Patents

Literature

141results about How to "Speed up reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

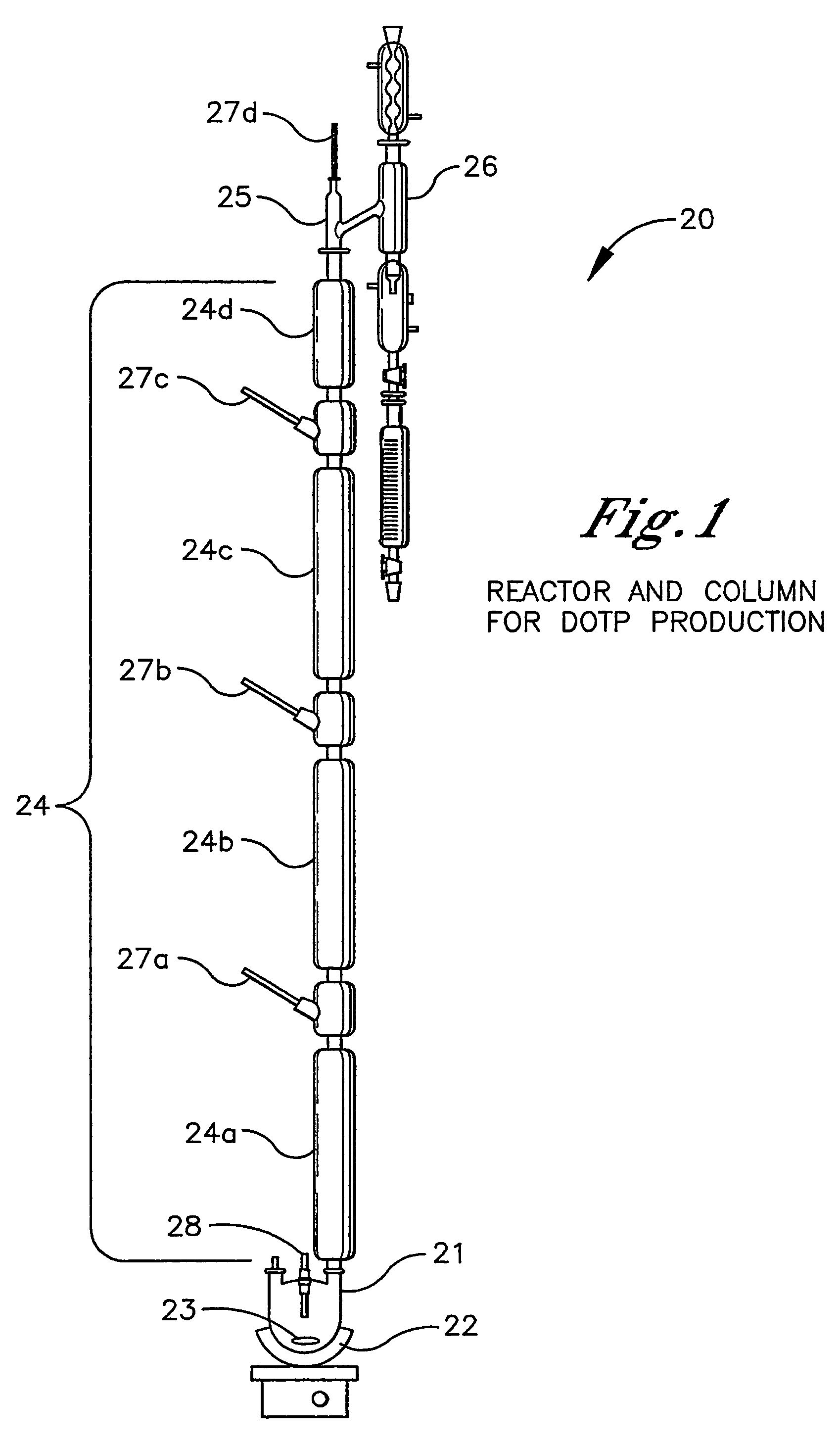

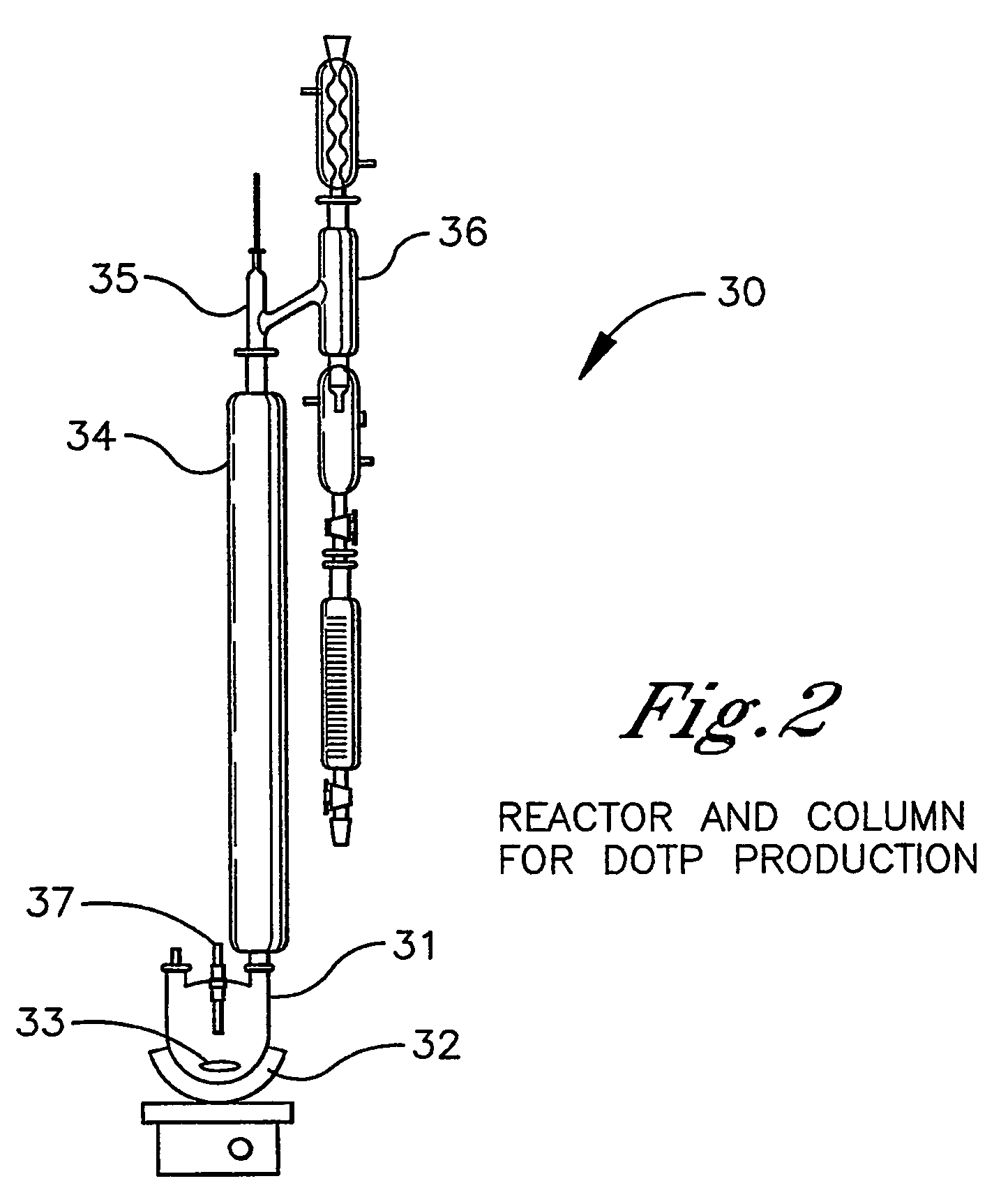

Production of terephthalic acid di-esters

InactiveUS7799942B2Speed up reactionSpeed up the conversion processPreparation from carboxylic acid halidesOrganic compound preparationAlcoholTerephthalic acid

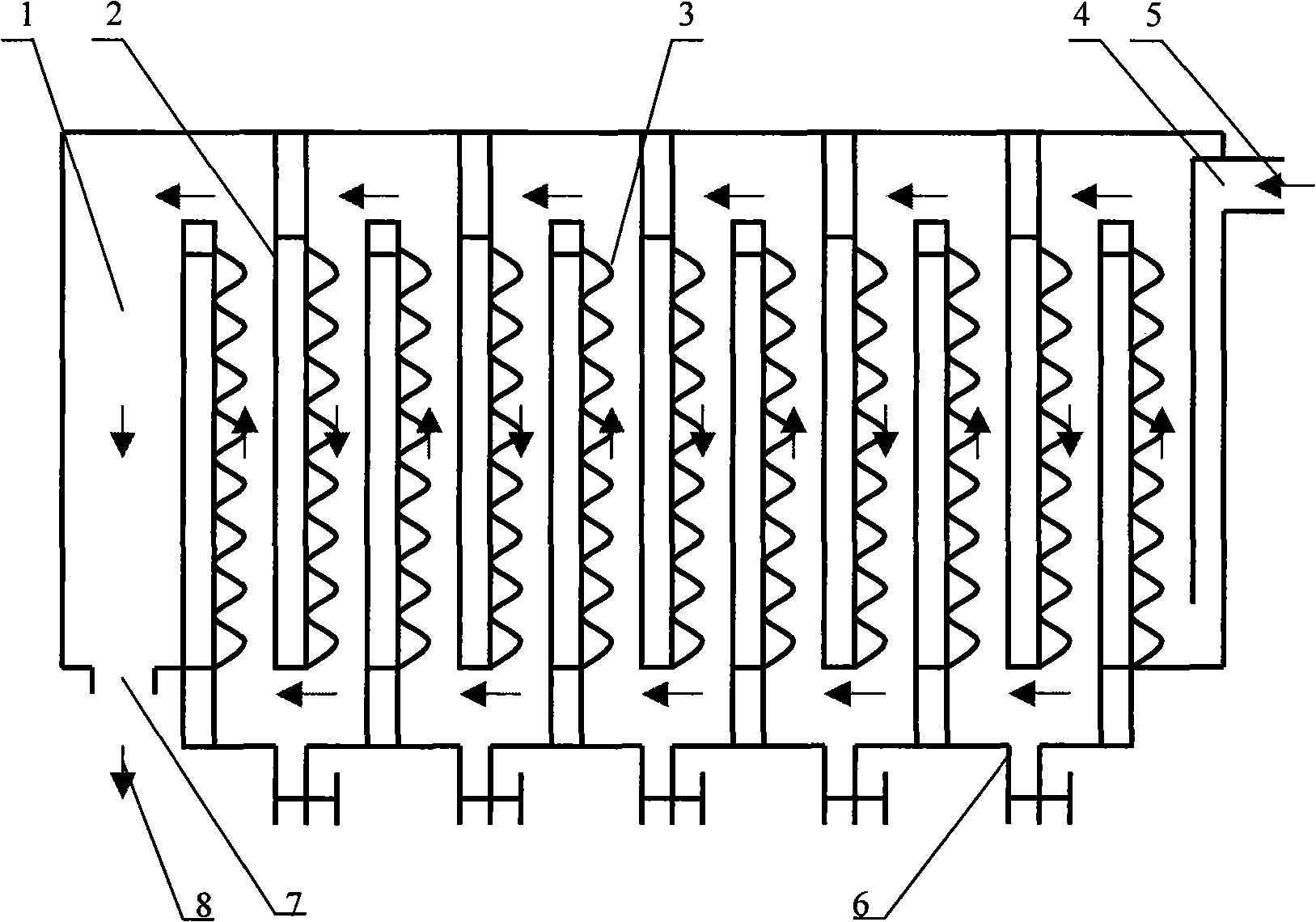

Disclosed is a process for the preparation of a terephthalic acid di-ester by the esterification of terephthalic acid with an alcohol at elevated and normal temperature and pressure while the water of the reaction is removed from the reaction mixture via an inert gas or a column.

Owner:EASTMAN CHEM CO

Production of di-(2-ethylhexyl) terephthalate

ActiveUS7276621B2Speed up the conversion processSpeed up reactionPreparation from carboxylic acid halidesOrganic compound preparation2-EthylhexanolETHYLHEXYL ACETATE

Disclosed is a process for the preparation of di-(2-ethylhexyl) terephthalate by the esterification of terephthalic acid with 2-ethylhexanol at elevated temperature and pressure while the water of reaction is removed from the reaction mixture.

