Super heat transfer working medium, super heat conducting element and manufacturing method of super heat conducting element

A heat transfer medium and heat transfer medium technology, applied in the field of heat transfer, can solve the problems of physical deterioration of the working liquid in the tube, unstable performance of the working medium, small adaptable temperature range, etc., to expand the applicable temperature range and expand the application capacity. , the effect of improving heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The super energy heat transfer working medium of the present invention is composed of the following components by weight:

[0061] Add in 1000 parts of water: 2.3 parts of zirconium dioxide, 1.6 parts of potassium dichromate, 1.3 parts of cobalt blue, 2.25 parts of trimanganese tetraoxide, 0.5 parts of dysprosium oxide, 0.9 parts of sodium dichromate, 2.8 parts of strontium chromate, green Pillar 0.8 part.

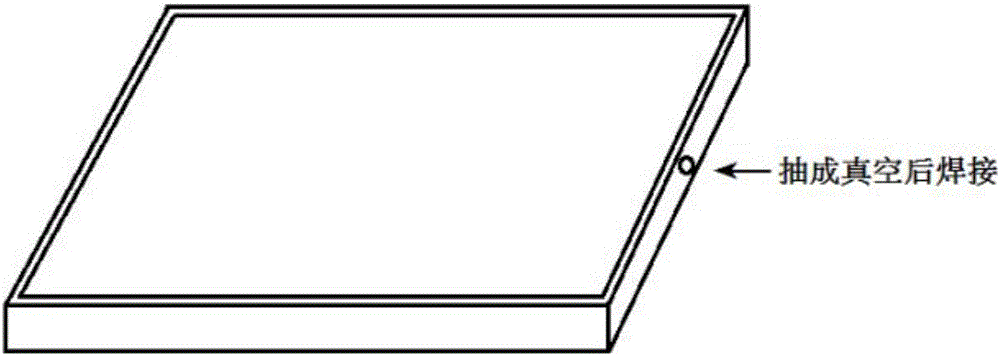

[0062] The specific steps of the manufacturing method of the super energy heat conduction element of the present invention are as follows:

[0063] First, add inorganic salts to ordinary heat transfer medium, and mix to obtain super energy transfer medium;

[0064] Secondly, heat-treat the super-energy heat transfer medium;

[0065] Finally, the super-energy heat transfer medium is filled into a hollow airtight container in a vacuum or heated state, and sealed to obtain a super-energy heat-conducting element.

Embodiment 2

[0067] The super energy heat transfer working medium of the present invention is composed of the following components by weight:

[0068] Add in 1000 parts of water: 2.0 parts of zirconium dioxide, 1.7 parts of potassium dichromate, 1.0 parts of cobalt blue, 2.3 parts of trimanganese tetraoxide, 0.3 parts of dysprosium oxide, 1.0 parts of sodium dichromate, 2.5 parts of strontium chromate, green Pillar 0.9 parts.

[0069] The manufacturing method of the super-energy heat-conducting element of the present invention is the same as that of Embodiment 1.

Embodiment 3

[0071] The super energy heat transfer working medium of the present invention is composed of the following components by weight:

[0072] Add in 1000 parts of water: 2.5 parts of zirconium dioxide, 1.5 parts of potassium dichromate, 1.5 parts of cobalt blue, 2.2 parts of trimanganese tetraoxide, 0.6 parts of dysprosium oxide, 0.8 parts of sodium dichromate, 3.0 parts of strontium chromate, green Pillar 0.6 part.

[0073] The manufacturing method of the super-energy heat-conducting element of the present invention is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com