Patents

Literature

65 results about "Strontium chromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium chromate is a chemical compound, with the formula SrCrO₄.

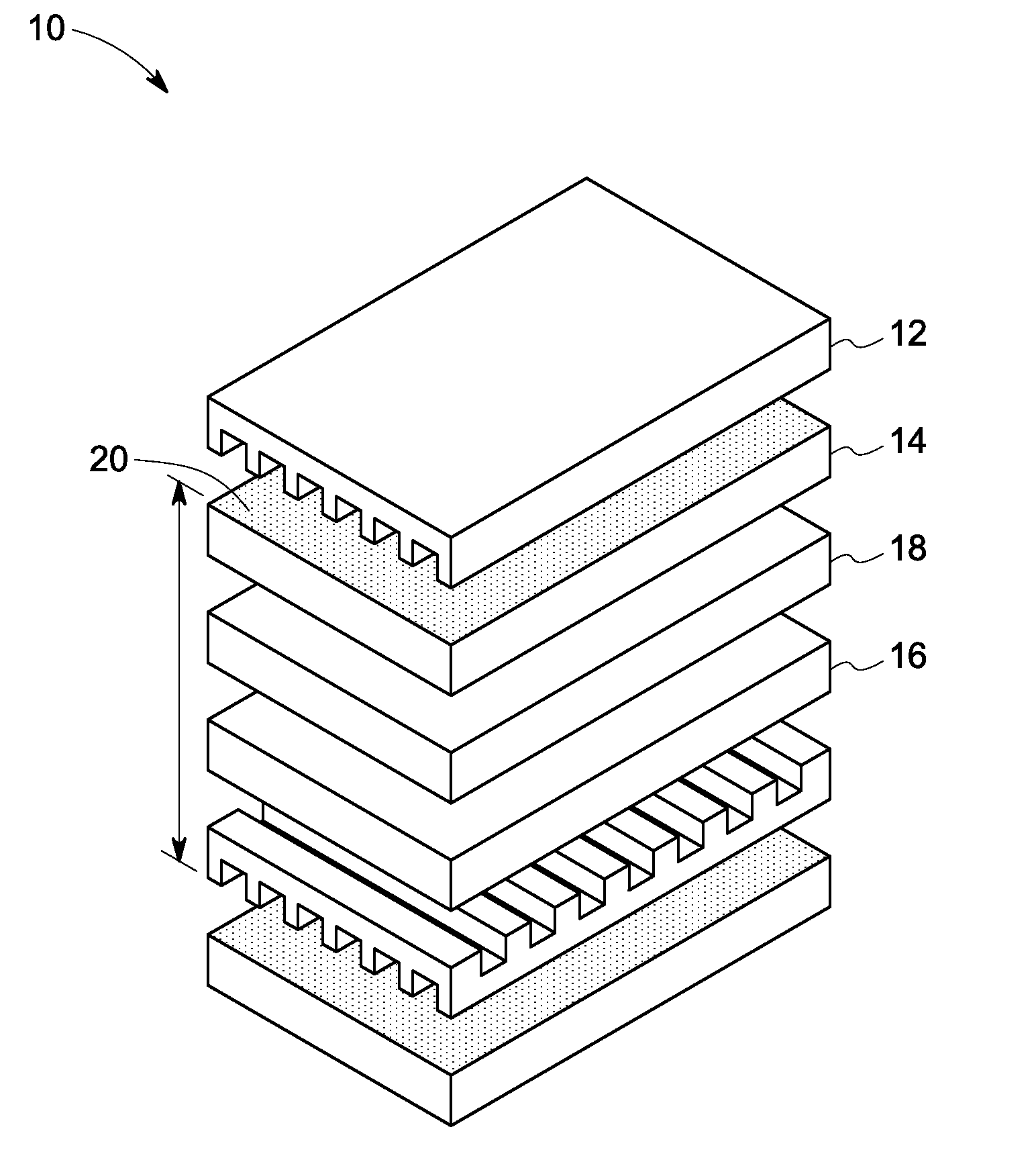

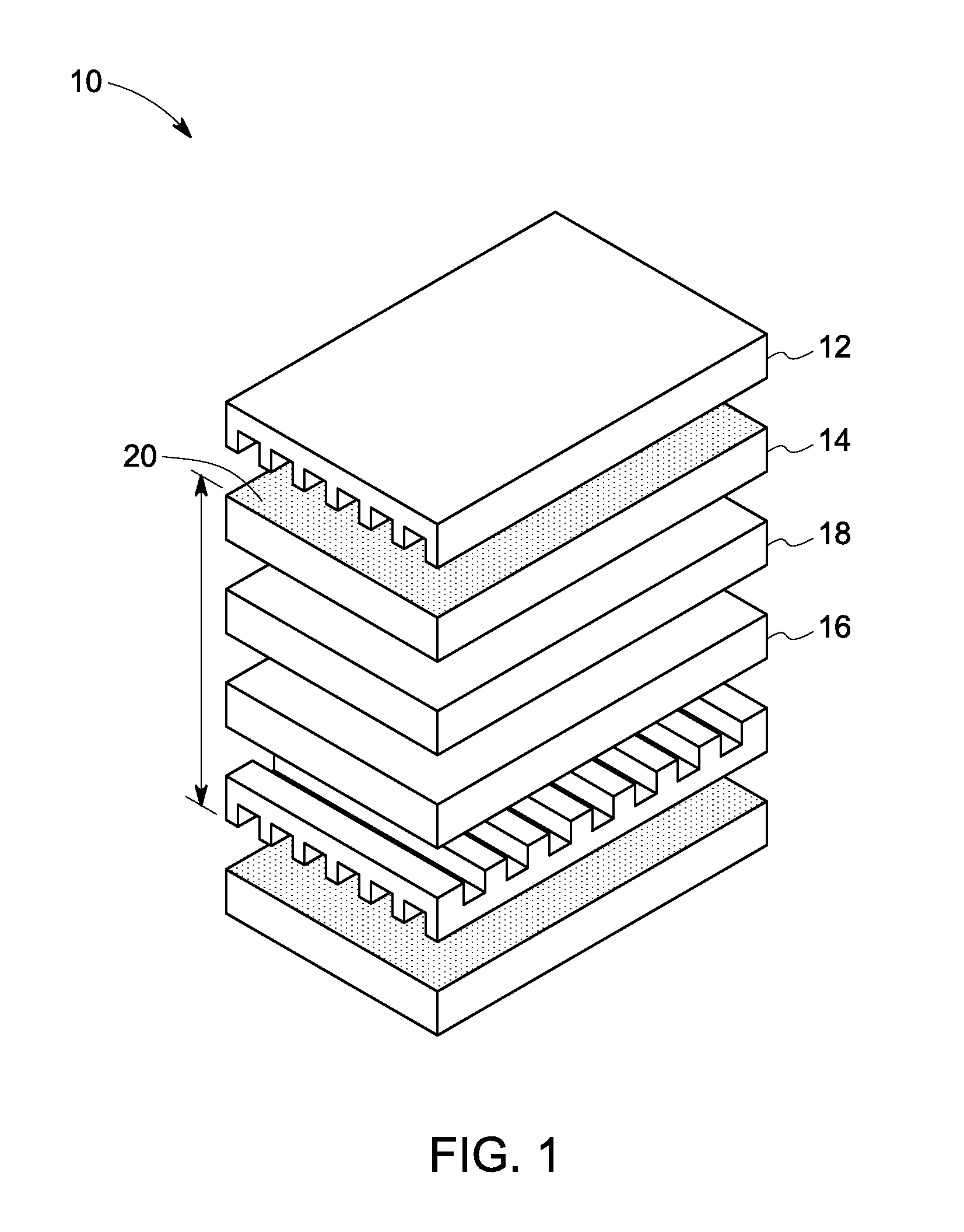

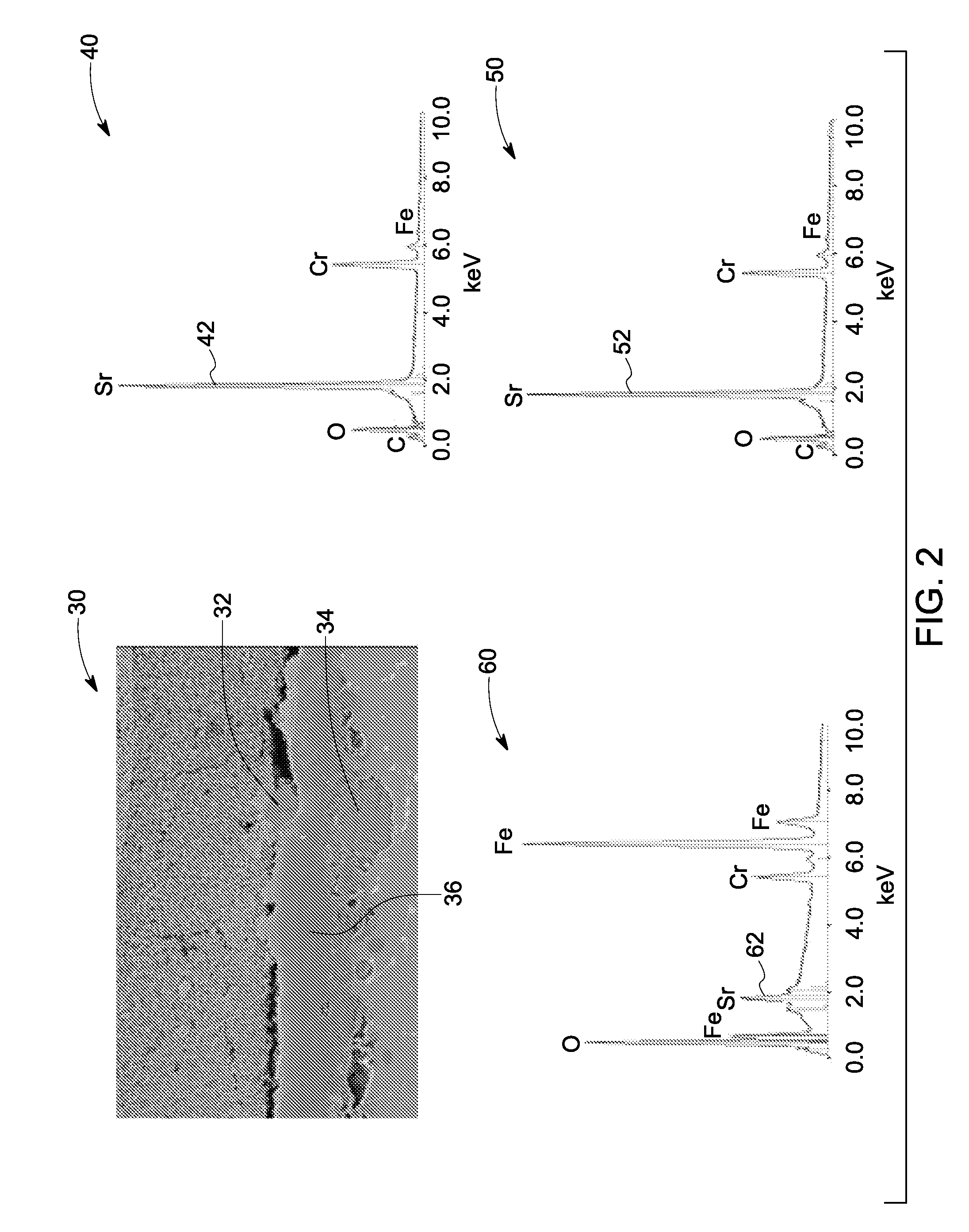

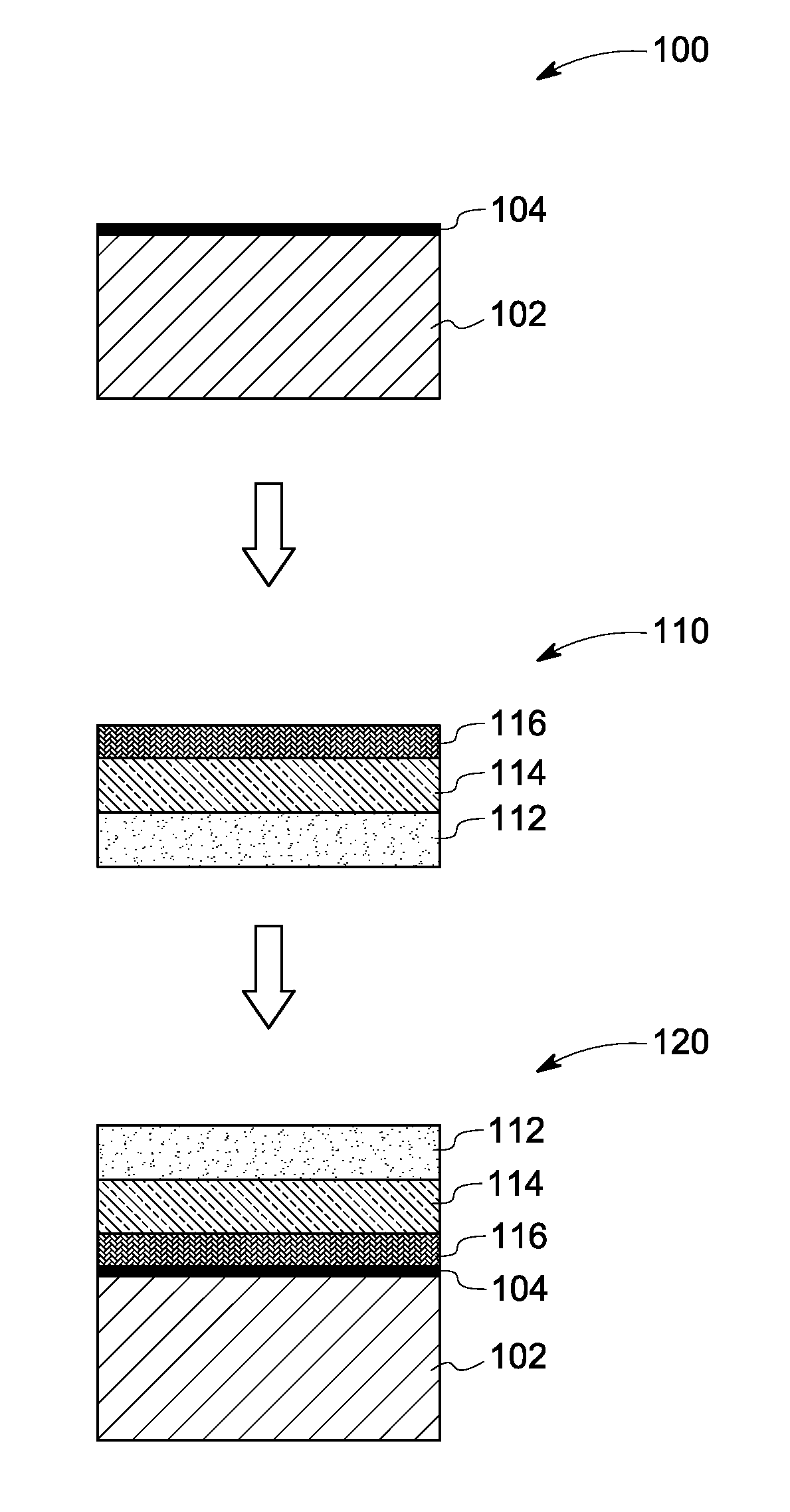

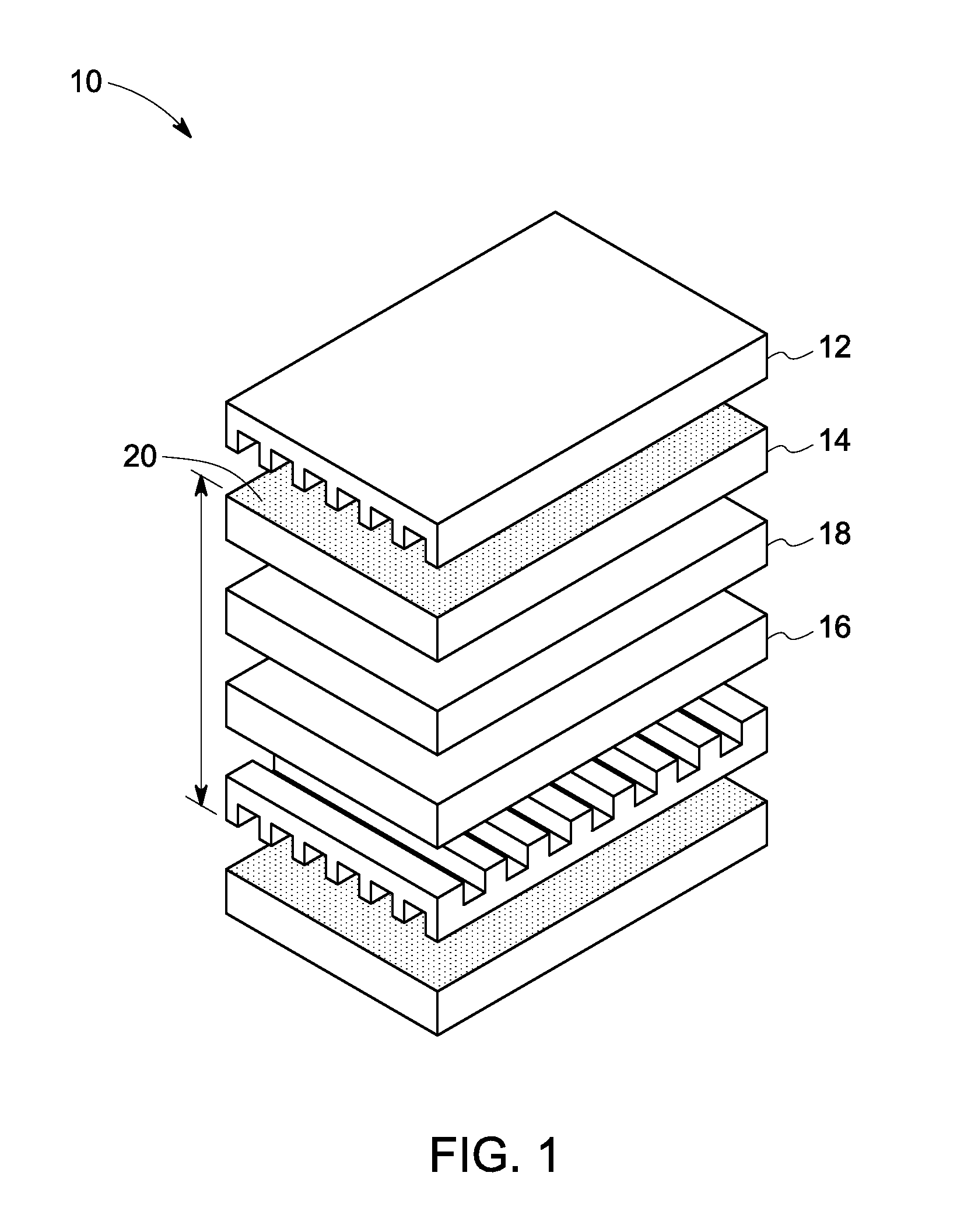

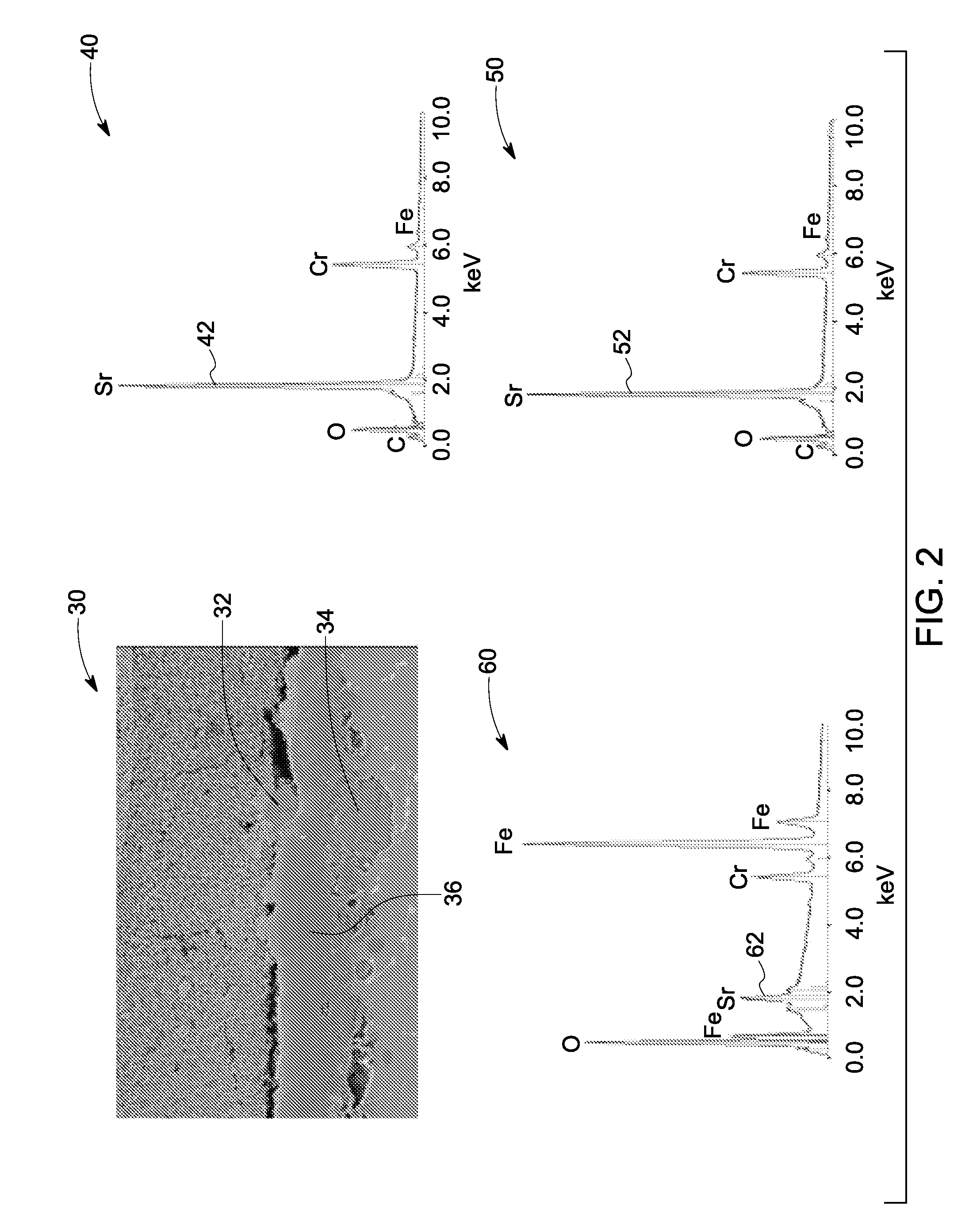

Barrier coatings for interconnects; related devices, and methods of forming

ActiveUS20100055533A1Inhibition formationMolten spray coatingVolume/mass flow measurementFuel cellsStrontium

A method of preparing a solid oxide fuel cell is described herein, as well as the fuel cell itself. The method comprises forming a cathode layer comprising a strontium composition on a ceramic electrolyte layer; and forming a barrier layer between the cathode layer and an overlying interconnect structure comprising chromium, so as to substantially prevent the formation of strontium chromate.

