Patents

Literature

46 results about "Lead Chromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A yellow, orange or red colored, crystalline, inorganic compound that emits toxic chromium fumes upon heating. Lead chromate is highly corrosive and is a strong oxidizing agent. This substance is used in printing inks, paints and to color vinyl, rubber and paper. Lead chromate primarily affects the lungs causing shortness of breath, bronchitis, pneumonia and asthma but can also affect the gastrointestinal tract, liver, kidneys and immune system. This substance is a known human carcinogen and is associated with an increased risk of developing lung cancer and cancer of the sinonasal cavity. (NCI05)

Anticorrosion wear-resistance coating

ActiveCN103773167AImprove anti-corrosion performanceEasy to diluteAnti-corrosive paintsCelluloseLead Chromate

The invention discloses an anticorrosion wear-resistance coating, comprising the following components in parts by weight: 12-20 parts of polyvinyl acetal modified phenolic resin, 8-9 parts of polyacrylic acid vinyl ester emulsion, 3-13 parts of lead chromate, 3-12 parts of cellulose hydroxypropyl methyl ether, 6-10 parts of m-xylene, 15-21 parts of nano aluminite powder, 3-7 parts of aluminium hydroxide, 12-17 parts of nano calcium oxide and 4-8 parts of zinc oxide. The anticorrosion wear-resistance coating has the advantages of good anticorrosion performance, excellent wear resistance, long service life and low cost.

Owner:ANHUI JINDUN PAINT

Antirusting paint for watercraft

InactiveCN101429406ASolve Thixotropic ProblemsImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyLead Chromate

The invention discloses antirust paint for ships, which is prepared by epoxy resin, butanol, phosphoric acid, antirust agent, thickening agent, dispersant, film forming agent, basic lead chromate silicate, coal tar pitch, V45 asphalt antirust paint thixotropic agent and water. The antirust paint has the advantages that the antirust paint not only can effectively solve the thixotropic problem of the paint, but also can improve adhesive force of the paint to a steel material greatly, reduce construction processes, and ensure film thickness of the paint, and has stable physical property of the paint film, low toxicity, chemical medium resistance, and strong weather resistance.

Owner:赵建飞

Anti-corrosion anti-rust wear-resistant paint

InactiveCN106010055AImprove anti-corrosion performanceImprove rust resistanceAnti-corrosive paintsLead ChromatePolyvinyl alcohol

The invention discloses anti-corrosion anti-rust wear-resistant paint. The paint is prepared from a modified fluorine silicone-acrylic emulsion, polyvinyl acetal modified phenolic resin, methyltrimethoxysilane, calcium naphthenate, silica sol, crystalline silicon oxide, a polyacrylic acid vinyl ester emulsion, lead chromate, methylcellulose, hydroxypropyl methyl cellulose, m-xylene, calcium carbonate, talcum powder, precipitated barium sulfate, nano aluminum powder, aluminum hydroxide, nano calcium oxide, zinc oxide, a dispersing agent, a defoaming agent and a coalescing agent. The anti-corrosion anti-rust wear-resistant paint has excellent anti-corrosion, anti-rust and wear-resistant properties.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

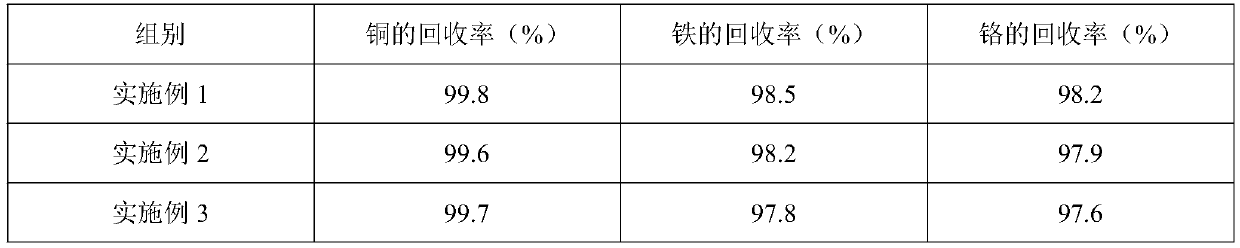

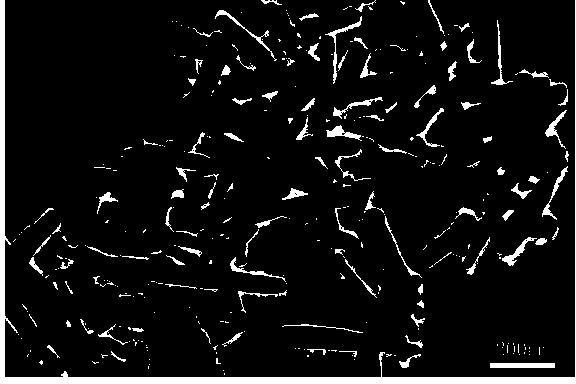

Recycling method for heavy metal in electroplating sludge

ActiveCN110055425AFull recoveryHigh recovery rateProcess efficiency improvementFerric hydroxideLead Chromate

The invention relates to the technical field of management of dangerous wastes and particularly relates to a recycling method for heavy metal in electroplating sludge. The recycling method comprises the following steps: (1) adding acid and carrying out sludge leaching; regulating the pH (Potential of Hydrogen) value to obtain a mixture A; (2) carrying out filter pressing on the mixture A to obtainfilter residue a1 and filtrate b1; (3) adding iron powder into the filtrate b1 and carrying out the filter pressing to obtain metal copper and filtrate b2; (4) adding an oxidant and alkali into the filtrate b2 and carrying out the filter pressing to obtain iron-chromium residue and filtrate b3; (5) adding the oxidant and the alkali into the obtained iron-chromium residue and carrying out the filter pressing to obtain iron hydroxide and filtrate b4; (6) calcining the obtained ferric hydroxide to obtain iron oxide red; and (7) adding sulfuric acid and lead nitrate into the filtrate b4 and carrying out the filter pressing to obtain lead chromate and filtrate b5. The treatment method provided by the invention has a heavy metal recycling rate, relatively small secondary pollution caused in theprocess and low energy consumption.

Owner:福建省固体废物处置有限公司

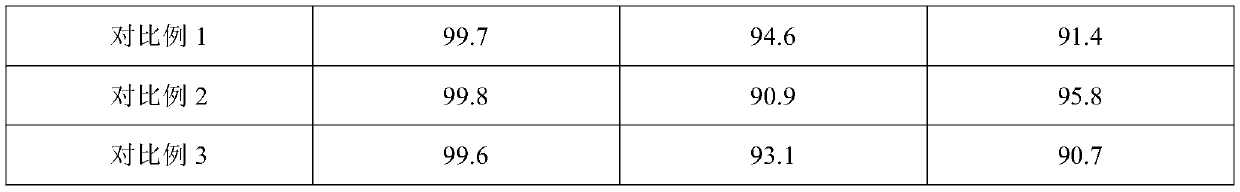

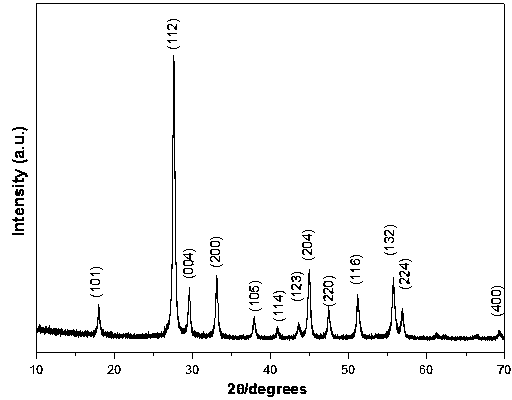

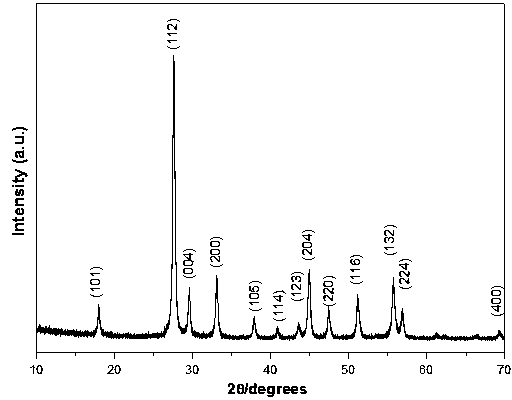

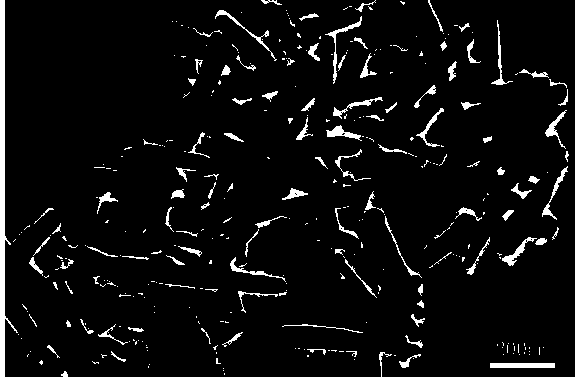

Lead molybdate nano crystal material and preparation method thereof

InactiveCN103387263AHigh aspect ratioMild reaction conditionsMaterial nanotechnologyMolybdeum compoundsLead ChromateLead nitrate

A lead molybdate nano crystal material and a preparation method thereof are disclosed. The preparation method comprises following steps: respectively dissolving sodium chromate, lead nitrate and sodium molybdate in deionized water to prepare a sodium chromate solution, a lead nitrate solution and a sodium molybdate solution, mixing the sodium chromate solution with the lead nitrate solution according to the mole ratio of CrO4<2-> to Pb<2+> of 1:1, obtaining a solution containing the lead chromate precipitation, then mixing the sodium molybdate solution with the solution containing the lead chromate precipitation according to the mole ration of MoO4<2-> to Pb<2+> of 1:1, standing for 3 to 10 hours, filtering to obtain the precipitation generated by the reactions, repeatedly washing the precipitation with deionized water and absolute ethanol, and then drying the precipitation so as to obtain the product. The preparation method produces a lead molybdate nano crystal material, which has good crystallinity, high purity and a high length-diameter ratio. The material has vast application prospects in the fields of acousto-optic devices, optical fibers, optical materials and photocatalyst.

