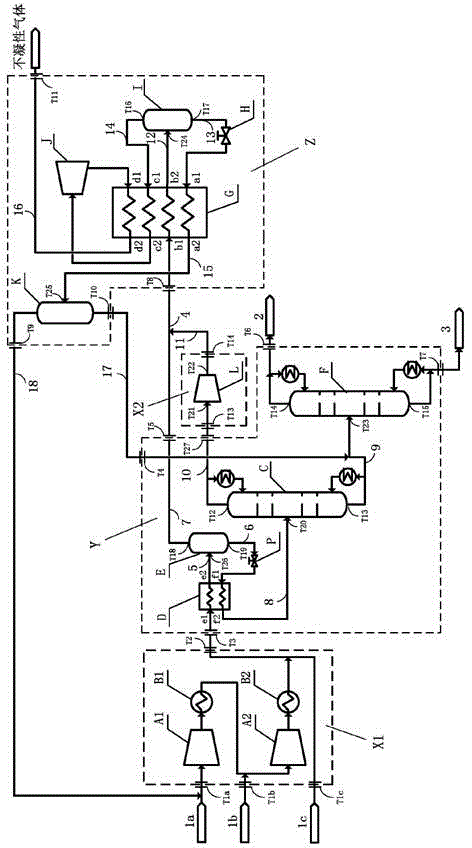

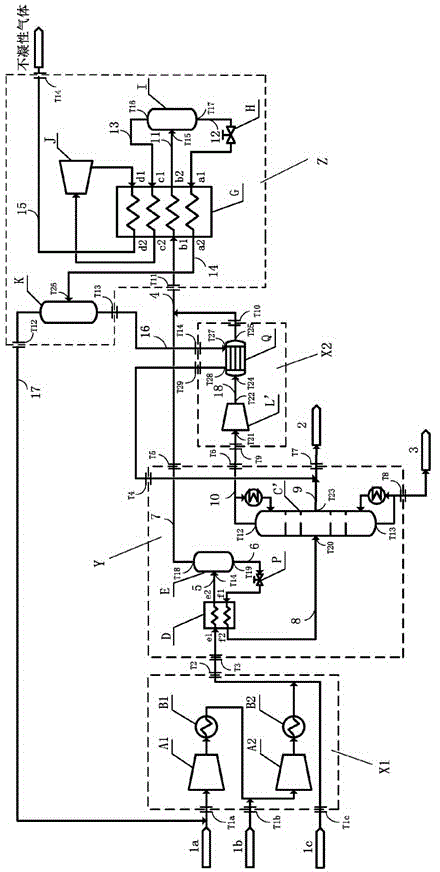

2-ethyl hexanol tail gas recovery system and method

A tail gas recovery and tail gas technology, applied in the direction of organic chemical methods, chemical instruments and methods, purification/separation/stabilization of organic compounds, etc., can solve the problems of large investment and energy consumption, large investment, etc., to reduce energy consumption consumption, reduce equipment cost, and avoid the effect of too low temperature at the top of the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

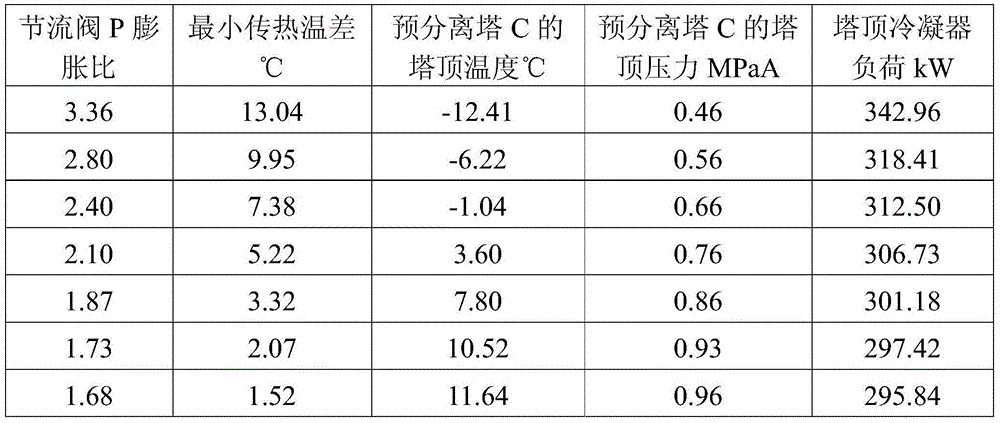

[0088] Compression step 1, receiving the tail gas, and compressing the pressure of each gas component in the tail gas to the same level, the specific operation is as follows: (1) Send the tail gas 1a from the butanol system to the inlet T1 of the compression mechanism X1, and pass it once The first compressor A1 is boosted to 0.4MPaA and then cooled to 40°C. (2) Mix the cooled tail gas with the tail gas 1b from the high-pressure evaporation system and the stabilization system, and enter the second compressor A2 to increase the pressure to 1.73MPaA and then cool down. (3) The exhaust gas cooled to 40°C is mixed with the purge gas 1c of the carboxyl synthesis reaction system and discharged from the outlet of the compression mechanism X1 in the form of output flow of the compression mechanism X1.

[0089] The rectification step recovers the butyraldehyde and propylene propane mixture in the tail gas. The specific operation steps are as follows: (1) The output flow from the outlet...

Embodiment 2

[0093] Compression step 1, receiving the tail gas, and compressing the pressure of each gas component in the tail gas to the same level, the specific operation is as follows: (1) Send the tail gas 1a from the butanol system to the inlet T1 of the compression mechanism X1, and pass through the first A compressor A1 is boosted to 0.4MPaA and then cooled to 40°C. (2) Mix the cooled tail gas with the tail gas 1b from the high-pressure evaporation system and the stabilization system, and enter the second compressor A2 to increase the pressure to 1.73MPaA and then cool down. (3) The exhaust gas cooled to 40°C is mixed with the purge gas 1c of the carboxyl synthesis reaction system and discharged from the outlet of the compression mechanism X1 in the form of output flow of the compression mechanism X1.

[0094] The rectification step recovers the butyraldehyde and propylene propane mixture in the tail gas. The specific operation steps are as follows: (1) The output flow from the outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com