Patents

Literature

116 results about "2-Ethylhexanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Ethylhexanol (abbreviated 2-EH) is a branched, eight-carbon chiral alcohol. It is a colorless liquid that is poorly soluble in water but soluble in most organic solvents. It is produced on a massive scale (>2,000,000,000 kg/y) for use in numerous applications such as solvents, flavors, and fragrances and especially as a precursor for production of other chemicals such as emollients and plasticizers. It is encountered in natural plant fragrances, and the odor has been reported as "heavy, earthy, and slightly floral" for the R enantiomer and "a light, sweet floral fragrance" for the S enantiomer.

Production of di-(2-ethylhexyl) terephthalate

ActiveUS7276621B2Speed up the conversion processSpeed up reactionPreparation from carboxylic acid halidesOrganic compound preparation2-EthylhexanolETHYLHEXYL ACETATE

Disclosed is a process for the preparation of di-(2-ethylhexyl) terephthalate by the esterification of terephthalic acid with 2-ethylhexanol at elevated temperature and pressure while the water of reaction is removed from the reaction mixture.

Owner:EASTMAN CHEM CO

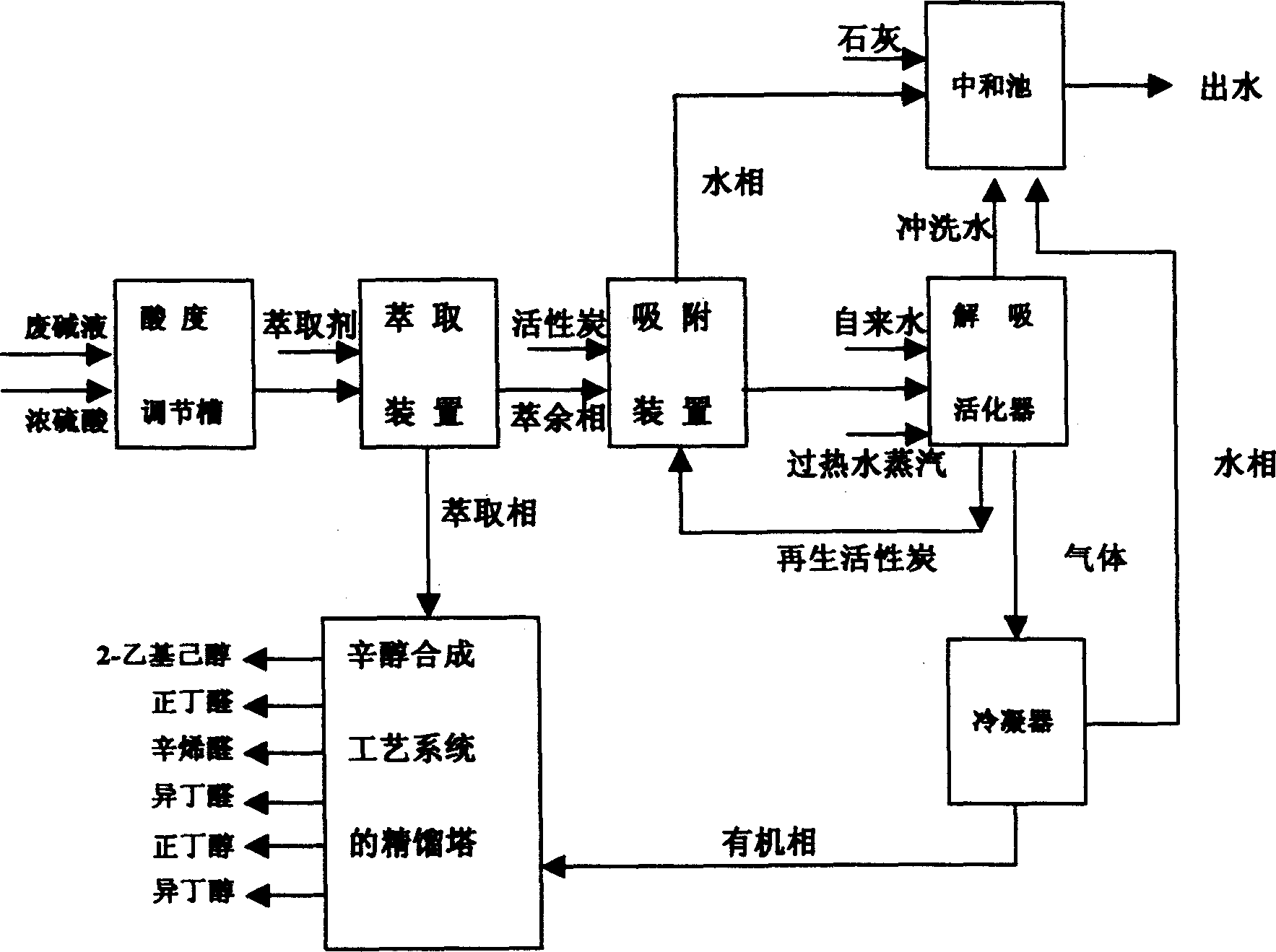

Treatment process for two stage recycling alkali waste liquid drained off by process system of synthesizing octanol

InactiveCN1462729AReduce liquiditySave investment costMultistage water/sewage treatmentWater/sewage treatment by neutralisationProcess systemsWastewater

A two-stage process for reclaiming the waste alkaline solution discharged by octanol synthesizing system includes "after-heat self-extracting" and "activated carbon adsorption" stages, that is, usingthe afterheat and inorganic acid to acidify the waste alkaline solution, extracting the organic components from waste solution by 2-ethylhexanol as the product of said octanol synthesizing system, adsorbing the residual phase by granular activated carbon, neutralizing by alkali, biochemical treating, and regenerating the used activated carbon. Its advantagesa re high effect etc.

Owner:SHANGHAI JIAO TONG UNIV

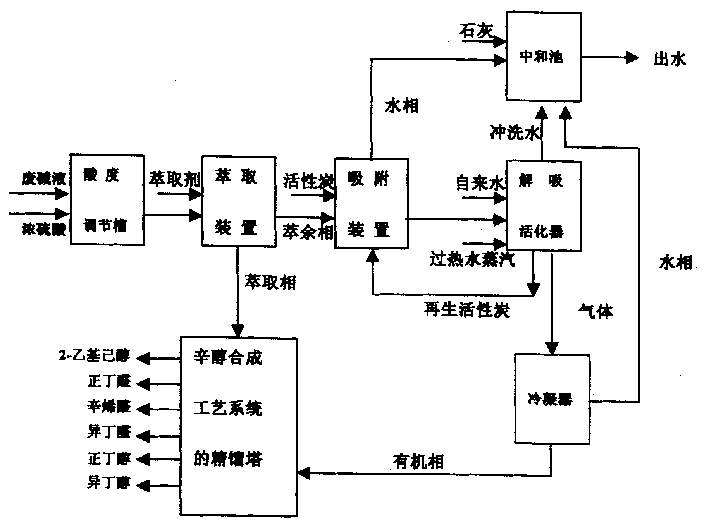

Production method of dioctyl terephthalate

InactiveCN102701984AImprove product qualityImprove quality rateOrganic compound preparationCarboxylic acid esters preparationAlcoholDioctyl terephthalate

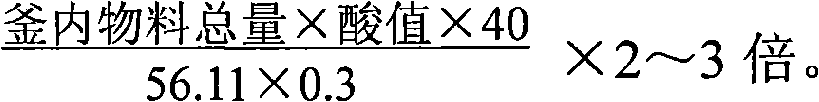

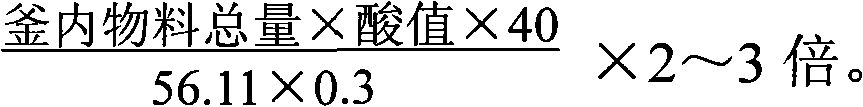

The invention provides a production method of dioctyl terephthalate. The production method comprises the steps 1) of feeding fine terephthalic acid and 2-ethyl hexyl alcohol into an esterfying reaction kettle by the weight ratio of 1 to 1-1.8, heating while stirring, adding catalyst when the temperature is increased to 170-210 DEG C, controlling the esterfying temperature within the range of 190-200 DEG C, reacting for 7-13h, and stopping esterfying when the acid value is less than 0.3mg KOH / g; and 2) of transferring the mixture into a neutralizing refining kettle after the temperature of the mixture is reduced below 100 DEG C, neutralizing and rinsing by water at 80-100 DEG C, removing superfluous reaction alcohol, separating water phase, adding a porous absorbing material, stirring, separating solid from liquid, so as to obtain a high-quality pure DOPT (dioctyl terephthalate) product, wherein the catalyst is reusable; the production method has the characteristics of low product pollution, high quality, and high product purity.

Owner:ANHUI XIANGFENG NEW MATERIALS

Azeotrope-like compositions of tetrafluoropropene and alcohols

ActiveUS8114828B2Cosmetic preparationsDomestic cooling apparatusIsobutanol1,3,3,3-Tetrafluoropropene

A composition including an effective amount of trans-1,3,3,3-tetrafluoropropene component combined with an effective amount of an alcohol selected from the group of methanol, ethanol, propanol, isopropanol, tert-butanol, isobutanol, 2-ethyl hexanol and any combination thereof, where the composition has azeotropic properties.

Owner:HONEYWELL INC

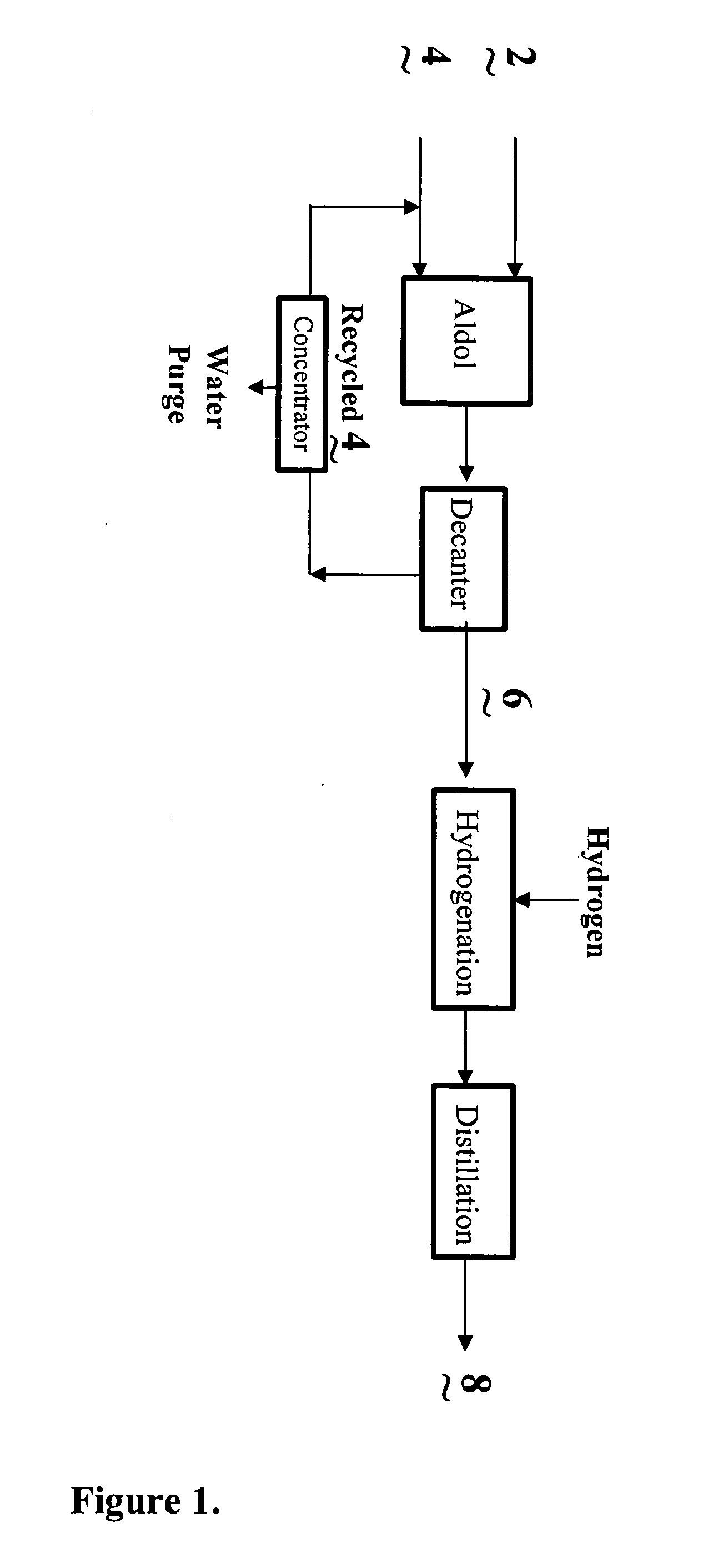

Process for the co-production of alcohols

InactiveUS20040138510A1Efficient processingPromote formationOrganic compound preparationPreparation by hydrogenationSalting outWater soluble