Owner:EASTMAN CHEM CO

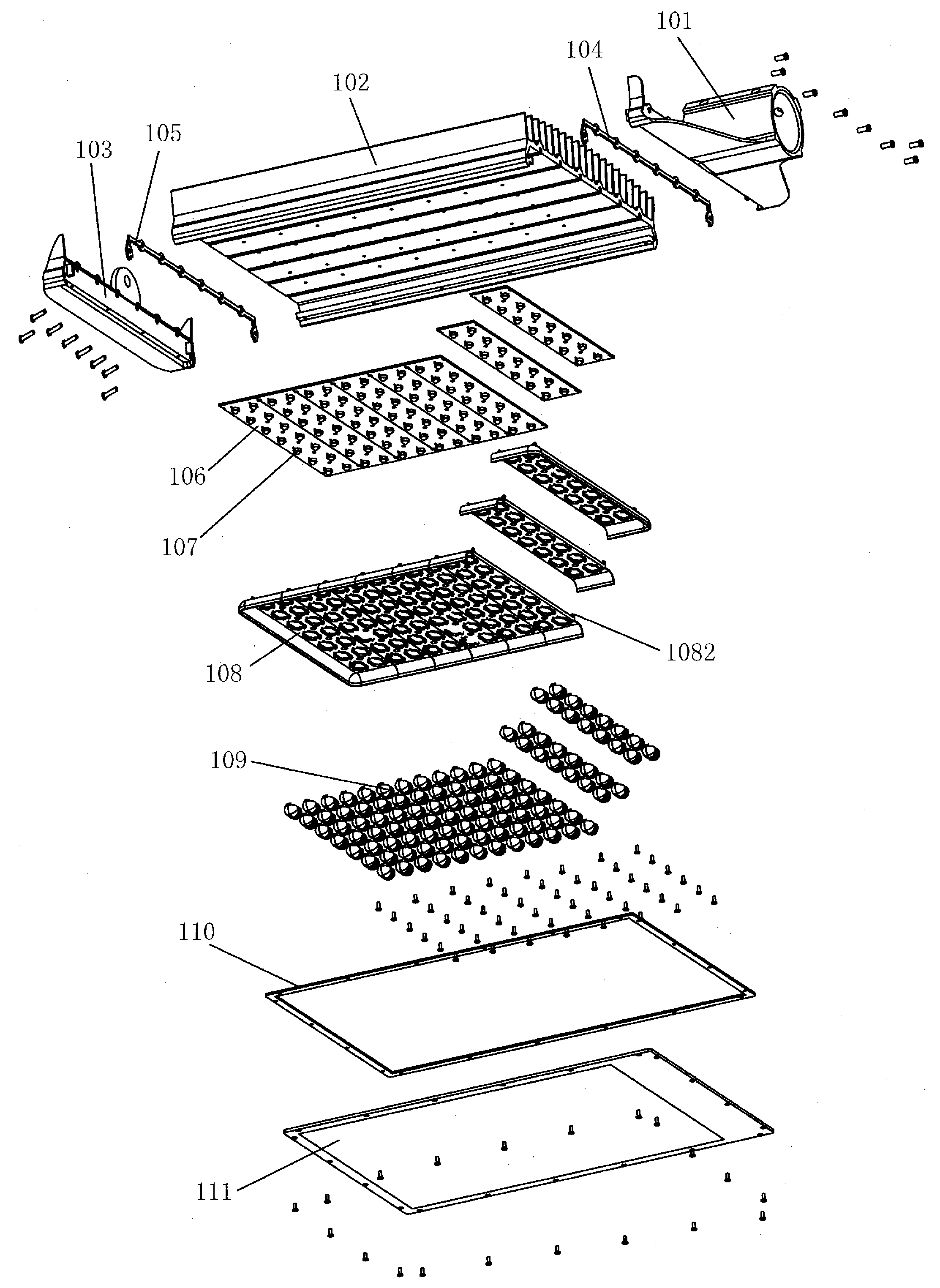

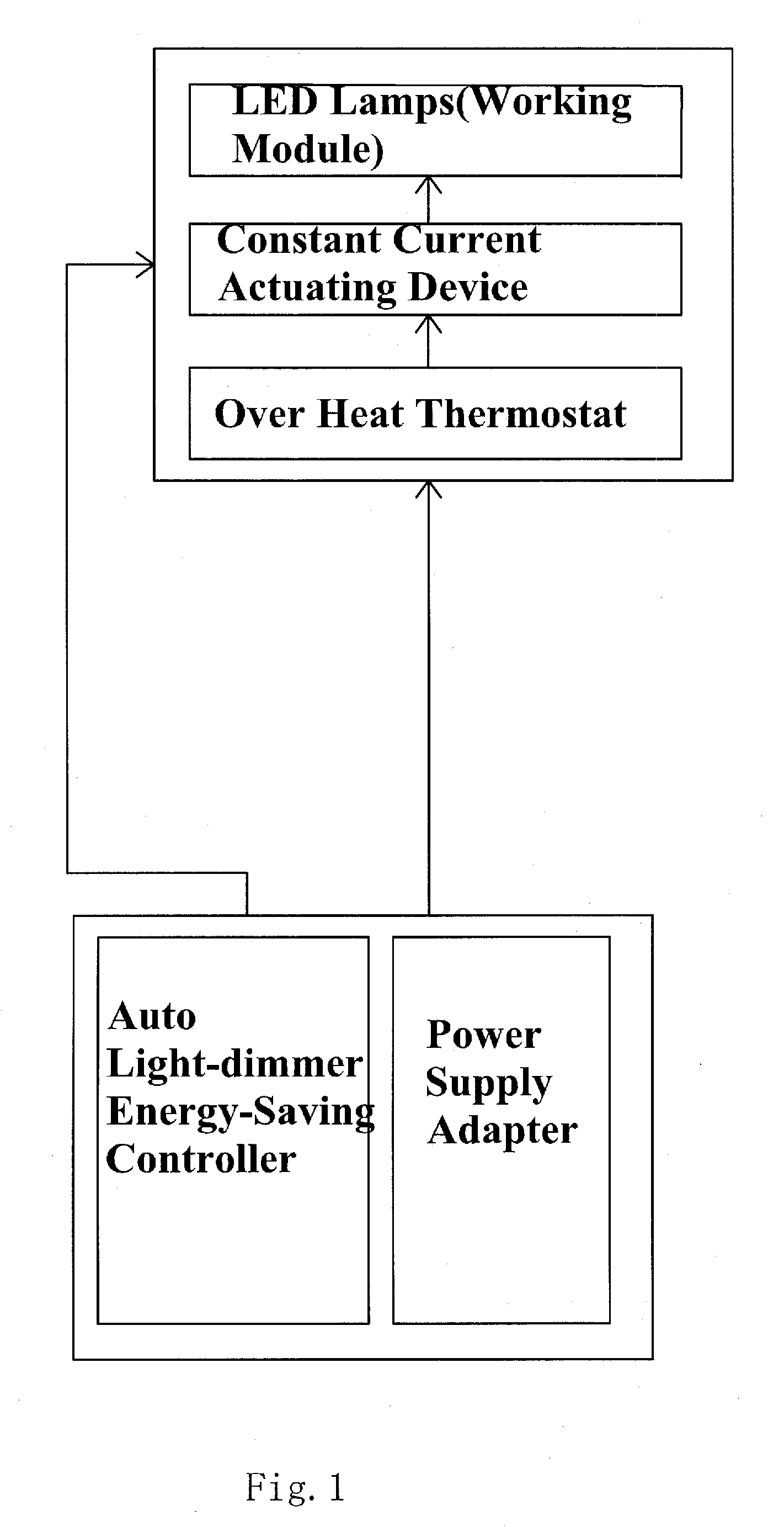

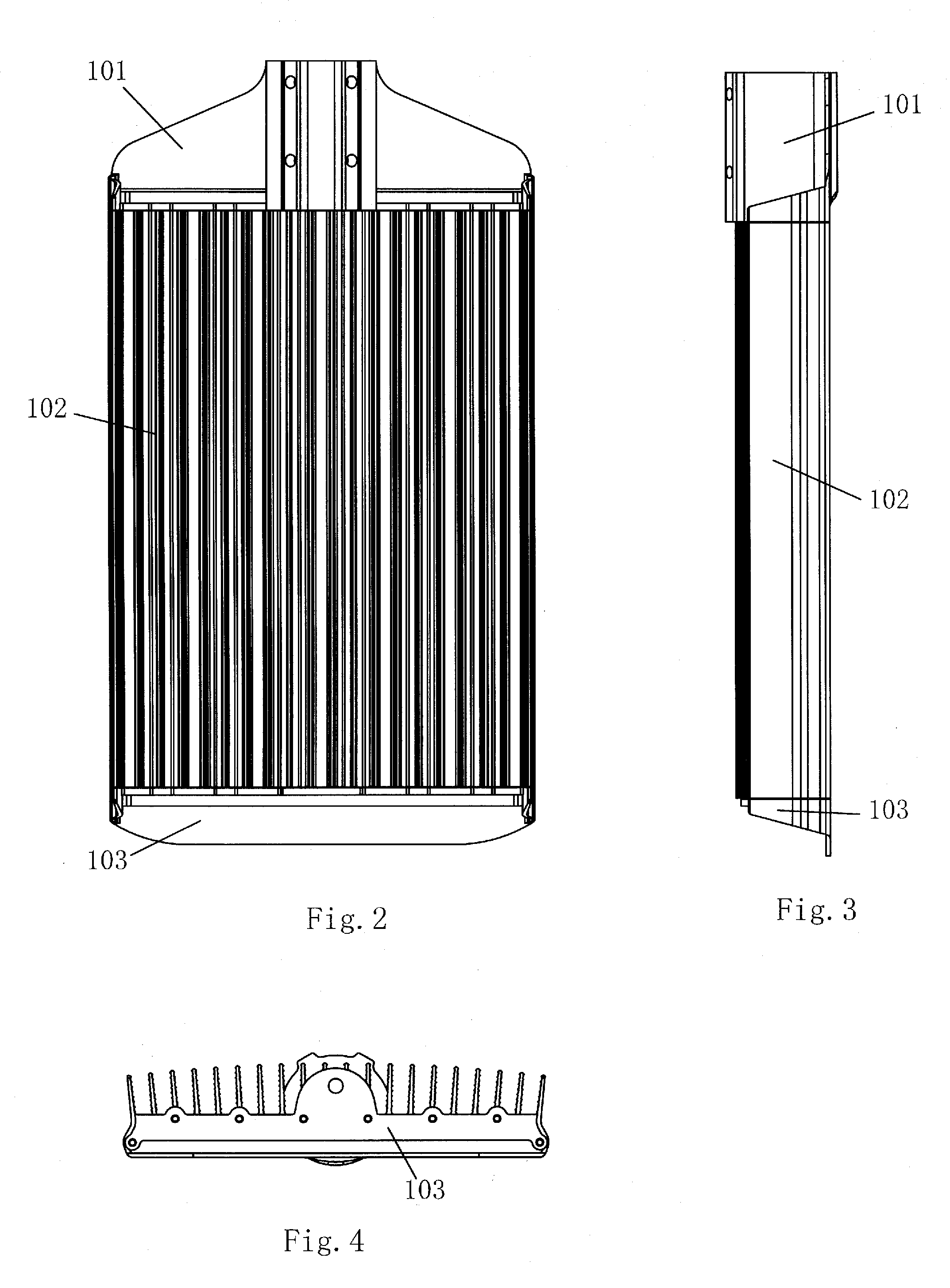

Energy-Saving LED Street Lamp and Method for Saving Energy with the Same

InactiveUS20090046460A1Save energyImprove controllabilityPlanar light sourcesPoint-like light sourceEnergy controlComputer module

The present invention provides an energy-saving LED street lamp and a method of saving energy with said LED street lamp. A energy-saving LED street lamp comprises lamp body, power supply adapters, constant current actuating device, and LED lamps. said constant current actuating device is connected in series with the output end of the Power supply adapter, supplying power to said LED lamps. Said energy-saving lamp also comprises auto light-dimmer energy-saving controller; the signal output end of said auto light-dimmer energy-saving controller being connected with constant current actuating device. Said LED lamps compose a plurality of working module; each of the said working module is connected with an independent Power supply adapter. Said auto light-dimmer energy-saving controller has a plurality of routes of output signal, and each of the route of signal output end is connected with a constant current actuating device, and sequentially control the lighten and extinguish time of a working module. A method of saving energy with said LED street lamp is published, too. The working time each day of LED street lamp is divided into a plurality of working time period on the basis of the measure of light used, and then different quantities of working modules are turned on in different time period controlled by the auto light-dimmer energy-saving controller on the basis of the measure of light used.

Owner:LI XULIANG

Method for preparing environment-friendly high-modulus glass fiber

The invention relates to an environment-friendly high-modulus glass fiber composition, and discloses a glass component combination used for preparing the high-modulus glass fiber. The glass fiber prepared by glass components is particularly applied to preparing glass fiber reinforced plastic composite material with higher rigidity requirement. The glass composition has no emission of harmful gas, greatly reduces the emission of greenhouse gas, and is an environment-friendly glass fiber formula. The environment-friendly high-modulus glass fiber composition is characterized in that: a blast furnace slag preferably serves as one of major raw materials for reducing the operational difficulty and prepares the high-modulus glass fiber, and the high-modulus glass fiber can be produced and wiredrawn on a tank furnace having an electro-boost structure on a large scale by adopting a direct method. The fiber mainly comprises the following main components: 57 to 62.5 weight percent of SiO2, 14.5 to 19.5 weight percent of Al2O3, 16 to 23.5 weight percent of RO (wherein RO is the sum of CaO, MgO, SrO and BaO), and less than and equal to 1.5 percent of alkali metal oxide. The glass composition and the adopted raw material mode are suitable for the mass production under the production technological condition of the electro-boost tank furnace, and the glass composition has low production cost.

Owner:TAISHAN FIBERGLASS INC

Production of di-(2-ethylhexyl) terephthalate

ActiveUS20070038001A1Speed up the conversion processSpeed up reactionPreparation from carboxylic acid halidesOrganic compound preparationHigh pressurePhotochemistry

Disclosed is a process for the preparation of di-(2-ethylhexyl) terephthalate by the esterification of terephthalic acid with 2-ethylhexanol at elevated temperature and pressure while the water of reaction is removed from the reaction mixture.

Owner:EASTMAN CHEM CO

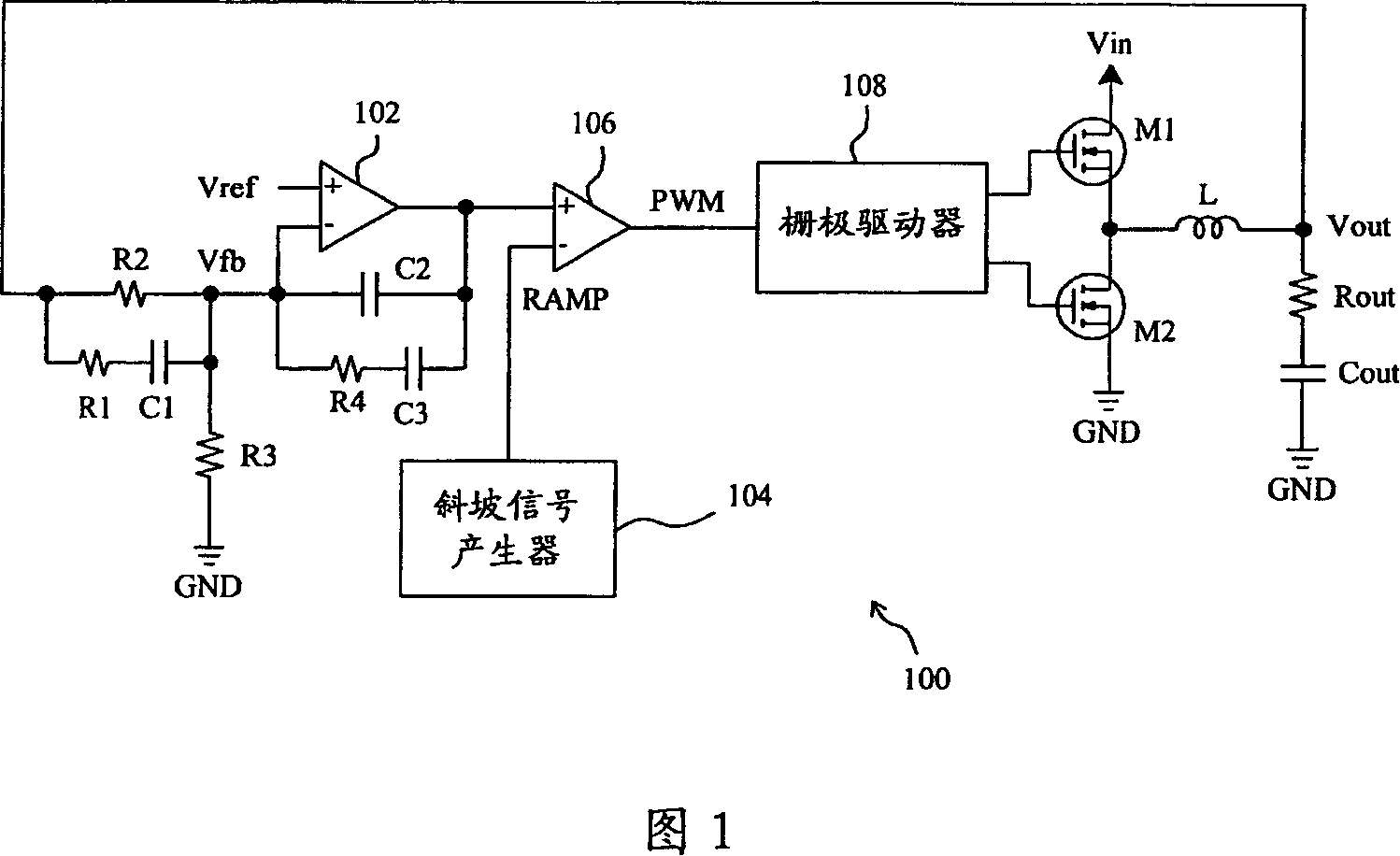

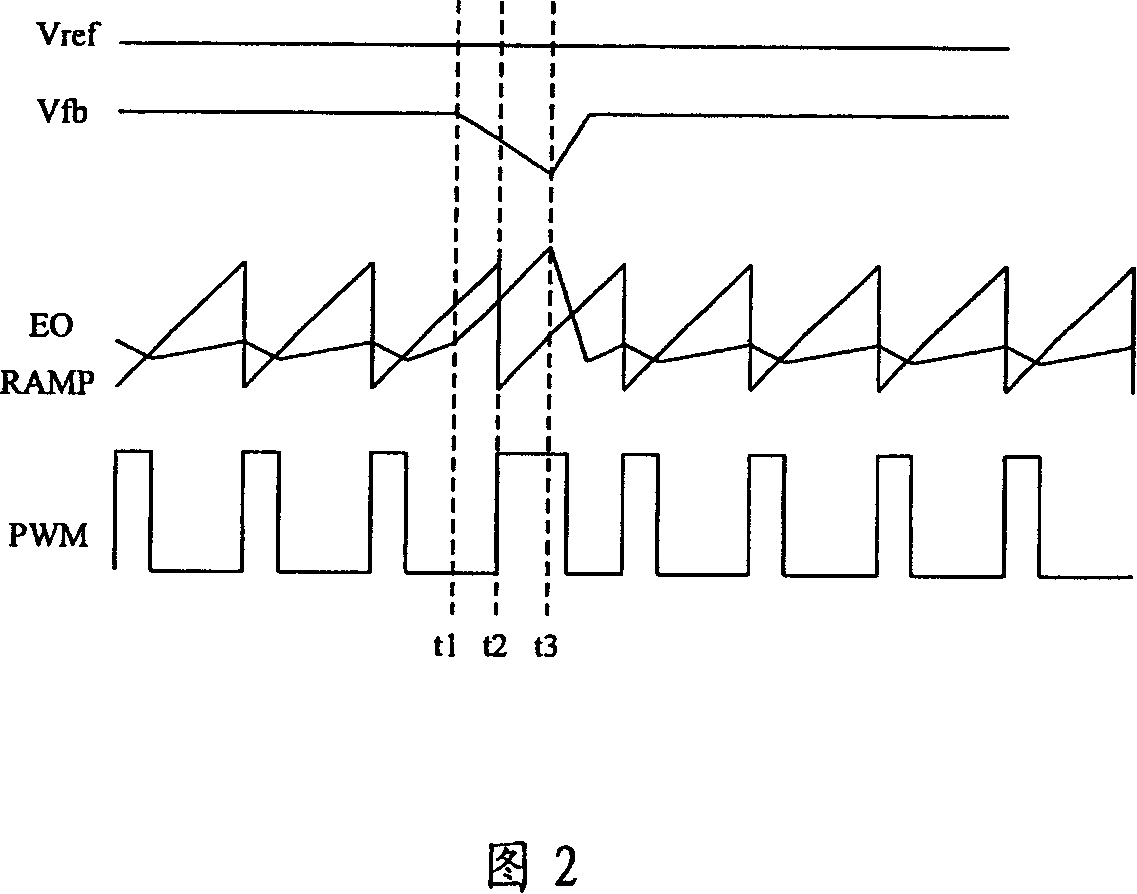

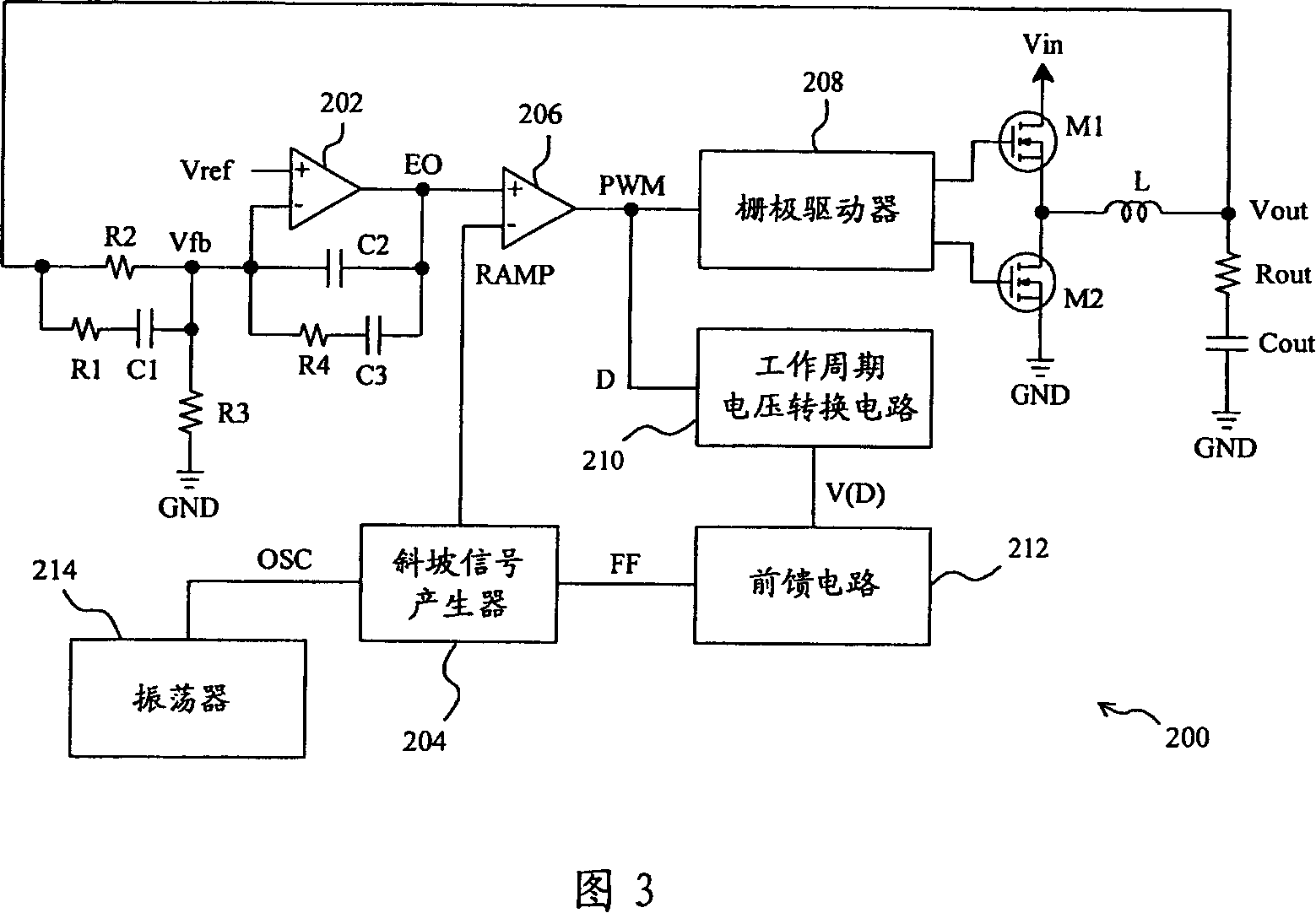

Method and device for generating impulse bandwidth modulation signals and its application

ActiveCN101150281AImprove stabilitySpeed up reactionPower conversion systemsEngineeringPulse-width modulation

This invention relates to a method and a device for generating pulse width modulation signals, a supply converting method and a supply converter using the method and the device including comparing an error signal with an oscillation linear slope signal to generate a pulse width modulation signal, in which, said signal provides a piece of information of a working period to modulate the slope of the oscillation slope signal or the quasi-position of the error signal to further modulate the period of the work so as to improve stability of instant response of the supply converter and pulse width modulation loop.

