Rust-proof coating

An anti-rust coating, uniform technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as component corrosion, unreasonable proportioning, complicated preparation process, etc., and achieve the effect of low production cost, reasonable proportioning and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

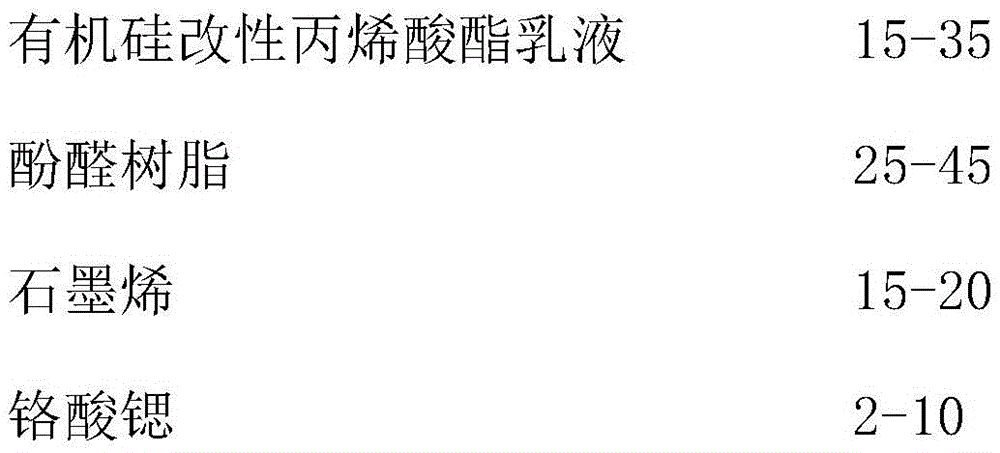

[0018] Antirust paint described in the present invention is made up of following components by weight:

[0019]

[0020]

[0021] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and rosin evenly, grind in a conical grinder until the fineness is <50 μm, then add silicone-modified acrylate emulsion, dibutyl phthalate Ester, propylene glycol methyl ether and other components are dispersed uniformly by ultrasonic.