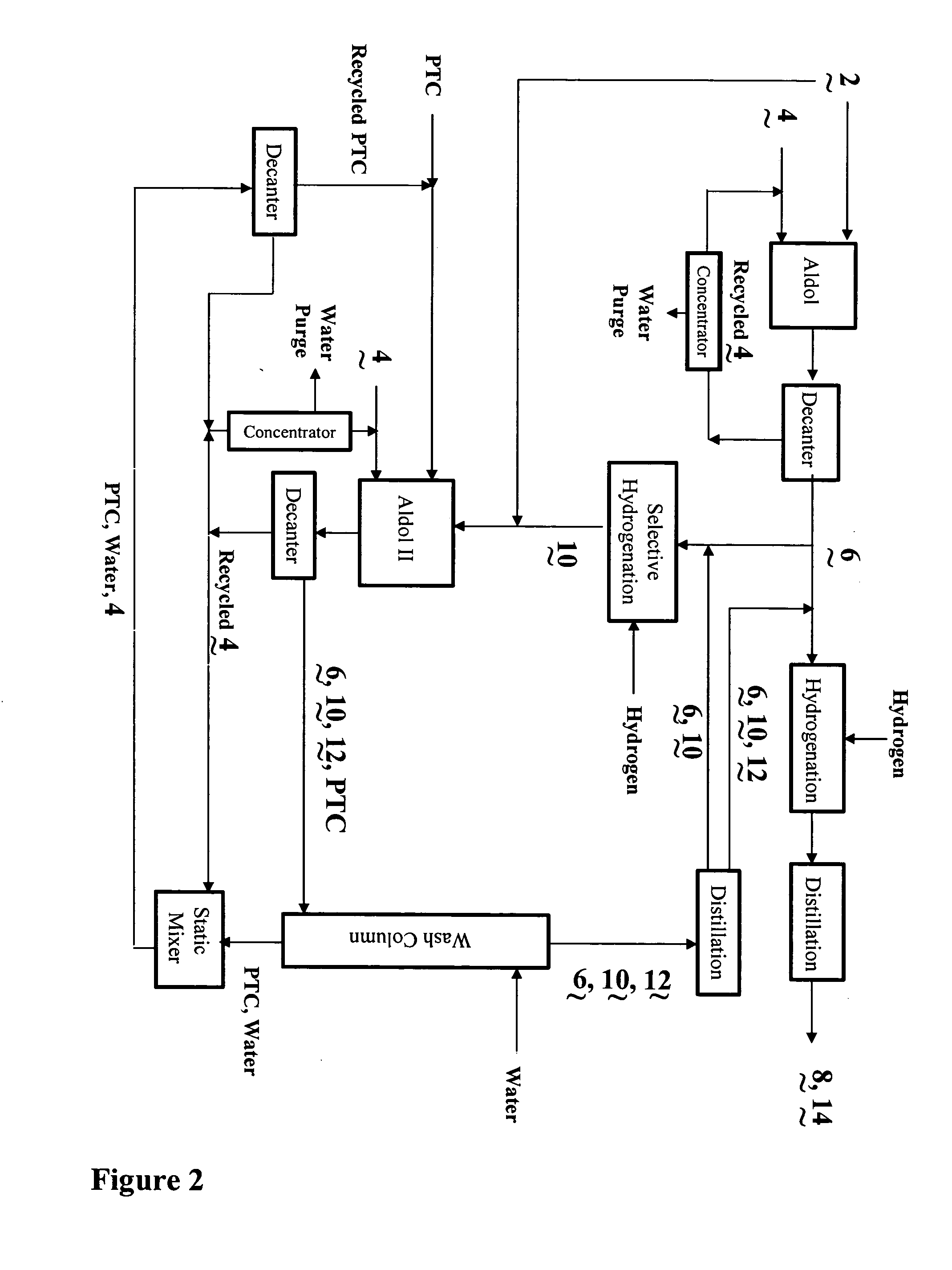

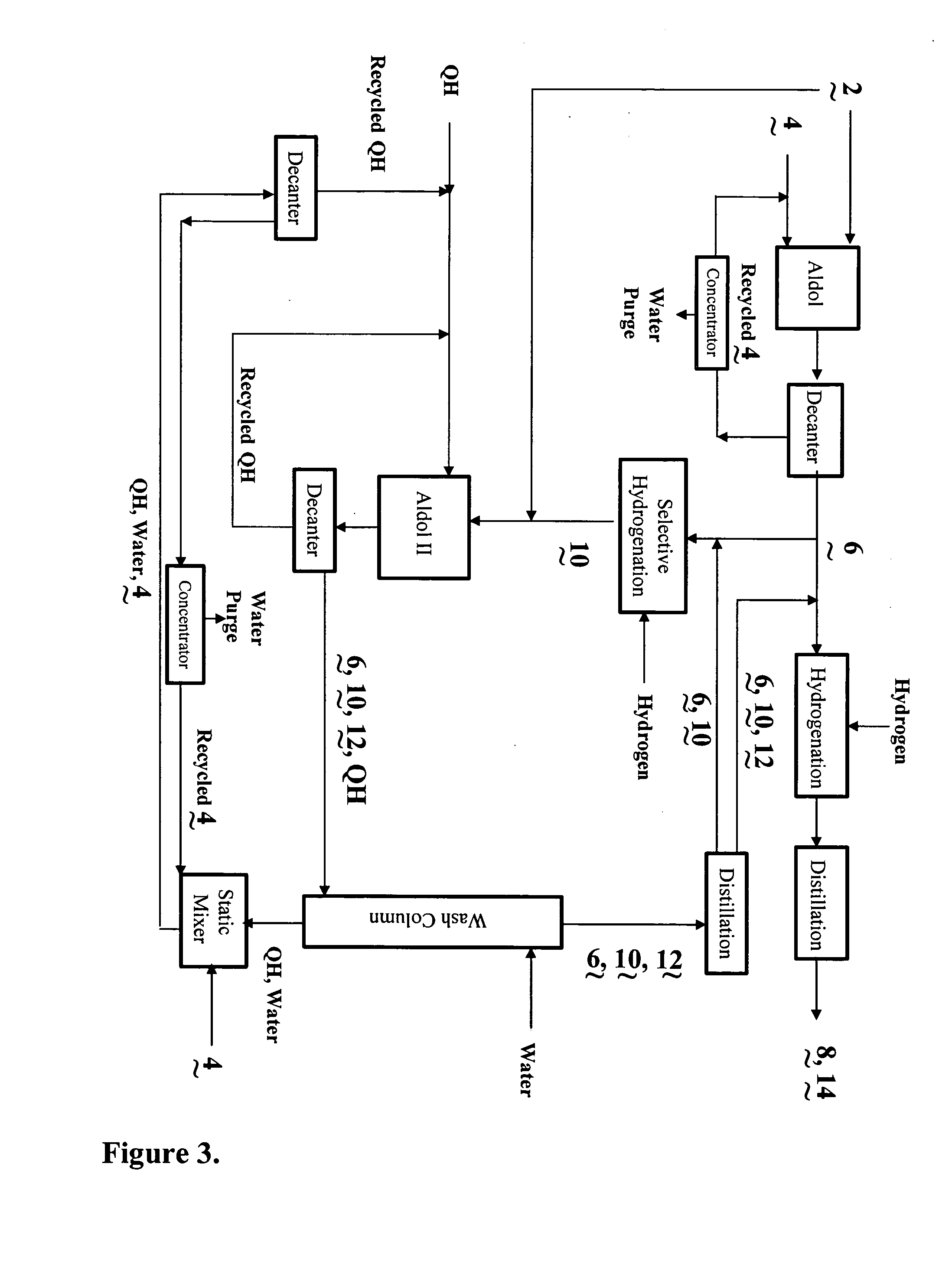

The present invention relates to the co-production of unsaturated aldehydes via a crossed-aldol condensation reaction catalyzed by recyclable water-soluble phase-transfer catalysts or the hydroxides thereof. The aldehydes are then hydrogenated to the desired alcohol products or saturated aldehyde feed stocks. Specifically, methods in which 2,4-diethyloctanol is co-produced with 2-ethylhexanol in batch and continuous processes are described. Recovery of the phase-transfer catalyst through water washing followed by "salting out" from the washings is also demonstrated.

Owner:BASF CORP

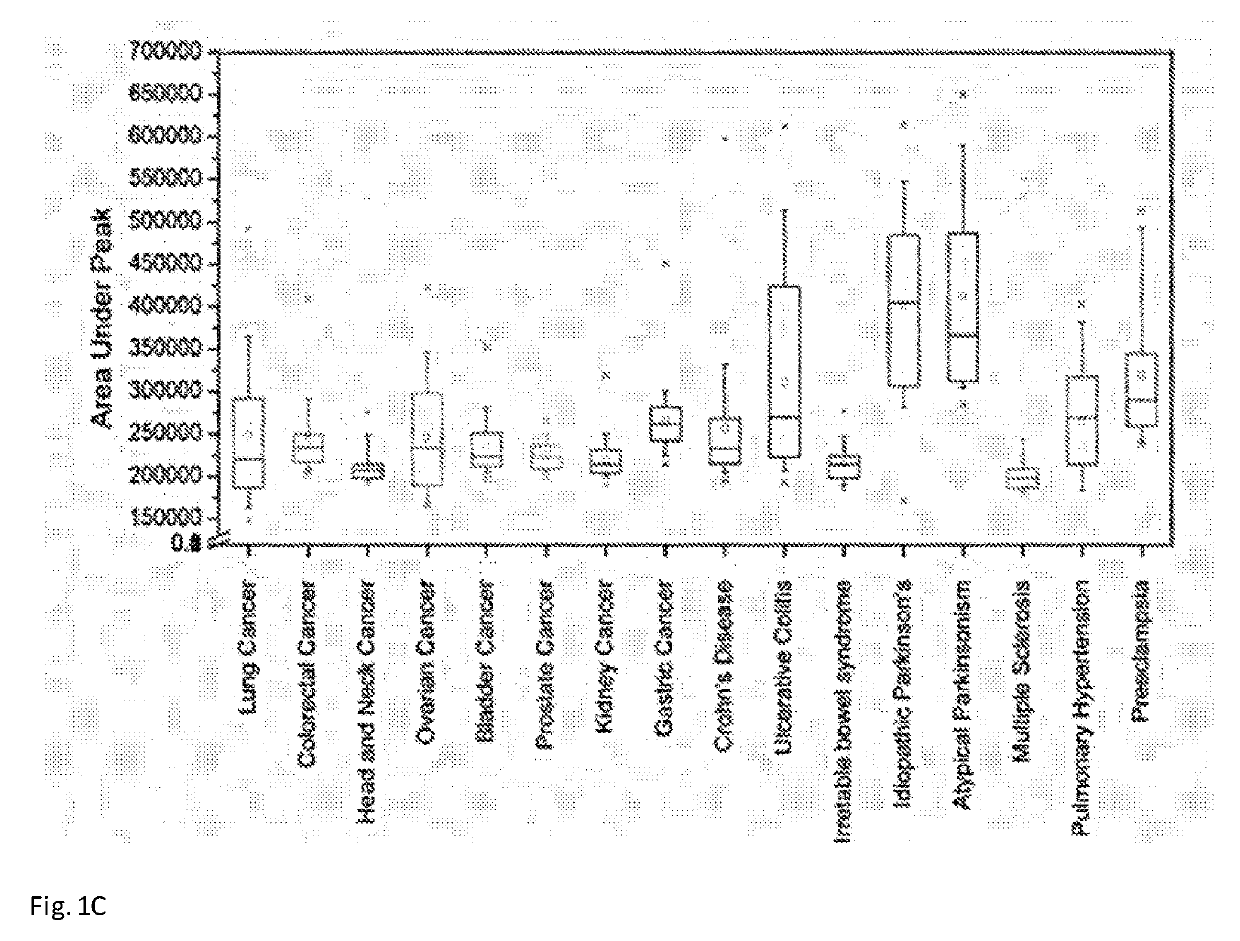

System and method for differential diagnosis of diseases

ActiveUS20190271685A1Adequate efficiencySolve the lack of reliabilityMedical automated diagnosisDisease diagnosisEthyl acetateBiomarker (petroleum)

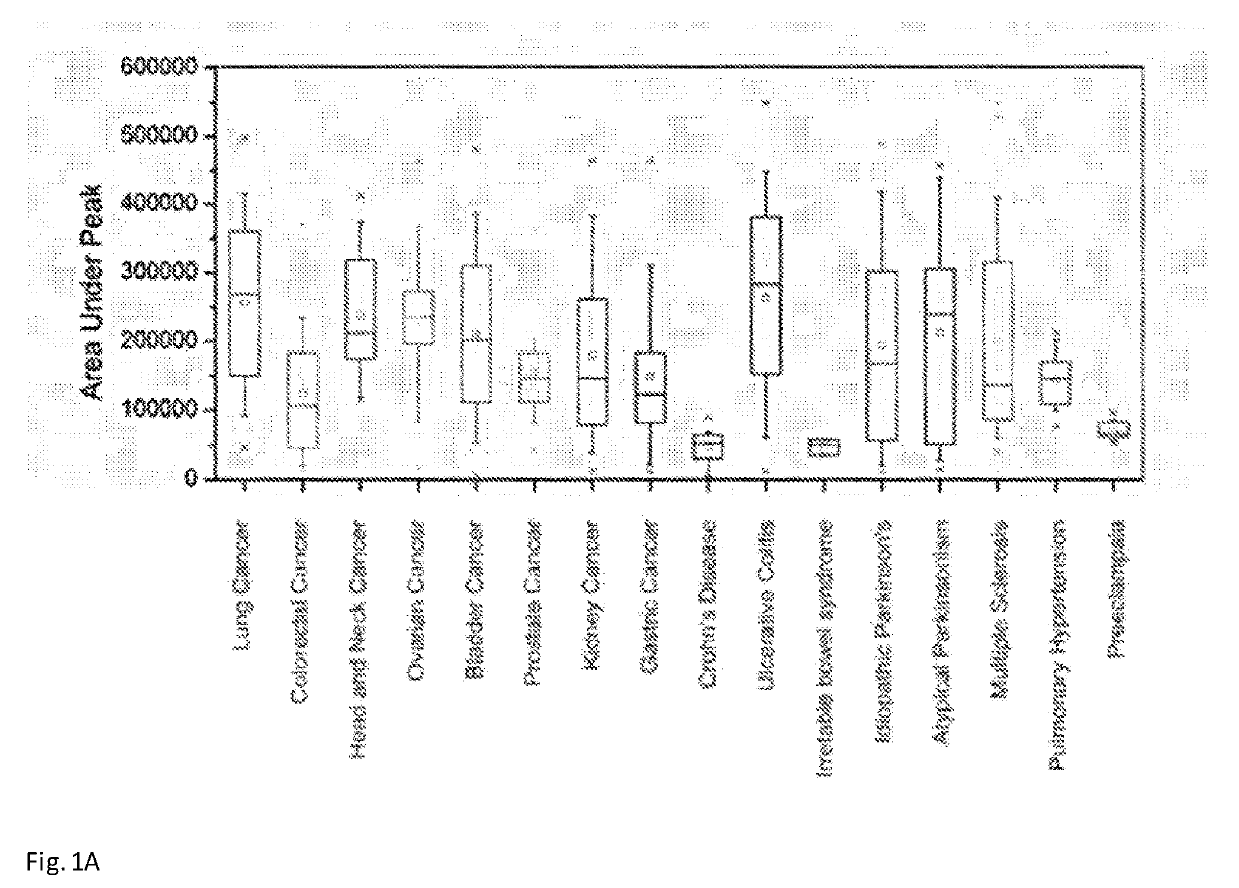

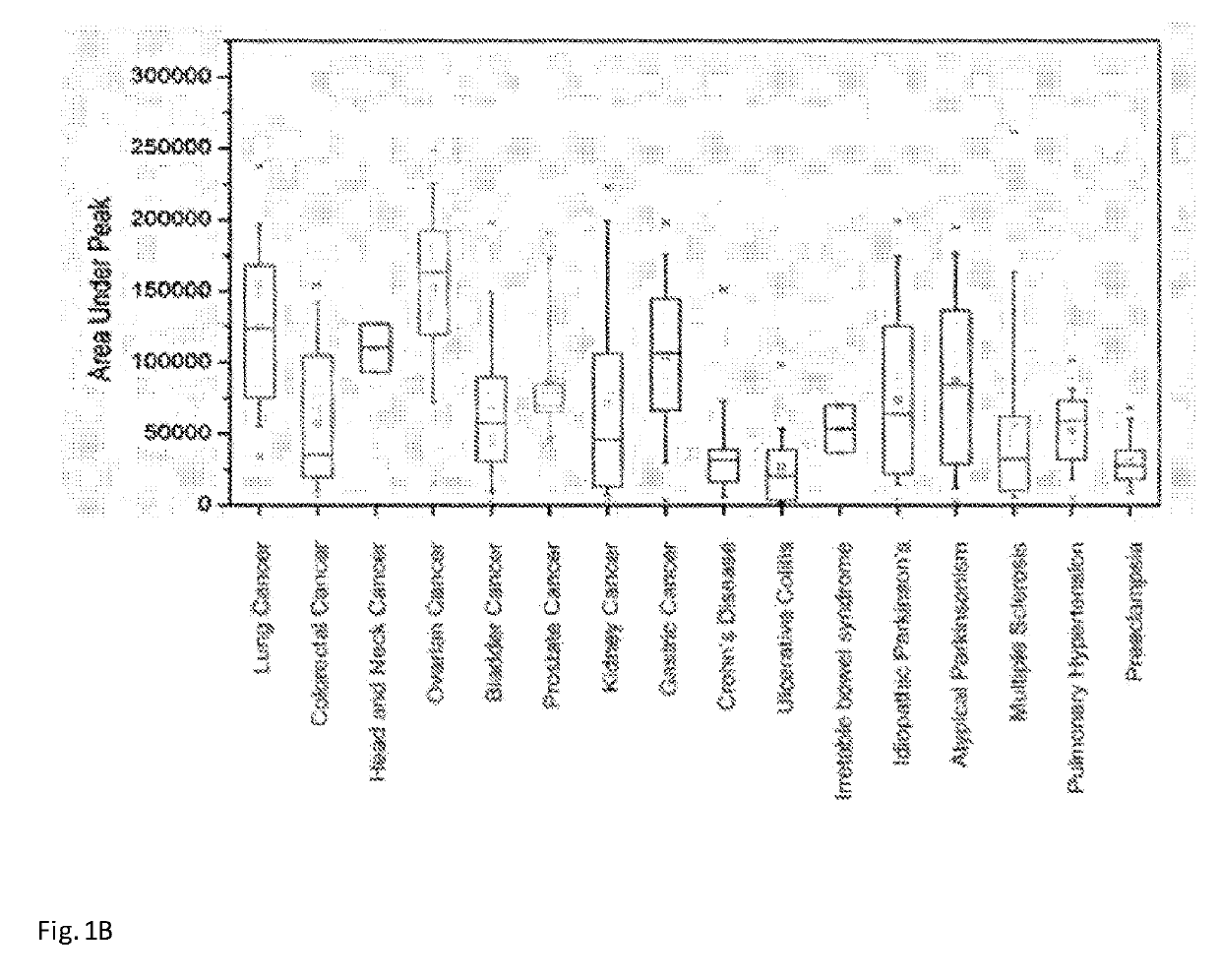

The present invention provides a system and method for diagnosing, screening or monitoring a disease by analyzing the breath of a test subject using a selected definitive sensor set in conjunction with a pattern recognition analyzer, wherein the pattern recognition analyzer receives output signals of the sensor set, compares them to disease-specific patterns derived from a database of response patterns of the sensor set to exhaled breath of subjects with known diseases, wherein each of the disease-specific patterns is characteristic of a particular disease, and selects a closest match between the output signals of the sensor set and the disease-specific pattern. The present invention further provides a method of diagnosing, screening or monitoring a disease based on the determination of levels of volatile organic compounds (VOCs) from a universal biomarker set, including 2-ethylhexanol, 3-methylhexane, 5-ethyl-3-methyl-octane, acetone, ethanol, ethyl acetate, ethylbenzene, isononane, isoprene, nonanal, styrene, toluene and undecane.

