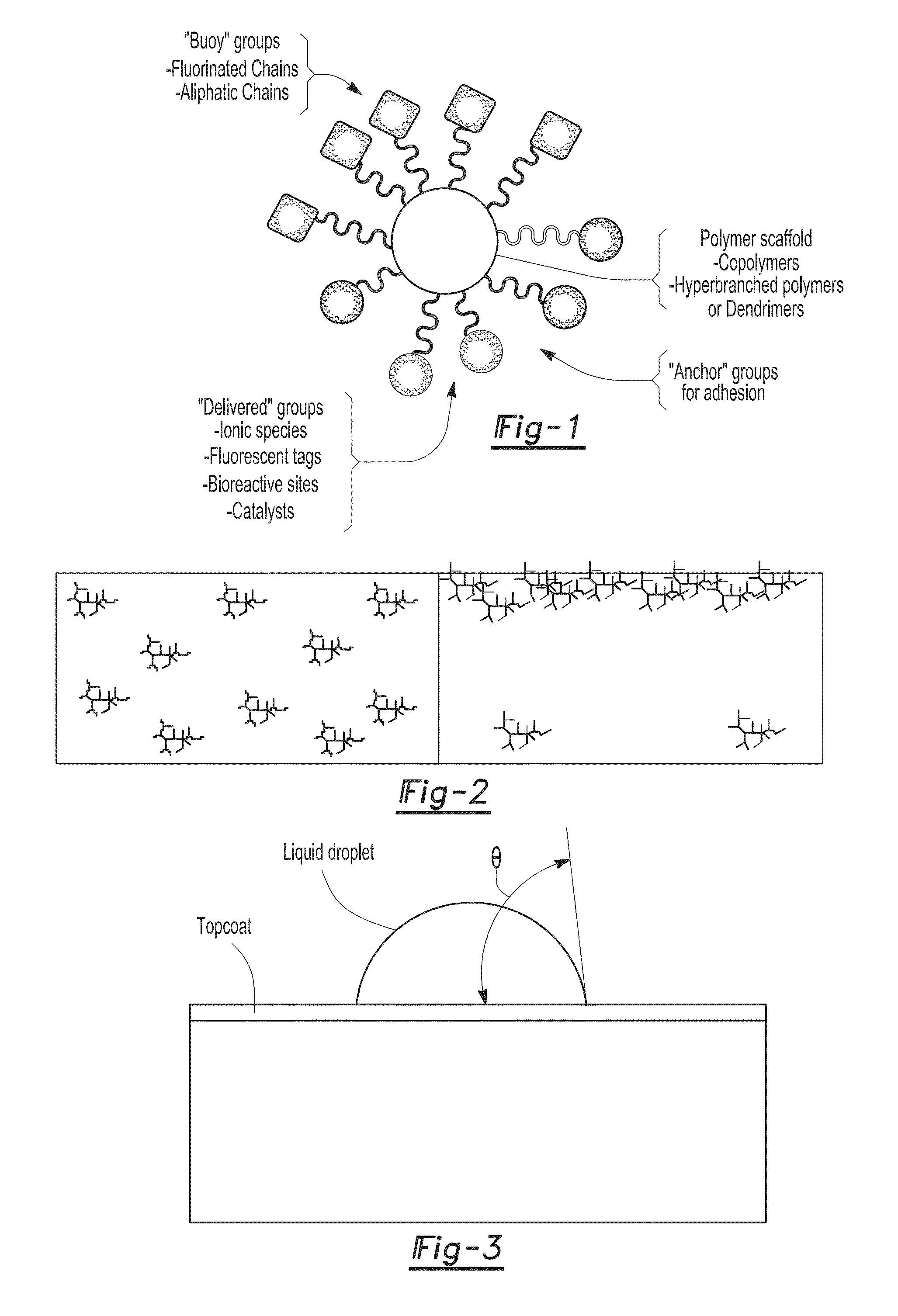

InactiveUS20130018144A1Good dispersionImprove hydrophobicityPolyurea/polyurethane coatingsPolyester coatingsEpoxyMeth-

A topcoat having a polyfunctional scaffold in the form of a hyperbranched polymer (HBP) with a buoy group coupled to the HBP. The HBP can also have a “delivered” group and / or an anchor group coupled thereto. The buoy group can be a fluorinated chain end, one or more fluorinated and aliphatic chain ends and / or one or more wholly aliphatic chain ends. The “delivered” group can contain at least one of an ionic species, a fluorescent tag, a bioreactive site, a catalyst and the like, and the anchor group an epoxy, a (meth)acrylate or an isocyanate. The water-disbursable topcoat can also include a solubilizing group such as 2-butanone or 4-methyl-2-pentanone coupled to the HBP.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Surface segregating additives for enhanced chemical agent resistant topcoats

A topcoat having a polyfunctional scaffold in the form of a hyperbranched polymer (HBP) with a buoy group coupled to the HBP. The HBP can also have a “delivered” group and / or an anchor group coupled thereto. The buoy group can be a fluorinated chain end, one or more fluorinated and aliphatic chain ends and / or one or more wholly aliphatic chain ends. The “delivered” group can contain at least one of an ionic species, a fluorescent tag, a bioreactive site, a catalyst and the like, and the anchor group an epoxy, a (meth)acrylate or an isocyanate. The water-disbursable topcoat can also include a solubilizing group such as 2-butanone or 4-methyl-2-pentanone coupled to the HBP.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Bactericidal waterproof paint

Disclosed bactericidal waterproof paint comprises the following raw materials in parts by weight: 40-50 parts of melamine, 3-5 parts of sodium hydroxide, 10-15 parts of nonylphenol, 4-7 parts of polyvinyl butyral, 0.1-0.3 parts of a dispersant, 1-3 parts of an anti-oxidant, 3-5 parts of methyl isobutyl ketone, 5-6 parts of aluminium chloride, and 8-10 parts of 4-hydroxy-4-methyl-2-pentanone. The elastic paint is soft in luster, uniform in color, long in service life and convenient to construct, and is widely applicable to smearing of surfaces of PC, resin materials and other base materials.

Owner:江苏中丽新材料有限公司

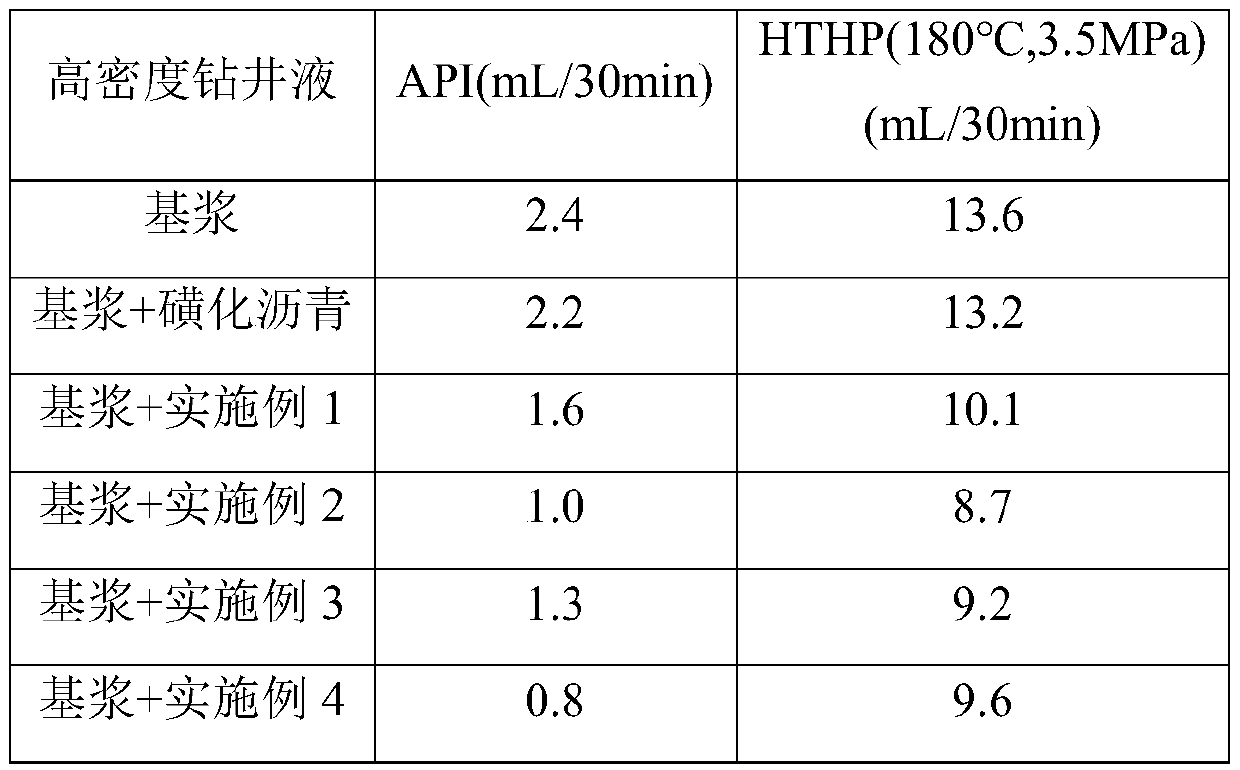

Drilling fluid and nanometer blocking agent for drilling fluid of oil field

InactiveCN109735312AEasy to prepareDry without heatMaterial nanotechnologyDrilling compositionCyclohexanoneMethyl isobutyl ketone

The invention discloses a drilling fluid and a nanometer blocking agent for the drilling fluid of oil field. The drilling fluid is modified ketal generated from reaction of diacetone, methyl isobutylketone, 4-hydroxy-4-methyl-2-pentanone, cyclohexanone and diethanol amine. The preparation method for the drilling fluid disclosed by the invention is simple; nitrogen protection is not required by the reaction process; the product acquired from reaction of various raw materials can be directly cooled and need not be heated for drying. The blocking agent disclosed by the invention has high fluidity; the effect of blocking microfractures, especially nanometer microfractures, on floor is obvious; after the blocking agent is added into the drilling fluid of oil field, mud cake can be effectivelyimproved, well wall can be stabilized and collapse can be prevented.

