Patents

Literature

52 results about "2 ethyl hexanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-ETHYL HEXANOL is an alcohol. Flammable and/or toxic gases are generated by the combination of alcohols with alkali metals, nitrides, and strong reducing agents.

Alcohol-free printing fountain solution and preparation method thereof

The invention discloses an alcohol-free printing fountain solution and a preparation method of the alcohol-free printing fountain solution. The alcohol-free printing fountain solution comprises, by weight, 10-15% of propylene glycol monomethyl ether, 2-4% of ethylene glycol, 4-8% of a citric acid, 0.5-1.5% of sodium hydroxide, 15-25% of glycerinum, 0.1-0.3% of sodium carboxymethyl cellulose, 0.05-0.1% of lauroyl diethanol amine, 0.4-0.6% of liquid tea saponin, 0.3-0.6% of dodecyl dimethyl benzyl ammonium chloride, 0.5-1% of dodecyl glucoside, 0.05-0.1% of 2-ethyl hexanol and 50-55% of water. The alcohol-free printing fountain solution does not contain isopropyl alcohol and is low in toxicity, safe, environmentally friendly, good in printing effect and low in cost, thereby having huge economic benefit and social benefit.

Owner:安徽唯宝印刷科技有限公司

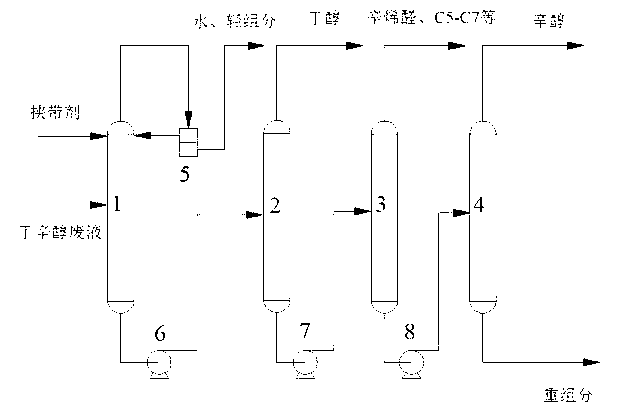

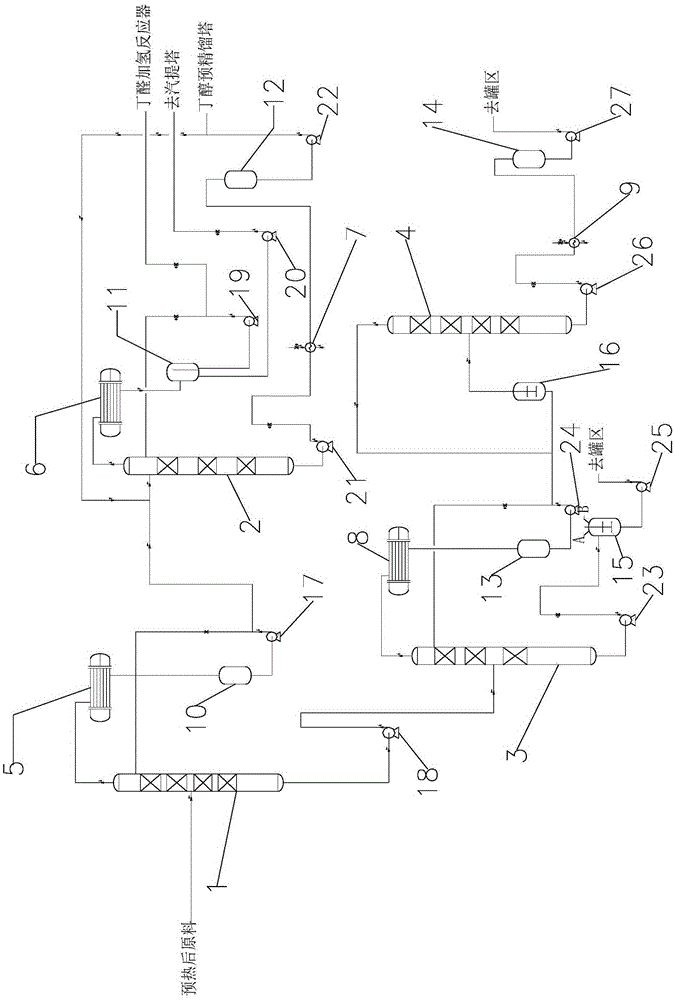

Treatment process of 2-ethyl hexanol liquid waste

InactiveCN103342625AAvoid crackingTake advantage ofOrganic compound preparationHydroxy compound preparationLiquid wasteSocial benefits

The invention discloses a treatment process of 2-ethyl hexanol liquid waste. The treatment process is suitable for processing the 2-ethyl hexanol liquid waste discharged by a 2-ethyl hexanol device. The treatment process comprises the following steps: heating the 2-ethyl hexanol liquid waste to 60-100 DEG C and then leading to a middle section of a first rectifying tower; removing moisture and light components from the top of the first rectifying tower under the effect of an entrainer; enabling tower kettle liquid of the first rectifying tower to enter the middle section of a second rectifying tower, so as to obtain a butanol product of which the purity is greater than 98% from the top of the second rectifying tower; enabling the tower kettle liquid of the second rectifying tower to enter the middle section of a third rectifying tower; removing C5-C7 and an octenal component from the top of the third rectifying tower; and enabling the tower kettle liquid of the third rectifying tower to enter the middle section of a fourth rectifying tower, so as to obtain an octanol product of which the purity is greater than 98% from the top of the fourth rectifying tower. The treatment process does not need any fuel; butanol and octanol, of which the purity is greater than 98%, can be effectively recovered, so that the useful components in the 2-ethyl hexanol liquid waste can be fully utilized; the resources are saved; the environmental pollution is also reduced; the treatment process has good economical benefits and social benefits.

Owner:SHANGHAI DONGHUA ENVIRONMENT ENG

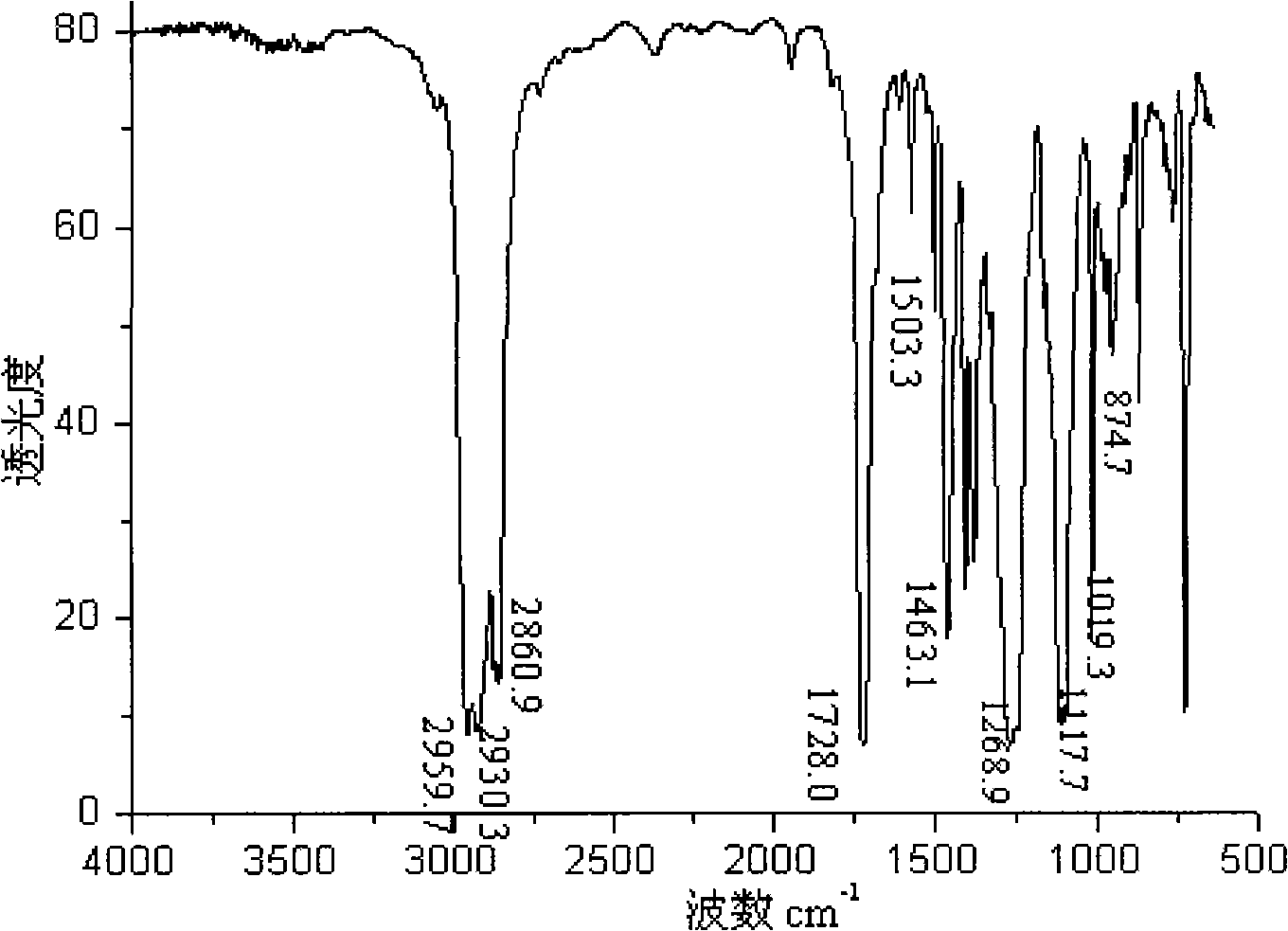

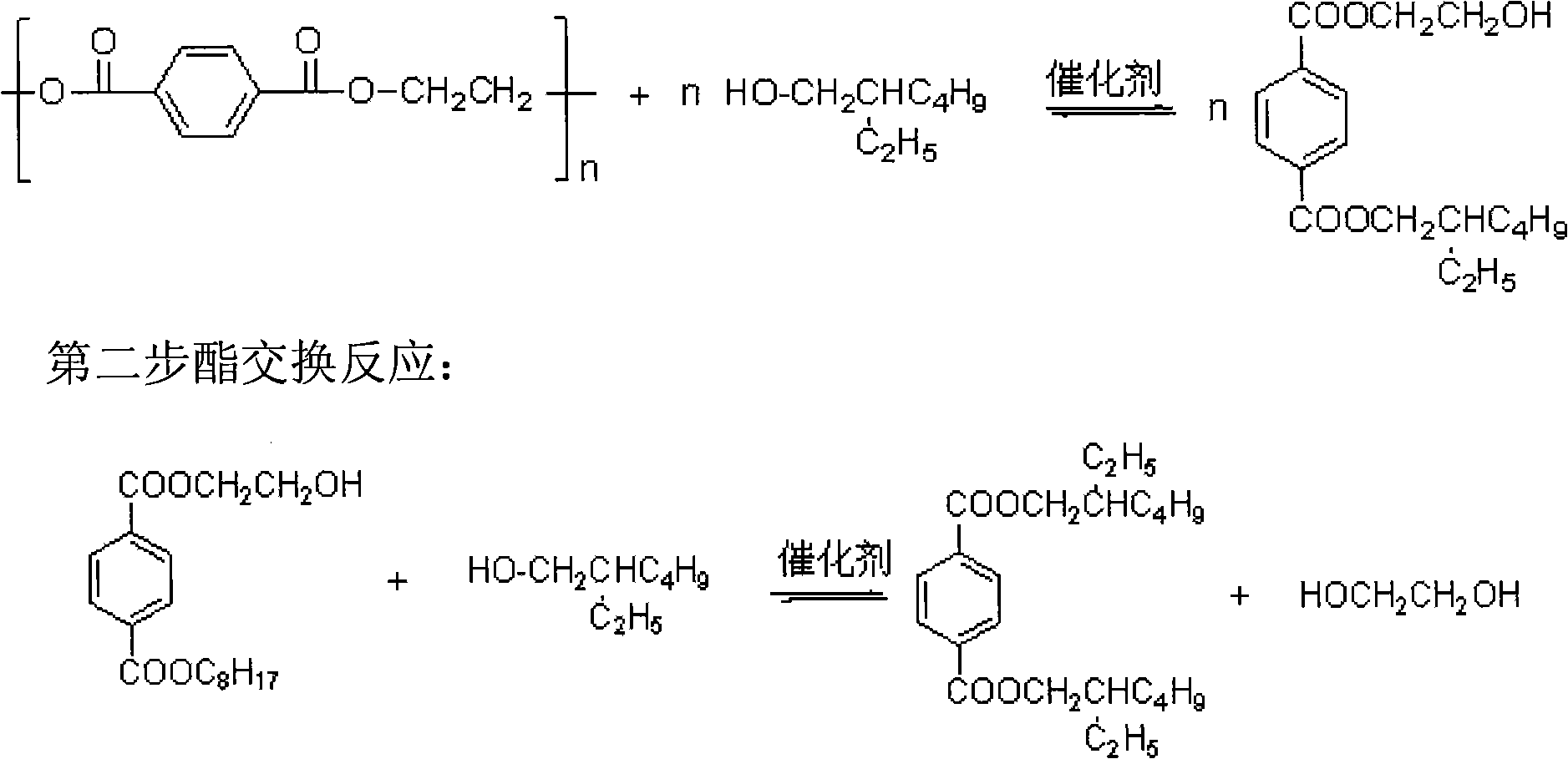

Method for synthesizing PVC plasticiser by reclaiming waste polyester

InactiveCN101302158AShort reaction timeShort processPreparation by ester-hydroxy reactionOrganic compound preparationPolyesterFiber