Owner:TECHNION RES & DEV FOUND LTD

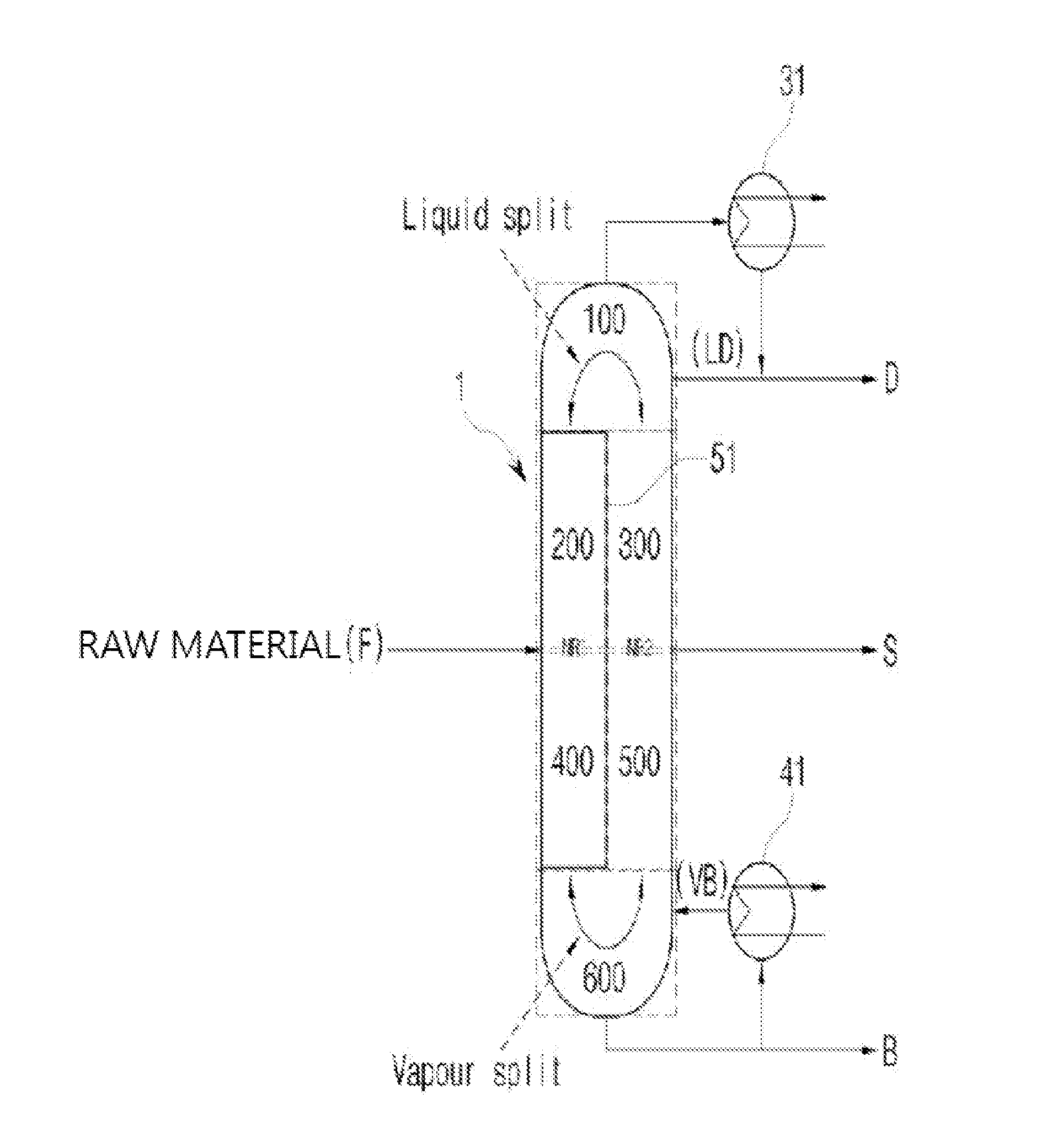

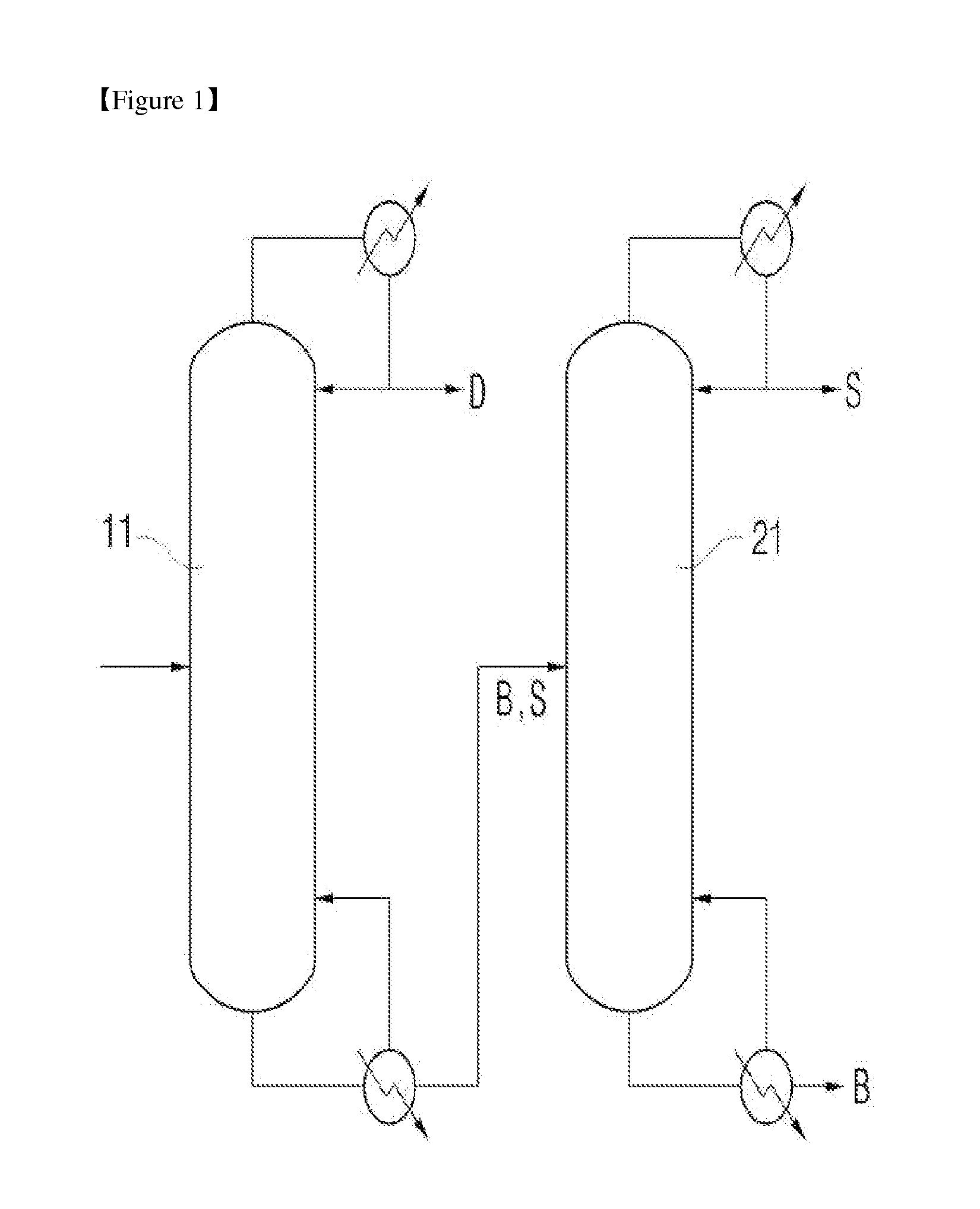

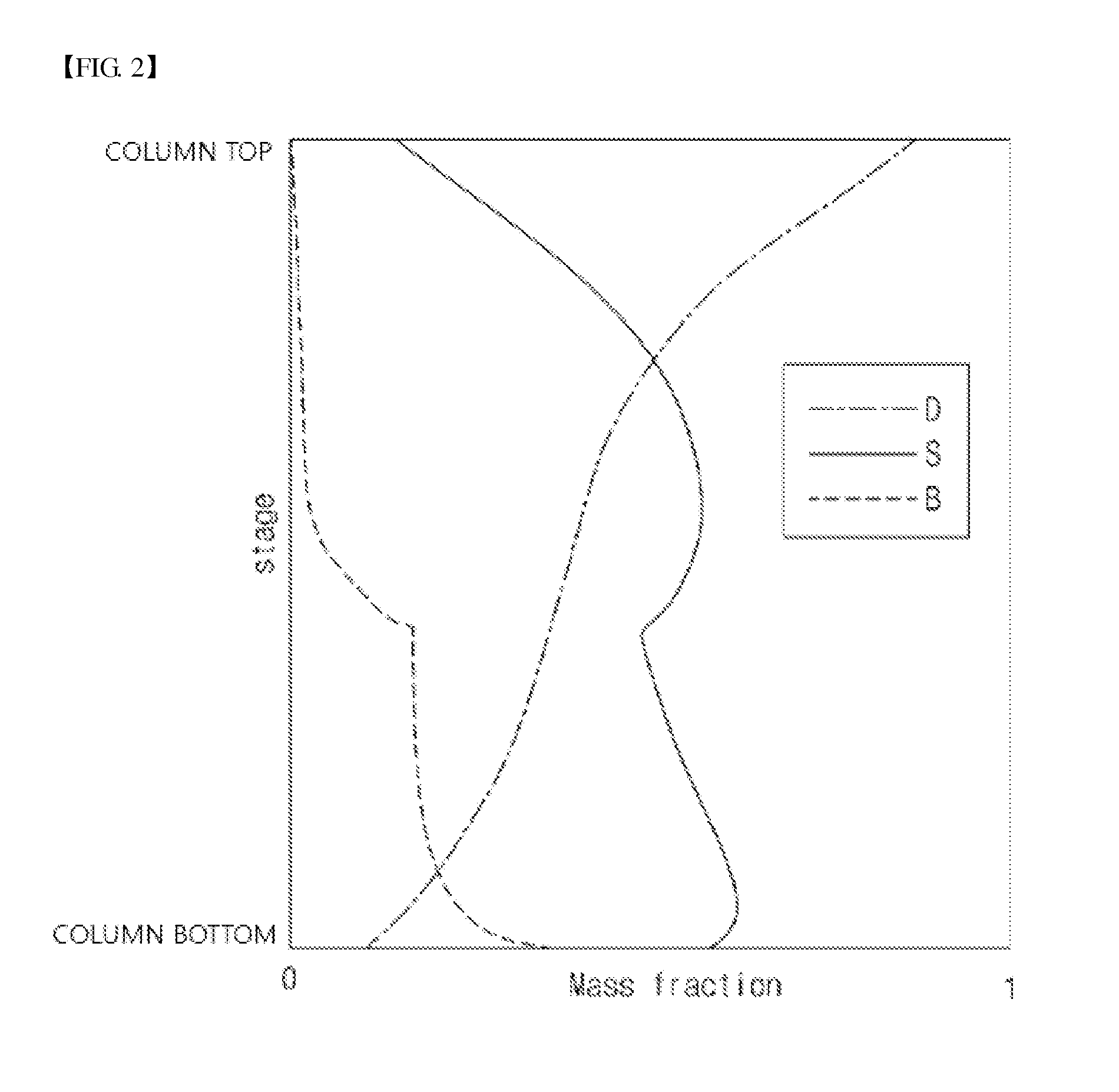

Dividing wall distillation columns for production of high-purity 2-ethylhexanol and fractionation method using same

ActiveUS20120004473A1Low costReduce equipment costsOrganic compound preparationOxygen compounds purification/separationProcess systemsBoiling point

There are provided a dividing wall distillation column for producing high-purity 2-ethyl hexanol, and a fractional distillation method using the same. The dividing wall distillation column includes a condenser, a reboiler and a main column having a dividing wall. Here, the main column is divided into a column-top zone, an upper feed zone, an upper outflow zone, a lower feed zone, a lower outflow zone and a column-bottom zone. Also, a crude 2-ethyl hexanol raw material (F) flows in a middle inflow plate NR1 in which the upper feed zone and the lower feed zone come in contact with each other, a low boiling point component (D) flows out from the column-top zone, a high boiling point component (B) flows out from the column-bottom zone, and a middle boiling point component (S) flows out through a middle outflow plate NR2 in which the upper outflow zone and the lower outflow zone come in contact with each other. In this case, the middle boiling point component is 2-ethyl hexanol. Accordingly, since one distillation column can be used to realize the same effect as that obtained from the use of two distillation columns, the dividing wall distillation column can have an effect of reducing the costs of equipment to produce high-purity 2-ethyl hexanol, as well as an energy-reducing effect, compared to a conventional process system.