Owner:北京培康佳业技术发展有限公司

Coloration-photosensitive resin composition

ActiveCN1504777AImproved stability over timeOptical filtersPhotosensitive materials for photomechanical apparatusSolvent4-Methyl-2-pentanone

Provided is a colored photosensitive resin composition having good stability over aging. The colored photosensitive resin composition contains: a coloring agent (A); a binder polymer (B); a photopolymerizable compound (C); a photopolymerization initiator (D); and a solvent (E). The solvent (E) contains propyleneglycolmonomethylether acetate and 4-hydroxy-4-methyl-2-pentanone. The colored photosensitive resin composition is preferably used for formation of a color filter.

Owner:SUMITOMO CHEM CO LTD

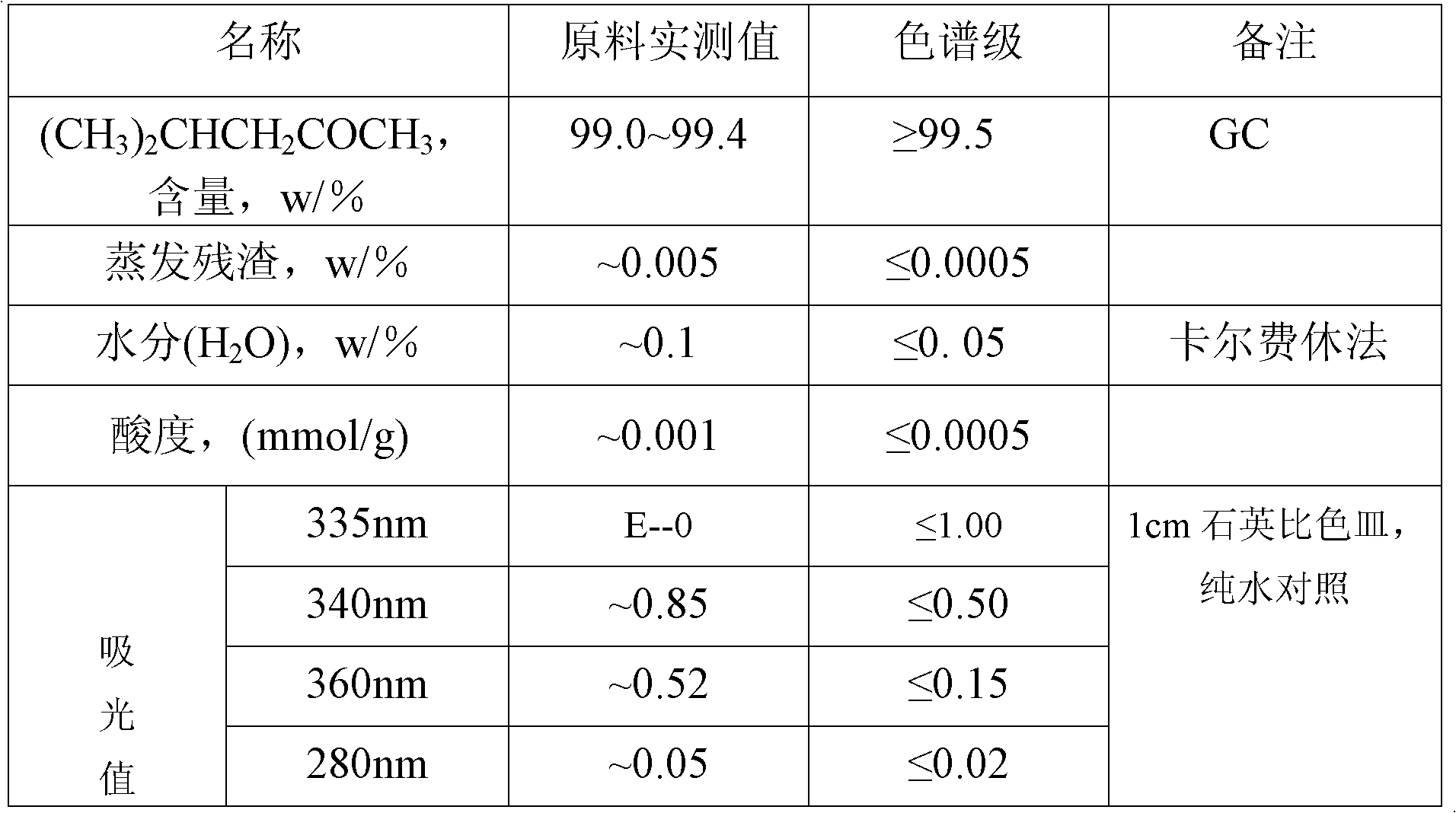

Purification method of high-purity organic solvent 4-methyl-2-pentanone

InactiveCN102040496AHigh purityEasy to separateCarbonyl compound separation/purificationOrganic solventPurification methods

The invention relates to a purification method of a high-purity organic solvent 4-methyl-2-pentanone, which comprises the following steps: carrying out adsorption and impurity removal on a raw material 4-methyl-2-pentanone by an acidic alumina adsorption column, drying and dewatering with anhydrous calcium sulphate, rectifying, filtering, and encapsulating to obtain the high-purity organic solvent 4-methyl-2-pentanone product. The obtained chromatographic 4-methyl-2-pentanone product has purity greater than 99.5%, a yield greater than 95% and a qualification rate greater than 95%, thereby meeting the application requirements of high-purity organic solvent users in scientific research and experiment. Simultaneously, compared with the conventional purification method, the invention has the advantages of simple and convenient operation process, stable running and high product purity, thereby being applicable to large-scale production.

Owner:天津市康科德科技有限公司

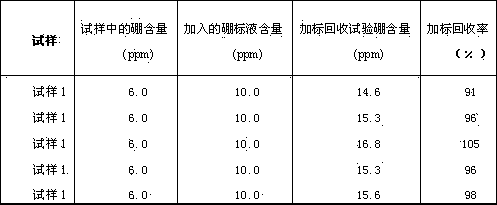

Determination method for content of trace boron in iron oxide powder

InactiveCN104062278AEasy to measureHigh measurement accuracyPreparing sample for investigationAnalysis by thermal excitationFull scaleVolumetric flask

The invention discloses a determination method for the content of trace boron in iron oxide powder. The method comprises the following steps: weighing iron oxide powder, putting the iron oxide powder into a quartz beaker, adding hydrochloric acid, then carrying out low-temperature heating for dissolving until a solution is almost dry, carrying out cooling and then adding hydrochloric acid to dissolve a medium; transferring an obtained solution to a separating funnel, carrying out flushing, combining washing liquor into the separating funnel, adding 4-methyl-2-pentanone, carrying out excitation, then carrying out standing for layering, putting a water phase into the quartz beaker for concentration, then transferring a concentrate to a volumetric flask and diluting the concentrate to full scale; acquiring a working curve from a standard boron solution; determining the iron oxide powder sample on a spectrometer, measuring spectral line intensity of elemental boron under the condition of no interference by microscale iron and carrying out comparison so as to obtain the content of boron in the iron oxide powder sample; and drafting a relation curve of the mass percentage content of elemental boron and the corresponding spectral line intensity of elemental boron and acquiring the percentage content of elemental boron according to the spectral line intensity of elemental boron. The method can conveniently determine the content of trace boron, improves work efficiency, eliminates interference by an iron matrix and enhances determination precision of the content of trace boron.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

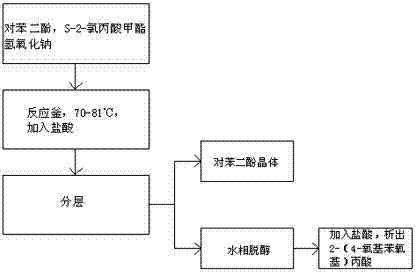

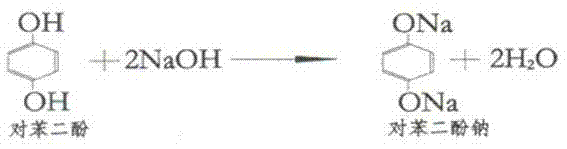

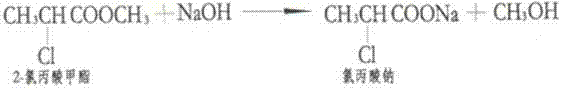

Method for preparing 2-(4-methoxy phenoxy) propionic acids

InactiveCN102775297AEasy to operateLow costPreparation from carboxylic acid esters/lactonesPropanoic acidOrganic layer

The invention relates to a method for preparing 2-(4-methoxy phenoxy) propionic acids. The method includes adding, by weight, 183 parts of hydroquinone and 202.5 parts of S-methyl 2-chloropropionate into a reaction kettle, adding, by weight, 100 parts of sodium hydroxide for a first batch, raising the temperature of the reaction kettle to 70 DEG C to 80 DEG C, reserving the temperature for 8 hours, and reducing the temperature of the reaction kettle to the room temperature after reaction; adding, by weight 128 parts of hydrochloric acid into the reaction kettle, keeping the pH to be about 5 to 6, and reacting the hydroquinone with the hydrochloric acid in a weak acidic environment to produce hydroquinone; adding an extracting agent 4-methyl-2-pentanone into the reaction kettle, layering the solution, wherein an organic layer is the hydroquinone and the extracting agent, and a water layer is an intermediate A / B, methanol and a salt solution; separating an organic phase mixture, reducing the pressure to distill the 4-methyl-2-pentanone, and subjecting hydroquinone crystals to centrifugal separation; and adding, by weight, 128 parts of hydrochloric acids into a dealcoholized aqueous phase, regulating the pH to be 1 to 2, reacting the intermediate under an acid precipitation condition, and precipitating the 2-(4-methoxy phenoxy) propionic acids after adding acids. The method for preparing 2-(4-methoxy phenoxy) propionic acids has the advantages of being simple to operate, low in cost, small in pollution, and suitable for industrial large scale application.