Owner:RICHTEK TECH

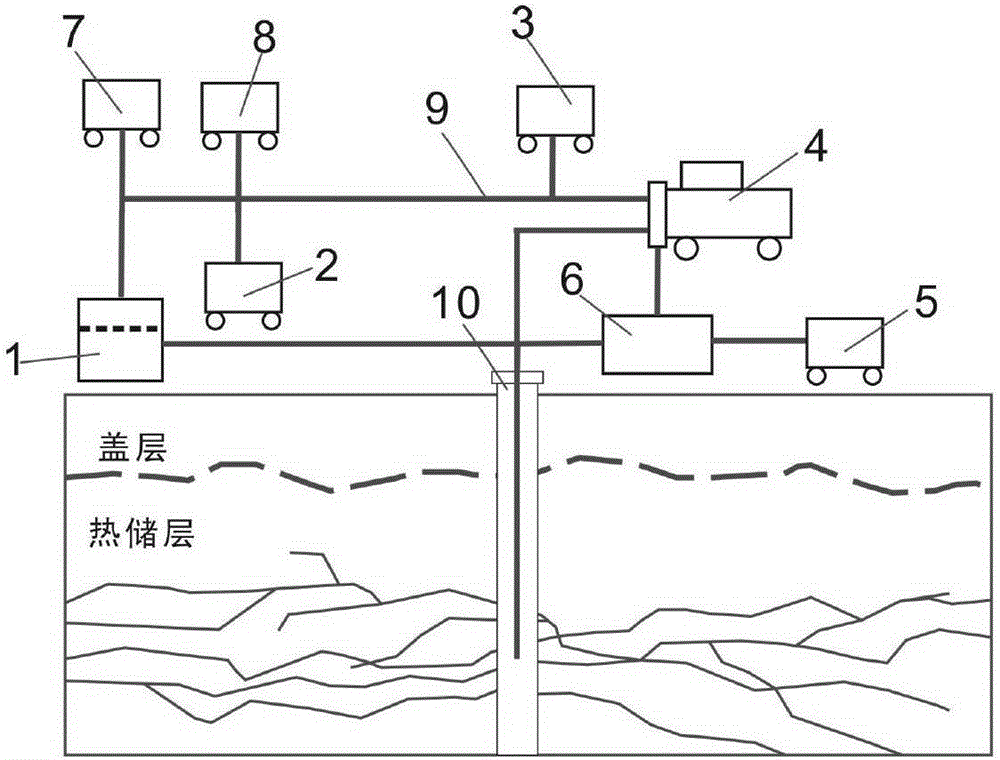

Thermal stimulation and chemical stimulation combined process of hot-dry-rock thermal reservoir

InactiveCN105332681AImprove diversion capacityEfficient removalCleaning apparatusFluid removalChemistryMicroseism

The invention relates to a novel modification system and process of a hot-dry-rock thermal reservoir, characterized by the combination of two stimulation measure processes, thermal stimulation and chemical stimulation. The process is characterized in that a naturally present fracture network is destructed by thermal stimulation to enhance permeability, partial minerals, scale and obstruction in shafts and fractures are dissolved by the chemical stimulation, and flow guiding capacity of the fractures is further improved. The repeating of the process enables a larger range of thermal reservoirs to be modified. By using the process, the problem of the prior art that after thermal stimulation, part of the fractures are closed along with the rise of the temperature of a cooling area and the problem that that a chemical stimulant disappears nearby an injection location during its excess speed of reacting with rock minerals at high temperature are solved, and the process enables greatly reduction in the risk of frequent microseism in a reservoir modification process when compared to traditional hydrofracturing. The process is widely applicable to the modification of hot-dry-rock thermal reservoirs.

Owner:JILIN UNIV +1

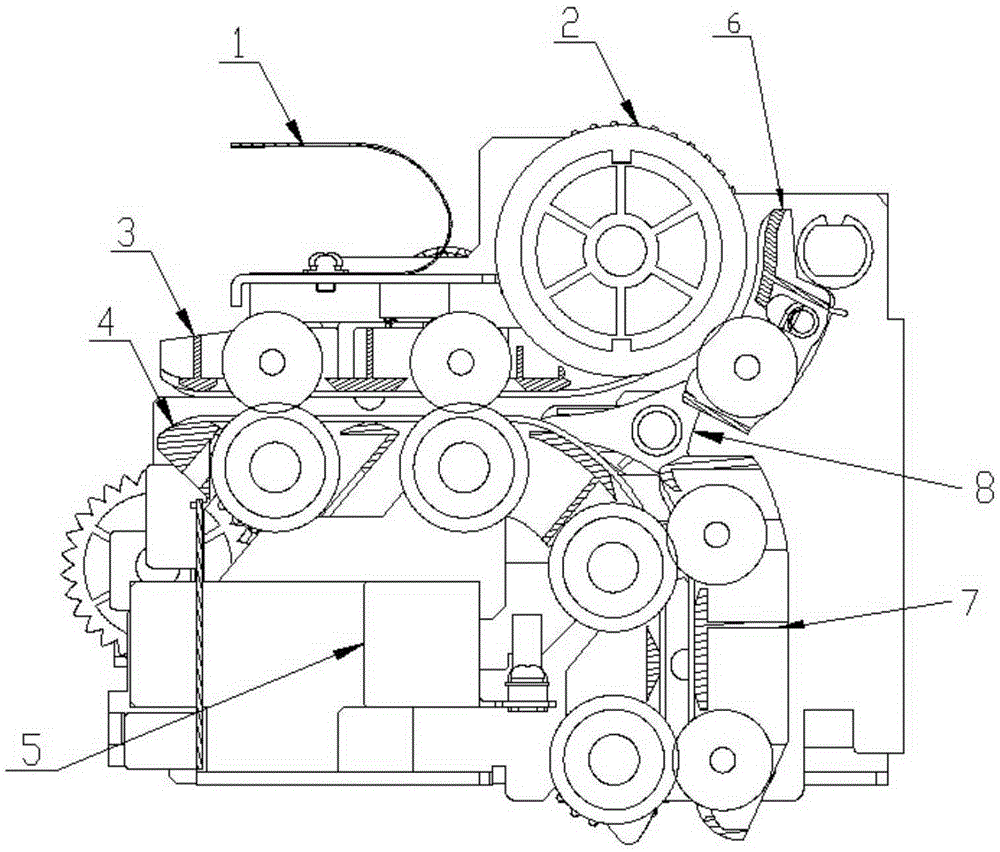

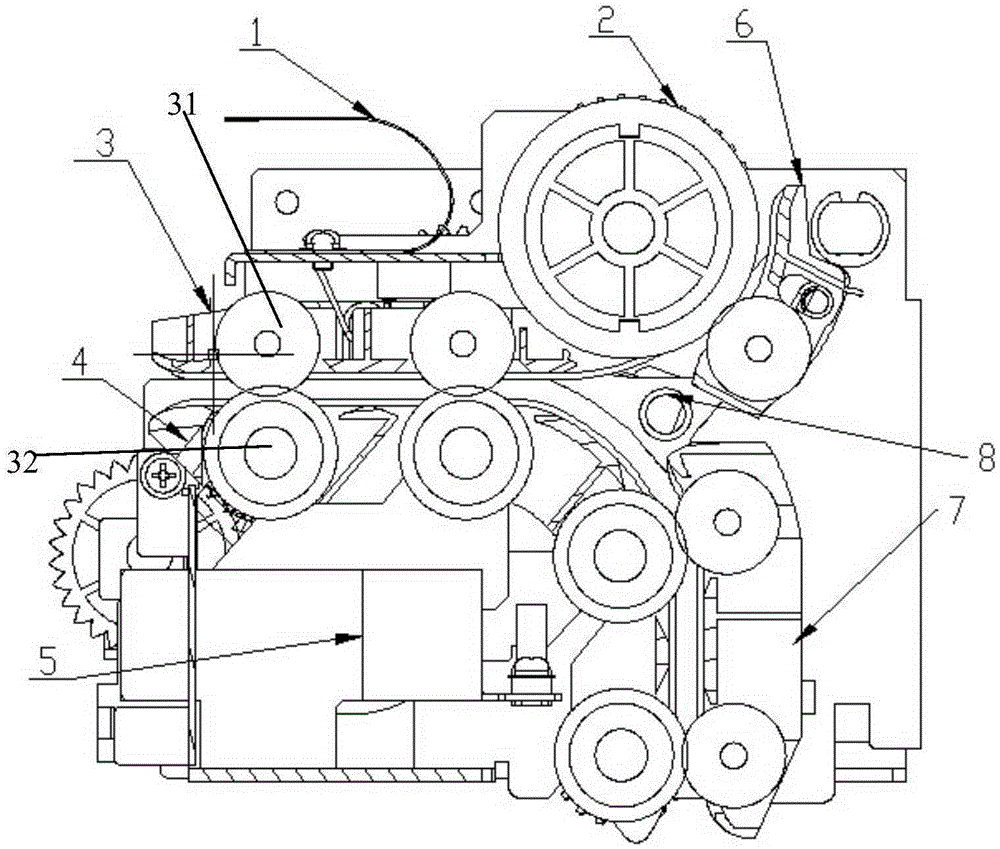

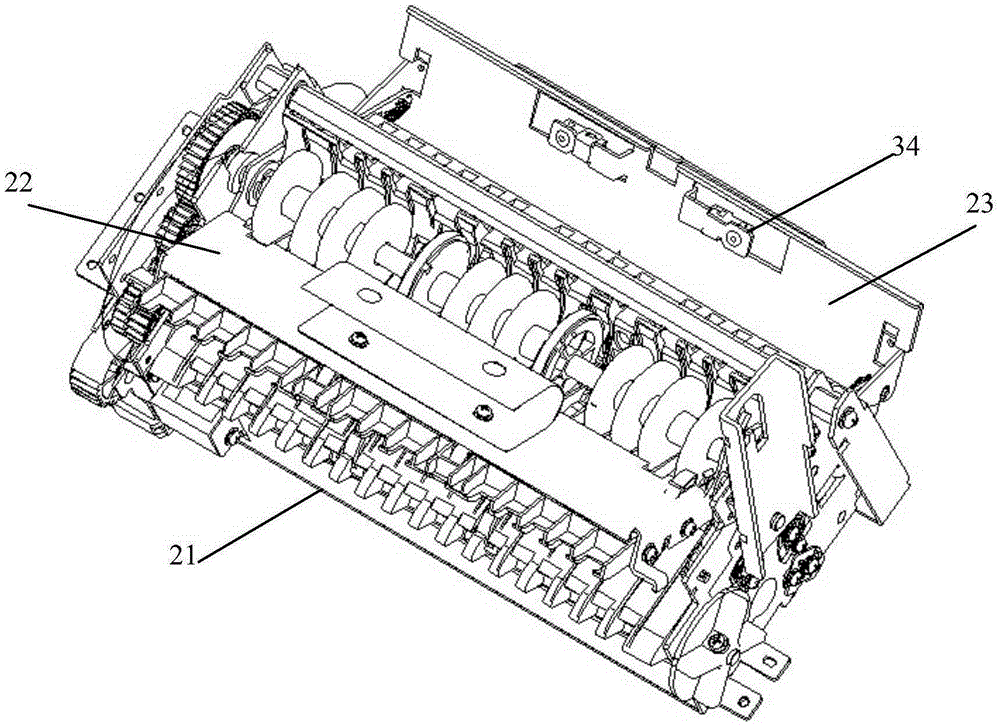

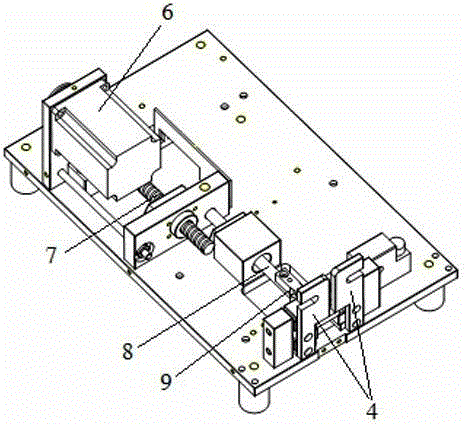

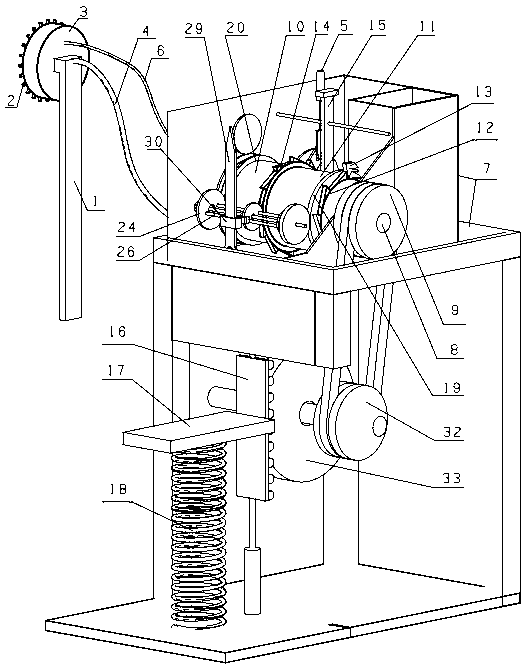

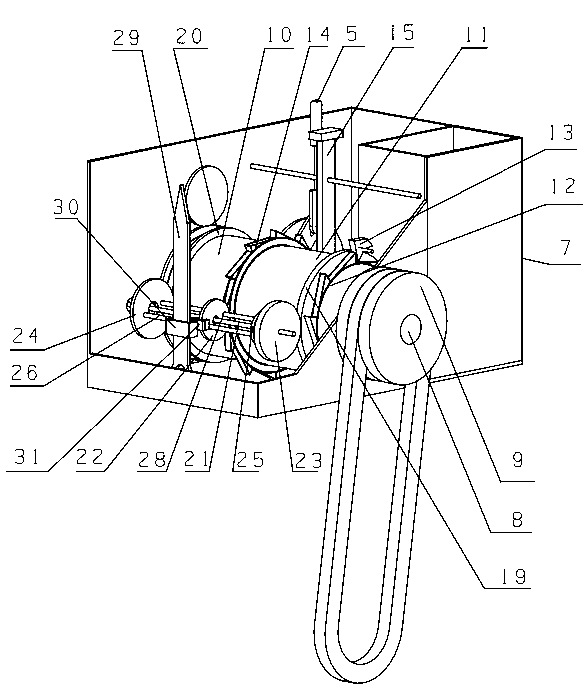

Reversible transmission device of paper currency

InactiveCN105405206AAchieving Velocity ConsistencySpeed up reactionCoin/currency accepting devicesDrive wheelTransmitted power

The invention discloses a reversible transmission device of paper currency. The transmission device comprises a framework, a herringbone transmission channel formed by a channel board, and a commutator which is arranged in the transmission channel and used for switching paths of the paper currency. A pair of driving wheels and a pair of floating wheels are arranged on the transmission channel and used for clamping and transmitting the paper currency. The driving wheels are in driving connection with each other and with an external module. According to the invention, manufacturing and control cost is reduced; consistency in speed of power wheels of all module pieces can be well achieved in a mechanical manner, e.g., gears are used for transmitting power; the whole transmission device transmits power via the gears; the whole transmission device is compact in structure, so the whole size is reduced; and the transmission speed responses at a quite fast speed, so paper currency detection and returning can be achieved.

Owner:CASHWAY FINTECH CO LTD

Method for improving zinc powder activity with ultrasonic, device and application thereof

InactiveCN101274262AFresh active surfaceEfficient removalEnergy based chemical/physical/physico-chemical processesUltrasonic cavitationUltrasound - action

The invention provides a method for improving the activity of zinc powders with supersonic and a devide as well as applications thereof, wherein, the method leads the zinc powder to always keep fresh and active surface under solution environment condition that the zinc powder is taken as reducing agent, the alkali-typed zinc salt passivation film on the surface of the zinc powder can be removed by the supersonic. The supersonic has the frequency of 15-60 kHz and the sound intensity of 1-1000w / cm2; the ultrasonic cavitation reaction time on the zinc powder is 1-45 minutes. Under the effect of supersonic, common ZnSO4 solution containing 100mg / L of cobalt can reduce the cobalt content to 0.8mg / L within 30 minutes. The device provided by the method of the invention improves the zinc powder activativity with the supersonic and comprises at least a reaction chamber where ZnSO4 solution is fully filled; at least a supersonic emitter and at least one mixing device are dipped and arranged in the reaction chamber. The applications of the method at least comprise a technique of cobalt removal with antimony salt and a technique of cobalt removal with antimony trioxide.