Owner:CUMMINS ENTERPRISE LLC

Epoxy organosilicon anticorrosion paint and preparing method thereof

InactiveCN101033370AImprove basic physical propertiesImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsTalcPhysical property

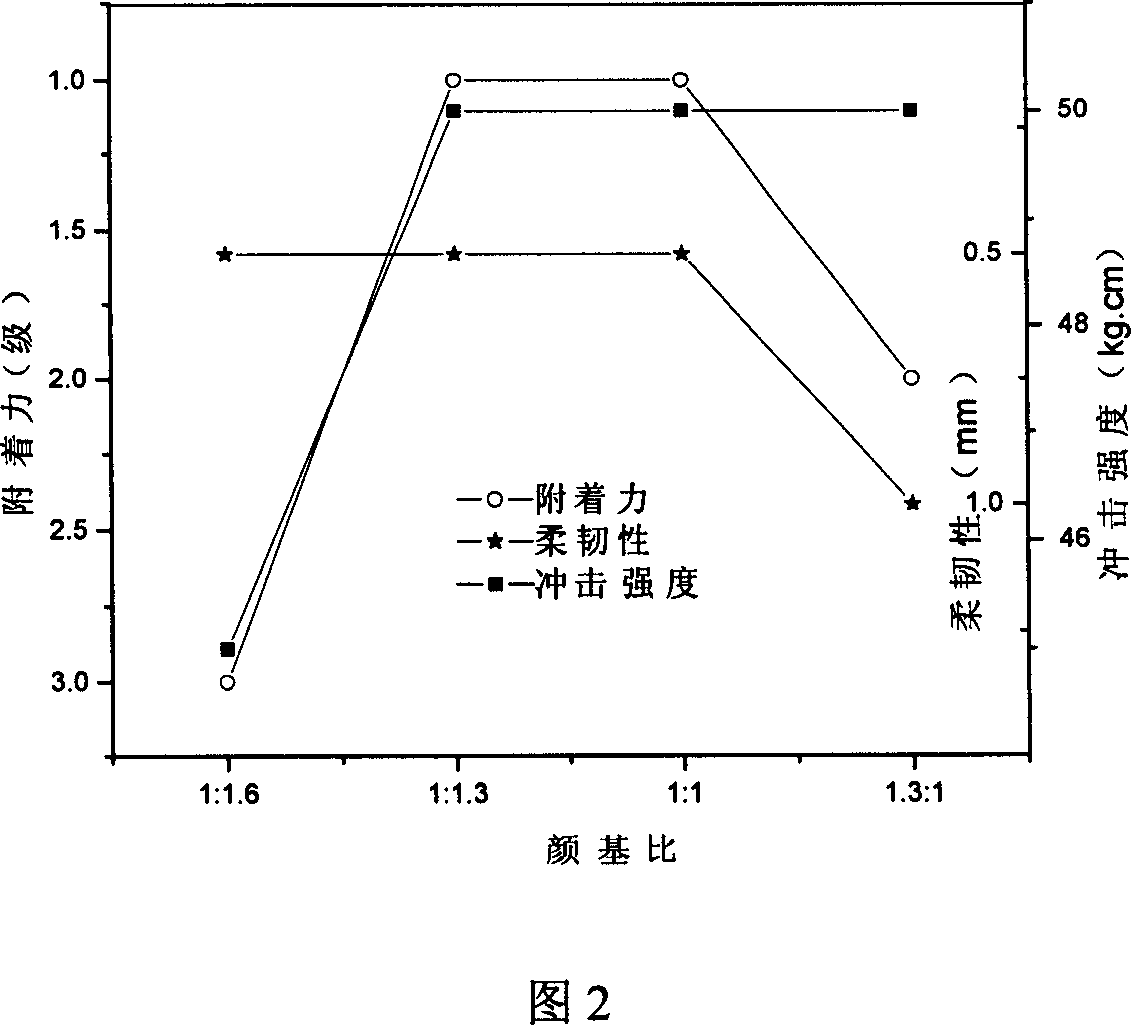

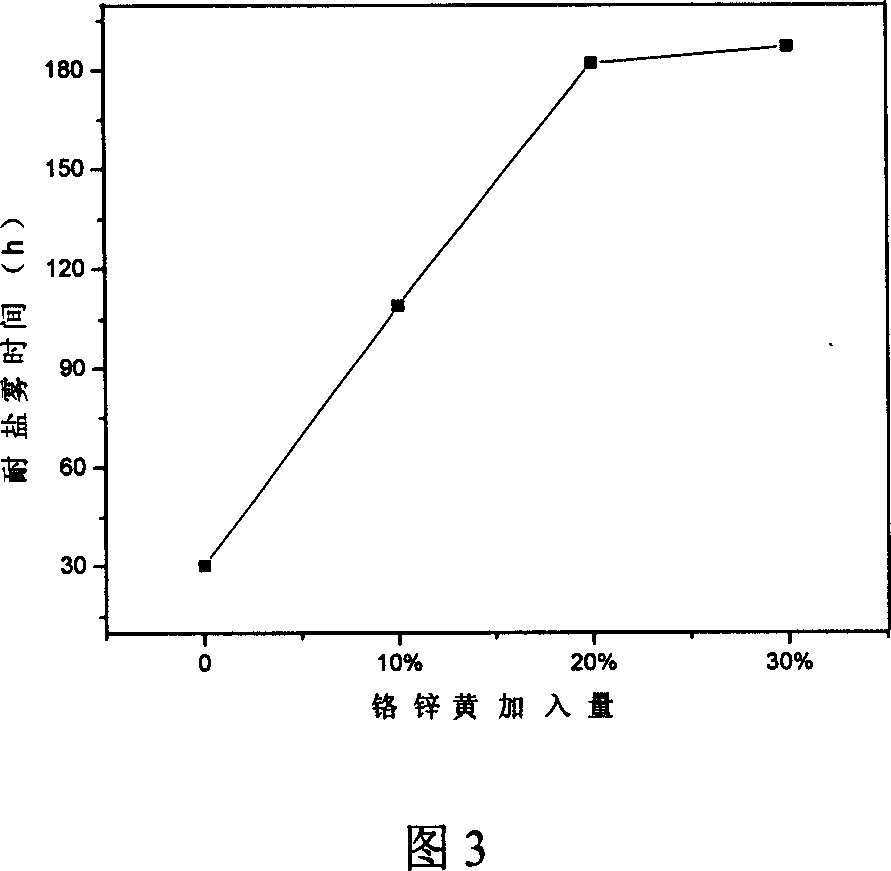

The invention relates to a kind of anti-corrosion epoxy-silicone resin coating and its preparation. In the invention, it takes the anti-corrosion epoxy-silicone resin ES-06 as material for the film, and polyamide 650 as curing agent, and it also includes anti-rust paint chrome yellow zinc, chromium and molybdenum acid strontium zinc, titanium dioxide pigments physique, mica, talc, defoamer 550, dispersant TM-950 and the solvent system of xylene and n-butyl alcohol. The advantage of the matiral is that the coating can be cured at room temperature, meanwhile, it has the properties such as the maximum adhesion of one class, a flexible of 0.5mm, a impact strength of 50kg.cm, a salt spray cumulative maximum time a 360 hours, and the coating has a good basic physical property and excellent corrosion resistance.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

Anti-corrosion paint capable of coating with rust

InactiveCN1821331AImprove permeabilityImprove rust resistanceAnti-corrosive paintsZinc phosphateManganese

The anticorrosive paint for painting on rusty surface consists of tong oil alcohol acid 40.0í½50.0 weight portions, anionic surfactant 0.4í½1.0 weight portions, anti-skimming agent 0.5í½2.0 weight portions, mixed drier 2.0í½5.0 weight portions, iron oxide red 10.0í½20.0 weight portions, zinc oxide 5.0í½10.0 weight portions, zinc tetrahydroxy yellow 2.0í½5.0 weight portions, strontium chromate 2.0í½5.0 weight portions, zinc phosphate 2.0í½3.0 weight portions, diphenyl guanidine chromate 2.0í½4.0 weight portions, toluene 15.0í½25.0 weight portions and xylene 6.0í½10.0 weight portions. The anticorrosive paint is suitable for rusty iron and steel surface, and may be painted on rusty surface to form corrosion inhibiting deactivating film to reach excellent antirust effect.