Owner:LUOYANG INST OF SCI & TECH

Impact-resisting ceramic tile and preparation method thereof

The invention discloses an impact-resisting ceramic tile and a preparation method thereof. The impact-resisting ceramic tile is composed of the following raw materials in part by weight: 33-46 parts of serpentine, 21-34 parts of illite, 17-29 parts of sericite, 14-22 parts of white paste mud, 18-32 parts of lead zinc slag, 10-15 parts of mung bean rock, 22-28 parts of composite clay, 8-14 parts of sulphurous acid sulfite lye, 3-6 parts of lithium carbonate, 2-4 parts of sodium thiosulfate, 1.5-2.5 parts of dodecyl phosphate glycine betaine, 2-3 parts of carboxymethyl inulin sodium, 10-15 parts of aluminum borate whisker, and 4-7 parts of alkali lead chromate. The ceramic tile prepared by the invention is strong in impact-resisting intensity, high in hardness, low in water absorbent, and good in thermal stability; besides, the impact-resisting ceramic tile has good erosion resistance, seepage resistance, temperature resistance and wear resistance, stable quality, good using effect and durability, and good application prospect.

Owner:安徽省亚欧陶瓷有限责任公司

Method for separating and recycling chromium from vanadium contained chromate solution

ActiveCN108754161AAvoid it happening againHigh recovery rateProcess efficiency improvementLead ChromateSlag

The invention relates to a method for separating and recycling chromium from a vanadium contained chromate solution. The method is characterized in that after vanadium in the vanadium contained chromate solution is separated, a lead-contained compound is added for serving as a precipitation enrichment reagent of chrome, the chrome is subject to precipitation enrichment in a manner of lead chromate, and after filter, chrome precipitation after liquid and chrome enrichment slag are obtained, the chrome enrichment slag is leached through sulfuric acid and / or sulfate solution, after filtering, chromium enrichment liquid and lead sulfate are obtained, the obtained lead sulfate directly returns back to be used as the precipitation enrichment reagent of chrome, or through transformation, the leadsulfate returns back to be used as the precipitation enrichment reagent of chrome, and therefore generation of chrome vanadium reduction slag in the vanadium extracting process from the vanadium slagis avoided, and circular use of the lead compound in the cadmium separation enrichment process is achieved. The chromium separating and recycling effect is good, the metal recycling rate is high, operation is easy and convenient, production cost is low, and the environment friendliness is achieved; the method is suitable for the industrial application of chromium separating and recycling from thevanadium contained chromate solution.

Owner:CENT SOUTH UNIV

Lead-containing paint coating standard substance and preparation method thereof

ActiveCN103293037AImprove uniformitySubstrate influence is smallPreparing sample for investigationPolymer scienceLead Chromate

The invention relates to a lead-containing standard substance and a preparation method thereof. The standard substance is a mixture formed by adding analytically pure lead chromate into polyvinyl or acrylic resin paint and fly ash. The preparation method comprises the following steps of: putting the paint and the fly ash into a vacuum heating stirrer gradually according to a mass ratio of 2:1, making the lead content according to needs, putting the pure lead chromate of the content into the stirrer, letting the heating stirrer to perform stirring for 2-4h, slowly heating the mixture to make the temperature of the mixture gradually raised to 50-60 degrees, and performing stirring for 1-2h, then taking the mixture out, smearing the mixture on a glass plate, placing the glass plate in a drying box, then carrying out scraping and crushing, conducting sieving by a 0.5mm sieve, and performing complete and uniform mixing, thus obtaining the lead-containing paint coating standard substance. The standard substance provided in the invention has good uniformity, can realize fast mass production, and the prepared lead-containing paint coating standard substance has high stability.

Owner:DONGGUAN LUNGCHEONG INST OF INTELLIGENT TECH +1

Medical antirust paint and preparation method thereof

InactiveCN105017928AThe appearance of the coating film is smooth and brightHigh strengthAnti-corrosive paintsEpoxy resin coatingsEpoxyCellulose

The invention discloses a medical antirust paint and preparation method thereof. The medical antirust paint comprises the following raw materials: basic lead chromate silicate, epoxy resin, coal tar pitch, dibutyl phthalate, ethyl cellulose, castor oil, diphenylamine, benzotriazol, lanolin and xylene. The medical antirust paint has functions of rust and corrosion resistance for the medical utensils, film appearance is smooth and bright, viscosity is 80-100s, and covering power is 240-280g / cm<2>; the medical magnetic red lead antirust paint has high intensity and first grade clunging power, no abnormality is generated through salt spray resistance for 10-30 days, no bubble and shedding are generated through salt water resistance for 5-25 days; surface drying time is 2-6 hours, hard drying time is 15-35 hours, preparation method is simple, raw materials are simple and easily available, and the antirust paint can be widely produced and continuously substitutes the current materials.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Extraction method for lead in sintering smoke dust

InactiveCN107142378AQuality improvementEfficient extractionProcess efficiency improvementPregnant leach solutionLead Chromate

The invention discloses an extraction method for lead in sintering smoke dust and belongs to the technical field of industrial waste treatment. The technical effect that through the provided novel extraction method for the lead in the sintering smoke dust, the lead in the sintering smoke dust is completely and effectively recovered is achieved. The extraction method for the lead in the sintering smoke dust comprises the following steps that A, the sintering smoke dust is leached by added water, and a leaching agent and leaching residues are obtained through separation; B, the leaching agent obtained in the step A is subjected to deposition through sodium chromate, and a lead chromate product and a filtrate are obtained through separation; C, the leaching residues obtained in the step A are leached through an EDTA solution, and a leaching agent and leaching residues are obtained through separation; and D, the leaching agent obtained in the step C is subjected to deposition through sodium chromate, and a lead chromate product and a filtrate are obtained through separation. The process route for efficiently recovering the lead in the sintering smoke dust is provided, meanwhile, potassium chloride in the sintering smoke dust can be extracted, the sintering smoke dust is fully used, and the method has good popularization prospects.

Owner:攀枝花火凤凰再生资源回收利用有限责任公司

Salt-fog-resistant phosphate modified acrylic waterborne antirust coating for building scaffold

InactiveCN109370349AImprove water resistanceImprove adhesionAnti-corrosive paintsLead ChromatePhosphate

The invention discloses a salt-fog-resistant phosphate modified acrylic waterborne antirust coating for a building scaffold. The salt-fog-resistant phosphate modified acrylic waterborne antirust coating is prepared from the following raw materials in parts by weight: 35-60 parts of salt-fog-resistant phosphate modified acrylic core-shell emulsion, 2-8 parts of cosolvent, 10-15 parts of cobalt naphthenate, 10-15 parts of lead chromate, 5-10 parts of iron laterite, 2-5 parts of strontium chromate, 1-3 parts of rosin, 2-9 parts of ammonium metaborate, 0.5-0.9 part of chlorinated paraffin, 0.3-0.6part of cellulose acetate, 0.2-1.2 parts of dibutyl phthalate, 0.2-1.5 parts of substrate modifier, 0.5-6 parts of auxiliaries and 12-35 parts of deionized water. According to the antirust coating disclosed by the invention, the adhesive force and compactness between a film and a substrate are enhanced, so that water molecules, chloride ions and sodium ions are effectively isolated from enteringbetween substrates, the adhesive force, water resistance and anti-flash rusting property of the film are improved in a wet environment, and the salt-fog-resistant phosphate modified acrylic waterborneantirust coating has good adhesive force, water resistance, salt fog resistance, anti-flash rusting property, acid and alkali resistance and corrosion resistance.

