Preparation method of 602 little smoke agent through mechanical mixing

A technology of mechanical mixing and micro-smoke medicine, applied in the direction of alkali metal composition, etc., can solve the problems of waste of manpower and material resources, affecting the reliability and stability of the performance of the medicine, to ensure the uniformity of mixing, and improve the reliability and stability of the medicine. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

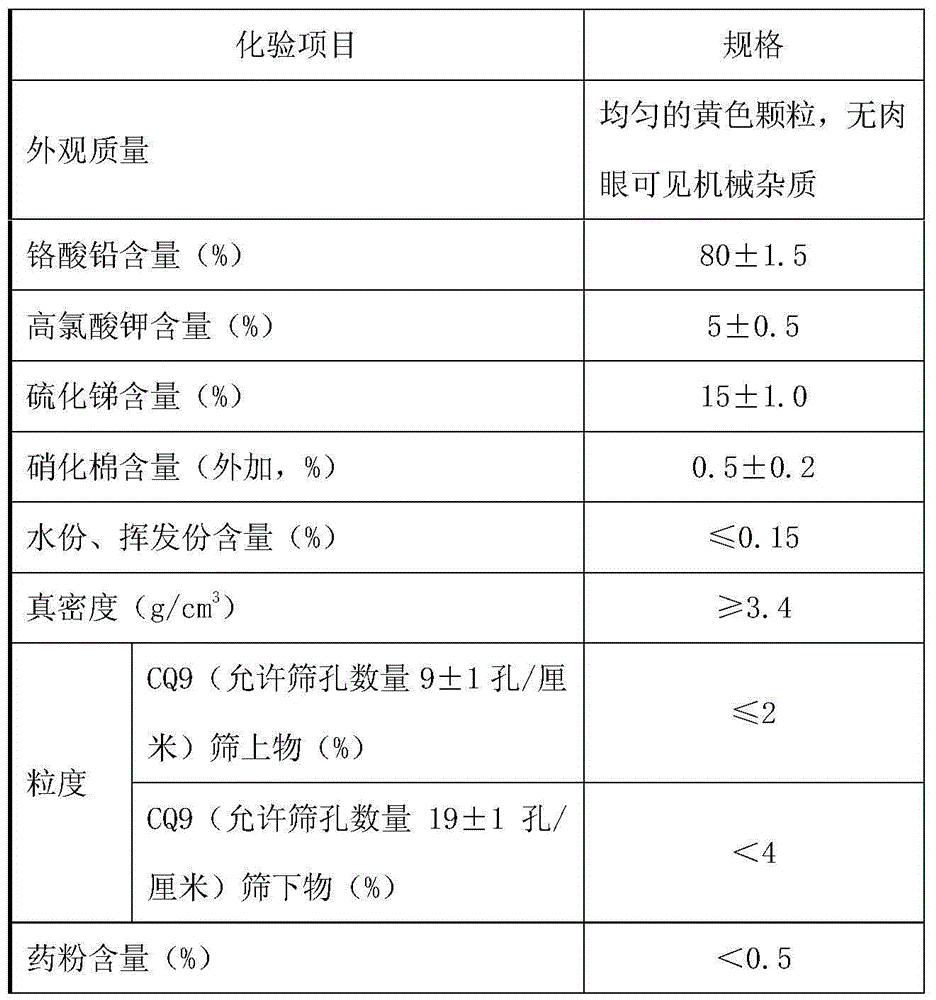

Embodiment 1

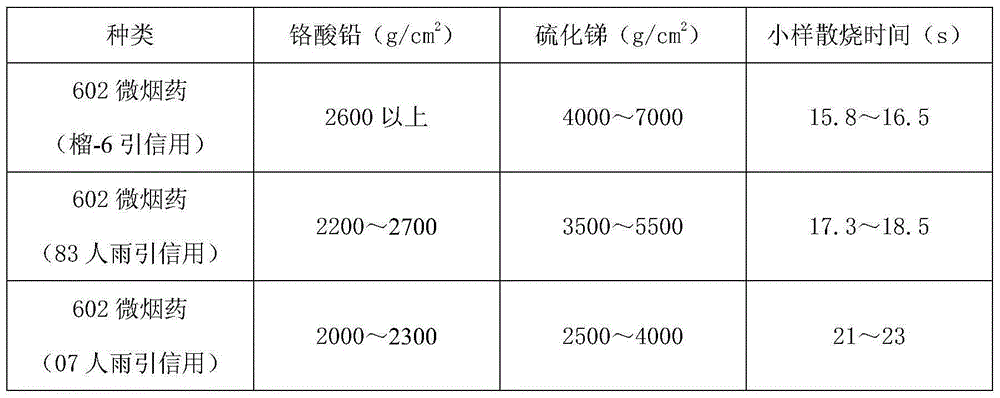

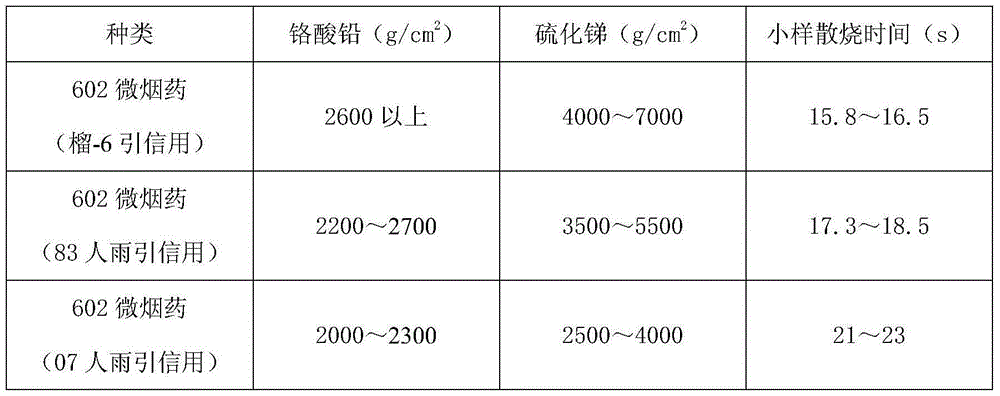

[0079] (5.5~9)s for the production of 602 micro-smoke medicine 50kg pomegranate-6 fuze

[0080] Step 1: Handling of Raw Materials

[0081] 1. Potassium perchlorate treatment

[0082] Weigh 10kg of the chemical reagent potassium perchlorate, put it into the vibration mill, add 60kg of copper balls of ∮10-20mm, carry out vibration grinding for 3-10 hours, take it out, and pass through the 60-65 hole / cm silk sieve as qualified particles. Dry the qualified particles, the water content is not more than 0.15%, after drying, they are classified according to different grinding times for later use;

[0083] 2. Treatment of vulcanizing ladder

[0084] Weigh 10kg of the refined and pulverized vulcanization ladder, put it into the vibration mill, add 60kg of steel balls of ∮15-25mm, carry out vibration grinding for 5-20 hours, take it out, and pass through the silk sieve with 60-65 holes / cm as qualified particle. Dry the qualified particles until the water content is not more than 0.2...

Embodiment 2

[0122] Production of 602 micro-smoke medicine 200kg83 person rain fuze (13~17)s

[0123] Step 1: Handling of Raw Materials

[0124] 1. Potassium perchlorate treatment