Owner:LG CHEM LTD

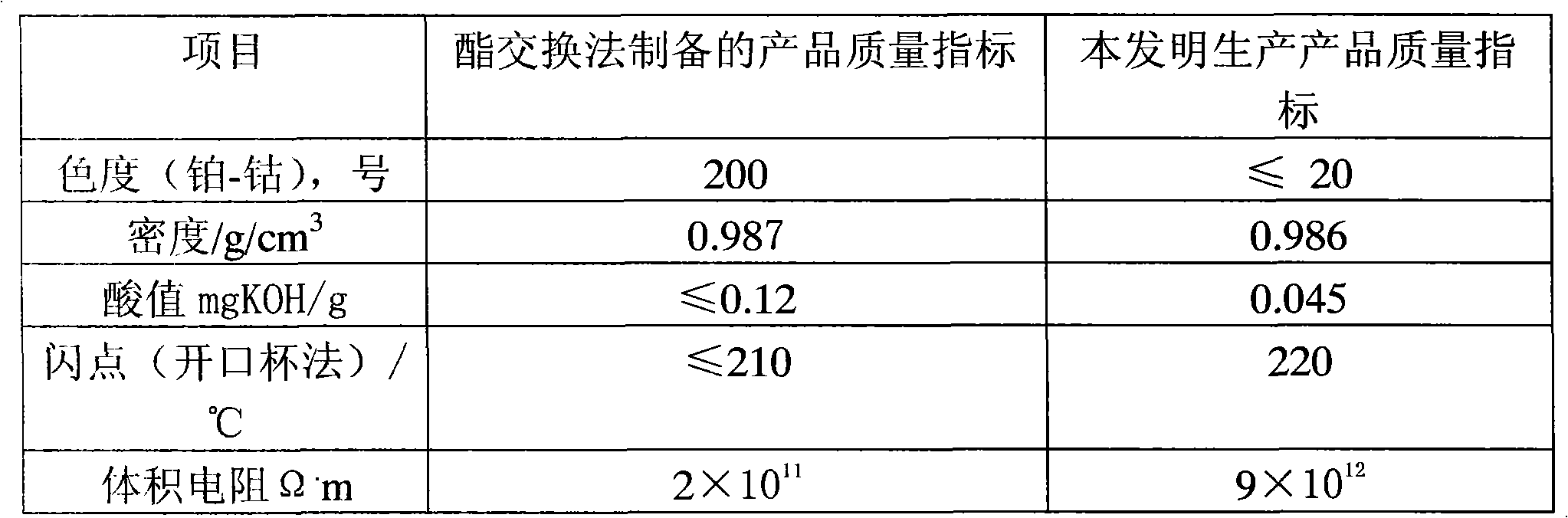

Method for producing trioctyl trimellitate with trimellitic acid

ActiveCN101429126ATemperature is not harshLower requirementOrganic compound preparationCarboxylic acid esters preparationTrimellitic acidOctanol

The invention relates to a method for producing trioctyl trimellitate through using trimellitic acid. Intermediate products of trimellitic acid and methanol in the process of producing the trimellitic anhydride are esterified to generate trimethyl trimellitate; the trimethyl trimellitate and 2-ethylhexanol (commonly called asoctanol) are subjected to ester exchange to produce trimellitate (2-ethyl) trihexyl ester (trioctyl trimellitate). The method of methyl esterification and ester exchange can reduce requirement on a technology and equipment so that the intermediate product of the trimellitic acid in the process of producing the trimellitic anhydride is flexibly utilized.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

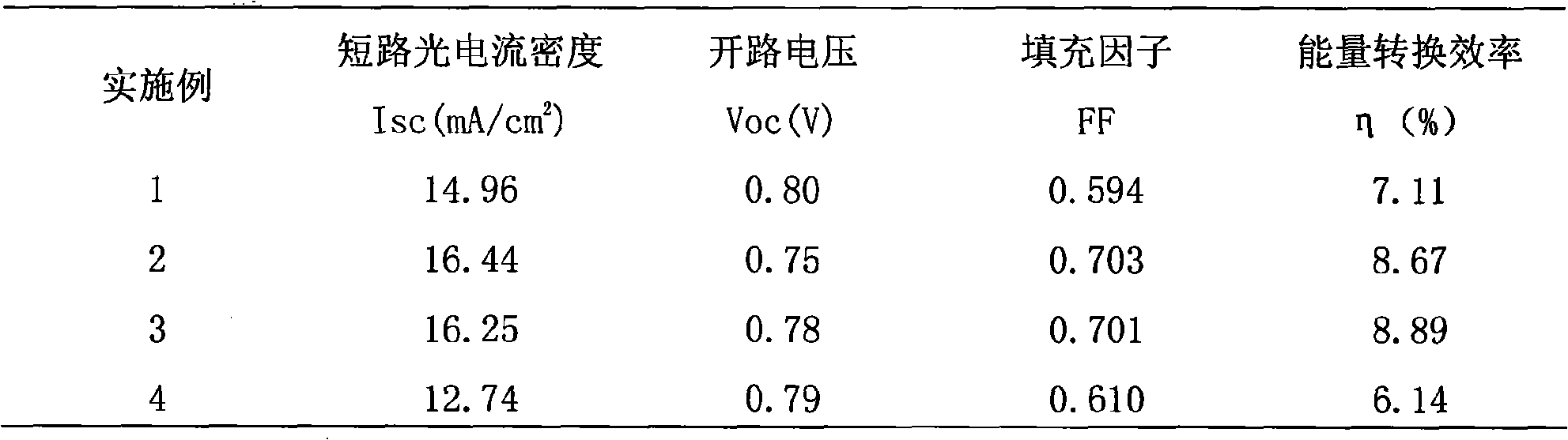

Preparation method for optical anode of dye sensitization solar battery

InactiveCN101345140AImprove conversion efficiencyRaw materials are easy to getLight-sensitive devicesFinal product manufactureReaction temperatureSlurry

The invention discloses a preparation method used for a dye sensitive solar battery photo-anode, comprising the steps as follows: preparation of TiO2 nanometer crystal slurry, preparation of TiO2 light scattering layer slurry and coating the TiO2 nanometer crystal slurry and the TiO2 light scattering layer slurry on an FTO electrode so as to prepare the dye sensitive solar battery photo-anode by sintering process. By adopting the method of the invention, the raw material is easily to be gained, the reaction temperature is low; more particularly, the PEG20000 and 2-ethylhexanol are used for preparing the TiO2 nanometer crystal slurry, thus greatly reducing the cost and improving the energy conversion efficiency simultaneously.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for synthesizing dioctyl terephthalate through esterification

ActiveCN102001948AEasy to recycleIncrease reaction rateOrganic compound preparationCarboxylic acid esters preparationDioctyl terephthalateChloride

The invention discloses a method for synthesizing dioctyl terephthalate through esterification, which is characterized by taking terephthalic acid and 2-ethylhexanol as raw materials, and synthesizing dioctyl terephthalate through esterification by using a chloride butyl pyridine stannous chloride ionic liquid as a catalyst. The synthesis method of the invention has the characteristics of quick response speed, high conversion rate, reusable catalyst, no pollution and environmental protection.

Owner:HUAQIAO UNIVERSITY

Azeotrope-like compositions of tetrafluoropropene and alcohols

A composition including an effective amount of trans-1,3,3,3-tetrafluoropropene component combined with an effective amount of an alcohol selected from the group of methanol, ethanol, propanol, isopropanol, tert-butanol, isobutanol, 2-ethyl hexanol and any combination thereof, where the composition has azeotropic properties.

Owner:HONEYWELL INC

Clean production method for preparing liquid antioxidant

ActiveCN102030647AQuick releaseSolve pollutionPreparation by ester-hydroxy reactionChemical recyclingPropionate2-Ethylhexanol

The invention provides a clean production method for a liquid hindered phenol antioxidant. The method comprises the following steps of: performing an ester exchange reaction on 3,5-ditertiary butyl-4-hydroxyphenylmethyl propionate and 2-ethylhexanol under the action of a small amount of catalyst; and adsorbing to remove the residual catalyst by using an adsorbent after the reaction, and filteringto prepare the liquid hindered phenol antioxidant. The method is a clean production method which does not require water washing, has no solvent in the reaction process and has no discharge of three wastes.

Owner:SHANDONG LINYI SUNNY WEALTH CHEM CO LTD

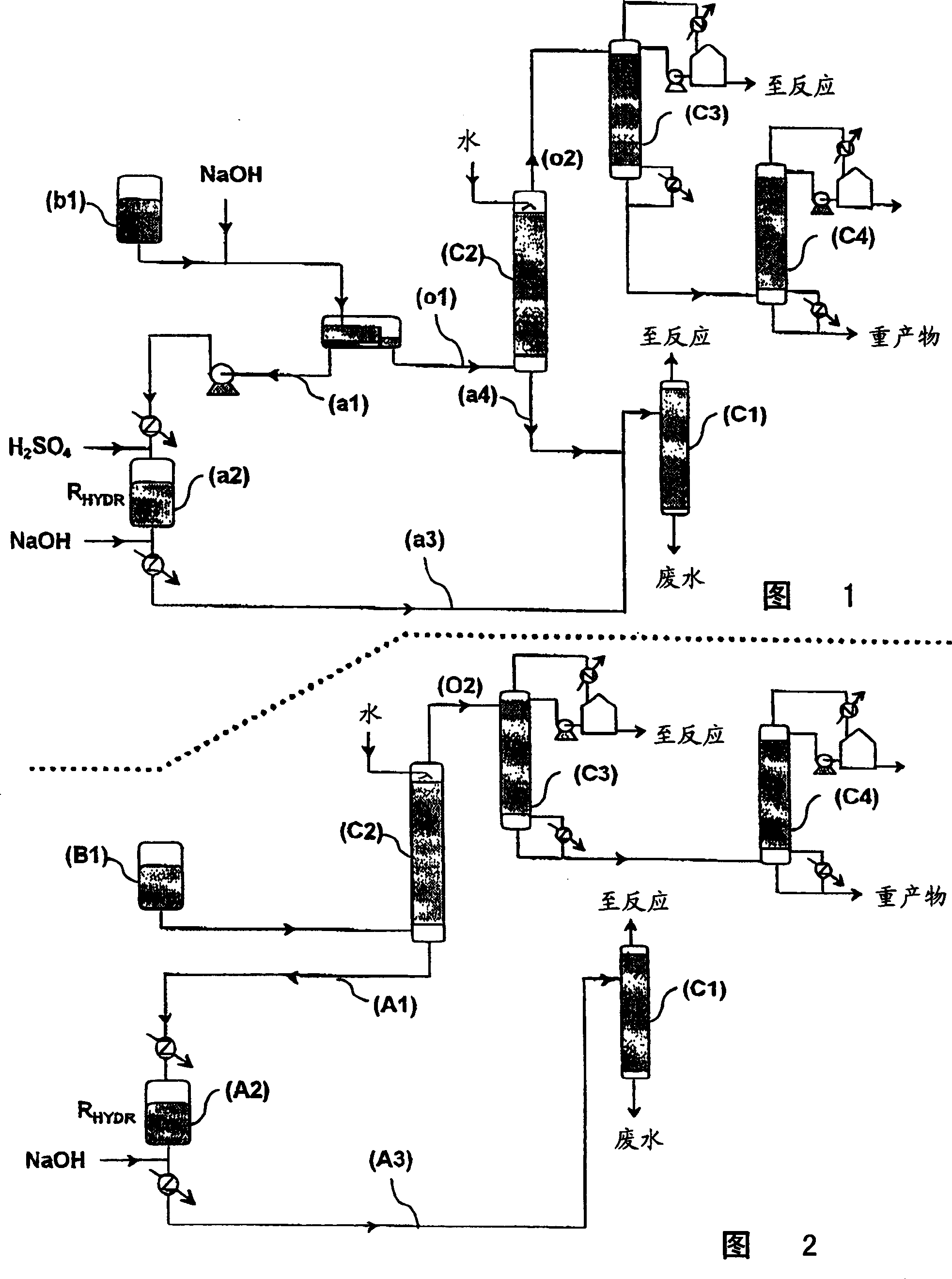

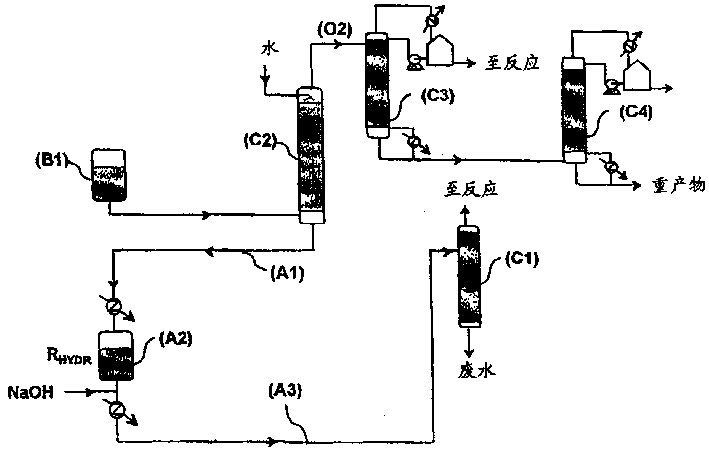

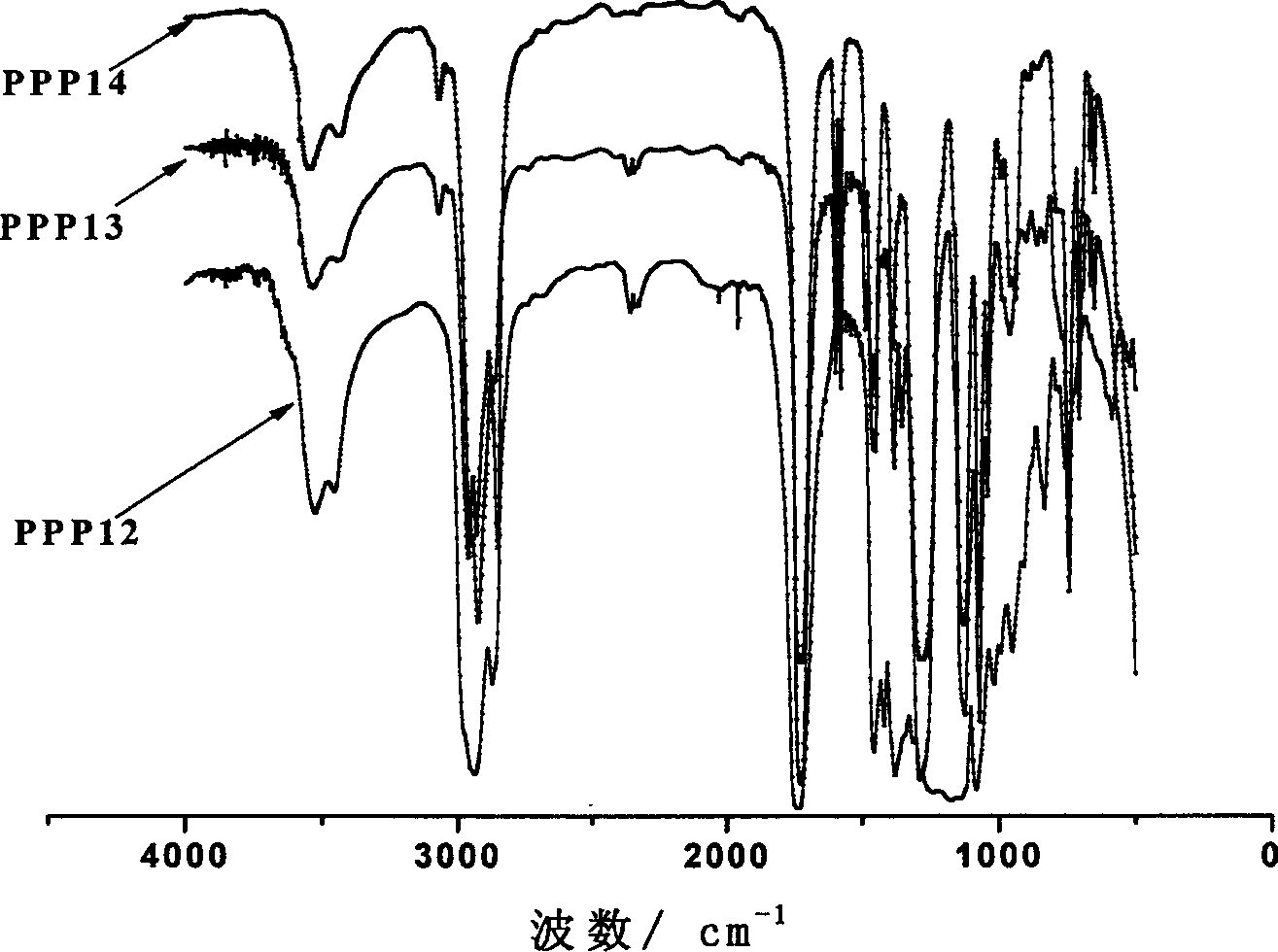

Improved method of preparing acrylic acid-2-ethyl caproite

InactiveCN1379015AOrganic compound preparationOrganic chemistry methods2-EthylhexanolEsterification reaction

Production of 2-ethylhexyl acrylate involves esterification of acrylic acid with 2-ethylhexanol. The esterification produces a reaction mixture (B1) comprising 2-ethylhexyl acrylate, 2-ethylhexanol, acrylic acid, 2-ethylhexyl acid sulfate, traces of sulfuric acid and impurities. (B1) is washed in a column enabling separation of an organic phase from which 2-ethylhexyl acrylate is distilled off. Production of 2-ethylhexyl acrylate involves esterification of acrylic acid with 2-ethylhexanol. The esterification produces a reaction mixture (B1) comprising 2-ethylhexyl acrylate, 2-ethylhexanol, acrylic acid, 2-ethylhexyl acid sulfate, traces of sulfuric acid and impurities. The mixture (B1) is water washed in a column enabling separation of an organic phase at the head and elimination of an aqueous phase at the foot. The organic phase is directed to a heading column from which acrylic acid and 2-ethylhexanol can be recycled to the esterification reaction, and 2-ethylhexyl acrylate from the base directed to another distillation column and headed off free from heavy products. The aqueous phase is directed to a hydrolysis stage to hydrolyse the acid sulfate, the acid species resulting being neutralized with a base. The resulting aqueous phase passes to a distillation column to separate off remaining 2-ethylhexanol which is recycled to the reaction.