Owner:ANHUI ZULIN NEW MATERIALS

Novel wear-resistant coating

InactiveCN109554062AImprove anti-corrosion performanceEasy to diluteAnti-corrosive paintsLead ChromatePolyvinyl alcohol

A novel wear-resistant coating comprises 12-20 parts of polyvinyl acetal modified phenolic resin, 8-9 parts of polyacrylic acid vinyl ester emulsion, 3-13 parts of lead chromate, 3-12 parts of cellulose hydroxypropyl methyl ether, 6-10 parts of m-xylene, 15-21 parts of nano aluminum powder, 3-7 parts of aluminum hydroxide, 12-17 parts of nano calcium oxide, 4-8 parts of zinc oxide, 15-35 parts ofultra-high molecular weight polyethylene, 5-20 parts of styrene-acrylic emulsion, 5-20 parts of epoxy resin, 2-10 parts of styrene-butadiene rubber, 1-5 parts of molybdenum disulfide, 0.2-1 part of athickening agent, 1-5 parts of a catalyst, 0.2-1.5 parts of a synergist, 1-5 parts of quartz powder, 1-5 parts of nano copper oxide, 0.2-1 part of butanone, 0.3-2 parts of butyl acetate, 20-50 parts of deionized water and 2-10 parts of pentaerythritol.

Owner:菏泽广泰耐磨制品股份有限公司

Environment-friendly waterproof corrosion-resistant marine coating

InactiveCN104927553AImprove mechanical propertiesImprove waterproof performanceAnti-corrosive paintsPolyester coatingsLead ChromatePhosphate

The invention discloses an environment-friendly waterproof corrosion-resistant marine coating. The environment-friendly waterproof corrosion-resistant marine coating consists of the following materials in parts by weight: 30 to 40 parts of polyvinyl acetal-modified phenolic resin, 10 to 15 parts of poly(ethyl acrylate) emulsion, 20 to 30 parts of organic silicon-modified polyester resin, 10 to 15 parts of isophthalic unsaturated polyester resin, 3 to 13 parts of lead chromate, 3 to 12 parts of hydroxypropyl methylcellulose, 2 to 6 parts of sodium carboxymethylcellulose, 1 to 5 parts of hydroquinone, 5 to 15 parts of aluminium nanopowder, 10 to 15 parts of modified mica, 10 to 15 parts of aluminium hydroxide, 15 to 20 parts of nano calcium oxide, 5 to 10 parts of zinc oxide, 2 to 4 parts of chromium phosphate, 1 to 3 parts of barium phosphate, 5 to 10 parts of calcium phosphate, 1 to 3 parts of iron oxide red and 2 to 5 parts of phthalocyanine blue. The waterproofness of the environment-friendly waterproof corrosion-resistant marine coating is good, the corrosion resistance of the environment-friendly waterproof corrosion-resistant marine coating is excellent, and moreover, the environment-friendly waterproof corrosion-resistant marine coating does not pollute the environment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Comprehensive utilization method for iron ore sintering smoke ash leaching liquid

InactiveCN110607452ARealize resource utilizationIncrease added valueCalcium/strontium/barium sulfatesSulfate/bisulfate preparationLead ChromateKerosene

The invention discloses a comprehensive utilization method for iron ore sintering smoke ash leaching liquid and belongs to the technical field of industrial waste treatment. According to the comprehensive utilization method, iron ore sintering smoke ash is leached with water, and leaching liquid and leaching residues are obtained through separation; sodium oxalate is added to the leaching liquid,precipitation is conducted, bismuth trioxide products are obtained through washing, drying and calcination, a bismuth precipitation filtrate is subjected to a precipitation reaction with sodium chromate, and lead chromate products are obtained; a lead-separation filtrate is subjected to P507+sulfonated kerosene organic phase extraction and sulfuric acid solution reverse extraction, hydrothermal treatment is conducted, and calcium sulfate whisker products are obtained; and an organic phase extracted aqueous solution is subjected to purification and two stages of conversion reactions, potassiumsulphate and industrial sodium chloride products are obtained. The comprehensive utilization method is simple in technological equipment and easy and safe to operate, potassium, sodium, calcium, lead,bismuth and other elements in sintering ash can be efficiently recycled, additional value of raw materials is increased, resource utilization of sintering smoke ash is achieved, waste is changed intowealth, environmental pollution is reduced, and the comprehensive utilization method has good industrialized application and popularization prospects.

Owner:攀枝花火凤凰再生资源回收利用有限责任公司

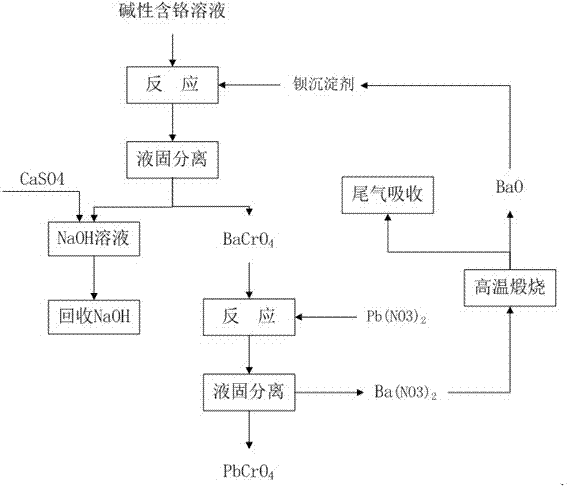

Method for treating chromium-containing alkali solution

ActiveCN103880214ANo need to adjust pHEasy to handleMultistage water/sewage treatmentAlkali metal oxides/hydroxidesLead ChromateHydrogen

The invention discloses a method for treating a chromium-containing alkali solution. The method comprises the following steps: (1) mixing a chromium-containing alkali solution with a barium precipitant according to a molar ratio Cr / Ba of 0.8:2, reacting, subsequently performing liquid-solid separation to obtain precipitate containing barium chromate and a solution containing sodium hydroxide; (2) adding the precipitate containing barium chromate into a Pb(NO3)2 solution according to a molar ratio Ba / Pb of 1:(1-2), reacting, performing liquid-solid separation to obtain lead chromate precipitate and a solution containing barium nitrate; (3) evaporating and roasting the solution containing barium nitrate at a high temperature to obtain BaO. The method disclosed by the invention is simple to operate, the power of hydrogen of the solution does not need to be adjusted, alkali in an alkali solution can be recycled; the chromium-containing alkali solution, particularly a chromium-containing solution under high alkali condition, can be effectively treated; and the method has the characteristics of low production cost and good economic benefits.

Owner:HEBEI IRON AND STEEL

High-burning-rate pyrotechnic compound for activating thermal batteries, preparation method of pyrotechnic compound and application

InactiveCN109438148AActivation is reliableMeet the need for quick activationDeferred-action cellsPrimary cell maintainance/servicingLead ChromateAdhesive

The invention discloses a high-burning-rate pyrotechnic compound for activating thermal batteries. The pyrotechnic compound comprises an oxidizing agent, a reducing agent and a forming adhesive, and the oxidizing agent comprises potassium chlorate and lead chromate. The invention further discloses a preparation method of the pyrotechnic compound. The high-burning-rate pyrotechnic compound is a novel pyrotechnic compound for the thermal batteries and applied to activation of the thermal batteries, and the pyrotechnic compound has the advantages of high burning speed, reliable activation, no jump burning and micro-short circuit, safe and convenient to use and the like. The thermal batteries can be more rapidly activated, rapid activation requirements of the thermal batteries are completely met, and the pyrotechnic compound is applicable to the thermal batteries in the field of quick response and the like and particularly applied to rapid activation of the thermal batteries.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Anti-corrosion automobile powder coating with good adhesive force

InactiveCN104387952AReduce internal stressLow melting pointRosin coatingsAnti-corrosive paintsDibutyl tin dilaurateLead Chromate

The invention discloses an anti-corrosion automobile powder coating with a good adhesive force. The anti-corrosion automobile powder coating comprises the components in parts by weight: 45-50 parts of polyamide resin, 1-2 parts of bisphenol A epoxy resin, 15-25 parts of modified rosin resin, 20-25 parts of titanium dioxide, 3-6 parts of lead chromate, 5-10 parts of organosilicone, 2-3 parts of phenolic aldehyde amine, 0.3-0.6 part of dibutyltin dilaurate, 2-3 parts of curing agent, 0.5-1 part of stabilizer and 2-2.5 parts of flatting agent. The anti-corrosion automobile powder coating has the good adhesive force and corrosion resistance.

Owner:李永志

Rust-containing antirusting paint

ActiveCN103897505AAvoid corrosionPrevent oxidationAnti-corrosive paintsBituminous coatingsLead ChromateLacquer

The invention relates to rust-containing antirusting paint which comprises the following components in parts by weight: 10-13 parts of rust-containing antirusting paint emulsion, 4-7 parts of calcium ferrite, 3-6 parts of zinc oxide, 12-15 parts of talcum powder, 5-8 parts of wollastonite in powder, 4-6 parts of alkali silicon lead chromate, 11-16 parts of rosin, 1-4 parts of asphalt, 2-4 parts of white spirit, 5-8 parts of a curing agent, 7-12 parts of ammonia water and 5-8 parts of a drier. By adopting the rust-containing antirusting paint, iron rust on the surface of an object can be removed, and then the object can be reused; moreover as metal and paint corrosion and oxidation caused by rain or insolation for a long time can be effectively avoided, the paint is applicable to hostile environment.

