Patents

Literature

39 results about "Isononyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

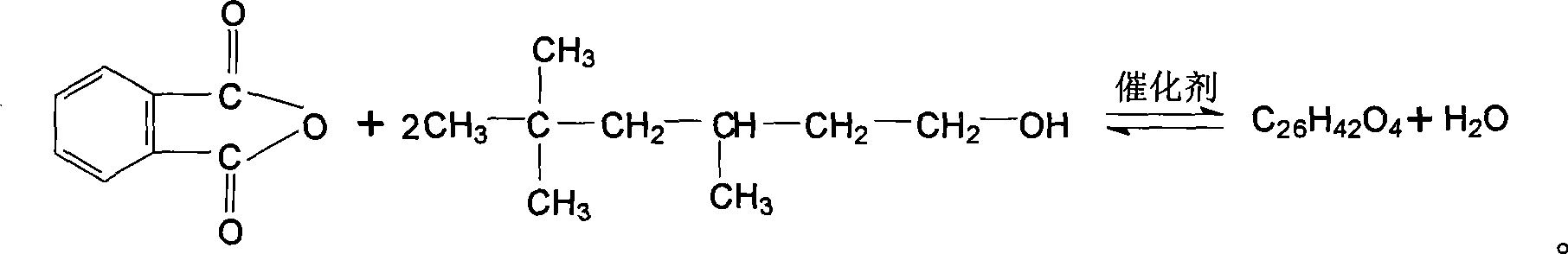

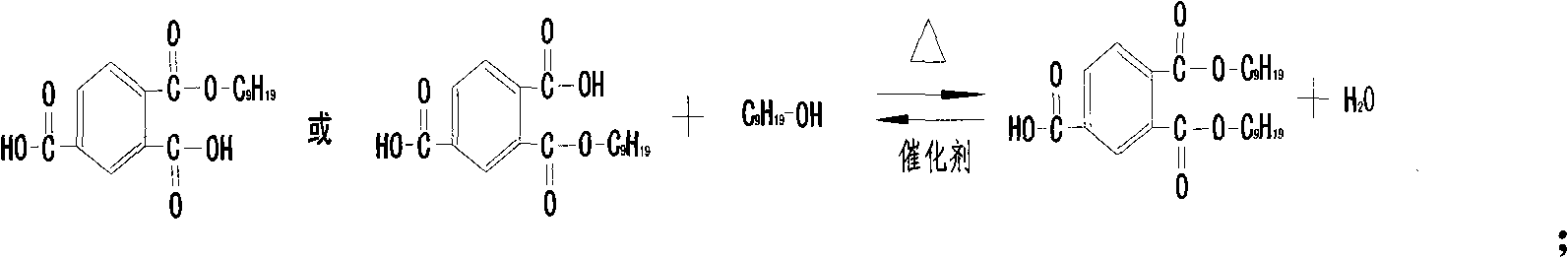

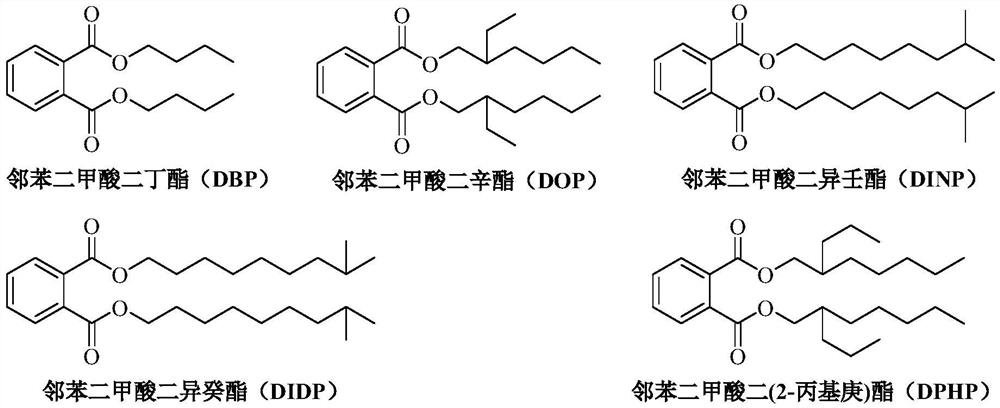

Method for producing plasticizer phthalic acid dinonyl

InactiveCN101157615AWon't happenShorten the production cycleOrganic compound preparationCarboxylic acid esters preparationIsononyl alcoholAcid catalysis

The invention relates to a production method for organic chemical product plasticizer, in particular to a production method for plasticizer phthalic acid diisononyl. The method comprises the steps as follows that: firstly, 3 to 4 portions of isononyl alcohol and one portion of bengan are filled into a reaction kettle, and then the solution is heated up when being stirred to carry a single-etherifying reaction; secondly, 0.001 to 0.002 parts of compound catalyst are filled in the solution after heating the solution to 150 to 180 DEG C; thirdly, the solution is continuously heated to 225 to 235 DEG C, and the solution is remained in the same temperature for 2 to 3 hours to carry a double-etherifying reaction, so that the in-kettle solution can be reacted fully and completely; fourthly, the solution is cooled down to 190 to 195 DEG C, and rude product of the plasticizer phthalic acid diisononyl is gained after traditionally depressurizing and dealcoholizing the solution; fifthly, the plasticizer phthalic acid diisononyl is obtained after traditionally discoloring and filtering the rude product. The invention has the advantages of avoiding the environment pollution due to acid catalysis method and decreasing the energy consumption.

Owner:无锡双象新材料有限公司

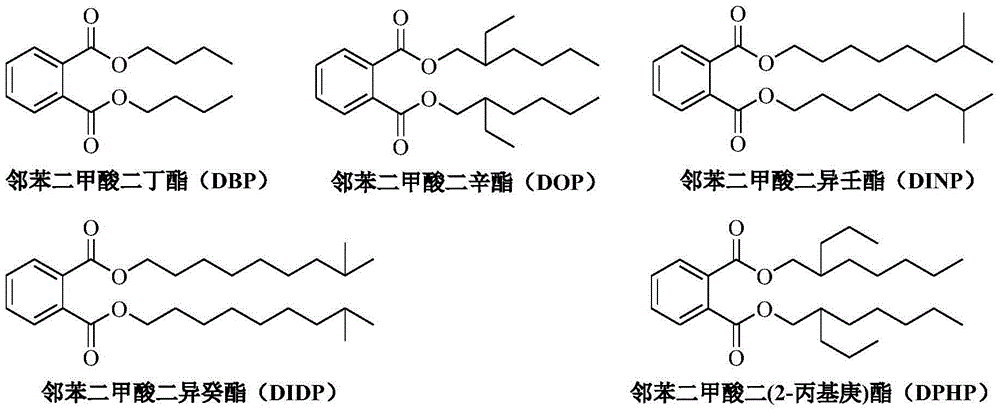

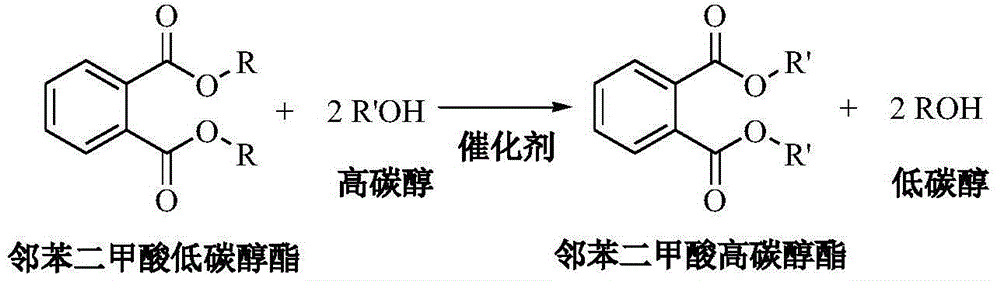

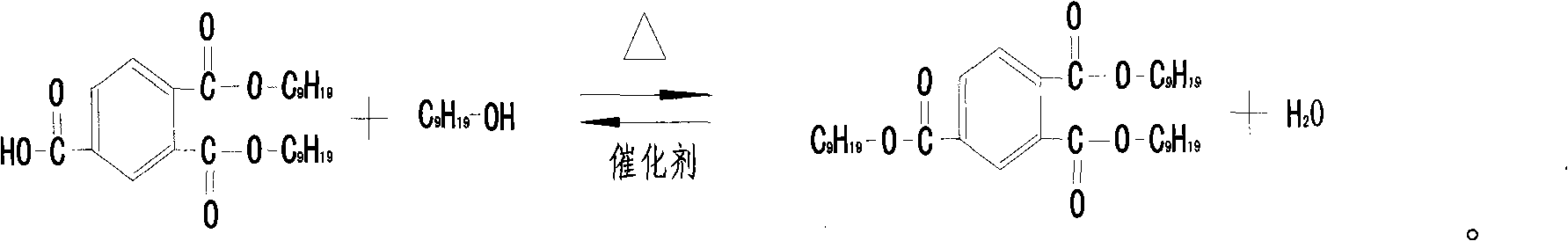

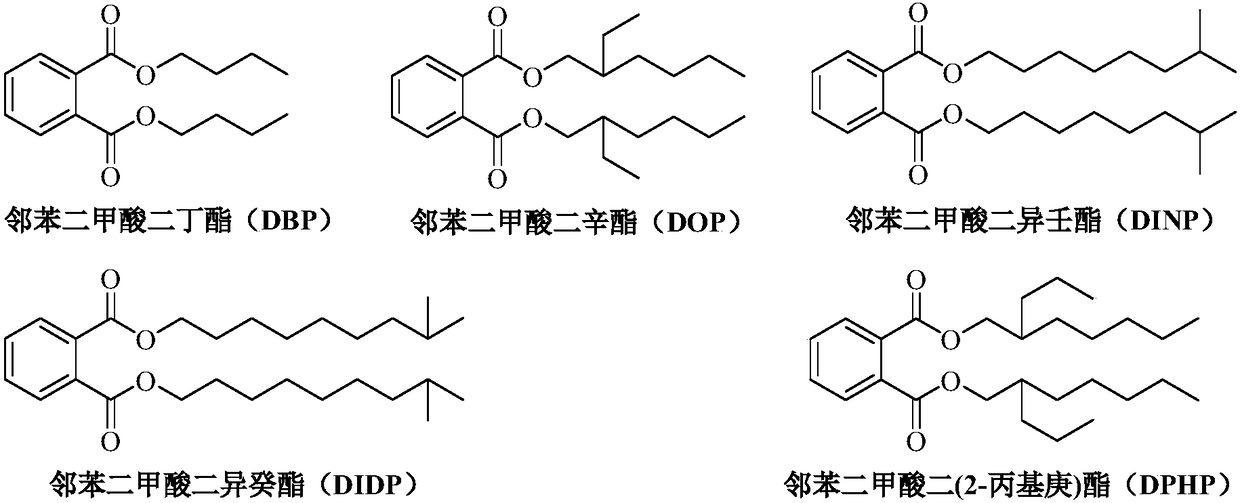

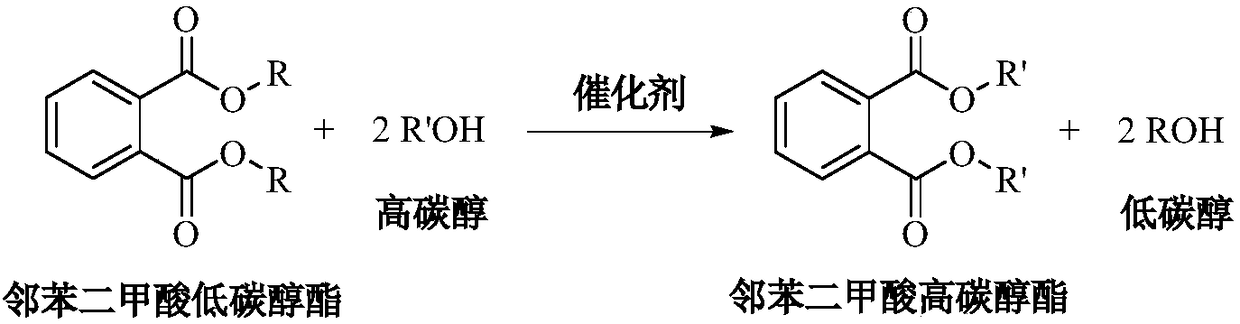

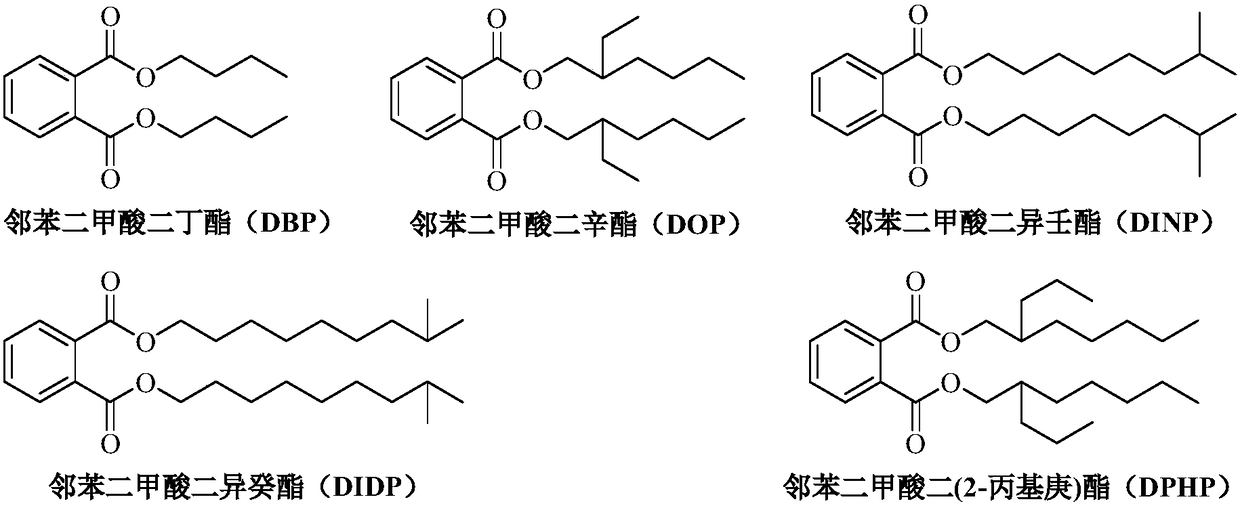

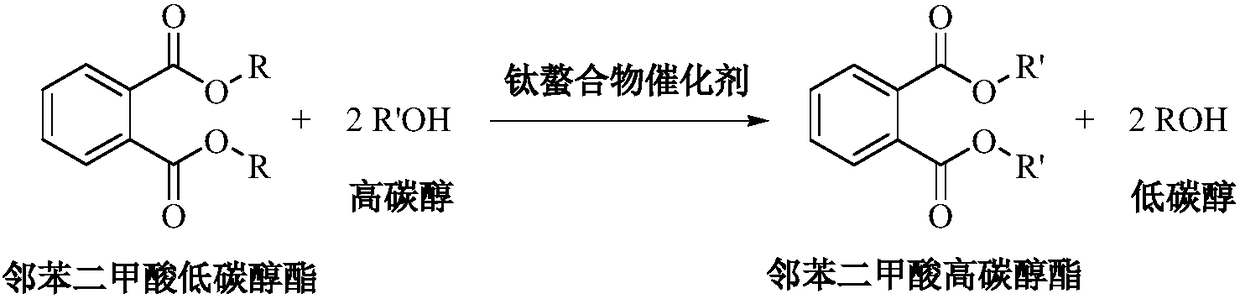

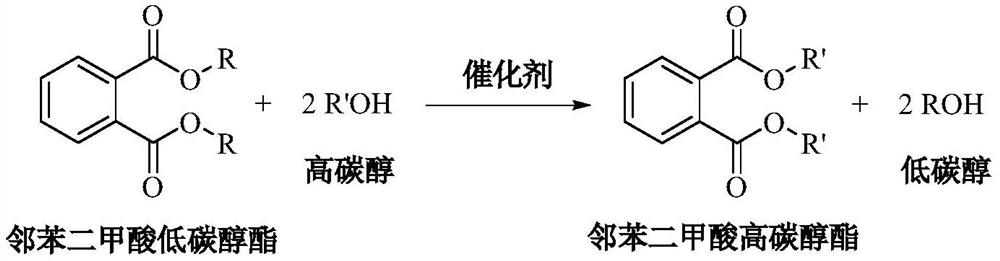

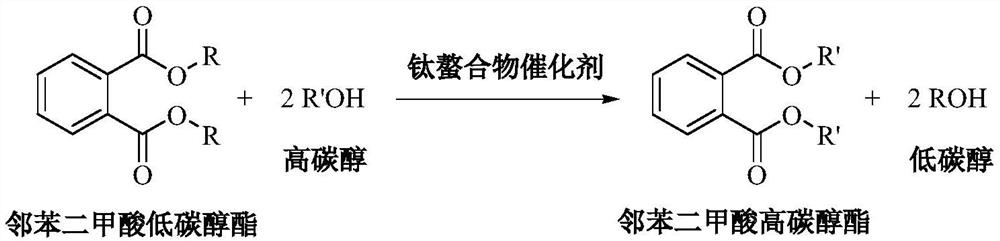

Method used for preparing higher aliphatic phthalates via ester exchange

ActiveCN105646229AGood storage and transportation stabilityReduce consumptionOrganic compound preparationCarboxylic acid esters preparationBarium titanateTitanites

