Synthetic method of novel adipate cold-resistant plasticizing agent

A cold-resistant plasticizer and technology of synthesis method, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of volatility resistance, poor extraction resistance and migration resistance, short molecular chain, molecular weight Small and other problems, to achieve better migration resistance, increase molecular weight, and increase the effect of molecular chain length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Put 400g of decanol and 120g of adipic acid into a three-necked flask, then add 1.2g of sulfuric acid and 0.5g of activated carbon, control the heating rate under vacuum, react at 120-150°C for 1 hour, release the vacuum after the reaction, and then wash with neutral water , The finished product is obtained after dehydration.

Embodiment 2

[0018] Put 358g of decanol and 120g of adipic acid into the three-necked flask, then add 1.2g of sulfuric acid and 0.5g of activated carbon, control the heating rate under vacuum, react at 120-150°C for 1 hour, release the vacuum after the reaction, and then neutralize and wash with water , The finished product is obtained after dehydration.

Embodiment 3

[0019] Embodiment 3HOOC (CH 2 ) 4 COOH+2ROH=ROOC(CH 2 ) 4 COOR+2H 2 o

[0020] Put 400g of decanol and 120g of adipic acid into a three-necked flask, then add 1.1g of sulfuric acid and 0.5g of activated carbon, control the heating rate under vacuum, react at 120-150°C for 1 hour, release the vacuum after the reaction, and then wash with neutral water , The finished product is obtained after dehydration.

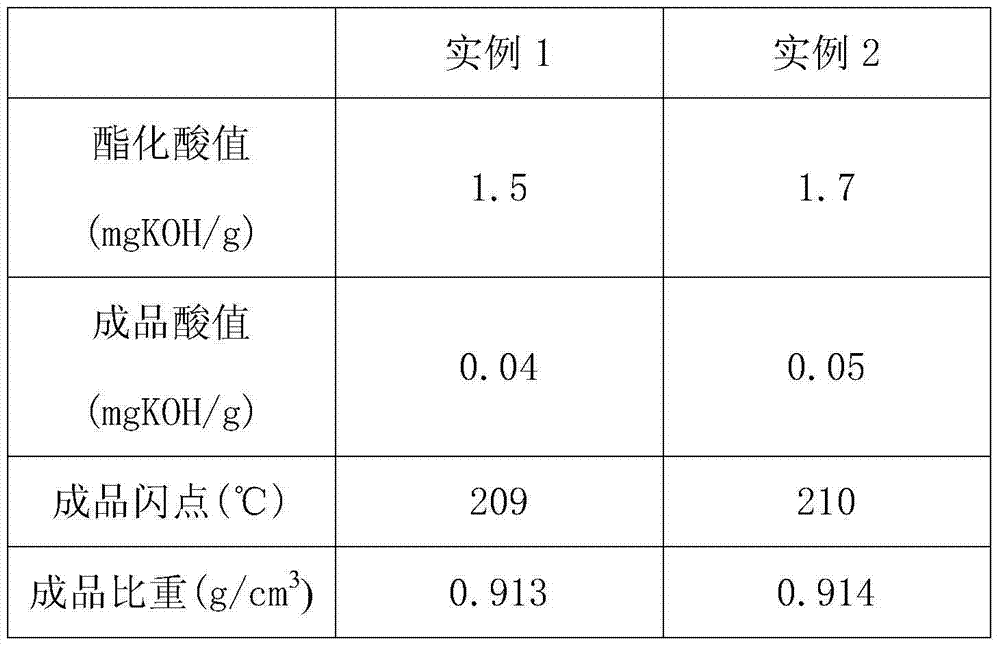

[0021] Each parameter of the product made by 3 embodiments of the present invention is as follows:

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com