Plasticizer composition and resin composition comprising the plasticizer composition

A technology of composition and plasticizer, which is applied in the field of plasticizer composition and resin composition containing the plasticizer composition, can solve the problems of insufficient development of plasticizer, and achieve excellent safety and good plasticization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

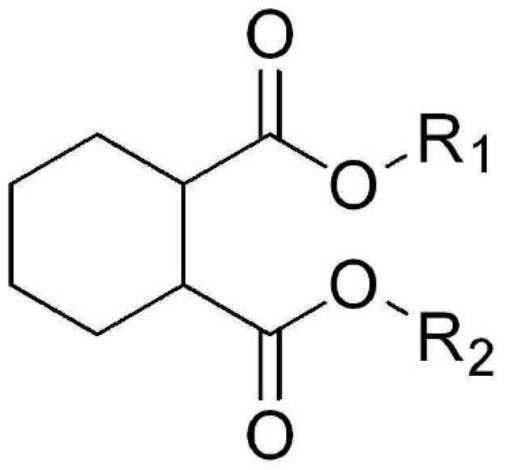

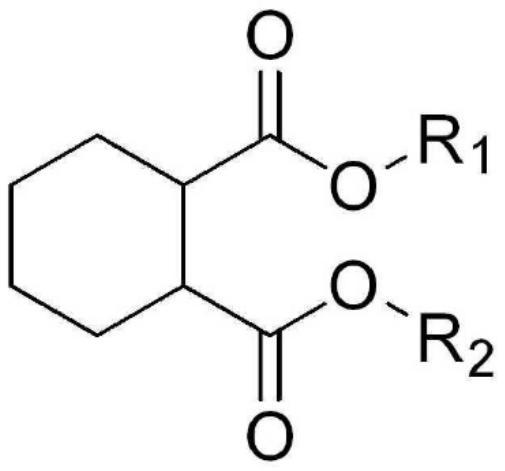

[0119] To a 3-liter four-neck reactor equipped with a cooler, condenser, decanter, reflux pump, temperature controller and stirrer was added 516.5 g of cyclohexane-1,2-dicarboxylic acid, 1,296 g of iso-iso Nonanol and 1.55 g of tetraisopropyl titanate as a catalyst, and the reaction temperature was set to 230°C. The direct esterification reaction was carried out for about 6 hours while continuously feeding nitrogen, and the reaction was terminated when the acid value reached 0.1.

[0120] After completion of the reaction, distillation extraction was performed under reduced pressure in order to remove unreacted raw materials. After distillation extraction was performed, a neutralization process, a dehydration process, and a filtration process were performed to prepare 1,240 g of diisononyl cyclohexane-1,2-dicarboxylate (yield: 97%).

[0121]

preparation Embodiment 2

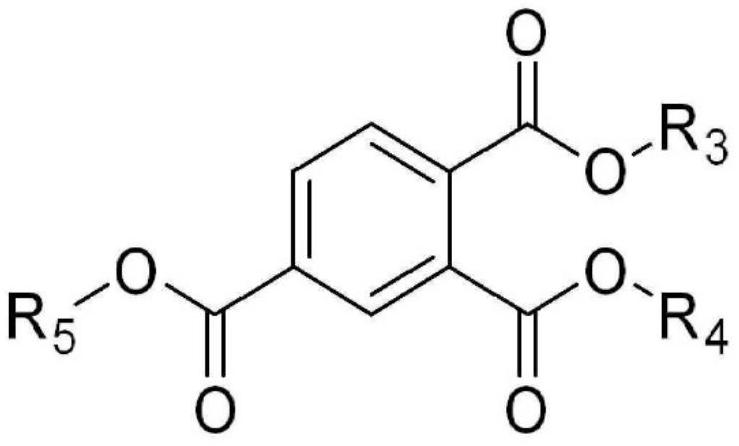

[0123] The same method as in Preparation Example 1 was carried out except that 384 g of trimellitic anhydride and 1,170 g of 2-ethylhexanol were charged into the reactor to prepare 1,060 g of tris(2-ethyl trimellitic acid) ethylhexyl) ester (TEHTM) (yield: 97%).

preparation Embodiment 3

[0125] The same method as in Preparation Example 1 was carried out except that 384 g of trimellitic anhydride and 1,296 g of isononyl alcohol were added to the reactor to prepare 1,140 g of triisononyl trimellitic acid (TINTM) ( Yield: 97%).

[0126] The cyclohexane-1,2-diesters prepared in Preparation Example 1, the trimellitic acid tris(2-ethylhexyl) ester prepared in Preparation Example 2, and the In triisononyl trimellitic acid, epoxidized oil, diisodecyl phthalate (DIDP) and phenyl alkyl sulfonate (ASPE, CAS No. 91082-17-6) prepared in 3 The plasticizer compositions of the Examples and Comparative Examples were prepared by mixing one or more of these, the details of which are summarized in Table 1 below. The evaluation of the physical properties of the plasticizer composition was performed according to the following test items. For substances other than those prepared in Preparation Examples, commercially available products were used.

[0127] [Table 1]

[0128]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com