The invention discloses a method for synthesizing PVC plasticizer DOTP by waste polyester resource utilization, which belongs to the plasticizer technical field. The method comprises the following steps that: 1. under the existence of catalyst, waste polyester scraps are heated with 2-ethyl hexanol to carry out the degradation reaction; 2. glycol produced by the reaction and the 2-ethyl hexanol are coboiled and condensed, and then the glycol is removed through water scrubbing and is reclaimed; 3. reactant coarse ester is orderly subject to aqueous alkali and water for washing, an aqueous layer and an organic layer are separated; the organic layer is added with adsorbent, then the unreacted 2-ethyl hexanol is steamed out, and the plasticizer product dioctyl terephthalate (DOTP) is obtained after the filtration. The raw material of the invention, namely waste polyester can be polyester fiber, waste terylene cloth, leftover materials, waste polyester bottles, and polyester films and so on; the removal method of the catalyst adopts a water scrubbing filtration mode, the catalyst is simultaneously removed during neutralization, water scrubbing and filtration processes, and no additional process operation needs to be added for the removal of the catalyst, so the method has short process flow and low production cost.

Owner:JIANGNAN UNIV

Azeotrope-like compositions of tetrafluoropropene and alcohols

ActiveUS8114828B2Cosmetic preparationsDomestic cooling apparatusIsobutanol1,3,3,3-Tetrafluoropropene

A composition including an effective amount of trans-1,3,3,3-tetrafluoropropene component combined with an effective amount of an alcohol selected from the group of methanol, ethanol, propanol, isopropanol, tert-butanol, isobutanol, 2-ethyl hexanol and any combination thereof, where the composition has azeotropic properties.