Owner:周珮

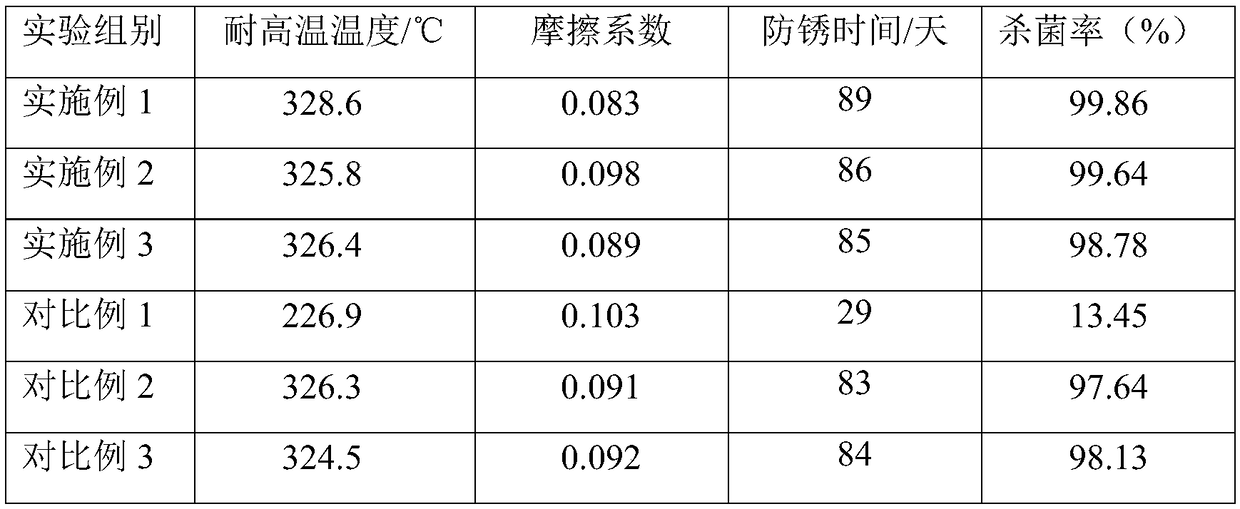

Graphene lubricating oil and preparation method thereof

InactiveCN109504507AGuaranteed bondingGuaranteed contentLubricant compositionOctanolAntibacterial agent

The invention discloses graphene lubricating oil and a preparation method thereof. The graphene lubricating oil is prepared from the following raw materials: engine oil, rice bran oil, ethylene glycoldipolynaphthenate, cyclohexane, triethanolamine, a silane coupling agent KH-570, octylphenol, 4-hydroxyl-4-methyl-2-pentanone, styrenated phenol, jojoba oil, alkenyl succinate, castor oil polyoxyethylene ether, benzotriazole, cinnamyl alcohol, secondary octanol, polyoxyethylene glyceryl ether laurate, methylisothiazolinone, uracil, carbon black, wax powder, corundum powder, nano silicon dioxide,stearic acid, pentaerythritol, naphthenic acid, ammonium bicarbonate, zinc acetylacetonate, nano graphene, aluminum nitride and an antibacterial agent; the graphene lubricating oil is prepared throughsteps of preparing a base material, preparing a modified material, mixing and the like. The graphene lubricating oil provided by the invention has excellent high-temperature resisting, antirust and antibacterial performance.

Owner:中国人民解放军空军勤务学院 +1

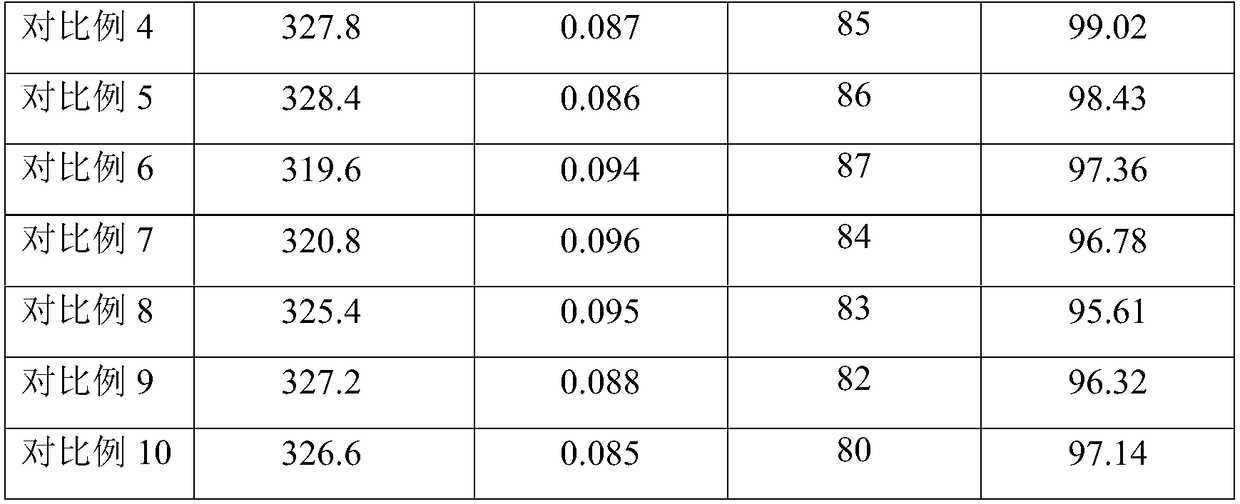

Installation cable for electric power distribution cabinet

InactiveCN106084479ASoft textureExcellent flame retardantPlastic/resin/waxes insulatorsClimate change adaptationDiacetone alcoholPhosphate

The invention relates to an installation cable for an electric power distribution cabinet. The installation cable comprises a plurality of copper alloy wires and protective sheaths, wherein the copper alloy wires are arranged in parallel to each other, and the outer layer of each copper alloy wire is coated with the protective sheath; each protective sheath comprises the following components: polypropylene resin, aldehyde resin, brominated bisphenol A epoxy resin, Litsea cubeba oil, 4-hydroxy-4-methyl-2-pentanone, castor oil, amyl propionate, propiconazole, sodium monofluorophosphate, carbendazim, tetramethyl thiuram disulfide, tourmaline powder, molybdenum disilicide powder, titanium dioxide powder, weathered coal, corundum powder, sodium zirconate powder, strontium chromate powder, silica gel powder, tris(2-chloroethyl) phosphate, hexabromo-benzene, modacrylic, decabrominated iphenyl ethane, diaminodiphenyl methane, diphenyl silanediol, diphenylmethane bismaleimide, diacetone alcohol, dibutyltin dilaurate, diethylene glycol dibenzoate, and dimethyl ketoxime. The installation cable provided by the invention has the advantage of improving the operation performance of a product.

