Special high-temperature-resistant and high-absorption coating for die-casting mold

A high-adsorption, die-casting mold technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of reduced service life, shedding, cracking, etc., and achieve the effects of improved high temperature resistance, high dynamic viscosity, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

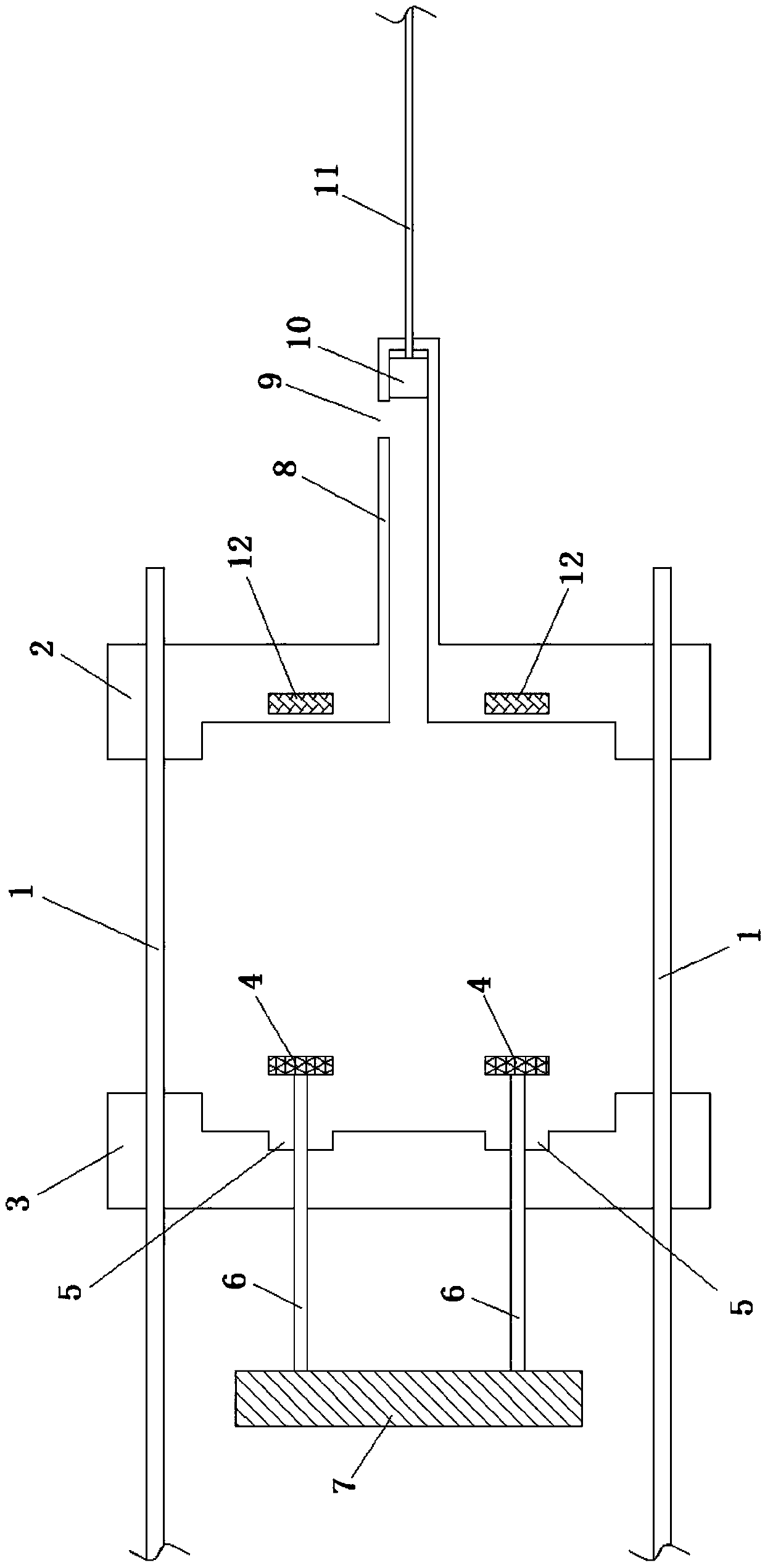

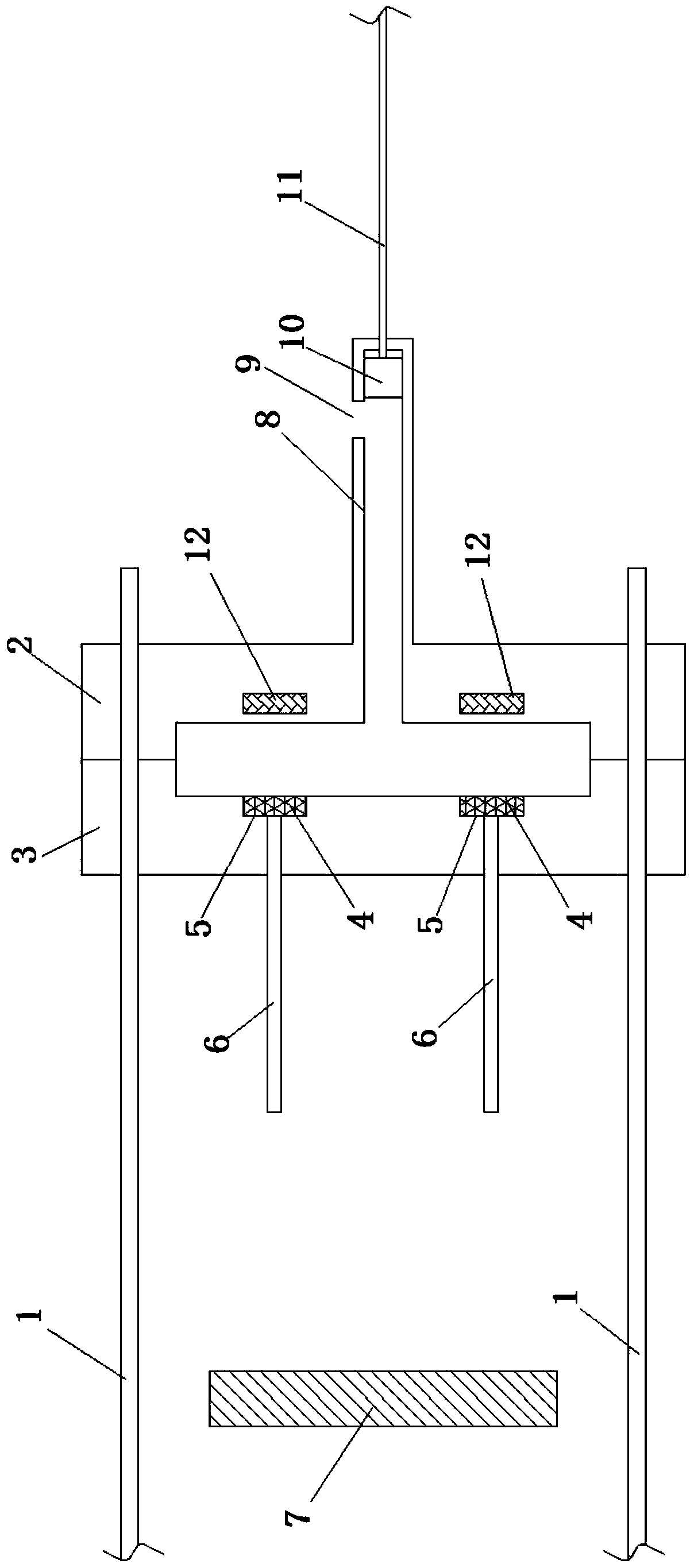

Image

Examples

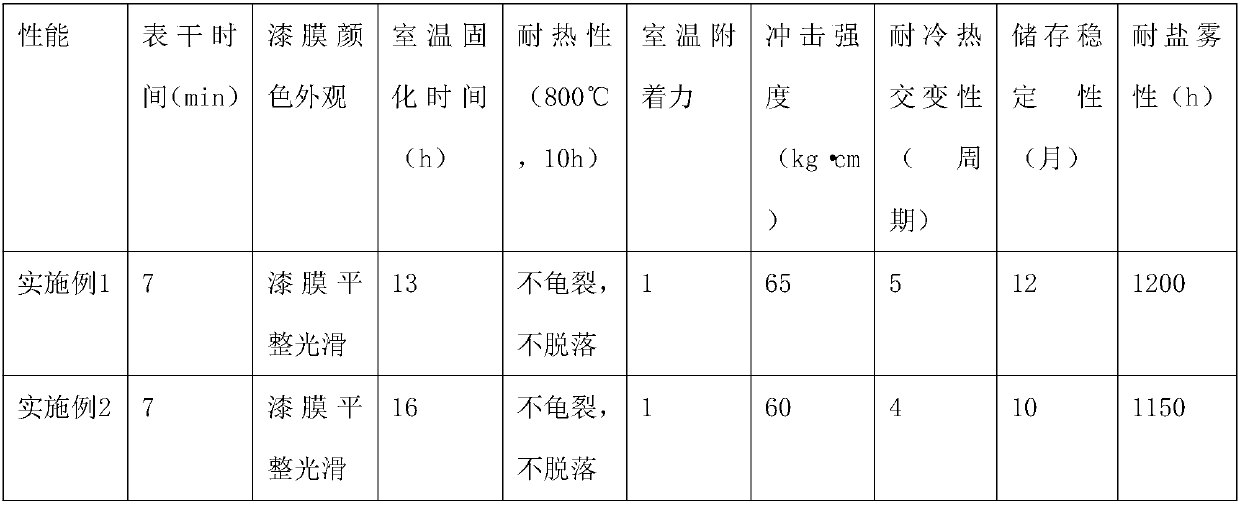

Embodiment 1

[0026] A special high-temperature-resistant high-adsorption coating for die-casting molds, which is composed of the following raw materials in parts by weight: 180 parts by weight of epoxy resin, 35 parts by weight of silicon-acrylic emulsion, 28 parts by weight of deionized water, and 12 parts by weight of polydimethylsiloxane Parts by weight, 8 parts by weight of dipentaerythritol, 6 parts by weight of composite inorganic pigments, 3 parts by weight of strontium chromate powder, 2 parts by weight of magnesium oxide powder, 12 parts by weight of graphite powder, 1 part by weight of yttrium oxide, 8 parts by weight of sodium citrate, 4 parts by weight of melamine