Owner:ATOFINA

Method for synthesizing trimellitic triesters

ActiveCN106008204AReduce generationReduce cost pressureOrganic compound preparationPreparation by transesterificationEconomic benefits2-Ethylhexanol

The invention discloses a method for synthesizing trimellitic triesters. The method comprises the following steps: carrying out a methyl esterification reaction on trimellitic anhydride light and heavy components and methanol used as raw materials under the catalysis of a catalyst to generate trimethyl trimellitate, rectifying the trimethyl trimellitate to obtain high-purity and low-color number trimethyl trimellitate, and carrying out ester exchange on trimethyl trimellitate and 2-ethylhexanol, and purifying the obtained ester exchange product to obtain a tri(2-ethylhexyl) trimellitate product. The method has the advantages of effective recycling of the trimellitic anhydride light and heavy components, reduction of generation of pollutants, increase of economic benefits, reduction of the product cost and the environmental protection pressure, low requirements of the content and the color number of the raw material trimellitic anhydride, and realization of high content and low color number of obtained trihexyl ester, and allows the quality of the trihexyl ester to be better than the quality of trihexyl ester obtained through direct esterification of trimellitic anhydride and 2-ethylhexanol.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +2

Cosmetic Oil Substances

A storage-stable, smooth-feeling, non-comedogenic fatty acid ester mixture of 2-ethylhexanol and fatty acids comprising 2-ethylhexyl fatty acid esters, wherein the aggregate amount of C12 and C14 2-ethylhexyl fatty acid esters is 85% or more of the mixture, based on the total weight of all fatty acid esters in the mixture, which mixtures are useful in or as an oil component of a cosmetic or pharmaceutical preparation.

Owner:COGNIS IP MANAGEMENT GMBH

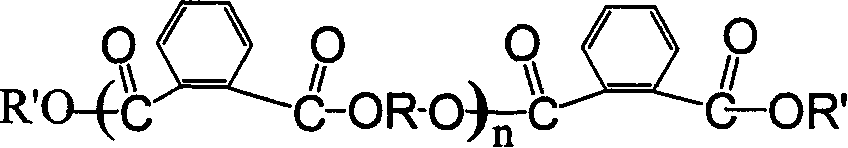

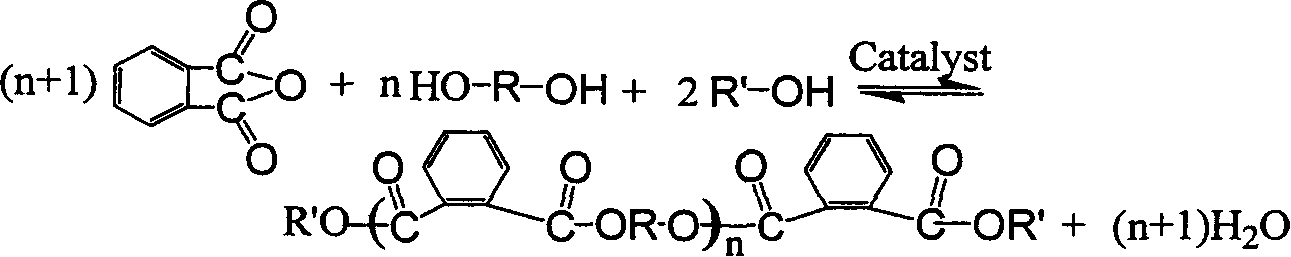

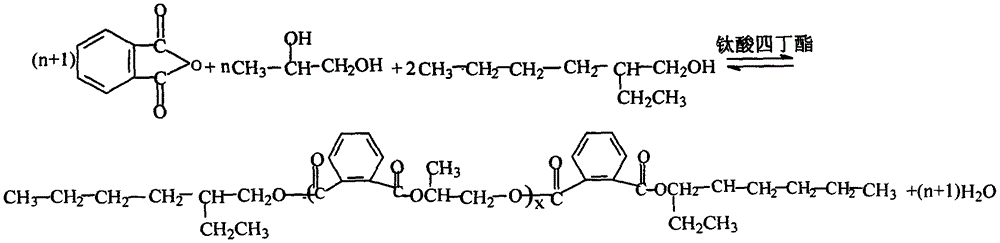

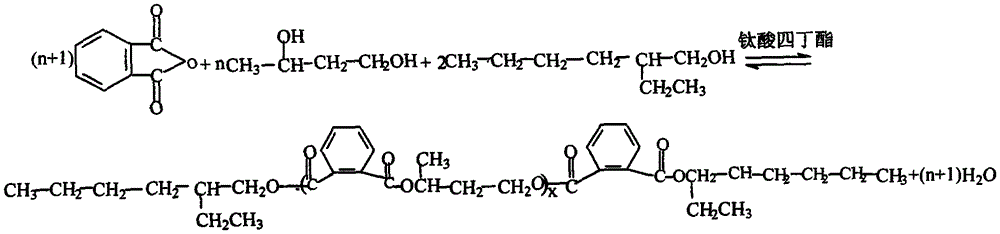

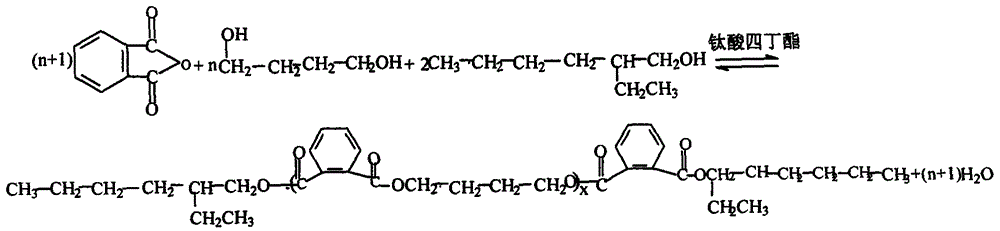

O-phthalic acid polyester plasticizer and its preparation method

The present invention provides a kind of phthalic polyester plasticizers and their preparation method, belonging to the field of polyester plasticizer technology. Said invention includes the products of poly-1,2-propylene glycol ester phthalate, poly-1,3-butylene glycol ester phthalate and poly-1,4-butylene glycol ester phthatae. Said products are made up by using phthalic anhydride and correspondent dibasic alcohol and 2-ethylhexanol and using tetrabutyl titanate as catalyst through a certain polymerization reaction.

Owner:JIANGNAN UNIV

Method for preparing 2-ethylhexyl chloroformate

InactiveCN101602667AAccurate measurementIncrease weightOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDicarbonateChemical synthesis

The invention relates to a method for preparing 2-ethylhexyl chloroformate, which belongs to the technical field of organic chemical synthesis. The method comprises the steps of: evenly mixing solid phosgene, a catalyst, and alkaline substance (carbonate or hydrocarbonate) in an organic solvent according to a certain molar ratio; stirring the mixture for 10 to 30 minutes at a temperature of between 5 DEG C below zero and 25 DEG C; adding 2-ethylhexanol diluted by the organic solvent into the mixture; reacting for 1 to 48 hours at a temperature of between 5 DEG C below zero and 25 DEG C; and obtaining the 2-ethylhexyl chloroformate through suction filtration and reduced pressure distillation. The method has the advantages of simple process method, mild reaction conditions, and replacement of the phosgene by the solid phosgene as a raw material; the solid phosgene has safe use, is environment-friendly, has accurate metering, and is convenient to store and transport, and the synthesized 2-ethylhexyl chloroformate has higher yield and purity. The method is applicable to the industrialized production of the 2-ethylhexyl chloroformate further to synthesize an initiator, namely bis-(2-ethylhexyl)peroxydicarbonate (EHP).

Owner:ZHENGZHOU UNIV

Preparation method of rubber plasticizer dioctyl sebacate

InactiveCN104592015AReduce dosageLight colorOrganic compound preparationCarboxylic acid esters preparationDibutyl sebacateDistillation

The invention discloses a preparation method of a rubber plasticizing agent dioctyl sebacate. The method includes the following steps: 1, adding sebacic acid, 2-ethyl hexanol and a catalyst stannous oxide into a four-neck flask equipped with a thermometer, a reflux distributor and an agitator, introducing nitrogen, and conducting esterification reaction under 200 DEG C-230 DEG C; 2, after the reaction, cooling to 90 DEG C, adding lye water for neutralization, washing, standing for layering, releasing lye water, conducting reduced pressure distillation, and finally add activated carbon for adsorption and filleting to obtain the dioctyl sebacate product. The preparation method provided by the invention employs a non-solid acid catalyst stannous oxide for catalytic synthesis of dioctyl sebacate, and has the advantages of high catalytic activity, short reaction time, small amount of catalyst, light color of the obtained product, simple post treatment process, no corrosion of the catalyst on the equipment, no waste liquid produced, green, and environment-friendliness.