Owner:虞永华

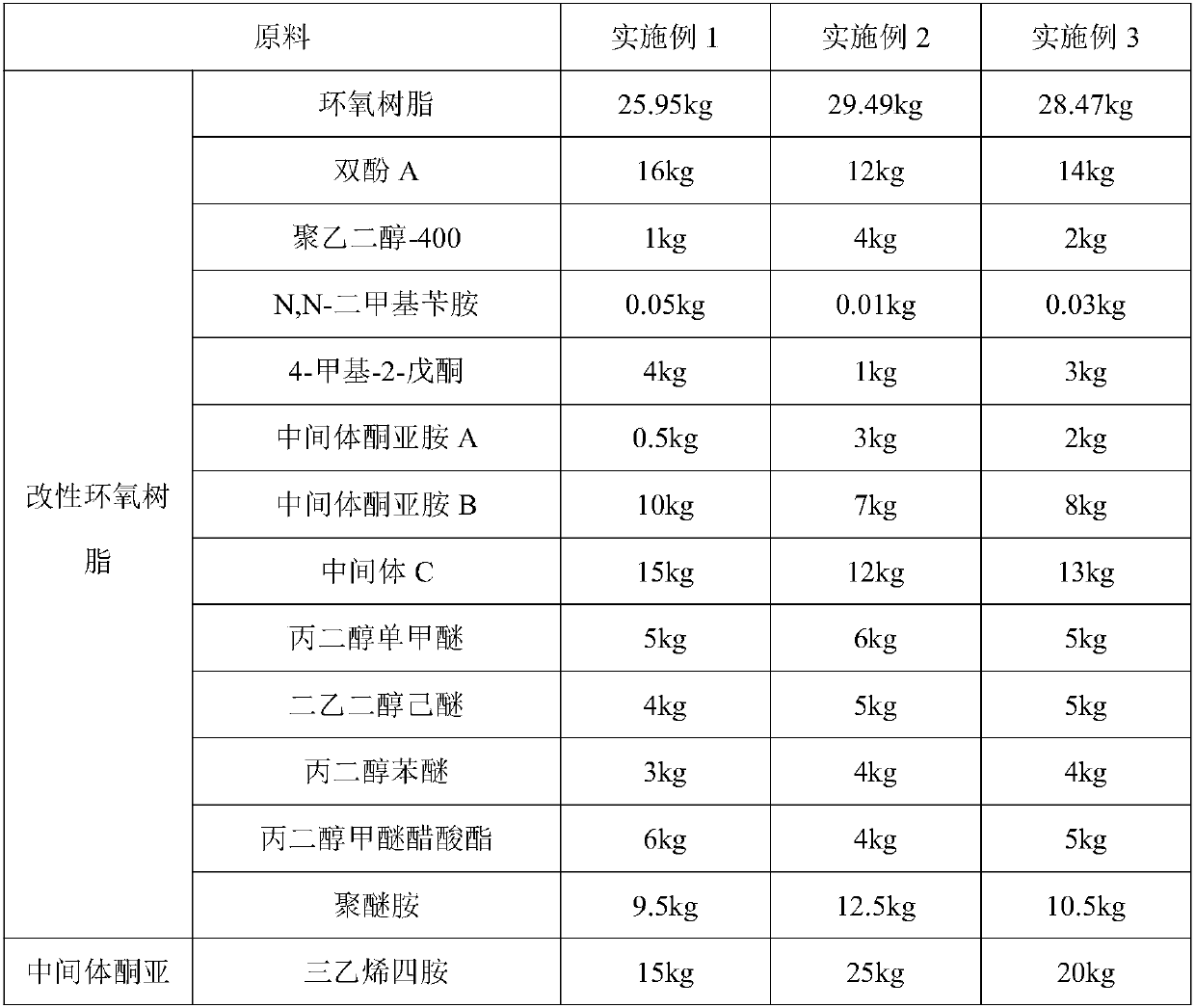

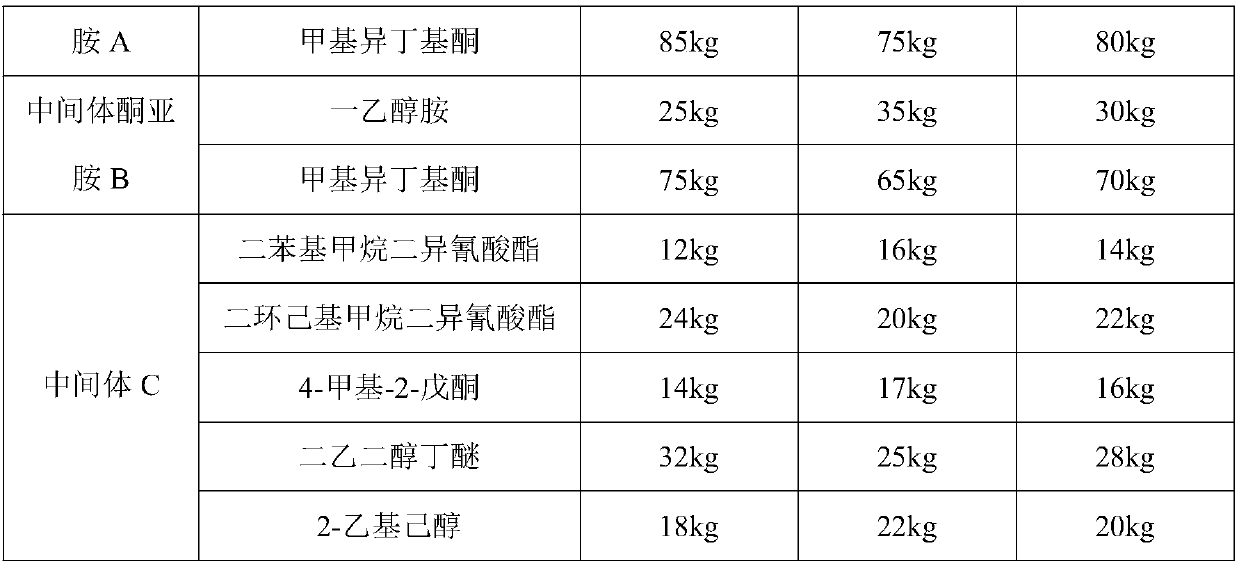

Modified epoxide resin and preparing method thereof and high-throwing-power cathode electrophoretic coating

ActiveCN109627951AImprove corrosion resistanceUniform thicknessAnti-corrosive paintsPolyurea/polyurethane coatingsPolyethylene glycolBenzylamine

The invention belongs to the technical field of environment-friendly waterborne coatings, and particularly relates to modified epoxide resin and a preparing method thereof and a high-throwing-power cathode electrophoretic coating with the modified epoxide resin. The modified epoxide resin is prepared from epoxy resin, bisphenol, polyethylene glycol, N,N-dimethyl benzylamine, 4-methyl-2-pentanone,midbody ketimine A, midbody ketimine B, midbody ketimine C, an alcohol ether solvent, propylene glycol methyl ether acetate and polyether amine; corresponding emulsion and color paste are prepared through the modified epoxide resin, and then the emulsion and the color paste are mixed in proportion to prepare the cathode electrophoretic coating. Compared with an existing cathode electrophoretic coating, the throwing power of the cathode electrophoretic coating is remarkably improved, electrophoretic painting of the surface of a workpiece with the complex surface structure can be well met, the surface, the sunken portion, the gap portion and the shielded portion of the painted workpiece are coated with coating layers with the even thickness, the whole corrosion resistance and the like of theworkpiece are effectively improved accordingly, and the application range is wide.