Owner:XINGMIN TECH ZHUZHOU

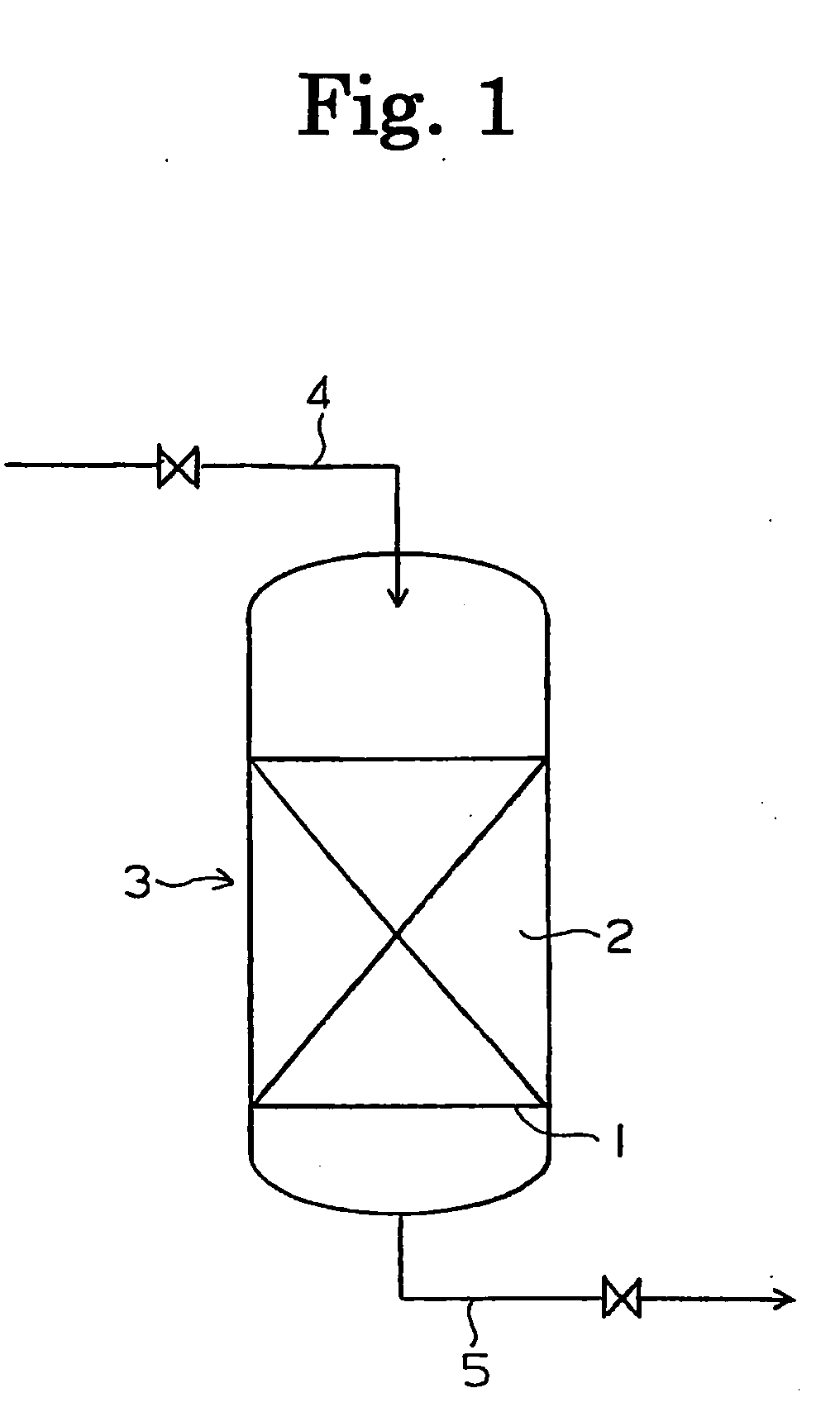

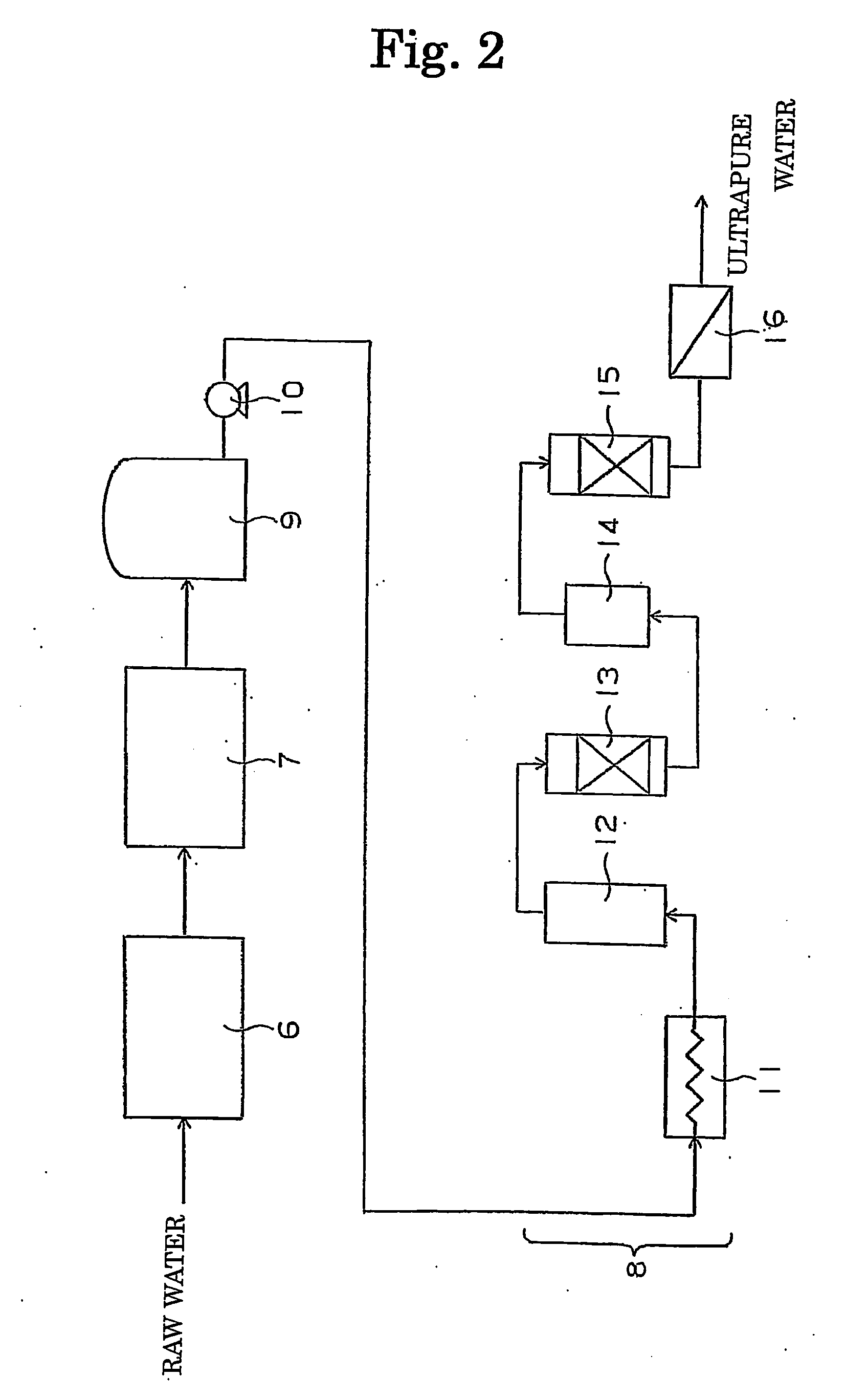

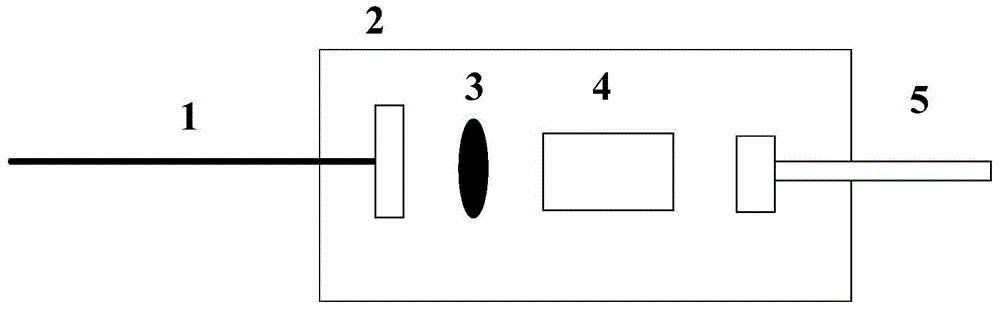

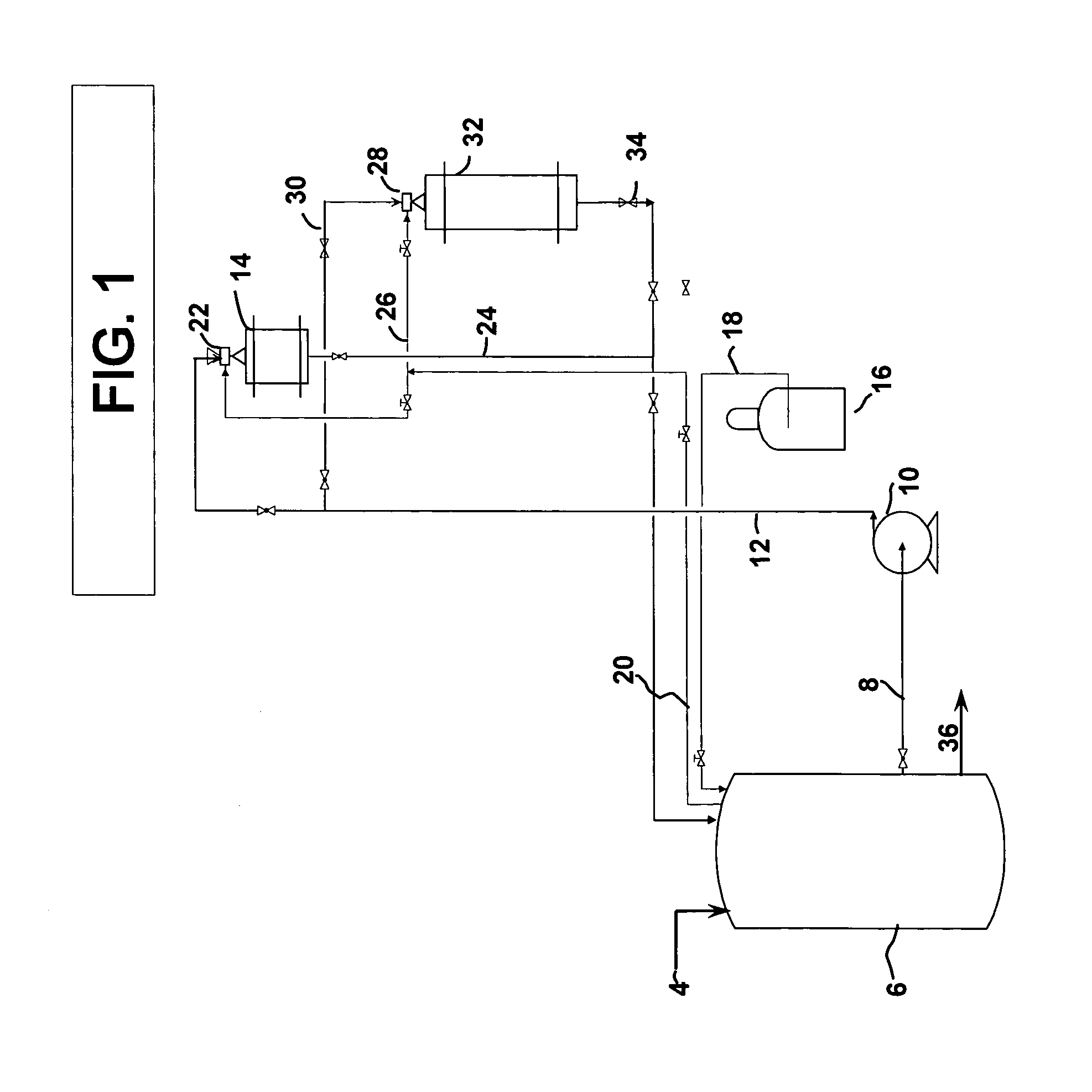

Process and Apparatus for Removing Hydrogen Peroxide

InactiveUS20090127201A1Rapidly and surely removeSpeed up reactionMaterial nanotechnologyLiquid degasificationChemistryNanometre

A process for removing hydrogen peroxide in water which comprises bringing water for treatment containing hydrogen peroxide into contact with a catalyst for decomposing hydrogen peroxide obtained by depositing nano-colloid particles of a metal of a platinum group which have an average diameter of 1 to 50 nm to be supported on a support; and an apparatus for removing hydrogen peroxide which comprises an apparatus for decomposing hydrogen peroxide packed with a catalyst obtained by depositing nano-colloid particles of a metal of a platinum group which have an average diameter of 1 to 50 nm to be supported on a support, a means for supplying water which supplies water for treatment containing hydrogen peroxide to the apparatus and a means for discharging water which discharges the water from the apparatus after being brought into contact with the catalyst. Hydrogen peroxide in water for treatment can be removed rapidly and surely. The process and the apparatus are suitable for removing hydrogen peroxide in ultrapure water in an apparatus for producing ultrapure water used in industries handling electronic materials such as semiconductors and liquid crystals.

Owner:KURITA WATER INDUSTRIES LTD

Hydrogenation of acetone

ActiveUS7041857B1Promote conversionSpeed up reactionOrganic compound preparationBeer fermentationHydrogenMetal catalyst

This invention relates to an improvement in a liquid phase process for producing isopropanol by the hydrogenation of acetone in the presence of a hydrogenation catalyst; the improvement comprising;contacting acetone with hydrogen under continuous liquid phase conditions; and,employing a sponge metal catalyst promoted with an effective amount of chromium.

Owner:TAMINCO NV

Process for preparing N-(hydrocarbyl) phosphoric or thiophosphoric triamides

The invention provides a process for preparing N-(hydrocarbyl)phosphoric or thiophosphoric triamides with substantially improved yields and purity. Two equivalents of hydrocarbylamine are used in the reaction with phosphoryl or thiophosphoryl chloride and then with ammonia in an aromatic solvent. The invention further relates to N-(hydrocarbyl)phosphopric or thiophosphoric triamides having the purity of at least 98% wherein R is a hydrocarbyl group and X is O or S.(RNH)(NH2)2P=X (I).

Owner:AGRA GROUP AS

Process for preparing n-(hydrocarbyl) phosphoric or thiophosphoric triamides

ActiveUS20110196172A1Easily filter offEasy to separatePhosphorus organic compoundsAromatic solventsMedicinal chemistry

The invention provides a process for preparing N-(hydrocarbyl)phosphoric or thiophosphoric triamides with substantially improved yields and purity. Two equivalents of hydrocarbylamine are used in the reaction with phosphoryl or thiophosphoryl chloride and then with ammonia in an aromatic solvent. The invention further relates to N-(hydrocarbyl)phosphopric or thiophosphoric triamides having the purity of at least 98% wherein R is a hydrocarbyl group and X is O or S.(RNH)(NH2)2P=X (I)

Owner:AGRA GROUP AS

Floride-free low-boron and alkaline-free glass fiber prescription and preparation method

The invention relates to a glass fiber production prescription, in particular to an environment-friendly alkaline-free glass fiber prescription emitting less toxic gas. The prescription is characterized in that the components include SiO2, Al2O3, B2O3, CaO, MgO, K2O and Na2O2. Compared with the E glass fiber widely applied presently, the glass fiber prepared with the prescription of the invention is improved as follows: the raw material containing floride which is most harmful is completely abandoned and the raw material containing volatile boron is largely reduced, but the glass fiber of the invention still remains similar electric performance and mechanical performance. The invention is characterized in that an alkaline-free glass fiber using blast furnace slag as one of the main raw materials, realizing reduction of operation difficulty and great reduction of exhaust emission is preferential and can be produced directly in large scale in a tank furnace including an electric boosting structure. The use of an industrial raw material easy for melting and clearing, namely, the blast furnace slag, ensures the glass fiber to have similar operating performance as the E glass fiber and to adapt to large-scale production under the existing E glass fiber tank furnace production technology.