Embodiment 2

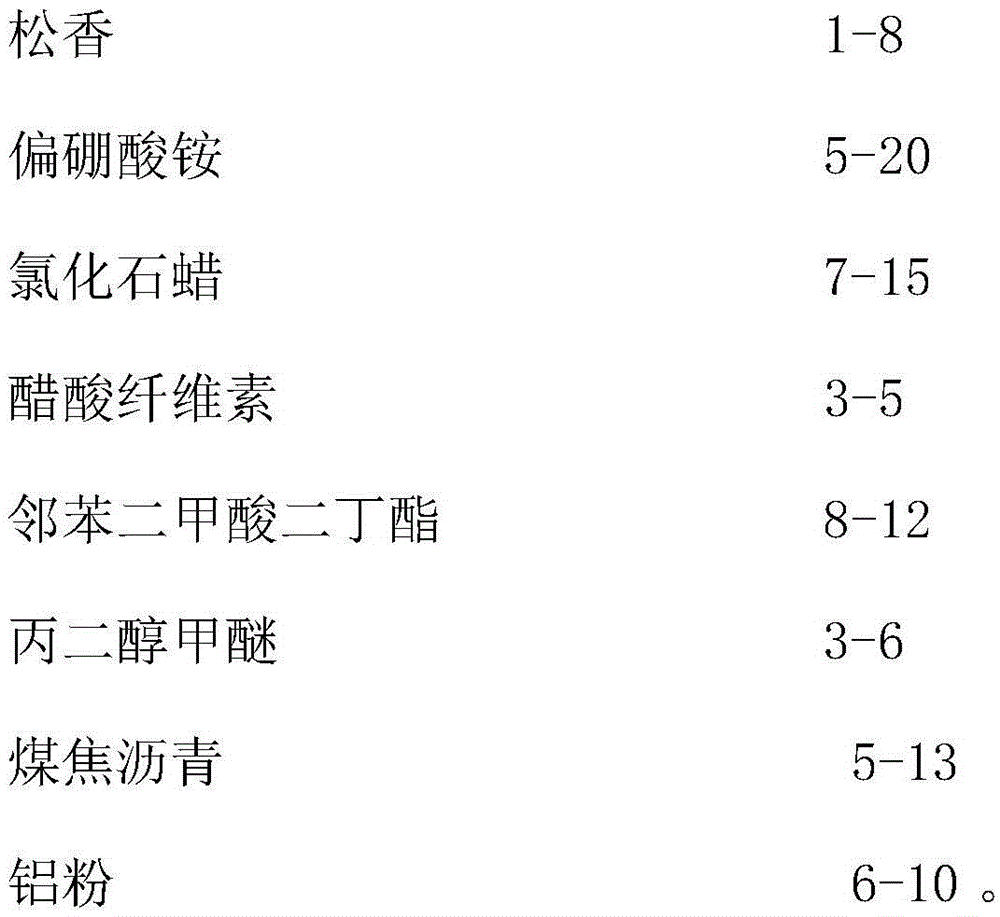

[0023] Antirust paint described in the present invention is made up of following components by weight:

[0024]

[0025] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and rosin evenly, grind in a conical grinder until the fineness is <50 μm, then add silicone-modified acrylate emulsion, dibutyl phthalate Ester, propylene glycol methyl ether and other components are dispersed uniformly by ultrasonic.

Embodiment 3

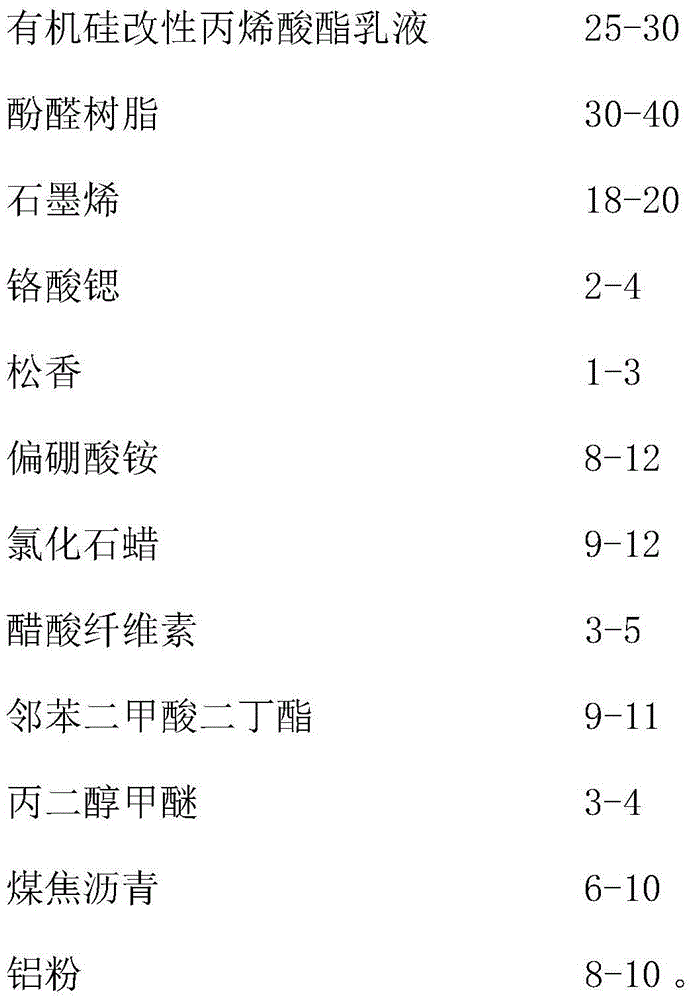

[0027] Antirust paint described in the present invention is made up of following components by weight:

[0028]

[0029] Mix and stir graphene, strontium chromate, ammonium metaborate, chlorinated paraffin, and rosin evenly, grind in a conical grinder until the fineness is <50 μm, then add silicone-modified acrylate emulsion, dibutyl phthalate Ester, propylene glycol methyl ether and other components are dispersed uniformly by ultrasonic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com