High-temperature-resistant metal rustproof paint

A metal rust-proof and high-temperature-resistant technology, applied in anti-corrosion coatings, fire-proof coatings, asphalt coatings, etc., can solve problems such as peeling off, anti-rust coating discoloration, anti-rust coatings not resistant to high temperatures, etc., to achieve not easy to fall off, strong adhesion, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below:

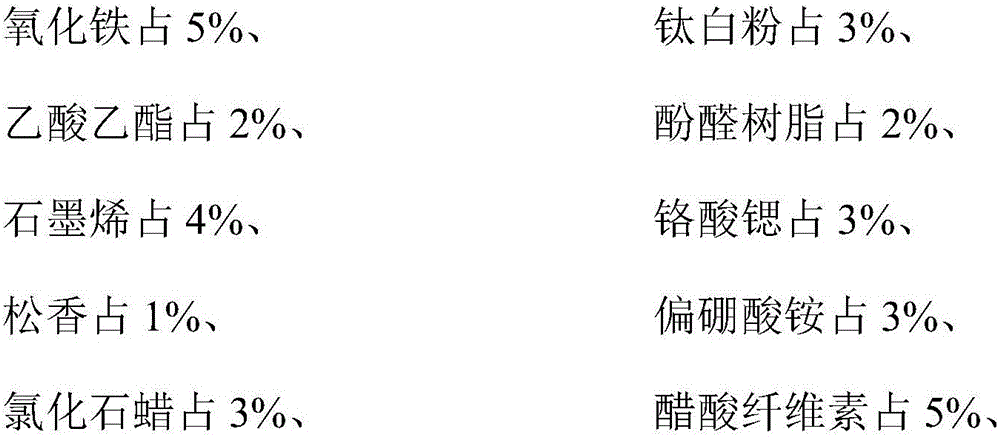

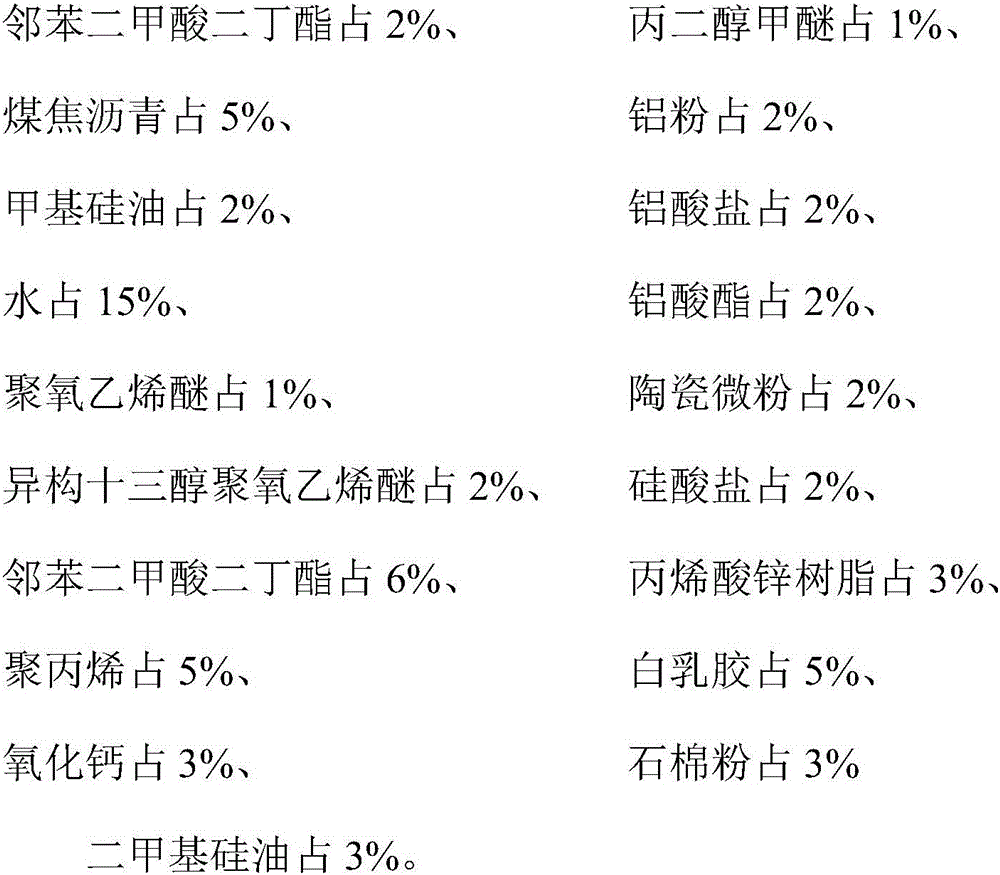

[0012] The present invention consists of acrylic resin, epoxy resin, iron oxide, titanium dioxide, ethyl acetate, phenolic resin, graphene, strontium chromate, rosin, ammonium metaborate, chlorinated paraffin, cellulose acetate, dibutyl phthalate Ester, propylene glycol methyl ether, coal tar pitch, aluminum powder, methyl silicone oil, aluminate, water, aluminate, polyoxyethylene ether, ceramic micropowder, isomerized tridecanol polyoxyethylene ether, silicate, ortho Dibutyl phthalate, zinc acrylate resin, polypropylene, white latex, calcium oxide, asbestos powder and simethicone.

[0013] Specifically, by weight, acrylic resin accounts for 2%, epoxy resin accounts for 3%,

[0014]

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com