Owner:HONEYWELL INC

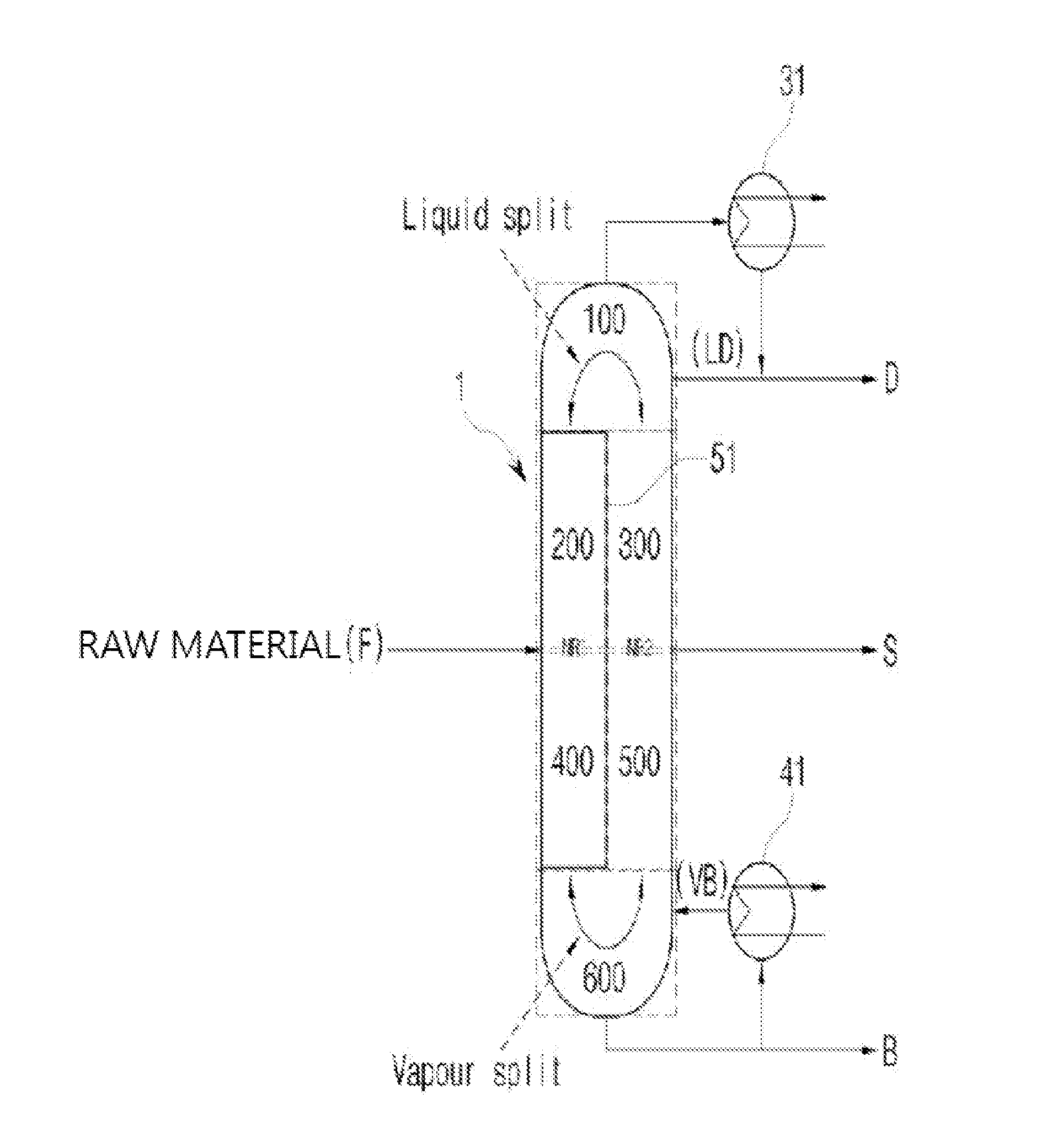

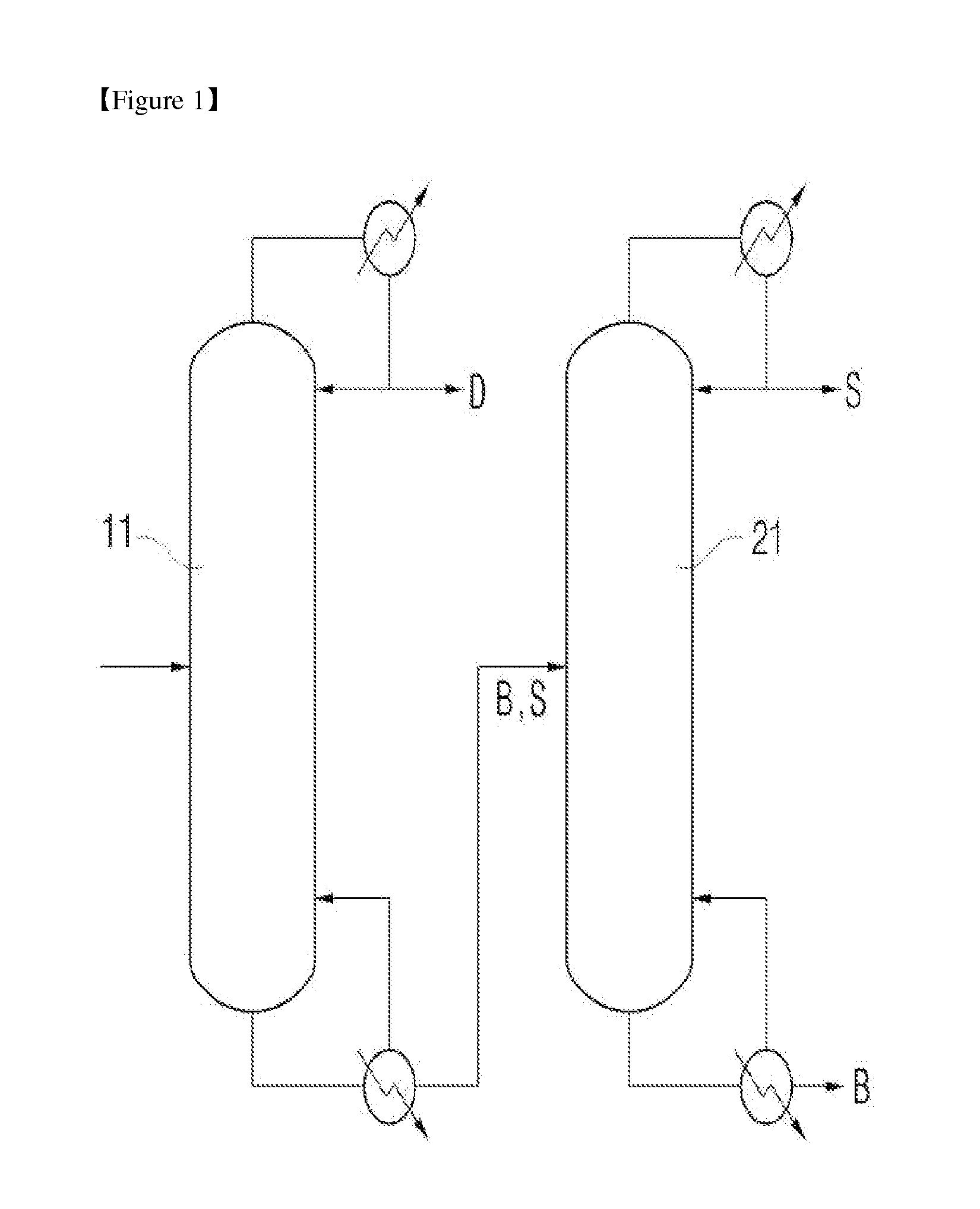

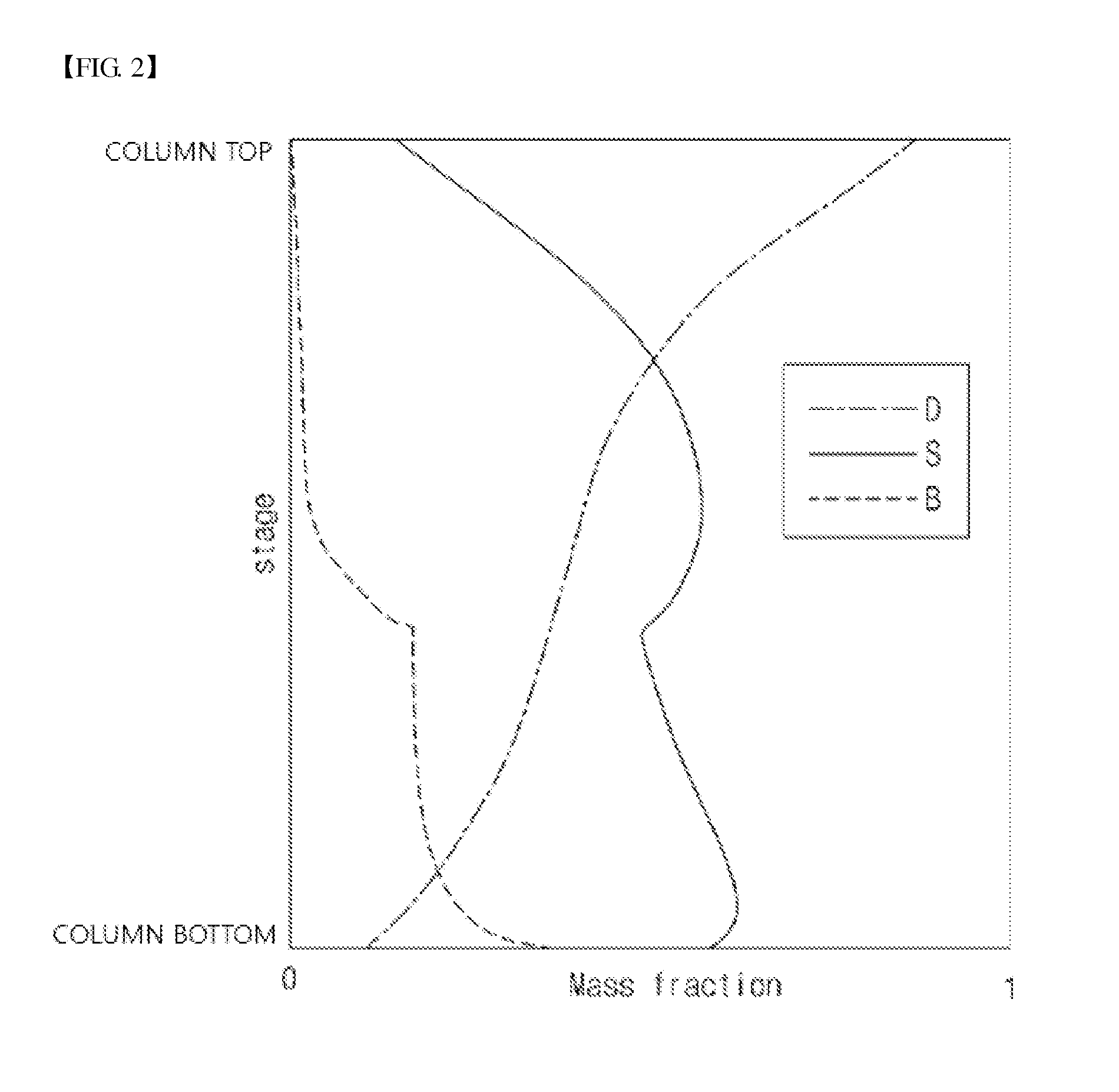

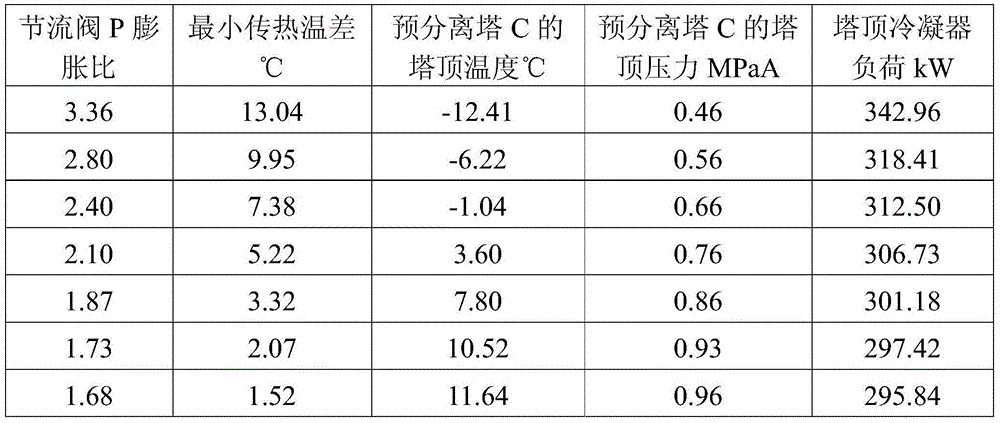

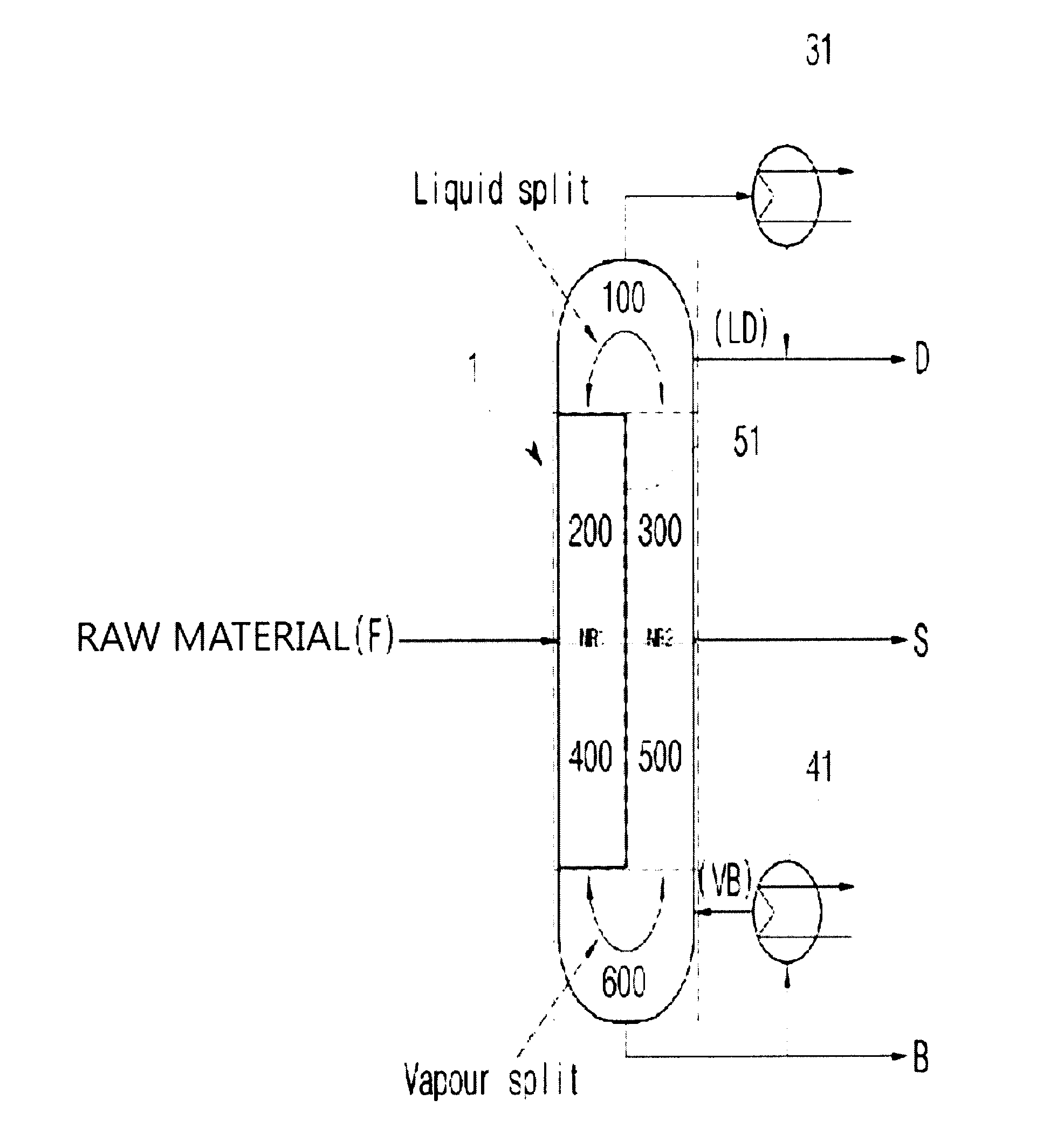

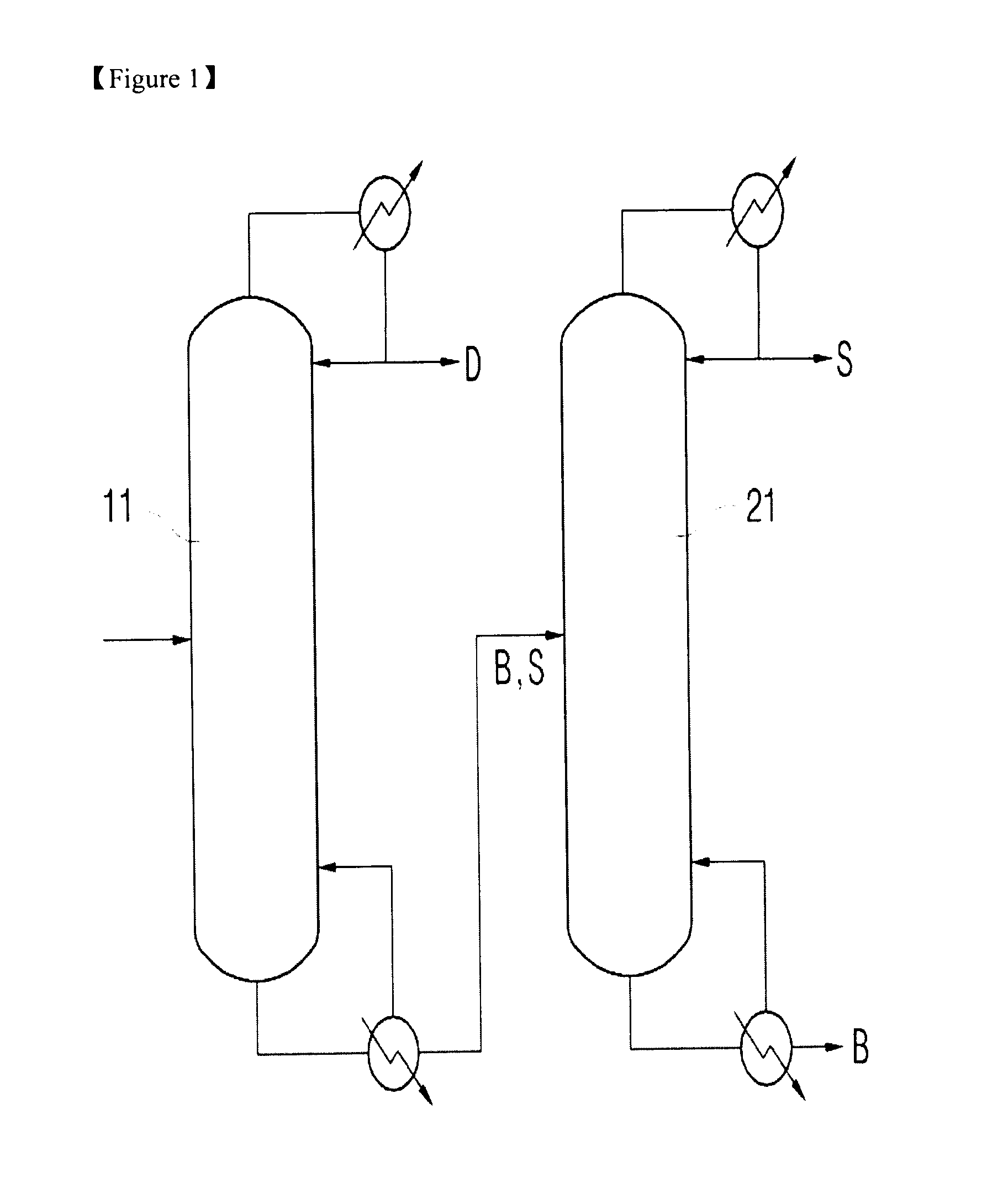

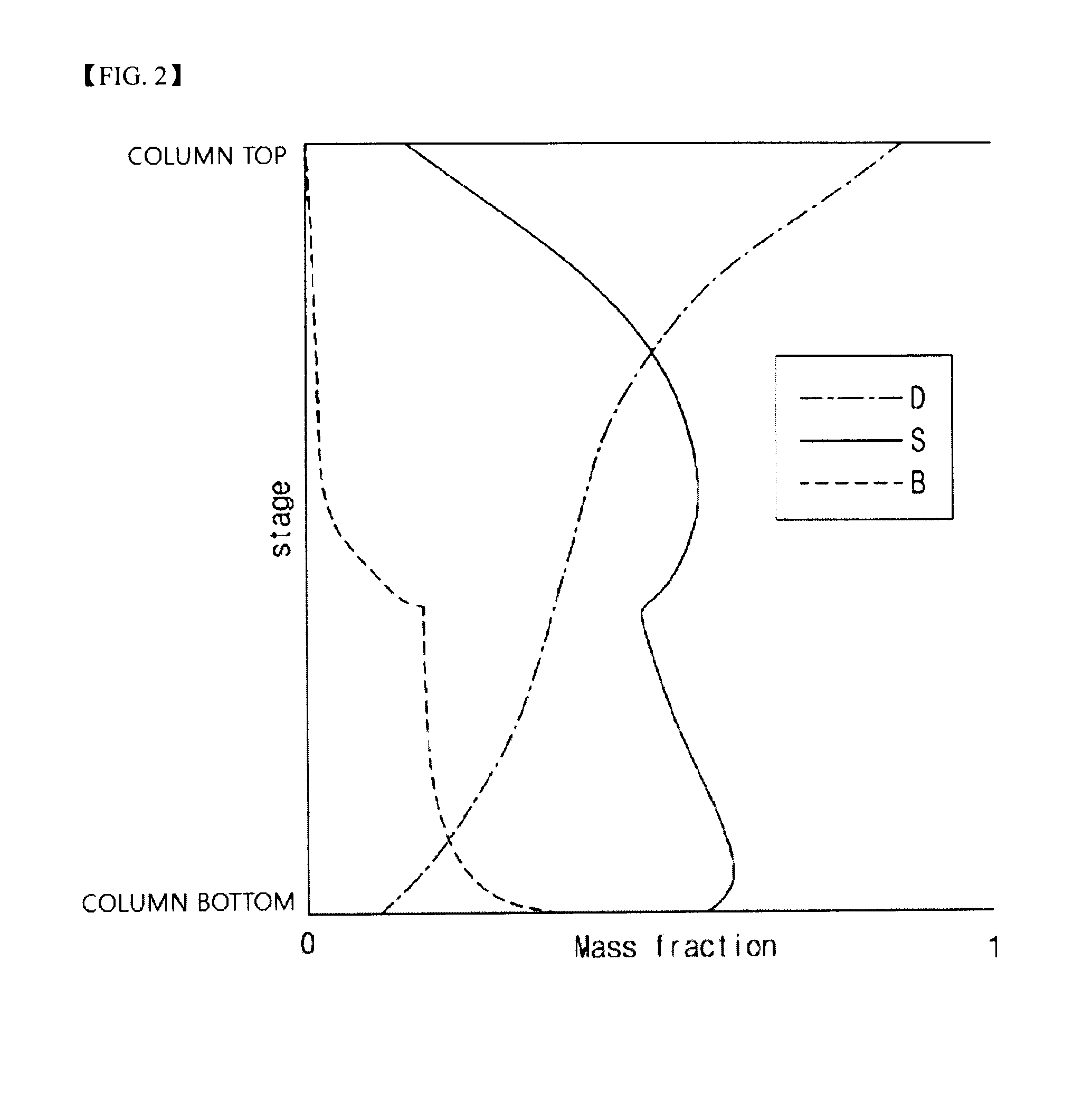

Dividing wall distillation columns for production of high-purity 2-ethylhexanol and fractionation method using same

ActiveUS20120004473A1Low costReduce equipment costsOrganic compound preparationOxygen compounds purification/separationProcess systemsBoiling point

There are provided a dividing wall distillation column for producing high-purity 2-ethyl hexanol, and a fractional distillation method using the same. The dividing wall distillation column includes a condenser, a reboiler and a main column having a dividing wall. Here, the main column is divided into a column-top zone, an upper feed zone, an upper outflow zone, a lower feed zone, a lower outflow zone and a column-bottom zone. Also, a crude 2-ethyl hexanol raw material (F) flows in a middle inflow plate NR1 in which the upper feed zone and the lower feed zone come in contact with each other, a low boiling point component (D) flows out from the column-top zone, a high boiling point component (B) flows out from the column-bottom zone, and a middle boiling point component (S) flows out through a middle outflow plate NR2 in which the upper outflow zone and the lower outflow zone come in contact with each other. In this case, the middle boiling point component is 2-ethyl hexanol. Accordingly, since one distillation column can be used to realize the same effect as that obtained from the use of two distillation columns, the dividing wall distillation column can have an effect of reducing the costs of equipment to produce high-purity 2-ethyl hexanol, as well as an energy-reducing effect, compared to a conventional process system.

Owner:LG CHEM LTD

Art oil paint containing nano-pigment and method for manufacturing same

InactiveCN101225253ABright and brightSaturated and IntenseWax coatingsArtist's paintsALUMINUM STEARATESCobalt

The invention relates to art oil paint with nano-pigment and the preparation method, which is characterized in that the beeswax is added into refined linseed oil and polly seed salad oil and blended evenly to make bond after heating and melting. The nano-pigment is added into the bond to blend evenly and then the pigment is added in and blended evenly. Then aluminum stearate, 2-ethyl hexanol