Owner:SHANGHAI DABAO CHEM PROD

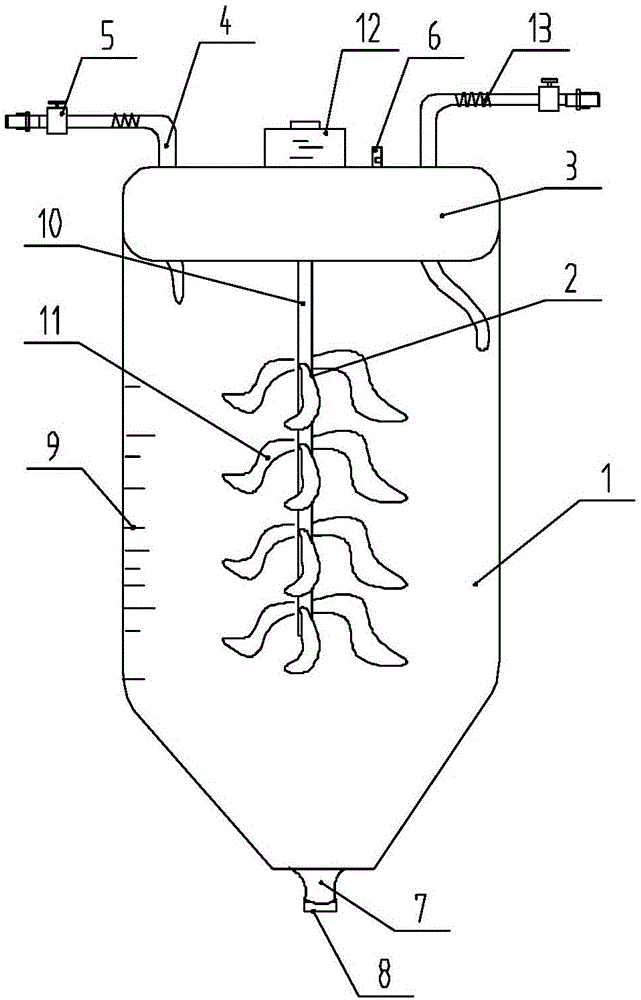

Paint film standard substance, preparation process and stirring equipment used during preparation of paint film standard substance

PendingCN106323710AImprove stabilityEasy to operateRotary stirring mixersTransportation and packagingLead ChromateAcrylic resin

The invention provides a paint film standard substance. The standard substance is prepared by adding a solvent, filler, white lead and lead chromate into acrylic resin paint and carrying out uniform stirring and mixing through stirring equipment. A preparation process of the paint film standard substance includes the steps that firstly, the solid content of wet paint is calculated; then a proper amount of wet paint is put in a container containing a proper amount of solvent, white lead and lead chromate with corresponding contents are put according to the solid content of the wet paint and the lead content needing to be manufactured, and the materials are stirred for 2-3 hours; the stirred wet paint mixture is evenly smeared on a base material; the base material on which the wet paint mixture is smeared is put in an air box to be dried; the dried base material is taken out, a paint coating is shoveled from the base material, the paint coating is ground and then screened, and the materials are fully mixed to be uniform. According to the preparation process, the paint film standard substance can be prepared rapidly and simply, precision is high, uniformity is good, and the stability of the prepared paint film standard substance is high.

Owner:TECHN CENT FOR SAFETY OF INDAL PRODS TIANJIN ENTRY EXIT INSPECTION QUARANTINE BUREAU

Photosensitive ceramic material and preparation method thereof

The invention discloses a photosensitive ceramic material composed of the following substances by weight: 3-8 parts of zinc chloride, 5-10 parts of lead sulfide, 10-15 parts of silicon carbide, 3-6 parts of barium carbonate, 2-5 parts of copper sulfide, 1-3 parts of cobalt oxide, 2-5 parts of lead chromate, 0.5-2 parts of tin fluoride, 1-3 parts of iridic oxide, 2-4 parts of indium chloride, and 15-30 parts of 3,7-dimethyl-3-octanol. The sensitivity of the ceramic material is improved and the spectral range of the ceramic is broadened by adding a plurality of ingredients.

Owner:苏州耐思特塑胶有限公司

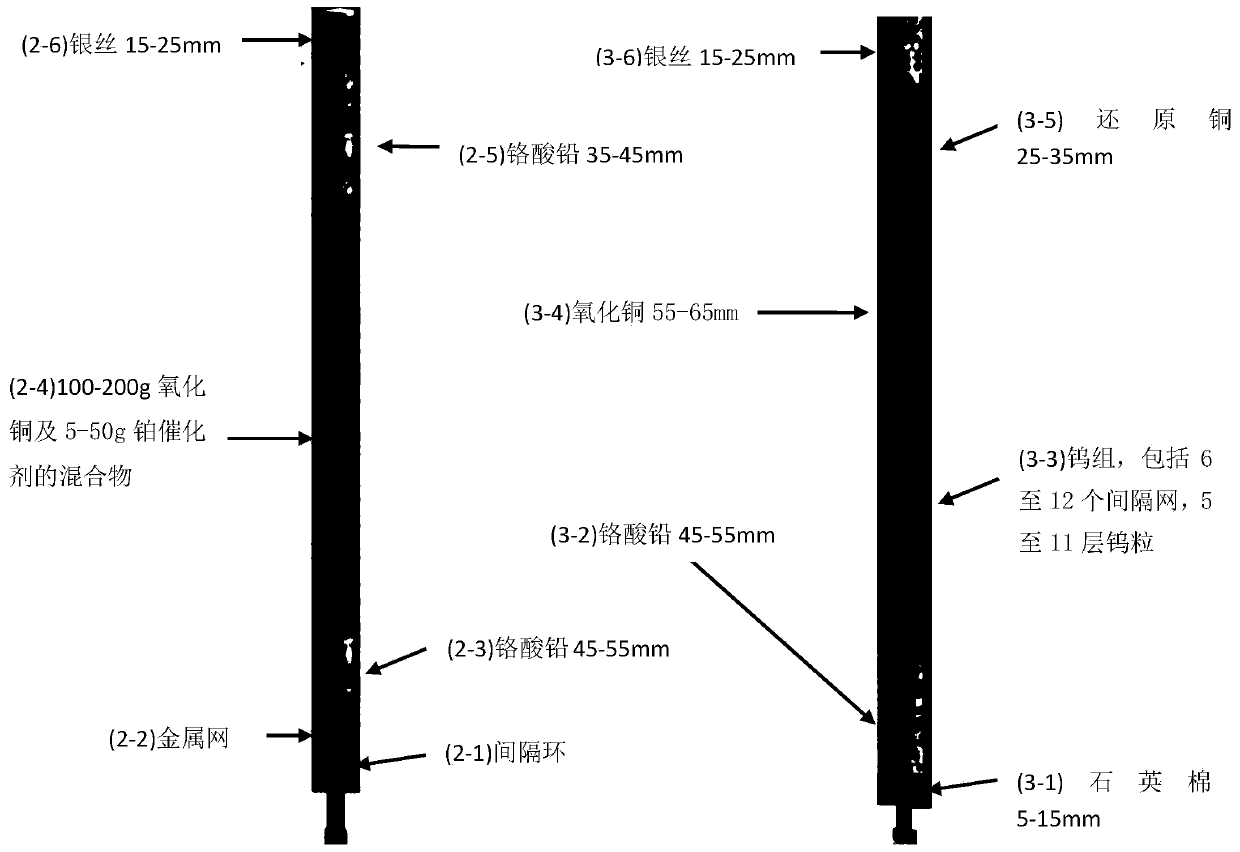

Dumas azotometer reaction tube

The invention discloses a Dumas azotometer reaction tube. The Dumas azotometer reaction tube comprises a first-stage combustion tube, a second-stage combustion tube and a reduction tube. The advantages of two-stage combustion are reserved, and lead chromate for adsorbing sulphur is also filled by adopting the technical scheme of keeping the filling mode of the conventional primary combustion tubeunchanged, replacing corundum ball and partial copper oxide in the second-stage combustion tube with the lead chromate, and replacing the corundum ball at the lower part of the reduction tube into thecorundum ball; and when the Dumas azotometer reaction tube is used for analyzing a sample with high sulphur content, the baseline of the azotometer is stable, and the parallelism of the analysis results is good no matter the sample feeding amount is large or not.