Owner:QINGDAO WANGYU RUBBER

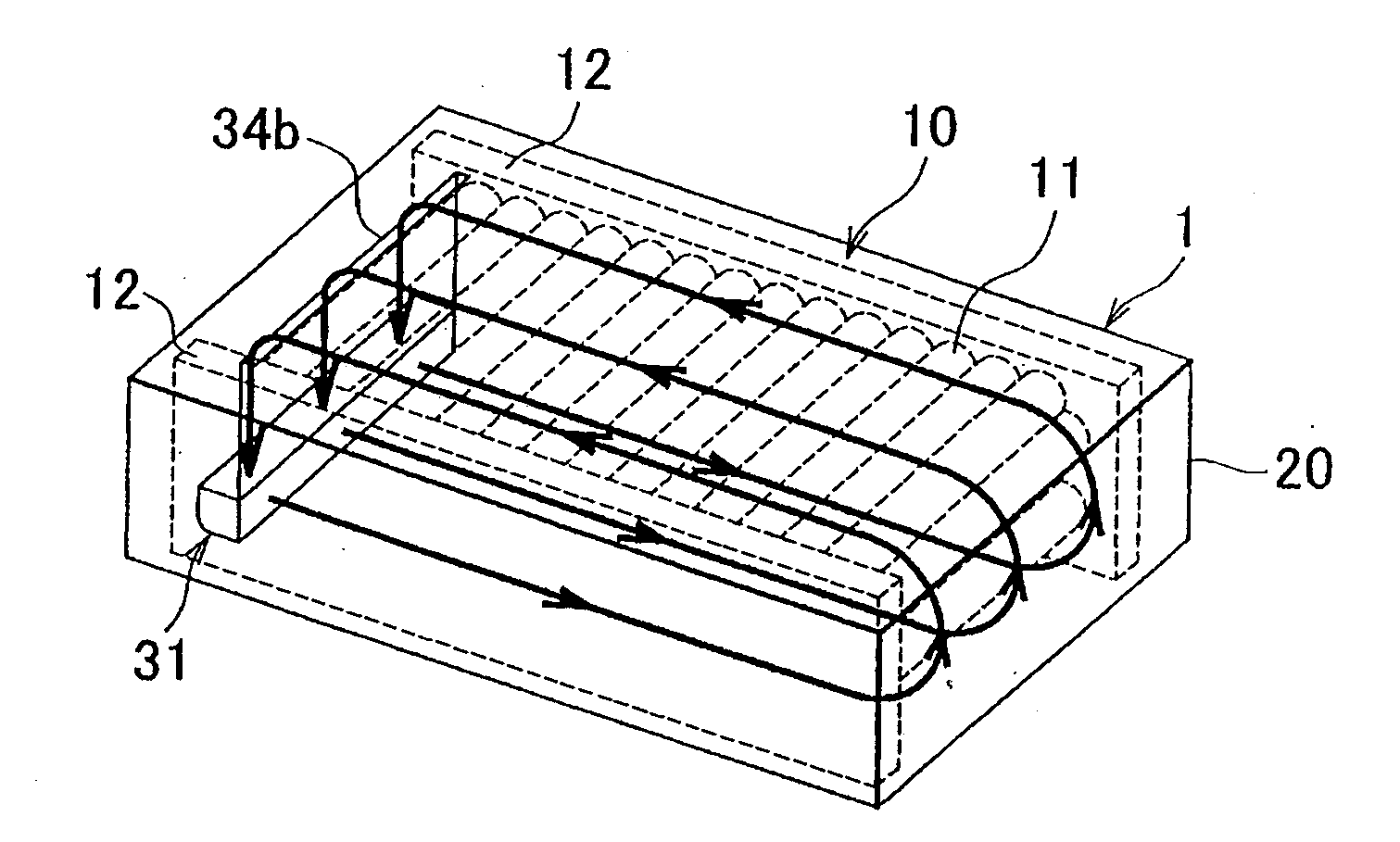

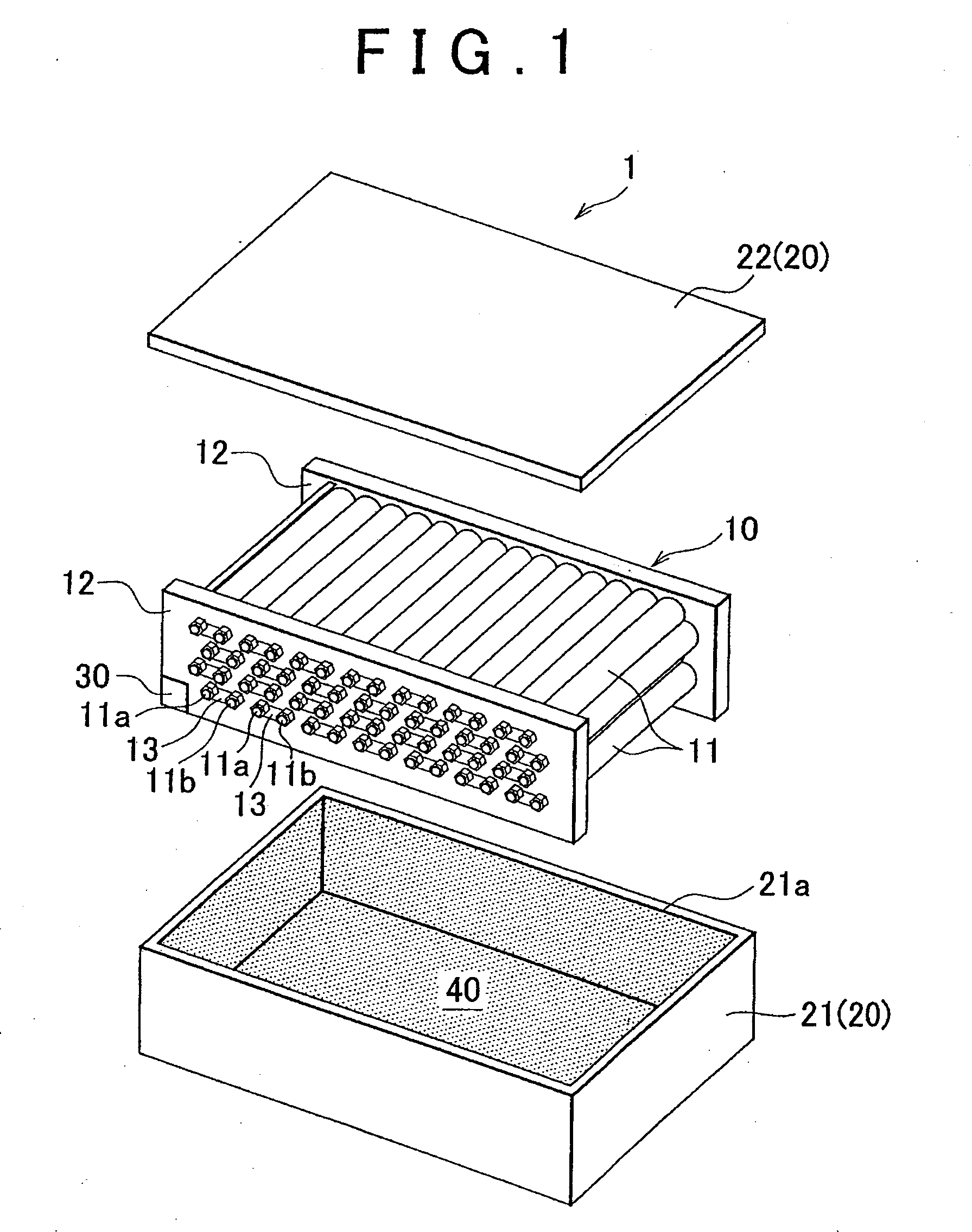

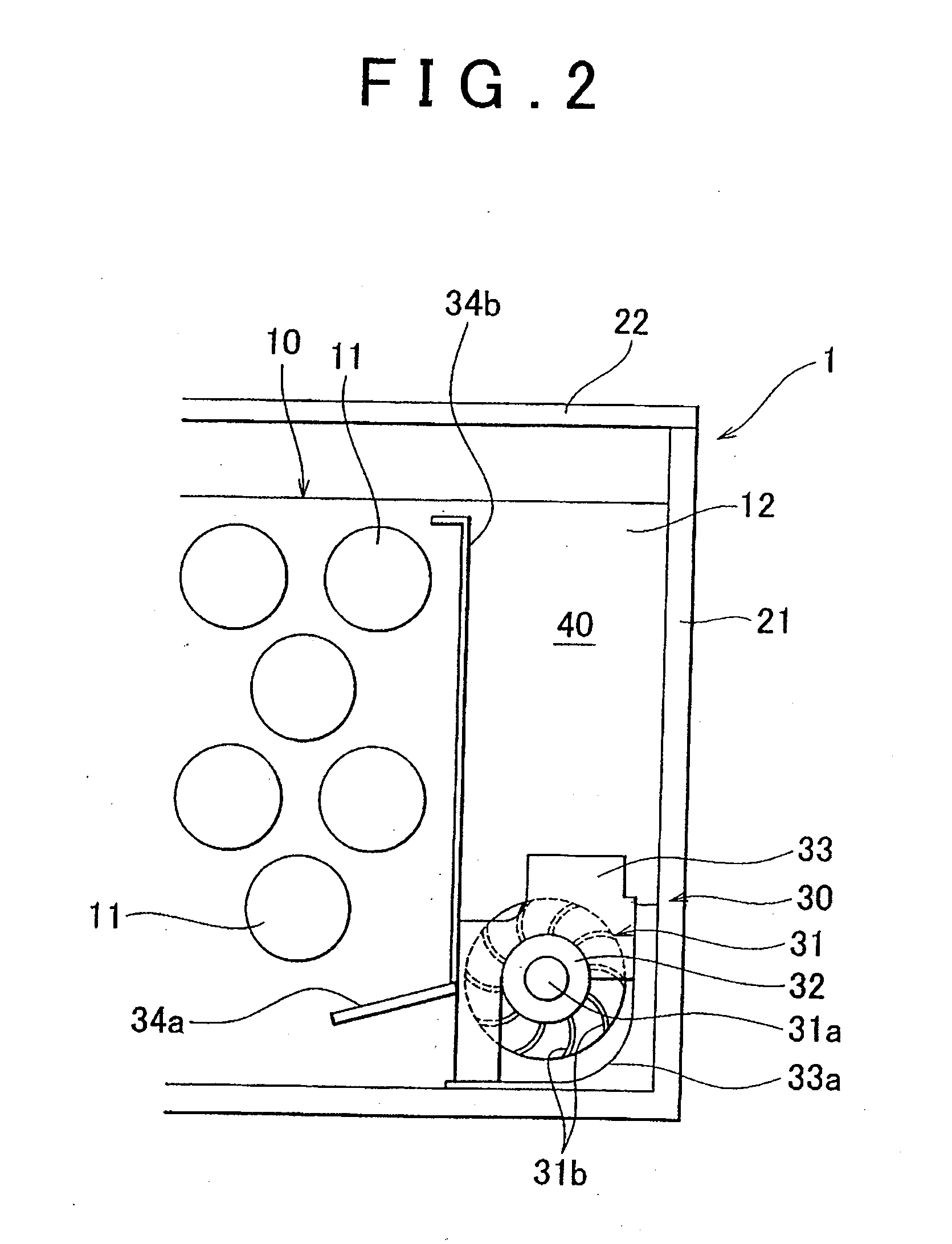

Heat exchange medium and electric storage device

InactiveUS20120026690A1Avoid corrosionPartial dispersion of the temperature within the electric storage element may be minimizedElectrolytic capacitorsCell temperature controlCarbon number2-Ethylhexanol

A liquid heat exchange medium (40) is provided in a case (20) together with an electric storage element (11) to exchange heat with the electric storage element. The heat exchange medium is an ester compound of a fatty acid with a carbon number of 6 to 8 and 2-ethyl hexanol. The heat exchange medium contains 90 or more volume % of 2-ethylhexyl caprylate.Selected Drawing: FIG. 1

Owner:TOYOTA JIDOSHA KK +1

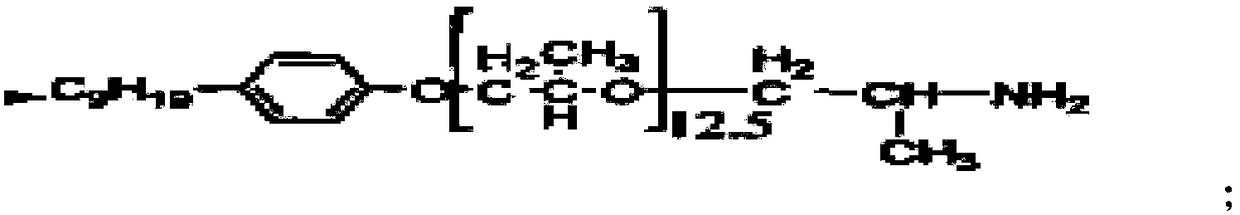

Multi-effect disassembly-free cleaning agent for fuel system

InactiveCN108865300AEfficient decompositionBreak down sharplyLiquid carbonaceous fuelsFuel additivesDecompositionInlet valve

The invention discloses a multi-effect disassembly-free cleaning agent for a fuel system. The multi-effect disassembly-free cleaning agent is prepared from the following components: polyether amine, polyisobutylene amine, 1,1,3-trimethyl-3-phenylindan, oil-soluble polyether PPG, 1,2,4-trimethylbenzene, naphthalene, 2-ethylhexanol and aromatic hydrocarbon. According to the multi-effect disassembly-free cleaning agent for the fuel system, deposits of an air inlet valve / a fuel spray nozzle are efficiently cleared by utilizing the polyisobutylene amine, deposits of a combustion chamber are clearedby mainly adopting the polyether amine, and therefore, proper high-temperature stability and degradability are achieved, the deposits of the air inlet valve and the fuel spray nozzle can be effectively cleared, in addition, completed decomposition can be guaranteed in the combustion chamber at the high temperature, the deposits of the combustion chamber can also be greatly cleared, and the amountof the total deposits of the combustion chamber can be decreased.

Owner:深圳市龙威科技发展有限公司

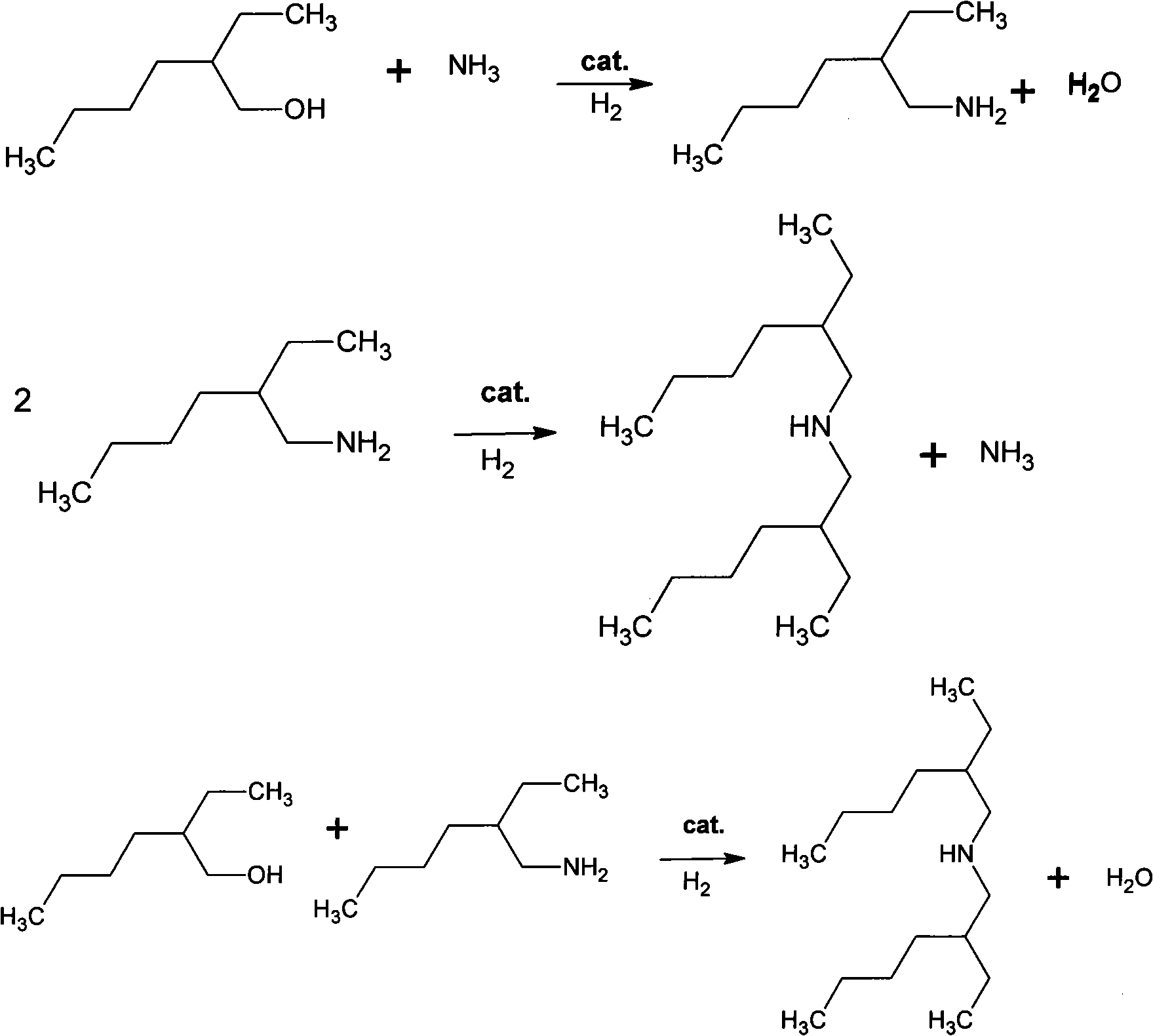

Preparation method of bi-(2-ethylhexyl)

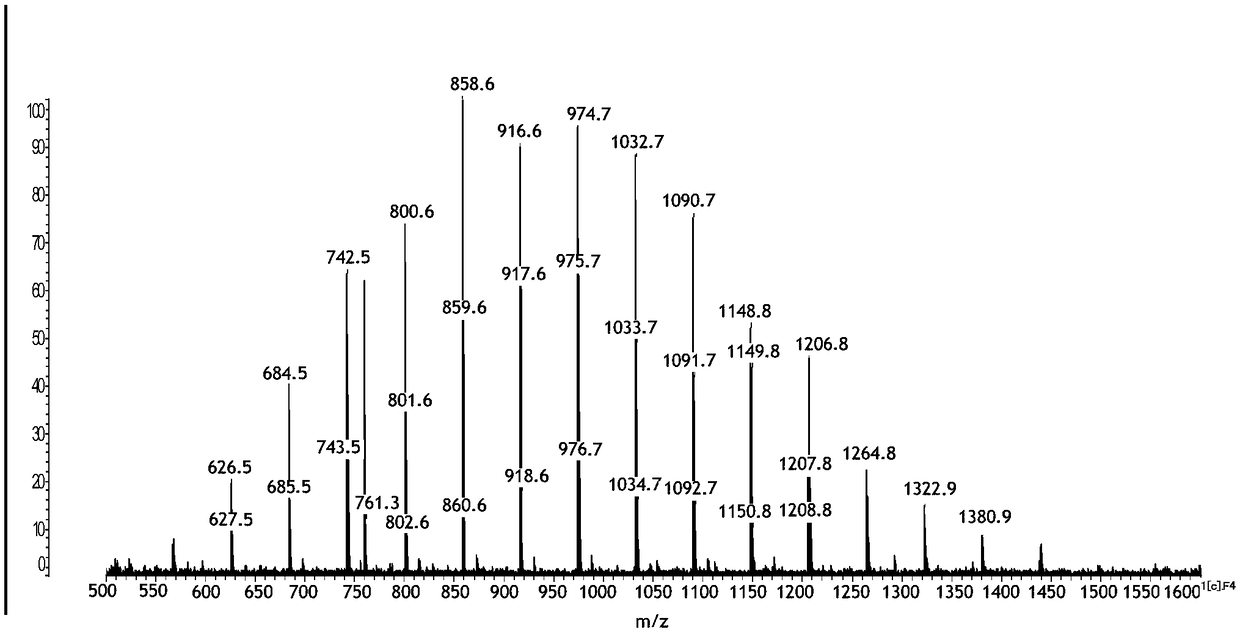

InactiveCN101844987AThe process steps are simpleReduce investmentOrganic compound preparationAmino compound preparation by condensation/addition reactionsHydrogen atmosphere2-Ethylhexanol

The invention discloses a preparation method of bi-(2-ethylhexyl), mainly comprising the following steps of: adding 2-ethylhexanol, ammonia, hydrogen and a catalytic agent in a high-pressure reaction kettle and stirring at high speed; carrying out catalysis and amination reaction at the temperature of 120-260 DEG C to prepare a mixture containing2-ethylhexylamine, 2-ethylhexanol and bi-(2-ethylhexyl); continuously carrying out condensation deamination reaction on the mixture in a hydrogen atmosphere to obtain a reactant taking bi-(2-ethylhexyl) ammonia as the main component, wherein the product selectivity is higher than 90 percent, and then rectifying to obtain the bi-(2-ethylhexyl), wherein the purity of the bi-(2-ethylhexyl) is higher than 99 percent. The bi-(2-ethylhexyl) prepared by the method is mainly used for the synthesis of high-grade lubricant oil extreme-pressure antiwear agents.

