Inorganic pigment and preparation method and application thereof

A technology of inorganic pigments and raw materials, applied in fibrous fillers and other directions, can solve the problems of limited application scope, toxic and harmful inorganic pigments, poor performance, etc., and achieve the effects of expanding application scope, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

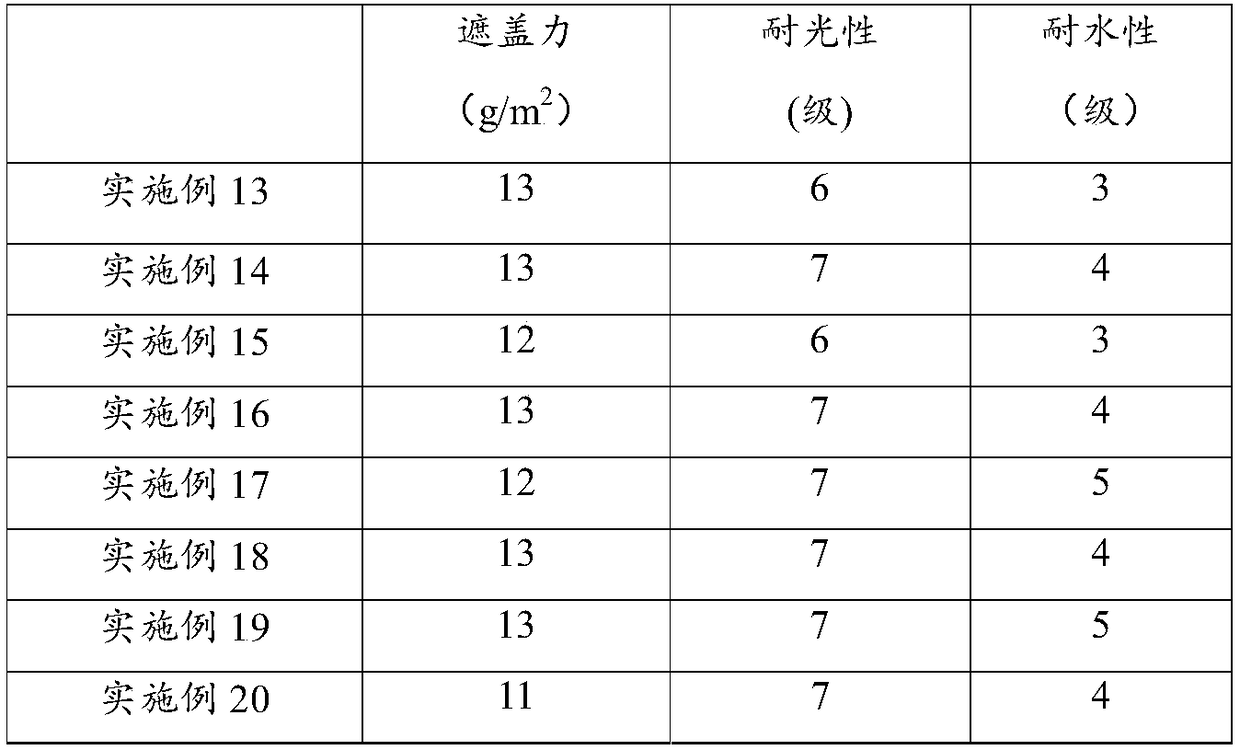

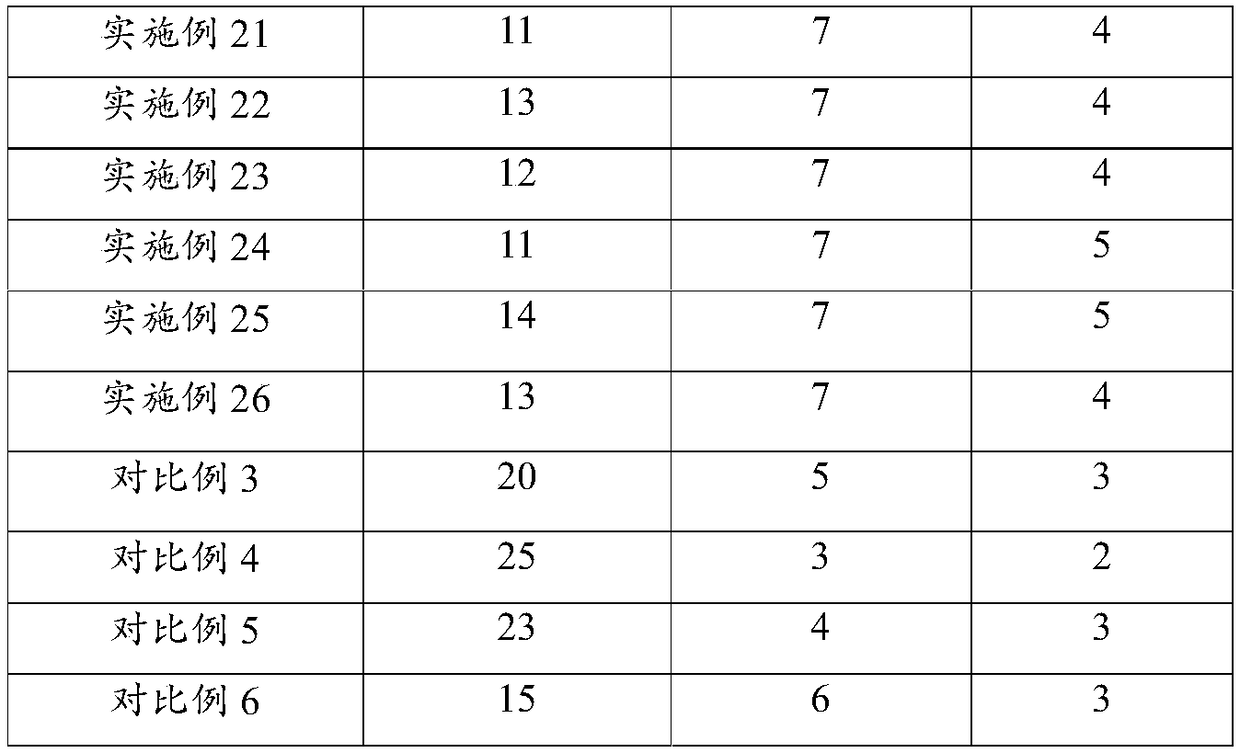

Examples

preparation example Construction

[0037] In another aspect, the present invention provides a method for preparing the above-mentioned inorganic pigment, comprising the following steps: mixing raw materials, calcining at a temperature of 850-1250° C., and obtaining the inorganic pigment after cooling.

[0038] Calcination is an important process for material preparation. The calcination process directly affects the microstructure such as grain size and distribution, pore size and distribution, and grain boundary volume fraction in the calcined compact. Calcination is a general term for the densification process and phenomenon of materials at high temperatures. As the temperature rises and the time prolongs, the solid particles are bonded to each other, the grains grow, and the voids (pores) and grain boundaries gradually decrease. During the calcination process, through the transfer of substances, its total volume shrinks, its density increases, and finally it becomes a hard polycrystalline sintered body.

[...

Embodiment 1

[0056] This embodiment provides an inorganic pigment, which includes the following raw materials in parts by weight: 20 parts of titanium dioxide, 15 parts of calcium oxide and 30 parts of Suzhou Yangshan kaolin.

Embodiment 2

[0058] This embodiment provides an inorganic pigment, which includes the following raw materials in parts by weight: 50 parts of titanium dioxide, 10 parts of calcium oxide and 55 parts of Suzhou Yangshan kaolin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com