Owner:北京诺德泰科仪器仪表有限公司

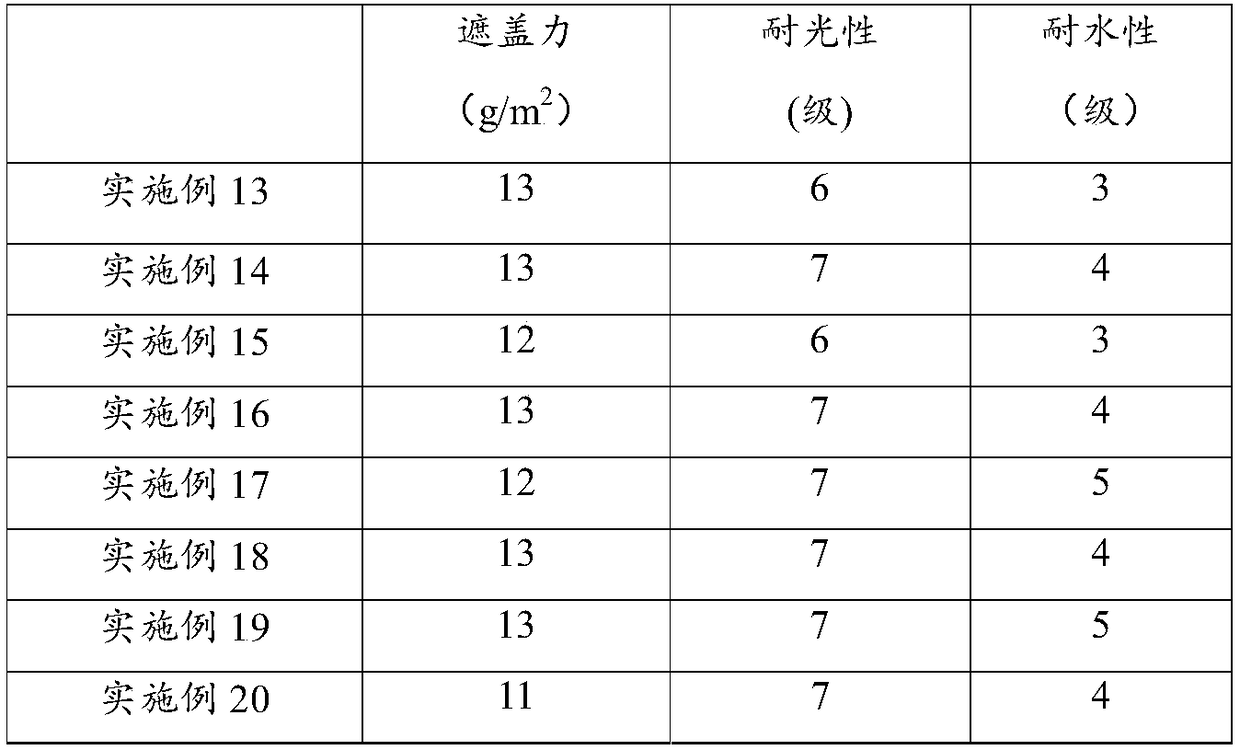

Inorganic pigment and preparation method and application thereof

InactiveCN108456437AGood light fastnessHigh tinting strengthPigmenting treatmentLead ChromateInorganic pigments

The invention relates to the field of pigment processing, and particularly provides inorganic pigment and a preparation method and application thereof. The inorganic pigment is mainly prepared from titanium dioxide, calcium oxide and kaolin. According to the inorganic pigment, the kaolin is used for replacing traditional harmful materials such as lead chromate and cadmium sulfide, the applicationrange of the pigment is expanded, and pollution cannot be caused to a human body and the environment. Meanwhile, the inorganic pigment is completely prepared from inorganic materials, the properties of light resistance, tinting strength, hiding power, water resistance and the like are very good, the ingredients are uniform, the performance is stable, resources of raw materials are wide, and therefore the cost is low. The preparation method of the inorganic pigment comprises the steps that mixed raw materials are calcined under the condition of 850-1,250 DEG C, cooling is conducted, and the inorganic pigment is obtained. According to the method, operation is easy, no special requirements are needed for equipment, the cost is low, and the method can be used for large-scale industrial production.

Owner:HANDAN SHENGHUO CERAMIC PROPPANT CO LTD

Instrument cabinet paint with good heat dissipation and preparation method thereof

The invention provides an instrument cabinet paint with good heat dissipation, which is characterized in that the product is prepared by the following raw materials by weight: 43-46 parts of E-44 epoxy resins, 16-19 parts of cis butenedioic anhydride, 1-2 parts of N-methylolacrylamide, 10-14 parts of vermiculite powder, 10-12 parts of aluminium nitride powder, 1-2 parts of ethylenebis(stearamide), 2-5 parts of tetrabutylammonium bromide, 1-2 parts of yttrium oxide, 17-19 parts of ethyl acetate, 1-2 parts of aminopropyltriethoxysilane, 9-12 parts of basic lead chromate silicate, 1-2 parts of triethanolamine, 24-28 parts of acrylic resin and 4-5 parts of auxiliary agents. The auxiliary agent provided by the invention can improve optical performance, thereby the paint is uniformly dispersed, and stability of paint is maintained and film forming effect is improved; the paint material of the present invention has the characteristics of fast drying, good decorative effect, easy construction, good yellowing resistance, good adhesion, etc. the formula contains aluminium nitride powder and has good heat radiation performance, and the product is suitable for cabinet with large caloric power.