cobalt (CAS No.13586-82-8), silicon dioxide hydrate, hydrafil, phenoxetol, butyl-p-cresol and lithopone are added in and then blended evenly. The product can be obtained after grinding. The preparation method first disperses the nano-pigment into the bond and drains most air on the surface of the common pigment grain, and then disaggregates the large grain and small gobbet of the sizing agent by the large shearing force, extrusion force and grinding force between the two rollers generated by the turn of the three-roller muller. During the grinding process, the bond with nano-pigment or latex covers the surface of the pigment grain and then permeates through the gaps of the grains. The product made has the advantages of rich color, bright colour and luster, fresh tint, strong tinctorial strength and good chromaticity.

Owner:宋健

Azeotrope-like compositions of tetrafluoropropene and alcohols

A composition including an effective amount of trans-1,3,3,3-tetrafluoropropene component combined with an effective amount of an alcohol selected from the group of methanol, ethanol, propanol, isopropanol, tert-butanol, isobutanol, 2-ethyl hexanol and any combination thereof, where the composition has azeotropic properties.

Owner:HONEYWELL INC

Preparation method of rubber plasticizer dioctyl sebacate

InactiveCN104592015AReduce dosageLight colorOrganic compound preparationCarboxylic acid esters preparationDibutyl sebacateDistillation

The invention discloses a preparation method of a rubber plasticizing agent dioctyl sebacate. The method includes the following steps: 1, adding sebacic acid, 2-ethyl hexanol and a catalyst stannous oxide into a four-neck flask equipped with a thermometer, a reflux distributor and an agitator, introducing nitrogen, and conducting esterification reaction under 200 DEG C-230 DEG C; 2, after the reaction, cooling to 90 DEG C, adding lye water for neutralization, washing, standing for layering, releasing lye water, conducting reduced pressure distillation, and finally add activated carbon for adsorption and filleting to obtain the dioctyl sebacate product. The preparation method provided by the invention employs a non-solid acid catalyst stannous oxide for catalytic synthesis of dioctyl sebacate, and has the advantages of high catalytic activity, short reaction time, small amount of catalyst, light color of the obtained product, simple post treatment process, no corrosion of the catalyst on the equipment, no waste liquid produced, green, and environment-friendliness.

