High-temperature-resistant powder coating

A technology of powder coating and high temperature resistance, applied in the direction of powder coating, coating, etc., can solve the problems of harsh construction conditions, unfriendly environment, large waste, etc., and achieve simple pre-treatment requirements, avoid gelling and deterioration, and optimize the environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

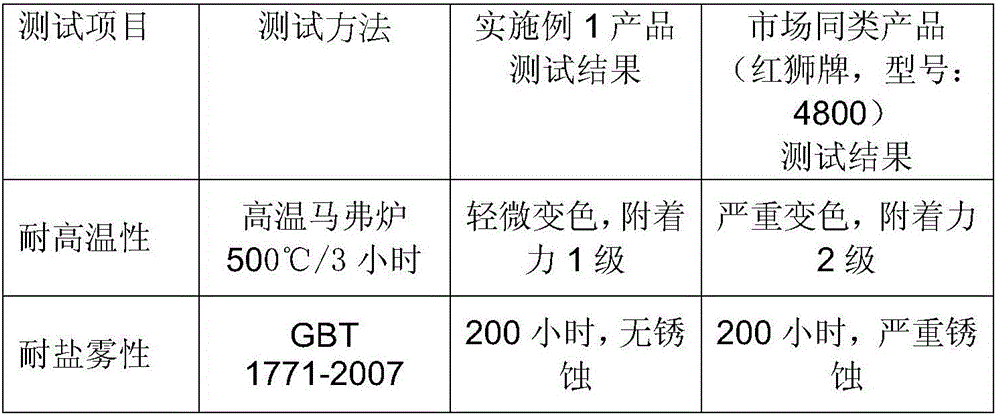

Examples

Embodiment 1

[0047] Embodiment 1 high temperature resistant powder coating

[0048] High temperature resistant powder coatings, by mass percentage, its raw materials are composed of the following components:

[0049] Solid silicone resin: 50%

[0050] Curing agent: 5%, the curing agent is polyvinyl butyral resin;

[0051] Strontium chromate powder: 3.5%

[0052] Zinc phosphate powder: 5%

[0053] Flaky mica powder: 33.5%

[0054] Other additives: 3%, based on the mass percentage of high-temperature-resistant powder coatings, the remaining additives are composed of 2% flow control agent of methyl methacrylate and ethyl acrylate copolymer and 1% benzoin degasser ; The product model of the flow control agent is PV88.

[0055] In the preparation of high-temperature resistant powder coatings in this example, the raw materials are mixed in a high-speed mixer, then extruded through a high-speed extruder and cooled by a tablet press, and then ground into a particle size of 30-35 μm by an ACM ...

Embodiment 2

[0058] Embodiment 2 high temperature resistant powder coating

[0059] High temperature resistant powder coatings, by mass percentage, its raw materials are composed of the following components:

[0060] Solid silicone resin: 46%

[0061] Curing agent: 6%, the curing agent is polyvinyl butyral resin;

[0062] Strontium chromate powder: 4%

[0063] Zinc Phosphate Powder: 6%

[0064] Flaky mica powder: 36%

[0065] Other additives: 2%, based on the mass percentage of the high-temperature-resistant powder coating, the remaining additives are composed of 1.2% flow control agent of methacrylic acid monomer and 0.8% diphenylethanolone degasser.

[0066] In the preparation of high-temperature resistant powder coatings in this example, the raw materials are mixed in a high-speed mixer, then extruded through a high-speed extruder and cooled by a tablet press, and then ground into a particle size of 30-35 μm by an ACM airflow turbine mill. fine particle powder coating.

Embodiment 3

[0067] Embodiment 3 high temperature resistant powder coating

[0068] High temperature resistant powder coatings, by mass percentage, its raw materials are composed of the following components:

[0069] Solid silicone resin: 54%

[0070] Curing agent: 4%, the curing agent is polyvinyl butyral resin;

[0071] Strontium chromate powder: 3%

[0072] Zinc Phosphate Powder: 4%

[0073] Flaky mica powder: 32.5%

[0074] Other additives: 1.5%, based on the mass percentage of the high-temperature-resistant powder coating, the remaining additives are composed of 1% flow control agent of methyl methacrylate monomer and 0.5% xylyl ethanol ketone degasser.

[0075] In the preparation of high-temperature resistant powder coatings in this example, the raw materials are mixed in a high-speed mixer, then extruded through a high-speed extruder and cooled by a tablet press, and then ground into a particle size of 30-35 μm by an ACM airflow turbine mill. fine particle powder coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com