The invention relates to a method used for preparing higher aliphatic phthalates via ester exchange. According to the method, lower aliphatic phthalates such as dimethyl phthalate, diethyl ester, and dibutyl ester, and high alcohols such as isononyl alcohol, isodecanol, and 2-propyI-1-heptanol are taken as raw materials, one or a mixture of more than one ingredient selected from titanium potassium oxalate, aluminium titanate, potassium titanate, magnesium titanate, calcium titanate, zirconium titanite, barium titanate, aluminium trichloride, antimony trichloride, titanium tetrachloride, zirconium tetrachloride, titanium methoxide, tetra(2-propyl heptanol)titanium, tetra isononanol titamium, and tetra isodecanol titamium is taken as a catalyst; reaction is carried out for 2 to 6h at 160 to 200 DEG C; and the highest lower aliphatic phthalate conversion rate and the highest higher aliphatic phthalate selectivity are higher than 99%. The production process is clean; energy is saved; raw material storage and transportation stability is high; feeding is convenient; catalyst corrosivity is less; reaction conditions are mild; less side effect is caused; and raw material consumption is low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

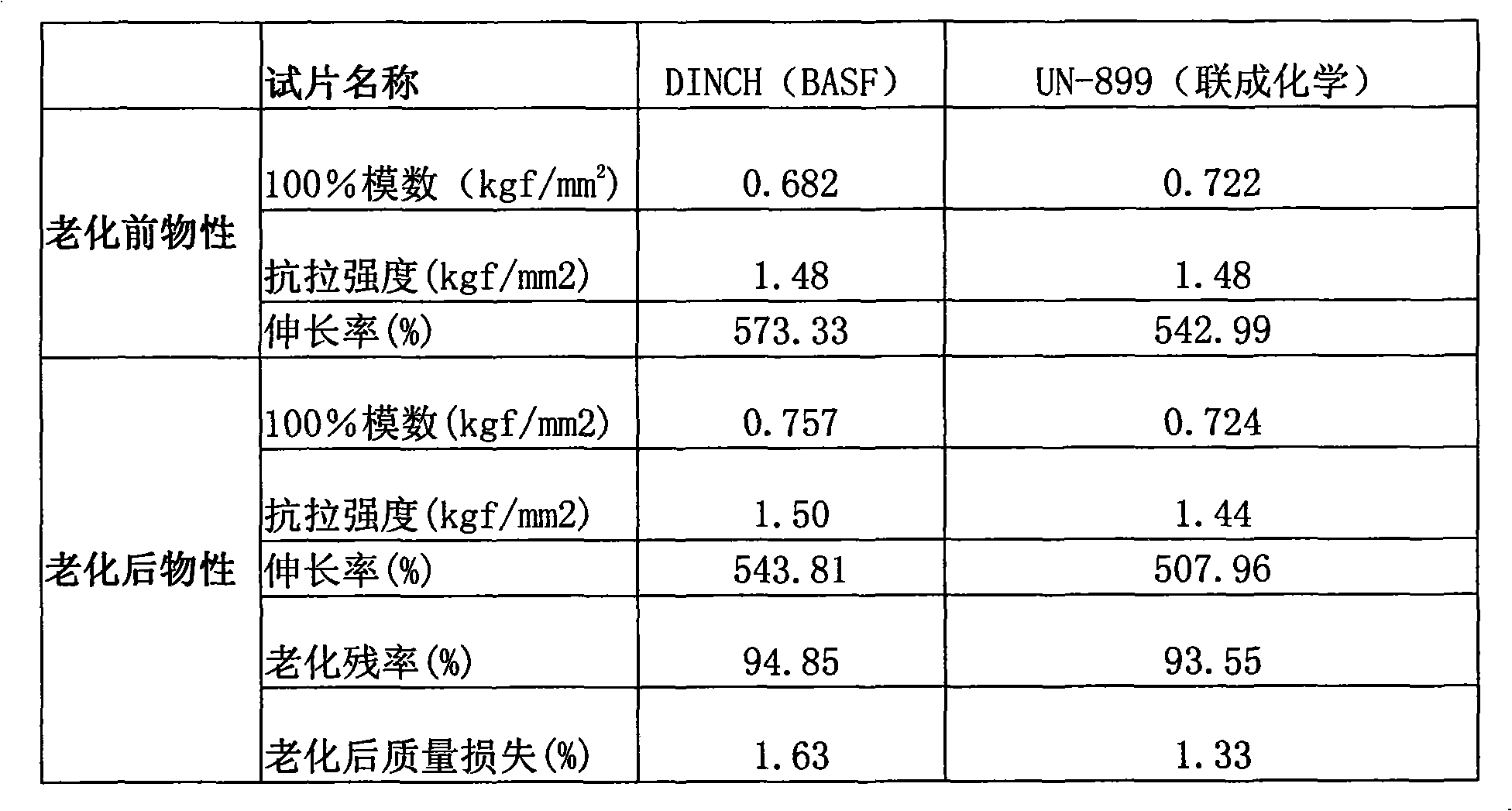

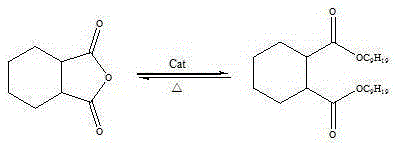

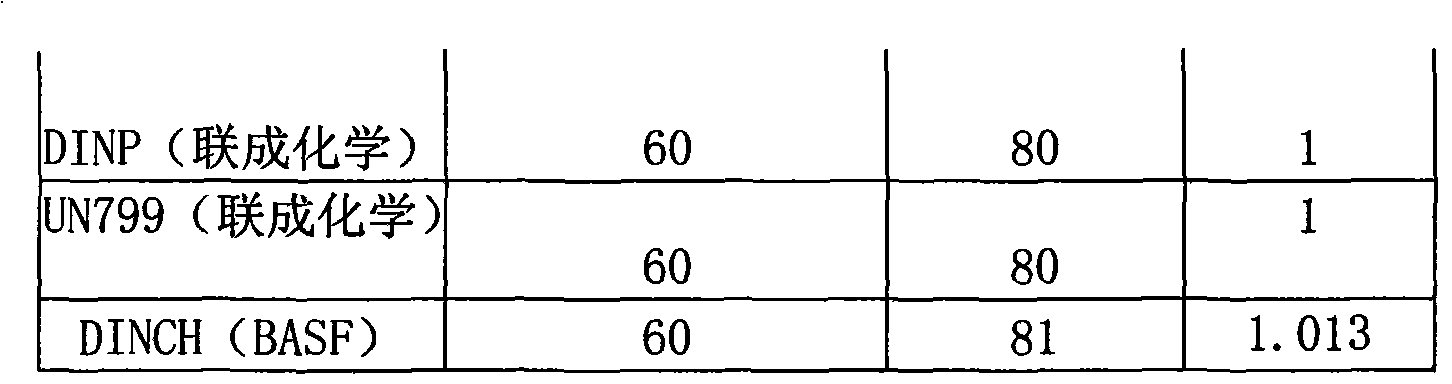

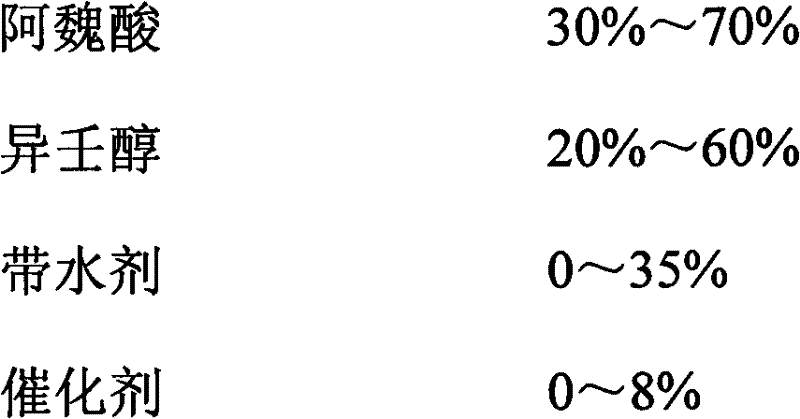

Preparation method of cyclohexane-1,2-diisononyl phthalate

InactiveCN105254501ALow costReduce dosageOrganic compound preparationCarboxylic acid esters separation/purificationIsononyl alcoholFiltration

The invention discloses a preparation method of cyclohexane-1,2-diisononyl phthalate. Isononyl alcohol, cyclohexane-1,2-dimethyl anhydride, a catalyst and a water-carrying agent are put into a reaction kettle; after reaction is completed, the water-carrying agent and the un-reacted isononyl alcohol are removed, the reactant is cooled to be at room temperature after alcohol is completely removed, and a filtration solvent is added for filtration; silica gel H is added into the obtained filtrate, and filtration is performed to remove the solvent in the filtrate so as to a pure product of the cyclohexane-1,2-diisononyl phthalate. This preparation method is low in energy consumption, 'three wastes' emission is less, operation is simple, the catalyst and the reactant can be recycled, a production process is improved by lowering reaction temperature, shortening reaction time, reducing the proportion of the raw materials and adopting other measures, reaction is stably performed, and the quality and purity of the product are high.

Owner:HUAIYIN TEACHERS COLLEGE

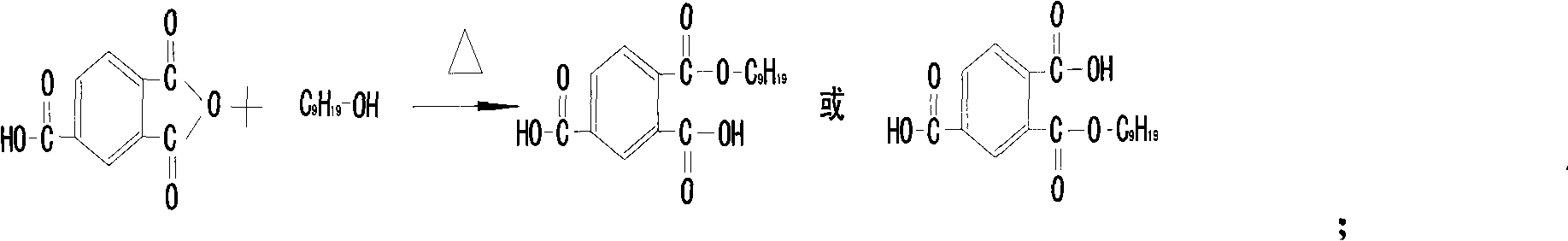

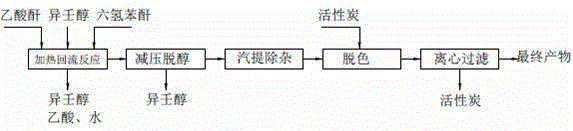

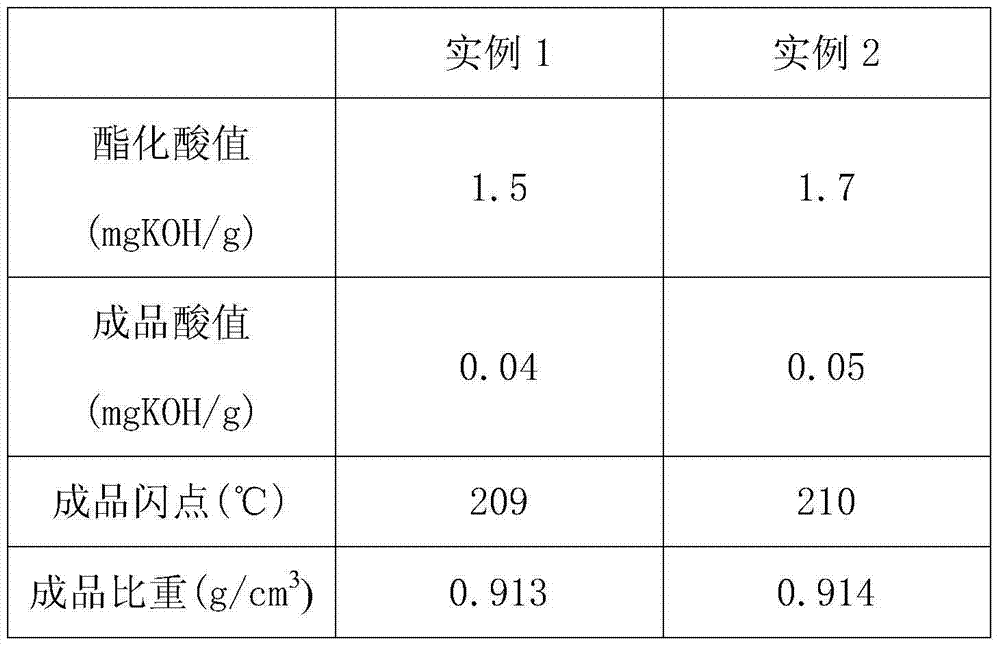

Method for preparing triisononyl trimellitate (TINTM)

InactiveCN101973884AImprove product qualityReduce consumptionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsononyl alcoholActivated carbon

The invention discloses a method for preparing triisononyl trimellitate (TINTM), comprising the following steps: adding trimellitic acid anhydride and isononyl alcohol with a mole ratio of 1:3.5-1:4.5 as well as activated carbon the weight of which is 0.1-0.3% of the weight of the trimellitic acid anhydride into a reaction kettle; stirring the mixture and raising the temperature to 185-195 DEG C; then, adding catalyst the weight of which is 0.05-0.2% of the weight of the trimellitic acid anhydride, continuing to raise the temperature to 185-245 DEG C and reacting for 3-4 hours; controlling the acid value to be below 0.50mgKOH / g, and carrying out negative pressure dealcoholization until no return liquid exists; adding sodium hydroxide solution with the mass percent concentration of 10-15%, and controlling the acid value to be below 0.07mgKOH / g; introducing water into the reaction kettle to serve as an entrainer, and carrying out dealcoholization refining; and lowering the temperature to 150 DEG C, adding dried atlapulgite the weight of which is 0.07-0.2% of the total mass of the end product, evenly mixing and filtering. The method of the invention has the characteristics of no pollution, low energy consumption, short process time, high efficiency and good product quality.