[0125] Weigh 10kg of the chemical reagent potassium perchlorate, put it into the vibration mill, add 60kg of copper balls of ∮10-20mm, carry out vibration grinding for 3-10 hours, take it out, and pass through the 60-65 hole / cm silk sieve as qualified particles. Dry the qualified particles, the water content is not more than 0.15%, after drying, they are classified according to different grinding times for later use.

[0126] 2. Treatment of vulcanizing ladder

[0127] Weigh 10kg of the refined and pulverized vulcanization ladder, put it into the vibration mill, add 60kg of steel balls of ∮15-25mm, carry out vibration grinding for 5-20 hours, take it out, and pass through the silk sieve with 60-65 holes / cm as qualified particle. Dry the qualified particles until the water content is not more than 0.2%. Mea...

Embodiment 3

[0167] Production of 602 micro-smoke medicine 200kg07 person rain fuze (12~17)s

[0168] Step 1: Handling of Raw Materials

[0169] 1. Potassium perchlorate treatment

[0170] Weigh 10kg of chemical reagent potassium perchlorate, put it into the vibrating mill, add 60kg of copper balls of ∮ (10-20) mm, carry out vibrating grinding (3-10) hours, take it out, and pass through (60-65) holes / cm silk sieve Those under the sieve are qualified particles. Dry the qualified particles, the water content is not more than 0.15%, after drying, they are classified according to different grinding times for later use.

[0171] 2. Treatment of vulcanizing ladder

[0172] Weigh 10kg of the refined and pulverized vulcanization ladder, put it into the vibration mill, add 60kg of steel balls of ∮ (15-25) mm, carry out vibration grinding (5-20) hours, take it out, and pass through (60-65) holes / cm The particles under the silk sieve are qualified particles. Dry the qualified particles until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com