Owner:TAISHAN FIBERGLASS INC

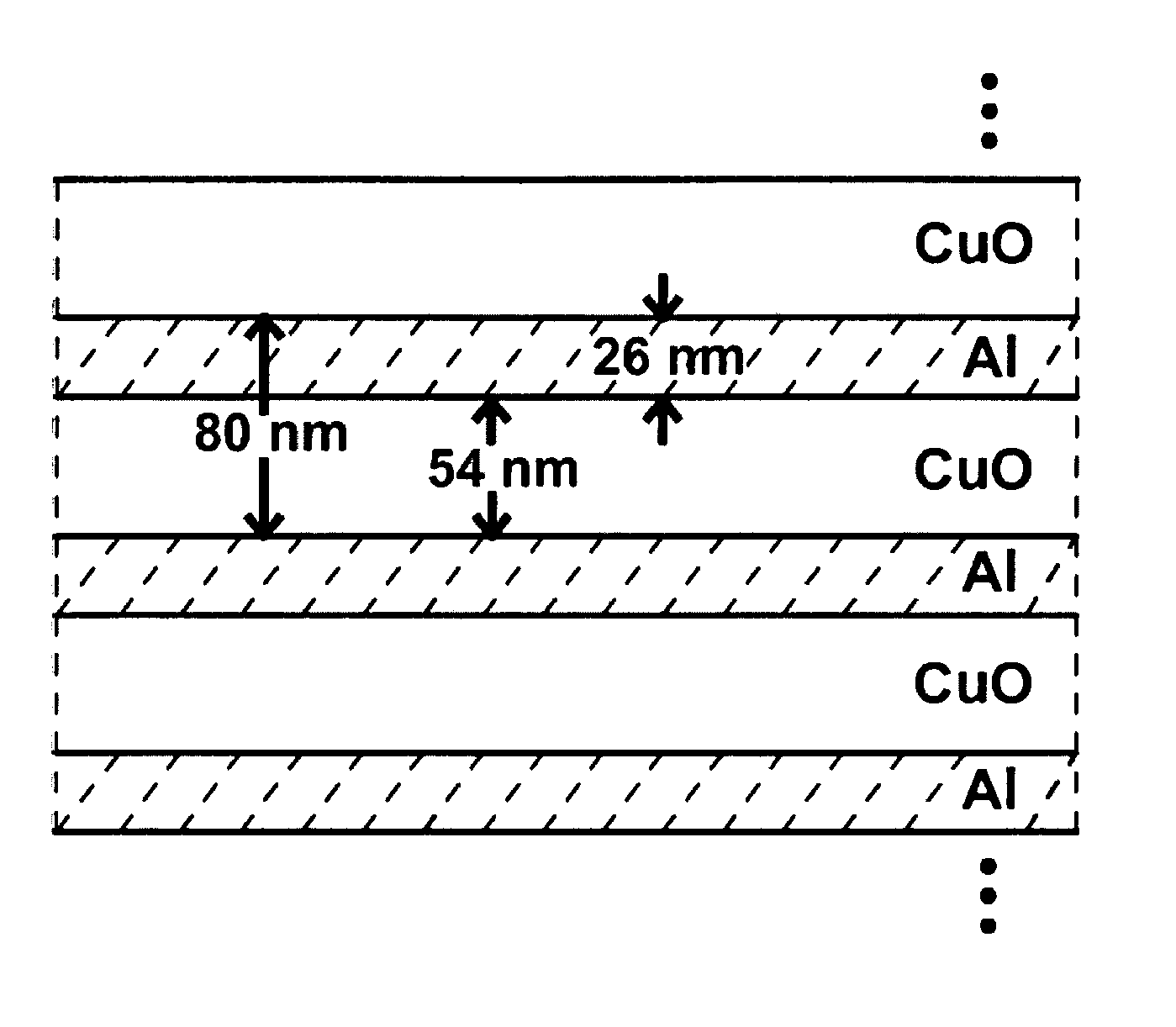

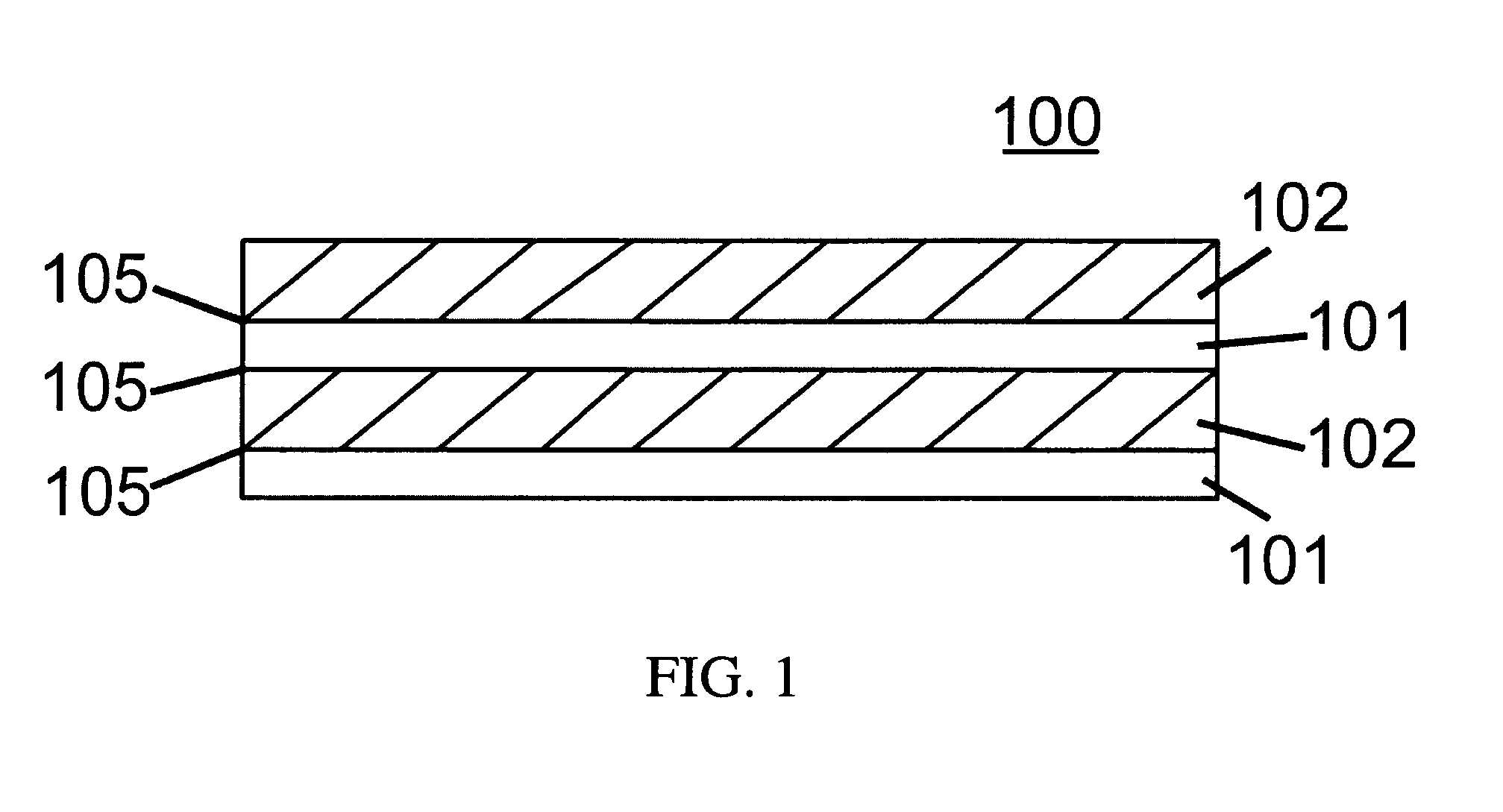

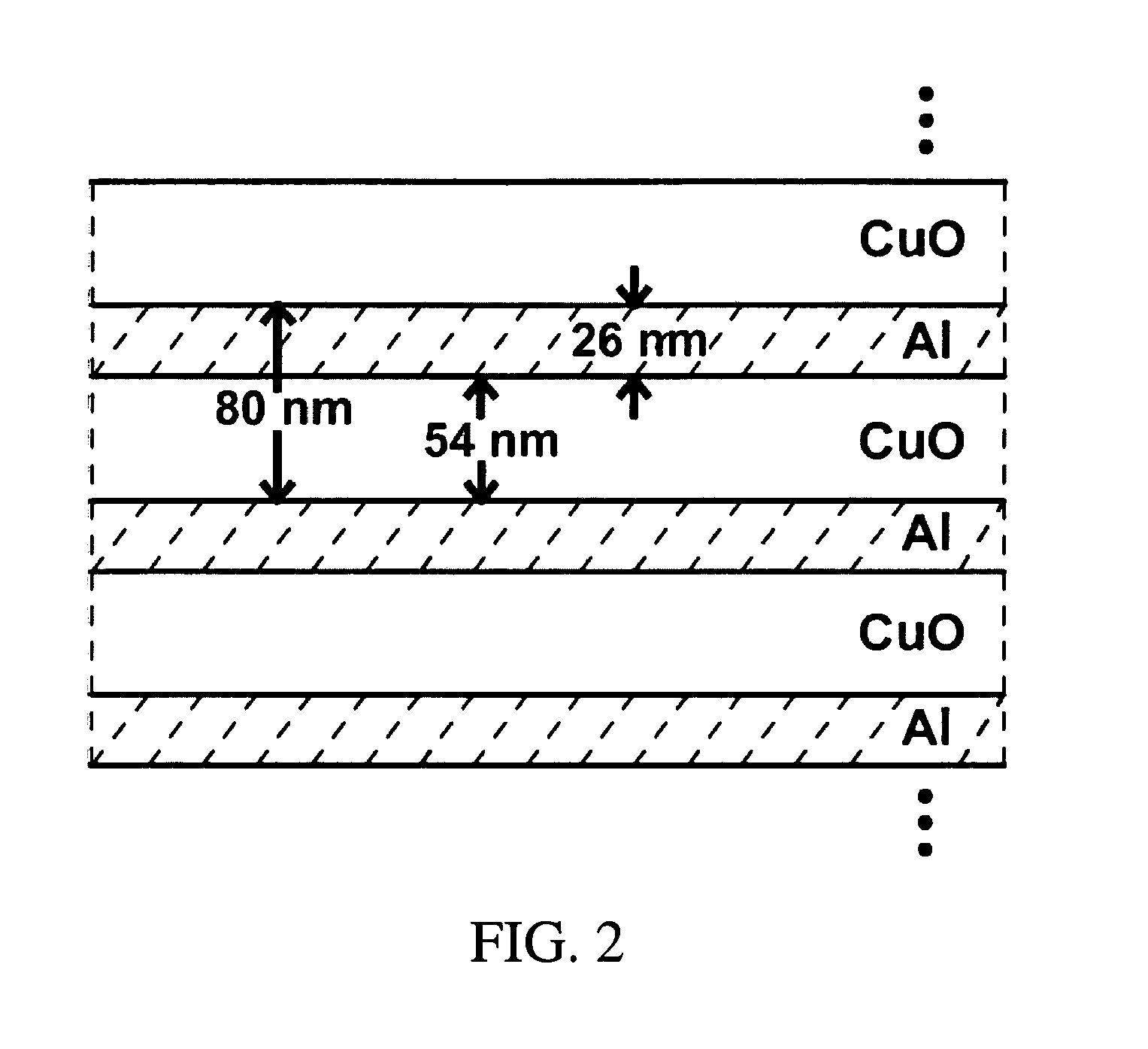

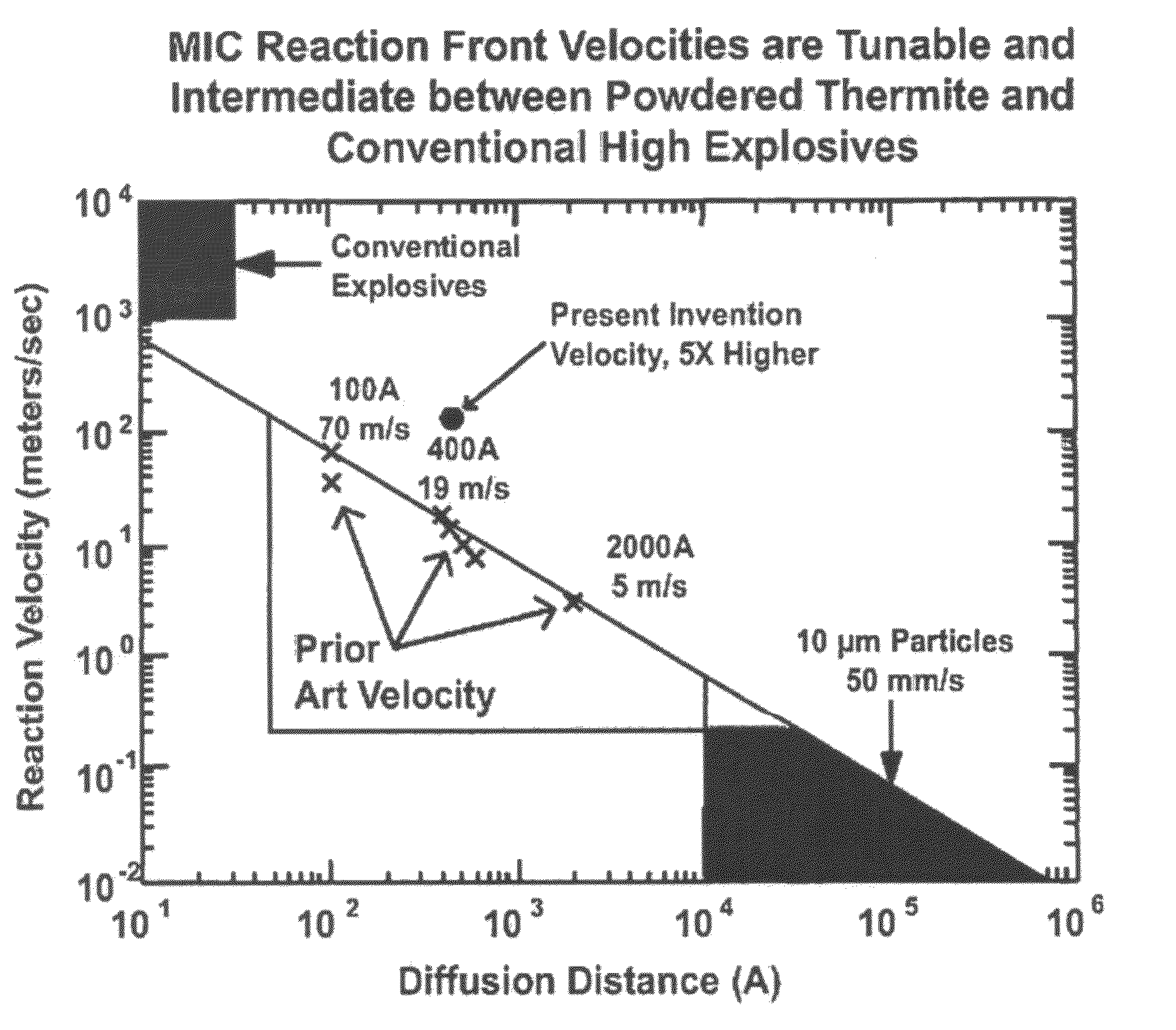

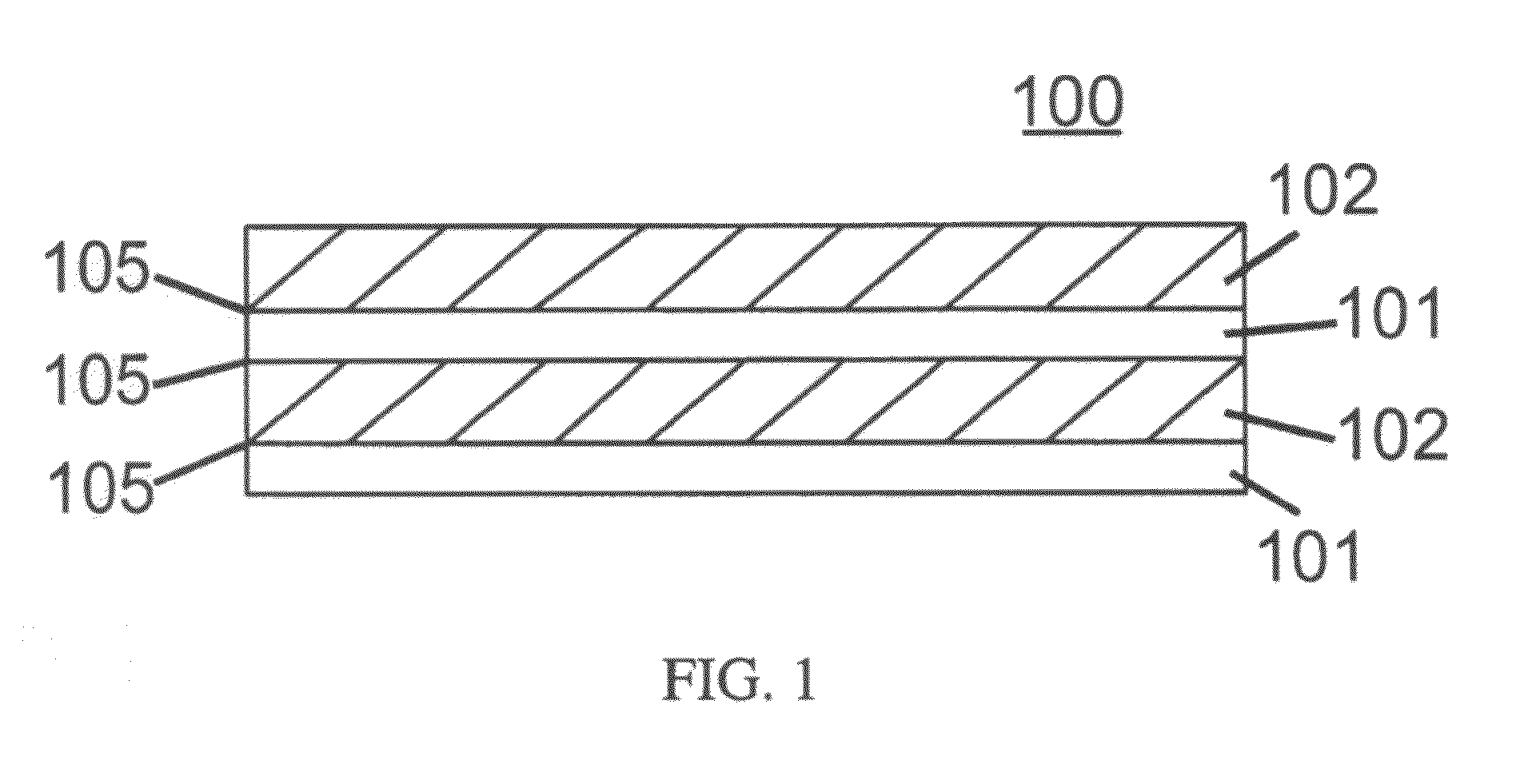

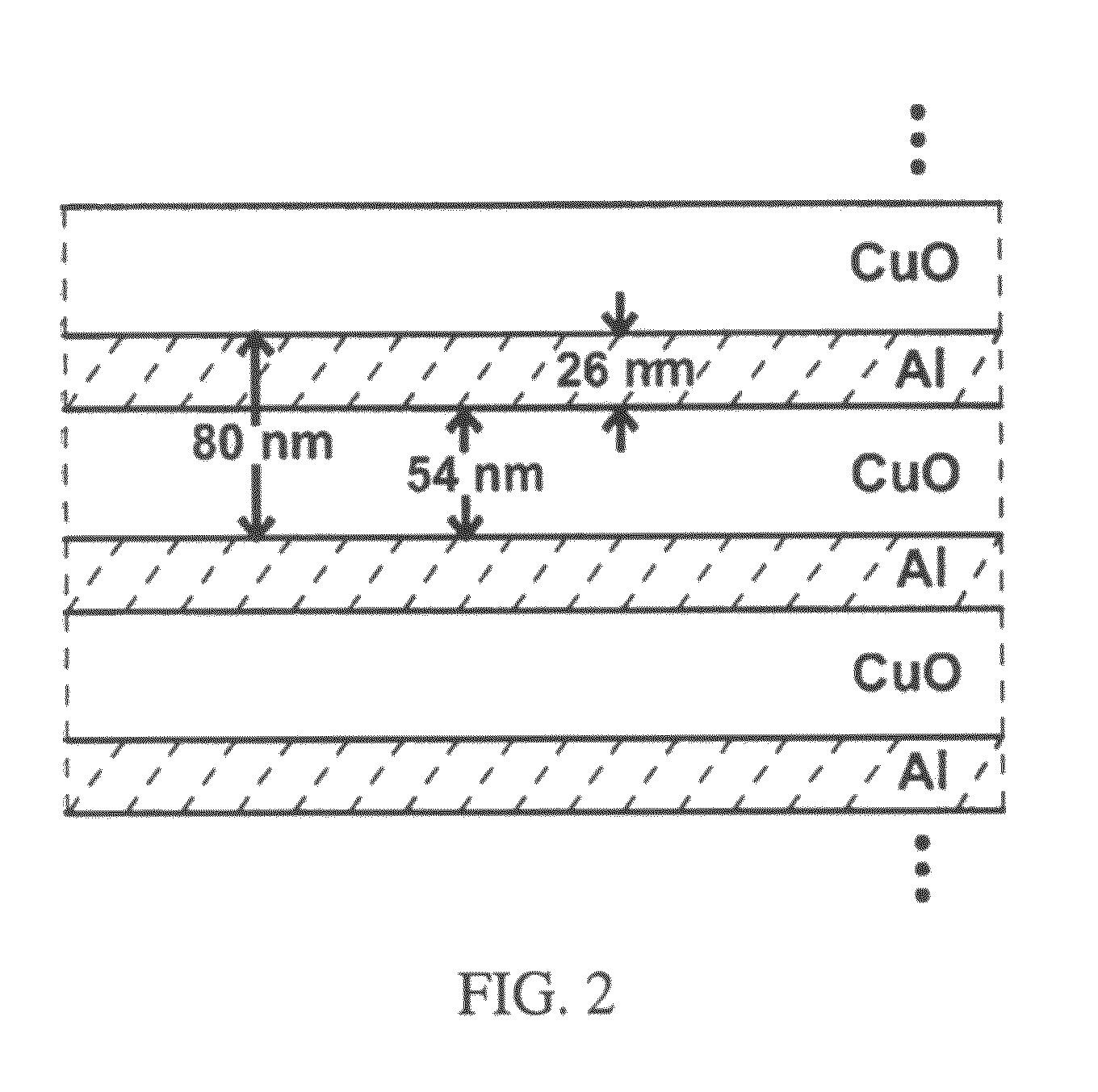

Ignitable heterogeneous structures and methods for forming

A metastable intermolecular composite (MIC) and methods for forming the same includes a first material and a second material having an interfacial region therebetween. The first and second material are capable of an exothermic chemical reaction with one another to form at least one product and are in sufficiently close physical proximity to one another so that upon initiation the exothermic reaction develops into a self initiating reaction. At least one of said first and second materials include a metal that is reactive with water vapor at room temperature. The interfacial region averages <2 nm thick, such as <1 nm thick. In one embodiment, the first material is Al and the second material is CuOx.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

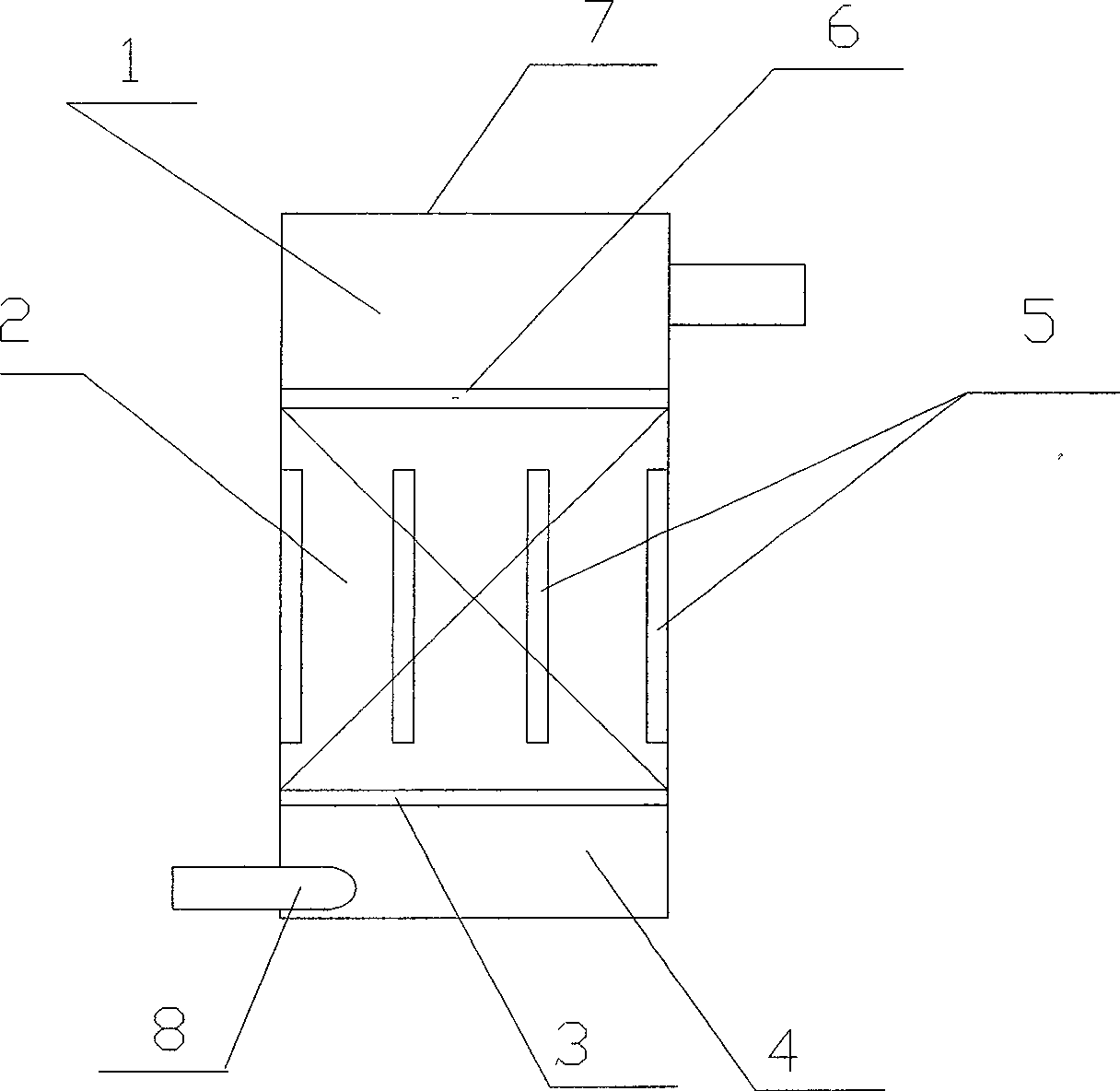

Photocatalysis oxidation water purification tank

InactiveCN101468845AHigh activityImprove the degree of purificationWater/sewage treatment by irradiationWater treatment compoundsVena contracta diameterFluidized bed

