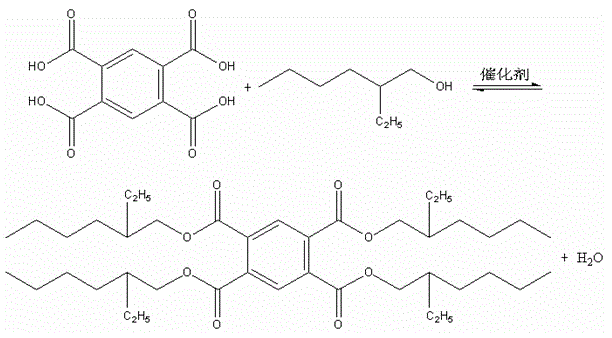

Method for preparing tetraoctyl pyromellitate

A technology for pyromellitic acid and tetraoctyl ester, which is applied in the field of preparation of tetraoctyl pyromellitic acid, can solve the problems of pollution, complex catalyst preparation process, poor product quality and the like, and achieves high purity, good product quality, The effect of less energy and water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] A laboratory preparation example of tetraoctyl pyromellitate, comprising the steps of:

[0027] Step 1. Esterification

[0028] Add 0.7 mol (178 g) of pyromellitic acid and 3.5 mol (455 g) of 2-ethylhexanol into a 1000 ml glass three-neck flask equipped with a stirrer, thermometer, condenser, and water separator, and heat at 160°C 3 g of tetraisopropyl titanate catalyst was added, and the reaction time was 2.5 hours at 220° C., and the measured acid value of the product was 0.20 mgKOH / g.

[0029] Wherein the catalyst can be not only tetraisopropyl titanate, but also one or more of titanium metal compounds and tin metal compounds, and the titanium metal compounds include tetrabutyl titanate, tetraisopropyl titanate, titanium Tetramethyl ester and titanium dioxide, etc., the tin metal compounds include stannous oxalate, stannous oxide, dibutyltin oxide and dibutyltin phthalate, etc.

[0030] Step two, dealcoholization

[0031] At 160-220°C, dealcoholization under norma...

specific Embodiment 2

[0039] A kind of industrial production example of tetraoctyl pyromellitate, comprises the steps:

[0040] Step 1. Esterification

[0041] Add 1.2 tons of pyromellitic acid and 3.1 tons of 2-ethylhexanol into a stainless steel esterification reaction kettle with a packing tower and a condenser with a volume of 6 cubic meters, raise the temperature to 160°C, and add 6 Kg of titanic acid Tetraisopropyl ester catalyst. At 220° C., esterification reaction was carried out for 3 hours. The acid value measured by sampling was 0.22 mgKOH / g.

[0042]Wherein the catalyst can be not only tetraisopropyl titanate, but also one or more of titanium metal compounds and tin metal compounds, and the titanium metal compounds include tetrabutyl titanate, tetraisopropyl titanate, titanium Tetramethyl ester and titanium dioxide, etc., the tin metal compounds include stannous oxalate, stannous oxide, dibutyltin oxide and dibutyltin phthalate, etc.

[0043] Step two, dealcoholization

[0044] At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com