Owner:ANHUI MINGDU ELECTRICAL

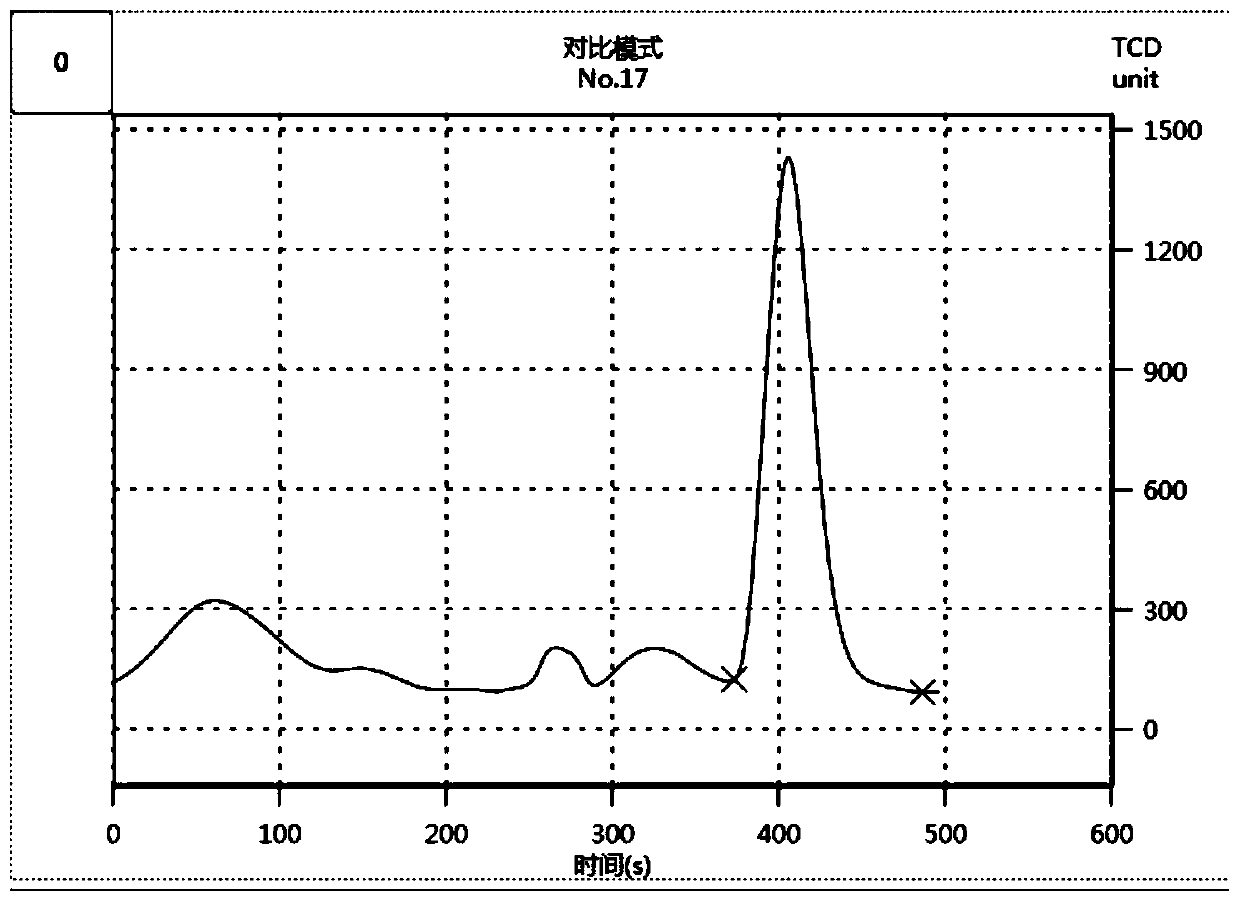

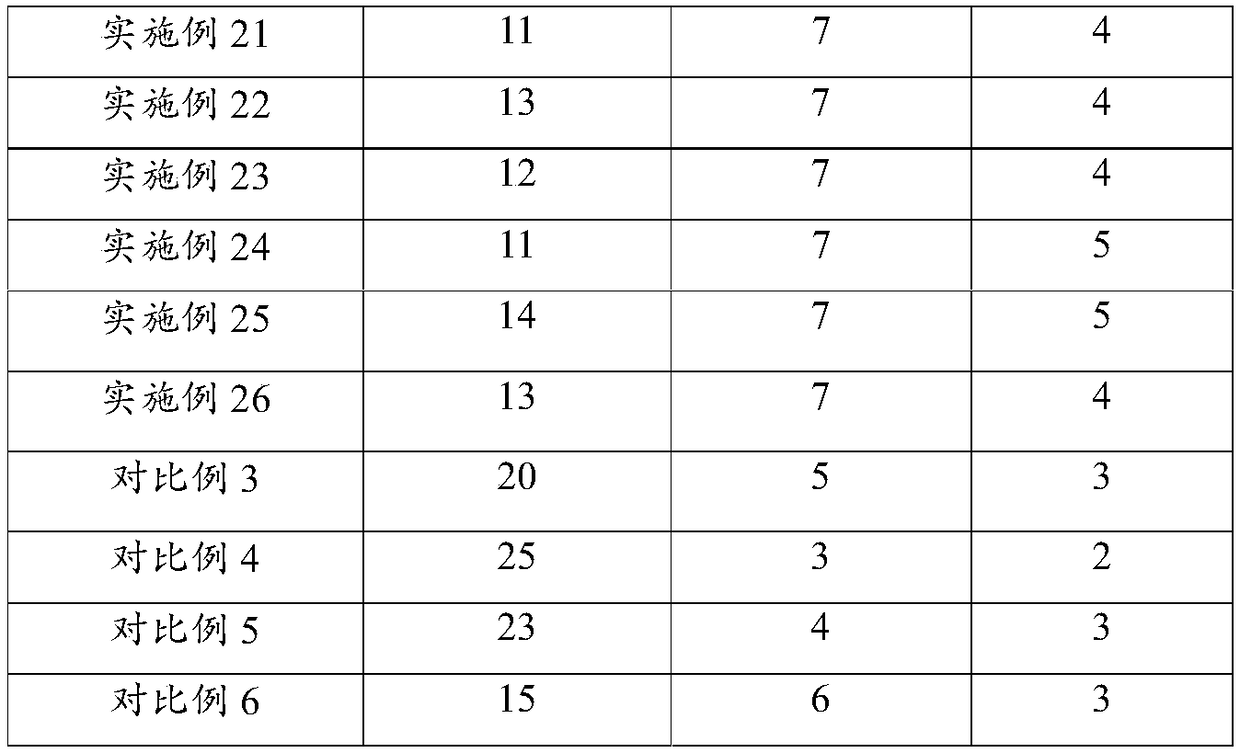

Preparation method of 602 little smoke agent through mechanical mixing

InactiveCN105130716AEnsure mixing uniformityImprove reliabilityAlkali metal salt explosive compositionsLead ChromateDry mixing

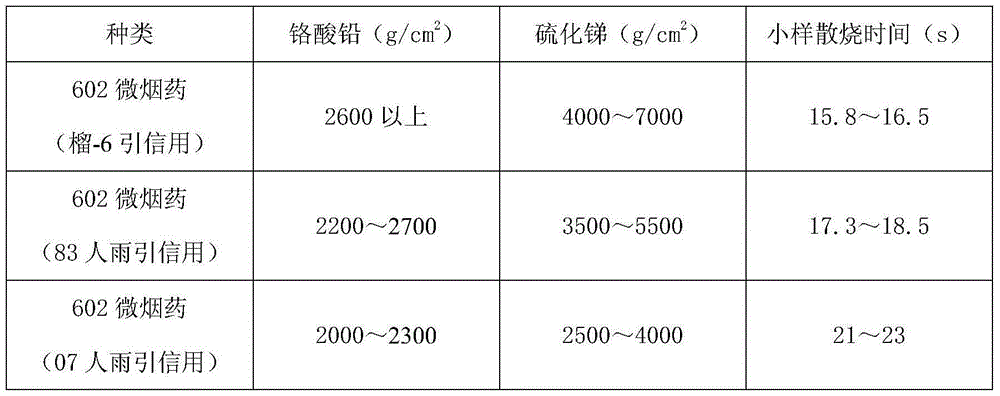

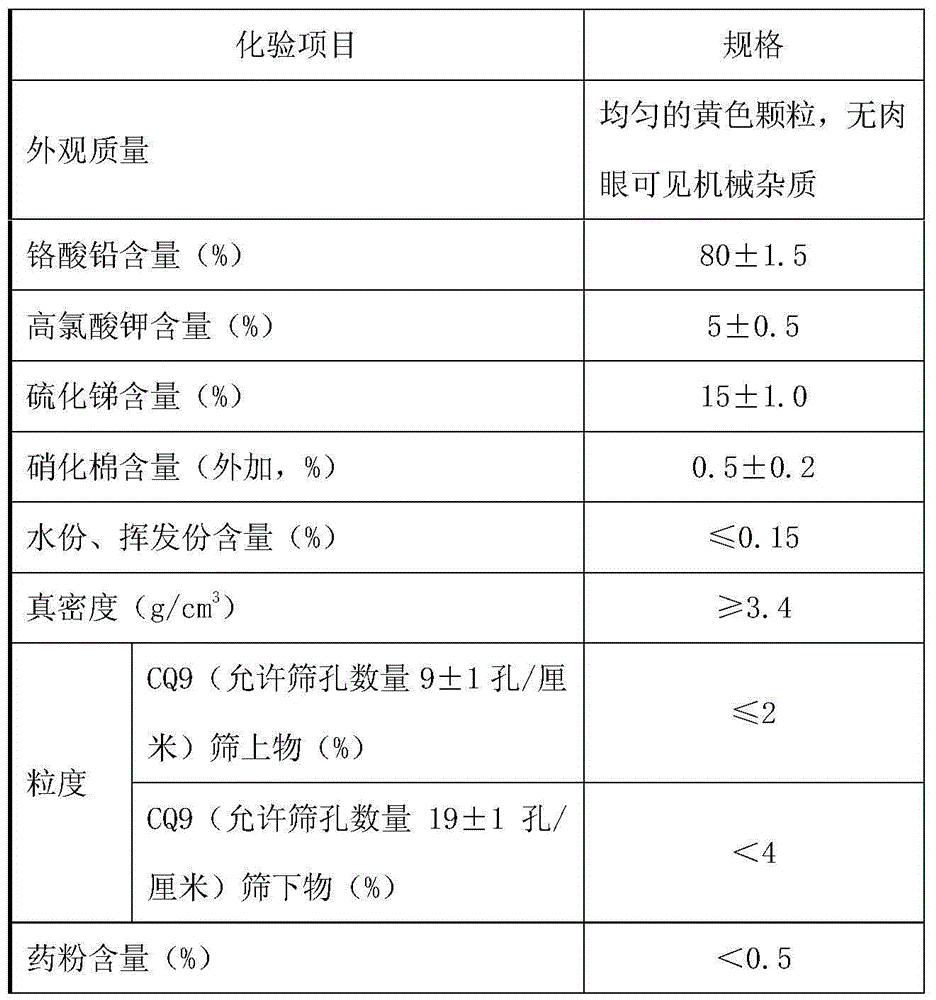

The invention discloses a preparation method of 602 little smoke agent through mechanical mixing. The preparation method comprises the following steps: processing raw materials, selecting raw materials, weighing raw materials, preparing a nitro-cotton adhesive, dry-mixing a tertiary mixture, controlling the grinding time, wet-drying the tertiary mixture, increasing density, granulating, polishing, drying, batching, mixing, and screening qualified particles. The 602 little smoke agent is composed of 78.5 to 81.5% of lead chromate, 14 to 16% of antimony sulfide, 4.5 to 5.5% of potassium perchlorate, and 0.3 to 0.7% of weak cotton additive. The particle size of the agent is in a range of 9 pores / cm (screen underflow) and 19 pores / cm (oversize product). By adjusting the raw materials and dry-mixing and grinding time, the agent can meet the special time requirements of grenade-6 fuze (5.5 to 9 seconds), 83 artificial rainfall fuze (13 to 17 seconds), 07 artificial rainfall fuze (12 to 17 seconds) and the like. The provided agent can be mixed uniformly, the reliability and stability of the agent are high, and the agent is safe to manufacture.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

A kind of method for preparing lead chromate from electroplating chromium slag

ActiveCN106315676BEfficient extractionEfficient use ofChromates/bichromatesLead ChromateProcess equipment

Owner:KUNMING UNIV OF SCI & TECH

Light green electrostatic powder raw material formula

InactiveCN103305082AReasonable collocationReduce collocationEpoxy resin coatingsPolyester coatingsAdhesion forceEpoxy

The invention discloses a light green electrostatic powder raw material formula which comprises the following components: 18kg of epoxy resin, 18kg of polyester resin, 10kg of titanium dioxide, 7.2kg of barium sulfate, 2.5kg of leveling agent, 0.36kg of lead chromate, 0.03kg of phthalocyanine blue and 0.1kg of Hansa yellow. According to the light green electrostatic powder raw material formula, stable color on the molding powder spraying plastic surface can be ensured, the surface is smooth and bright, and the adhesion force is high.