Owner:GUANGDONG KODEST EP SC CO LTD +1

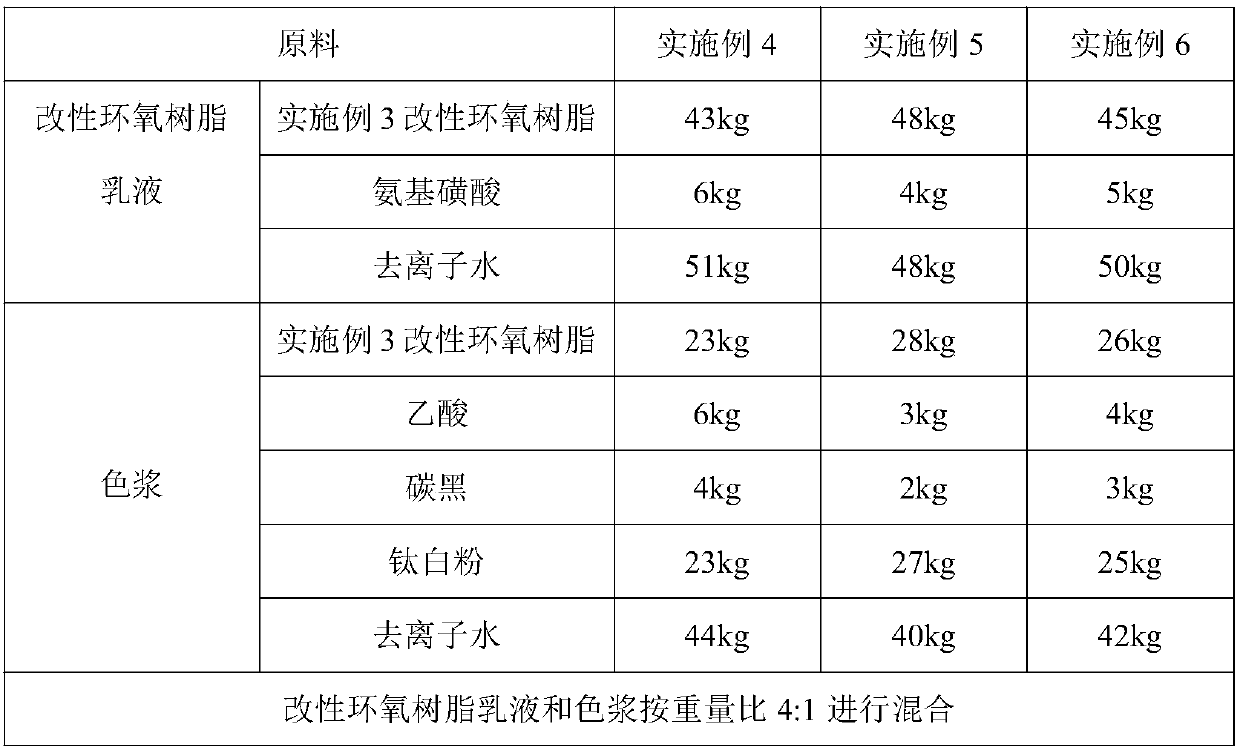

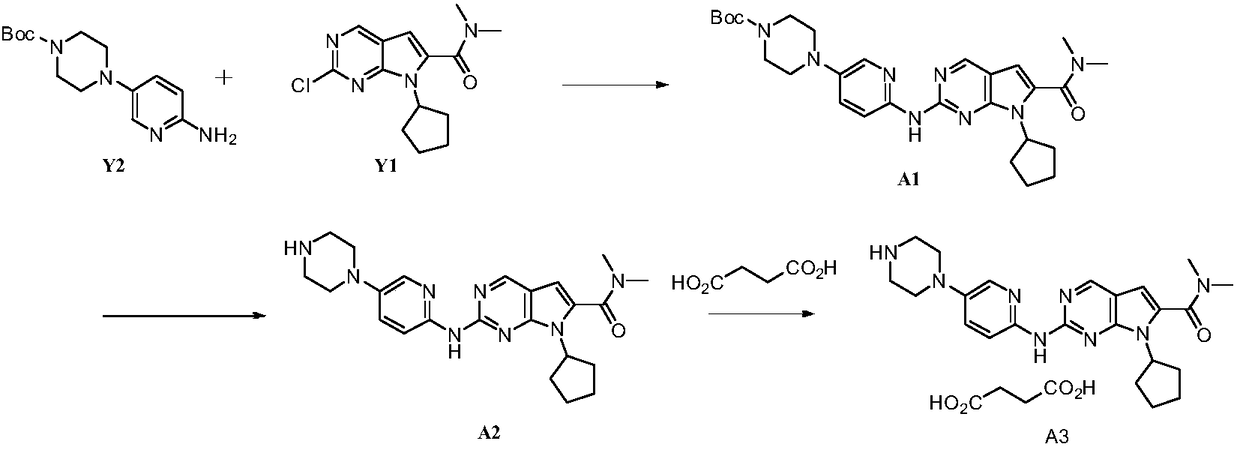

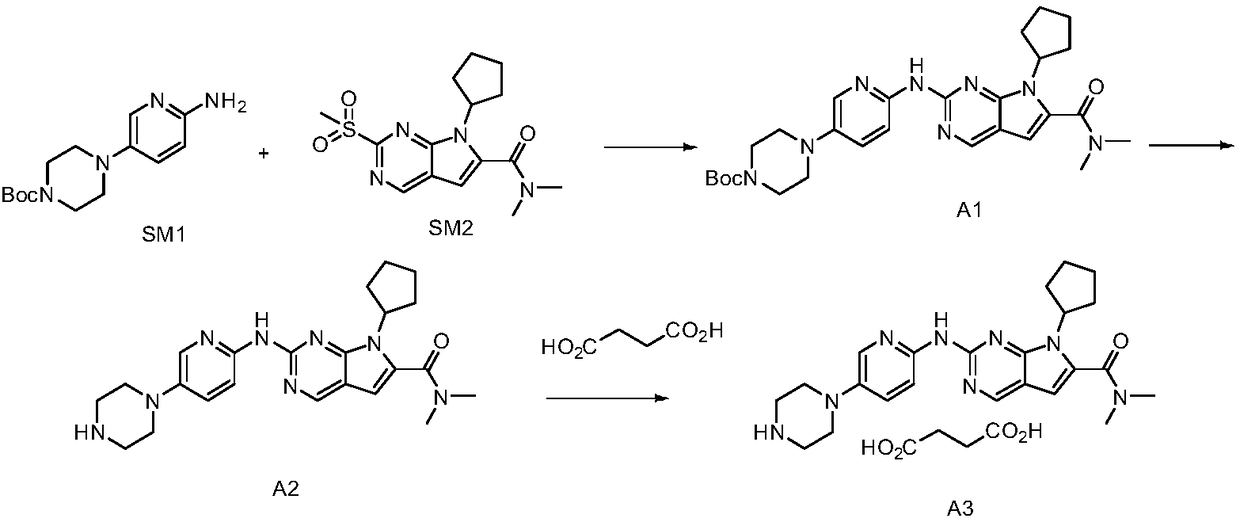

Preparation method of ribociclib and product and use thereof

InactiveCN109400612AAchieve primary separationMild responseOrganic chemistryCarboxylic acidRibociclib

A preparation method of ribociclib comprises the following steps: 1) utilizing 4-(6-aminopyridine-3-yl)piperazine-1-carboxylic acid tert-butyl ester and 2-chloro-4-cyclopentyl-N,N-dimethyl-7H-pyrrole[2,3-d]pyrimidine-6-formamide as raw materials and conducting reaction in a protective atmosphere with palladium acetate / BINAP as a catalyst, cesium carbonate as an acid absorber and 4-methyl-2-pentanone as a solvent to obtain 4-(6-(7-cyclopentyl-6-(dimethylaminoformyl)-7H-pyrrolo[2,3-d]pyrimidine-2-yl)aminopyridine-3-yl)piperazine-1-carboxylic acid tert-butyl ester); 2) dissolving the4-(6-(7-cyclopentyl-6-(dimethylaminoformyl)-7H-pyrrolo[2,3-d]pyrimidine-2-yl)aminopyridine-3-yl)piperazine-1-carboxylic acid tert-butyl ester) obtained in step 1) in an organic solvent, adding acid dropwise at the room temperature to remove tert-butyl formate, conducting liquid separation, adding a water-soluble organic solvent to an aqueous layer, separating solids and filtering to obtain ribociclib acid salt; 3) adding water to the ribociclib acid salt for dissolving, adding an adsorbent, filtering and adding alkali to the filtrate to obtain the ribociclib.

Owner:CHONGQING SANSHENG IND CO LTD

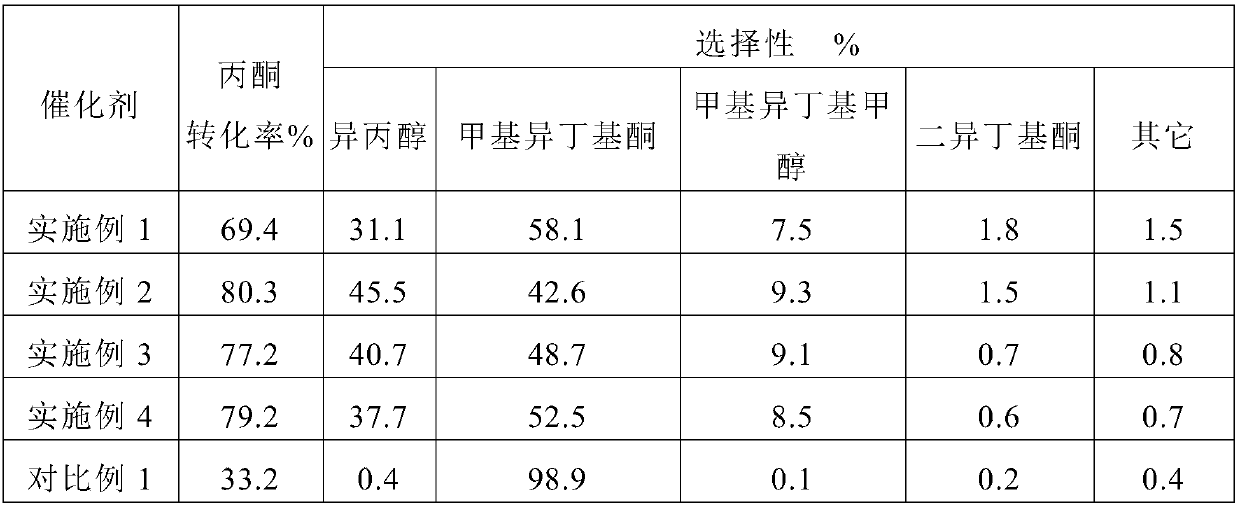

Catalyst for co-producing 4-methyl-2-pentanone and 4-methyl-2-pentanol through one-step method

ActiveCN107930640ALow costEasy to operateOrganic compound preparationHeterogenous catalyst chemical elementsAlkaline earth metalPalladium catalyst

The invention relates to a catalyst, and belongs to the technical field of applications and development of acetone downstream products, wherein copper, an alkaline earth metal, cerium and chromium areused as loading components, aluminum oxide, silicon oxide or an aluminum oxide-silicon oxide composite carrier with rich pH value is selected to promote a reaction, the catalyst is used under a mildreaction condition, the yield of 4-methyl-2-pentanone in the application of the catalyst of the present invention is higher than the yield of 4-methyl-2-pentanone in the application of the palladium / resin catalyst used in the current industrial apparatus, and 4-methyl-2-pentanol is economically by-produced. According to the present invention, the obtained catalyst has the ideal stability, has thecost significantly lower than the cost of the existing palladium catalyst, and has good economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