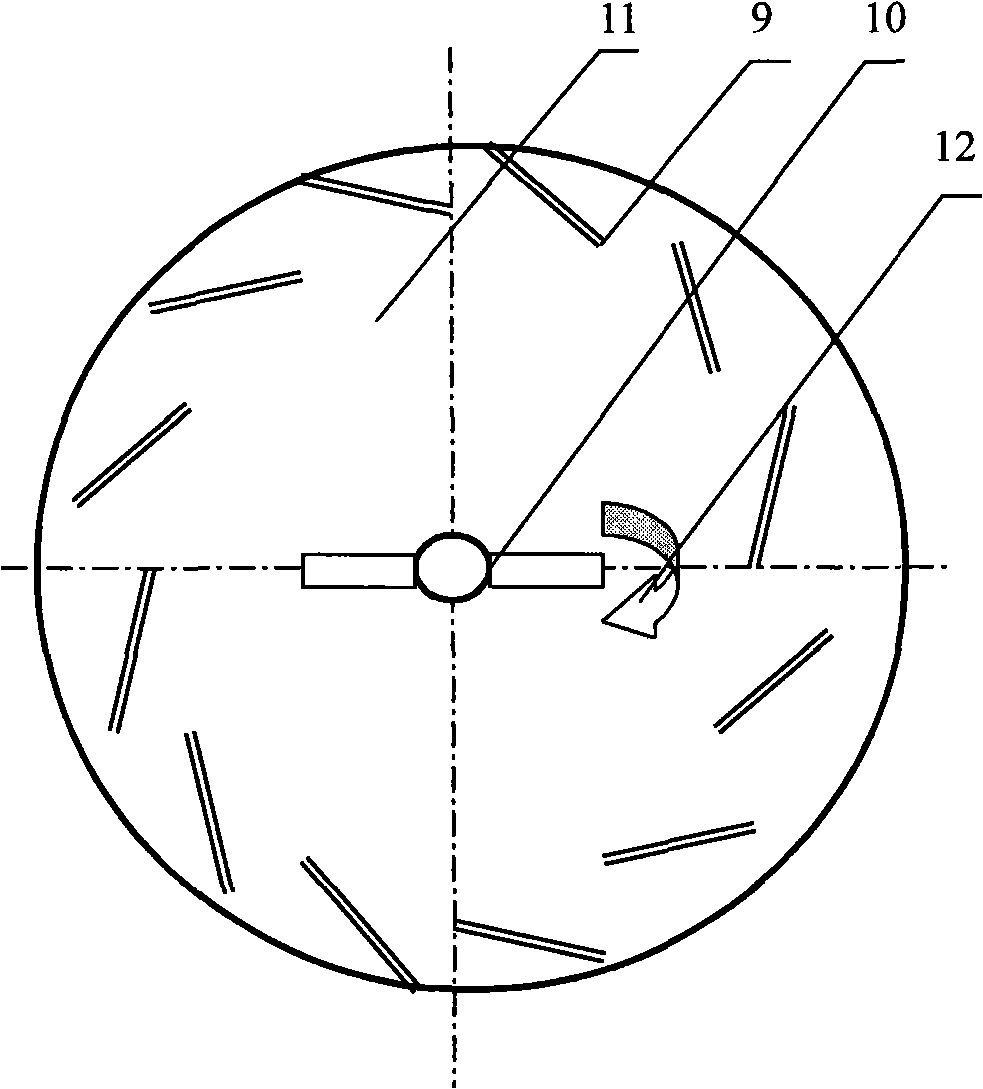

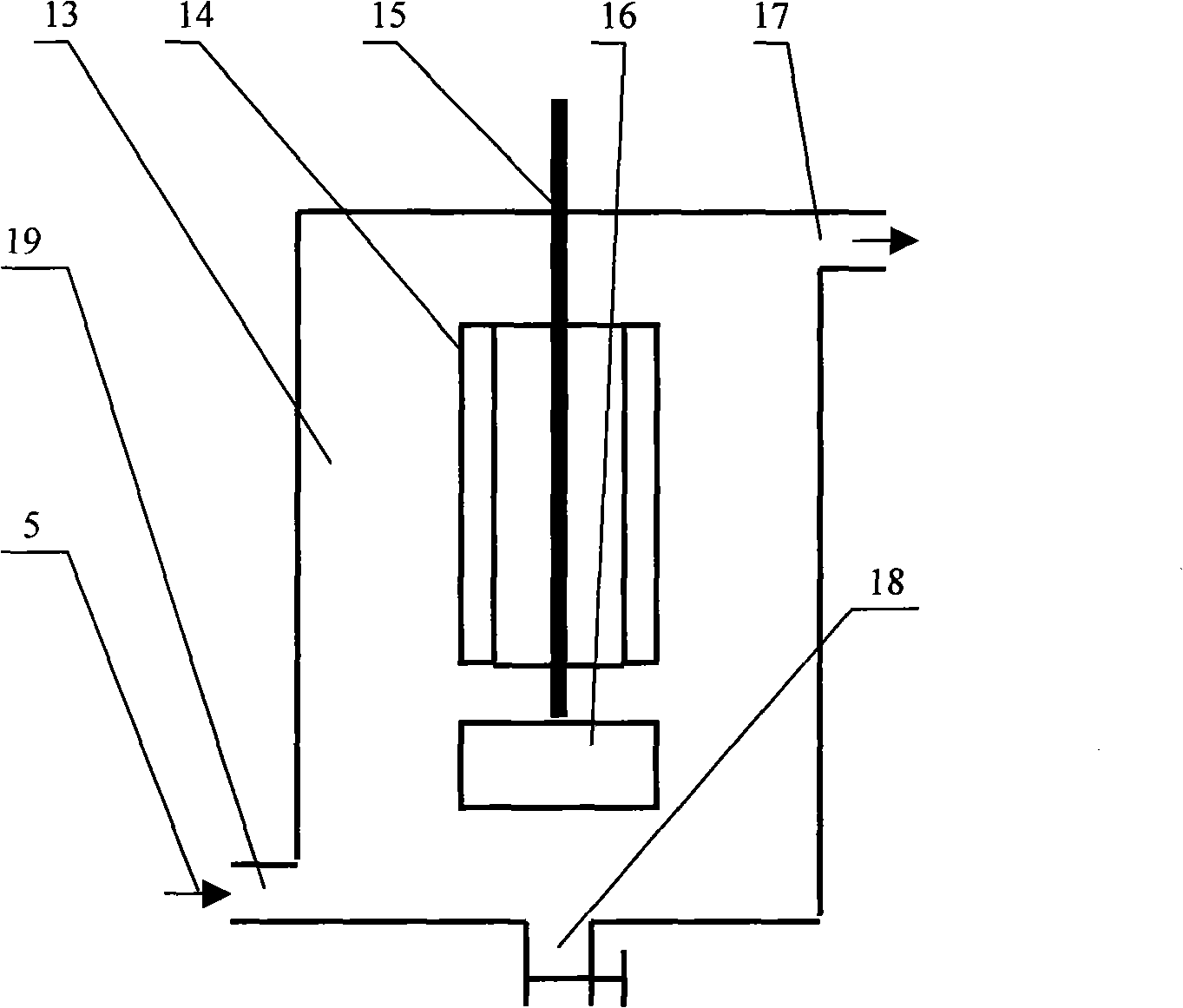

The invention relates to a photocatalytic oxidation and purification tank. The photocatalytic oxidation and purification tank is provided with an upper transverse clapboard and a lower transverse clapboard to divide a space of the tank into a middle part, an upper part and a lower part; the upper clapboard and the lower clapboard are orifice plates, wherein the upper clapboard is a small orifice plate; the lower clapboard is a large orifice plate; the middle part of the space in a tank body is a fluidized bed chamber; the lower part is a mixed chamber; the upper part is a steady flow chamber; the fluidized bed treatment chamber is provided with a plurality of ultraviolet lamps; the inside of each ultraviolet lamp is filled with photocatalyst particles; the surfaces of the photocatalyst particles are distributed with photocatalyst; a water inlet pipe of the purification tank is connected with the mixing chamber; the extending direction of the water inlet pipe is oblique or tangential; a water outlet pipe of the purification tank is connected with the steady flow chamber; the extending direction of the water outlet pipe is radial; and the tank body is also provided with an ozone inlet pipe which can be independently mounted or can adopt the same pipe with the water inlet pipe. The device has high purification degree, relatively large treatment amount and relatively lower treatment cost and is mainly suitable for occasion with higher requirement on purification degree of outlet water.

Owner:BEIJING JINAOHUARONG TECH

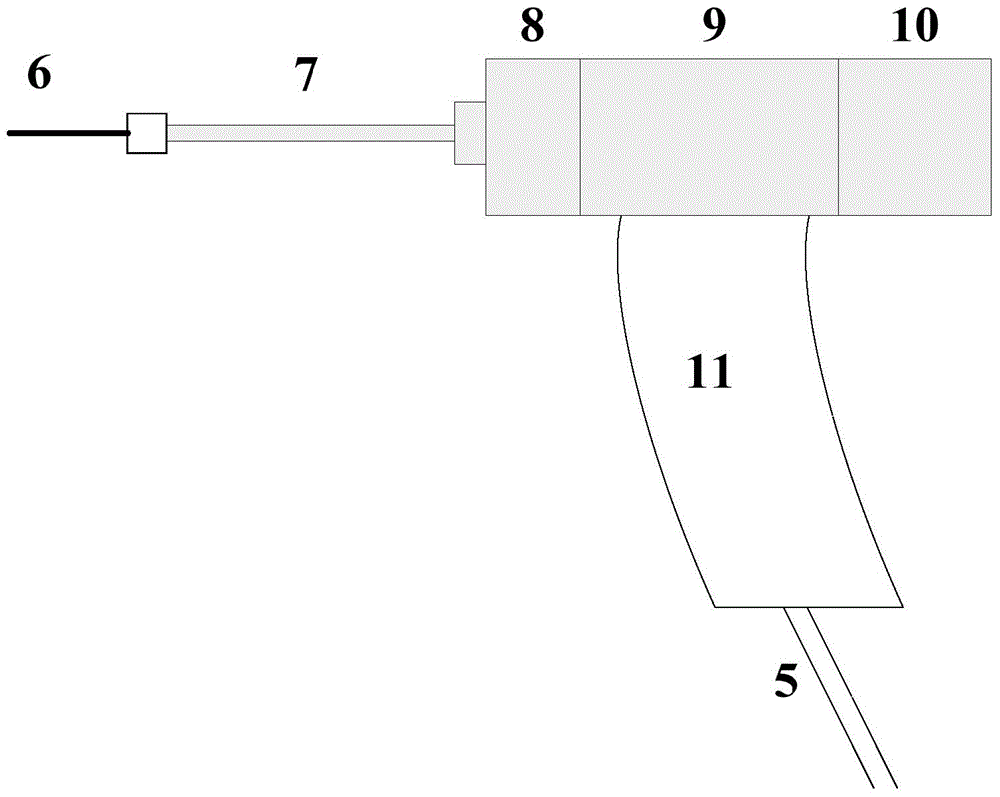

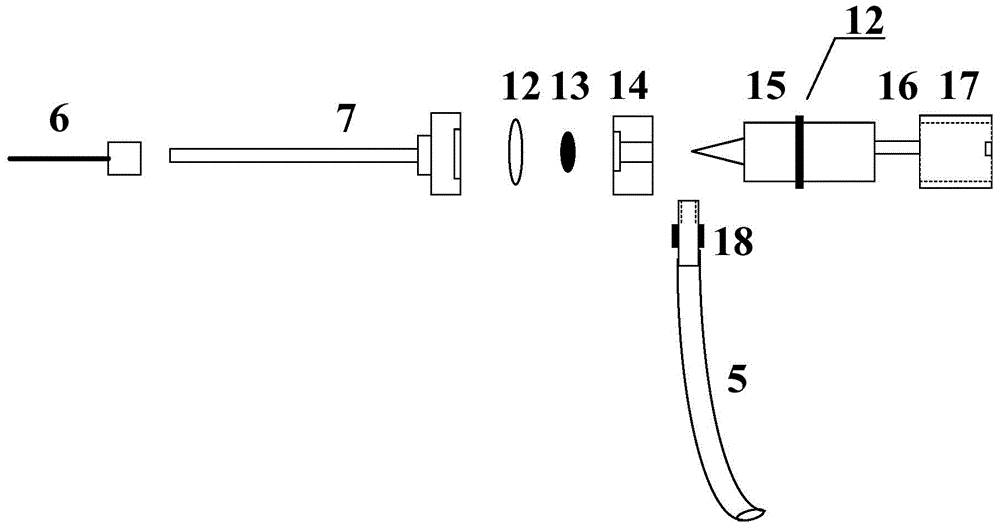

Helium mass spectrometer leak detector suction gun for spacecraft leak detection

InactiveCN103604568ASpeed up reactionImprove leak detection efficiencyDetection of fluid at leakage pointEngineeringSpacecraft

The invention discloses a helium mass spectrometer leak detector suction gun for spacecraft leak detection. The helium mass spectrometer leak detector suction gun comprises an external structure and an internal structure. The external structure comprises a medical needle, a suction gun rod, a front cavity chamber, a middle cavity chamber, a rear cavity chamber, a suction gun handle and a flexible pipe which are mechanically connected and arranged in turn. The suction gun handle is arranged below the three cavity chambers. The flexible pipe is arranged on the lower end of the handle and used for being connected with a leak detector. The internal structure comprises sealing rubber rings, a filtering sheet, a cylinder with a hole and a conical head, a connecting rod and a pressure regulating column which are arranged in turn. The rear end of the suction gun rod and an air outlet end of the front cavity chamber are respectively provided with the sealing rubber rings and the filtering sheet. The two sealing rings are used for sealing the internal structure and the external structure of the suction gun. Pressure or flow of air entering into the leak detector is regulated via distance between the hole and the conical head. The conical cylinder and the pressure regulating column are connected by the connecting rod. The suction gun is applicable to helium mass spectrometer leak detectors with different models, and pressure of leak detection openings of the leak detectors can be controlled within a range from being greater than a dozen Pa to several hundred Pa so that test of the leak detectors with various models is facilitated, response speed in the detection test can be effectively improved and leak detection efficiency is enhanced.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

