Method for synthesizing PVC plasticiser by reclaiming waste polyester

A technology of waste polyester and plasticizer, applied in the field of plasticizer, can solve problems such as waste of resources, and achieve the effects of low production cost, shortened process flow, and reduced reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

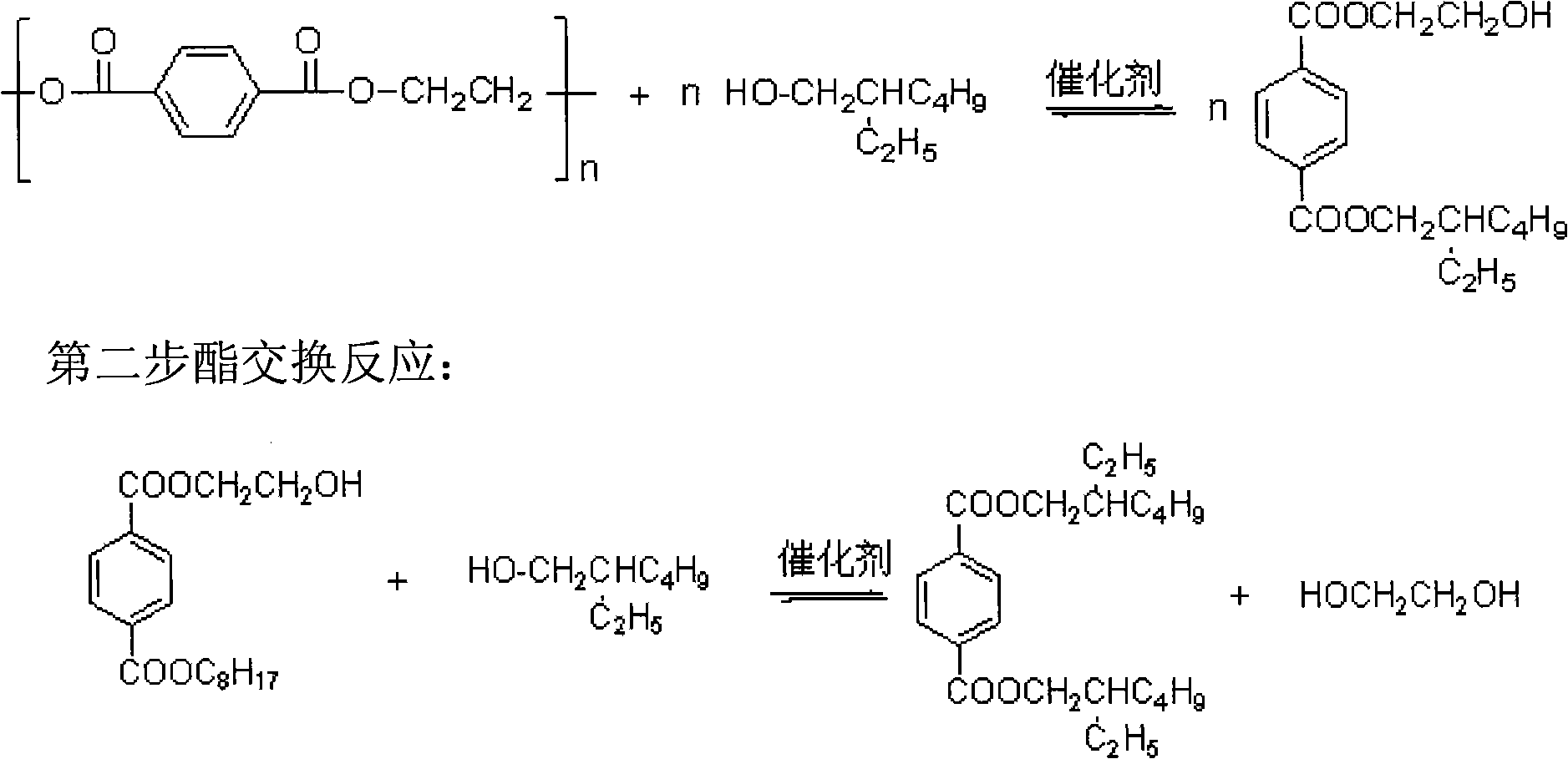

Method used

Image

Examples

Embodiment 1

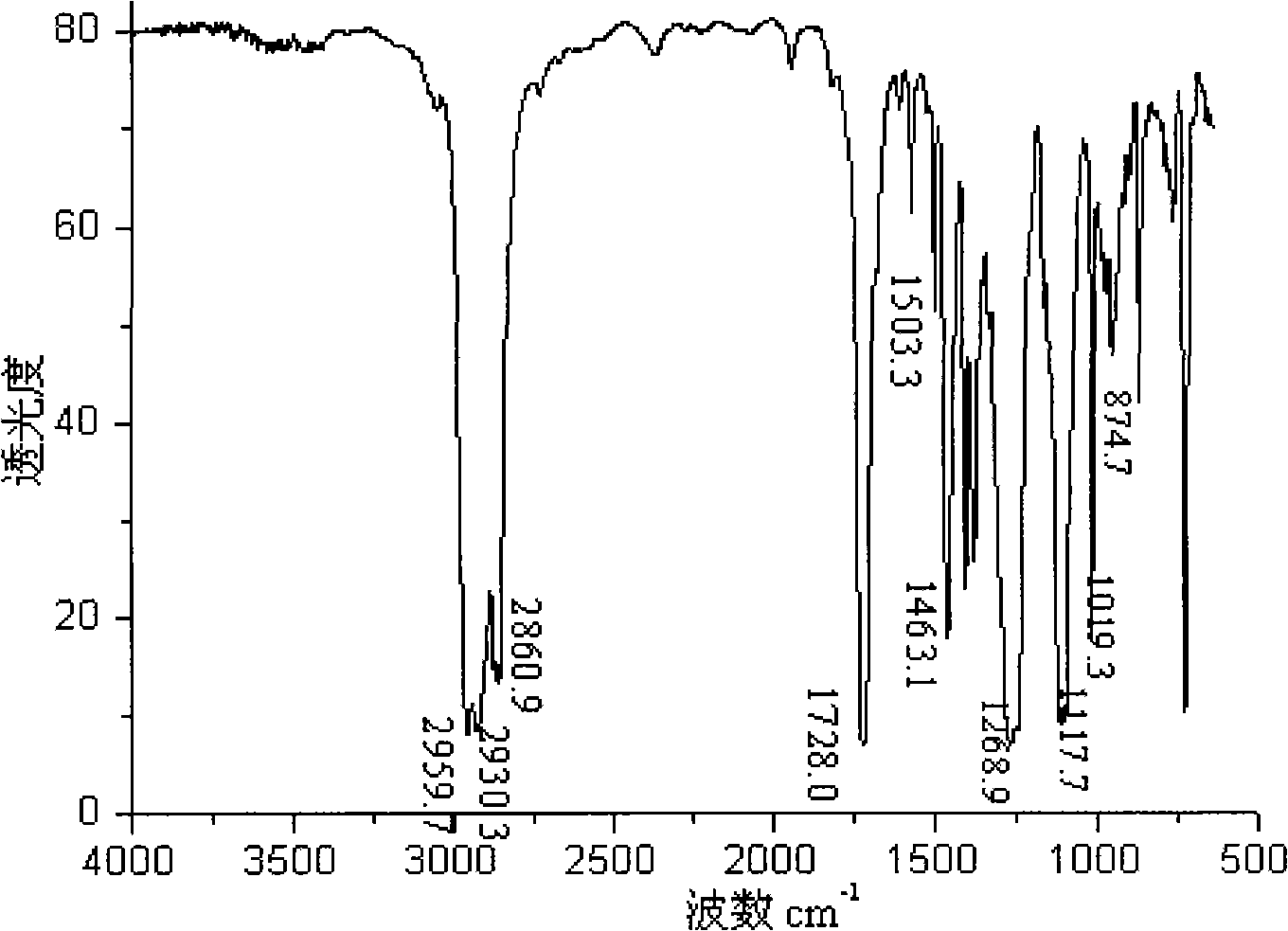

[0024] Add a certain amount of polyester bottle flakes, 2-ethylhexanol, and tetrabutyl titanate into a three-necked flask equipped with a stirrer, a thermometer, and an oil-water separator, wherein the moles of polyester and 2-ethylhexanol The ratio is 1:4, and the amount of tetrabutyl titanate is 0.5% of the polyester mass. Control the temperature at 180°C-220°C, stir for 5 hours, cool to 70°C-90°C, neutralize with 3% sodium carbonate aqueous solution, then wash with water, separate the water layer and the organic layer; add an adsorbent to the organic layer to neutralize Alumina, the dosage is 5% of the quality of polyester bottle flakes, heated under reduced pressure to remove excess 2-ethylhexanol, and filtered to remove neutral alumina to obtain light yellow transparent liquid product plasticizer DOTP. The infrared spectrum of the product DOTP as figure 1 Shown: 1728.0cm -1 is the stretching vibration of C=O in the ester group, 1268.9cm -1 and 1117.7cm -1 It is the ch...

Embodiment 2