Owner:QINGDAO WANGYU RUBBER

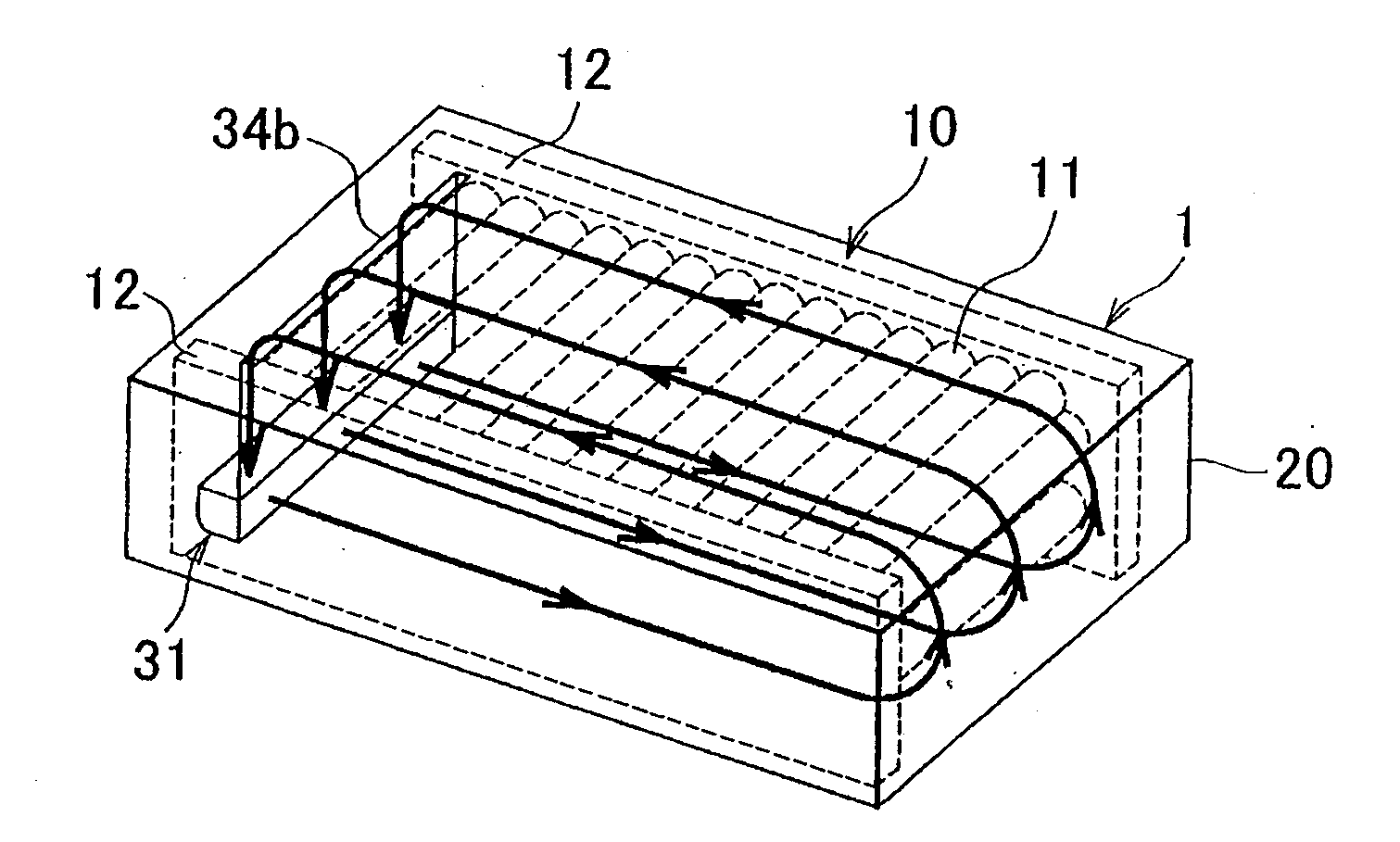

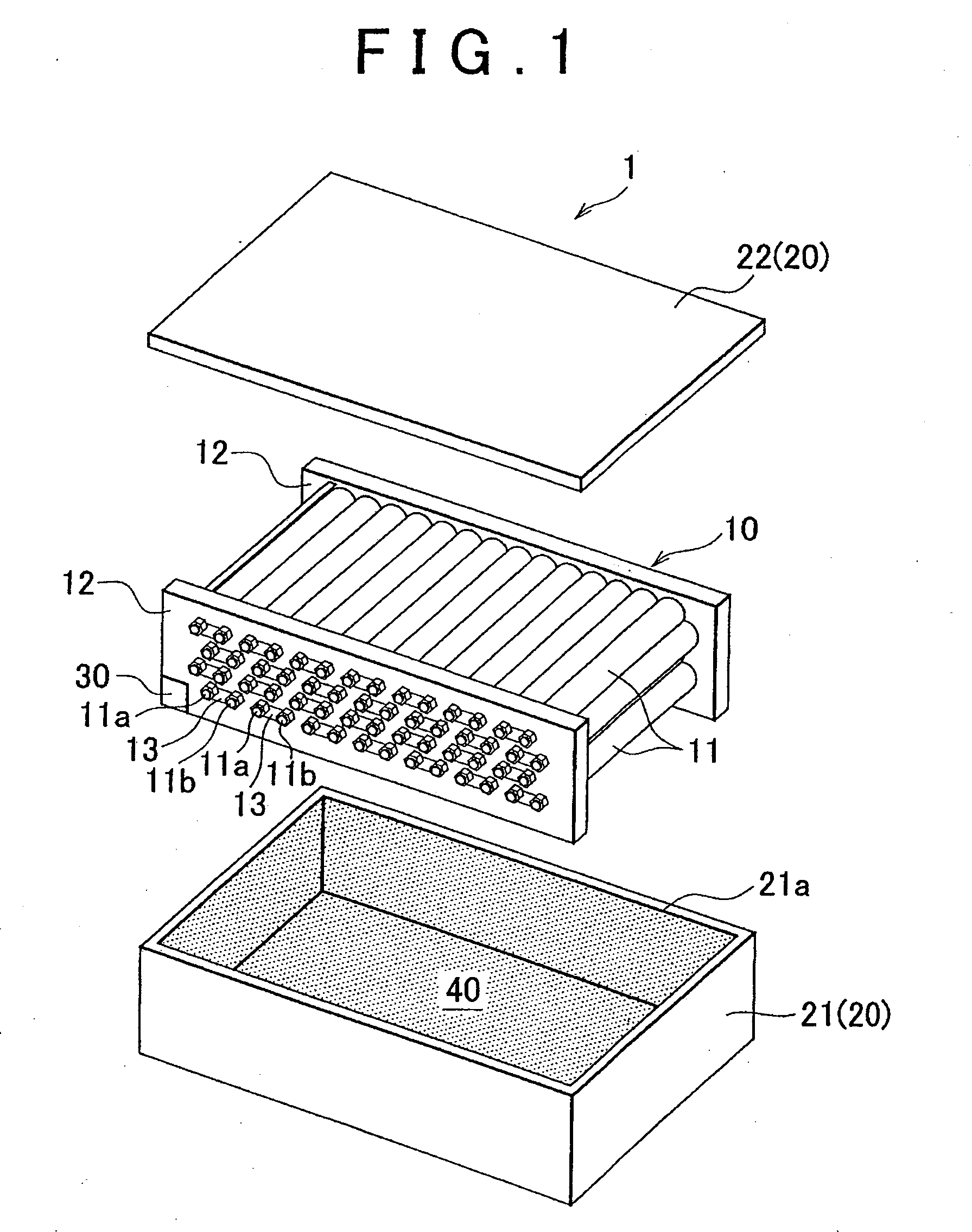

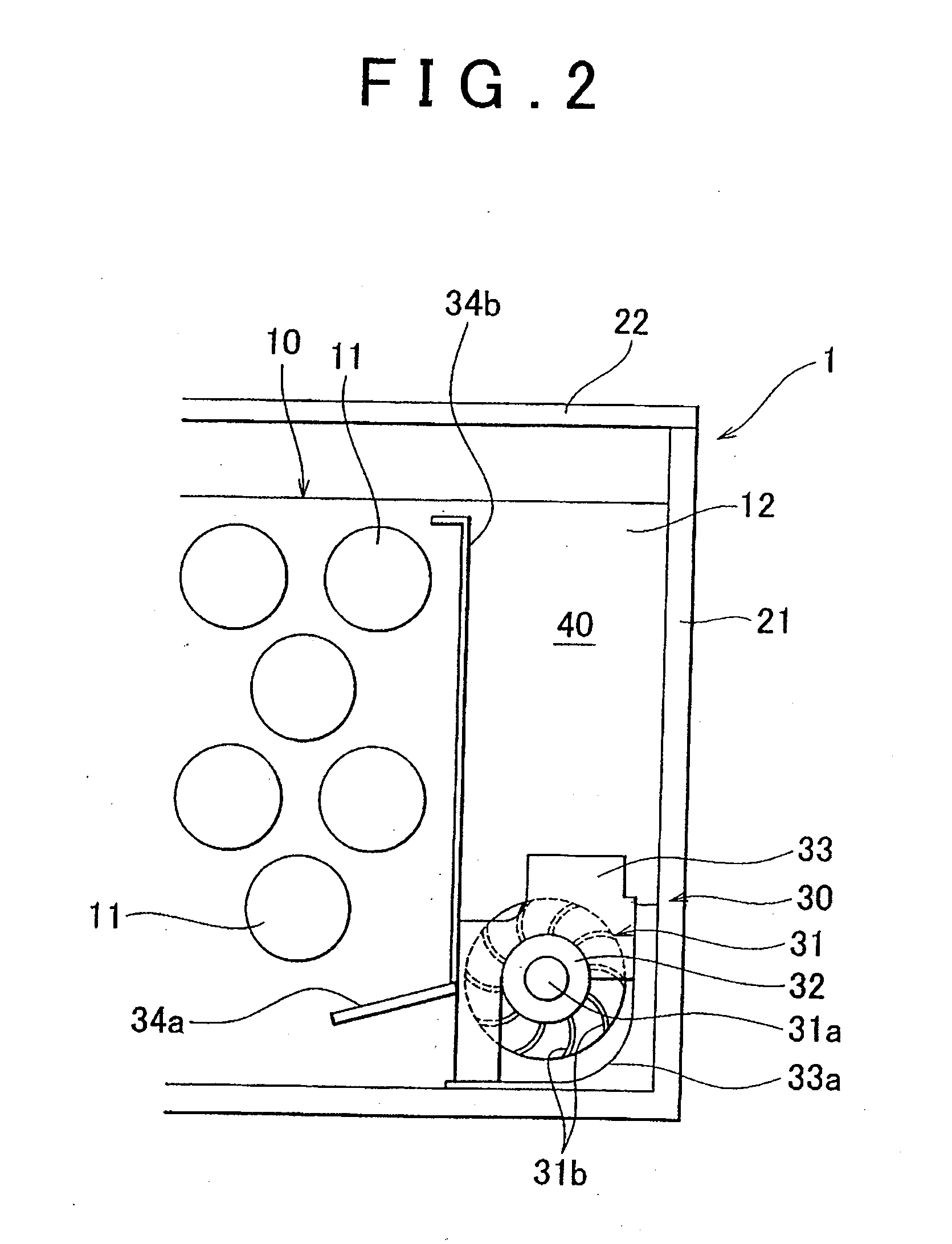

Heat exchange medium and electric storage device

InactiveUS20120026690A1Avoid corrosionPartial dispersion of the temperature within the electric storage element may be minimizedElectrolytic capacitorsCell temperature controlCarbon number2-Ethylhexanol

A liquid heat exchange medium (40) is provided in a case (20) together with an electric storage element (11) to exchange heat with the electric storage element. The heat exchange medium is an ester compound of a fatty acid with a carbon number of 6 to 8 and 2-ethyl hexanol. The heat exchange medium contains 90 or more volume % of 2-ethylhexyl caprylate.Selected Drawing: FIG. 1

Owner:TOYOTA JIDOSHA KK +1

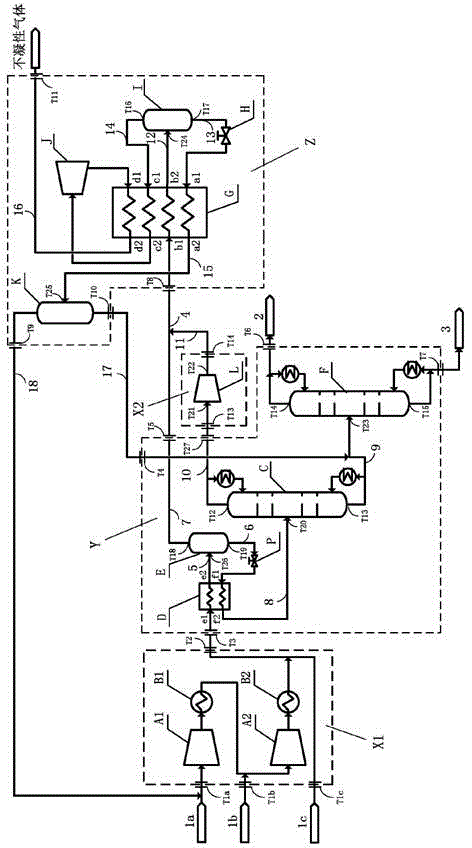

2-ethyl hexanol tail gas recovery system and method

ActiveCN104649858AReduce energy consumptionReduce consumptionOrganic compounds purification/separation/stabilisationDistillation purification/separationGas compositionProduct gas

The invention discloses a 2-ethyl hexanol tail gas recovery system and method. The system comprises a compressing mechanism 1, a rectification mechanism, a compressing mechanism 2 and a copious cooling mechanism, wherein the compressing mechanism 1 is used for receiving tail gas, and compressing the pressure of each gas composition in the tail gas to a same level; the rectification mechanism is used for receiving an output flow from the compressing mechanism 1, and respectively outputting a recovered butyraldehyde flow, a recovered propylene-propane mixed flow and a residual tail gas flow; the compressing mechanism 2 is used for receiving the residual tail gas flow from the rectification mechanism, and outputting the compressed residual tail gas flow; and the copious cooling mechanism is used for receiving the residual tail gas flow from the compressing mechanism 2, separating non-condensable gas in the residual tail gas flow, and receiving propylene-propane in the non-condensable gas. The system disclosed by the invention realizes the acquisition of high-recovery butyraldehyde and a propylene-propane mixture under low energy consumption conditions through the collaborative cooperation of the compressing mechanism 1, the rectification mechanism, the compressing mechanism 2 and the copious cooling mechanism.

Owner:ZHEJIANG UNIV

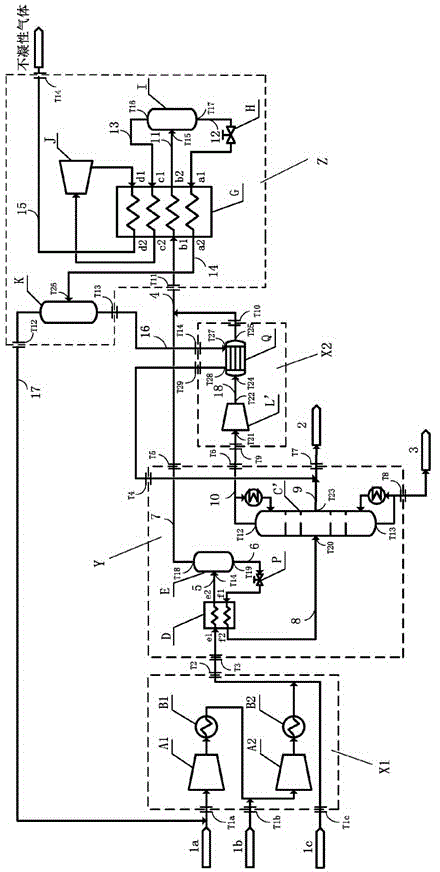

Butyl alcohol and 2-ethyl hexanol production equipment industrial waste comprehensive utilization method

ActiveCN105237350AAchieving zero emissionsSolve the emission problemOrganic compound preparationPreparation by hydrogenationCarbon number2 ethyl hexanol

The invention discloses a butyl alcohol and 2-ethyl hexanol production equipment industrial waste comprehensive utilization method. The butyl alcohol and 2-ethyl hexanol production equipment industrial waste comprehensive utilization method comprises following steps: (1) butyl alcohol and 2-ethyl hexanol industrial waste is pumped into a first rectifying tower so as to degrade the industrial waste into components with a single molecule carbon number of 4 or less and a single molecule carbon number higher than 4, the obtained light components are delivered into a second rectifying tower, and the obtained heavy components are delivered into a third rectifying tower; (2) the light components delivered into the second rectifying tower are separated, mixed butyraldehyde and water are collected from the tower top, are subjected to condensation, and then are delivered into a second oil-water separation tank for separation; (3) the components with a single molecule carbon number higher than 4 are delivered into the third rectifying tower, and are separated in the third rectifying tower so as to obtain components with a single molecule carbon number of 8 and a single molecule carbon number higher than 8; and (4) a liquid obtained via liquid phase hydrogenation is pumped into a fourth rectifying tower, 2-ethyl hexanol with a purity as high as a preset standard is collected from the tower kettle of the fourth rectifying tower, is delivered into a fourth liquid receiving tank after condensation in a fifth condenser, and at last is pumped into a tank field. The butyl alcohol and 2-ethyl hexanol production equipment industrial waste comprehensive utilization method is capable of realizing industrial zero emission in butyl alcohol and 2-ethyl hexanol industrial production processes.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Multifunctional bio-diesel composite additive for vehicles and preparation method thereof

InactiveCN102559304AEnsure safetyEfficient captureLiquid carbonaceous fuelsAntioxidantCleansing Agents

The invention relates to additives for engine fuel, in particular to a multifunctional bio-diesel composite additive for vehicles, which is characterized by selecting an appropriate cetane number improver, a clean agent, a dispersing agent and a shielding phenol type antioxidant. The additive comprises ethylene glycol dinitrate, 2-methyl cellosolve, 2-ethyl hexanol, diphenylamine, ethylene glycol alkyl benzene ether, succinimide, shielding phenol type antioxidants, hexadecyl dimethyl ammonium chloride and polyethyleneglycol hexadecyl phenolic ether. The additive adopting the components greatly improves operating performance of diesel and driving performance and acceleration performance of automobiles, keeps a fuel system to have good operating conditions, can reduce emission amount of harmful substances in tail gas, and has remarkable fuel-saving effect.

