Preparation method for optical anode of dye sensitization solar battery

A solar cell and dye sensitization technology, applied in the field of dye-sensitized solar cell materials, can solve the problems of low energy conversion efficiency and high cost, and achieve the effects of improving energy conversion efficiency, low reaction temperature and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

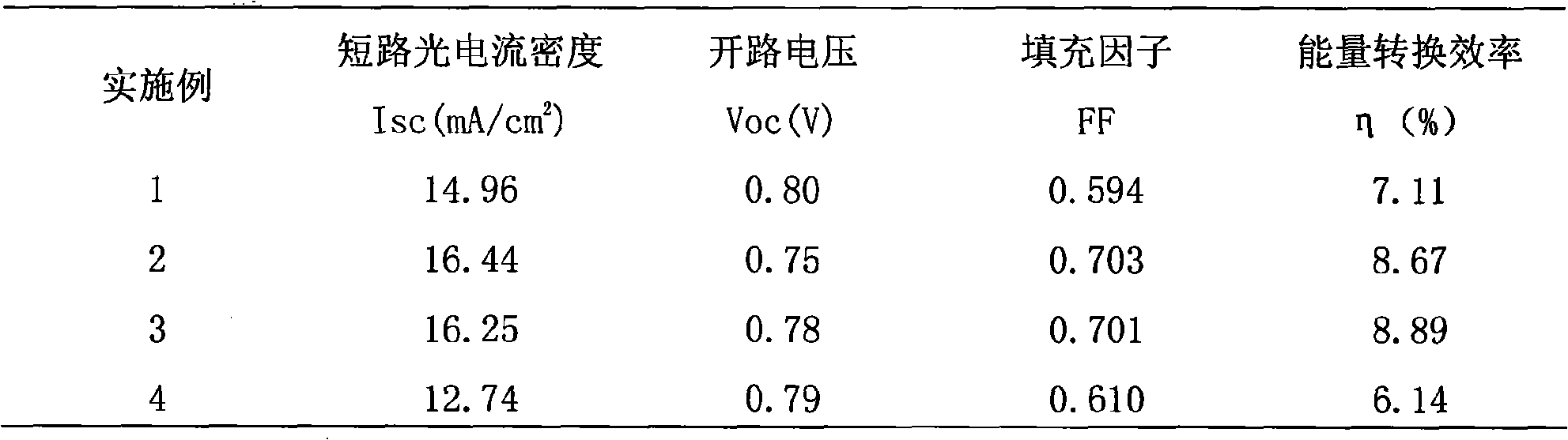

Examples

Embodiment 1

[0017] 1) Preparation of TiO 2 Nanocrystalline slurry: Add acetic acid dropwise in the titanium tetrachloride solution, the weight ratio of titanium tetrachloride and acetic acid is 4:1, then pour the mixed solution of titanium tetrachloride and acetic acid into the amount of titanium tetrachloride 4.8 times the water, stir to produce precipitation; then add nitric acid with a weight of 0.05 times the amount of titanium tetrachloride, and dissolve it for 60 minutes at a temperature of 80°C to obtain a blue-light transparent sol; put the transparent sol into the titanium reaction kettle, At 250°C, react for 24 hours, remove water by rotary evaporation, add film-forming agent PEG20000 and dispersing solvent terpineol to obtain TiO 2 Nano crystal slurry, TiO in the slurry 2 The weight content is: 15%, and the weight content of PEG20000 is: 4.5%.

[0018] 2) Preparation of TiO 2 Light scattering layer slurry: TiO with a particle size of 200nm 2 , PEG20000 and terpineol are mix...

Embodiment 2

[0024] 1) Preparation of TiO 2 Nanocrystalline slurry: Add acetic acid dropwise in the tetrabutyl titanate solution, the weight ratio of tetrabutyl titanate and acetic acid is 4.8:1, then pour the mixed solution of tetrabutyl titanate and acetic acid into the titanic acid Stir in water with 4.8 times the amount of tetrabutyl titanate, and stir to produce precipitation; then add nitric acid with a weight of 0.09 times the amount of tetrabutyl titanate, and dissolve it at 60°C for 100 minutes to obtain a transparent sol with bluish light; put the transparent sol into In a titanium reactor, react at 200°C for 24 hours, remove water by rotary evaporation, add film-forming agent PEG20000 and dispersing solvent 2-ethylhexanol to obtain TiO 2 Nano crystal slurry, TiO in the slurry 2 The weight content is: 16%, and the weight content of PEG20000 is: 4.5%.

[0025] 2) Preparation of TiO 2 Light scattering layer slurry: TiO with a particle size of 200nm 2 , PEG20000 and 2-ethylhexan...

Embodiment 3

[0029] 1) Preparation of TiO 2 Nanocrystalline slurry: add acetic acid dropwise in the tetraisopropyl titanate solution, the weight ratio of tetraisopropyl titanate and acetic acid is 4.8:1, then pour the mixed solution of tetraisopropyl titanate and acetic acid into the weight Stir in water containing 4.8 times the amount of tetraisopropyl titanate; add nitric acid whose weight is 0.09 times the amount of tetraisopropyl titanate, and dissolve at 80°C for 70 minutes to obtain a bluish transparent sol; Put the transparent sol in a titanium reactor, react at 240°C for 12 hours, remove water by rotary evaporation, add film-forming agent PEG20000 and dispersing solvent 2-ethylhexanol to obtain TiO 2 Nano crystal slurry, TiO in the slurry 2 The weight content is: 16%, and the weight content of PEG20000 is: 4.5%.

[0030] 2) Preparation of TiO 2 Light scattering layer slurry: TiO with a particle size of 200nm 2 , PEG20000 and 2-ethylhexanol are mixed, ultrasonically formed into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com