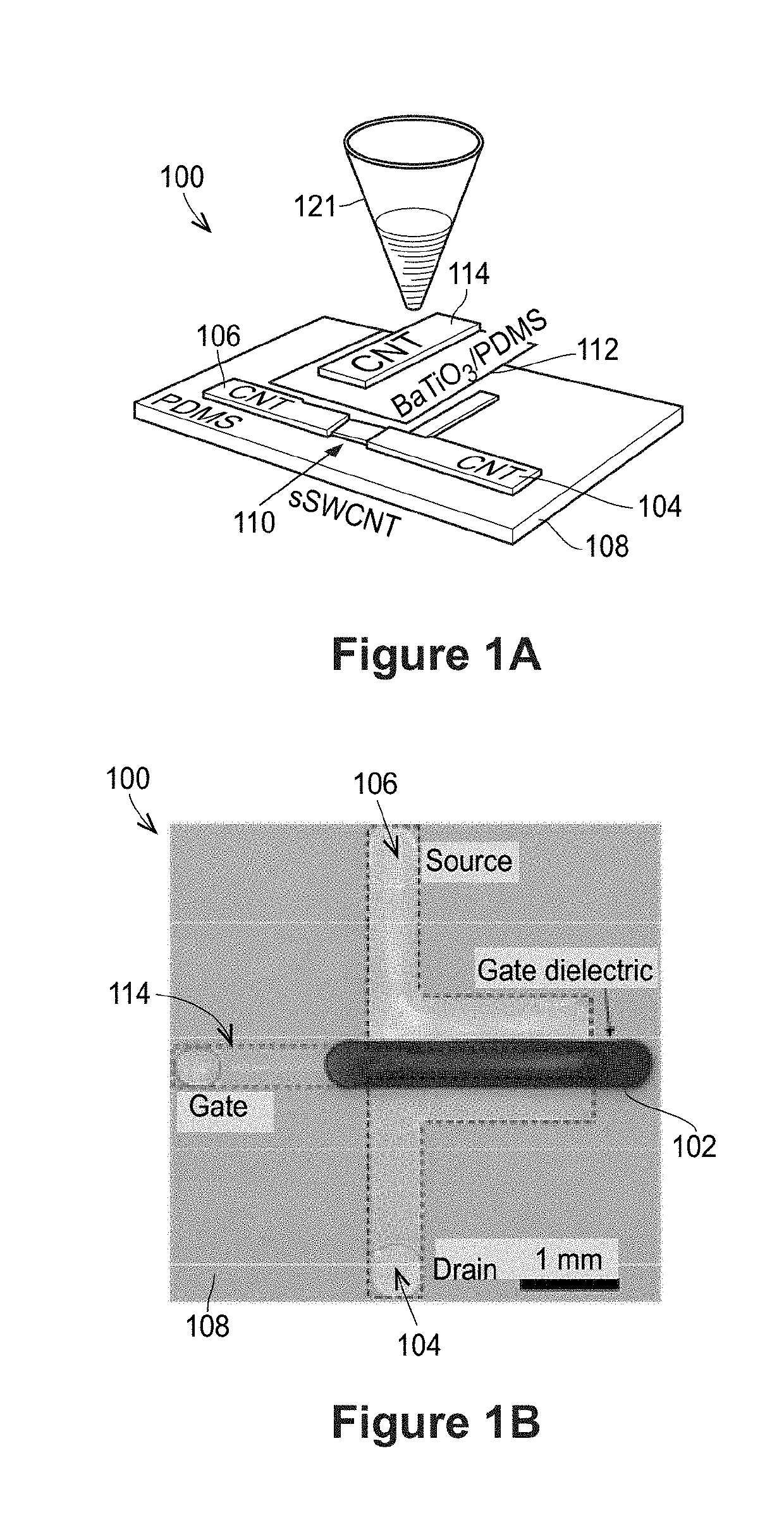

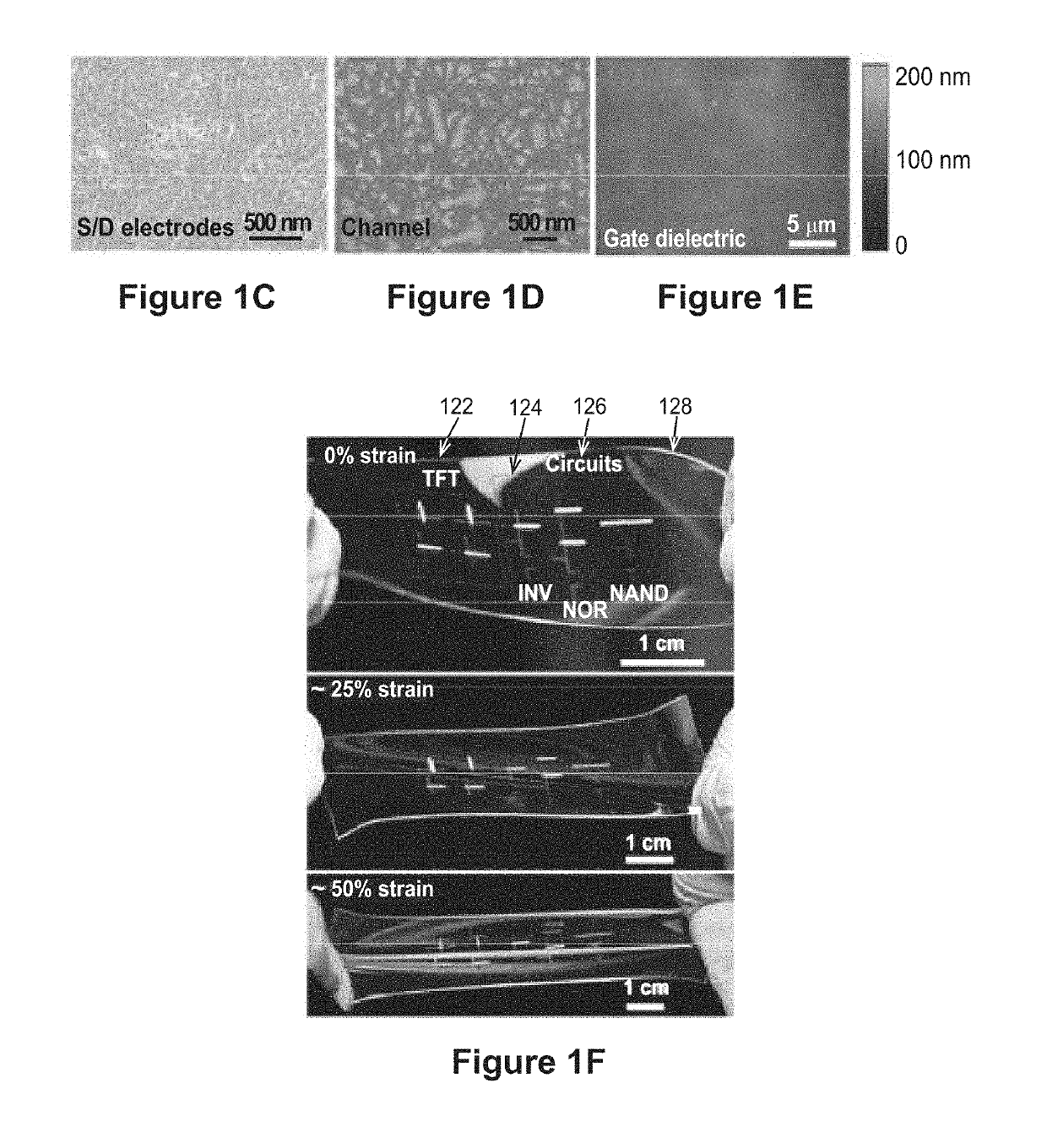

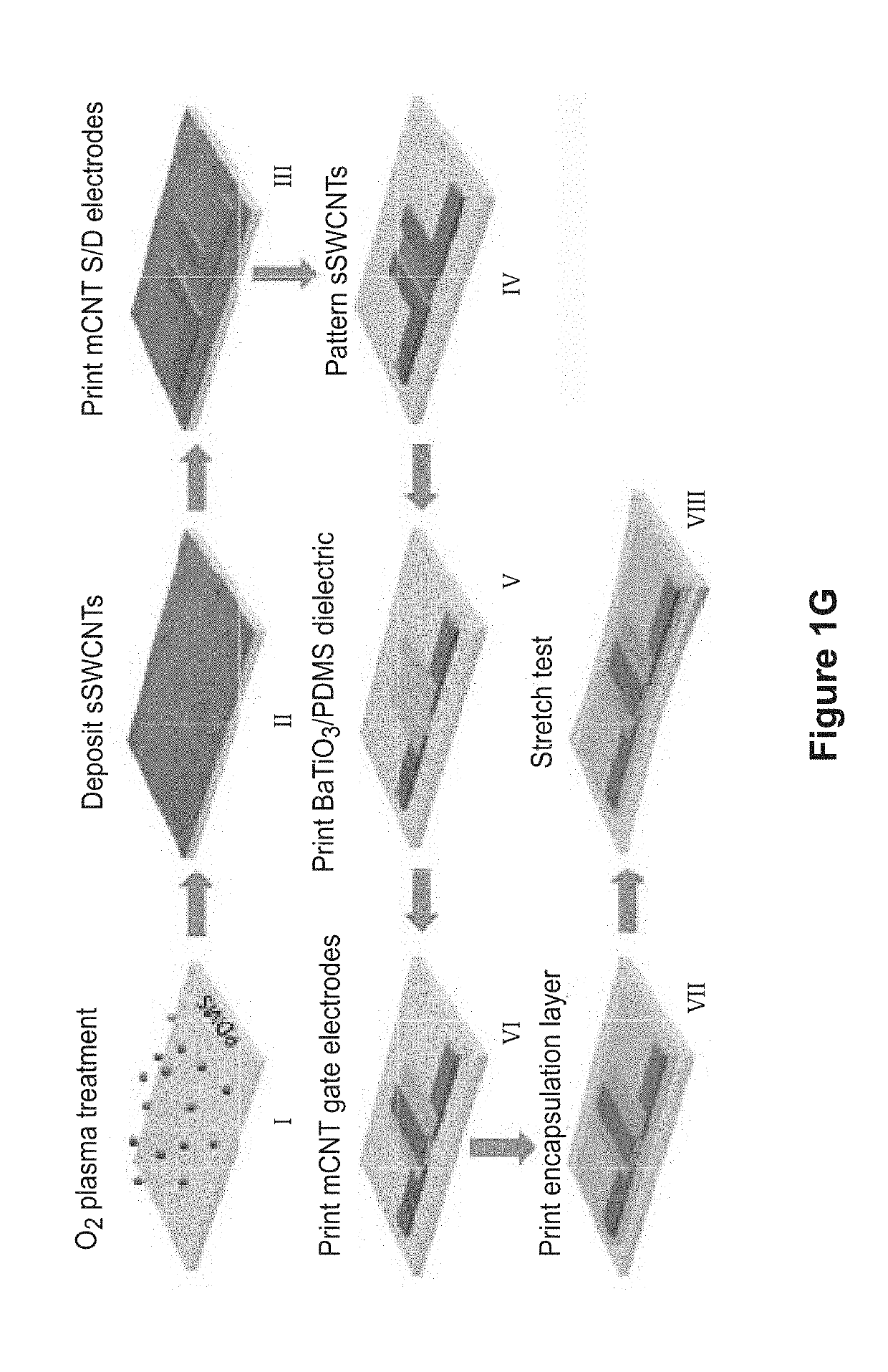

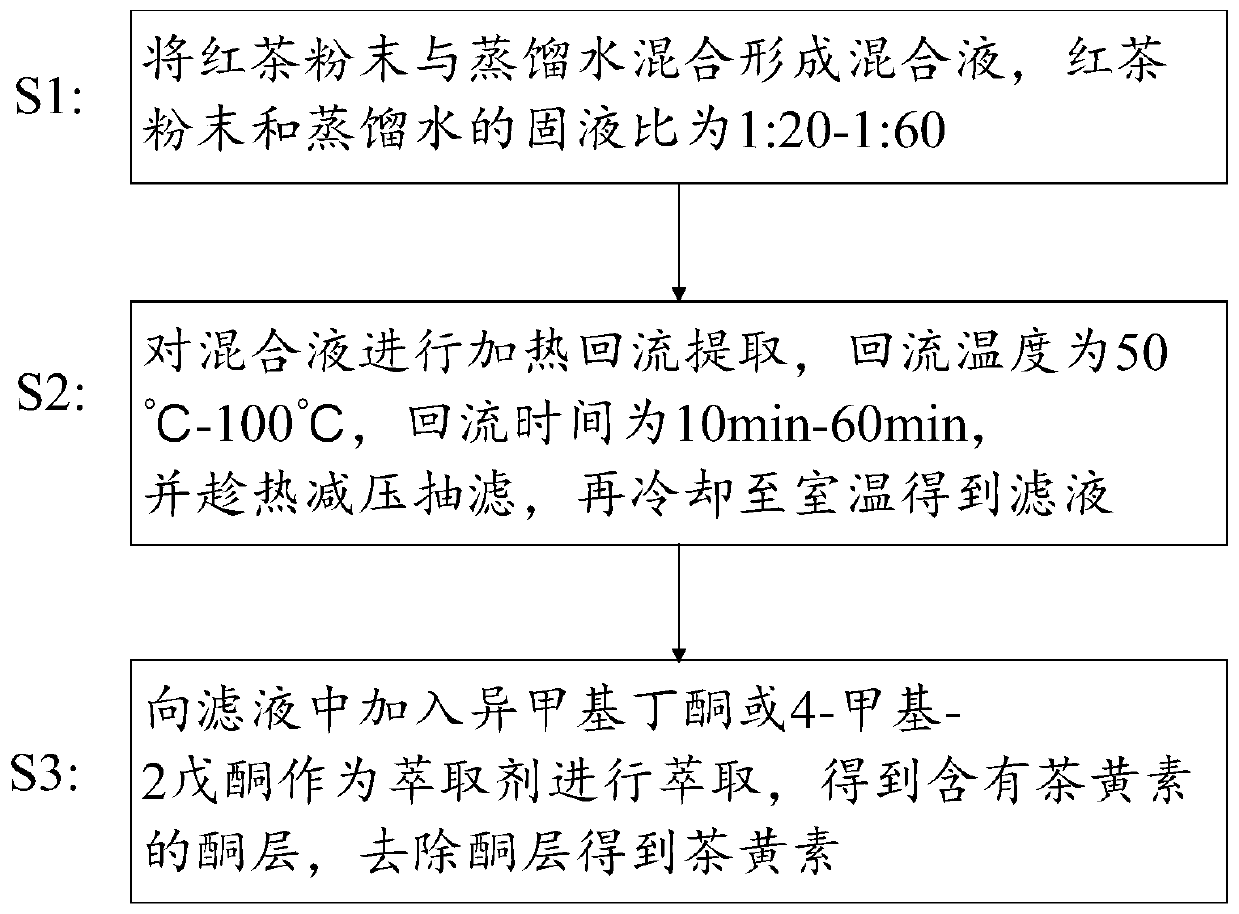

Fully-Printed Stretchable Thin-Film Transistors and Integrated Logic Circuits

ActiveUS20190157256A1High dielectric constantExclusive-OR circuitsSemiconductor/solid-state device detailsElastomerGate dielectric

Printable and stretchable thin-film devices and fabrication techniques are provided for forming fully-printed, intrinsically stretchable thin-film transistors and integrated logic circuits using stretchable elastomer substrates such as polydimethylsiloxane (PDMS), semiconducting carbon nanotube network as channel, unsorted carbon nanotube network as source / drain / gate electrodes, and BaTiO3 / PDMS composite as gate dielectric. Printable stretchable dielectric layer ink may be formed by mixing barium titanate nanoparticle (BaTiO3) with PDMS using 4-methyl-2-pentanone as solvent.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Free-radical chain polymerization thinly-coated ultraviolet-cured nanometer paint

InactiveCN104403550AReduce thicknessReduce lossAnti-corrosive paintsPolyurea/polyurethane coatingsPolyesterUltraviolet

Related free-radical chain polymerization thinly-coated ultraviolet-cured nanometer paint comprises the following compositions in percent by weight: 33-39% of aliphatic polyurethane acrylate, 22-28% of epoxy acrylate, 20-24% of polyester acrylate, 8-15% of a solvent, 3-5% of a photoinitiator, 0.5-3% of a dispersant, and 0.5-3% of a leveling agent. The solvent is one or two of butyl acetate and 4-methyl-2-pentanone. The beneficial effects comprise that the paint is thinly coated, is resistant to smudge and prevents fingerprints, helps to improve the chemical performances of conventional ultraviolet-cured material coatings, reduce energy consumption and save cost, and has strong weatherability, corrosion resistance and chemical corrosion resistance. A coating of the paint is relatively small in yellowing property and is reduced in tensile strength, and the ultraviolet paint with relatively good comprehensive performances is obtained.

Owner:深圳市千浪化工有限公司

Special corrosion-resistant oil paint for outer frame