Owner:王新成

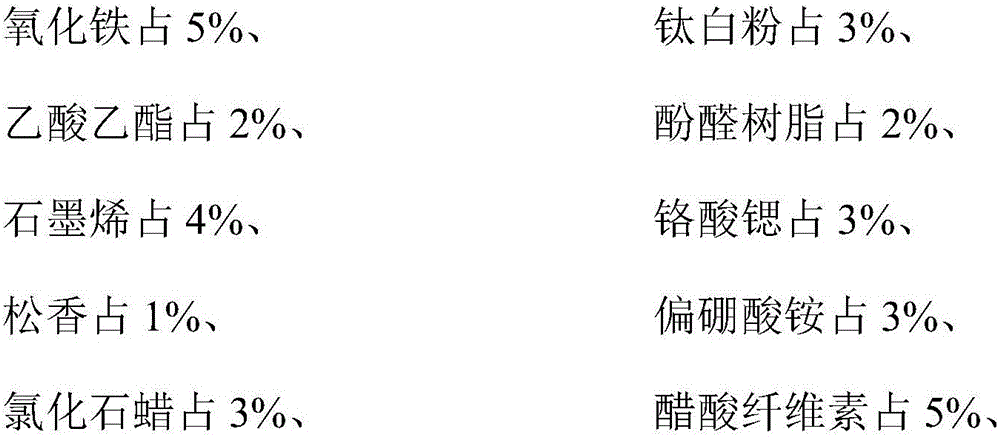

Rust-proof coating

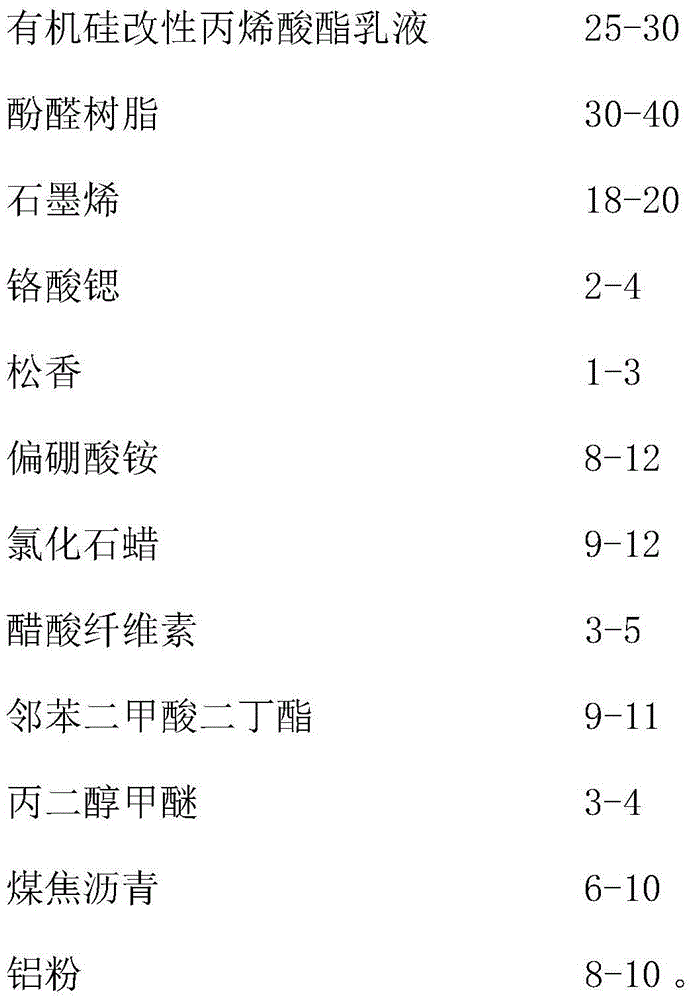

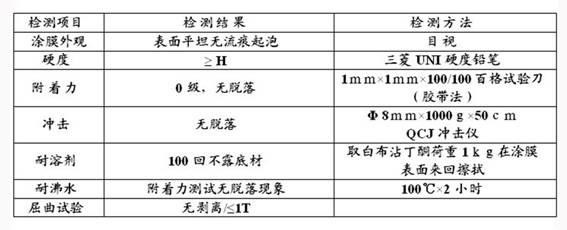

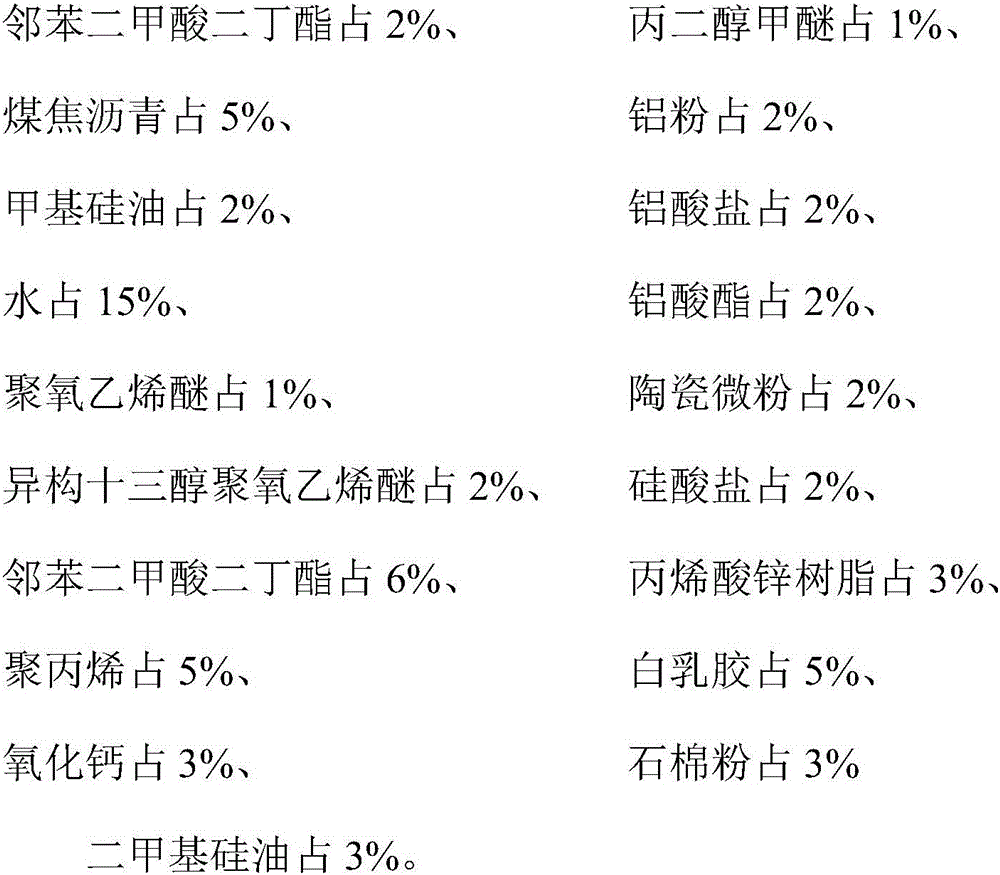

ActiveCN105602391ACorrosion resistanceWith wear resistanceAnti-corrosive paintsCellulose acetateRust

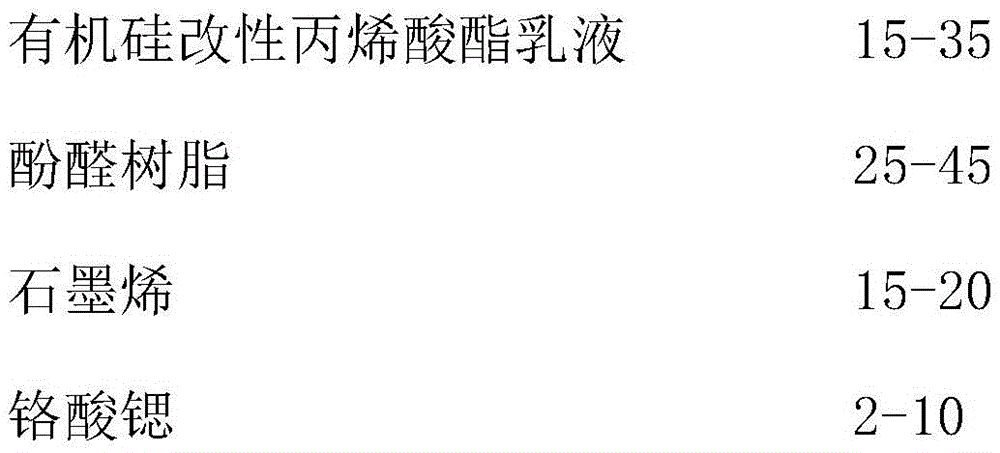

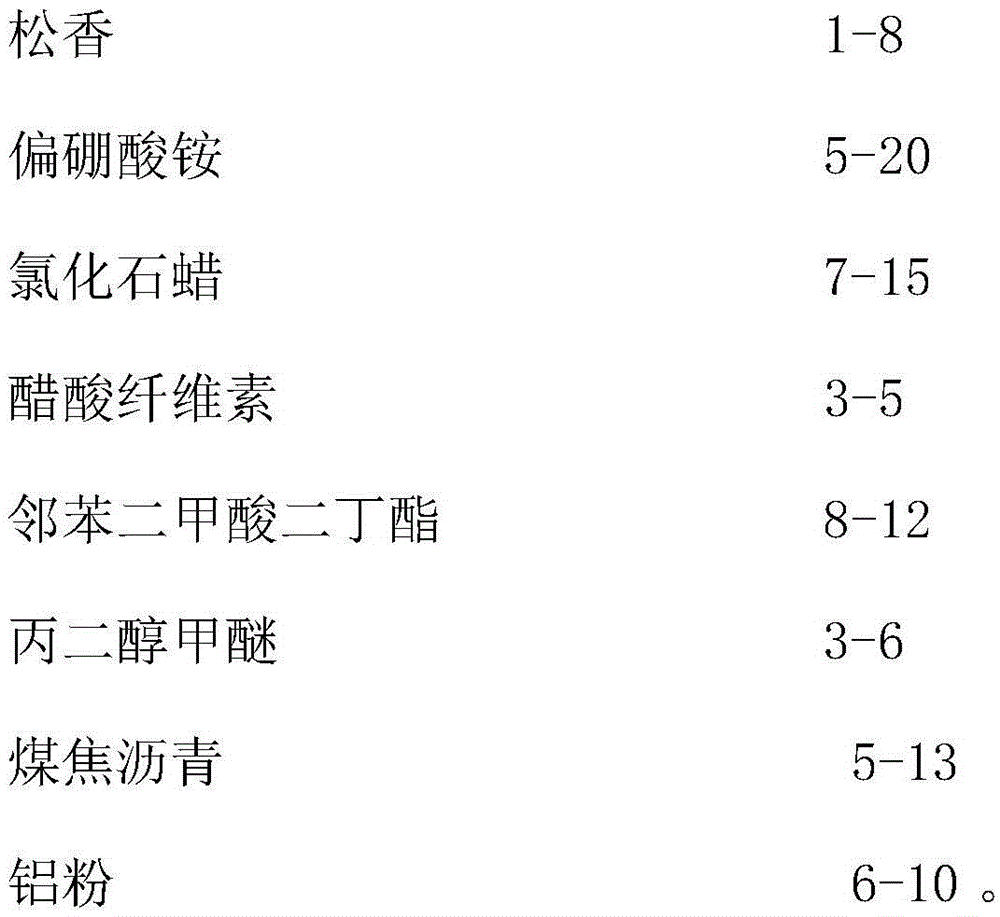

The invention discloses a rust-proof coating which is characterized by being prepared from, by weight, silicone modified acrylate emulsion, phenolic resin, grapheme, strontium chromate, rosin, ammonium metaborate, chlorcosane, cellulose acetate, dibutyl phthalate, propylene glycol monomethyl ether, coal tar pitch and aluminite powder. The rust-proof coating aims to overcome defects in the prior art and is simple in component, reasonable in matching and low in production cost. The invention further aims to provide a method for preparing the rust-proof coating.

Owner:邳州蒙特里安家具有限公司

Barrier coatings for interconnects; related devices, and methods of forming

ActiveUS8163434B2Inhibition formationMolten spray coatingVolume/mass flow measurementFuel cellsStrontium

A method of preparing a solid oxide fuel cell is described herein, as well as the fuel cell itself. The method comprises forming a cathode layer comprising a strontium composition on a ceramic electrolyte layer; and forming a barrier layer between the cathode layer and an overlying interconnect structure comprising chromium, so as to substantially prevent the formation of strontium chromate.

Owner:CUMMINS ENTERPRISE LLC

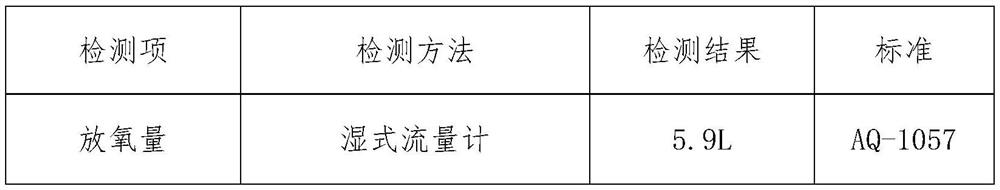

A kind of primer for building curtain wall aluminum veneer and preparation method thereof

InactiveCN102277068AImprove adhesionIncreased durabilityWallsGroup 5/15 element organic compoundsPhosphatePolyamide

The invention relates to a primer for building curtain wall aluminum veneers and a preparation method thereof. The primer includes 45% to 55% of saturated polyester resin, 4% to 6% of amino resin, and 1% of epoxy phosphate by weight percentage. %~1.5%, calcium ion exchange antirust pigment 5%~10%, titanium dioxide 10%~15%, kaolin 5%~10%, dispersant 0.5%~1%, silicon titanium or silicon zirconium type coupling agent 0.5%~2%, anti-settling agent 0.1%~0.3%, S-150 aromatic hydrocarbon solvent 5%~10%, ethylene glycol butyl ether 5%~10%; among them, the dispersant is polyamide-amide-amine type Dispersant; the anti-settling agent is fumed silica. The primer of the present invention abandons heavy metal compounds such as strontium chromate in the traditional formula, so it will not cause heavy metal pollution and is more environmentally friendly; the use of silicon-titanium or silicon-zirconium coupling agent makes the adhesion of the primer on the surface of the aluminum veneer strong For the increase, the durability is also better. The formula of the primer of the invention is reasonable, the preparation method is simple, and the primer has good protection performance for non-ferrous metal materials such as aluminum veneer and galvanized sheet.

Owner:苏州金近幕墙有限公司

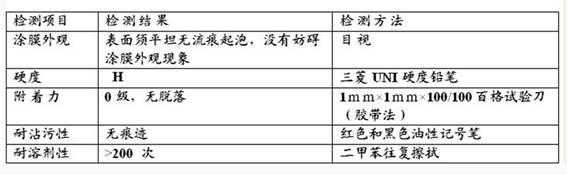

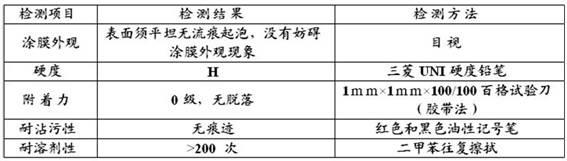

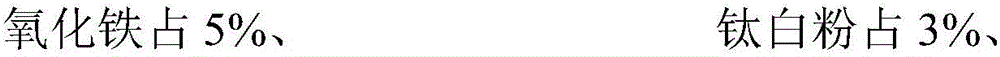

High-temperature-resistant metal rustproof paint

InactiveCN105860680AHas the function of waterproof and antirustGood adhesionFireproof paintsAnti-corrosive paintsPhenol formaldehyde resinAcetic acid

The invention discloses a high-temperature-resistant metal rustproof paint. The high-temperature-resistant metal rustproof paint is prepared from acrylic resin, epoxy resin, iron oxide, titanium dioxide, ethyl acetate, phenolic resin, graphene, strontium chromate, rosin, ammonium metaborate, chlorinated paraffin, cellulose acetate, dibutyl phthalate, propylene glycol monomethyl ether, coal tar pitch, aluminum powder, methyl silicone oil, aluminate, water, aluminate ester, polyoxyethylene ether, fine ceramic powder, iso-tridecanol polyoxyethylene ether, silicate, dibutyl phthalate, zinc acrylate resin, polypropylene, white emulsion, calcium oxide, asbestos powder and dimethyl silicon oil. Compared with the prior art, the high-temperature-resistant metal rustproof paint can resist the high temperature of 1500 DEG C or so, also has the waterproof and rustproof functions, is strong in adhesion, not likely to shed and convenient to use and has application and popularization value.