Owner:昆山合峰化工有限公司

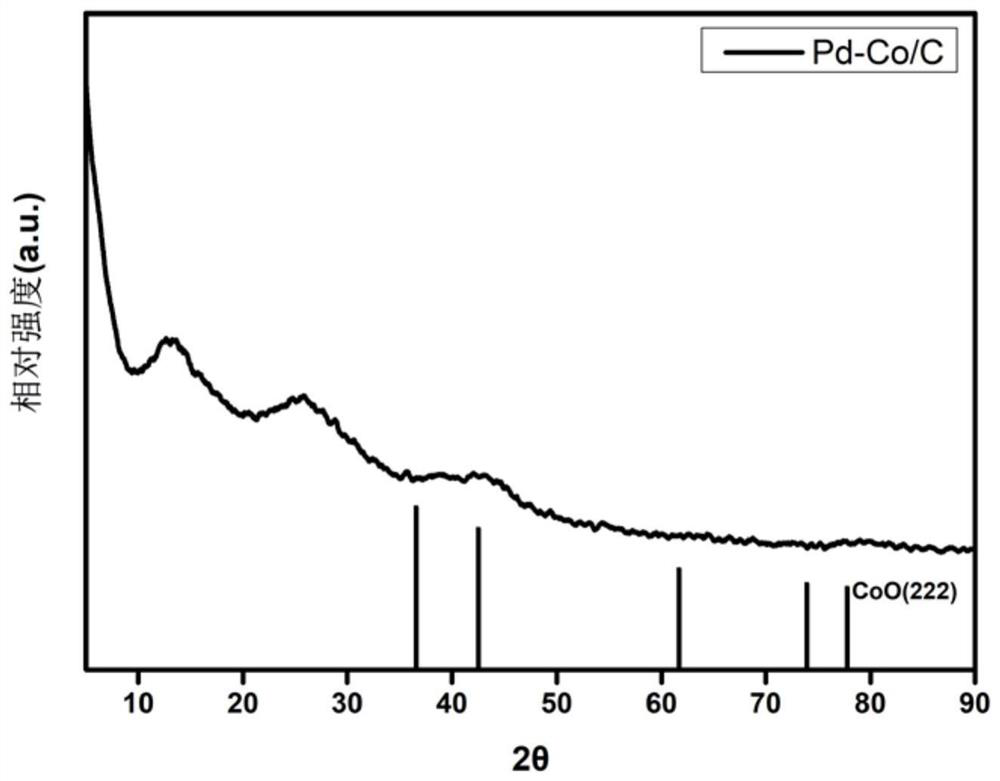

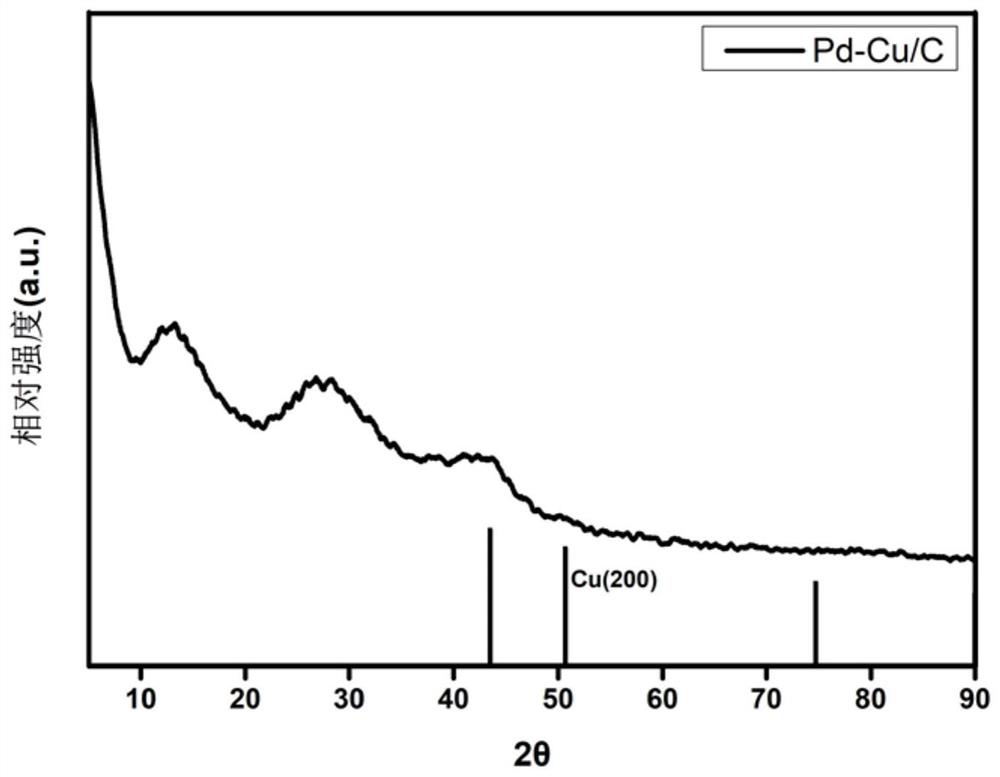

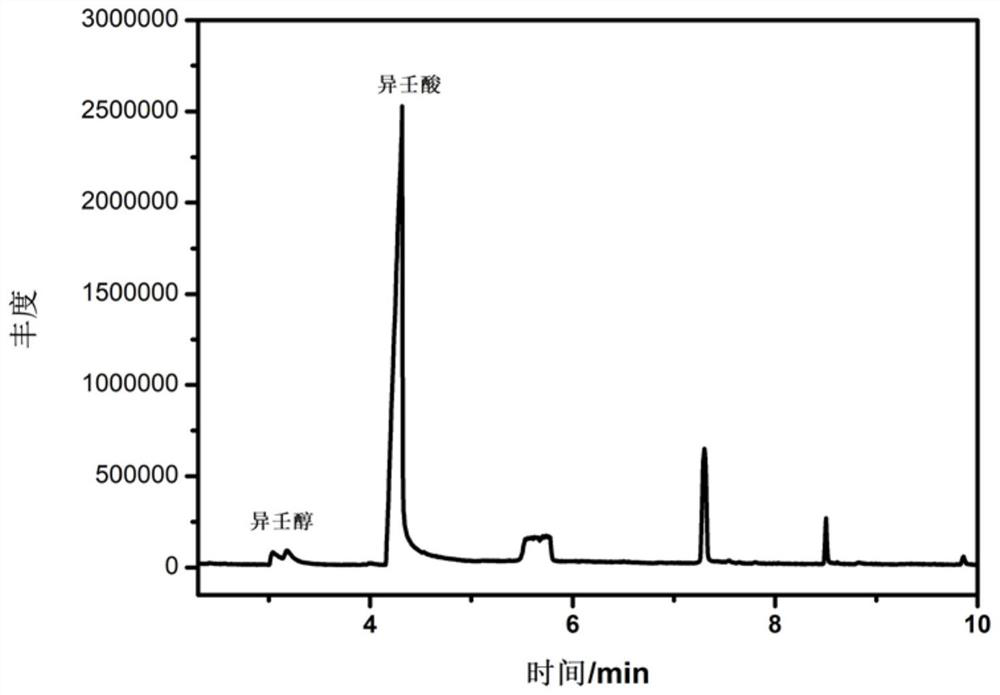

Catalyst for preparing isononanoic acid through catalytic oxidation of isononyl alcohol as well as preparation method and application thereof

ActiveCN112657510AImprove performanceEasy to prepareOrganic compound preparationCatalyst activation/preparationIsononyl alcoholActivated carbon

The invention discloses a catalyst for preparing isononanoic acid through catalytic oxidation of isononyl alcohol as well as a preparation method and application of the catalyst. The preparation method comprises the following steps: (1) uniformly dispersing carrier activated carbon in dilute nitric acid, and carrying out pretreatment modification; (2) dissolving an active metal salt palladium chloride in concentrated hydrochloric acid to prepare a chloropalladic acid solution; preparing an active additive into an aqueous solution, and mixing the aqueous solution with the chloropalladic acid solution to obtain an impregnation solution; adding the pretreated carrier activated carbon into the impregnation solution, and stirring and impregnating; and (3) adjusting the pH value of the system by using an alkaline solution to pre-disperse the active components. And (4) carrying out wet reduction on the active component, separating and drying to obtain the target composite catalyst. Meanwhile, the route for preparing isononanoic acid by oxidizing isononyl alcohol disclosed by the invention is relatively high in isononyl alcohol conversion rate and high in isononanoic acid selectivity, the energy consumption and investment of a separation section can be effectively reduced, and the reaction route for obtaining isononanoic acid by directly oxidizing isononyl alcohol is more friendly to raw material transportation conditions and has a good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing high-carbon alcohol phthalate ester through ester exchange continuous reaction

ActiveCN108976117AGood storage and transportation stabilityReduce consumptionPreparation by ester-hydroxy reactionHeterogenous catalyst chemical elementsAluminateContinuous use

The invention relates to a method for preparing high-carbon alcohol phthalate ester through ester exchange continuous reaction. In a fixed bed reactor, low carbon alcohol phthalate esters such as dimethyl phthalate, diethyl phthalate and dibutyl phthalate, and high-carbon alcohols such as isononyl alcohol, isodecanol and 2-propyl heptanol are taken as raw materials; one or more than two of calciummagnesium aluminate, sodium silicoaluminate, potassium aluminosilicate, magnesium aluminosilicate, calcium aluminosilicate, aluminum magnesium titanate, calcium magnesium titanate and magnesium aluminum zirconate are taken as catalysts; the mole ratio of high-carbon alcohols to low-carbon alcohol phthalate esters is at 2.1-4.0; the reaction temperature is at 160-220 DEG C; the volume airspeed is0.5-2h-1; the maximal conversion rate of low-carbon alcohol phthalate esters and the maximal selectivity of high-carbon alcohol phthalate ester are above 99%. The method provided by the invention hasthe advantages of high stability in raw material storage and transportation, feeding convenience, little side reaction, low raw material consumption, no corrosion and continuous use of catalysts, clean and energy-saving process, no generation and emission of wastewater, continuous reaction in the fixed bed reactor and high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of cycloalkane anhydride plasticizer

ActiveCN101607905AGood lookingLight colorOrganic compound preparationCarboxylic acid esters preparationActivated carbonIsononyl alcohol

The invention relates to the preparation of an additive used for the production of plastics, in particular to a preparation method of a cycloalkane anhydride plasticizer. The method comprises a first step of conducting mono-esterification reaction of 2-4 portions of isononyl alcohol and 1 portion of hexahydrophthalic anhydride; a second step of adding a catalyst when the temperature is increased to 160-180 DEG C; a third step of continuing to increase the temperature to 225 DEG C and then conducting bi-esterification reaction; a fourth step of decreasing the temperature to 210-215 DEG C and then conducting decompression and dealcoholization for 1-2 hours until the alcohol-containing mass percent is less than 0.05 percent; a fifth step of decreasing the temperature to 85-98 DEG C and adding pure water with 2-5 mass percent of reactants in a reactor to kill titanium isopropylate, and then increasing the temperature to 100-110 DEG C for decompression and dehydration after full reaction; and a sixth step of adding activated carbon and diatomaceous earth for bleaching and filtration so as to obtain a finished product. The product obtained does not contain a benzene ring structure, is environment friendly and non-toxic to human body, has high-impedance, and can be added and applied to various PVC plastic products.

Owner:ZHENJIANG UNION CHEM IND

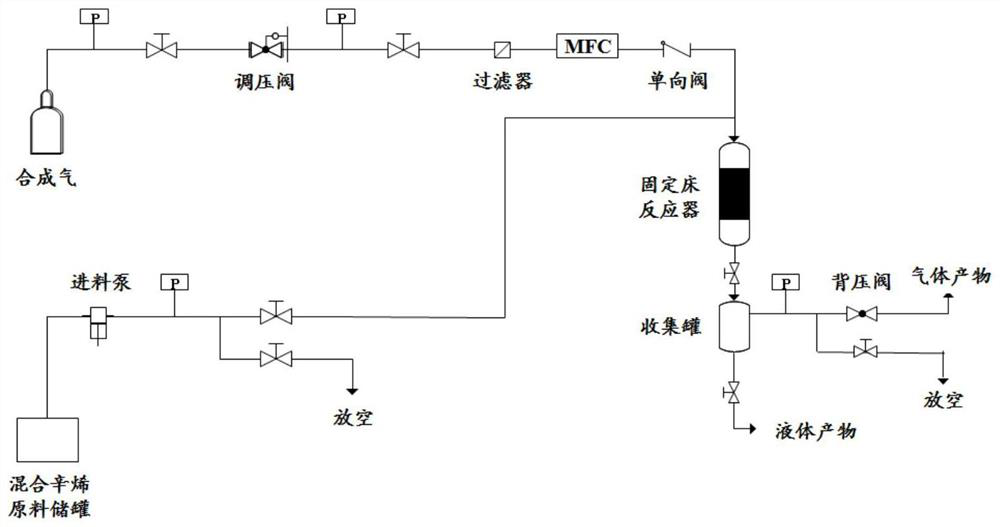

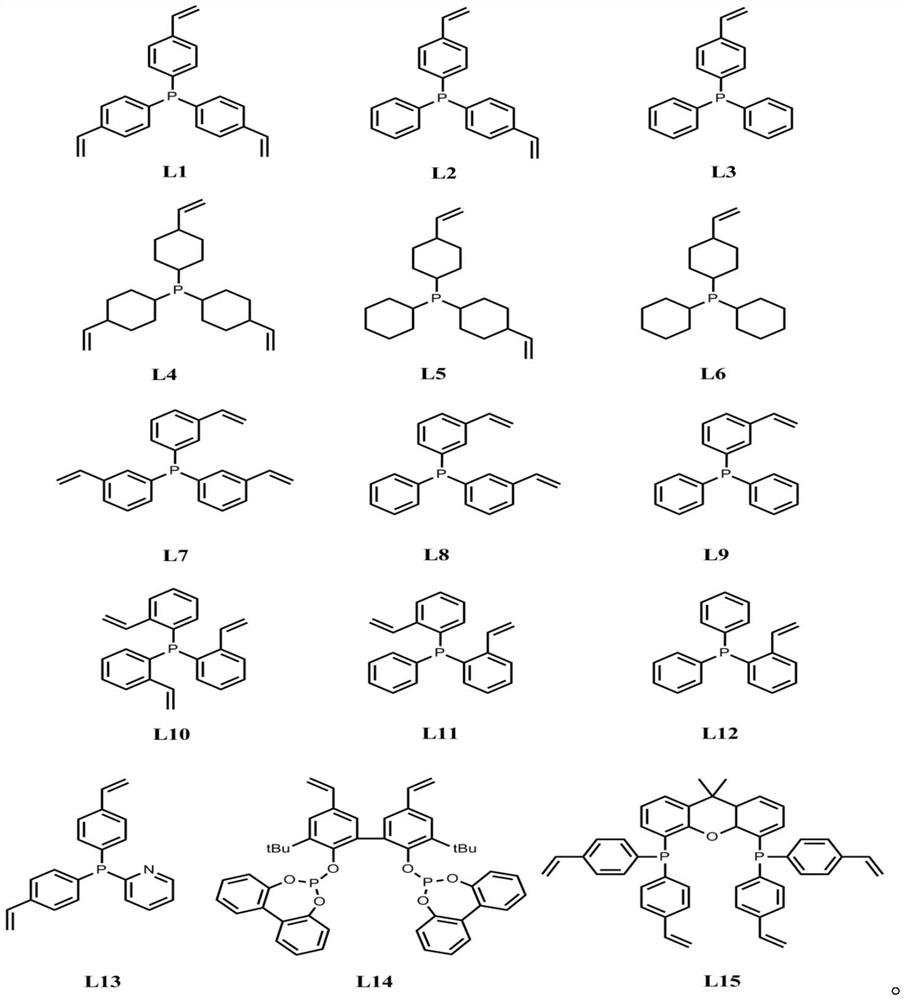

Method for preparing isononyl alcohol from mixed octylene

InactiveCN112898122AGood activity at low temperatureReduce separation costsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHexaldehyde

The invention relates to a method for preparing isononyl alcohol from mixed octylene, which is characterized in that the isononyl alcohol is synthesized by taking the mixed octylene as a raw material under the action of a catalyst through a two-step method. The method comprises the following steps: 1) reacting raw material mixed octylene with synthesis gas on a hydroformylation heterogeneous catalyst to generate 3, 5, 5-trimethyl hexanal; and 2) continuing the reaction, and carrying out aldehyde hydrogenation reaction on the hydrogenation catalyst to generate the target product 3, 5, 5-trimethyl-1-hexanol. The method is characterized in that 1) the hydroformylation solid heterogeneous catalyst is composed of a metal component and an organic ligand polymer, and the component forms a coordinate bond; the method is characterized in that the hydrogenation catalyst in the step 2) comprises the main components of Ni, Mg, Na, a selectivity improver and a carrier material treated by ammonia, the novel solid heterogeneous catalyst is adopted in the reaction in the method, the reaction activity and selectivity are excellent, the stability is good, and the method is suitable for large-scale industrial production; and the cost of separating the catalyst from reactants and products is reduced, and the industrial application prospect is wide.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

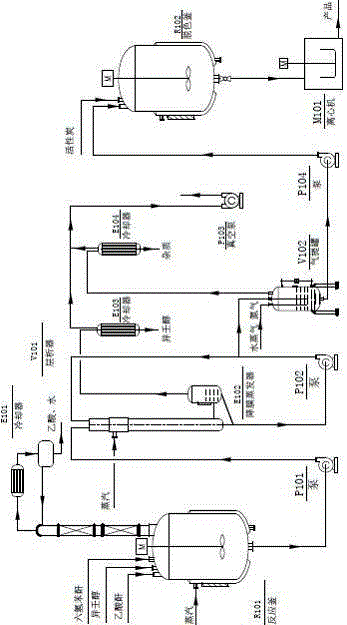

Preparation method for diisononyl cyclohexane-1,2-dicarboxylate

ActiveCN106565470ANo pollution in the processReduce usageOrganic compound preparationCarboxylic acid esters preparationAcetic anhydrideRetention time

The invention provides a preparation method for diisononyl cyclohexane-1,2-dicarboxylate. The preparation method comprises the following steps: 1) adding hexahydrophthalic anhydride, isononanol and acetic anhydride into a reaction vessel at the same time, carrying out heating to 180 to 300 DEG C and then carrying out stirring and dehydration for 2 to 5 h, wherein a mol ratio of hexahydrophthalic anhydride to isononanol is 1: (2-5), and the addition amount of acetic anhydride is 1 to 10% of the mass of hexahydrophthalic anhydride; 2) removing excess alcohol through flash evaporation by using a falling-film evaporator at a negative pressure of -0.02 MPa to 0.096 MPa, wherein retention time is 0.001 to 0.05 h; 3) introducing water vapor and nitrogen into a stripping tank for bubbling and removing low-molecular-weight impurities in a material 2 through evaporation; and 4) adding active carbon accounting for 1 to 10% of the mass of a material 3 into a decoloring kettle and carrying out decoloring and filtering so as to obtain the final product diisononyl cyclohexane-1,2-dicarboxylate, wherein yield reaches 98.5% and purity reaches 99.8%. According to the invention, a single-step high-temperature esterification process is employed, so reaction time is greatly shortened; excess alcohol is removed through pressure-reduced flash evaporation, so energy consumption is lowered, and the phenomenon of emulsification is avoided; and neutralization and washing are not needed, so alkaline waste water is not produced, and the preparation method is suitable for large-scale industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing PVC plasticizer from by-products of production of fumaric acid and recovery alcohol

ActiveCN101875609BEfficient use ofReduce pollutionOrganic compound preparationCarboxylic acid esters preparationIsononyl alcoholIsooctyl alcohol

The invention relates to a method for preparing a PVC plasticizer by taking by-products of production of fumaric acid and recovery alcohol as raw materials. The method comprises the following steps of: 1, adding 1 part of acid water residues, 2 to 4 parts of recovery isooctanol or recovery isononyl alcohol and 200 to 400ppm of esterification catalyst into a reactor with a thermometer, a distillation and condensing device and a stirring device, and heating the mixture with stirring to the temperature of between 120 and 160 DEG C for yielding water; 2, continuing heating to the highest reactiontemperature of 220 DEG C, controlling the temperature of cut fraction to be between 80 and 102 DEG C all the time in the process of a reaction, and reacting until an acid value is less than 1.0 mgKOH / g; and 3, reducing the temperature until the temperature is 190 DEG C or 215 DEG C, performing dealcoholization under the reduced pressure of between -600 and -740 mmHg for 1 to 2 hours, stopping thereaction, and cooling and filtering to obtain a finished product. The method can utilize scrap materials of enterprises effectively, reduce the production cost of the plasticizer and the treatment cost of waste liquor and reduce environmental pollution.