InactiveCN107746660AImprove bindingImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses special corrosion-resistant oil paint for an outer frame. The special corrosion-resistant oil paint is prepared from the following raw materials: epoxy resin, acrylic resin, amodified silica gel solution, diphenyl dimethoxysilane, isobutyltriethoxysilane, polyethylene, graphene, silicon dioxide, boron phosphate, nano titanium dioxide, talcum powder, ethylene glycol monoethyl ether acetate, 4-methyl-2-pentanone, butyl cellosolve, acetic acid-1-methoxy-2-propyl ester, alkyd resin and auxiliaries. The special corrosion-resistant oil paint for a scaffold is good in corrosion resistance, and is excellent in wear resistance and weather resistance.

Owner:NANNING KEYU ENERGY TECH CO LTD

Heat-insulating coating for energy-saving doors and windows and preparation method thereof

InactiveCN107033777ANo pollution in the processObvious discolorationAnti-corrosive paintsThermosensitive paintsPolyethylene vinyl acetateCyclohexanone

The invention discloses a heat-insulating coating for energy-saving doors and windows and a preparation method thereof. The coating includes organic silicone resin, ethyl cellulose, talcum powder, sodium phosphate, borate, polyethylene-vinyl acetate copolymer, 1-23 parts of cyclohexanone, iron oxide magnetic powder, 4-methyl-2-pentanone, tetrabutyl titanate, zinc acetate, maleic anhydride, silicone oil, 15 DEG C temperature sensing particles, 25 DEG C temperature sensing particles and diluent. The organic silicone resin, ethyl cellulose, polyethylene-vinyl acetate copolymer, cyclohexanone, 4-methyl-2-pentanone, tetrabutyl titanate and maleic anhydride are mixed; after fusion, spraying drying is performed to obtain a first mixture; ethyl cellulose, sodium phosphate, borate, zinc acetate and silicone oil are fused and then all other substances are added, and the viscosity is adjusted, so that the product is obtained. The coating can be cured at room temperature, is waterproof, also resistant to corrosion, good in heat protection performance and excellent in mechanical property, color change is obvious, and the temperature range of the environment can be visually reflected.