Owner:YANTAI MINWANG ELECTROMECHANICAL TECH CO LTD +1

Method for producing super conducting heat pipe

InactiveCN1673663AImprove explosive powerLong rangeIndirect heat exchangersHeat transfer modificationManganeseSodium superoxide

The production process of superconductive heat pipe includes the following steps: mixing any two of sodium superoxide, potassium dichromate or sodium, and strontium chromate, adding hydrochloric acid to react, adding water while heating to dissolve, cooling to crystallize, adding mercurochrome and dissolving in distilled water to prepare No. 1 medium; mixing any two of sesqui manganese hydride potassium dichromate or sodium, monocrystal silicon, beryllium oxide, barium oxide and sodium peroxide, adding titanium trichloride or butyl Rodan solution, letting stand to laminate, centrifuging to obtain crystal, diluting with absolute ethanol to obtain No. 2 medium; heating the No. 1 medium in metal pipe to exhaust air; adding No. 2 medium into the No. 1 medium, further heating and sealing metal end. Thus prepared superconductive pipe can meet the requirement of large heat supplying system.

Owner:刘锡汉

Anti-corrosion coating

InactiveCN104087070ALow costSimple preparation processAnti-corrosive paintsEpoxy resin coatingsSodium nitrateMethanol

The invention discloses an anti-corrosion coating comprising the following components in parts by weight: 8-12 parts of epoxy-acrylic acid, 2-4 parts of iron oxide, 2-4 parts of talcum powder, 4-8 parts of strontium chromate, 6-9 parts of tributyl phosphate, 2-8 parts of ethylene glycol-butyl ether, 8-16 parts of carboxymethyl cellulose sodium, 4-8 parts of dibutyl phthalate, 2-6 parts of ethylene glycol, 8-12 parts of ammonium phosphate, 4-12 parts of sodium nitrate, 6-8 parts of tributyl phosphate and 2-4 parts of methanol. The anti-corrosion coating disclosed by the invention is low in cost and simple in manufacturing process, and can be used for effectively preventing acid and alkali corrosion.

Owner:杨美

High-temperature-resistant powder coating

The invention discloses a high-temperature-resistant powder coating. The high-temperature-resistant powder coating is prepared from, by mass, 41-62% of solid silicone resin, 3-7% of a curing agent, 2.5-5% of strontium chromate powder, 3-7% of zinc phosphate powder, 26-39% of lamellar mica powder and 1-4% of other auxiliaries. The high-temperature-resistant powder coating can completely replace liquid paint for painting and has the advantages that no volatile organic solvent is contained, no toxin exists, and the '4E' green principle for environmental protection is met; the coating can be recycled, the coating without workpieces adsorbed can be sprayed again, and the utilization rate of the coating is close to 100%; the painting work environment is optimized, an operator only needs to wear a conventional dustproof mask, and no pungent smell or toxin caused by paint painting exists in a work site; the shelf life of the coating is prolonged and can reach up to 1 year; the requirement for pretreatment of workpieces in painting work is simple, and both sanding treatment and parkerizing treatment are allowed.

Owner:TAISHAN GUANG AN LIN CHEM CO LTD

Method for preparing wear-resistant anticorrosive conductive coating

InactiveCN107474697AImprove toughnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsWear resistantSlurry

The invention relates to the technical field of conductive coatings and in particular relates to a method for preparing a wear-resistant anticorrosive conductive coating. The method comprises the following steps: mixing perfluoroalkylpolyether, a modified organic silicone resin, bisphenol A epoxy resin and zinc powder, blending with biogas slurry to ferment, decomposing the modified organic silicone resin to produce hydroxyl, amino and alkoxy by utilizing microbes, introducing the hydroxyl, amino and alkoxy onto the surface of the epoxy resin under the self-crosslinking action of the microbes, and generating a block polymer, so that the finally prepared conductive coating has excellent wear resistance; adding a mixed solvent of ethyl acetate, methyl isobutyl ketone and methylbenzene as well as quartz sand powder, so that the anticorrosive property and wear resistance of the conductive coating is improved; and adding a certain amount of conductive zinc powder, copper powder, talcum powder and strontium chromate, so that the wear resistance and corrosion inhibition capacity of the conductive coating are further improved. The conductive coating has wide application prospects.

Owner:薛向东

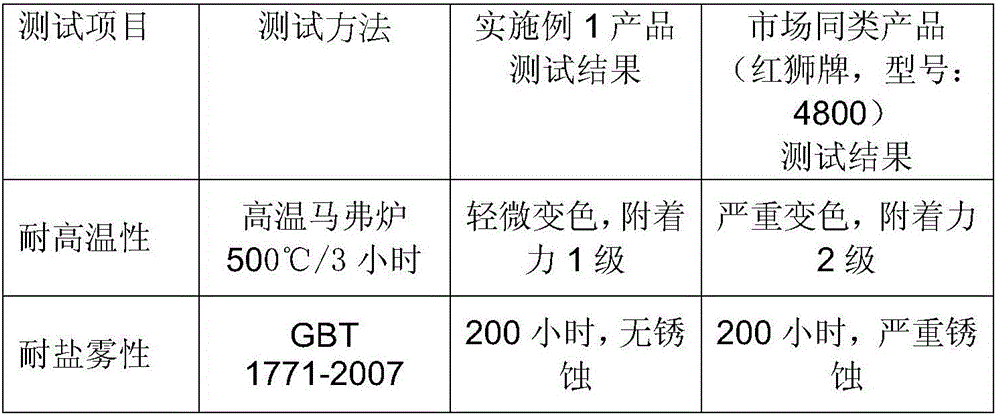

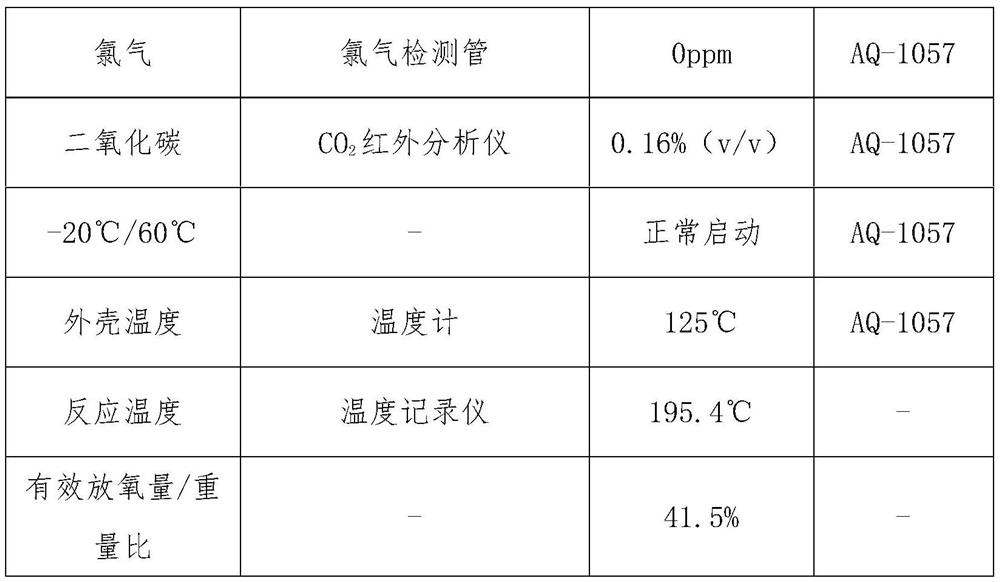

an oxygen candle

ActiveCN108083234BLower decomposition temperatureReduce demandOxygen preparationChlorate ionPtru catalyst

An oxygen-generating candle, comprising an absorption flammable layer, a heat generating layer and a main candle body layer; the heat generating layer is provided between the absorption flammable layer and the main body layer; according to mass percentage, the main body layer is made of 90% to 96% chlorate, 1.5% to 5% catalyst, 0 to 3% fuel, 1.5% to 2.5% binder and 0.5% to 1.5% stabilizer; the heat generating layer is made of 70% to 80% chlorate, 5% to 15% catalyst, 5% to 12% fuel and 3.0% to 6.0% binder; the absorption flammable layer is made of 5% to 15% fuel, 80% to 90% strontium chromate, 3% to 5% binder and 0 to 1% chlorate; the catalyst is a combination of two or more from among cobalt oxide, manganese dioxide and titanium oxide; the amount of catalyst in the main candle body layer is 4-5 times greater than the amount of the catalyst of the heating layer; the fuel comprises one or more from among magnesium powder, titanium powder, cobalt powder, and zirconium powder. Due to the adjustment of the type and proportion of the catalyst, the decomposition temperature of the oxidizing agent chlorate is lowered and the demand for an active metal of the flammable layer is lowered; in addition, the addition of a flame retardant may control the rate of energy release of the active metal.

Owner:SHAANXI STAR EXPLOSION SAFETY POLYTRON TECH INC

Epoxy priming paint

InactiveCN101205438ASolve the pollution of the environmentStrong adhesionPolyester coatingsEpoxyALUMINUM PHOSPHATE

The invention discloses paint, in particular epoxy primer used for back protection of a hot dipping plate, an aluminum-zinc plate, a cold rolling plate and an aluminum plate, etc. The paint comprises the following raw materials of corresponding part by weight: 0.3 portion of auxiliary agent, 50 portions of linear polyester resin, 6 portions of trimeric aluminum phosphate, 7 portions of zinc phosphate, 8 portions of titanium pigment, 8 portions of barium sulfate, 3 portions of zinc chrome yellow, 2.7 portions of strontium chromate, 0.3 portion of white carbon black, 10 portions of solvent, 4 portions of aminoresin, 1 portion of flatting antifoam agent and 0.4 portion of catalyst. The epoxy primer of the invention contains less volatile organic solvent than the prior products, thereby solving the problem that the prior products cause environmental pollution; moreover, the epoxy primer has strong adhesive force, excellent anticorrosion and salt - fog resistance and low cost.

Owner:解居会

Salt-fog-resistant phosphate modified acrylic waterborne antirust coating for building scaffold

InactiveCN109370349AImprove water resistanceImprove adhesionAnti-corrosive paintsLead ChromatePhosphate

The invention discloses a salt-fog-resistant phosphate modified acrylic waterborne antirust coating for a building scaffold. The salt-fog-resistant phosphate modified acrylic waterborne antirust coating is prepared from the following raw materials in parts by weight: 35-60 parts of salt-fog-resistant phosphate modified acrylic core-shell emulsion, 2-8 parts of cosolvent, 10-15 parts of cobalt naphthenate, 10-15 parts of lead chromate, 5-10 parts of iron laterite, 2-5 parts of strontium chromate, 1-3 parts of rosin, 2-9 parts of ammonium metaborate, 0.5-0.9 part of chlorinated paraffin, 0.3-0.6part of cellulose acetate, 0.2-1.2 parts of dibutyl phthalate, 0.2-1.5 parts of substrate modifier, 0.5-6 parts of auxiliaries and 12-35 parts of deionized water. According to the antirust coating disclosed by the invention, the adhesive force and compactness between a film and a substrate are enhanced, so that water molecules, chloride ions and sodium ions are effectively isolated from enteringbetween substrates, the adhesive force, water resistance and anti-flash rusting property of the film are improved in a wet environment, and the salt-fog-resistant phosphate modified acrylic waterborneantirust coating has good adhesive force, water resistance, salt fog resistance, anti-flash rusting property, acid and alkali resistance and corrosion resistance.

