Installation cable for electric power distribution cabinet

A technology for power distribution cabinets and cables, which is applied in the field of electric power to achieve the effects of soft texture, superior flame retardancy, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

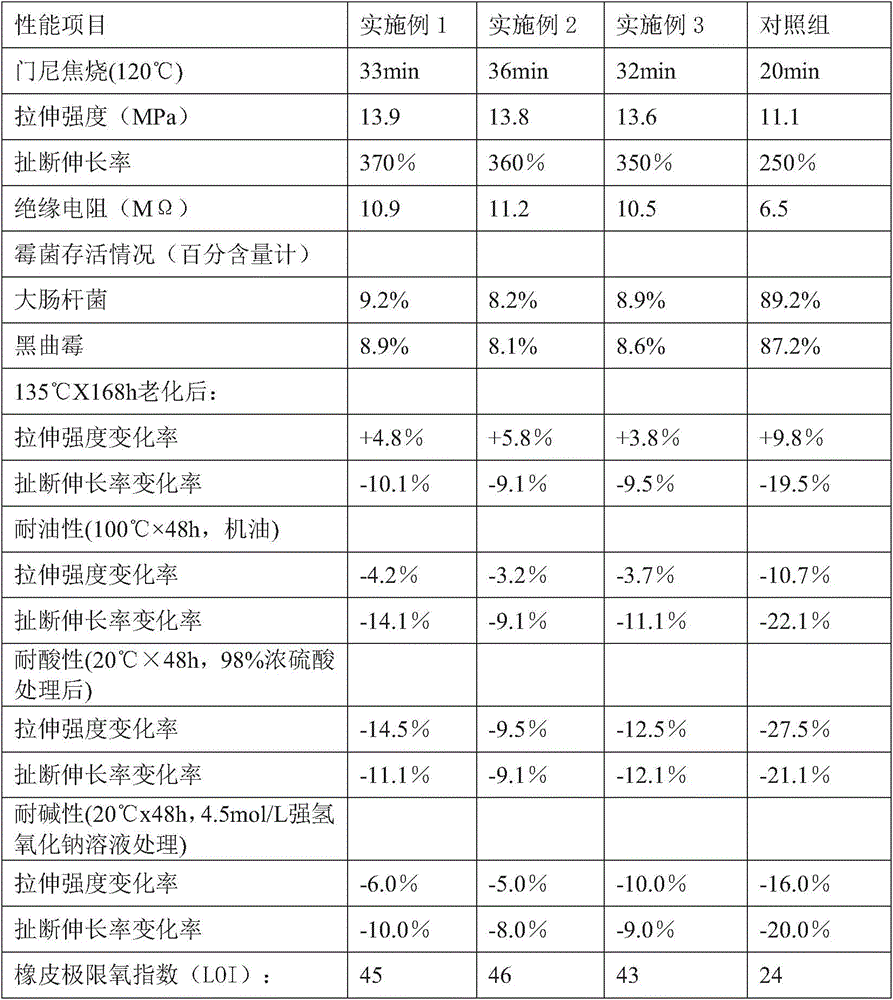

Embodiment 1

[0017] The installation cable for a power distribution cabinet in this embodiment includes a plurality of copper alloy wires and a protective sheath. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sheath. The protective sheath is of the following quality Component composition of parts: 12 parts of polypropylene resin, 10 parts of polyaldehyde resin, 10 parts of brominated diphenol-based propane epoxy resin, 8 parts of Litsea cubeba oil, 4-hydroxy-4-methyl-2-pentene 10 parts of ketones, 10 parts of castor oil, 8 parts of amyl propionate, 10 parts of propiconazole, 10 parts of sodium monofluorophosphate, 8 parts of carbendazim, 8 parts of tetramethylthiuram disulfide, 8 parts of tourmaline powder , 10 parts of molybdenum disilicide powder, 8 parts of titanium dioxide powder, 6 parts of weathered coal, 10 parts of corundum powder, 8 parts of sodium zirconate powder, 6 parts of strontium chromate powde...

Embodiment 2

[0024] The installation cable for a power distribution cabinet in this embodiment includes a plurality of copper alloy wires and a protective sheath. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sheath. The protective sheath is made of the following quality Component composition of parts: 14 parts of polypropylene resin, 12 parts of polyaldehyde resin, 12 parts of brominated diphenol-based propane epoxy resin, 10 parts of Litsea cubeba oil, 4-hydroxy-4-methyl-2-pentene 12 parts of ketones, 12 parts of castor oil, 10 parts of amyl propionate, 12 parts of propiconazole, 12 parts of sodium monofluorophosphate, 10 parts of carbendazim, 10 parts of tetramethylthiuram disulfide, 10 parts of tourmaline powder , 12 parts molybdenum disilicide powder, 10 parts titanium dioxide powder, 8 parts weathered coal, 12 parts corundum powder, 10 parts sodium zirconate powder, 8 parts strontium chromate powder, 10 ...

Embodiment 3

[0031] The installation cable for a power distribution cabinet in this embodiment includes a plurality of copper alloy wires and a protective sheath. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sheath. The protective sheath is made of the following quality Component composition of parts: 16 parts of polypropylene resin, 14 parts of polyaldehyde resin, 14 parts of brominated diphenol propane epoxy resin, 12 parts of Litsea cubeba oil, 4-hydroxy-4-methyl-2-pentan 14 parts of ketones, 14 parts of castor oil, 12 parts of amyl propionate, 14 parts of propiconazole, 14 parts of sodium monofluorophosphate, 12 parts of carbendazim, 12 parts of tetramethylthiuram disulfide, 12 parts of tourmaline powder , 14 parts molybdenum disilicide powder, 12 parts titanium dioxide powder, 10 parts weathered coal, 14 parts corundum powder, 12 parts sodium zirconate powder, 10 parts strontium chromate powder, 12 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com