Owner:ZHENJIANG UNION CHEM IND

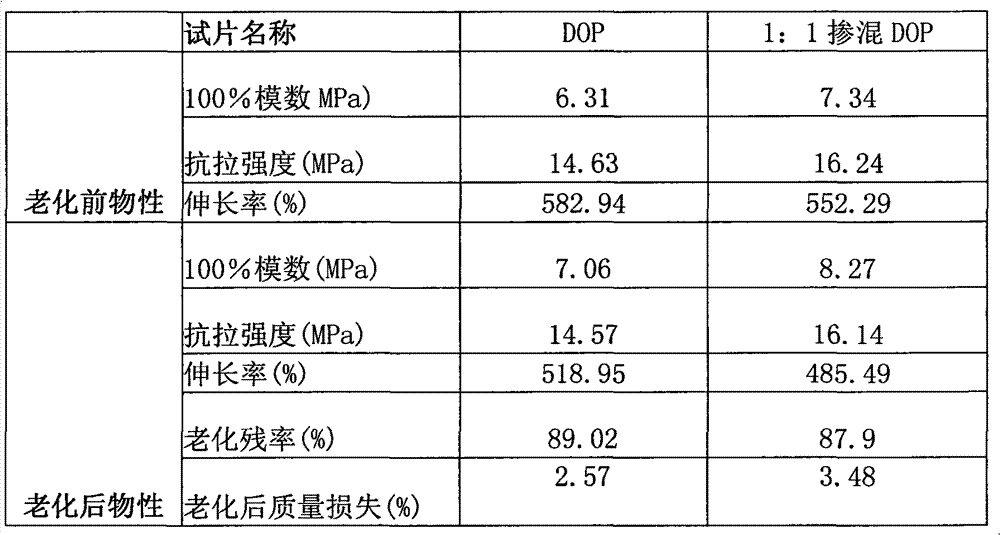

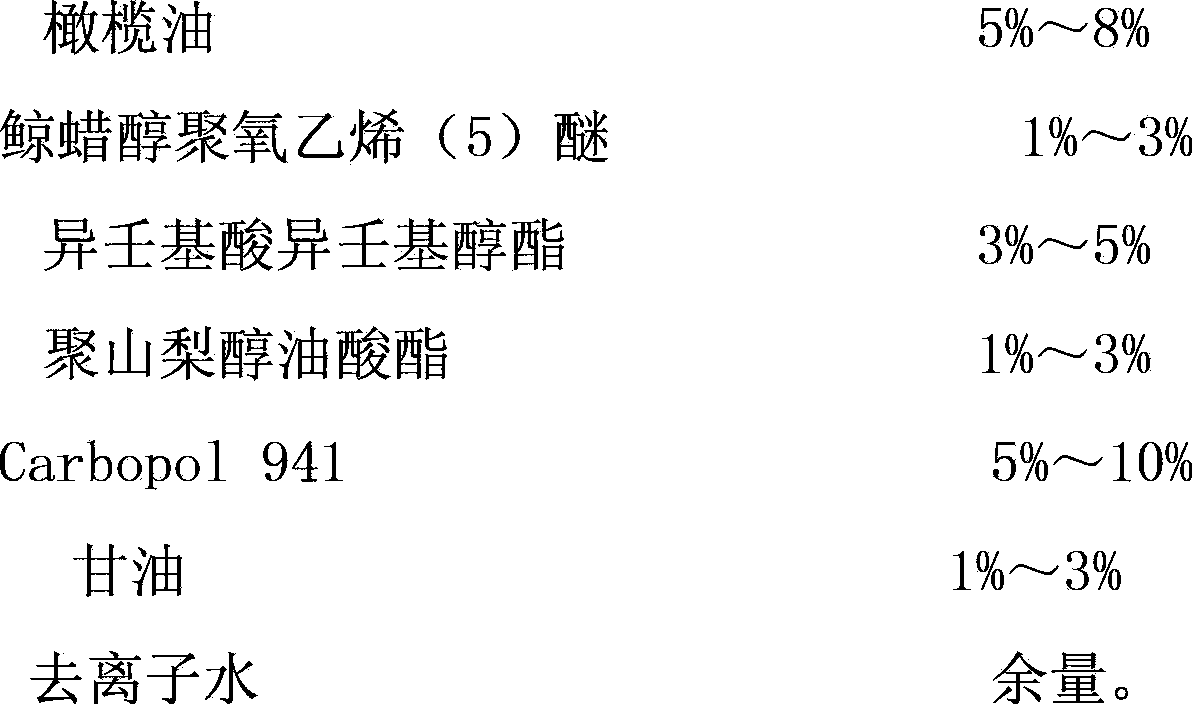

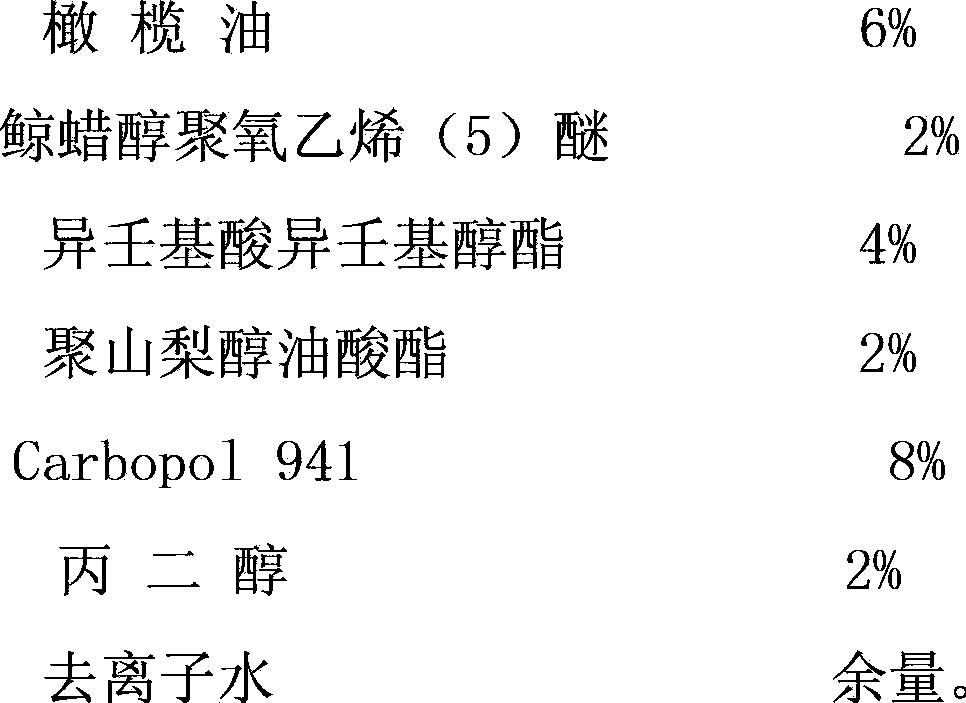

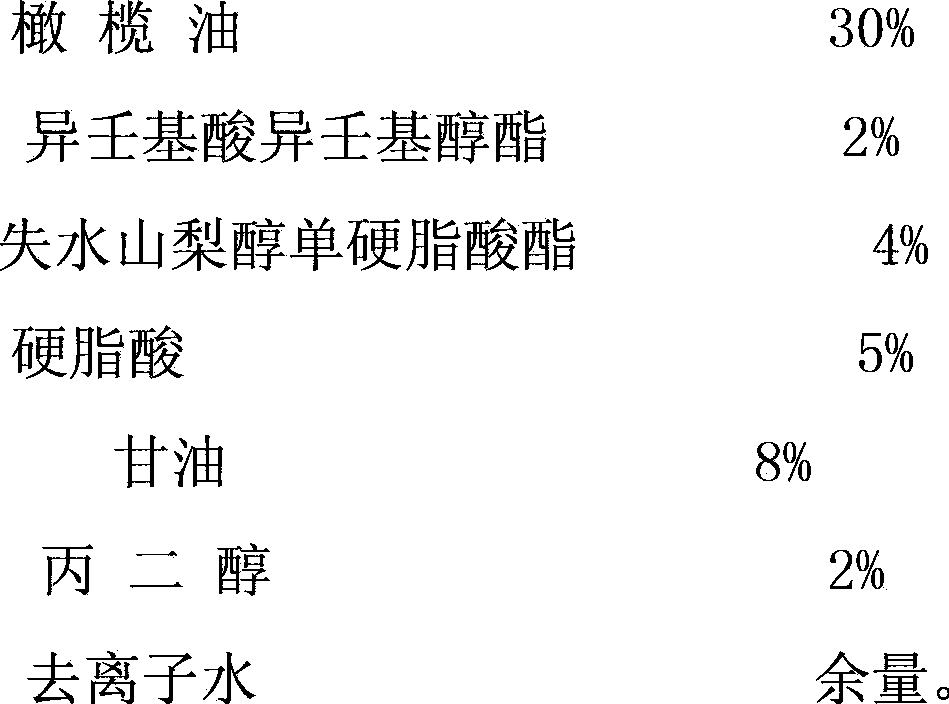

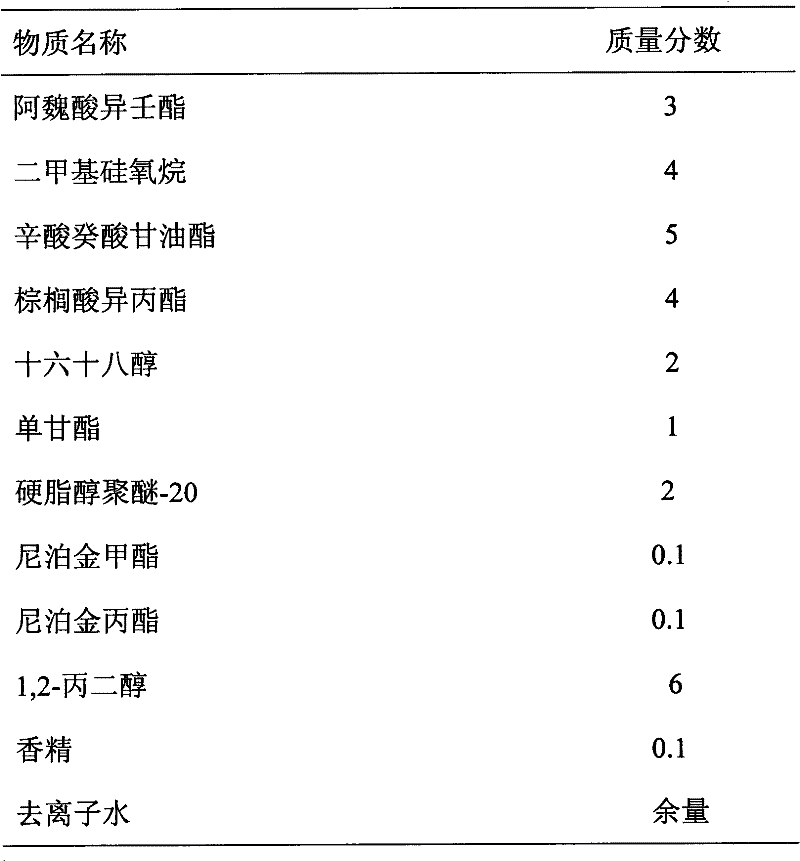

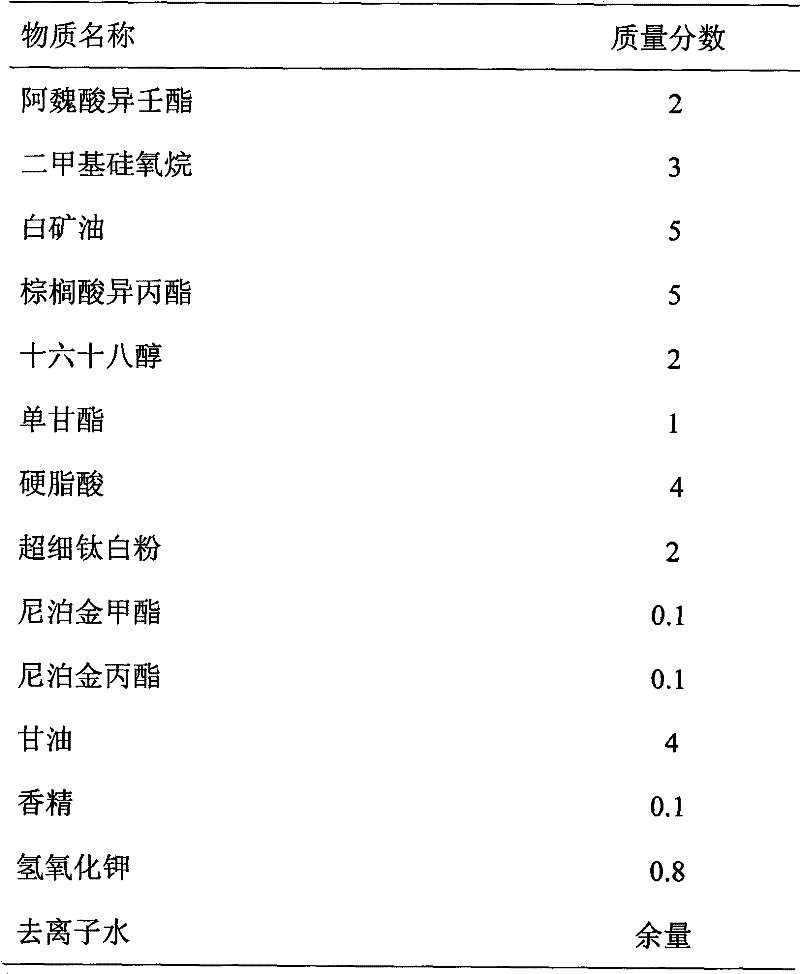

Fresh and cool O/W type cleansing cream

InactiveCN103860410ATo promote metabolismProtect or relieve irritationCosmetic preparationsMake-upIsononyl alcoholSkin surface

The invention relates to the technical field of cosmetics, and particularly relates to fresh and cool O / W type cleansing cream. The fresh and cool O / W type cleansing cream comprises olive oil, polyoxyethylene (5) cetanol ether, isononyl alcohol ester isononylate, polysorbitan oleate and Carbopol941 and glycerol. A finished product is obtained under the control of a certain stirring revolution. The fresh and cool O / W type cleansing cream provided by the invention not only can be softened by means of body temperature after being contacted with skins, and is moderate in viscosity and easy to smear, but also can quickly permeate into pores through the surfaces of skins to clean dirt in the pores. The fresh and cool O / W type cleansing cream easily wipes carried dirt, and a user feels comfortable and soft, so that the cream is particularly free from greasy sense.

