Novel PVC heat stablizer

A heat stabilizer, a new type of technology, applied in the field of plastics, can solve the problems of poor self-lubrication and adhesion, and achieve the effect of good stability and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Organozinc compounds:

[0071] Zinc isooctanoate, CAS No.: 136-53-8, Beijing Huawei Raycus Chemical Co., Ltd.

[0072] Organotin compounds:

[0073] Diisooctyl 2,2'-((dimethylstannyl)dithio)diacetate, CAS No.: 26636-01-1, Nantong Advan Chemical Co., Ltd.;

[0074] 1,1,3,3-Tetrabutyl-1,3-bis[(1-oxododecyl)oxy]distanthiolane, CAS No.: 15880-66-7, Kingston Chemistry.

[0075] Phthalates:

[0076] Diisooctyl phthalate, CAS No.: 27554-26-3, Beijing Huawei Raycus Chemical Co., Ltd.;

[0077] Diisooctyl terephthalate, CAS No.: 6422-86-2, Qingdao Tianxin Chemical Co., Ltd.

[0078] Alkyl esters:

[0079] Dioctyl adipate, CAS No.: 123-79-5, Liaocheng Ruijie Chemical Co., Ltd.;

[0080]Dibutyl glutarate, CAS No.: 6624-57-3, Kingston Chemistry;

[0081] Dibutyl succinate, CAS No.: 141-03-7, Anhui Sanxin Chemical Co., Ltd.;

[0082] Dibutyl adipate, CAS number: 105-99-7, Weifang Bincheng Chemical Co., Ltd.

[0083] Phosphite:

[0084] Trioctyl phosphite, CAS No.: 3028-88...