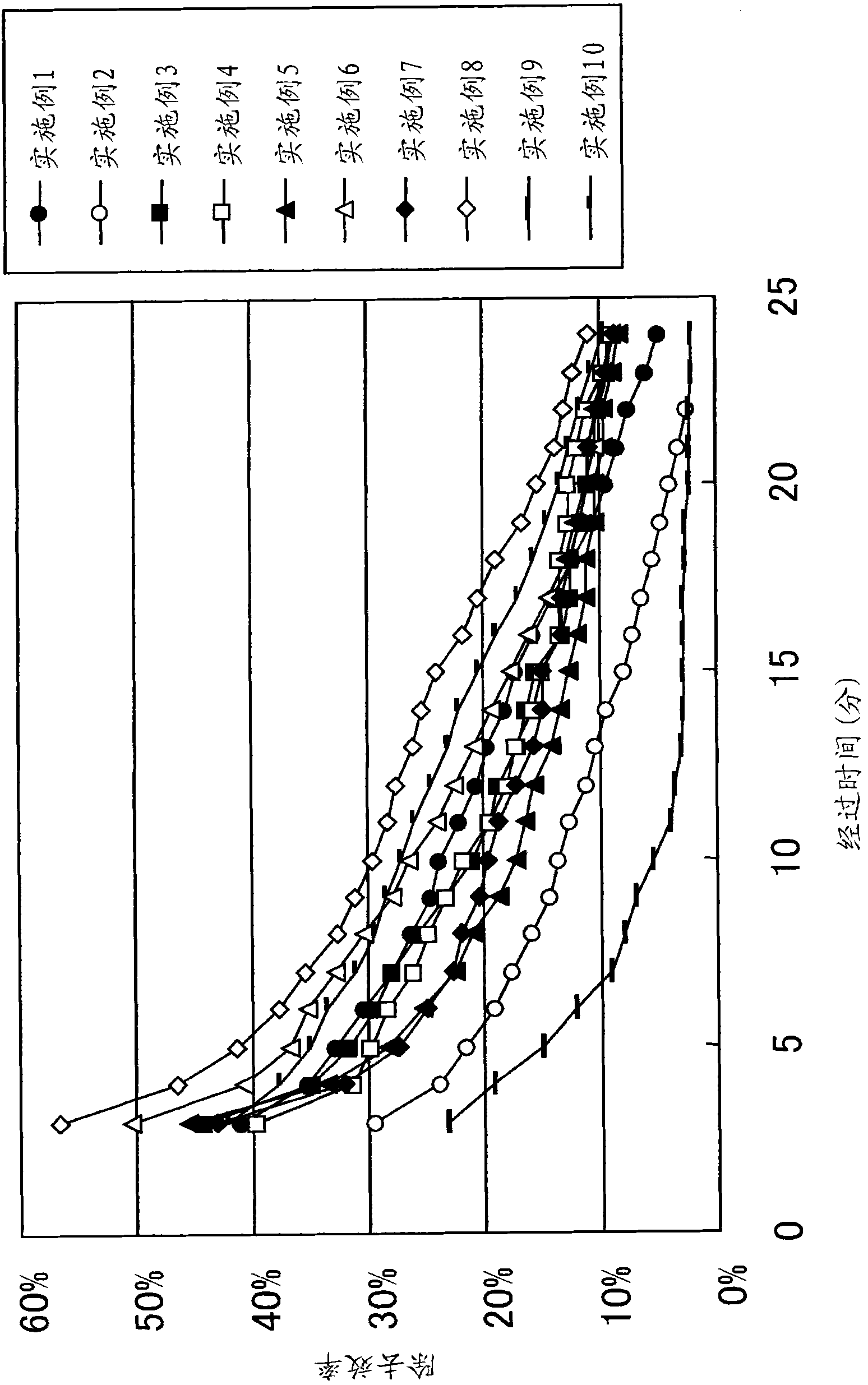

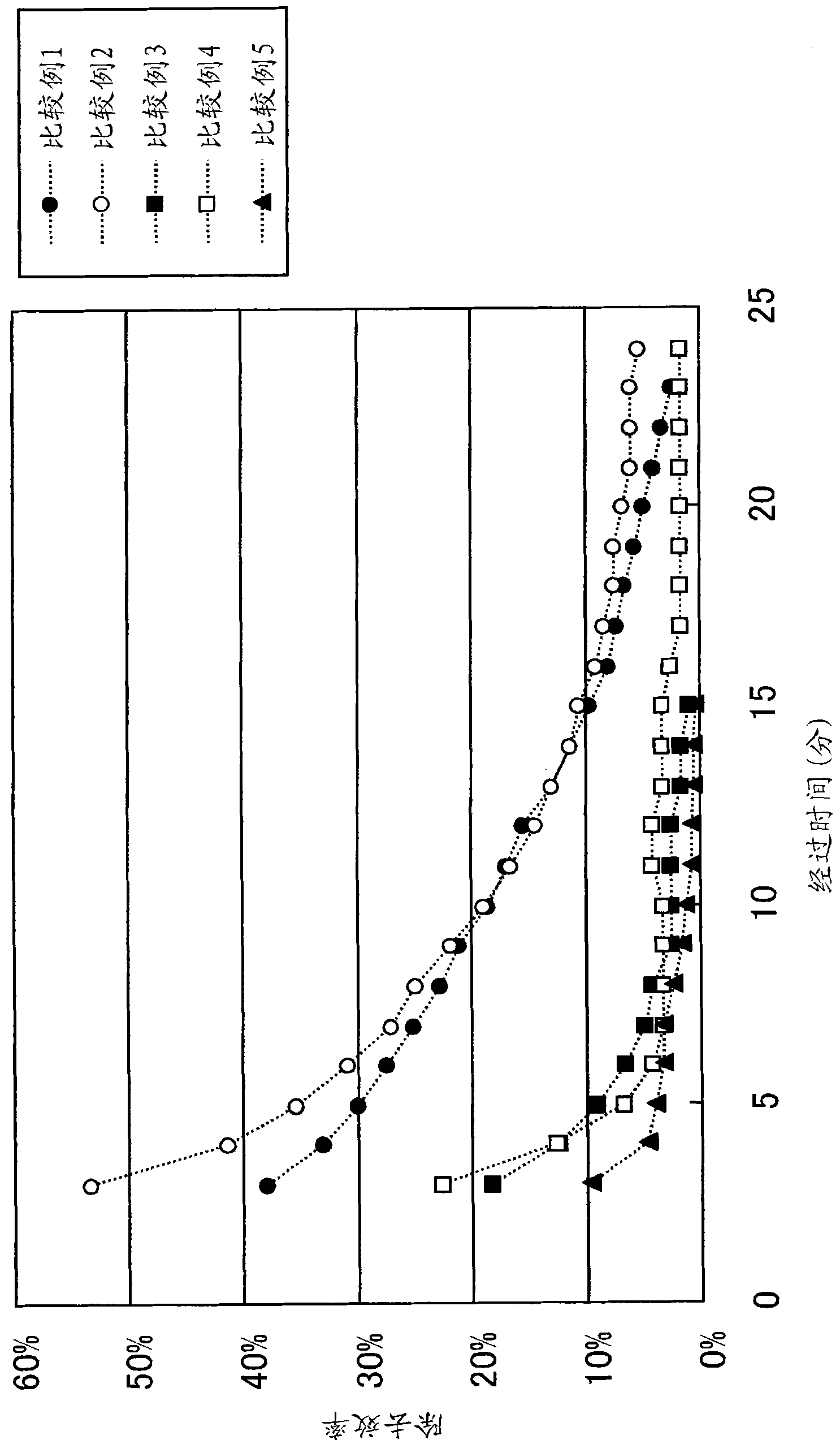

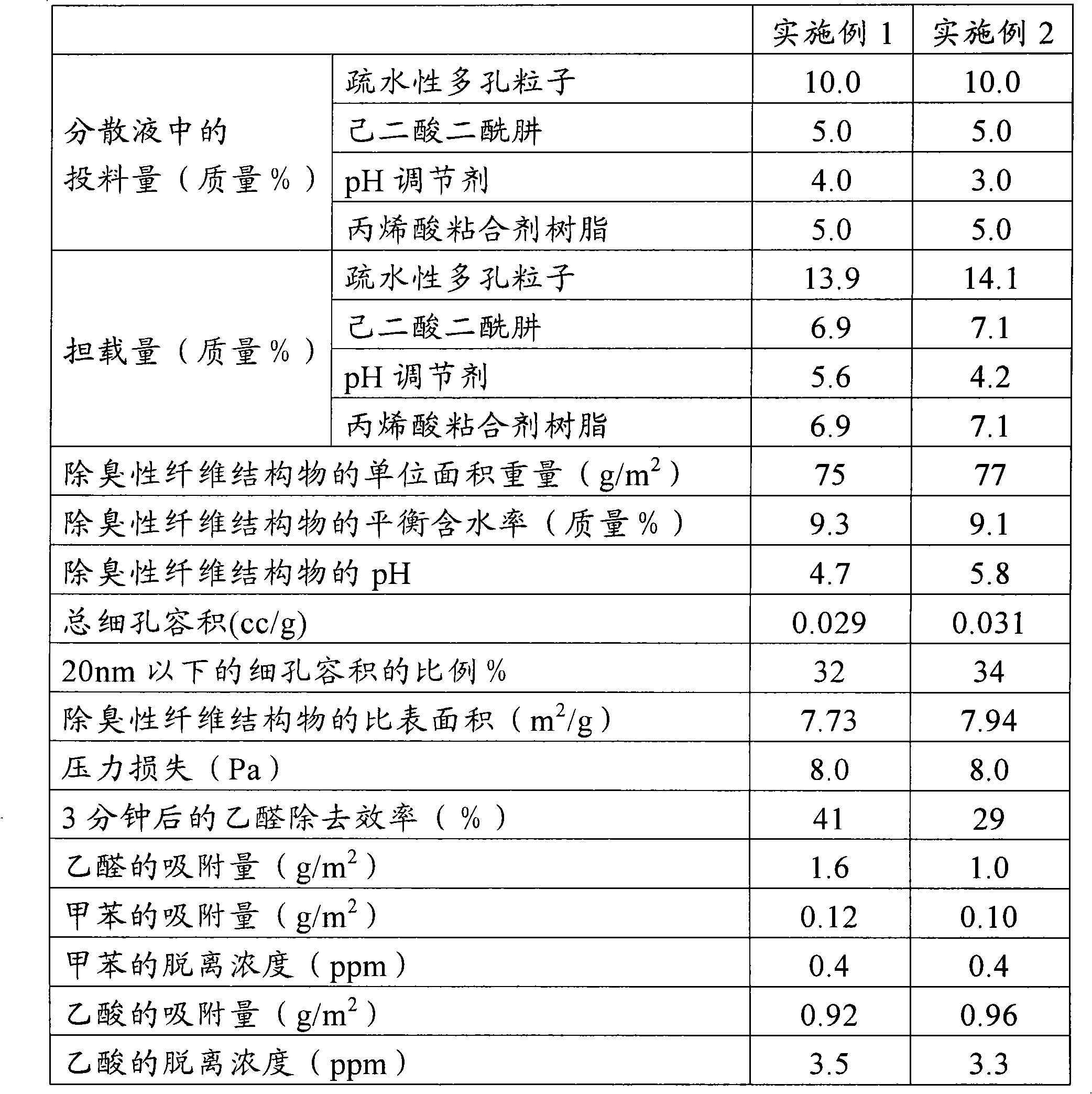

Deodorant fibrous structure and air filter

ActiveCN101983266ASpeed up reactionImprove adsorption capacityOther chemical processesFibre treatmentFiberPolymer science

A deodorant fibrous structure is provided which efficiently removes aldehydes such as acetaldehyde and is extremely small in the risk of secondary odor emission. The deodorant fibrous structure comprises a fibrous structure and, deposited thereon, inorganic particles and a water-soluble amine compound. In an environment having a temperature and relative humidity regulated to 25 DEG C and 75%, respectively, the structure has an equilibrium moisture content of 15 mass% or lower. When the deodorant fibrous structure is immersed in water in an amount of 3 mass% of the water, this water has a pH of 3.5-7.

Owner:TORAY IND INC

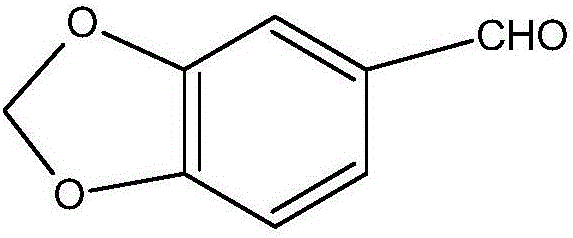

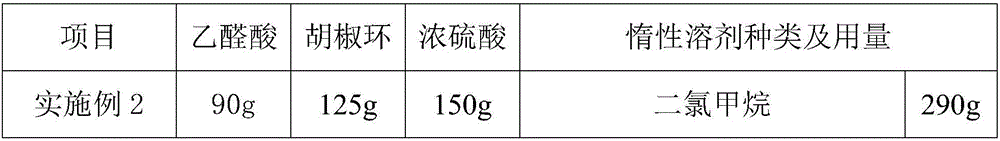

Reaction treatment method of heliotropin intermediate 3,4-dioxymethylene mandelic acid

The invention discloses a reaction treatment method of heliotropin intermediate 3,4- dioxymethylene mandelic acid. The method comprises the following reaction treatment steps: firstly, adding glyoxylic acid in a reaction kettle, adding 1,3-benzodioxole under stirring action, and cooling the glyoxylic acid and 1,3-benzodioxole mixed liquid with brine ice; adding a catalyst, namely concentrated sulfuric acid; then dripping a water-insoluble inert solvent, namely dichloromethane, into a head tank, carrying sampling detection on a reaction mixture, and stopping reaction when the content of 1,3-benzodioxole in the reaction mixture is not reduced any more; and finally, adding water into the reaction kettle, uniformly stirring, discharging and filtering by suction to obtain the solid material, namely 3,4- dioxymethylene mandelic acid. According to the reaction treatment method, the feeding sequence is regulated in the early stage to improve the mixing effect and increase the reaction speed, and the water-insoluble inert solvent is added to dilute the reaction mixture, so that the stirring effect is not influenced, the reaction time is shortened, and the problem of hard stirring in the late reaction stage can be solved.

Owner:福建仁宏医药化工有限公司

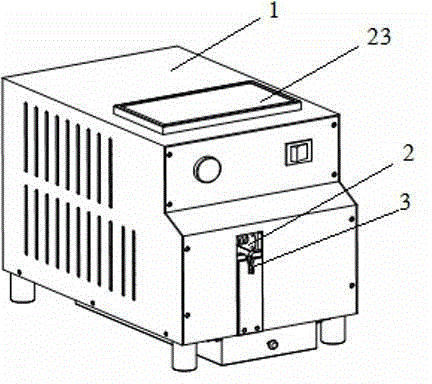

Electric stripping machine

ActiveCN103560441ASo as not to damageReduce demandLine/current collector detailsApparatus for removing/armouring cablesEngineeringReaction speed

The invention discloses an electric stripping machine which comprises a shell. A wire clamping mechanism, a stripping mechanism, a peeling mechanism and an electric control mechanism are arranged inside the shell, and an electric wire containing structure where electric wires stretch to be clamped by the wire clamping mechanism is formed in the side face of the shell. The electric stripping machine has the advantages of being capable of rapidly and accurately striping an insulated layer of the electric wires, good in stripping quality, and free of damage to an inner core; in addition, stripping for the electric wires of different specifications and different sizes is achieved simply by setting different technologies on a touch screen, production efficiency is improved, human cost is saved, and machine requirements are reduced; production cost is further greatly reduced, and due to the fact that electric control is adopted, mute performance is good, and reaction speed is high.

Owner:WELL SHIN ELECTRONICS KUNSHAN

Protein sterilisation by radiation and addition of a stabilising composition

InactiveUS20100029542A1Speed up reactionPeptide/protein ingredientsEnergy based chemical/physical/physico-chemical processesThiamineChemical compound

A method of sterilising a protein, comprises exposing to ionising radiation an at least substantially dry composition comprises a protein and a protective compound or combination of protective compounds having both of the following characteristics: (i) a rate of reaction with singlet oxygen greater than 1×10 7 L mol−1 S−1; (ii) being a reducing agent whilst at the same time containing a proton dissociable group with a pKa no more than 3 units from the pH of the composition. The compound having characteristic (i) is selected from histidine, thiamine and tryptophan, the compound having characteristic (ii) is selected from methionine, malate, citrate, lactate and tiron. The radiation is gamma radiation or electron beam, whereby the preferred dose is 15-40 kGy.

Owner:ARECOR LTD

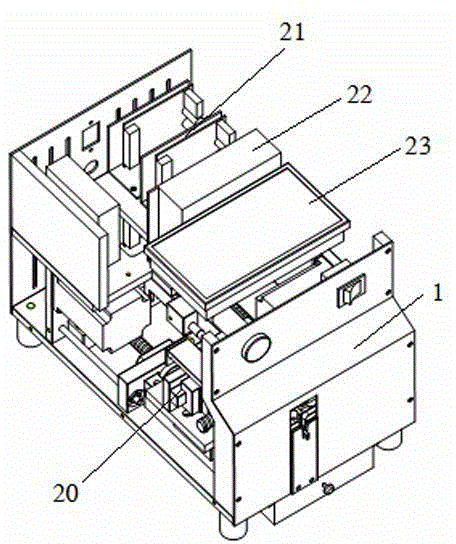

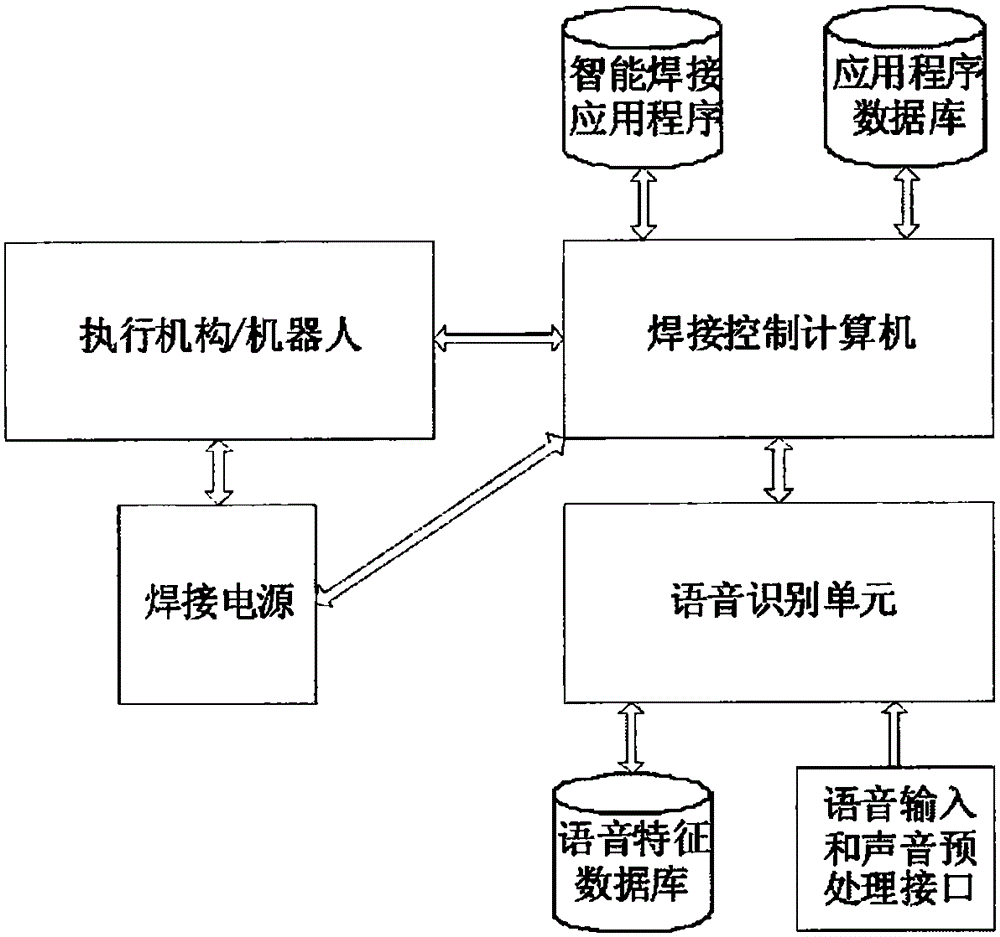

Intelligent welding system based on speech recognition technology

ActiveCN105127560AShort reaction timeReduce fatigueArc welding apparatusPlasma welding apparatusWelding power supplySpeech identification

The invention relates to an intelligent welding system based on a speech recognition technology. The intelligent welding system consists of an actuating mechanism / robot, a welding power supply, a welding control computer, a speech recognition unit, an intelligent welding application program, an application program database, a speech feature database, and a speech input and sound pre-processing interface. According to the intelligent welding system, the speech recognition technology is applied to intelligent welding equipment, so that the flexibility and the convenience of equipment operation are improved, the possibility that errors occur because of secondary response of an operator is reduced, reaction time of the operator is reduced, fatigue of the operator is reduced and the safety of the operator is improved. Response speed, stability and reliability during the equipment operation process are improved, and the product welding quality is improved.

Owner:AMET WELDING AUTOMATION TECH BEIJING

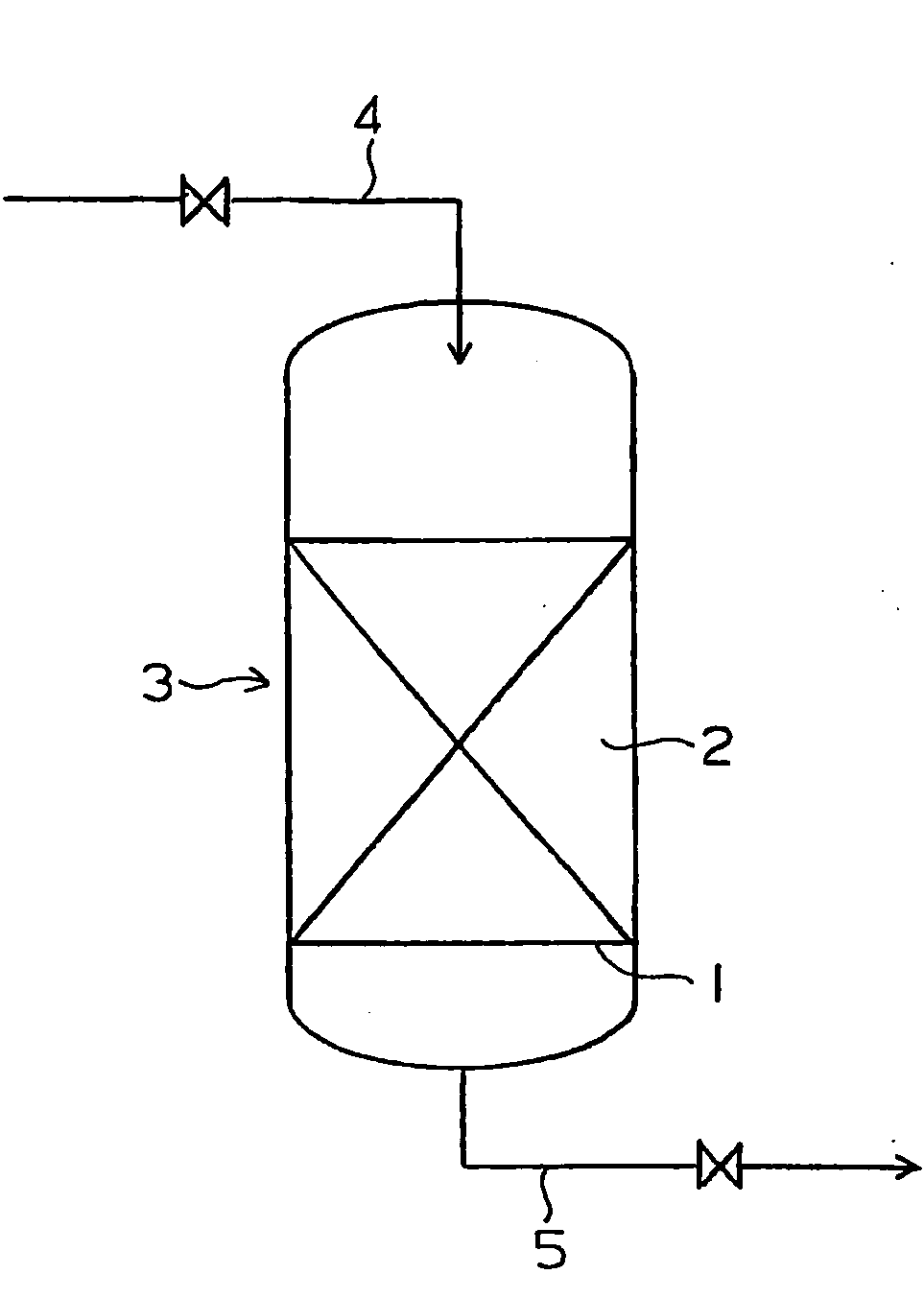

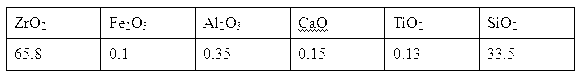

Process for hydrothermally preparing zirconium oxychloride with low alkali consumption

The invention relates to a process for hydrothermally preparing zirconium oxychloride with low alkali consumption, and belongs to the technical field of compound preparation. The process comprises the following steps: stirring crushed superfine zircon sand (ZrSiO4) powder with a NaOH solution to prepare slurry, and then placing the slurry into an autoclave to perform hydrothermal reaction, and thus generating amorphous or crystalline acmite sodium zirconium silicate (Na2ZrSiO5) precursors under a condition with the temperature of 200-300 DEG C, the pressure of 3-7MPa and the reaction time of 3-12 hours; and then removing sodium by use of hydrochloric acid, removing silicon, purifying, concentrating and crystallizing to obtain zirconium oxychloride crystals. The process can be used for not only solving the problems such as high NaOH consumption, high energy consumption, recycling incapability of excessive alkali and serious pollution to the environment in the process of preparing the zirconium oxychloride from zircon sand by an alkali fusion method, but also realizing low impurity content and high purity of a zirconium oxychloride product obtained by the method.