Owner:胡全会

Synthetic method of novel adipate cold-resistant plasticizing agent

InactiveCN104119226AHigh molecular weightIncrease the molecular chain lengthOrganic compound preparationCarboxylic acid esters preparationIsononyl alcoholFiltration

The invention belongs to the field of synthesis of chemicals and particularly relates to a synthetic method of a novel adipate cold-resistant plasticizing agent. The synthetic method comprises the following steps of: (1) adding alcohol and adipic acid which is 25%-40% of the weight of the alcohol to a reaction kettle, then adding sulfuric acid which is 0.1%-0.5% of the total weight and active carbon which is 0.1%-0.3% of the total weight, controlling heating speed in vacuum, and reacting at 120-150 DEG C for 1-5 hours; (2) after the reaction is finished, neutralizing, washing with water, and finally carrying out dehydration and pressure filtration to obtain a finished product, wherein the alcohol added to the reaction kettle in the step (1) can be decanol, isononyl alcohol or 810 alcohol. According to the synthetic method, 2-ethylhexanol in adipic acid (2-ethyl) hexyl is substituted with higher-class alcohol, so that the molecular weight is increased, the molecular chain length of a product is lengthened, and the product has better volatility resistance, extraction resistance and transfer resistance when used in a PVC (Polyvinyl Chloride) product.

Owner:TONGXIANG CHEM

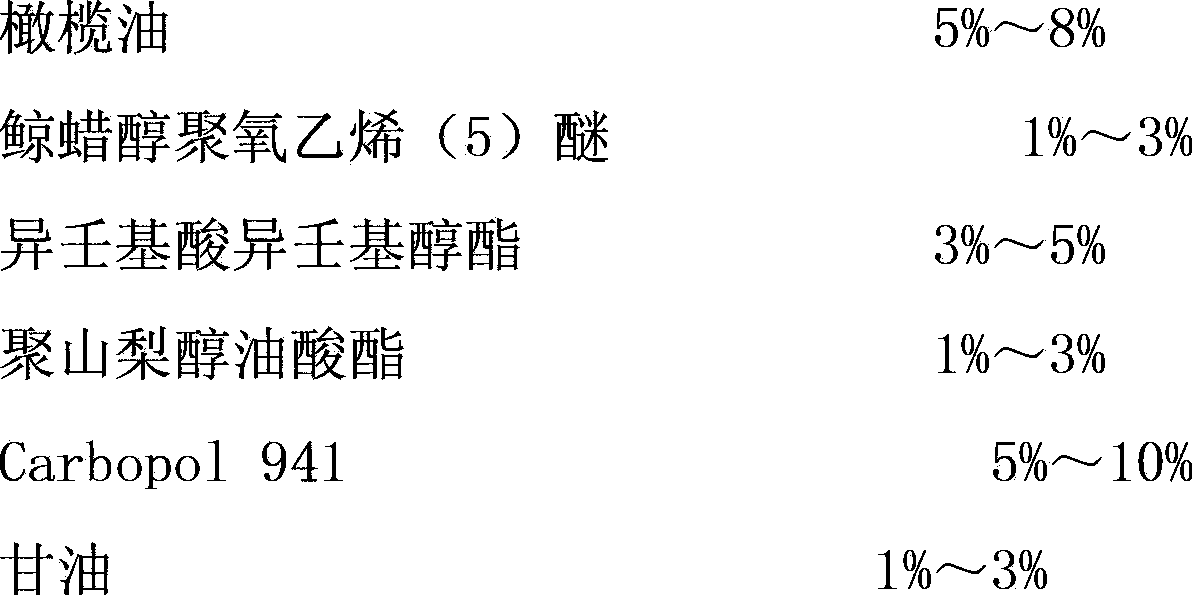

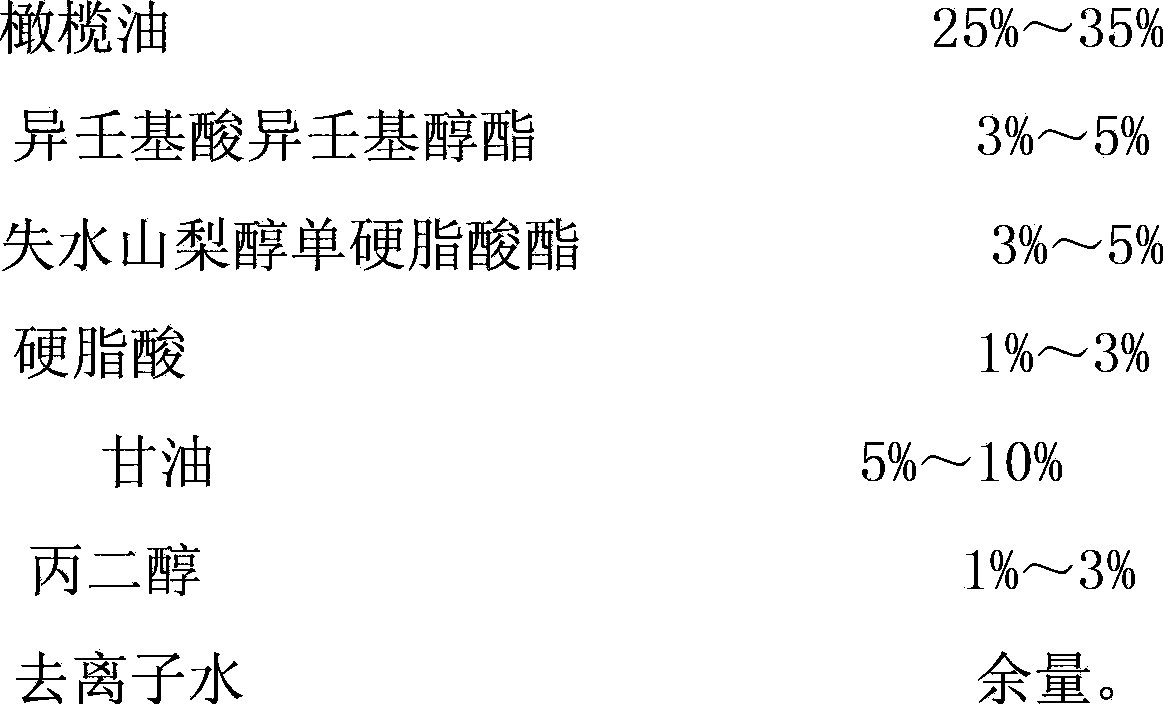

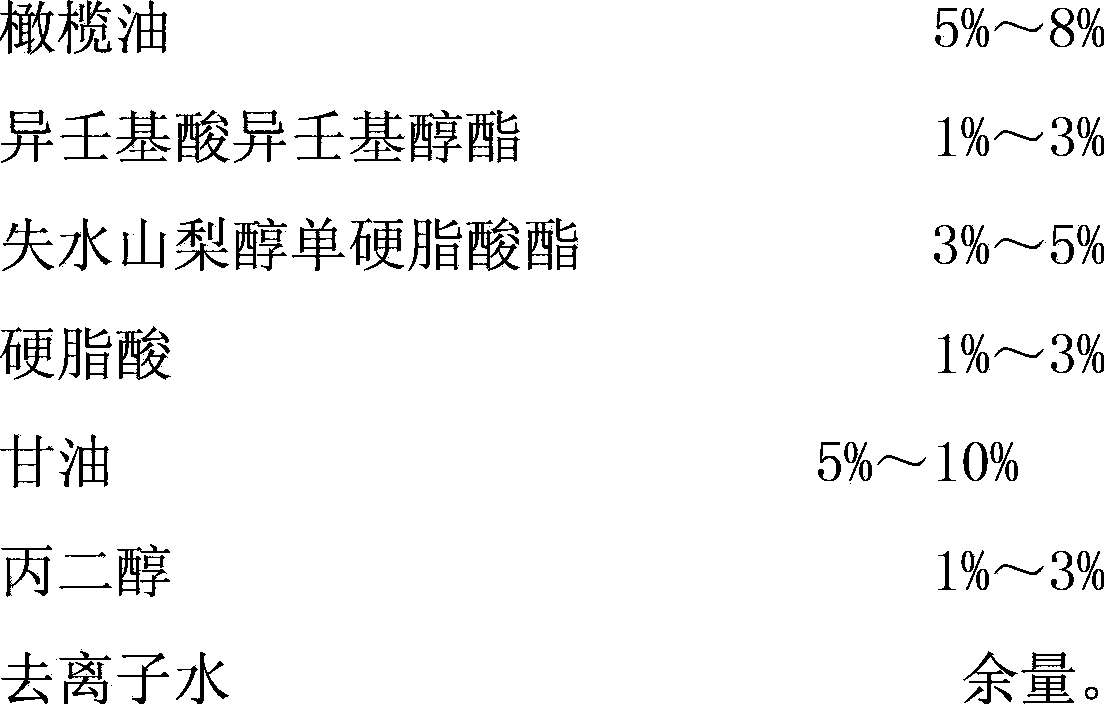

Fresh and cool facial cleanser

InactiveCN103860408ATo promote metabolismProtect or relieve irritationCosmetic preparationsToilet preparationsStearic acidStearate

The invention relates to the technical field of cosmetics, and particularly relates to a fresh and cool facial cleanser. The fresh and cool facial cleanser comprises olive oil, isononyl alcohol ester isononylate, sorbitan monostearate, stearic acid, glycerol and propylene glycol and is prepared by mixing the raw materials under controlling on a certain stirring speed. The fresh and cool facial cleanse provided by the invention not only can be softened by means of body temperature after being contacted with skins, and is moderate in viscosity and easy to smear, but also can quickly permeate into pores through the surfaces of skins to clean dirt in the pores. The carried dirt can be wiped easily, and a user feels comfortable and soft so that the cleanser is particularly free from greasy sense.

Owner:胡全会

Preparation method for cycloolefin anhydride plasticizer

InactiveCN101613283AGood miscibilityOrganic compound preparationCarboxylic acid esters preparationSolubilityActivated carbon

The invention relates to a preparation method for a cycloolefin anhydride plasticizer, which comprises the following steps: firstly, adding 2 to 4 portions of isononyl alcohol and one portion of 1,2,3,6-tetra hydro phthalic anhydride into a reaction kettle for mono-esterification reaction; secondly, increasing the temperature to between 160 and 180 DEG C, and adding a catalyst; thirdly, continuously increasing the temperature to 225 DEG C, and performing di-esterification reaction; fourthly, reducing the temperature to between 210 and 215 DEG C, and performing dealcoholization under reduced pressure for 1 to 2 hours until the alcohol-containing mass percent is less than 0.05 percent; fifthly, reducing the temperature to between 85 and 98 DEG C, adding pure water sterilizing tetraisopropyl titanic acid ester which accounts for 2 to 5 percent of the reaction product in the kettle, fully reacting the mixture, and increasing the temperature to between 100 and 110 DEG C for decompression dehydration; and sixthly, adding activated carbon and diatomite for decoloration and filtration to obtain a finished product. The obtained product does not contain a benzene ring structure, thereby having environmental-friendliness and non-toxic effect on a human body. Through practical detection, compared with the conventional product, the product has better solubility with a PVC system.

Owner:ZHENJIANG UNION CHEM IND

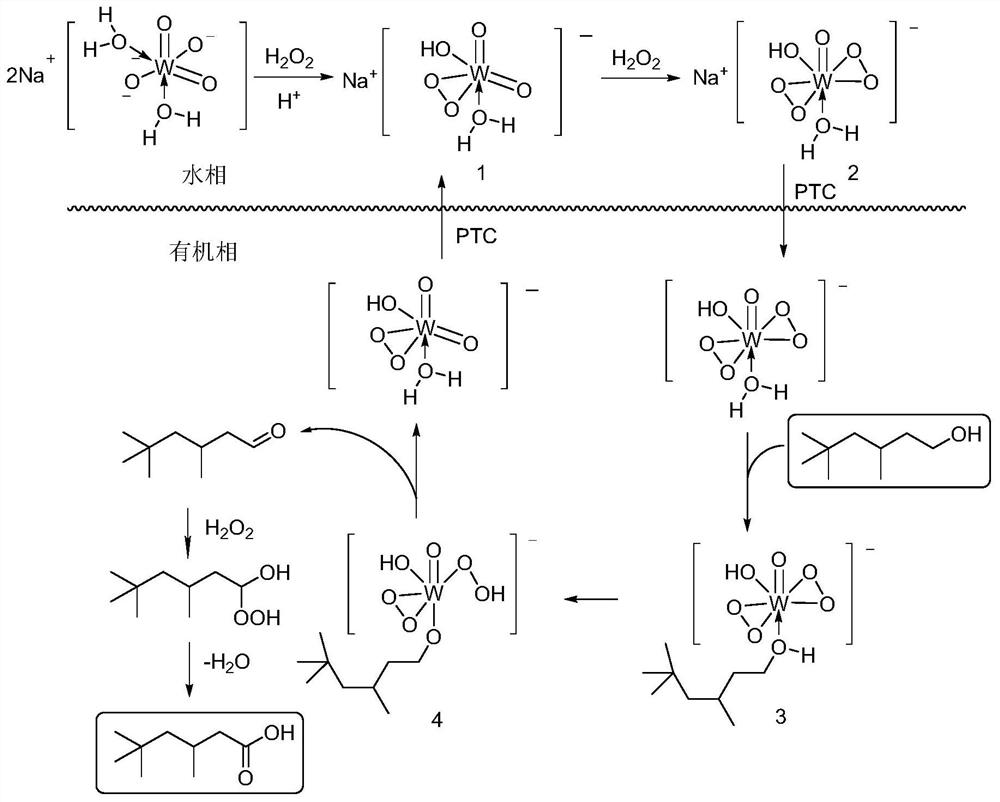

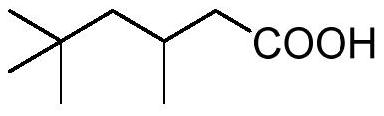

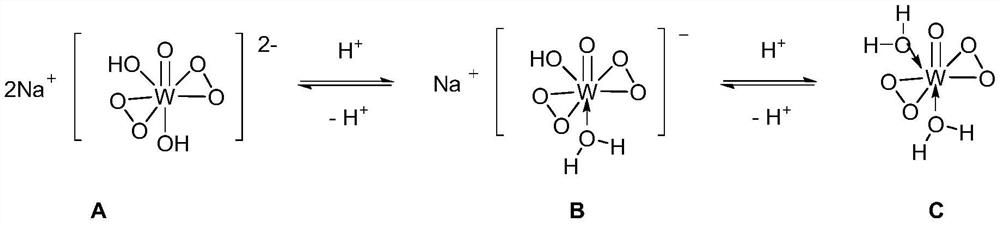

Method for preparing isononanoic acid from isononyl alcohol through green oxidation

ActiveCN112608227AAvoid excessive oxidationReduce riskOrganic compound preparationCarboxylic compound preparationIsoannonacinIsononyl alcohol

The invention relates to the technical field of biological medicines, and provides a method for preparing isononanoic acid from isononyl alcohol through green oxidation. The method is used for solving the problems of complex flow, long reaction time, fire blast danger in the reaction process, waste gas generation, low product yield and the like in the isononanoic acid preparation process in the prior art. According to the method, isononyl alcohol is used as a raw material, a hydrogen peroxide solution is used as an oxidant, and a co-oxidant and a phase transfer catalyst are added for one-step oxidation under acidic conditions to prepare isononanoic acid. According to the method, isononyl alcohol is used as a raw material, 30% hydrogen peroxide is used as an oxidant, a co-oxidant and a phase transfer catalyst are added, isononanoic acid is prepared through a reaction under an acidic condition, the reaction is rapid, safe, green and environmentally friendly, the highest yield of a reaction product can reach 91%, and the catalyst can be repeatedly used.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