Owner:温永林

A kind of colorful pattern paint

ActiveCN104119710BWrinkle-free skinNo sheddingMulticolor effect coatingsPolyvinyl butyralLead Chromate

The invention relates to a coating with colorful patterns. The coating comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride, 25-35 parts of methyl alcohol, 30-40 parts of lead chromate, 10-20 parts of polyvinyl butyral, 35-45 parts of calcium carbonate, 10-20 parts of ethylene glycol, 80-90 parts of deionized water, 15-35 parts of nitrile rubber, 10-20 parts of pigment, 5-15 parts of isobutyl isobutyrate, 40-50 parts of methylbenzene, 15-25 parts of isobutyl acetate, 4-10 parts of plasticizer, 25-45 parts of isopropyl alcohol, 30-40 parts of vinylidene chloride and 25-35 parts of methyl ethyl ketone. The coating has the advantages that the coating film is resistant to scrub 3000-5000 times; the coating does not foam or come off after being soaked in water at the temperature of 20 DEG C for 10-30 days; the coating does not wrinkle or drop after being soaked in 5% hydrochloric acid for 10-20 days; the surface drying time of the coating is 30-50 minutes and the hard drying time of the coating is 8-10 hours, so that the coating can be widely produced and can be used for continuously replacing the existing materials.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

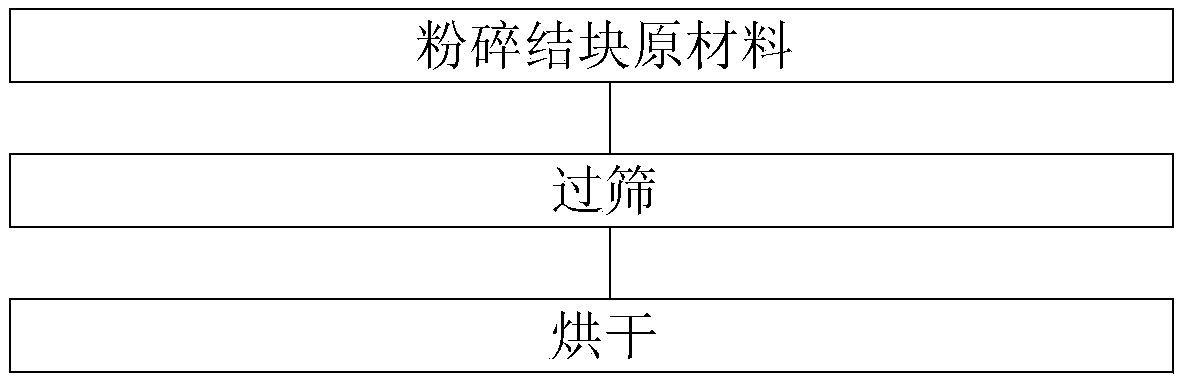

Pretreatment method of caked raw material

InactiveCN109127070AQuality improvementImprove efficiencyGrain treatmentsLead ChromatePretreatment method

The invention relates to a pretreatment method of a caked raw material. The method comprises the steps that the caked raw material is crushed through a crusher; powder obtained after crushing is sieved. Pretreatment of 1.6 Kg of caked lead chromate raw materials can be completed rapidly, the problems that an original technology is low in manual treatment efficiency, and the pretreatment effect cannot be guaranteed are reduced, and the quality of caked raw material pretreatment is guaranteed. The pretreatment efficiency is improved, the operating difficulty is lowered, and the potential qualityhazard is eliminated. Accordingly, the crusher is made of stainless steel materials, in the caked raw material pretreatment process, rapidness and reliability are achieved, the technical gap problemis effectively solved, the operating difficulty is lowered, the labor intensity is effectively lowered, the quality and efficiency of caked raw material crushing are improved, the problem that the power part has yellow spots is solved, and the product quality is guaranteed.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

Lead molybdate nano crystal material and preparation method thereof

InactiveCN103387263BHigh aspect ratioMild reaction conditionsMaterial nanotechnologyMolybdeum compoundsLead ChromateLead nitrate

A lead molybdate nano crystal material and a preparation method thereof are disclosed. The preparation method comprises following steps: respectively dissolving sodium chromate, lead nitrate and sodium molybdate in deionized water to prepare a sodium chromate solution, a lead nitrate solution and a sodium molybdate solution, mixing the sodium chromate solution with the lead nitrate solution according to the mole ratio of CrO4<2-> to Pb<2+> of 1:1, obtaining a solution containing the lead chromate precipitation, then mixing the sodium molybdate solution with the solution containing the lead chromate precipitation according to the mole ration of MoO4<2-> to Pb<2+> of 1:1, standing for 3 to 10 hours, filtering to obtain the precipitation generated by the reactions, repeatedly washing the precipitation with deionized water and absolute ethanol, and then drying the precipitation so as to obtain the product. The preparation method produces a lead molybdate nano crystal material, which has good crystallinity, high purity and a high length-diameter ratio. The material has vast application prospects in the fields of acousto-optic devices, optical fibers, optical materials and photocatalyst.