phosphate, 8 parts by weight of flaky mica powder, 3 parts by weight of calcium formate, 4 parts by weight of nano-silicon carbide powder, 1 part by weight of rare earth cerium fluoride, 3 parts by weight of curing agent, mixed lead-free boron glass powder 6 parts by weight, 4 parts by weight of adhesion promoter, 3 pa...

Embodiment 2

[0036] A special high-temperature-resistant high-adsorption coating for die-casting molds, consisting of the following raw materials in parts by weight: 165 parts by weight of epoxy resin, 45 parts by weight of silicon-acrylic emulsion, 33 parts by weight of deionized water, and 12 parts by weight of polydimethylsiloxane Parts by weight, 6 parts by weight of dipentaerythritol, 6 parts by weight of composite inorganic pigment, 3 parts by weight of strontium chromate powder, 2 parts by weight of magnesium oxide powder, 12 parts by weight of graphite powder, 1 part by weight of yttrium oxide, 7 parts by weight of sodium citrate, 3 parts by weight of melamine phosphate, 5 parts by weight of flake mica powder, 4 parts by weight of calcium formate, 4 parts by weight of nano silicon carbide powder, 2 parts by weight of rare earth cerium fluoride, 4 parts by weight of curing agent, 5 parts by weight of adhesion promoter , 4 parts by weight of viscosity adjusting solvent, 3 parts by wei...

Embodiment 3

[0046] A method for preparing a special high-temperature-resistant high-adsorption coating for a die-casting mold, comprising the following steps:

[0047] Step1, pour epoxy resin, silicone acrylic emulsion, deionized water, graphite powder, yttrium oxide, sodium citrate, melamine phosphate, flake mica powder, dispersant, leveling agent, coupling agent and defoamer into Dispersion cylinder, stir and mix at a high speed under the condition of 150-180°C, the stirring speed is 400-500 rpm, after mixing evenly, pour the mixture into the container and put it in a refrigerator at 4°C to stand until the temperature of the mixture Stable, then take out the mixed material and pour it into the cleaned and dried dispersion tank again, then add polydimethylsiloxane, dipentaerythritol, composite inorganic pigment, strontium chromate powder and magnesium oxide powder, at 200-250 ° C, Stir and react for 1-1.5 hours under the condition of 500-550 rpm;

[0048] Step2, pour the mixed material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com