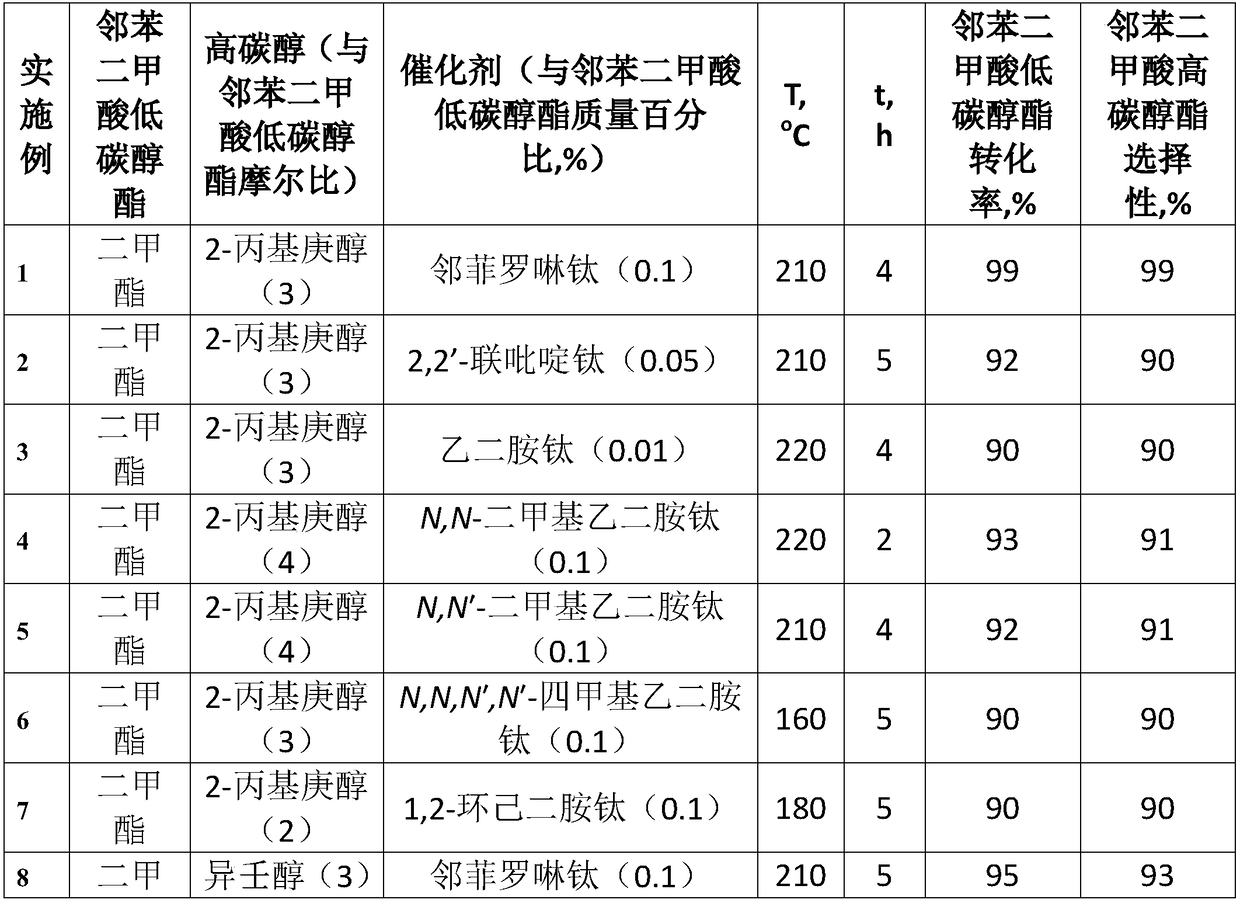

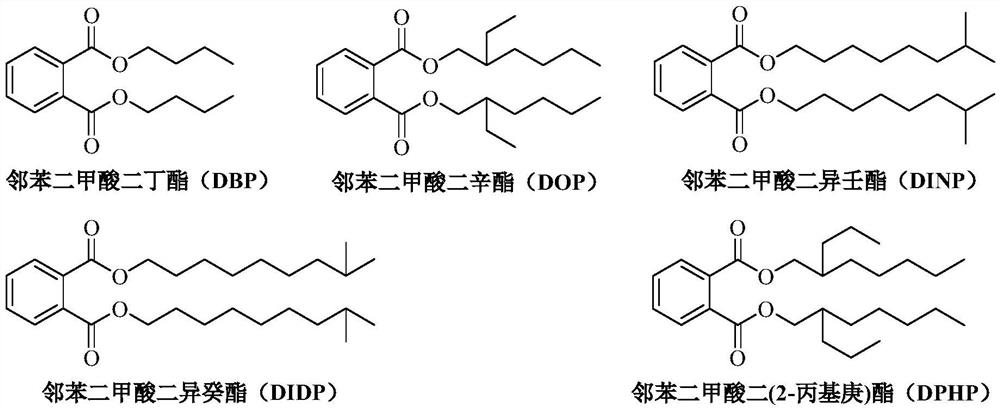

Method for preparing high-carbon alcohol phthalate through ester exchange under catalytic action of titanium chelates

ActiveCN108976116AGood storage and transportation stabilityEasy feedingPreparation by ester-hydroxy reactionEthylenediamineHigh carbon

The invention relates to a method for preparing high-carbon alcohol phthalate through ester exchange under a catalytic action of titanium chelates. Low-carbon alcohol phthalates, such as dimethyl phthalate, dicthyl ortho-phthalate and di-n-butyl phthalate, and high-carbon alcohols, such as isononyl alcohol, isodecano and 2-propyl heptanol, are taken as raw materials; titanium chelates of nitrogen-nitrogen bidentate ligands, such as phenanthroline, 2,2'-dipyridyl, quadrol, N,N- dimethyl ethylenediamine, N,N'- dimethyl ethylenediamine, N,N,N'N'- tetramethylethylenediamine and 1,2-cyclohexanediamine, are taken as catalysts; the dosage of the catalysts is 0.01-0.1% of the mass of the low-carbon alcohol phthalates; the mole ratio of high-carbon alcohols to low-carbon alcohol phthalates is 2-4;the reaction temperature is at 160-220 DEG C; the reaction time is 2-5 hours; the maximal conversion rate of low-carbon alcohol phthalates and the maximal selectivity of high-carbon alcohol phthalateboth can reach up to above 99%. The method disclosed by the invention has the advantages of high stability of raw material storage and transportation, convenience in feeding, few side effects, low consumption of raw materials, no corrosion and less dosage of catalysts, and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

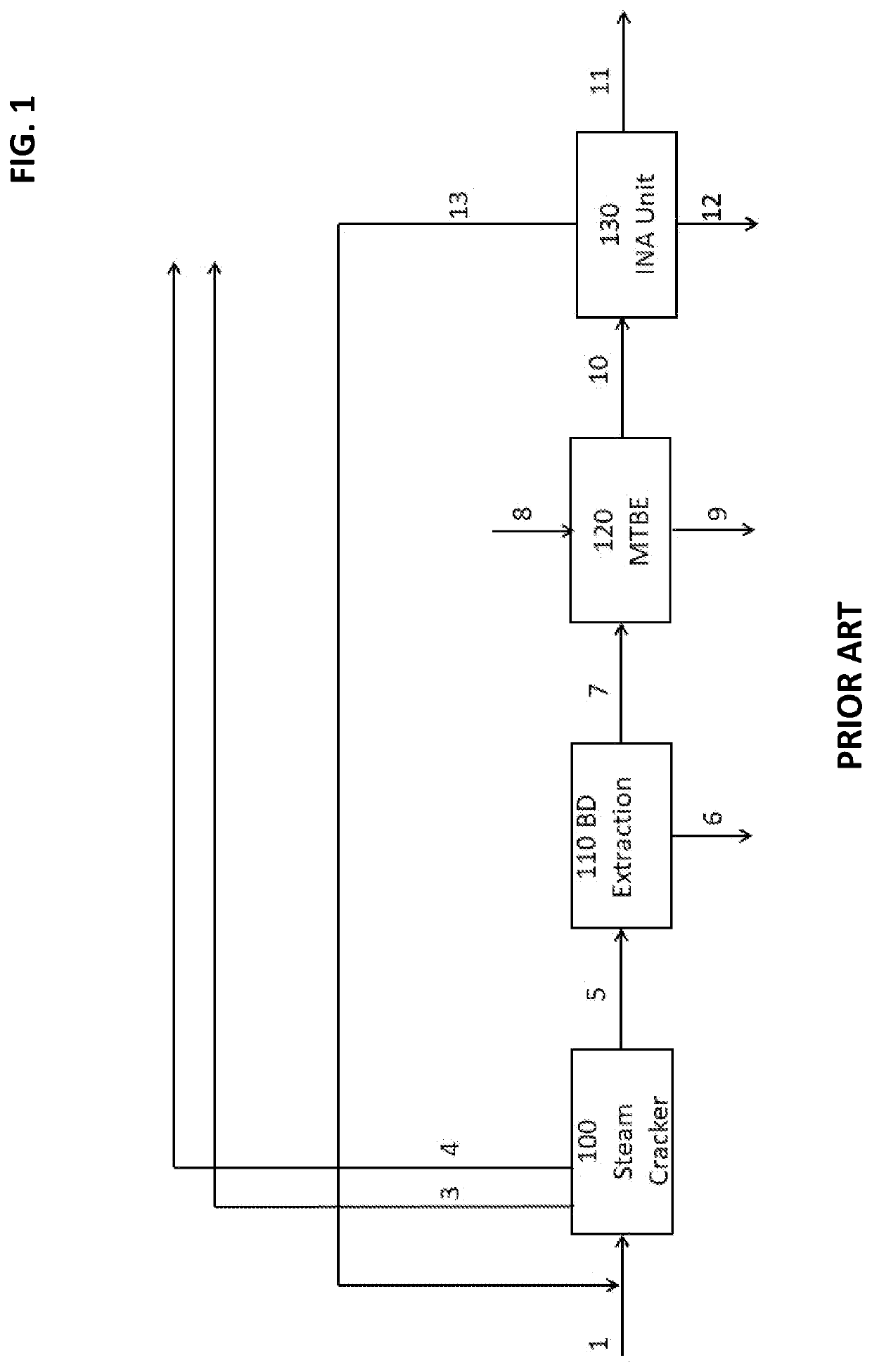

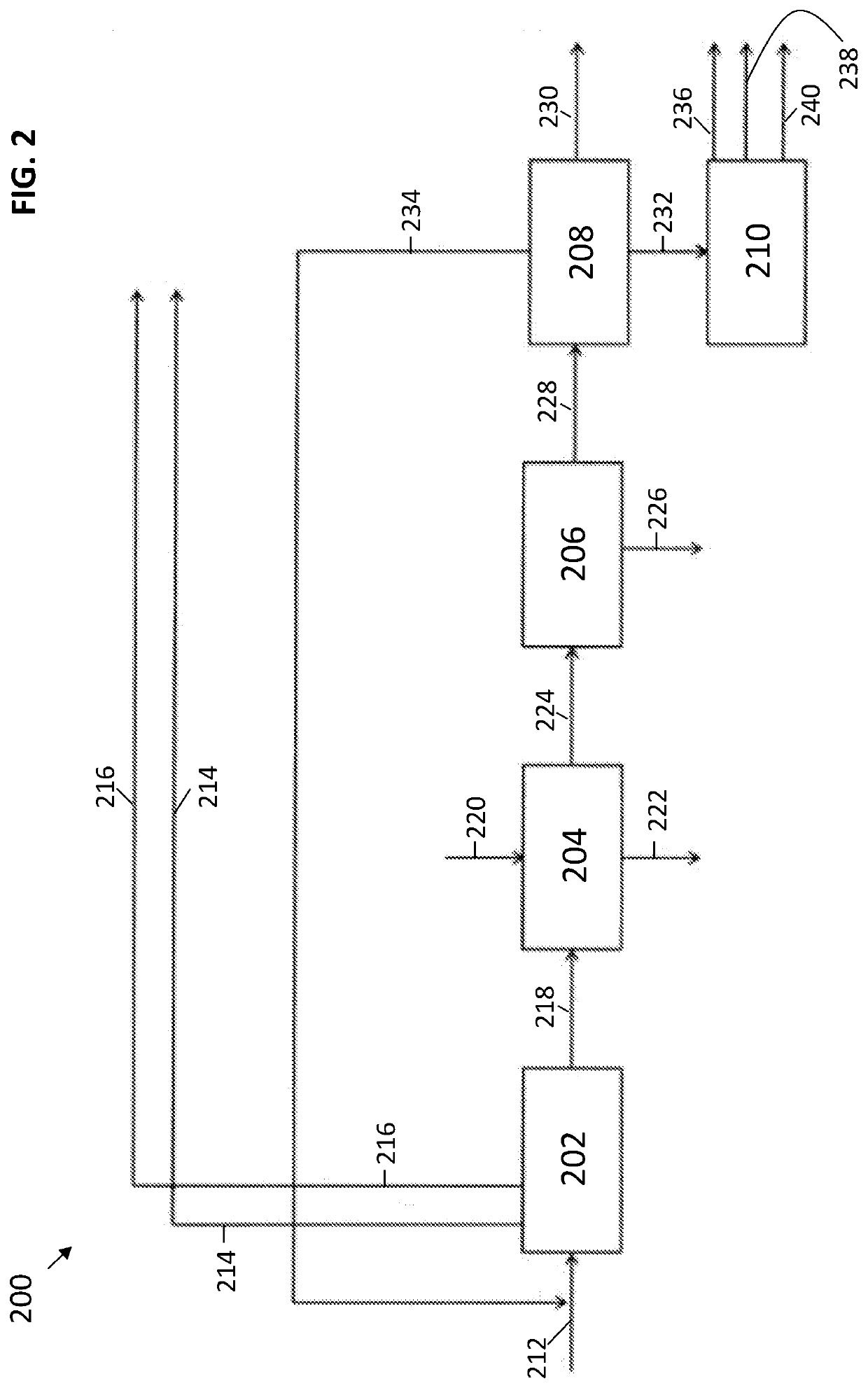

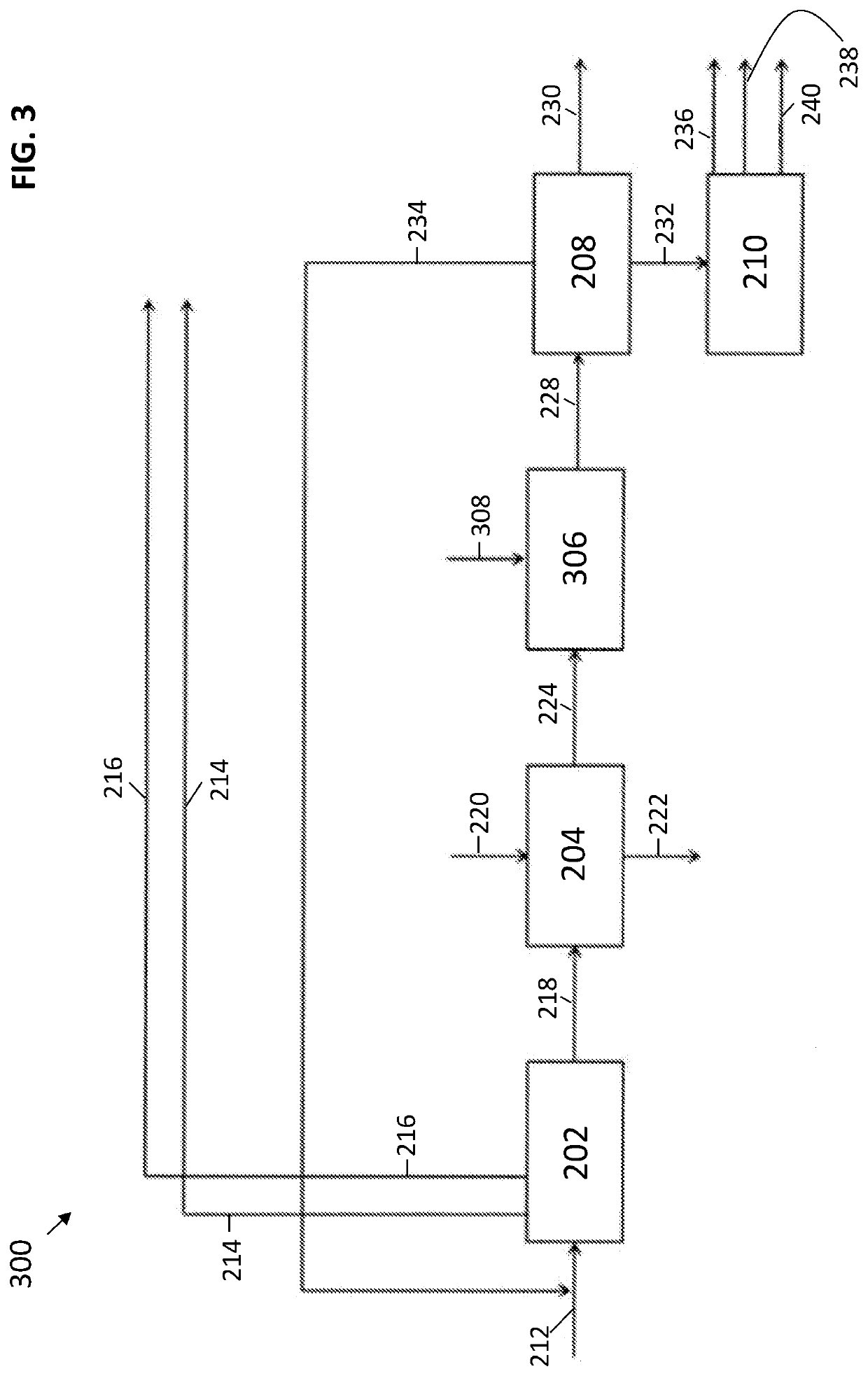

Integrated process for the production of isononanol and gasoline and diesel blending components

ActiveUS20210253504A1Thermal non-catalytic crackingHydrocarbon by hydrogenationButeneIsononyl alcohol

The present application provides systems and methods for producing isononanol and gasoline and diesel blending components. In at least one embodiment of the present systems and methods, a hydrocarbon feed is cracked in a steam cracker to form a first ethylene stream, a first propylene stream, and a C4 stream comprising isobutene and butadiene. The C4 stream is reacted with a methanol stream in a methyl tertiary butyl ether (MTBE) unit to form MTBE and a butadiene-rich C4 stream. The butadiene-rich C4 stream is selectively hydrogenated in a butadiene unit to form a butene-rich C4 stream. The butene-rich C4 stream undergoes a series of reactions in an isononanol unit to produce isononanol and an olefin-rich stream. The olefin-rich stream is then separate, in a separation unit, a C8, C12, and C16 fuel oil streams.