Owner:ANHUI ZULIN NEW MATERIALS

Anticorrosion decorative paint

InactiveCN103834246AImprove adhesionImprove impact resistanceAnti-corrosive paintsEpoxyWater dispersible

The invention discloses an anticorrosion decorative paint, which is mainly composed of a water dispersible epoxy-acrylic emulsion, iron red, strontium chromate, talcum powder, a dispersing agent, an anti-settling agent, a wetting agent, a film-forming auxiliary agent, and distilled water. The paint provided by the invention has good adhesion, and has good impact resistance, wear resistance, weather resistance, corrosion resistance and good environmental adaptability. The anticorrosion decorative paint has the characteristics of high strength, good chemical resistance and corrosion resistance of epoxy resin, and also has the characteristics of high gloss and good weather resistance of acrylic resin, thus being widely applicable in household appliances and instruments, etc.

Owner:HARBIN TAOYI ADVERTISING DECORATION ENG

Sun-resistant anti-ageing glass container and preparation method thereof

The invention discloses a sun-resistant anti-ageing glass container and a preparation method thereof. The glass container is prepared from the following raw materials in parts by weight: 33-46 parts of quartz powder, 8-14 parts of zinc borate, 14-26 parts of astrophyllite, 16-28 parts of monazite, 6-12 parts of bismuth vanadate, 22-34 parts of chalk powder, 4-7 parts of lanthanum hydroxide, 5-8 parts of strontium chromate, 3-5 parts of soda ash, 24-36 parts of gold tailings, 19-27 parts of siltstone, 4-6 parts of potassium pyrosulfate, 10-15 parts of nitronatrite, and 5-8 parts of an auxiliary agent. By adding bismuth vanadate, strontium chromate, zinc borate and other raw materials into the glass container, the glass container is enhanced in light ageing resistance and endurance, does not crack under long-term irradiation of daylight, and is durable. The glass container produced by employing the technology is resistant to light ageing, resistant to corrosion, resistant to impaction, high in mechanical strength, and greatly expanded in applicable scope.

Owner:安徽鑫民玻璃股份有限公司

Anti-corrosion aluminum coating for titanium alloy connecting part for aluminum alloy composite structure

InactiveCN110684423APrevent Galvanic CorrosionImprove high temperature resistanceFireproof paintsAnti-corrosive paintsPolyamideEthylic acid

The invention relates to an anti-corrosion aluminum coating for a titanium alloy connecting part for an aluminum alloy composite structure. The coating comprises the following material components in parts by weight: 300-600 parts of aluminum slurry, 400-1000 parts of strontium chromate, 0-300 parts of zinc chromate. 0-260 parts of molybdenum disulfide, 1000-4000 parts of thermal-resistant phenolicresin, 1000-8000 parts of ethylene glycol monoethyl ether acetate, 50-200 parts of polytetrafluoroethylene, 20-60 parts of bentonite, 60-120 parts of a polyamide wax liquid variation aid and 10-20 parts of a leveling agent. The coating is applicable to surface coating to a titanium alloy fastener, a titanium alloy pivot, and the like, is capable of preventing dissimilar metal galvanic corrosion of other metals such as an aluminum alloy with titanium alloy connecting parts, in addition, has very good high temperature resistance, paint peeling agent resistance and self lubrication performance.

Owner:沈阳市航达科技有限责任公司

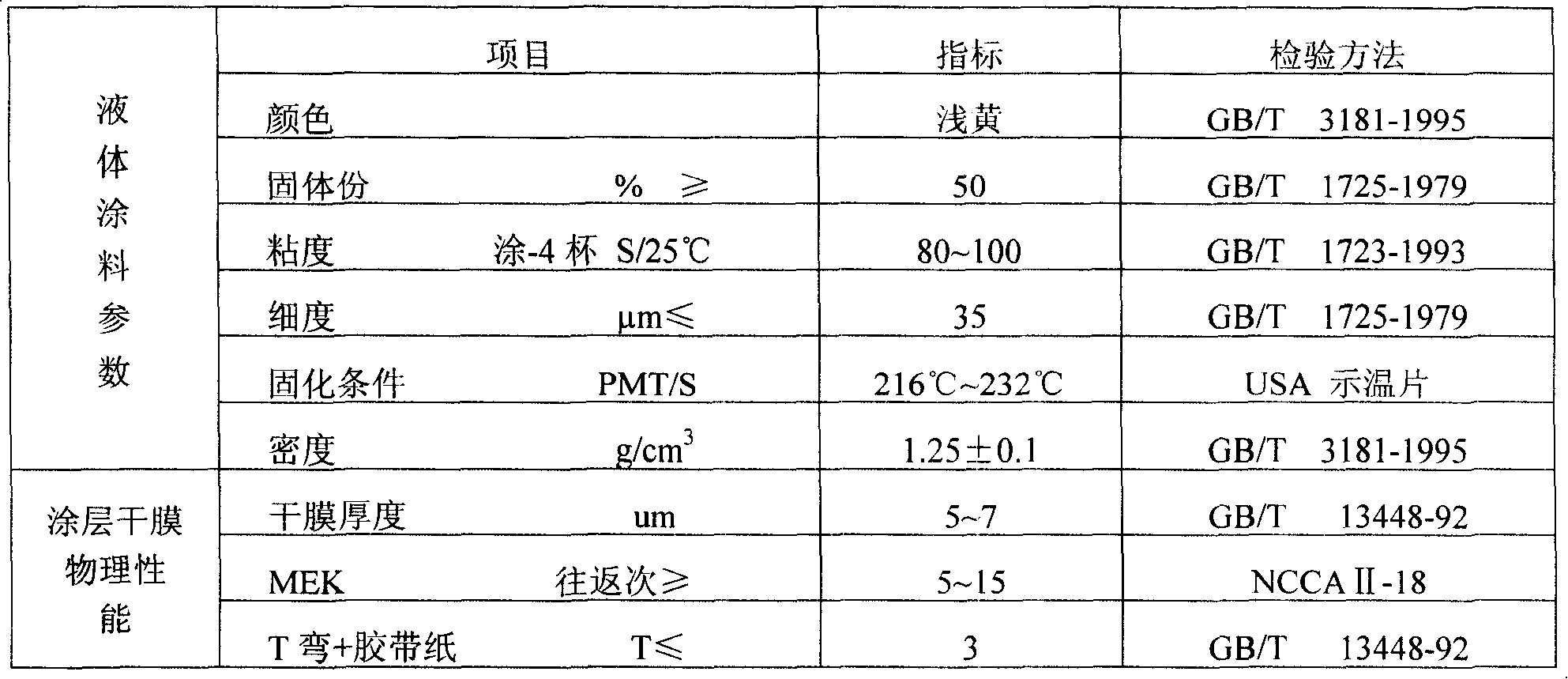

Installation cable for electric power distribution cabinet

InactiveCN106084479ASoft textureExcellent flame retardantPlastic/resin/waxes insulatorsClimate change adaptationDiacetone alcoholPhosphate

The invention relates to an installation cable for an electric power distribution cabinet. The installation cable comprises a plurality of copper alloy wires and protective sheaths, wherein the copper alloy wires are arranged in parallel to each other, and the outer layer of each copper alloy wire is coated with the protective sheath; each protective sheath comprises the following components: polypropylene resin, aldehyde resin, brominated bisphenol A epoxy resin, Litsea cubeba oil, 4-hydroxy-4-methyl-2-pentanone, castor oil, amyl propionate, propiconazole, sodium monofluorophosphate, carbendazim, tetramethyl thiuram disulfide, tourmaline powder, molybdenum disilicide powder, titanium dioxide powder, weathered coal, corundum powder, sodium zirconate powder, strontium chromate powder, silica gel powder, tris(2-chloroethyl) phosphate, hexabromo-benzene, modacrylic, decabrominated iphenyl ethane, diaminodiphenyl methane, diphenyl silanediol, diphenylmethane bismaleimide, diacetone alcohol, dibutyltin dilaurate, diethylene glycol dibenzoate, and dimethyl ketoxime. The installation cable provided by the invention has the advantage of improving the operation performance of a product.

Owner:虞永华

Formula of waterborne epoxy polyester dipping coating

ActiveCN105969106AHigh solid contentReduce viscosityAnti-corrosive paintsEpoxy resin coatingsPolyesterEpoxy

The invention discloses a formula of a waterborne epoxy polyester dipping coating. The waterborne epoxy polyester dipping coating comprises the following raw materials: 30 to 40 parts of waterborne epoxy polyester emulsions, 4 to 8 parts of iron oxide black, 1 to 1.5 parts of talcum powder, 2 to 3 parts of dispersants, 3 to 7 parts of distilled water, 0.5 to 1 part of an anti-settling agent, 0.1 to 0.3 part of a defoaming agent, 0.2 to 0.8 part of ethylene glycol, 1 to 3 parts of amino resin, 2 to 3 parts of carbon black, and 1 to 1.5 parts of strontium chromate. All the raw materials are calculated in parts by mass. Preferably, the waterborne epoxy polyester dipping coating comprises 35 parts of the waterborne epoxy polyester emulsions in parts by mass. The waterborne epoxy polyester dipping coating prepared by the formula disclosed by the invention has the advantages of high solid content and low viscosity, and further has the advantages of high impact resistance and corrosion resistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Special high-temperature-resistant and high-absorption coating for die-casting mold

InactiveCN107641431AImprove high temperature resistanceHigh viscosityEpoxy resin coatingsCrack resistanceMelamine phosphate

The invention discloses a special high-temperature-resistant and high-absorption coating for a die-casting mold. The special high-temperature-resistant and high-absorption coating is prepared from thefollowing materials of: epoxy resin, silicone acrylic emulsion, deionized water, polydimethylsiloxane, dipentaerythritol, compound inorganic pigment, strontium chromate powder, magnesium oxide powder, graphite powder, yttrium oxide, sodium citrate, melamine phosphate, lamellar mica powder, calcium formate, nano silicon carbide powder, rare-earth cerium fluoride, curing agent, adhesion promoter, viscosity regulating solvent, dispersing agent, leveling agent, coupling agent, defoaming agent and additive. The special high-temperature-resistant and high-absorption coating disclosed by the invention has the characteristics of good high-temperature resistance, ageing resistance and fatigue resistance, also has the advantages of high viscosity and crack resistance and the like; in addition, thecoating film is dense and neat and the adhesion is excellent.

Owner:李景春

Water-based flash-rust inhibitor and application thereof

InactiveCN105820633AExcellent flash rust inhibition effectNo flash rustAnti-corrosive paintsEpoxy resin coatingsWater basedElectron

The invention provides a water-based flash-rust inhibitor and application thereof. The water-based flash-rust inhibitor is prepared from, by weight, 2-10 parts of organic amine of lone pair electrons, 2-8 parts of an inorganic salt type corrosion inhibitor and 1-20 parts of a flash-rust inhibitor and further contains 15-30 parts of strontium chromate. The water-based flash-rust inhibitor serves as the flash-rust inhibitor to be applied to water-based paint. The water-based flash-rust inhibitor has an excellent flash-rust inhibiting effect, can still guarantee that no flash-rust phenomenon is produced in the construction process of the water-based paint in extreme construction environments, such as a low-temperature and high-humidity environment and a high-temperature and low-humidity environment and is good and stable in flash-rust inhibiting effect. The water-based flash-rust inhibitor is especially applied to water-based acrylic paint or water-based alkyd paint. The water-based paint added with the water-based flash-rust inhibitor is coated on a metal base material during construction, has a very good flash-rust inhibiting effect, and especially for steel parts, particularly the steel parts subjected to submerged-arc welding, has a very good flash-rust inhibiting effect.