Owner:临沂实能德环保燃料化工有限责任公司

Novel PVC heat stablizer

A novel PVC heat stabilizer is characterized by at least comprising the following raw materials in parts by weight: 10 to 30 parts of organic zinc compound, 2 to 10 parts of organic tin compound, 20 to 40 parts of phthalic acid ester, 10 to 30 parts of alkyl acid ester, 10 to 30 parts of phosphite, 5 to 20 parts of chloromethoxyl fatty acid methyl ester, 1 to 5 parts of phenol, and 2 to 8 parts of 2-ethyl hexanol, wherein the organic tin compound comprises 1 to 4 sulfur atoms.

Owner:邵卫东

Production method of environment-friendly polyester plasticizer

InactiveCN104403090AImprove product qualityQuality improvementOrganic compound preparationCarboxylic acid esters preparationEnvironmental resistancePolyester

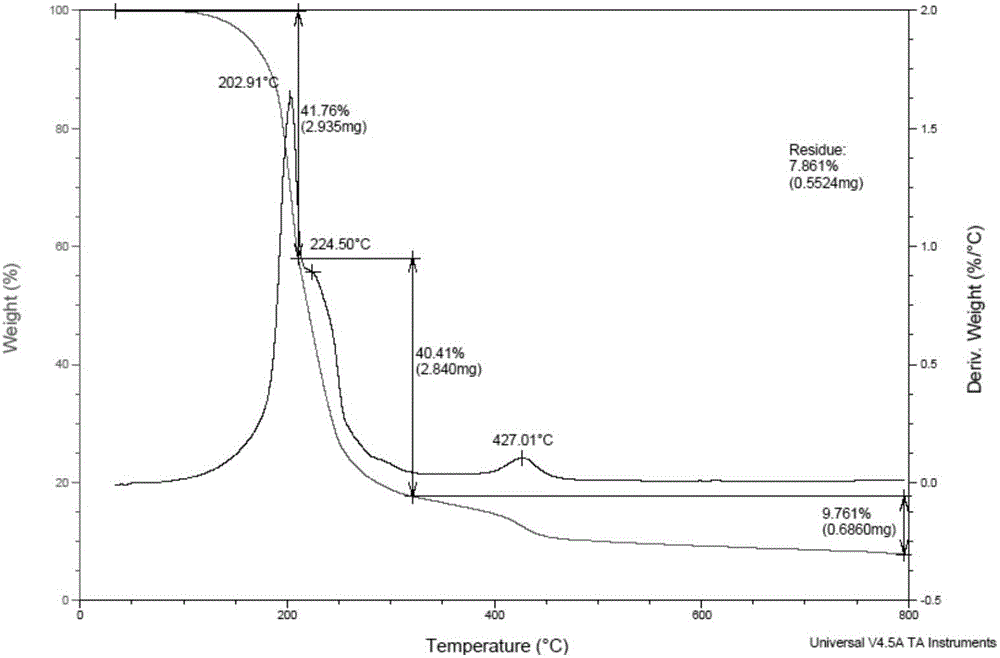

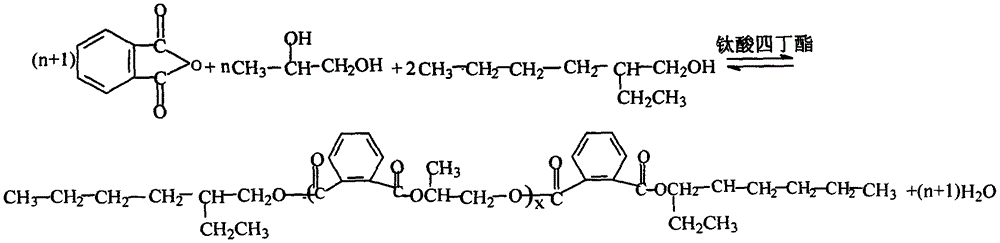

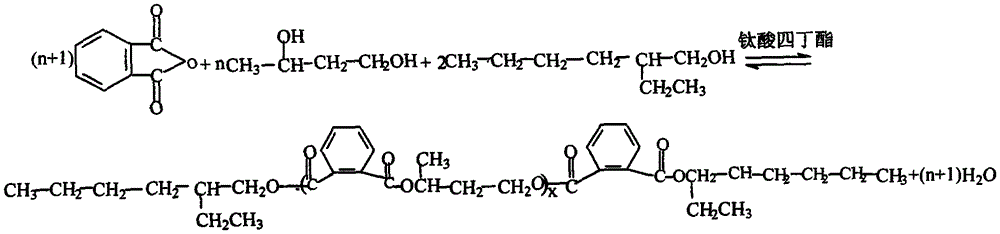

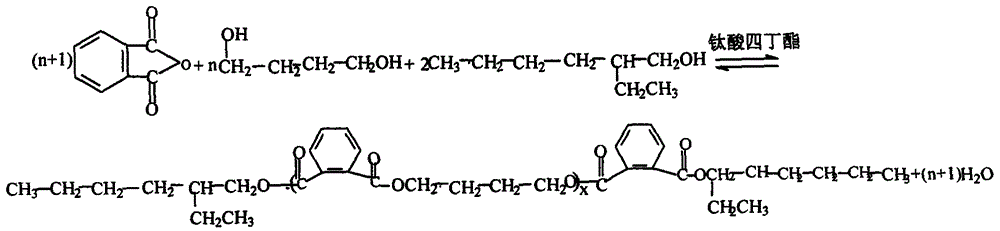

The invention discloses a catalytic synthesis method of an environment-friendly polyester plasticizer. The method comprises the following specific steps: adding dihydric alcohol and phthalic anhydride to a reactor according to a molar ratio of 1.1:1 to 1.2:1, adding an end-capping reagent 2-ethyl hexanol with a molar ratio to phthalic anhydride of 0.5:1 to 0.9:1, then adding a catalyst tetra-n-butyl titanate which accounts for 0.5-1% of the mass of phthalic anhydride, feeding high purity nitrogen, stirring and gradually raising the temperature to 180-230 DEG C, carrying out a reaction for 6-8 hours in a heat preservation manner under the condition that the acid value of the reaction solution is lower than 10 mg KOH*g<-1>, ending the reaction, and cooling to obtain the phthalic acid polyester plasticizer. The method disclosed by the invention adopts a little of catalyst during the process to improve the conversion efficiency and reduce the energy consumption; the obtained product is basically pale yellow, and has the special advantages of low toxicity and solvent extraction resistance; the whole process is low in pollution; the product is good in quality and high in purity.

Owner:郑建东

Novel efficient energy-saving environment-friendly flotation reagent

The invention discloses a novel efficient energy-saving environment-friendly flotation reagent, and belongs to the technical field of coal washing. The flotation reagent comprises, by weight, 30-70 parts of diesel, 10-50 parts of octanol, 25-45 pars of heptanol, and 15-35 parts of 2-ethyl hexanol. The flotation reagent is nontoxic, efficient, high in safety, and high in foaming and collecting performance, has no irritating smell, saves energy, is 0.1-0.5 kg in per ton of coal slime, is low in using amount, saves coal dressing cost, and improves clean coal productivity.

Owner:泰安远东化工科技有限公司

Permanent inflaming-retarding pbt material

ActiveCN104140648APermanent Flame RetardancyGood compatibilityAluminatePolytetramethylene terephthalate

The invention discloses a permanent inflaming-retarding pbt material. The permanent inflaming-retarding pbt material comprises, by weight, 73 parts to 80 parts of polybutylene terephthalate, 1 part to 2 parts of calcium aluminate, 1 part to 2 parts of epoxy chloropropane, 2 parts to 3 parts of ammoniummolybdat, 2 parts to 3 parts of hydroxystearic acid, 3 parts to 5 parts of polyethylene wax, 0.4 part to 1 part of ascorbic acid, 1 part to 2 parts of N-hydroxymethyl acrylamide, 0.7 part to 1 part of 2,6-di-tert-butyl-4-methylphenol, 2 parts to 3 parts of Poly(1,2-propylene glycol adipate), 2 parts to 3 parts of 2-ethyl hexanol, 1 part to 2 parts of sodium metaborate, 1 part to 2 parts of epoxy-2-ethylhexyl stearate and 1 part to 2 parts of processing agents. The permanent inflaming-retarding pbt material has the permanent flame retardance, and is reasonable in raw material compound, good in compatibility, high in finished product mechanical performance, high in resistance, simple in preparation technology and low in cost.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

Method for preparing tetraoctyl pyromellitate

InactiveCN104529777AReduce pollutionLess energy consumptionOrganic compound preparationCarboxylic acid esters preparationAlcoholAcid value

The invention discloses a method for preparing tetraoctyl pyromellitate. The method comprises the following steps: putting pyromellitic acid and 2-ethyl hexanol into a reaction vessel, heating to 150-170 DEG C, adding a catalyst and carrying out esterification reaction at a temperature of between 190 and 220 DEG C until the acid value is less than 0.25 mg KOH / g, wherein the catalyst is one or more of a titanium compound and a tin compound; carrying out natural atmospheric dealcoholization to remove excess 2-ethyl hexanol, controlling the dealcoholization temperature at 160-220 DEG C, sampling and testing the acid value and when the acid value is 0.2 mg KOH / g or less, stopping the dealcoholization process; neutralizing the product at 90-100 DEG C, and separating an aqueous phase; introducing high-purity steam and purifying; adding a porous material into the obtain product for adsorbing and decolorizing and carrying out solid-liquid separation to obtain the tetraoctyl pyromellitate product. The method is low in pollution and the high-quality and high-purity product can be obtained.

Owner:CHAOHU XIANGFENG PLASTIC AIDS

Method for synthesizing 2-ethyl-2-hexenal

ActiveCN103864587AReduce churnNo need for separation and recyclingOrganic compound preparationCarbonyl compound preparationWastewaterSolid base

The present invention relates to a method for synthesizing 2-ethyl-2-hexenal. The method comprises that: 2-ethyl hexanol and butyraldehyde are mixed according to a mass ratio of 0.1-10; a condensation dehydration reaction is performed at a temperature of 80-220 DEG C under pressure of 0.1-1.0 MPa under an effect of a solid base to obtain a single-phase mixture of 2-ethyl-2-hexenal, 2-ethyl hexanol and water; the reactant is distilled at a temperature of 100-110 DEG C under pressure of 0.1-0.15 MPa, the unreacted butyraldehyde circularly returns to the condensation reactor, and an organic phase and aqueous phase two-phase mixture of 2-ethyl-2-hexenal and 2-ethyl hexanol is extracted; and the organic phase and aqueous phase two-phase mixture is subjected to condensation and chromatography separation to obtain a 2-ethyl-2-hexenal and 2-ethyl hexanol mixture. With the method, the 2-ethyl-2-hexenal yield achieves 96%, the loss of the catalyst active ingredient is less, no basic organic wastewater is generated, and the solvent is not required to be separated and recovered.

Owner:PETROCHINA CO LTD

Amino-acylase immobilization carrier and preparation method thereof

The invention relates to an amino-acylase immobilization carrier and a preparation method thereof, and belongs to the technical field of enzyme immobilization. The carrier is prepared from epoxypropyl methacrylate, divinyl benzene, acrylonitrile, methylbenzene, 2-ethyl hexanol, dibenzoyl peroxide, polyvinyl alcohol, gelatin, NaCl, CaCO3 and deionized water. Matrix resin reacts with diethylamine to prepare the amino-acylase immobilization carrier. The activity of an immobilized enzyme obtained by immobilizing amino-acylase through the carrier ranges from 1,000 micromoles per gram to 1,200 micromoles per gram.

