Epoxy organosilicon anticorrosion paint and preparing method thereof

An epoxy organosilicon, anti-corrosion coating technology, applied in anti-corrosion coatings, polyamide coatings, coatings, etc., can solve the problems of high cost, unsatisfactory effect, complex process, etc., and achieve low cost, good basic physical properties, and technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Mix 50 parts of epoxy silicone resin with 50 parts of solvent, add 0.4 parts of defoamer, 0.6 parts of dispersant, and stir mechanically for 15 minutes;

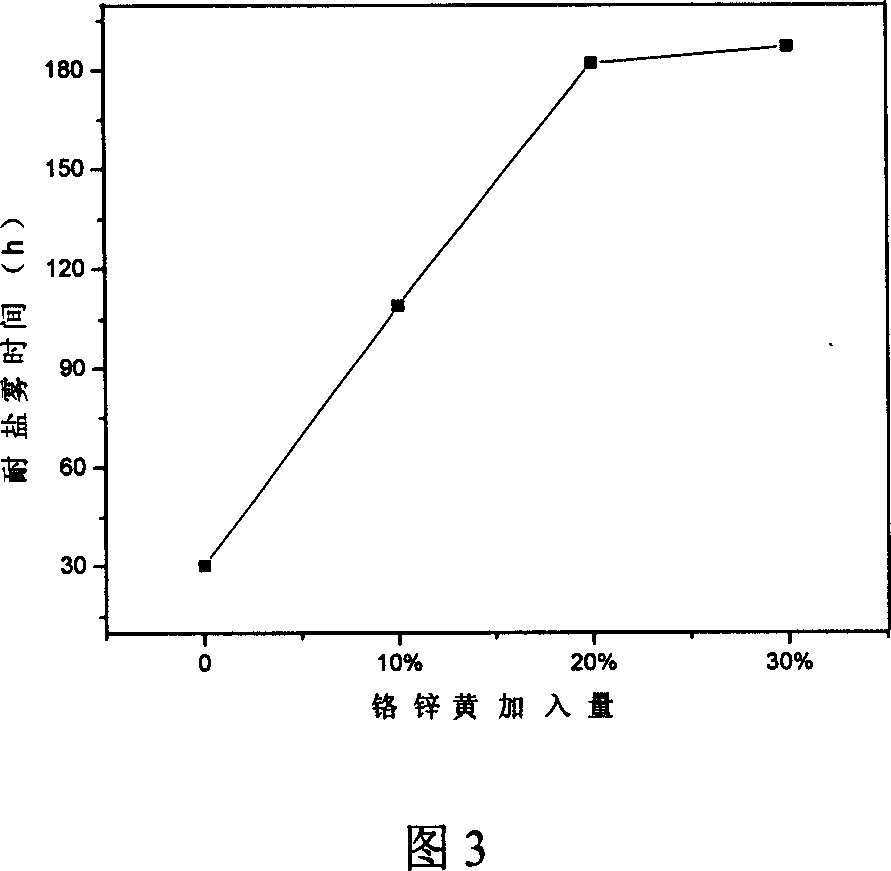

[0023] (2) Take 20 parts of chromium zinc yellow, 4 parts of strontium chromate, 20 parts of zinc molybdate, 10 parts of titanium dioxide, 20 parts of mica, and 25 parts of talcum powder into the above resin system, shear and grind for 30 minutes;

[0024] (3) Mix 50 parts of epoxy silicone resin with 50 parts of solvent, add to the solution prepared in step (2), and stir mechanically for 30 minutes;

[0025] (4) Mix 4 parts of solvent with 10 parts of polyamide, add to the solution prepared in step (3), and stir evenly.

Embodiment 2

[0027] (1) Mix 50 parts of epoxy silicone resin with 50 parts of solvent, add 0.4 parts of defoamer, 0.6 parts of dispersant, and stir mechanically for 15 minutes;

[0028] (2) Add 2 parts of strontium chromate, 30 parts of zinc molybdate, 10 parts of titanium dioxide, 20 parts of mica, and 37 parts of talcum powder into the above resin system, and shear and grind for 30 minutes;

[0029] (3) Mix 50 parts of epoxy silicone resin with 50 parts of solvent, add to the solution prepared in step (2), and stir mechanically for 30 minutes;

[0030] (4) Mix 4 parts of solvent with 10 parts of polyamide, add to the solution prepared in step (3), and stir evenly.

Embodiment 3

[0032] (1) Mix 50 parts of epoxy silicone resin with 50 parts of solvent, add 0.4 parts of defoamer, 0.6 parts of dispersant, and stir mechanically for 15 minutes;

[0033] (2) Take 10 parts of chromium zinc yellow, 6 parts of strontium chromate, 10 parts of titanium dioxide, 20 parts of mica, and 53 parts of talcum powder into the above resin system, shear and grind for 30 minutes;

[0034] (3) Mix 50 parts of epoxy silicone resin with 50 parts of solvent, add to the solution prepared in step (2), and stir mechanically for 30 minutes;

[0035] (4) Mix 4 parts of solvent with 10 parts of polyamide, add to the solution prepared in step (3), and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com