Owner:SICHUAN YANDING WATER BASED ENVIRONMENT FRIENDLY PAINT CO LTD

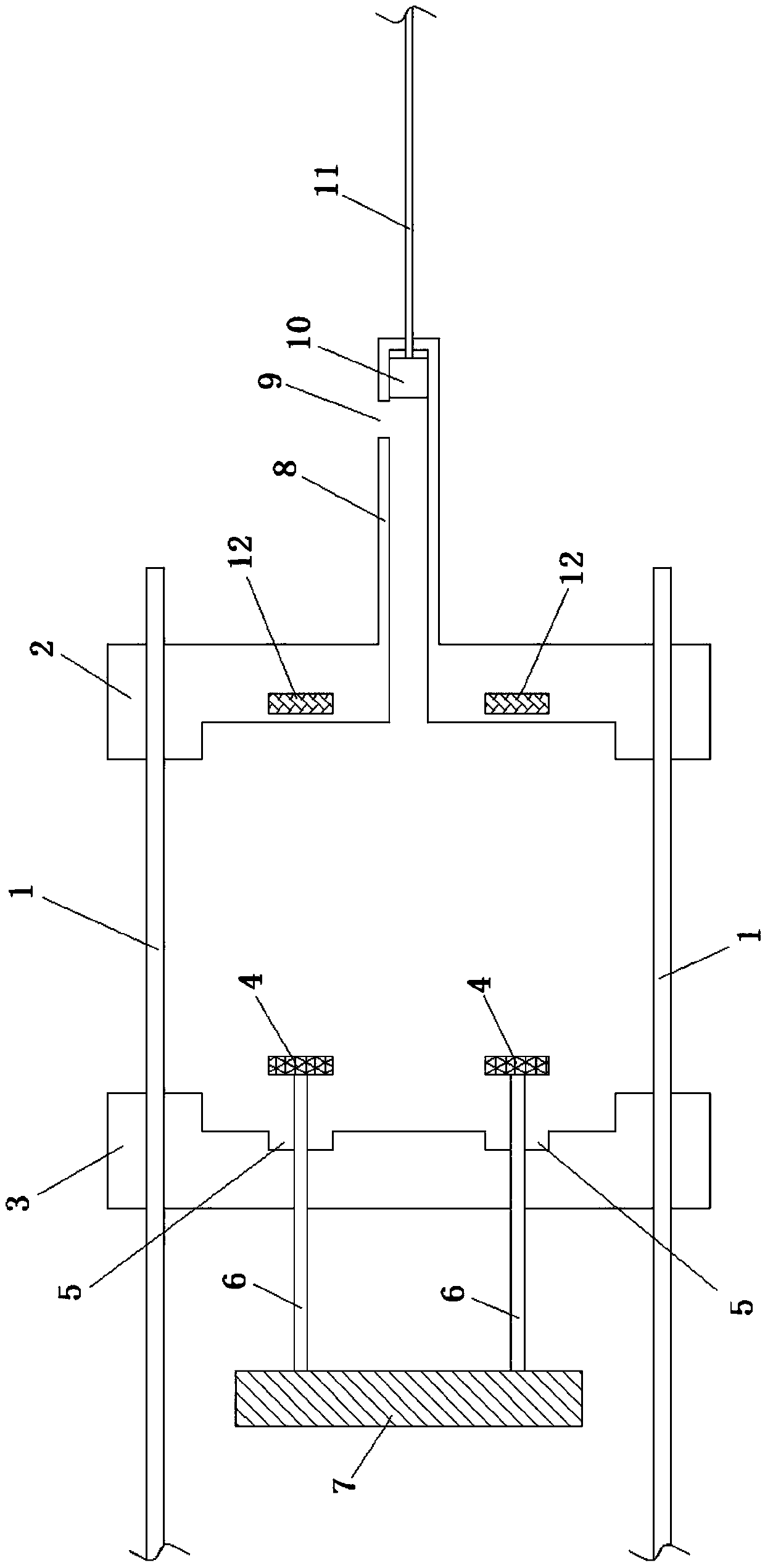

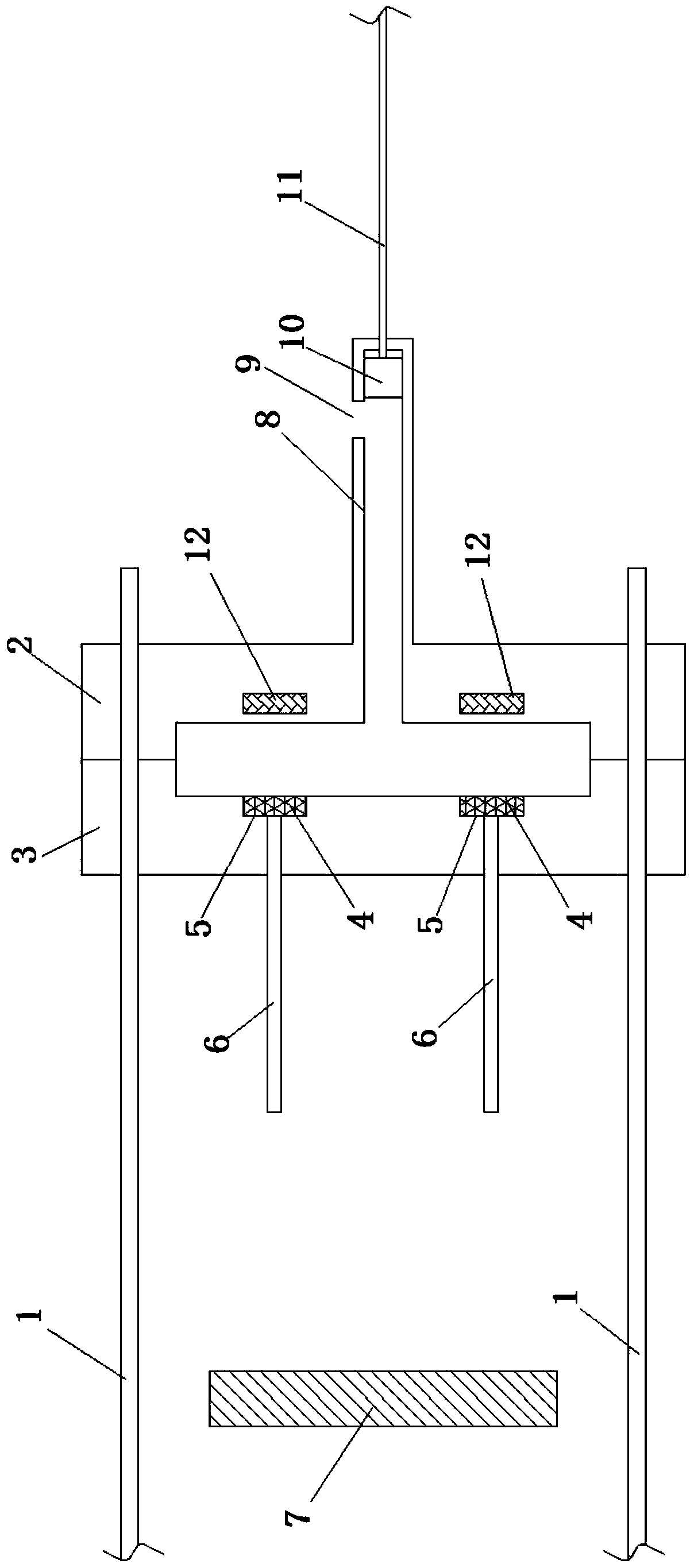

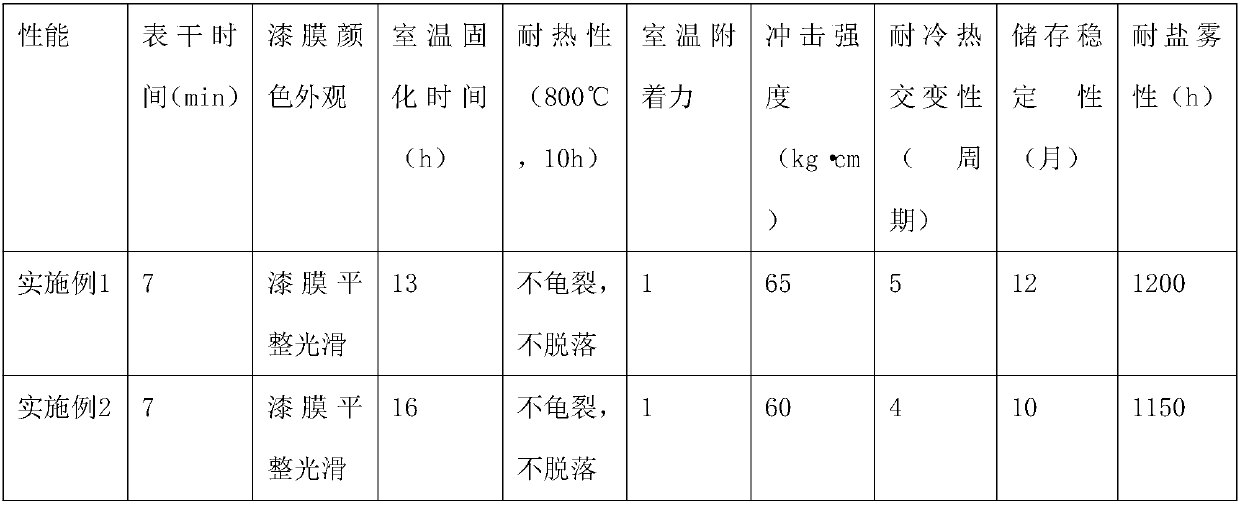

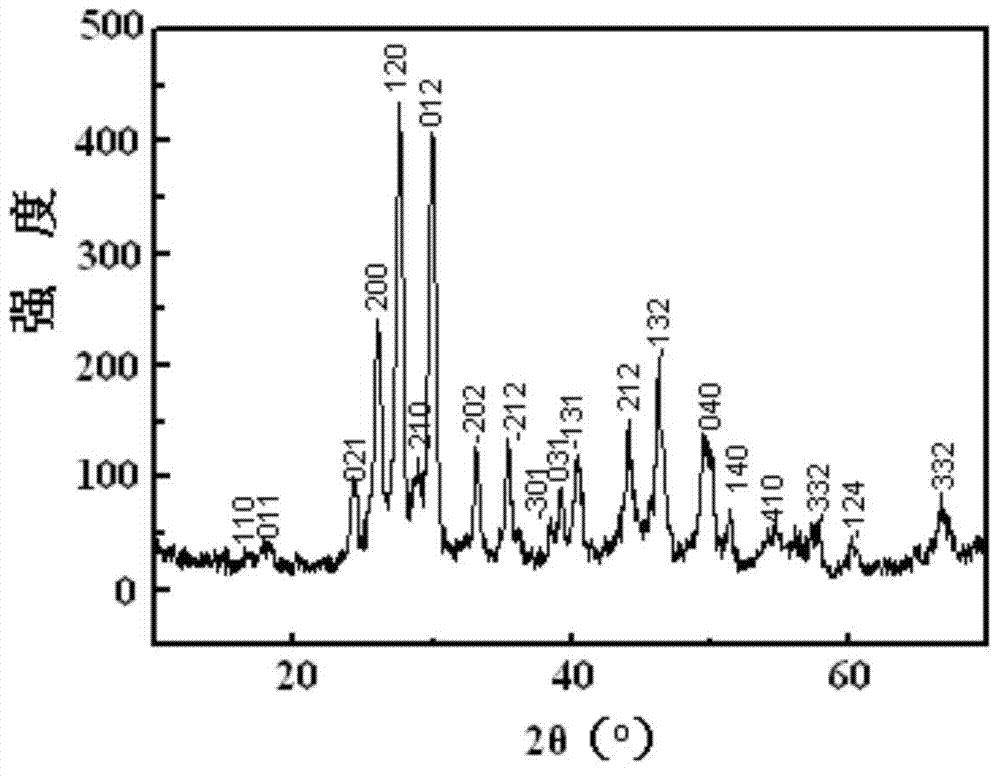

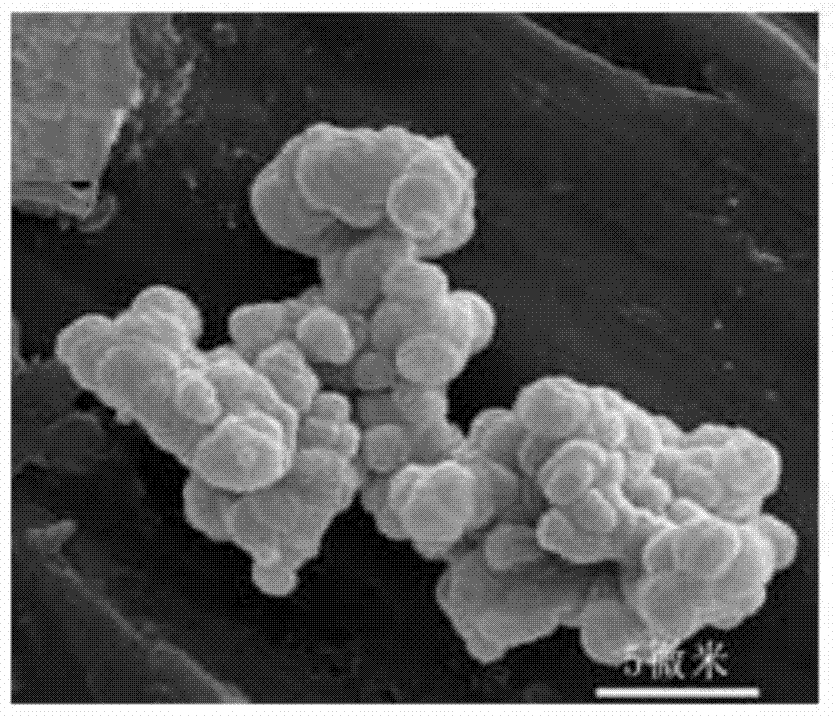

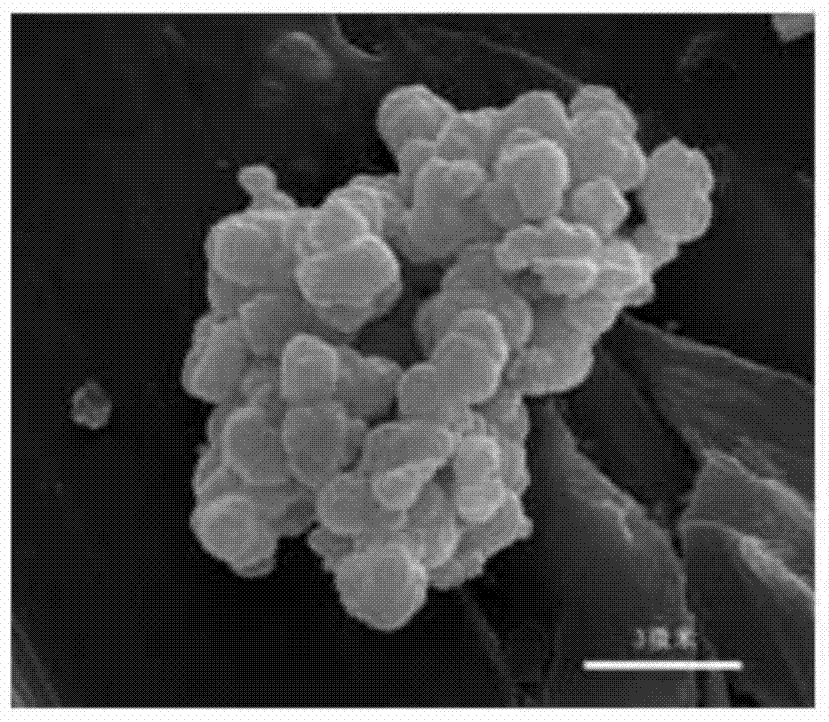

Preparation method of spherical strontium chromate powder controllable in micron-sized crystal growth morphology

ActiveCN103496743AMild and easy to controlLow costChromates/bichromatesRoom temperatureCrystal growth

The invention relates to a preparation method of inorganic non-metallic powder, in particular to a preparation method of spherical strontium chromate powder controllable in micron-sized crystal growth morphology, in order to solve the technical problems that an existing method for preparing the strontium chromate powder is complicated in technique, growth morphology under the condition of not adding active additives is mostly linear or rod-like and the strontium chromate powder micro-sized spherical in growth morphology cannot be obtained. The method includes: firstly, preparing a sodium chromate solution; secondly, preparing a mixed solution A; thirdly, preparing a mixed solution B; fourthly, preparing the spherical strontium chromate powder controllable in the micron-sized crystal growth morphology. Preparation is carried out only at the room temperature, conditions are mild and easy to control, cost is low, the preparation method is simple, and mass production is facilitated; the prepared strontium chromate powder is controllable in particle morphology and size, excellent in performance and capable of achieving large-scale batch production. The preparation method is applied to the field of preparation of the inorganic non-metallic powder.

Owner:HARBIN INST OF TECH

Preparation method of water-based epoxy ester rust-surface primer

InactiveCN108948963AAvoid defectsLow VOC contentAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a preparation method of a water-based epoxy ester rust-surface primer, relating to the technical field of antirust treatment of a metal surface. The preparation method comprises the following steps: firstly, mixing the water-based epoxy ester resin with a dryer, then mixing with a dispersant, pigment and filler and antirust pigment, then blending a film-forming assistant, adefoaming agent and a leveling agent into the mixture, regulating pH value and then blending a rust transforming agent, deionized water and thickening agent into the mixture, to obtain the water-based epoxy ester rust-surface primer, wherein the rust transforming agent contains strontium chromate and composite phosphate. No gas is generated in production technology, the defects of the phosphate rust transforming agent can be avoided, and the prepared product can be applied to rusted base material surfaces which are not subjected to sandblasting derusting and are only subjected to simple treatment, and has excellent adherence force with rusted base material. The product is high in surface treatment tolerance, provides good anti-corrosion protection for protected articles after being directly coated on the rusted base material surfaces, and is good in product application property and anti-corrosion property.

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

High-temperature-resisting powder coating

InactiveCN108250949AExtended shelf lifeAvoid the problem of easy gelation and deterioration during storagePowdery paintsHyaluronic acid coatingsPolyvinyl alcoholPolytetrafluoroethylene

The invention provides high-temperature-resisting powder coating. The high-temperature-resisting powder coating is prepared from the following raw materials: organic silicon resin, silicon micro-powder, strontium chromate, zinc phosphate, sheet-shaped mica powder, zeolite, glass powder, polytetrafluoroethylene wax, chitosan, polyphenylmethylsiloxane, polyvinyl alcohol and aluminum nitride. Compared with the prior art, the high-temperature-resisting powder coating has the following beneficial effects that the quality guarantee period of the coating is prolonged and can reach 1 year; the problemof existing paint coating that the paint coating is easy to gelatinize and go bad in a storage period is avoided; the gloss retention rate is greater than or equal to 50 percent and the attachment force is less than or equal to grade 2 under the condition that the coating is baked at high temperature of 500 DEG C for 24h. The temperature-resisting performance is greatly improved.

Owner:夏百庆

Temperature indicating paint