Owner:YINGJING LIHONG TECH PROMOTION SERVICES CO LTD

High-efficiency non-corrosion water-based soldering paste detergent

InactiveCN101338251ANo corrosionFast cleaningNon-ionic surface-active compoundsDetergent compounding agentsWater basedD-Glucose

The invention discloses a high efficiency non-corrosive water-based solder paste cleaning agent, comprising triethanolamine, glucose, imidazoline, 2-ethyl hexanol and tween. The glucose and the imidazoline are used as inhibitor. The portions of the high efficiency non-corrosive water-based solder paste cleaning agent are as follows: 60-70 percent of triethanolamine, 1-8 percent of glucose, 0.5-1 percent of imidazoline, 10-20 percent of 2-ethyl hexanol and 10-20 percent of tween. The high efficiency non-corrosive water-based solder paste cleaning agent uses the formation of the inhibitor and the cleaning agent, and so the high efficiency non-corrosive water-based solder paste cleaning agent has the advantages of high efficiency, non-corrosive, environmental protection, rapid cleaning speed and so on.

Owner:JIANGSU UNIV OF SCI & TECH

Composite gasoline additive

InactiveCN107746731AImprove the lubrication effectReduce wearLiquid carbonaceous fuelsFuel additivesCyclohexeneKetone

The invention provides a composite gasoline additive, comprising 70-85 parts of ethanol; 22-27 parts of brown humic acid; 8-10 parts of diisopropyl ether; 15-13 parts of isopropanol; 12-17 parts of methyl isobutyrate 8-10 parts of isooctane; 5-6 parts of polyisobutylamine; 7-8 parts of methyl ethyl ketone; 4-8 parts of di-n-butyl phosphite; 6-7 parts of hexamethylenetetramine; 5-6 parts of cyclohexyl glycidyl ether; 7-12 parts of cyclohexene; 4-8 parts of isopropyl nitrate; 5-6 parts of amyl biscyclohexyl ketone; 7-8 parts of fatty acid ethyl ester; 4-8 parts of hexyl alcohol; 2-6 parts of oleic acid; 5-6 parts of lanolin; 5-6 parts of oleic acid amide; 4-8 parts of p-xylene; 4-8 parts of tetrahydrofuran; share. The invention enhances fuel combustion efficiency and achieves the purpose of energy saving.

Owner:魏崇振

Method for preparing high-purity docusate sodium

The invention relates to a method for preparing docusate sodium. The method comprises the step of esterification between 2-ethyl hexanol and maleic anhydride and the step of sulfonation of the obtained ester and sodium hydrogensulfite in a water solution. The method is characterized in that the method further comprises the following steps of purification of rough products: crystallizing the sulfonated rough products in an alcohol and water system to obtain a water-containing crystal, dissolving the water-containing crystal in alcohol dehydratum, performing reduced pressure distillation to remove a solvent so as to obtain anhydrous docusate sodium, wherein alcohol in the alcohol and water system is selected from a group comprising methyl alcohol, ethanol, normal propyl alcohol and isopropyl alcohol, and the alcohol dehydratum is selected from ethanol, normal propyl alcohol and isopropyl alcohol. By the method provided by the invention, the high-purity docusate sodium can be prepared.

Owner:HUNAN WARRANT PHARMA

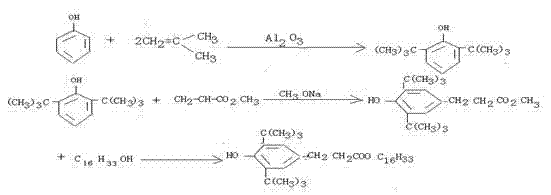

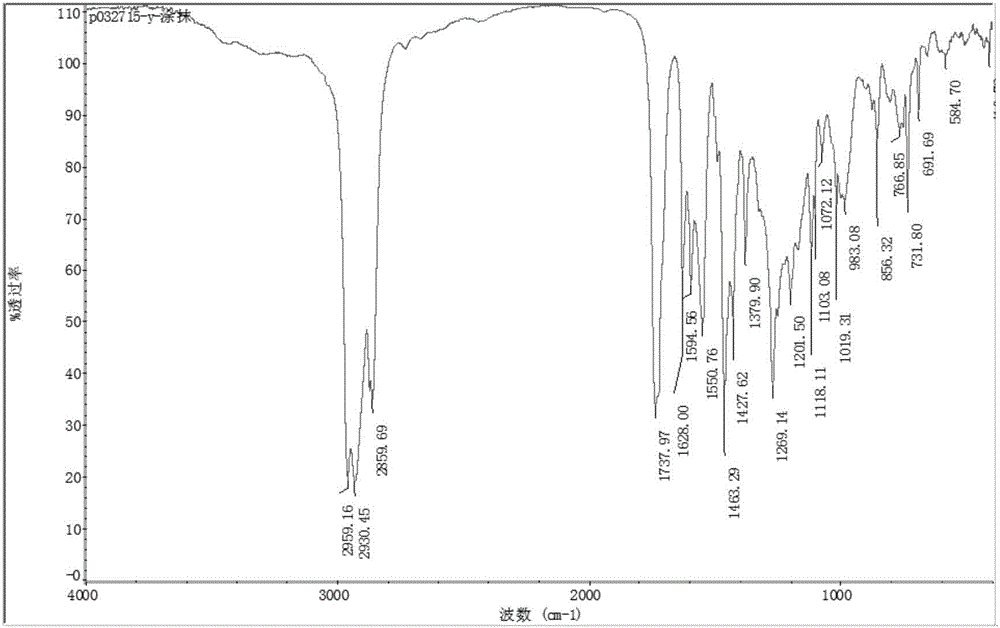

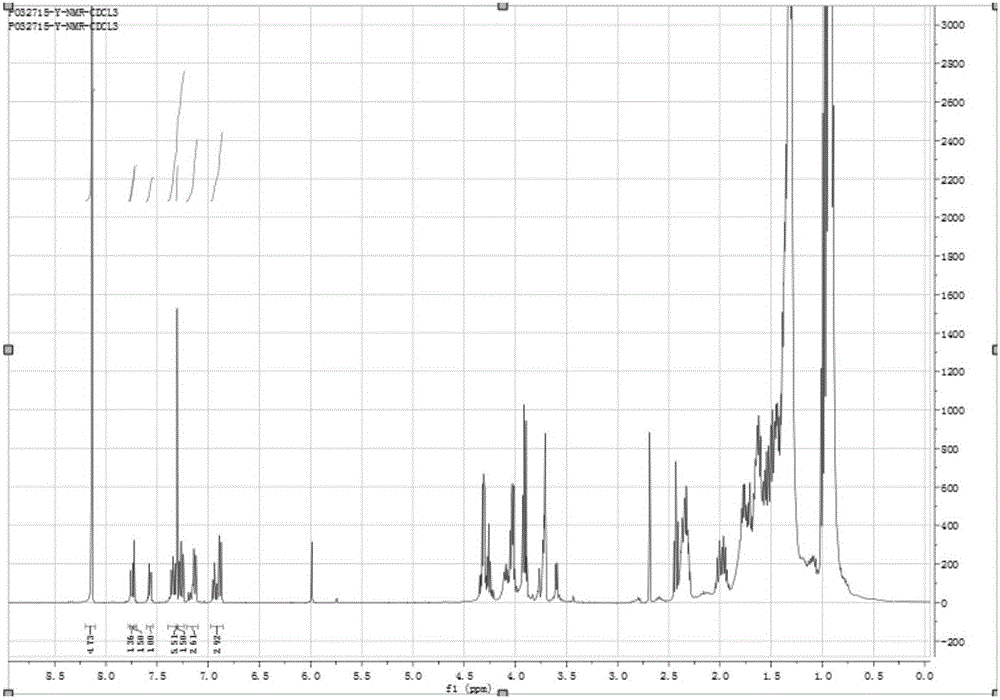

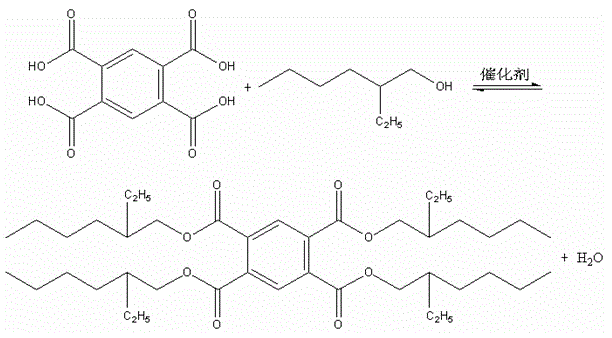

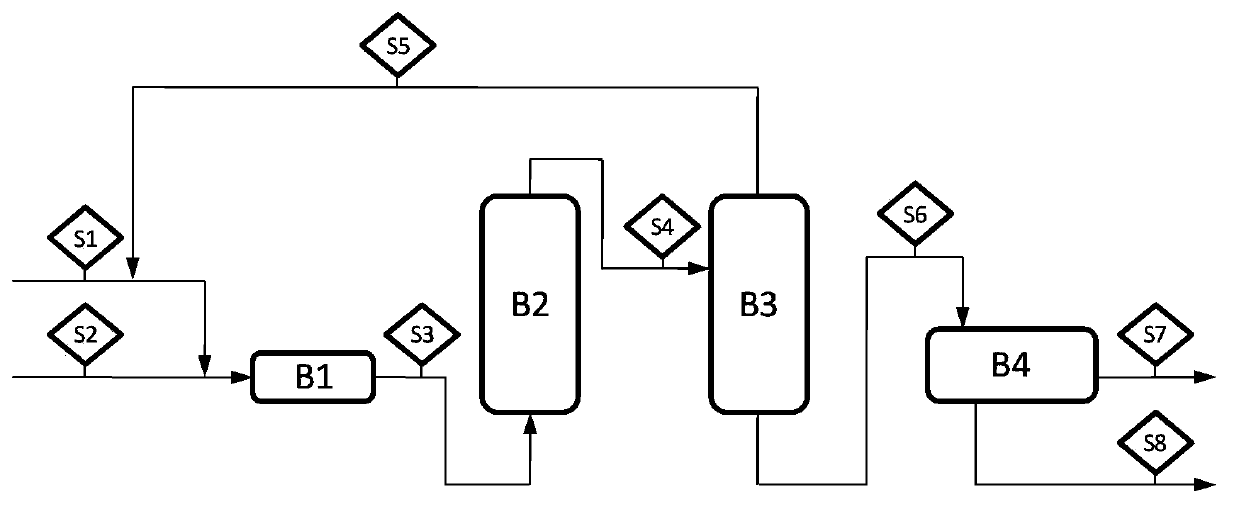

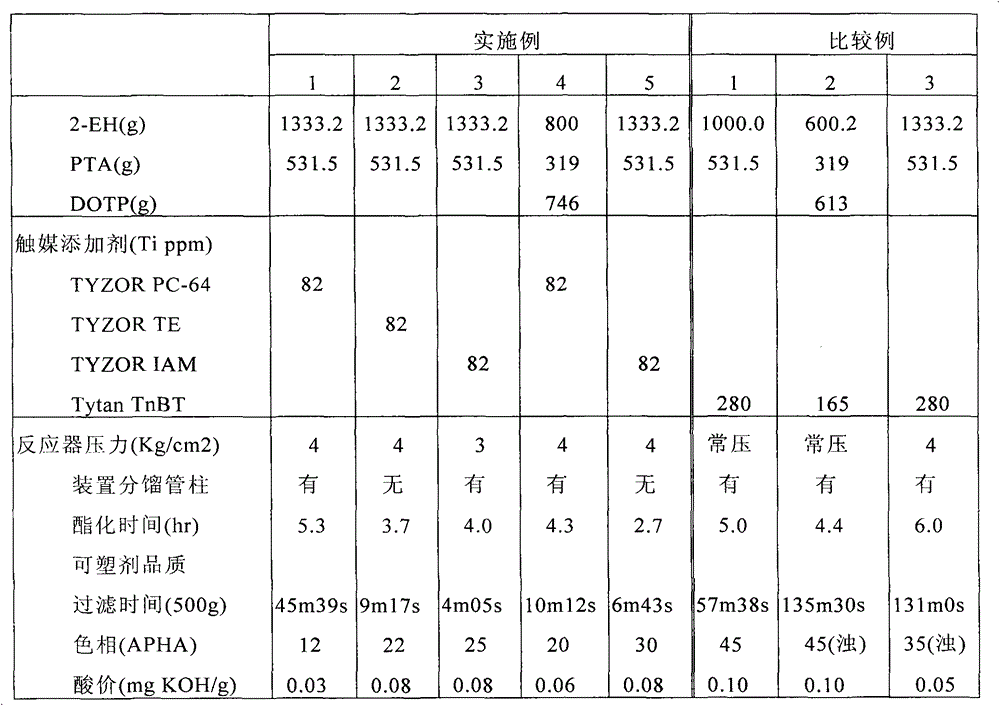

Manufacturing method of bis(2-ethylhexyl) terephthalate

ActiveCN104058968AEstimated conversion rateImprove filtration rateOrganic compound preparationCarboxylic acid esters preparation2-EthylhexanolReaction speed

The invention relates to a manufacturing method of bis(2-ethylhexyl) terephthalate, which comprises: performing an esterification reaction of terephthalic acid and 2-ethyl hexanol in the presence of a chelating catalyst. The method of the invention can increase the reaction speed, improve the filtering efficiency of the esterified product, and prepare bis(2-ethylhexyl) terephthalate with low hue (APHA).