Owner:SAUDI ARABIAN OIL CO

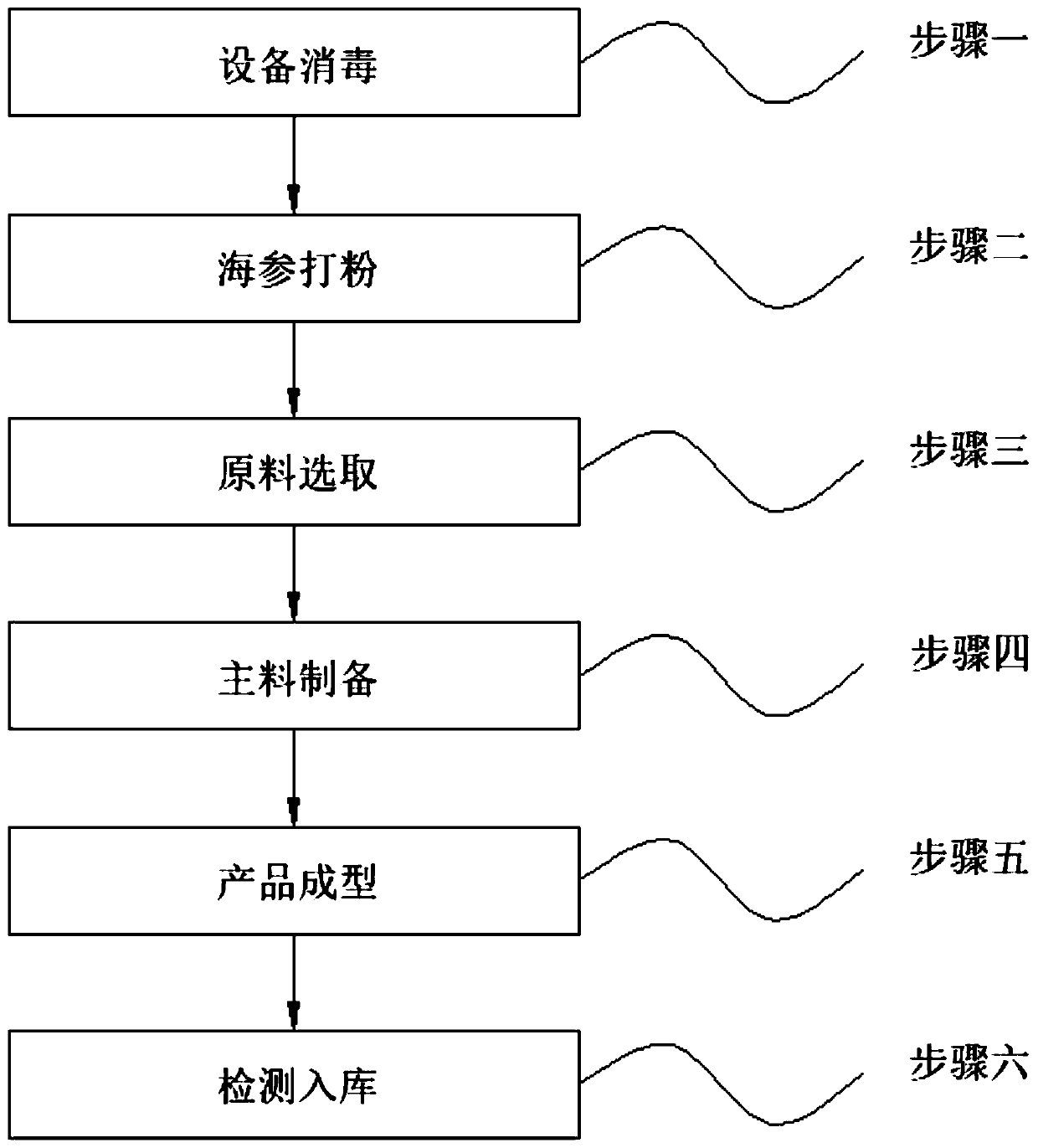

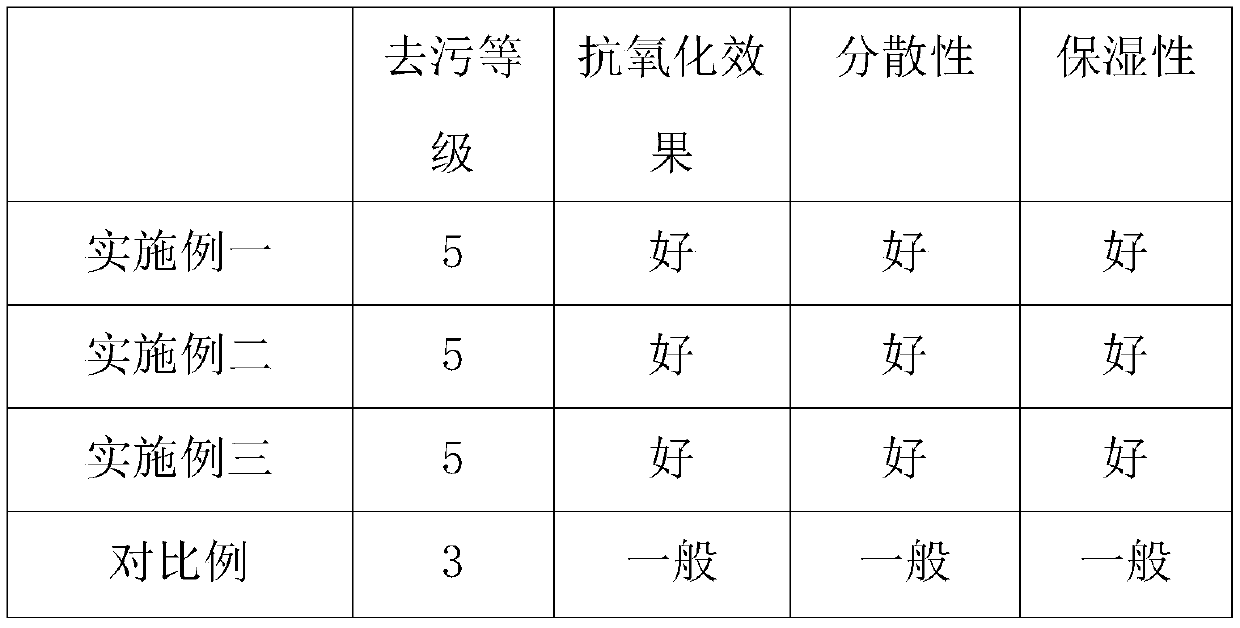

Sea cucumber facial cleanser formula and production process

InactiveCN110613675AImprove attributesEasy to save and useCosmetic preparationsToilet preparationsDispersityAntioxidant

The invention discloses a sea cucumber facial cleanser formula and a production process. The formula comprises superfine sea cucumber powder, glycerin, triglyceride caprylate, isononyl alcohol ester,olive oil, glyceryl monostearate, lauryl ether phosphate, cocoanutyl hydroxyethyl sulfonate sodium, 1,3-propylene glycol, disodium EDTA, an antioxidant, a thickener, a preservative, essence and deionized water. The production process comprises the steps as follows: step 1, equipment disinfection; step 2, sea cucumber powdering; step 3, raw material selection; step 4, main material preparation; step 5, product forming; and step 6, detection and storage; fresh sea cucumbers are cut by a long knife from bellies, a small opening is cut longitudinally forwards, intestines and respiratory trees areremoved after dissection, performing quick freezing in a freeze-drying bin after careful cleaning, and performing superfine grinding by a superfine grinder. The facial cleanser has good oxidation resistance, facial cleansing effects, moisture retention, dispersity and facial skin protection effects, and is convenient to use.

Owner:YANTAI HUAKANG SEAFOOD

Method for preparing PVC plasticizer from by-products of production of fumaric acid and recovery alcohol

ActiveCN101875609AEfficient use ofReduce pollutionOrganic compound preparationCarboxylic acid esters preparationIsononyl alcoholIsooctyl alcohol

The invention relates to a method for preparing a PVC plasticizer by taking by-products of production of fumaric acid and recovery alcohol as raw materials. The method comprises the following steps of: 1, adding 1 part of acid water residues, 2 to 4 parts of recovery isooctanol or recovery isononyl alcohol and 200 to 400ppm of esterification catalyst into a reactor with a thermometer, a distillation and condensing device and a stirring device, and heating the mixture with stirring to the temperature of between 120 and 160 DEG C for yielding water; 2, continuing heating to the highest reactiontemperature of 220 DEG C, controlling the temperature of cut fraction to be between 80 and 102 DEG C all the time in the process of a reaction, and reacting until an acid value is less than 1.0 mgKOH / g; and 3, reducing the temperature until the temperature is 190 DEG C or 215 DEG C, performing dealcoholization under the reduced pressure of between -600 and -740 mmHg for 1 to 2 hours, stopping thereaction, and cooling and filtering to obtain a finished product. The method can utilize scrap materials of enterprises effectively, reduce the production cost of the plasticizer and the treatment cost of waste liquor and reduce environmental pollution.

Owner:ZHENJIANG UNION CHEM IND

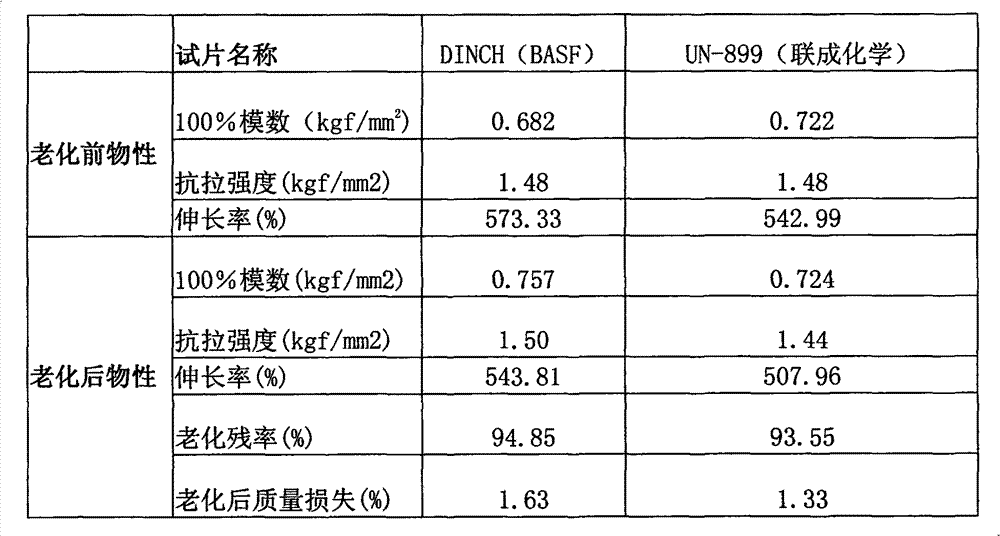

Diester base oil and preparation method thereof

The invention relates to the technical field of lubricating oil, in particular to diester base oil and a preparation method thereof. The diester base oil is prepared from raw materials including binary acid and isomeric alcohol through esterification reaction; the binary acid comprises one or two of adipic acid and sebacic acid; and the isomeric alcohol comprises one or more of isooctyl alcohol, isononyl alcohol, isodecyl alcohol and isotridecanol. The diester base oil provided by the invention has a high viscosity index and a low pour point, the low pour point can ensure good low-temperatureperformance, the high viscosity index can be used for a high operating temperature, and the diester base oil can be widely applied to production of lubricants in aviation, turbines, compressors and other industries. Particularly, the lubricating oil has high application value in the field of engine lubrication with high requirements on low-temperature performance and high operating temperature. Experiments show that the pour point of the diester base oil provided by the invention is not higher than 60 DEG C, and the viscosity index is not less than 140.

Owner:CHINA PETROLEUM & CHEM CORP

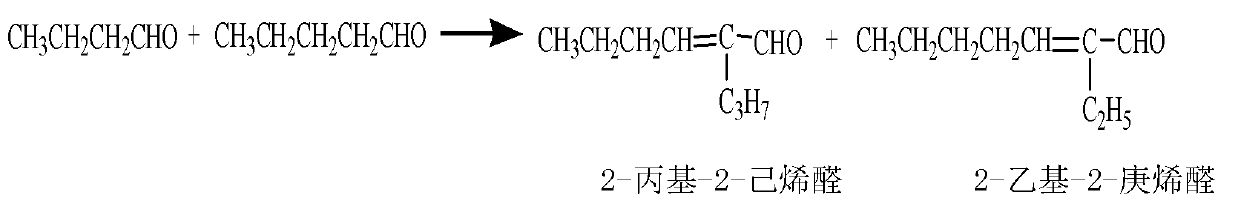

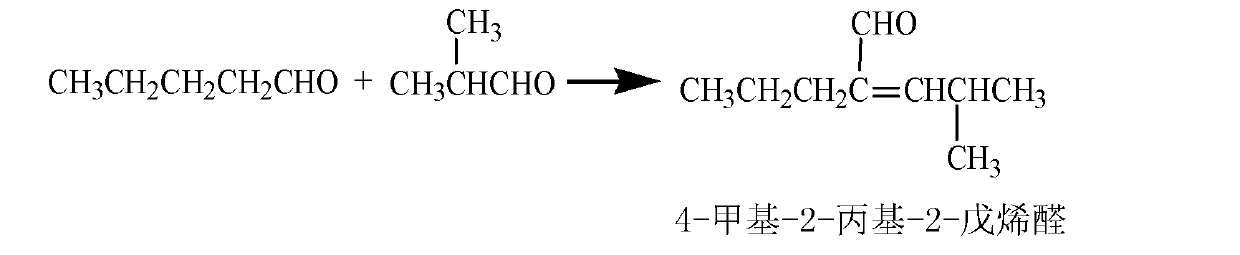

Method for preparing isononyl olefine aldehyde

InactiveCN102911024AHigh priceMild reaction conditionsOrganic compound preparationCarbonyl compound preparationIsononyl alcoholHydrogen

The invention provides a method for preparing isononyl olefine aldehyde by cross condensation reaction between n-butanal and n-pentanal, between n-butanal and 2-methyl butyl aldehyde or between 2-methyl propionic aldehyde and n-pentanal in a mild condition; and the reaction condition is that the molar ratio of butyraldehyde to valeraldehyde is 1:5 to 5:1, the concentration of a sodium hydroxide or potassium hydroxide solution is 0.5-5.0 percent, the nitrogen or argon gas pressure is 0-0.5 MPa, the reaction temperature is 30-140 DEG C, and the reaction time is 1-10 hours. Isononyl olefine aldehyde prepared by the technology can produce isononyl alcohol when hydrogen is added.