The invention discloses temperature indicating paint. The temperature indicating paint comprises the components in parts by weight as follows: 12-18 parts of phthalocyanine green, 4-8 parts of butanol, 4-12 parts of tetraethyl orthosilicate, 2-4 parts of cadmium red, 2-4 parts of talcum powder, 1-3 parts of grass green paint, 6-12 parts of lead carbonate, 4-8 parts of strontium chromate and 6-9 parts of tributyl phosphate. The temperature indicating paint is low in cost, simple in producing technology and capable of changing colors along with temperatures of the outside.

Owner:李忠平

Stabilizing aqueous anionic resinous dispersions with chelating agents

Owner:PPG IND OHIO INC

Super heat transfer working medium, super heat conducting element and manufacturing method of super heat conducting element

InactiveCN106147723AExtended service lifeGood application effectChemical industryIndirect heat exchangersBoron carbideSilicon oxide

The invention discloses a super heat transfer working medium, a super heat conducting element and a manufacturing method of the super heat conducting element. According to the super heat transfer working medium, one or more inorganic salts are added into one or more common heat transfer mediums; the common heat transfer mediums are sodium, naphthalene, potassium, cesium, heat conducting oil, water, mercury, acetone, ammonia, methyl alcohol, ethyl alcohol, F-22(monochlorodifluoromethane), ethane, nitrogen, biphenyl or dowtherm; the inorganic salts are manganous-manganic oxide, cobalt oxide, beryl, cobalt blue, cadmium borate, tungsten cadmium borate, potassium titanate, boron carbide, tantalum oxide, ferroferric oxide, titanium dioxide, silicon dioxide, zirconium dioxide, zirconium trioxide, strontium chromate, lithium metaaluminate, sodium dichromate, potassium dichromate, titanium oxide, yttrium oxide, beryllium oxide, ytterbium oxide, dysprosium oxide, boron oxide, silicon oxide or aluminum oxide. The heat transfer capacity of the common heat transfer working mediums is greatly improved, heat transfer efficiency is improved, the application temperature range of heat transfer is widened, and the pressure intensity of the working state is reduced.

Owner:中能国业(北京)科技有限公司

Anti-corrosion paint for copper

ActiveCN103666228AImprove bindingImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsXylyleneDiacetone alcohol

Anti-corrosion paint for copper comprises components in parts by mass as follows: 100 parts of methacrylic resin, 30-50 parts of isocyanate, 15-20 parts of n-butyl acetate, 20-25 parts of silicon dioxide, 10-15 parts of xylene, 20-25 parts of strontium chromate, 8-10 parts of a curing agent, 15-20 parts of carbon black, 25-30 parts of titanium dioxide, 0.1-1 part of tetraisopropyl titanate, 10-20 parts of methyl isobutyl ketone, 5-10 parts of cadmium yellow and 10-15 parts of diacetone alcohol. A product has a good binding force with copper, the adhesion reaches level 1; the weather resistance is high, and light is maintained; and the product is good in corrosion resistance, is resistant to acid rain corrosion, and can be widely produced and replace the conventional materials continuously.

Owner:江苏鑫美特金属科技有限公司

Stabilizing aqueous anionic resinous dispersions with chelating agents

ActiveUS20090045065A1Minimize presenceElectrolysis componentsVolume/mass flow measurementPigmentStrontium chromate

Owner:PPG IND OHIO INC

Power cable for water conservancy hydropower stations

InactiveCN106065166ASoft textureExcellent flame retardantPlastic/resin/waxes insulatorsInsulated cablesDecabromobiphenyl etherPolymethyl methacrylate

The invention relates to a power cable for water conservancy hydropower stations. The power cable comprises a plurality of copper alloy wires and a protective sheath which is composed of: polyethylene glycol terephthalate, polymethyl methacrylate, polyether sulfone, basic oil, tangerine oil, polypropylene glycol, polyglycerol polyricinoleate, polyvinyl acetate emulsion, nano zirconium phosphate silver-supported antibacterial agent, butylparaben, borax powder, cyanoethyl cellulose, pure calcium aluminate cement, lead difluoride powder, zirconium dioxide powder, bee wax, kaolin powder, strontium chromate powder, wollastonite powder, zirconium silicate powder, hexamethylene diisocyanate, zinc hydroxystannate, decabrominated diphenyl ether, sodium antimonate, N-phenyl-2-naphthylamine, N-methyl-2-pyrrolidone, N-tert-butyl-2-benzothiazole sulfenamide, N-nitroso-dimethylamine, [alpha]-cyano-acrylate, and [gamma]-(2,3-epoxypropoxyl)propyltrimethoxylsilane. The power cable is improved in use performance.

Owner:王小凤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com