Owner:CHANG CHUN PLASTICS

Method for preparing high-purity docusate sodium

The invention relates to a method for preparing docusate sodium. The method comprises the step of esterification between 2-ethyl hexanol and maleic anhydride and the step of sulfonation of the obtained ester and sodium hydrogensulfite in a water solution. The method is characterized in that the method further comprises the following steps of purification of rough products: crystallizing the sulfonated rough products in an alcohol and water system to obtain a water-containing crystal, dissolving the water-containing crystal in alcohol dehydratum, performing reduced pressure distillation to remove a solvent so as to obtain anhydrous docusate sodium, wherein alcohol in the alcohol and water system is selected from a group comprising methyl alcohol, ethanol, normal propyl alcohol and isopropyl alcohol, and the alcohol dehydratum is selected from ethanol, normal propyl alcohol and isopropyl alcohol. By the method provided by the invention, the high-purity docusate sodium can be prepared.

Owner:HUNAN WARRANT PHARMA

Tobacco axillary bud growth inhibitor and method for inhibiting tobacco axillary bud growth

ActiveUS20160113275A1Efficient processSustained chemical efficacyBiocideAnimal repellantsAxillary budNicotiana tabacum

An inhibitor for tobacco axillary bud growth, containing chlorthal-dimethyl and aliphatic alcohol selected from decyl alcohol, 2-ethyl hexanol and geraniol in combination; and a method for inhibiting tobacco axillary bud growth, which includes applying the inhibitor for tobacco axillary bud growth.

Owner:SDS BIOTECH CO LTD

Dividing wall distillation columns for production of high-purity 2-ethylhexanol and fractionation method using same

ActiveUS20130334029A1Reduce equipment costsOrganic compound preparationHydroxy compound preparationReboilerBoiling point

A dividing wall distillation column for producing high-purity 2-ethyl hexanol including a condenser, a reboiler and a main column having a dividing wall. The main column is divided into a column-top zone, an upper feed zone, an upper outflow zone, a lower feed zone, a lower outflow zone and a column-bottom zone. A crude 2-ethyl hexanol raw material (F) flows in a middle inflow plate NR1 in which the upper feed zone and the lower feed zone come in contact with each other, a low boiling point component (D) flows out from the column-top zone, a high boiling point component (B) flows out from the column-bottom zone, and a middle boiling point component (S) flows out through a middle outflow plate NR2 in which the upper outflow zone and the lower outflow zone come in contact with each other, where the middle boiling point component is 2-ethyl hexanol.

Owner:LG CHEM LTD

Automobile special lubricating oil with friction reducing effect and preparing method thereof

InactiveCN106010757AImprove anti-friction and anti-wear propertiesAvoid temperature riseLubricant compositionAlkylphenol2 ethyl hexanol

The invention discloses automobile special lubricating oil with a friction reducing effect and a preparing method thereof. The automobile special lubricating oil is prepared from, by weight, 25-45 parts of polydimethylsiloxane, 0.2-6 parts of dodecyl acid phosphite, 20-40 parts of 4-hydroxy-4-methyl-2-pentanone, 5-25 parts of carbon tetrachloride, 20-40 parts of alkenyl succinate, 1-10 parts of vulcanized calcium alkylphenol, 20-45 parts of benzotriazole, 0.2-10 parts of zinc naphthenate, 20-45 parts of polyoxyethylene glyceryl ether laurate, 1-10 parts of oxidized petrolatum, 20-40 parts of uracil, 0.1-3 parts of vitriol 2-ethyl hexanol zinc salt, 20-40 parts of paraffin powder, 0.1-5 parts of antiwear agent, 20-45 parts of zinc borate, 20-40 parts of granite powder, 0.1-4 parts of antirust agent and 0.1-4 parts of pour point depressant. All the raw materials are mixed and stirred to obtain the automobile special lubricating oil. The automobile special lubricating oil is stable in performance, good in rust resistance and corrosion resistance, simple in preparation process, low in production cost and suitable for the automobile field, improves friction reducing performance and abrasion resistance, improves oxidation resistance and controls the high-temperature oxidation conditions.

Owner:许云飞

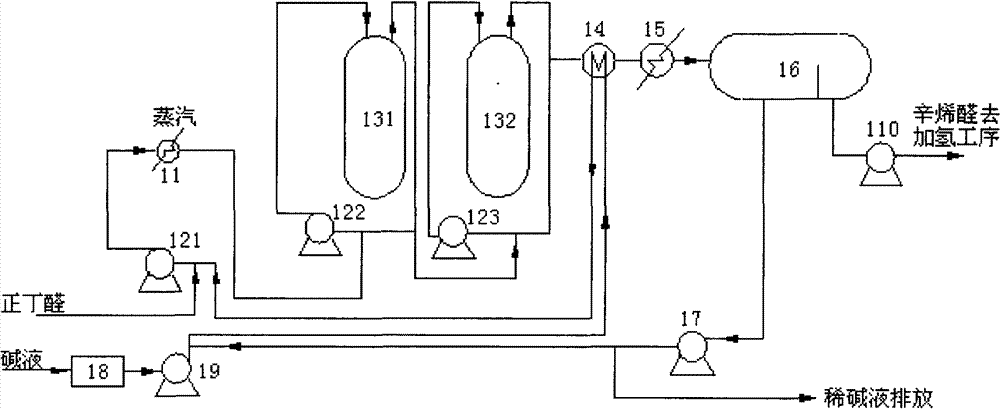

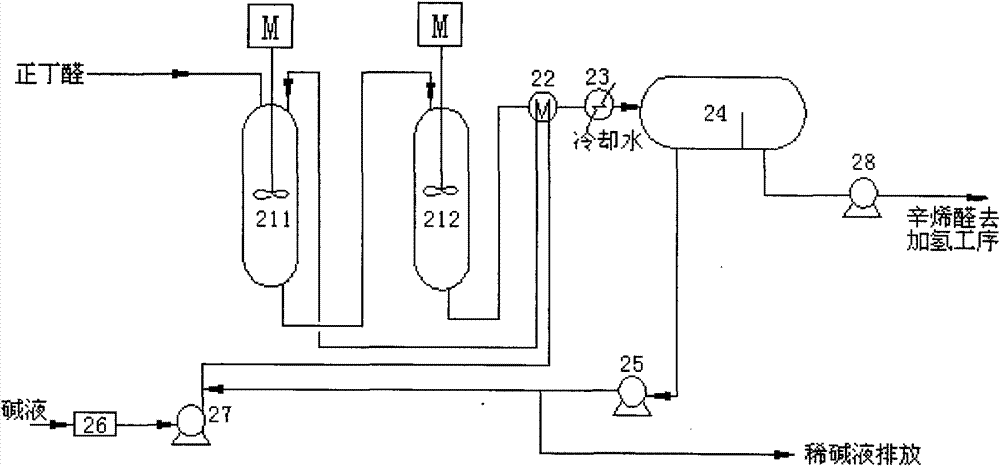

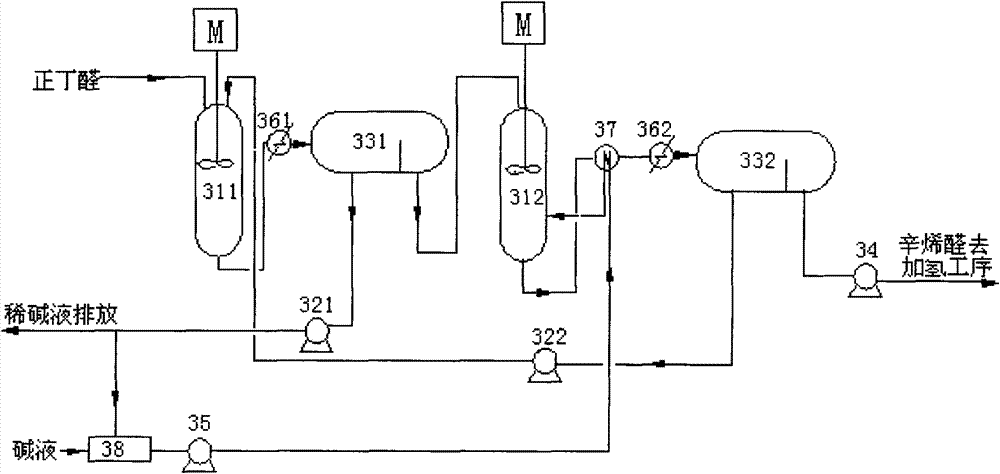

Preparation process of 2-ethyl hexenal and 2-ethyl hexanol

ActiveCN102260149BNot easy to produceMild responseOrganic compound preparationPreparation by hydrogenation2 ethyl hexanolImpurity

Owner:SHANGHAI HUAYI ENERGY CHEM

Antirust oil used after water cleaning

ActiveCN104087946AImprove rust resistanceImprove the lubrication effectAdditivesSarcosineSuccinic acid

The invention relates to antirust oil used after water cleaning. The antirust oil comprises following components by weight percent: 2-3% of petroleum barium sulfonate, 1.5-2% of wool fat magnesium soap, 2-3% of 2-ethyl hexanol, 0.1-0.25% of sorbitol anhydride oleate, 0.2-0.3% of polymethyl hexadecyl acrylate, 1.5-2.5% of sulfonated wool fat sodium, 0.1-0.2% of isopropyl palmitate, 1.5-3% of sorbitan monooleate polyoxyethylene ether, 2-4% of sorbitan aliphatic ester, 0.2-0.4% of 2,6-ditertiary butyl-4-cresol, 2-3% of sulfuric acid 2-ethyl haxanol zinc salt, 1-1.5% of heptadecene imidazoline oleate, 1-1.6% of laurylene succinic acid semi-aluminum soap, 0.3-0.5% of pentachlorodiphenyl, 0.5-1.5% of N-oleoyl sarcosine octadecylamine and the balance of transformer oil. All the components have a synergistic effect, so that the antirust oil is obviously superior to common antirust oil in antirust effect and lubricating effect, and is particularly suitable for antirust protection of equipment washed with water.

Owner:南通达克罗新材料科技有限公司

Normal temperature degreasing agent

The invention provides a normal temperature degreasing agent which is prepared into aqueous solution in a container by weight percent. The aqueous solution comprises the following components in percentage by weight: 14.23-15.02% of octyl polyoxyethylene ether, 4.22-4.4% of polyvinyl alcohol 400, 6.4-6.51% of octadecyl dimethyl amine oxide, 2.83-2.9% of unsaturated fatty acid, 0.66-0.79% of 2-ethyl hexanol, 5.33-5.47% of triethanolamine, 0.16-0.21% of 2-amino-2-methyl-1-propyl alcohol, and the balance of water. The invention has the advantages: (1) heating is not needed when the temperature is above 8 DEG C, the operation is easy with no need of other auxiliary equipment, and the agent is environmental friendly; and (2) equipment maintenance is omitted, the consumptions of the two types of degreasing agents are the same, and the cost can be greatly saved by using the normal temperature degreasing agent.

Owner:SHIYAN FANGDING AUTOMOTIVE BODY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com