Owner:LUOYANG INST OF SCI & TECH

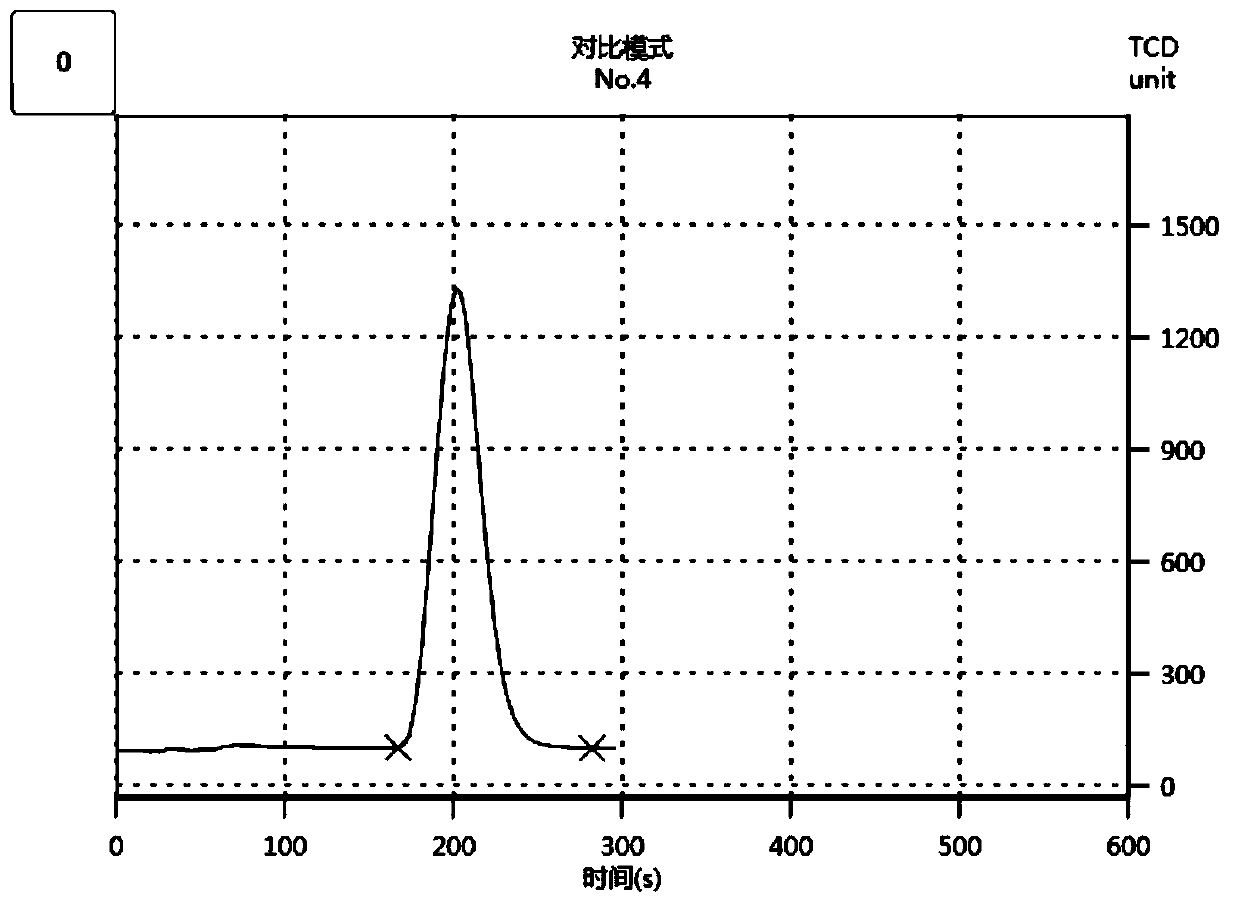

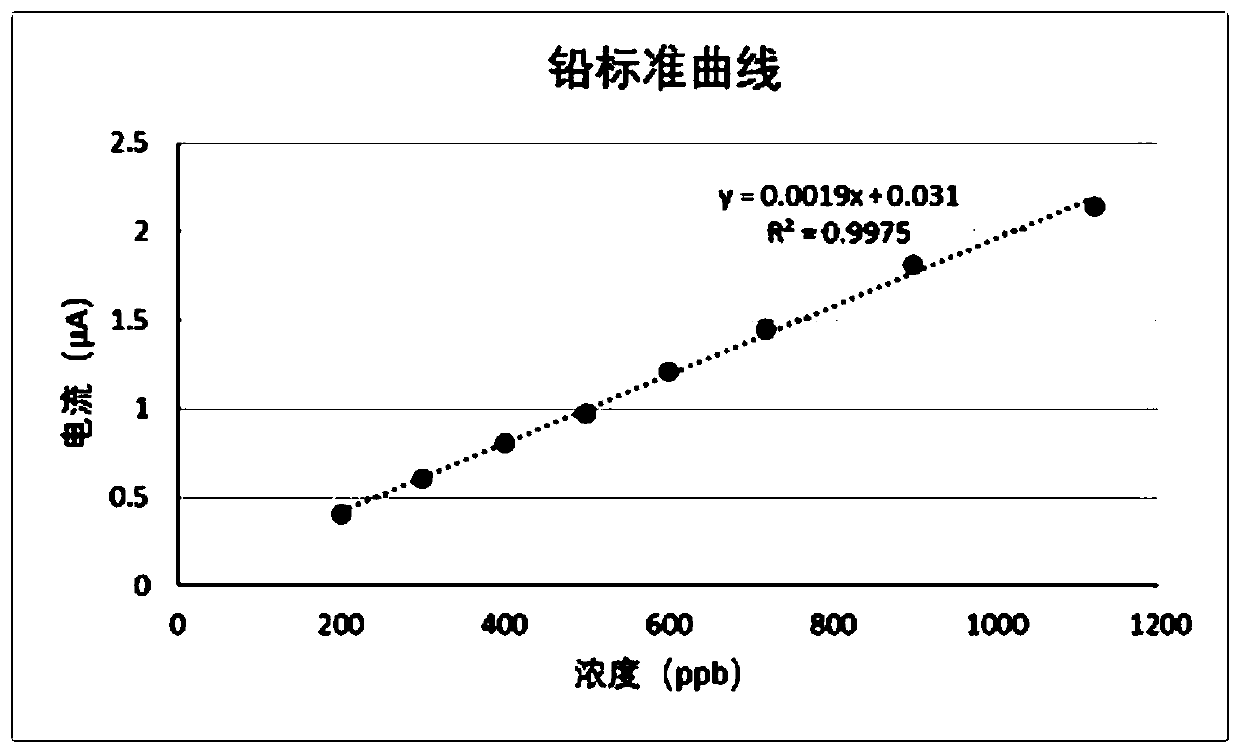

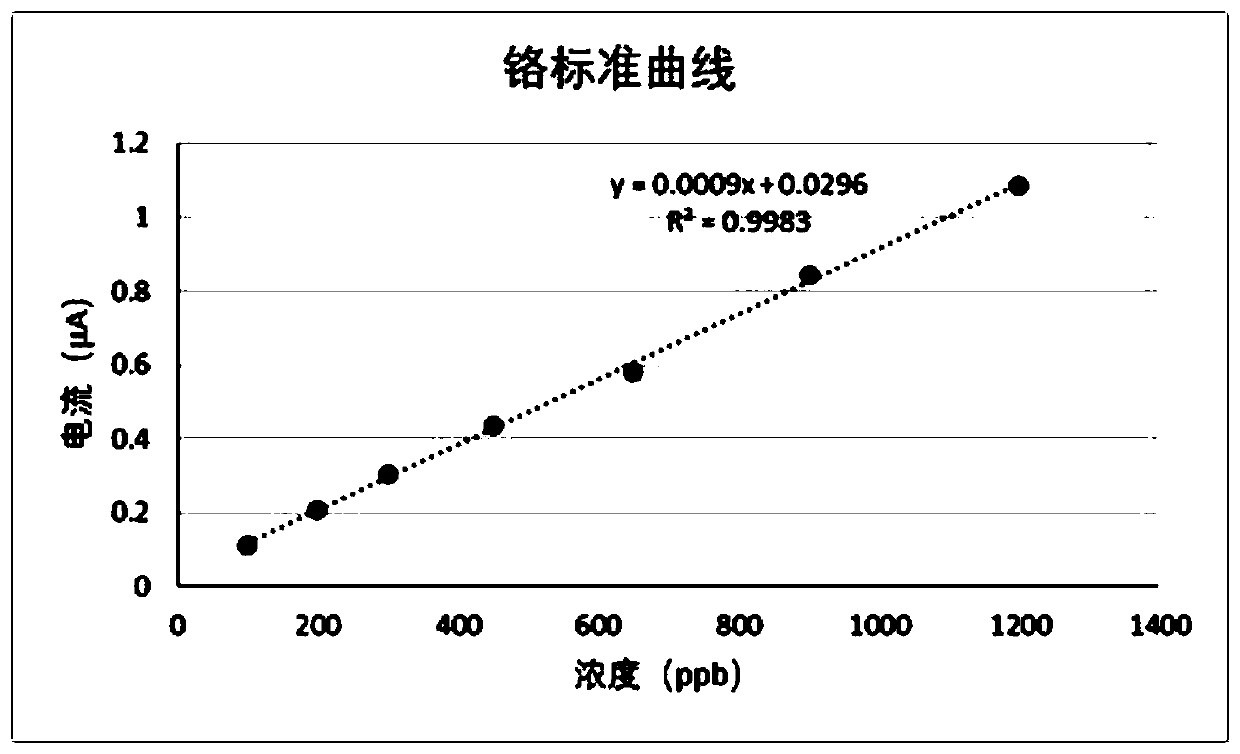

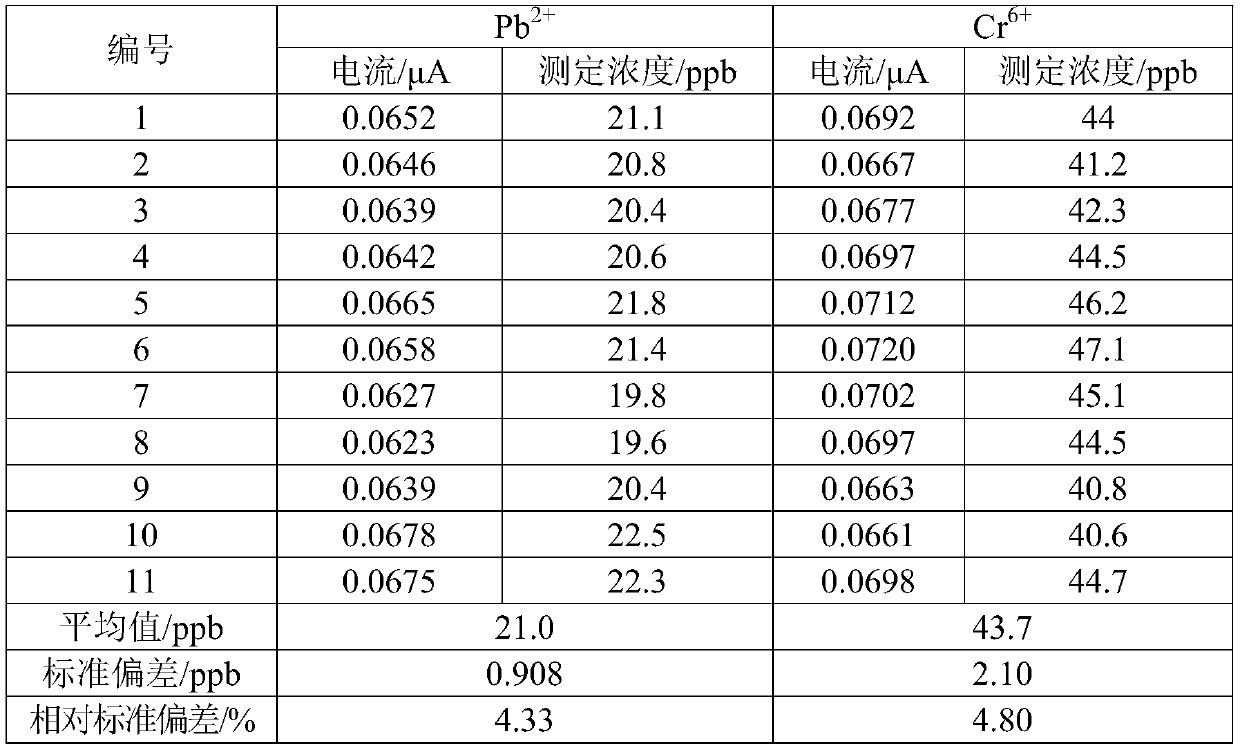

Method for rapidly detecting lead chromate in tea leaves

InactiveCN110579517AQuick extractionHigh sensitivityPreparing sample for investigationMaterial electrochemical variablesLead ChromateChemical reaction

The invention relates to the technical field of detection of heavy metals in food, and particularly discloses a method for rapidly detecting lead chromate in tea leaves. The method comprises the following steps: an extracting solution is added to react with lead chromate solids on the surfaces of tea leaves so that lead chromate is converted into detectable lead ions and chromium ions; and the contents of lead ions and chromium ions in the extracting solution are detected by using a portable heavy metal analyzer, and the content of lead chromate is calculated according to the contents of leadions and chromium ions. The method is simple to operate and safe, does not involve strong acid, strong alkali, high temperature and high pressure, has short pretreatment time and is suitable for quickly screening a large number of samples on site.

Owner:WUHAN ACADEMY OF AGRI SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com