Owner:QINGDAO SANLI BENNUO CHEM IND +1

A kind of method for transesterification continuous reaction to prepare higher carbon alcohol phthalate

ActiveCN108976117BGood storage and transportation stabilityReduce consumptionPreparation by ester-hydroxy reactionHeterogenous catalyst chemical elementsHeptyl alcoholPtru catalyst

The invention relates to a method for preparing higher alcohol phthalate through continuous transesterification reaction. In a fixed-bed reactor, dimethyl phthalate, diethyl phthalate, diphthalate Low-carbon alcohols such as butyl phthalate and high-carbon alcohols such as isononanol, isodecyl alcohol, and 2-propylheptanol are used as raw materials, and magnesium calcium aluminate, sodium aluminosilicate, potassium aluminosilicate, silicon One or more of magnesium aluminate, calcium aluminosilicate, aluminum magnesium titanate, magnesium calcium titanate, and aluminum magnesium zirconate are catalysts, and the molar ratio of higher alcohol to lower alcohol phthalate is 2.1-4.0 , reaction temperature 160~220℃, volume space velocity 0.5~2h ‑1 , The conversion rate of low-carbon alcohol phthalate and the selectivity of high-carbon alcohol phthalate are above 99%. The invention has the following advantages: good stability of raw material storage and transportation, convenient feeding; less side reactions, low raw material consumption; no corrosion of the catalyst and continuous use; clean and energy-saving process, no waste water generation and discharge; reaction in a fixed bed reactor Continuous, high efficiency.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation and application of isononyl ferulate as cosmetic additive with whitening and sunscreen functions

InactiveCN102503828ACosmetic preparationsOrganic compound preparationSunscreen agentsHydrogen Sulfate

The invention discloses synthesis of isononyl ferulate as cosmetic additive with both whitening and sunscreen functions and application of isononyl ferulate in cosmetics. Isononyl ferulate is synthesized by esterification of ferulic acid and isononyl alcohol as major raw materials in the presence of p-toluenesulfonic acid (or sulfamic acid or sodium hydrogen sulfate) as catalyst. Isononyl ferulate has both the whitening function of inhibiting production of skin melanin and the sunscreen function of absorbing UV, and can be used as a whitening agent in whitening cosmetic production and also used as a sunscreen agent in sunscreen cosmetic production. Isononyl ferulate is modified from a natural compound ferulic acid by esterification; has the advantages of good whitening effect, high safety, stable chemical property, easily-accessible raw material and low cost; overcomes the problems of hydroquinone, superoxide dismutase (SOD), vitamin C and other common whitening agents, such as severe irritation, poor stability, non-ideal effect and high price; and has good application prospects.

Owner:GUANGDONG IND TECHN COLLEGE

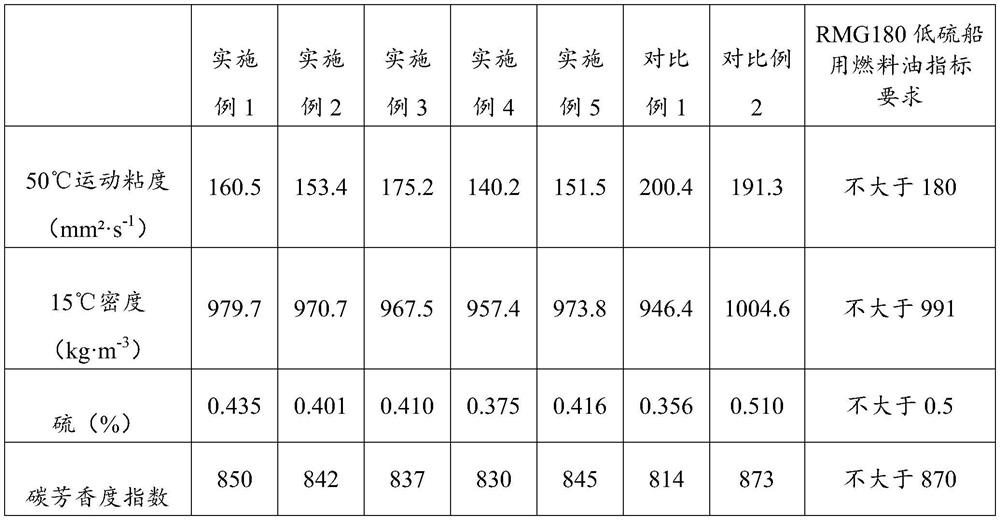

Low-sulfur marine fuel oil and preparation method thereof

ActiveCN113969196AImprove flammabilityWell mixedLiquid carbonaceous fuelsIsononyl alcoholProcess engineering

The invention discloses low-sulfur marine fuel oil and a preparation method thereof, and relates to the technical field of marine fuel oil. The invention provides low-sulfur marine fuel oil, which comprises the following components: residue oil, catalytic slurry oil and isononyl alcohol heavy oil. The invention provides low-cost and low-sulfur marine fuel oil, which has the characteristic of low sulfur content, and meets increasingly strict environmental protection requirements. According to the invention, a proper amount of isononyl alcohol heavy oil component is added, so that the problem that a large amount of cheap catalytic slurry oil cannot be added due to high sulfur content and carbon aromaticity index is solved, and the production cost can be reduced; and isononyl alcohol heavy oil has the characteristics of low sulfur content and low carbon aromaticity index, and the price of the isononyl alcohol heavy oil is lower than that of a hydrogenated diesel oil component by more than 60%, so that the production cost is further reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of cycloalkane anhydride plasticizer

ActiveCN101607905BGood lookingLight colorOrganic compound preparationCarboxylic acid esters preparationActivated carbonIsononyl alcohol

Owner:ZHENJIANG UNION CHEM IND

Cold-resistant plasticizer

The invention discloses a cold-resistant plasticizer. The cold-resistant plasticizer is characterized by consisting of the following ingredients in part by weight: 199-201 parts of hexanedioic acid, 498-501 parts of isononyl alcohol, 1.4-1.6 parts of activated carbon and 0.4-0.6 part of magnesium oxide. By the cold-resistant plasticizer, the cold resistance of plastic products can be improved, and the quality of plastics can also be improved.

Owner:ZHANGJIAGANG DANENG PLASTIC PROD

Juice of job's tears seeds

InactiveCN106135881AFull and efficient extractionEasy to prepareFood preparationIsononyl alcoholRoom temperature

The invention discloses juice of job's tears seeds. The juice is made from, by weight, 20-50 parts of job's tears seed leaf essence oil, 3-7 parts of isononanoic acid isononyl alcohol ester, 0.1-0.5 part of triethanolamine, 5-9 parts of glycerinum and a proper amount of additive liquid. The additive liquid is prepared through the steps that 20-30 parts by weight of job's tears seeds, 30-40 parts by weight of lotus seeds and 20-25 parts by weight of lily are placed in 100-120 parts by weight of water to be soaked for 3 h, the materials are drained and placed in an oven to be baked at 70 DEG C for 15 min and then taken out to be cooled to room temperature, the materials are smashed by a smashing machine, the mixture is prepared into pulp by means of 300 parts by weight of water at 80 DEG C, finally the mixture is filtered through 110-mesh filter cloth to obtain filter liquid, and the juice is obtained. The juice has the advantages that the making method is simple, nutrients of the job's tears seeds are efficiently and fully extracted, and the juice has the nourishing function; the nourishing effect is remarkable, and the juice is suitable for loose stools, lower limb eczema, facial acne and other symptoms.

Owner:苏会静

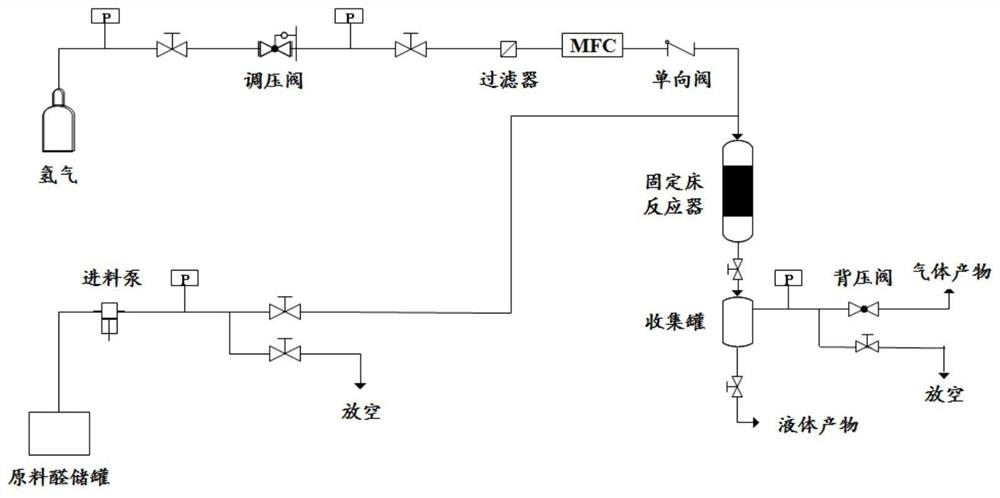

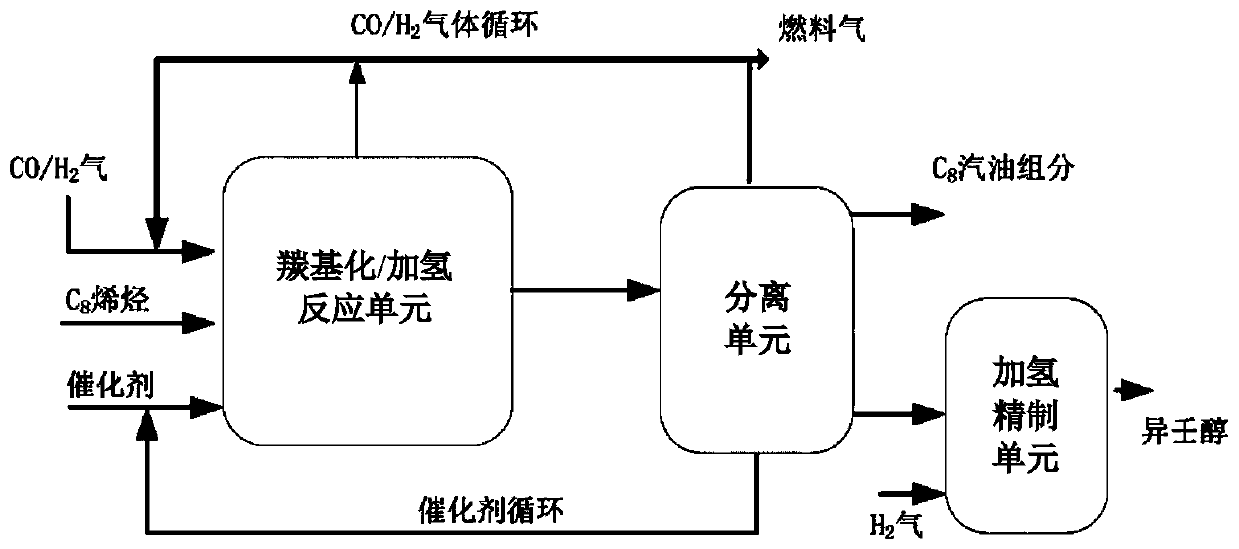

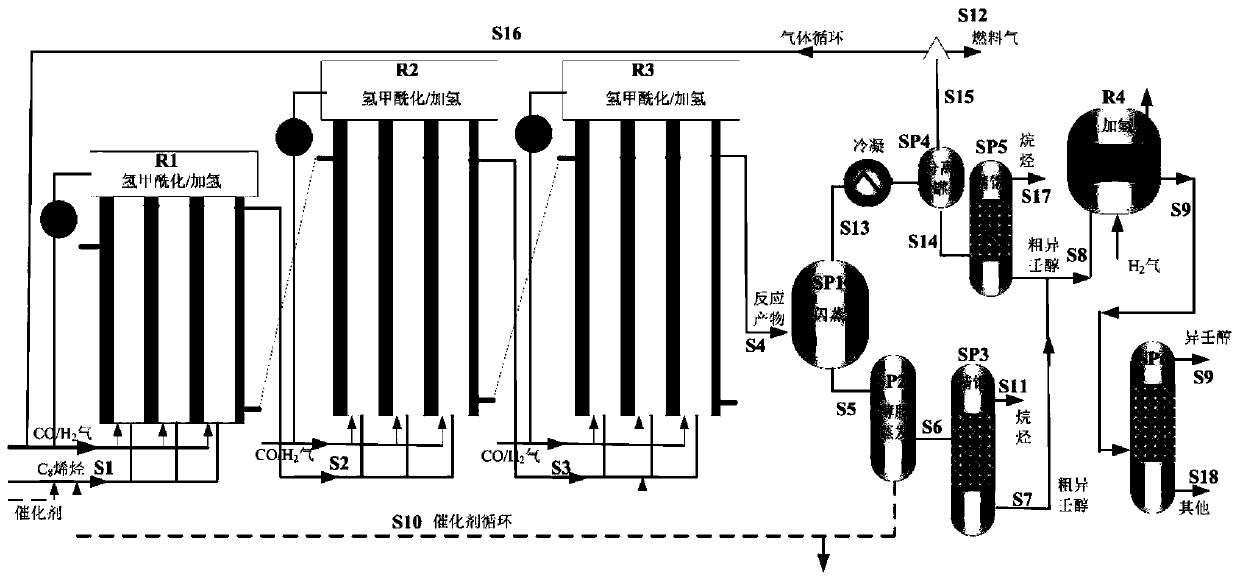

Method and system for coproducing isononyl alcohol and C8 alkane

InactiveCN110981692ALow purityHigh purityOrganic compound preparationHydrocarbon by hydrogenationAlkaneIsononyl alcohol

The invention discloses a method and a system for coproducing isononyl alcohol and C8 alkane. The method comprises the following steps: in a H2 / CO mixed atmosphere, carrying out carbonylation / hydrogenation reaction on a mixed reaction system containing C8 olefin and a cobalt phosphine catalyst at 150-210 DEG C under the pressure of 5-11 Mpa to obtain a crude isononyl alcohol product and C8 alkane;and carrying out hydrogenation reaction on a hydrogenation reaction system containing the crude isononyl alcohol product and a hydrogenation catalyst at 60-190 DEG C under the hydrogenation pressureof 1-9 Mpa to obtain isononyl alcohol. The invention provides the method for coupling hydroformylation reaction and hydrogenation reaction. A cheap and efficient coupling catalyst is developed, through reasonable design of a reaction separation system, a heterogeneous system is well mixed and efficient in reaction, C8 olefin is finally converted into C8 alkane and isononyl alcohol, and high-quality gasoline components and high-end plasticizer raw materials can be produced at the same time.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

A kind of method that titanium chelate catalyzes transesterification to prepare higher carbon alcohol phthalate

ActiveCN108976116BGood storage and transportation stabilityEasy feedingPreparation by ester-hydroxy reactionHeptyl alcoholPtru catalyst

The present invention relates to a kind of method that titanium chelate catalyzes transesterification to prepare higher carbon alcohol ester of phthalate, with dimethyl phthalate, diethyl phthalate and dibutyl phthalate Low-carbon alcohol phthalate and high-carbon alcohols such as isononanol, isodecyl alcohol, and 2-propylheptanol are used as raw materials, with o-phenanthroline, 2,2'-bipyridine, ethylenediamine, N,N ‑Dimethylethylenediamine, N,N′‑dimethylethylenediamine, N,N,N′,N′‑tetramethylethylenediamine, 1,2‑cyclohexanediamine, etc. The titanium chelate of the ligand is the catalyst, the amount of the catalyst is 0.01-0.1% of the mass of the lower alcohol phthalate, the molar ratio of the higher alcohol to the lower alcohol phthalate is 2-4, and the reaction temperature is 160- 220°C, the reaction time is 2 to 5 hours, the conversion rate of lower alcohol phthalate and the selectivity of higher alcohol phthalate are up to 99%. The invention has the advantages of good raw material storage and transportation stability, convenient feeding, less side reactions, low raw material consumption, no corrosion of the catalyst, and less consumption.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

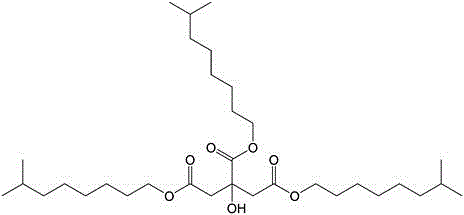

Triisononyl citrate compound and preparation method thereof

ActiveCN105461561AImprove oxidation capacityImprove conversion rateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsononyl alcoholActivated carbon

The invention provides a triisononyl citrate compound and a preparation method thereof; the preparation method comprises preparation of a loaded heteropoly acid catalyst and preparation of triisononyl citrate; the invention belongs to the citric acid plasticizer field. The preparation method comprises the steps: esterifying citric acid and isononyl alcohol under the action of a catalyst at the temperature of 110-170 DEG C to synthesize triisononyl citrate with the reaction time of 1-3 hours, during reaction, taking cyclohexane as a water carrying agent, after the completion of the reaction, cooling the solution to 50-80 DEG C, filtering to obtain the catalyst, recycling and reusing, and carrying out reduced pressure dealcoholization, alkali washing and water washing to be neutral; and adding activated carbon, carrying out adsorption decolorization, drying, and thus obtaining the product triisononyl citrate. The catalyst used in the method has high catalytic activity and high repeated utilization rate, the purity of the obtained product is high, and the shortcomings that a conventional citric acid low-carbon alcohol ester plasticizer has high volatility, poor low-temperature resistance, poor extraction resistance and the like are overcome.

Owner:HUNAN ER KANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com