Owner:JIANGSU JINGDUN ENERGY SAVING TECH CO LTD

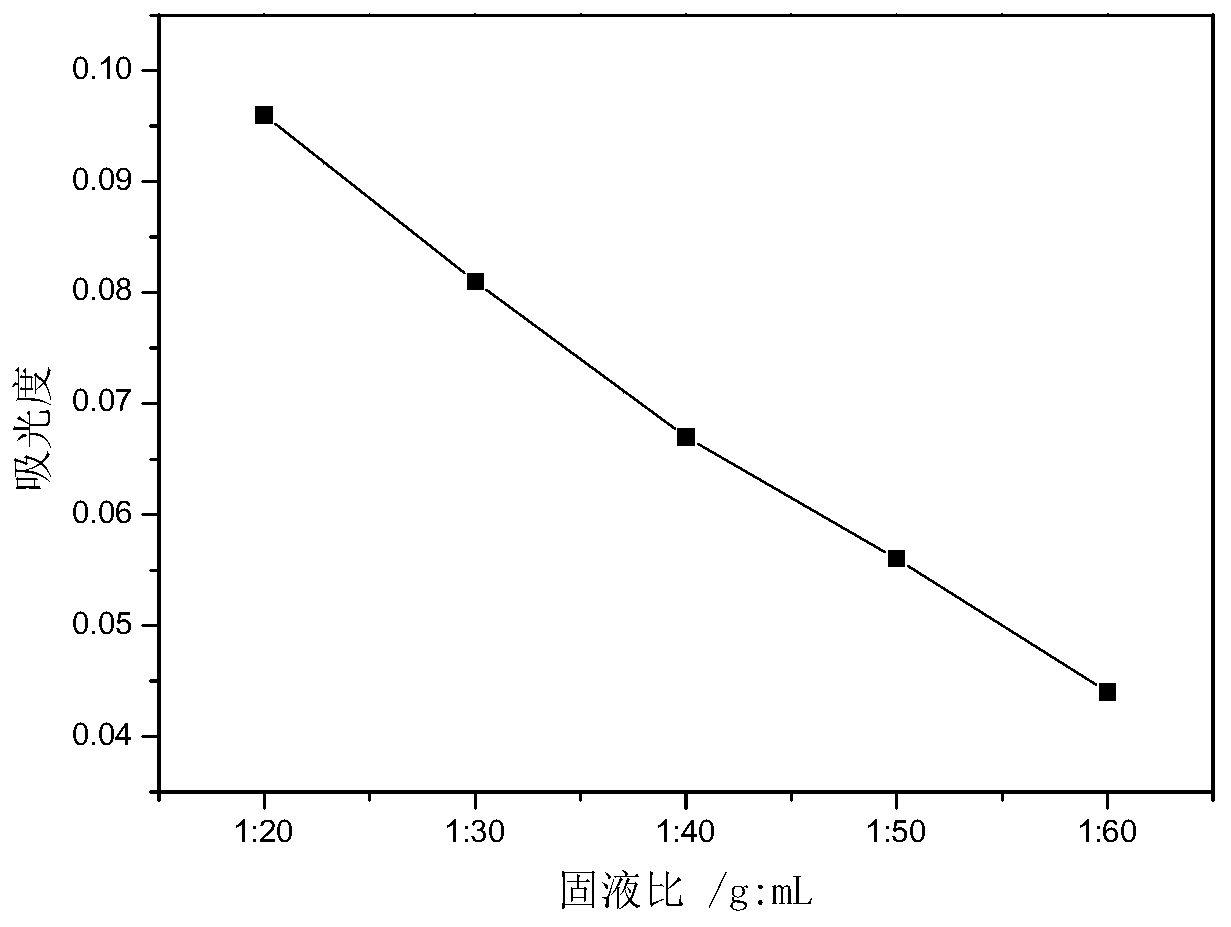

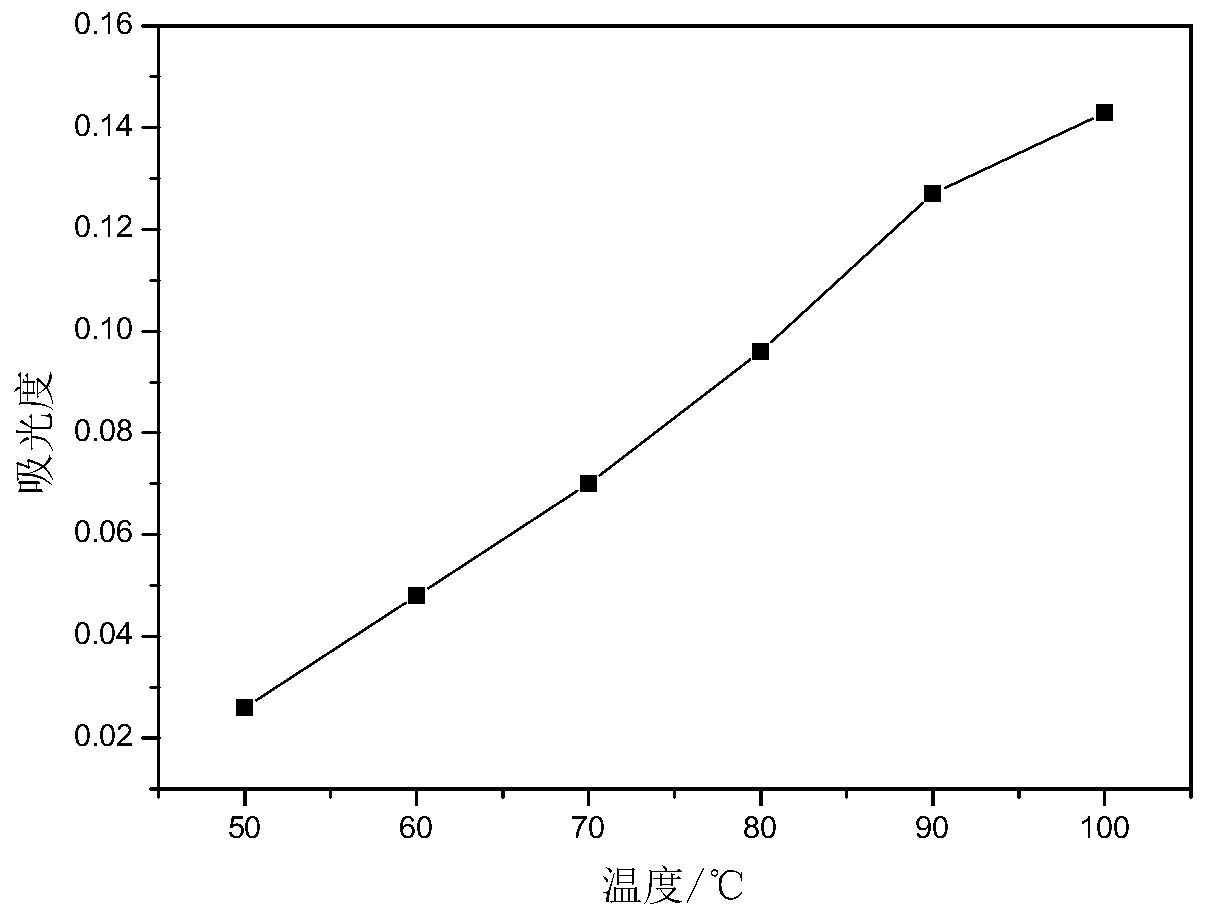

Method for extracting theaflavin from black tea

PendingCN110183412ASimple processSuitable for mass productionOrganic chemistryReflux extractionTheaflavin

The invention provides a method for extracting theaflavin from black tea. The method comprises the steps: mixing black tea powder with distilled water so as to form a mixed liquid at a solid-liquid ratio of black tea powder to distilled water at (1:20)-(1:60), heating the mixed liquid for reflux extraction at a reflux temperature of 50-100 DEG C for a reflux period of time of 10-60 min, performingvacuum suction filtration on the hot product, then performing cooling to room temperature so as to obtain a filtrate, adding isomethylbutanone or 4-methyl-2-pentanone which is adopted as an extractant for extraction so as to obtain a ketone layer containing theaflavin, and removing the ketone layer so as to obtain the theaflavin.

Owner:NINGDE NORMAL UNIV

Flame-resistant antibacterial additive for lubricating oil

InactiveCN106190438AThe preparation process is simpleGood acid and alkali resistanceAdditivesSodium BentoniteDiethylenetriamine

The invention relates to a flame-resistant antibacterial additive for lubricating oil. The flame-resistant antibacterial additive is prepared from the following components of silicon carbide micro powder, molybdenum disilicide powder, 4-hydroxyl-4-methyl-2-pentanone, styrenated phenol, hydroxyethyl cellulose, titanium oxide powder, tributyl phosphate, molybdenum dioxide powder, zinc borate, coumarone, diethylenetriamine, diatomite, barium metaborate, montmorillonite, vinyl triethoxysilane, bentonite, tricresyl phosphate, polycarbonate, polyhexamethylene biguanidine hydrochloride, glycyrrhizin, antibacterial peptide, propylene glycol, acetamiprid, natamycin, pyrethrin and cerium oxide powder. The product disclosed by the invention has excellent flame resistance, acid and alkali resistance, mildew prevention and bacterium resistance, and the properties of the product are improved.

Owner:王义金

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com