[0026] In the reaction device of embodiment 1, add polyester bottle flakes, 2-ethylhexanol, zinc acetate of a certain proportion, solid acid catalyst, wherein the mol ratio of polyester and 2-ethylhexanol is 1: 6, The total consumption of zinc acetate and solid acid catalyst is 1.0% of the quality of polyester bottle flakes. Heat and stir, control the reaction temperature at 180°C-220°C, stir for 6 hours, cool to 70°C-90°C, neutralize with 3% aqueous sodium hydroxide solution, wash with water and separate the water layer and the organic layer; add clay to the organic layer , the dosage is 5% of the quality of polyester bottle flakes, heated under reduced pressure to remove excess 2-ethylhexanol, and filtered to remove clay to obtain light yellow transparent liquid product plasticizer DOTP.

Embodiment 3

[0028] Add a certain proportion of polyester rags, 2-ethylhexanol, and solid acid catalyst in the reaction device of Example 1, wherein the molar ratio of polyester rags to 2-ethylhexanol is 1: 20 , the consumption of solid acid catalyst is 0.5% of the quality of polyester polyester rags. Heat and stir, control the reaction temperature at 180°C-220°C, react for 5 hours, cool to 70°C-90°C, wash with 3% sodium carbonate aqueous solution, and then separate the water layer and the organic layer after washing with water; add active Carbon, the consumption is 5% of the quality of polyester polyester rags, heated under reduced pressure to remove excess 2-ethylhexanol, and filtered to remove active carbon to obtain light yellow transparent liquid product plasticizer DOTP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com