Embodiment 5

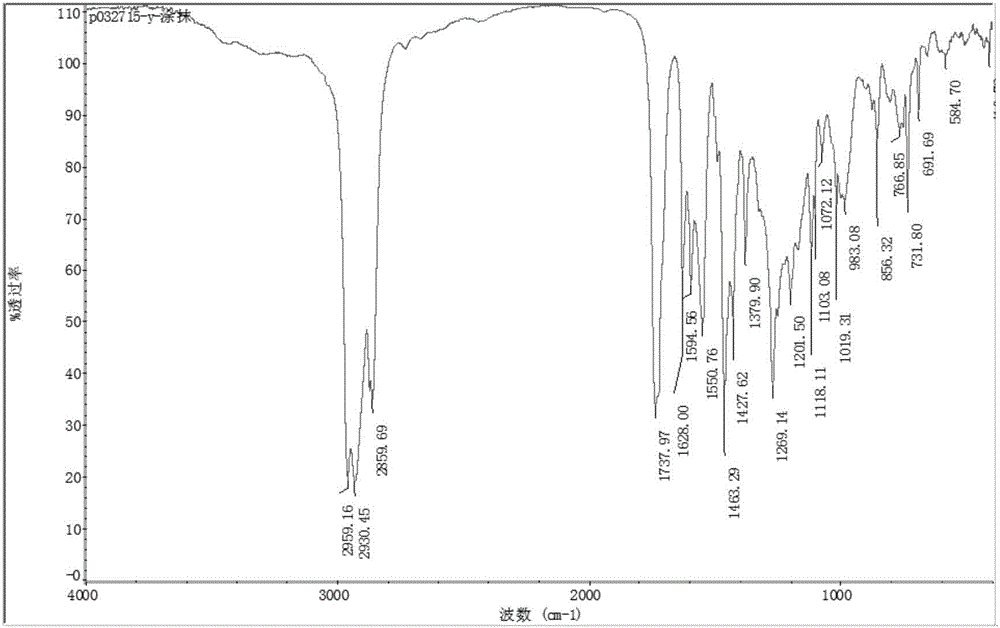

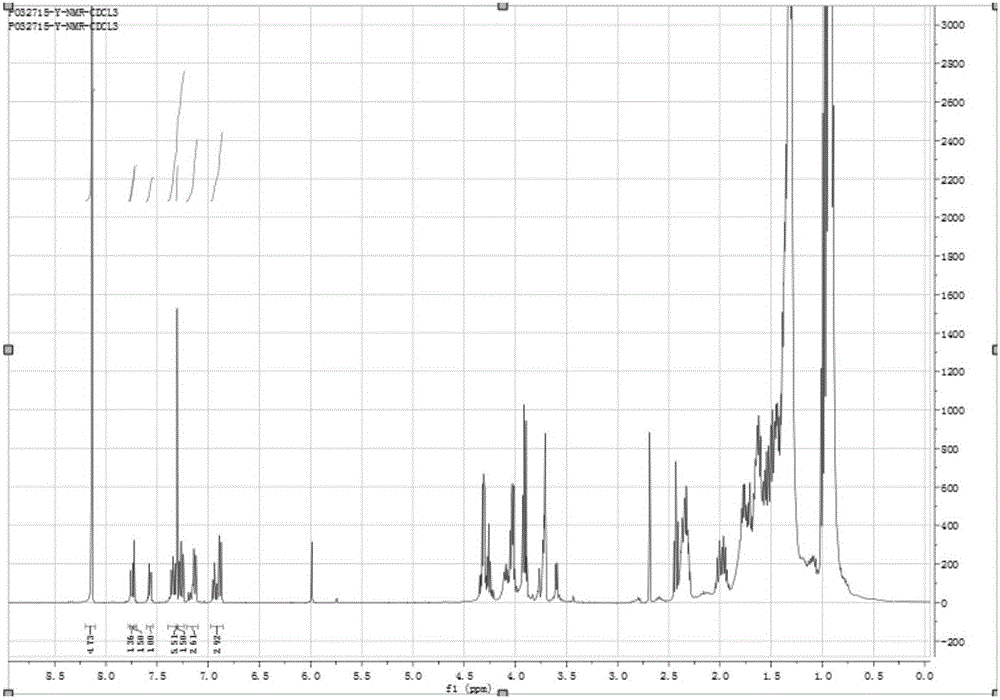

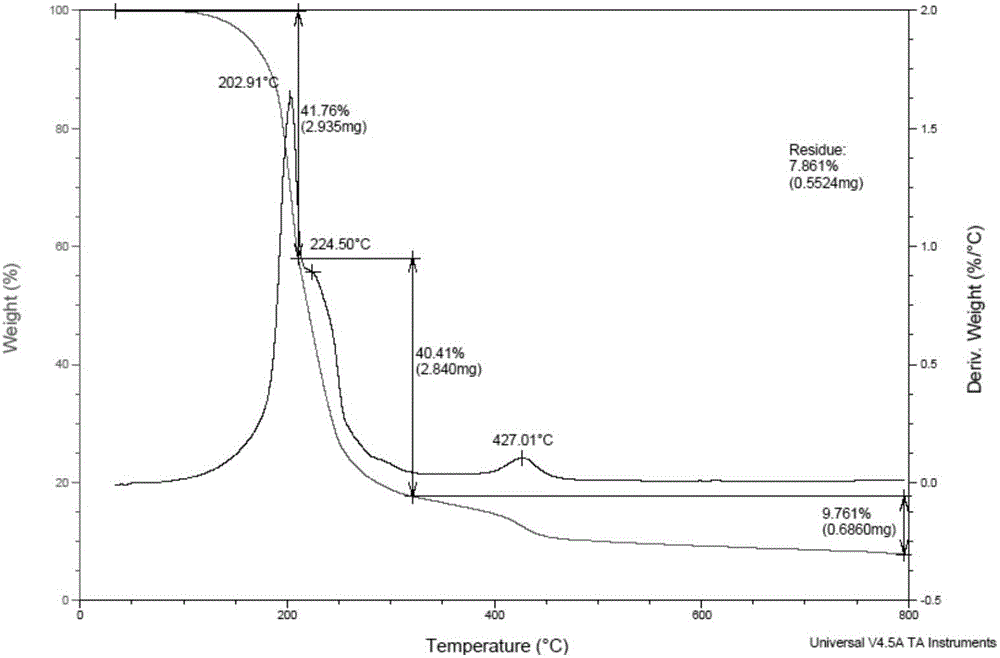

[0114] Embodiment 5 is carried out infrared, nuclear magnetic proton spectrum and thermogravimetric analysis test, test result is respectively in the accompanying drawing figure 1 , figure 2 and image 3 .

[0115] Nicolet Nexus Fourier-infrared spectrometer was used for the infrared test; BRUKER DSX300 was used for the NMR test, and the solvent was deuterated chloroform; the thermogravimetric analysis was tested by Mettler-Toledo thermal analyzer.

[0116] Performance Testing

[0117] Get the novel PVC heat stabilizer that embodiment 5-15 makes, make PVC sample respectively according to following formula. PVC sample formula: PVC (SG-5) 100g, Example 0.6g, OPE 0.3g, ACR-401 1.2g, CPE 1g, TiO 2 1.8g, light CaCO 3 25g.

[0118] 1. Determination of static thermal stability

[0119] Weigh the PVC sample formula, mix it evenly, and knead it on an open plastic mixer at a temperature of 190°C for 3 minutes to make a sample with a thickness of about 1mm. Record the time fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com