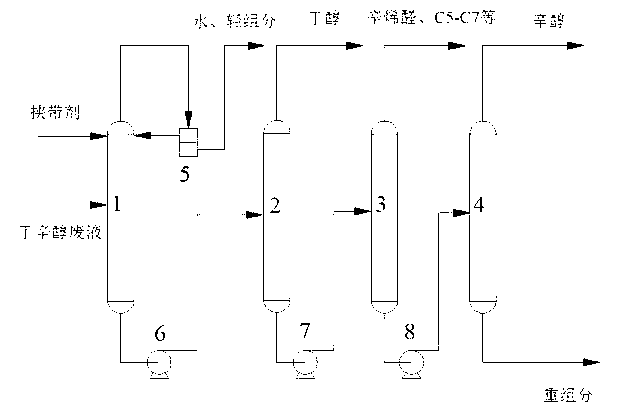

Treatment process of 2-ethyl hexanol liquid waste

A waste liquid treatment and process technology, which is applied in the field of butyl-octyl alcohol waste liquid treatment process, can solve the problems of wasting organic matter, poor product quality, and inconspicuous economic benefits, and achieve environmental pollution reduction, good economic and social benefits, and saving resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The raw material of butanol waste liquid is heated to 60°C and enters the first rectification tower from the middle, and the heat of material evaporation is provided by the reboiler of the tower kettle. The entrainer toluene is added from the first tray, the flow rate is 2Kg / h, and the material temperature is 40°C. After the material extracted from the top of the first rectification tower passes through the decanter for stratification, the upper liquid circulates back to the first rectification tower. The temperature at the top of the tower is controlled at 70°C, controlled by the circulating liquid flow. The temperature of the tower bottom is controlled at 120°C, which is controlled by the amount of steam heated by the tower bottom. The pressure at the top of the tower is -0.05MPa.

[0024] The bottom liquid of the first rectification tower is sent to the feed port in the middle of the second rectification tower through the liquid extraction pump 1. The temperature a...

Embodiment 2

[0029] The raw material of butanol waste liquid is heated to 90°C and enters the first rectification tower from the middle, and the heat of evaporation of the material is provided by the reboiler of the tower kettle. The entrainer benzene is added from the first tray, the flow rate is 2Kg / h, and the material temperature is 40°C. After the material extracted from the top of the first rectification tower passes through the decanter for stratification, the upper liquid circulates back to the first rectification tower. The temperature at the top of the tower is controlled at 100°C, controlled by the circulating liquid flow. The temperature of the tower bottom is controlled at 150°C, which is controlled by the heating steam volume of the tower bottom. The pressure at the top of the tower is -0.08MPa.

[0030] The bottom liquid of the first rectification tower is sent to the feed port in the middle of the second rectification tower through the liquid extraction pump 1, the tempera...

Embodiment 3

[0035] The raw material of butanol waste liquid is heated to 100°C and enters the first rectification tower from the middle, and the heat of evaporation of the material is provided by the reboiler of the tower kettle. The entrainer benzene is added from the first tray, the flow rate is 0.5Kg / h, and the material temperature is 40°C. After the material extracted from the top of the first rectification tower passes through the decanter for stratification, the upper liquid circulates back to the first rectification tower. The temperature at the top of the tower is controlled at 50°C, controlled by the circulating liquid flow. The temperature of the tower bottom is controlled at 130°C, which is controlled by the heating steam volume of the tower bottom. The pressure at the top of the tower is -0.01MPa.

[0036] The bottom liquid of the first rectification tower is sent to the feed port in the middle of the second rectification tower through the liquid extraction pump 1. The tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com