Recycling method for heavy metal in electroplating sludge

A technology for electroplating sludge and heavy metals, applied in the direction of improving process efficiency, can solve the problems of large organic pollution, low recovery rate of heavy metals, and high energy consumption, and achieve the effects of reducing organic pollution, simple and easy operation, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

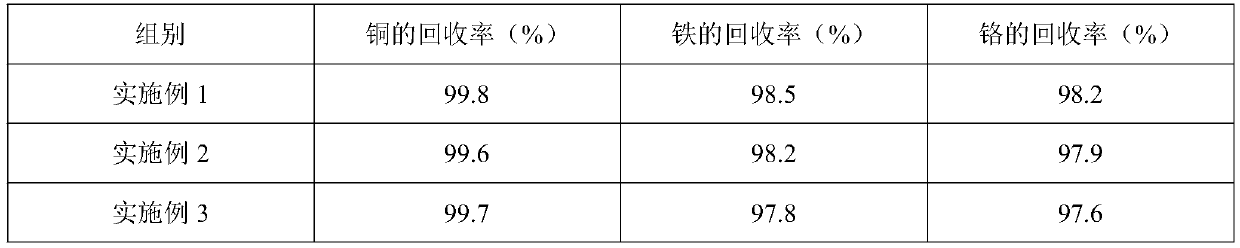

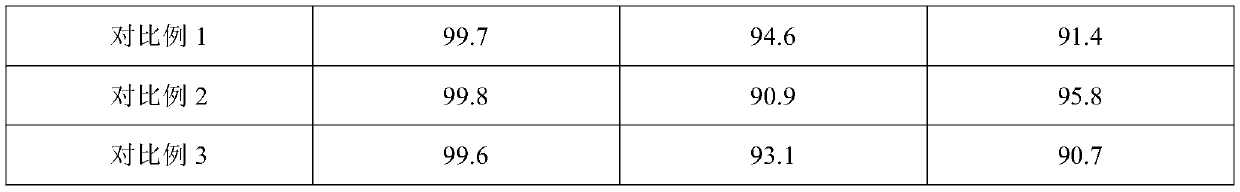

Examples

Embodiment 1

[0068] (1) add sulfuric acid with pH=1 to carry out sludge leaching, by weight, sludge: sulfuric acid=4:1, leaching temperature is 25 ℃, leaching time is 45min, obtains mixture A;

[0069] (2) A is subjected to pressure filtration with a pressure of 0.2 MPa to obtain filter residue a1 and filtrate b1, and the obtained filter residue a1 is solidified and landfilled;

[0070] (3) add iron powder in filtrate b1, by weight, filtrate b1: iron powder=4:1, carry out pressure filtration then, obtain metallic copper and filtrate b2;

[0071] (4) add hydrogen peroxide in filtrate b2, by weight, filtrate b2: hydrogen peroxide=50:1, then add sodium hydroxide, by weight, hydrogen peroxide: sodium hydroxide=1:9, pressure filtration obtains iron Chromium slag and filtrate b3, filtrate b3 leads to sewage treatment station;

[0072] (5) Add sodium hypochlorite and sodium hydroxide to iron chromium slag, the temperature is 20 ℃, by weight, iron chromium slag: sodium hypochlorite=1:1, sodium hy...

Embodiment 2

[0076] (1) adding hydrochloric acid with pH=1 to carry out sludge leaching, in parts by weight, sludge: hydrochloric acid=5:1, leaching temperature is 30°C, leaching time is 40min, and mixture A is obtained;

[0077] (2) A is subjected to pressure filtration with a pressure of 0.4 MPa to obtain filter residue a1 and filtrate b1, and the obtained filter residue a1 is solidified and landfilled;

[0078] (3) add iron powder in filtrate b1, by weight, filtrate b1: iron powder=5:1, carry out pressure filtration then, obtain metal copper and filtrate b2;

[0079] (4) add hydrogen peroxide in the filtrate b2, by weight, filtrate b2: hydrogen peroxide=55:1, then add potassium hydroxide, by weight, hydrogen peroxide: potassium hydroxide=1:10, pressure filtration obtains iron Chromium slag and filtrate b3, filtrate b3 leads to sewage treatment station;

[0080] (5) Add hydrogen peroxide and potassium hydroxide to the iron-chromium slag at a temperature of 25° C., in parts by weight, ir...

Embodiment 3

[0084] (1) adding nitric acid with pH=1 for sludge leaching, in parts by weight, sludge: nitric acid=4.5:1, leaching temperature is 27°C, leaching time is 60min, and mixture A is obtained;

[0085] (2) A is subjected to pressure filtration with a pressure of 0.3 MPa to obtain filter residue a1 and filtrate b1, and the obtained filter residue a1 is solidified and landfilled;

[0086] (3) add iron powder in filtrate b1, by weight, filtrate b1:iron powder=4.5:1, carry out pressure filtration then, obtain metal copper and filtrate b2;

[0087] (4) add hydrogen peroxide in the filtrate b2, by weight, filtrate b2: hydrogen peroxide=52:1, then add potassium hydroxide, by weight, hydrogen peroxide: potassium hydroxide=1:9.5, pressure filtration obtains iron Chromium slag and filtrate b3, filtrate b3 leads to sewage treatment station;

[0088] (5) Add sodium hypochlorite and potassium hydroxide to iron chromium slag, the temperature is 20 ℃, by weight, iron chromium slag: sodium hypoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com