Pretreatment method of caked raw material

A raw material and pretreatment technology, applied in the direction of grain processing, etc., can solve the problem that powder caking cannot be completely solved, and achieve the effect of reducing labor intensity, reducing operation difficulty, and overcoming technical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

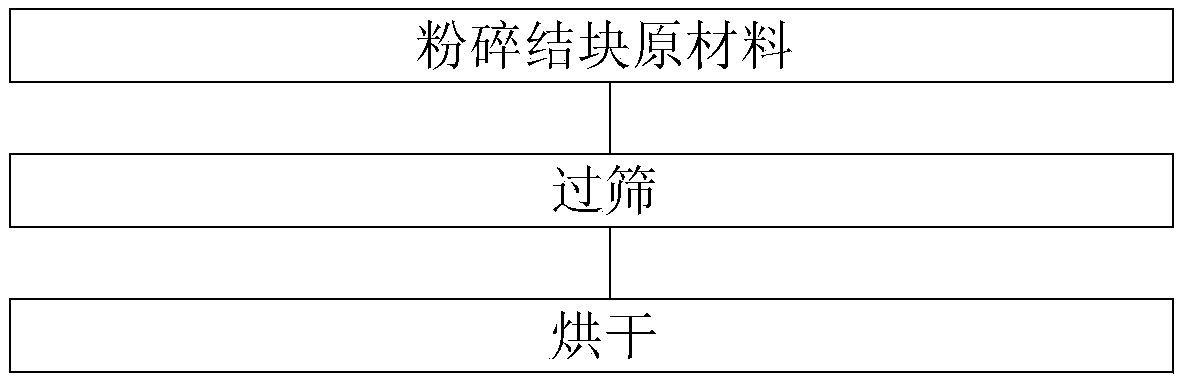

[0021] Optimize the raw material pretreatment process, and change the original treatment process from directly passing through a 20-mesh sieve to pre-drying to using a pulverizer to crush and then sieve.

[0022] The present embodiment is a kind of agglomerated raw material pretreatment method, and concrete process is:

[0023] Step 1, crushing agglomerated raw materials. A pulverizer is used to pulverize the agglomerated lead chromate raw material to obtain powdered lead chromate raw material. In this embodiment, the agglomerated raw material is lead chromate raw material; the pulverizer selected is YB-2000A type.

[0024] include:

[0025] 1. Add the agglomerated lead chromate raw material into the crushing bin of the crusher. The lead chromate raw material added should not exceed two-thirds of the crushing bin.

[0026] 2. Turn on the pulverizer to pulverize the agglomerated lead chromate raw material in the pulverization chamber. The pulverization time is determined t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com