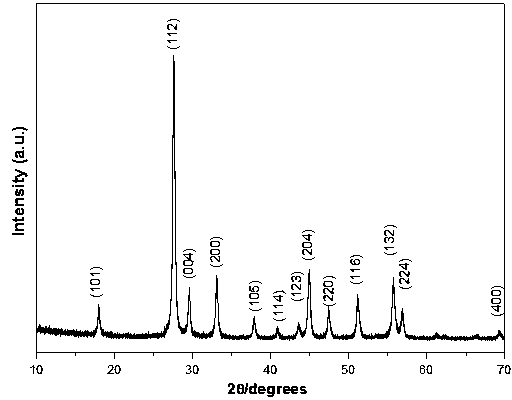

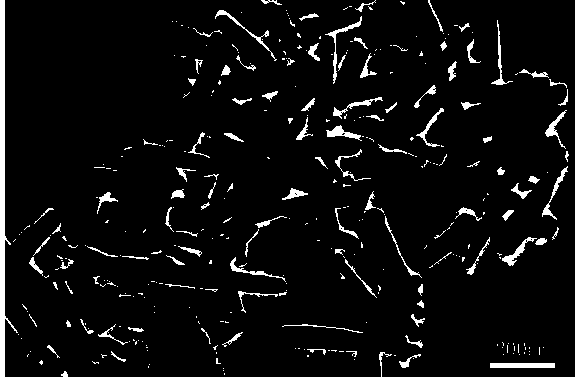

Lead molybdate nano crystal material and preparation method thereof

A nanocrystal, lead molybdate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as difficulty in controlling grain size and morphology, low purity of lead molybdate nanocrystal materials, and easy agglomeration. , to achieve the effect of saving energy and production time, simple equipment and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The method for preparing rod-shaped lead molybdate nanocrystal material comprises the following steps:

[0022] 1) Dissolve sodium chromate, lead nitrate and sodium molybdate in deionized water to prepare sodium chromate solution with a concentration of 0.1mol / L, lead nitrate solution with a concentration of 0.1mol / L and lead nitrate solution with a concentration of 0.1mol / L Sodium molybdate solution, for subsequent use;

[0023] 2) Get the sodium chromate solution and lead nitrate solution that step 1) makes according to CrO 4 2- and Pb 2+ The molar ratio is mixed at a ratio of 1:1 to obtain a solution containing lead chromate precipitate and stand for 1 hour;

[0024] 3) get step 1) the sodium molybdate solution that makes and step 2) the solution that contains lead chromate precipitation that obtains according to MoO 4 2- and Pb 2+ After mixing at a molar ratio of 1:1, let it stand for 3 hours, filter to obtain the precipitate generated by the reaction, then re...

Embodiment 2

[0027] The method for preparing rod-shaped lead molybdate nanocrystal material comprises the following steps:

[0028] 1) Dissolve sodium chromate, lead nitrate and sodium molybdate in deionized water to prepare sodium chromate solution with a concentration of 0.5mol / L, lead nitrate solution with a concentration of 0.5mol / L and lead nitrate solution with a concentration of 0.5mol / L Sodium molybdate solution, for subsequent use;

[0029] 2) Get the sodium chromate solution and lead nitrate solution that step 1) makes according to CrO 4 2- and Pb 2+ The molar ratio was mixed at a ratio of 1:1 to obtain a solution containing lead chromate precipitate and left to stand for 2 hours;

[0030] 3) get step 1) the sodium molybdate solution that makes and step 2) the solution that contains lead chromate precipitation that obtains according to MoO 4 2- and Pb 2+ After mixing with a molar ratio of 1:1, let it stand for 5 hours, filter to obtain the precipitate generated by the react...

Embodiment 3

[0033] The method for preparing rod-shaped lead molybdate nanocrystal material comprises the following steps:

[0034] 1) Dissolve sodium chromate, lead nitrate and sodium molybdate in deionized water to prepare sodium chromate solution with a concentration of 1.5mol / L, lead nitrate solution with a concentration of 1.5mol / L and lead nitrate solution with a concentration of 1.5mol / L Sodium molybdate solution, for subsequent use;

[0035] 2) Get the sodium chromate solution and lead nitrate solution that step 1) makes according to CrO 4 2- and Pb 2+ The molar ratio is mixed at a ratio of 1:1 to obtain a solution containing lead chromate precipitate and stand for 3 hours;

[0036] 3) get step 1) the sodium molybdate solution that makes and step 2) the solution that contains lead chromate precipitation that obtains according to MoO 4 2- and Pb 2+ After mixing at a molar ratio of 1:1, let it stand for 10 hours, filter to obtain the precipitate formed by the reaction, then rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com