Owner:张家港市大伟助剂有限公司

Metalworking fluid, metal working method and metal work product

InactiveUS20120177938A1Low costImprove productivityPig casting plantsIngot casting plantsMetalworking fluidCarboxylic acid

The invention provides a metalworking fluid which contains (A) a base oil including 2-ethylhexanol palmitate or 2-ethylhexanol stearate, and (B) an anionic surfactant that is a salt of a branched aliphatic carboxylic acid having 8 to 18 carbon atoms with a branched alkanolamine having 3 to 12 carbon atoms. The metalworking fluid of the invention is excellent in the cutting performance, anti-foaming properties, stability of stock solution, emulsion stability and resistance to hydrolysis, and shows low kinematic viscosity at low temperatures.

Owner:KYODO YUSHI CO LTD +1

Method for producing di(2-ethylyhexyl) terephthalate

ActiveUS20140288325A1Improve reaction efficiencyImprove filtration ratePreparation from carboxylic acid halidesOrganic compound preparationDioctyl terephthalateReaction rate

Disclosed is a method for producing di(2-ethylhexyl)terephthalate (DOTP), which comprises subjecting terephthalic acid and 2-ethylhexanol to esterification in the presence of a chelate catalyst. The method of the present invention increases the reaction rate, improves the filtration efficiency of the ester product and yields DOTP with low APHA.

Owner:CHANG CHUN PLASTICS +1

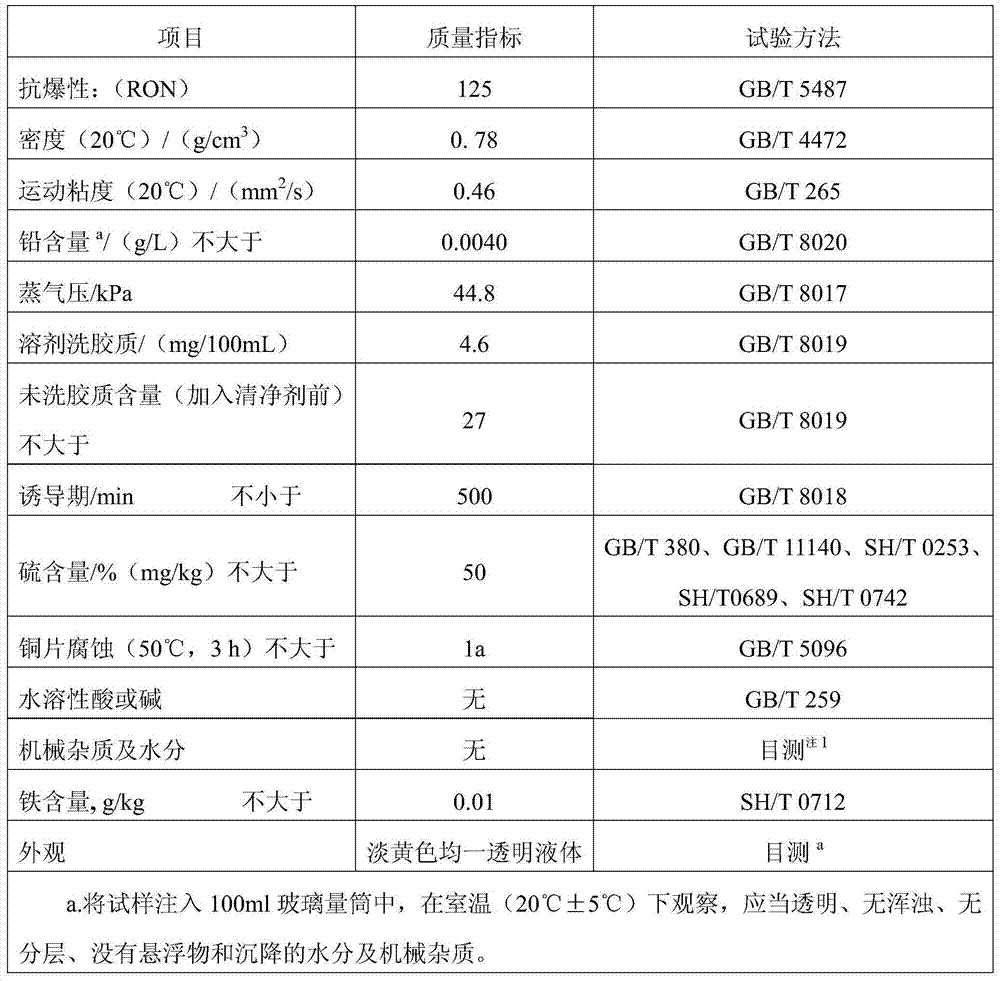

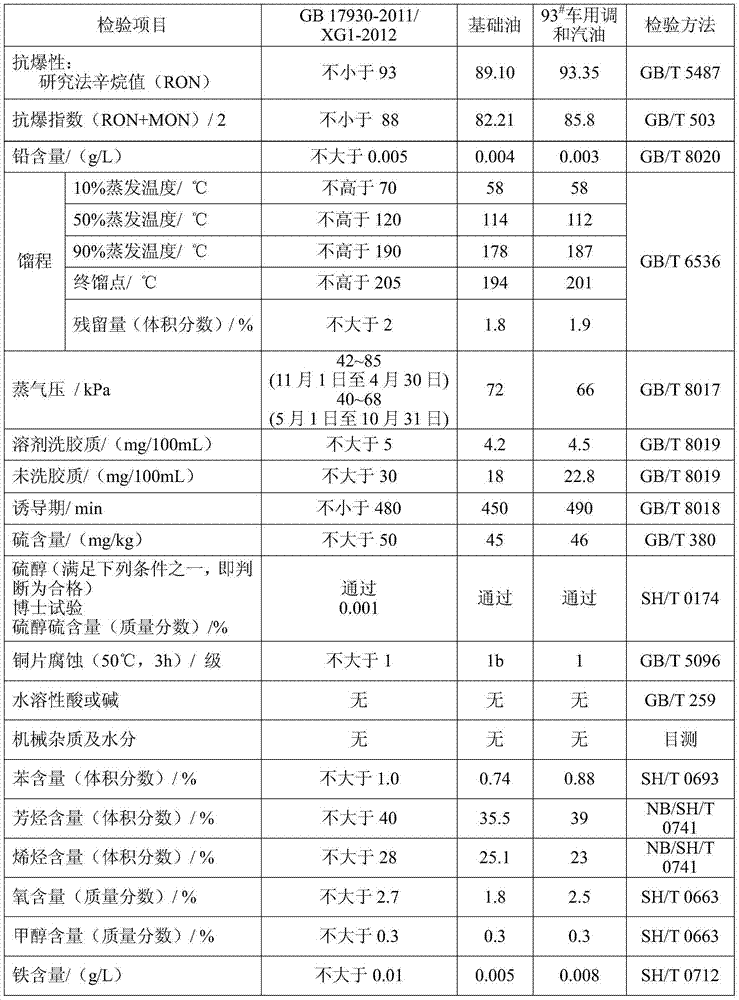

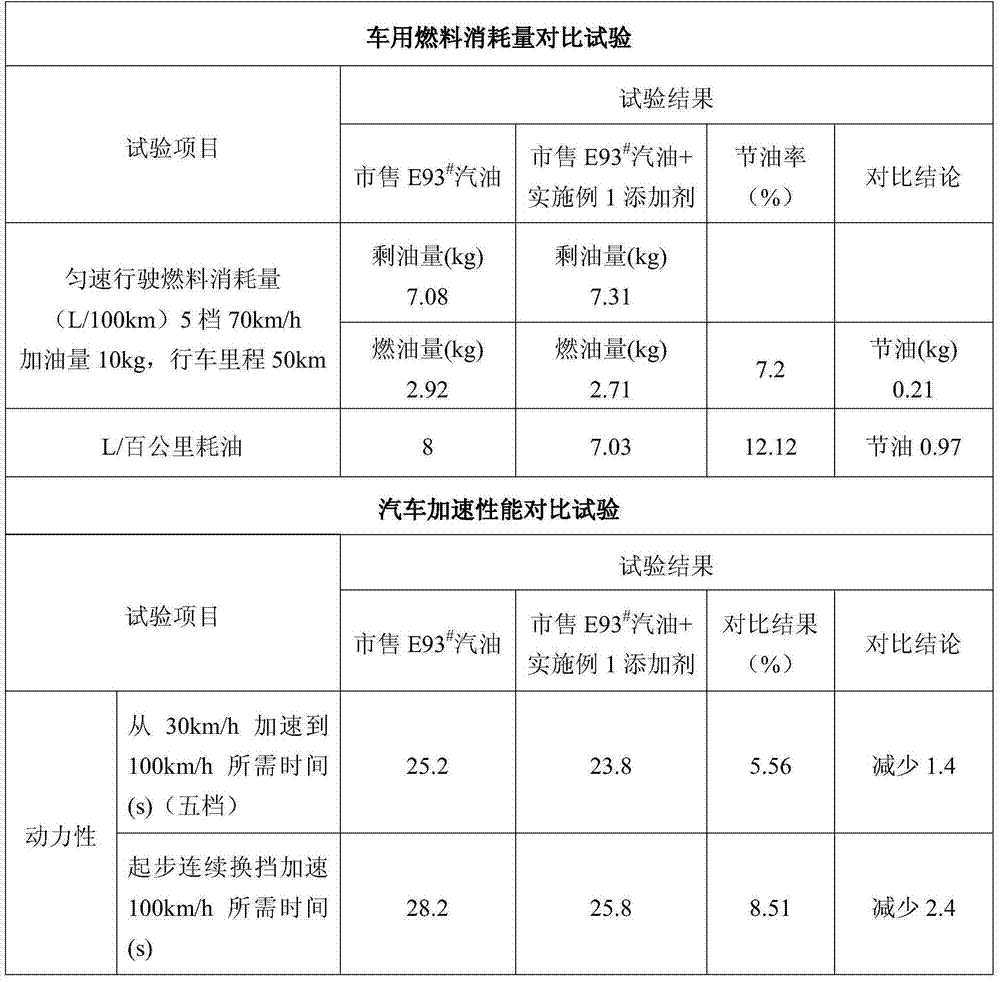

Composite additive for producing National Standard IV 93# gasoline from refinery base oil

InactiveCN104119967AIncrease powerIncrease torqueLiquid carbonaceous fuelsFuel additivesMass ratioMethyl carbonate

The invention provides a vehicle fuel oil composite additive which comprises the following components in percentage by mass: 35-80% of octane number enhancer, 15-38% of combustion improver and 5-27% of assistant. The octane number enhancer is composed of ethanol, tert-butyl acetate, methyl tert-butyl ether, cyclopentane and polymethoxy dimethyl ether in a mass ratio of 40:10:40:7:3; the combustion improver is composed of diisopropyl ether, dimethyl carbonate, nitromethane, acetone and glycol dimethyl ether in a mass ratio of 45:30:10:5:10; and the assistant is composed of isoamyl alcohol, isopropanol, 2-ethylhexanol, dipolylinoleic acid, metal passivator and antioxidant in a mass ratio of 20:60:8:10:0.4:1.6.When being applied to vehicle fuel oil, the composite additive can reduce or eliminate knocking, enable the fuel oil to have high octane number performance and ensure the fuel in the cylinder to be combusted completely, so that both the exhaust emission and fuel consumption are lowered, and the power and torsion of the engine are enhanced.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

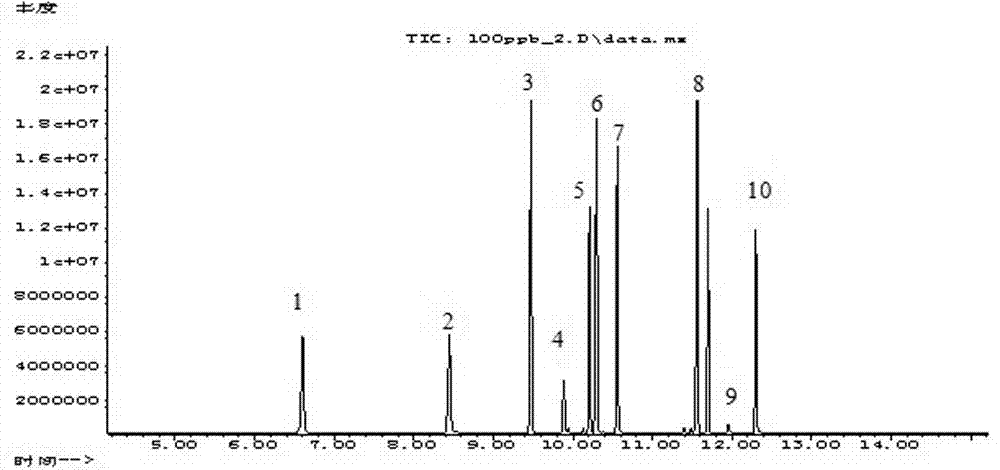

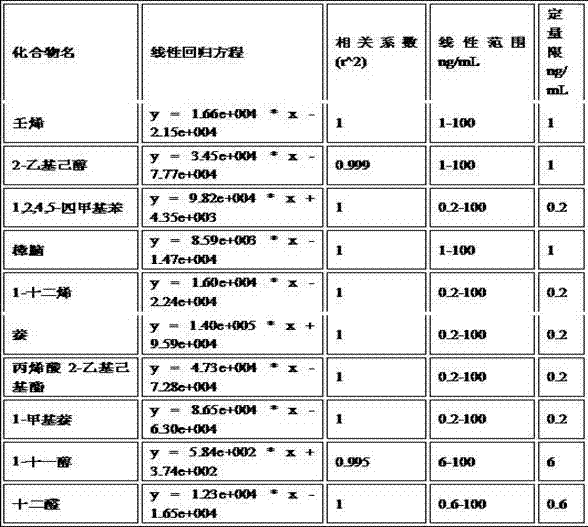

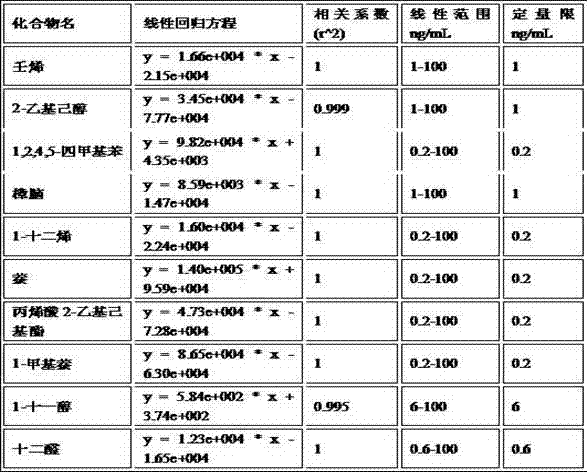

Method for determining migration quantity of volatile organic compounds in adhesive sticker for food label in water-based food simulating object

ActiveCN103575848AOvercome the disadvantage of not being able to directly enter water samplesHigh detection sensitivityComponent separationWater basedMass spectrometry detector

The invention discloses a method for determining the migration quantity of volatile organic compounds in an adhesive sticker for a food label in a water-based food simulating object. The method comprises the following steps: performing a direct or indirect migration test on the adhesive sticker for the food label through a water-based food simulating solution; sampling the water-based food simulating solution through purging and trapping; separating 10 volatile organic compounds through HP-5ms or chromatographic columns with similar properties; performing detection through a mass spectrometry detector; performing quantification through an external standard method, wherein the 10 volatile organic compounds include nonene, 2-ethylhexanol, 1,2,4,5-tetramethylbenzene, camphor, 1-dodecene, naphthalene, 2-ethylhexyl acrylate, 1-methylnaphthalene, 1-undecanol and dodecyl aldehyde. The method is accurate in test, easy to operate, high in efficiency, quick, high in sensitivity and high in practicality, is applicable to qualitative and quantitative determination on the volatile organic compounds in the adhesive sticker for the food label through a manufacturing enterprise of the adhesive sticker for the food label and relevant government supervision departments, and can be used for avoiding harm to the physical health of a consumer caused by over-large migration quantity of the volatile organic compounds.

Owner:厦门佰能检验技术服务有限公司

Preparation method of polymerization type environment-friendly plasticizer diethylene glycol dicyclohexyl-1,3-diisobutyl dicarboxylate

InactiveCN102060707AOrganic compound preparationCarboxylic acid esters preparationElectric wirePolymerization

The invention discloses a preparation method of polymerization type environment-friendly plasticizer diethylene glycol dicyclohexyl-1,3-diisobutyl dicarboxylate. The preparation method comprises the following steps of: putting 1 molar of diethylene glycol, 4.25 molar of cyclohexane-1,3-dicardoxylic acid anhydride and a catalyst into a reactor, and then stirring and heating the obtained mixture to 150 DEG C for cross-linking reaction; adding 1.7-2.1 molar of 2-ethylhexanol and a catalyst in the reaction system, and then stirring and heating the mixture to 220 DEG C for esterification reaction; removing the excessive alcohol to obtain the crude diethylene glycol dicyclohexyl-1,3-diisobutyl dicarboxylate; cooling the crude diethylene glycol dicyclohexyl-1,3-diisobutyl dicarboxylate to 85 DEG C, then adding 1% Na2CO3 aqueous solution for neutralization; washing the neutralized product with non-ion water at the temperature of 90 DEG C; and steaming stripping and refining for 3-4 hours under the condition of reduced pressure, adding activated carbon for absorption and decoloration, filterng and then obtaining the purified product. The heat-resisting environment-friendly plasticizer prepared by the method can be used for heat-resisting and perdurable articles, such as heat-resisting electric wire and cable materials, plank stuffs, sheets, sealing gaskets and the like.

Owner:ZHEJIANG SHANGTONG TECH

Method for preparing environment-friendly plasticizer cyclohexane-1, 2-dicarboxylic acid diethylhexyl ester

InactiveCN101613282AQuality improvementExtend the life cycleOrganic compound preparationCarboxylic acid esters separation/purificationCarboxylic acidMedical treatment

The invention discloses a method for preparing environment-friendly plasticizer cyclohexane-1, 2-dicarboxylic acid diethylhexyl ester. The method comprises the steps: 1) 1 mole of cyclohexane-1, 2-dicarboxylic acid ahhydride, 2.4-2.6 mole of 2-ethylhexanol and catalyst are mixed together and then heated; the temperature is raised to 220 DEG C from 185 DEG C, and the reaction is carried out for 3-4h; crude product of the cyclohexane-1, 2-dicarboxylic acid diethylhexyl ester is obtained after dealcoholization; 2) the obtained crude product of the cyclohexane-1, 2-dicarboxylic acid diethylhexyl ester is cooled and added with NaOH water solution to be neutralized; after being washed and processed by steam stripping, the reaction product is refined for 3-4h and added with active carbon having the quantity being 0.1-0.2% of the total quantity of the materials for adsorption and decoloration, and purified product can be obtained after filter pressing. The product is a non-phthalate esters environment-friendly plasticizer which is suitable for sensitive application of PVC, has high safety, and is used for low peculiar smell automobile cables, automobile internal decorating parts, medical equipment such as a medical nutrition supply pipe and the like, food touching products such as domestic food touching gloves, refreshing films, food suction tubes and the like, environment-friendly indoor wallpaper, decorative sheet, toys for children, etc.

Owner:ZHEJIANG SHANGTONG TECH

PVC preparation process for wire plastic particles

InactiveCN109354808ASuitable for a wide rangeGood heat resistance and high temperature resistanceOrganozinc compoundPolyester

The invention discloses a PVC preparation process for wire plastic particles. The preparation process includes the following materials: by weight, 50-150 parts of PVC resin, 10-15 parts of a thermal stabilizer, 30-60 parts of epoxy resin, 30-60 parts of thermoplastic polyester, 5 parts of a foaming agent, 10 parts of a toughening agent, 2 parts of an antioxidant, 1 part of a lubricant and 10-30 parts of vinyl chloride resin. The thermal stabilizer includes, by weight, 10-30 parts of organic zinc compound, 2-10 parts of organic tin compound, 20-40 parts of phthalates, 10-30 parts of alkyl esters, 10-30 parts of phosphite ester, 5-20 parts of chloro-methoxy fat diethylene glycol dinitrate, 1-5 parts of phenol and 2-8 parts of 2-ethylhexanol. The toughening agent includes a mixture of methylmethacrylate-butadiene and styrenic terpolymer (MBS), and the antioxidant is 2,6-tertiary butyl-4 methylphenol. The wire plastic particles prepared by the process are obviously superior to common PVCplastic granules on the market, have good heat resistance and high temperature resistance, high insulation capacity, high aging resistance and good toughness, and are suitable for wider electric wireindustry.

Owner:广东正品智慧科技股份有限公司

Production method of environment-friendly polyester plasticizer

InactiveCN104403090AImprove product qualityQuality improvementOrganic compound preparationCarboxylic acid esters preparationEnvironmental resistancePolyester

The invention discloses a catalytic synthesis method of an environment-friendly polyester plasticizer. The method comprises the following specific steps: adding dihydric alcohol and phthalic anhydride to a reactor according to a molar ratio of 1.1:1 to 1.2:1, adding an end-capping reagent 2-ethyl hexanol with a molar ratio to phthalic anhydride of 0.5:1 to 0.9:1, then adding a catalyst tetra-n-butyl titanate which accounts for 0.5-1% of the mass of phthalic anhydride, feeding high purity nitrogen, stirring and gradually raising the temperature to 180-230 DEG C, carrying out a reaction for 6-8 hours in a heat preservation manner under the condition that the acid value of the reaction solution is lower than 10 mg KOH*g<-1>, ending the reaction, and cooling to obtain the phthalic acid polyester plasticizer. The method disclosed by the invention adopts a little of catalyst during the process to improve the conversion efficiency and reduce the energy consumption; the obtained product is basically pale yellow, and has the special advantages of low toxicity and solvent extraction resistance; the whole process is low in pollution; the product is good in quality and high in purity.

Owner:郑建东

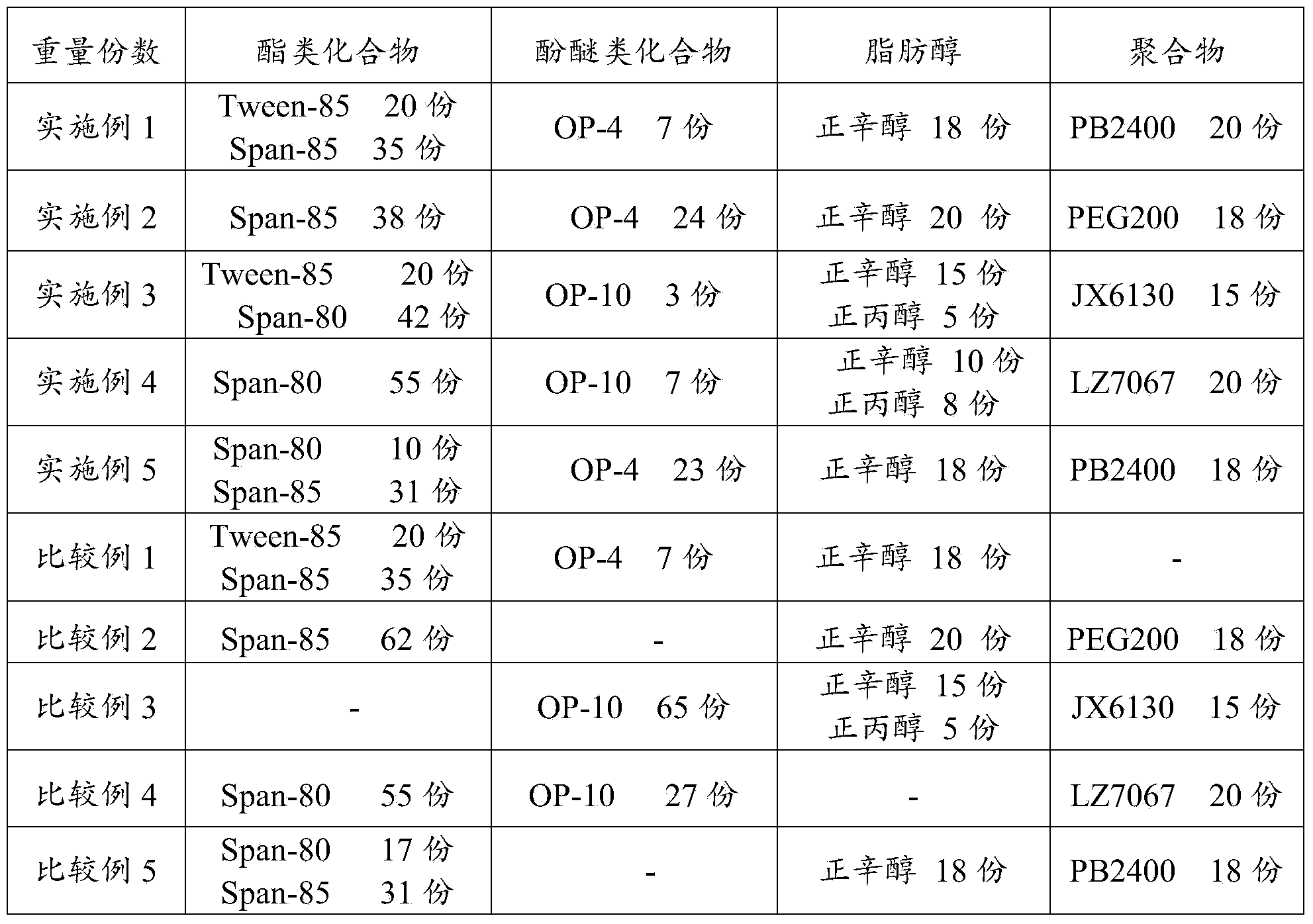

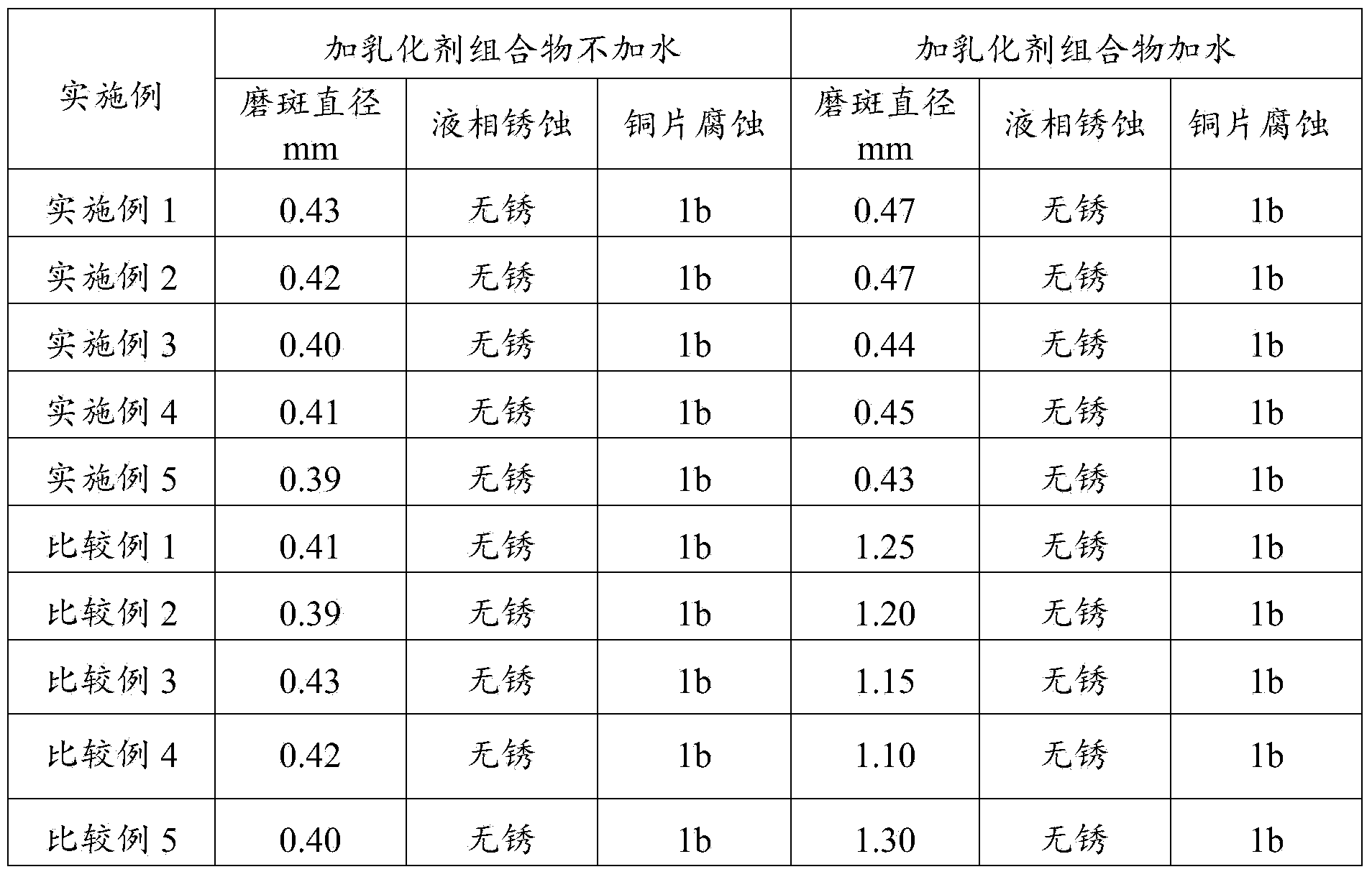

Bunker oil emulsifier composition and applications thereof

ActiveCN104263464AGood emulsifying effectAffect extreme pressure and wear resistanceAdditivesN-HeptanolPolyethylene glycol

The invention relates to a bunker oil emulsifier composition and applications thereof, which are mainly designed for solving the problem that in the prior art, system oil applied to screw shafts, after meeting water, can not form stable emulsified oil. The bunker oil emulsifier composition disclosed by the invention comprises the following components in parts by weight: a) 0.1-80 parts of an ester compound, b) 0.1-50 parts of a phenolic ether compound; c) 0.1-50 parts of fatty alcohol, and d) 0.1-50 parts of a polymer; and a technical scheme that the ester compound is selected from at least one of sorbitan fatty acid ester, polyoxyethylene sorbitan fatty acid ester or poly-ethylene glycol fatty acid ester, the phenolic ether compound is selected from at least one of TX series or OP series, the fatty alcohol is selected from at least one of methanol, ethanol, n-propanol, n-butanol, n-amyl alcohol, n-hexanol, n-heptanol, n-octanol or 2-ethylhexanol, and the polymer is selected from at least one of polyethylene glycol, polyisobutylene or ethylene-propylene copolymer solves the problem well. The bunker oil emulsifier composition can be applied to the industrial production of bunker oil emulsifier compositions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com