Owner:安徽通湾科技有限公司

Petroleum Fracturing Proppant Prepared from Flyash and Waste Ceramic, and Preparation Method Thereof

ActiveUS20150152319A1Improve stress resistanceReduce energy consumptionFluid removalFlushingApparent densityPotassium

Provided is a petroleum fracturing proppant prepared from flyash and waste ceramics, the petroleum fracturing proppant being prepared from the following components: 40 wt. %-90 wt. % of main material, the main material being flyash and waste ceramics; 1 wt. %-40 wt. % of auxiliary material, the auxiliary material being potassium feldspar powder and manganese ore powder; and the sum of the main material and the auxiliary material is 100%. The present invention employs low-cost flyash and waste ceramics as raw material, and the petroleum fracturing proppant prepared under a low temperature has low apparent density and strong crushing resistance, and is also low cost and reduces energy consumption.

Owner:HEBI TIANRUI PETROLEUM PROPPANT

Medical dirt eraser

InactiveCN103191876AIncrease distanceReduce the amount of movementCleaning using toolsCleaning using liquidsInfection riskEngineering

The invention discloses a medical dirt eraser which comprises a brush head rotatably installed on a brush handle. The brush handle is fixedly provided with a brush cover covering the brush head. The brush head is in transmission connection with the output shaft of a power device through a universal hose. The eraser further comprises a liquid sprayer driven by the power device. The liquid sprayer is connected with a cavity of the brush cover through a water pipe. A speed regulating unit is arranged between a main wheel and a rack. The rack drives the main wheel to rotate through the speed regulating unit. The speed regulating unit comprises a transmission wheel and a driving gear axially and fixedly arranged. The transmission wheel is in transmission match with the main wheel, and the driving gear is in transmission match with the rack. The medical dirt eraser in the structure is reasonable in structure, and can quickly clean or eliminate splodge or dirt to prevent medical personnel from being contacted with dirt manually, so that the medical infection risk is reduced. The eraser is time-saving and labor-saving and convenient to operate, so that the safety and sanitation of medical personnel are ensured.

Owner:孙英华 +2

Methods for forming ignitable heterogeneous structures

A method for forming a metastable intermolecular composite (MIC) includes providing a vacuum level of <10−8 torr base pressure in a deposition chamber. A first layer of a first material of a metal that is reactive with water vapor is deposited, followed by depositing a second layer of a second material of a metal oxide on the first layer. The first and second material are capable of an exothermic chemical reaction to form at least one product, and the first and second layer are in sufficiently close physical proximity so that upon initiation of the exothermic reaction the reaction develops into a self initiating chemical reaction. An interfacial region averaging <1 nm thick is formed between the first layer and second layer from a reaction of the first material with water vapor. In one embodiment, the first material is Al and the second material is CuOx.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

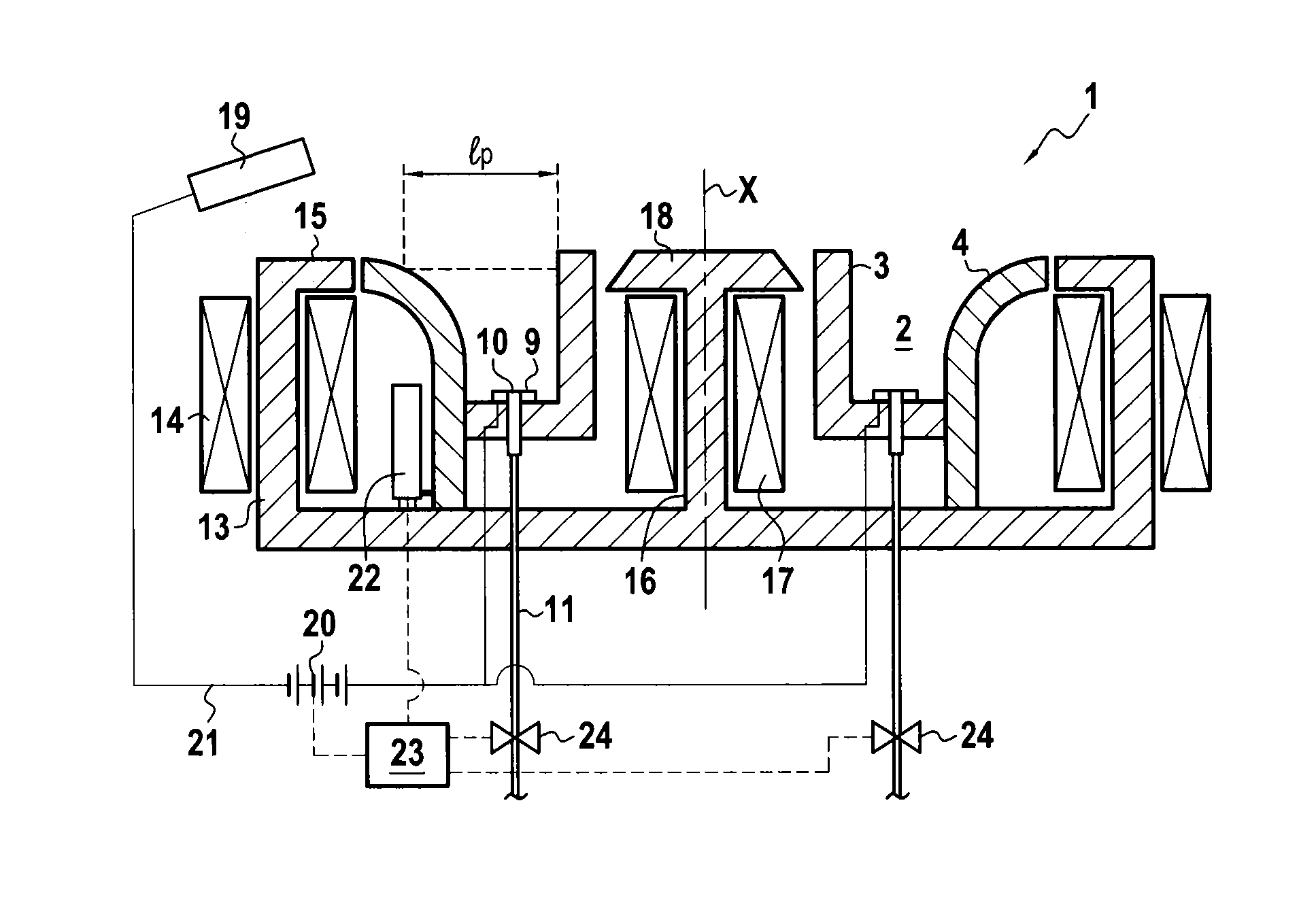

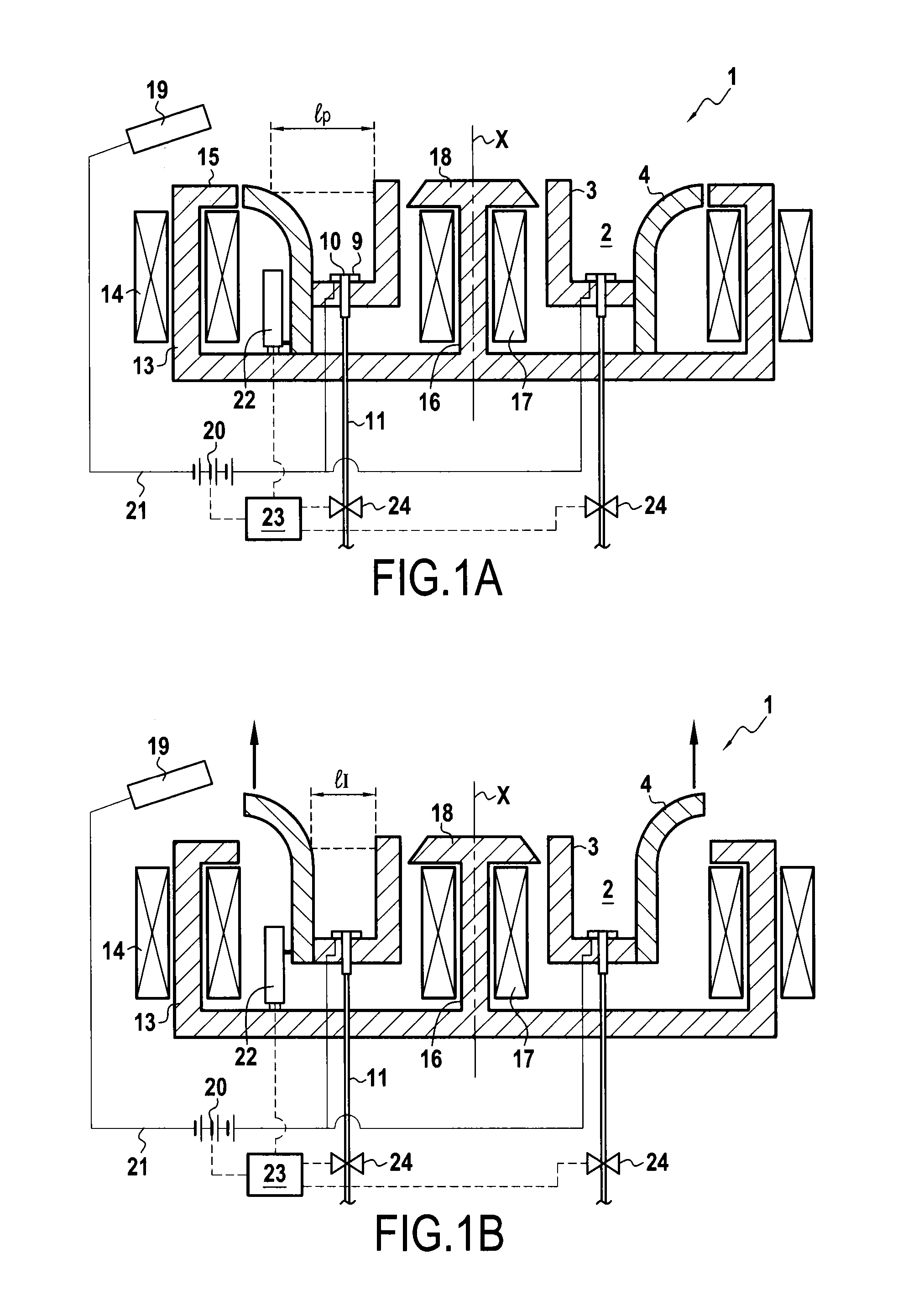

Hall effect thruster

ActiveUS20150000250A1Stability is not affectedConstant densityCosmonautic vehiclesCosmonautic partsMechanical engineeringPhysics

A Hall effect thruster including a downstream end of its annular channel presenting a cross-section that is variable to vary a thrust and a specific impulse of the thruster.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method for acquiring and exhibiting general-purpose web medium

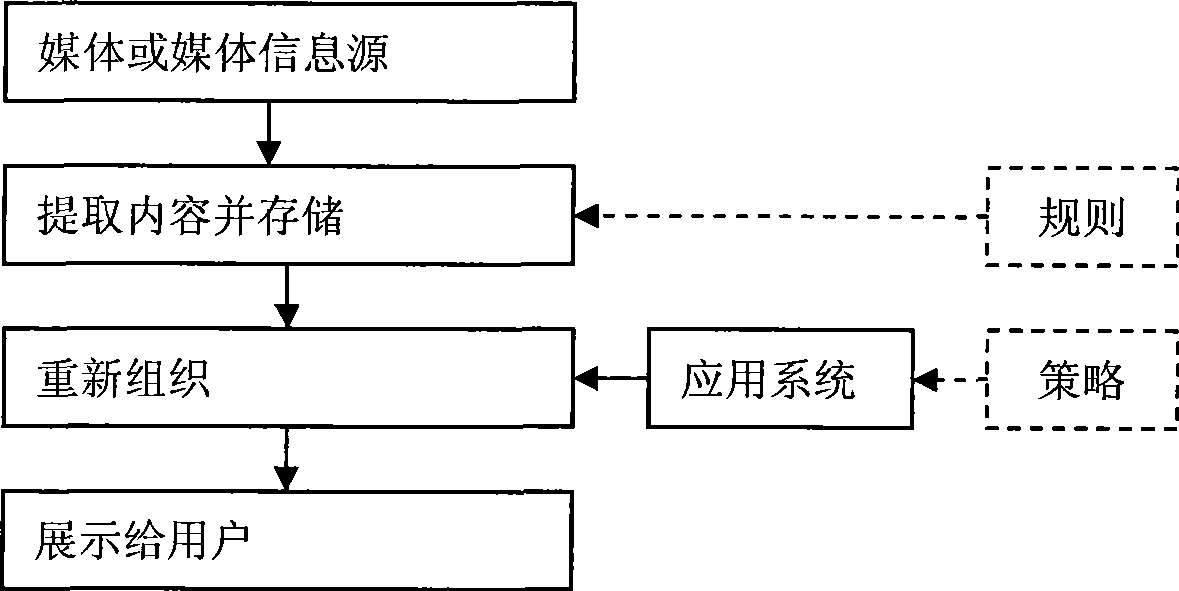

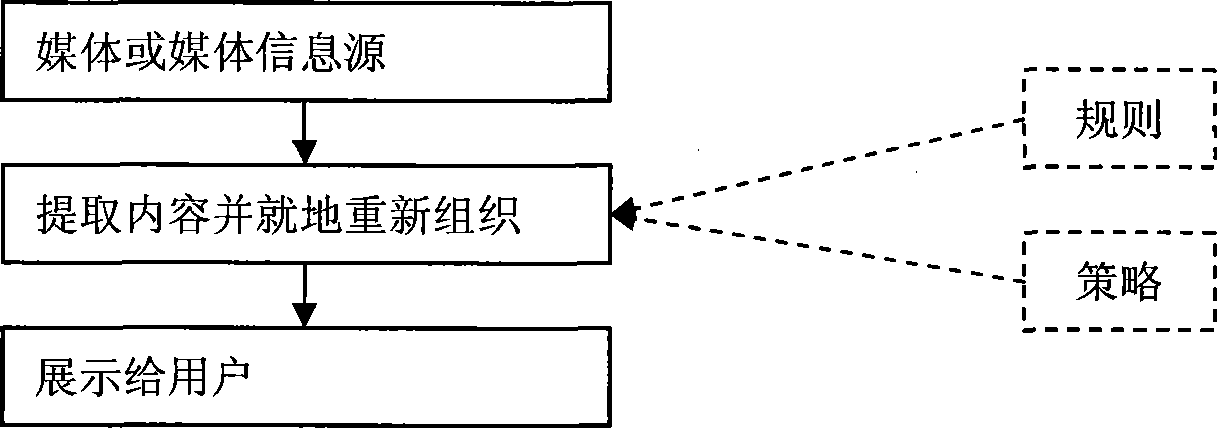

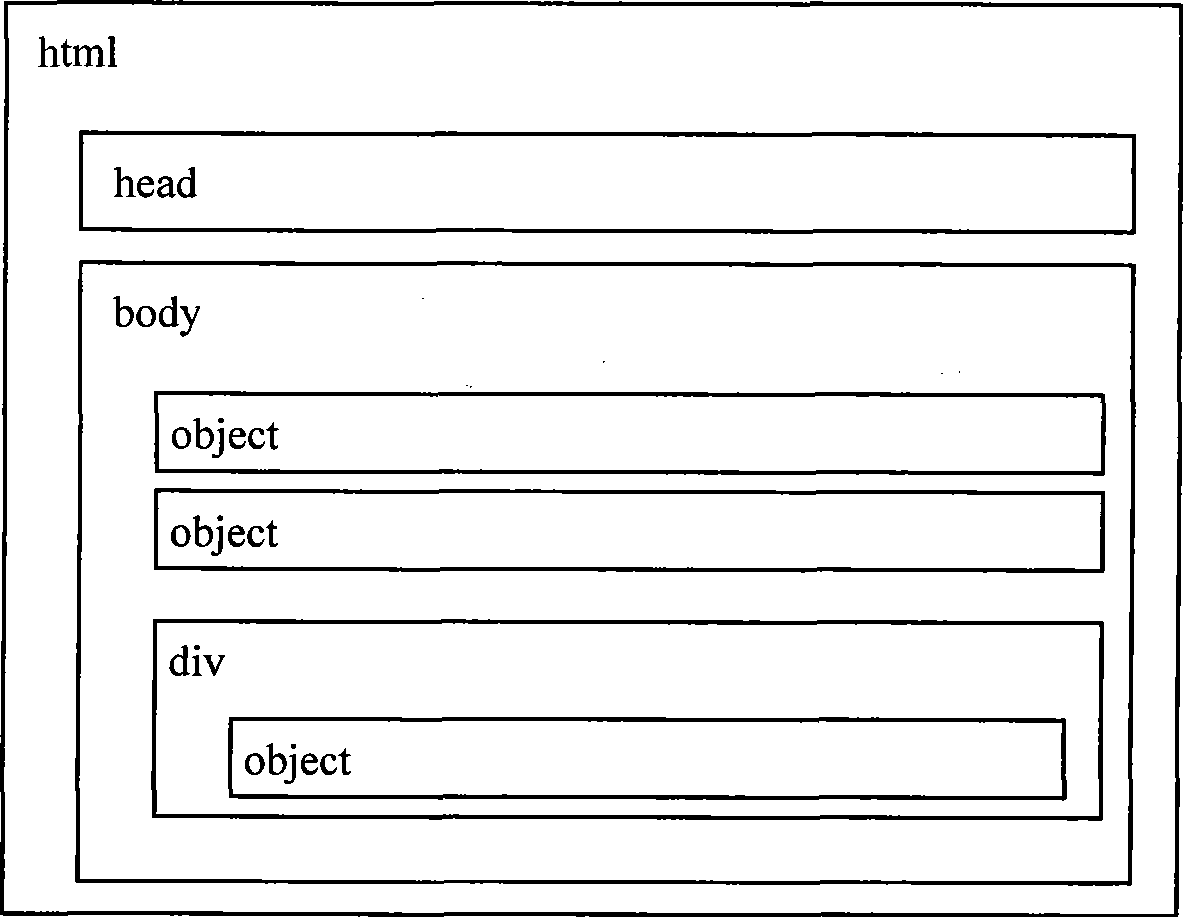

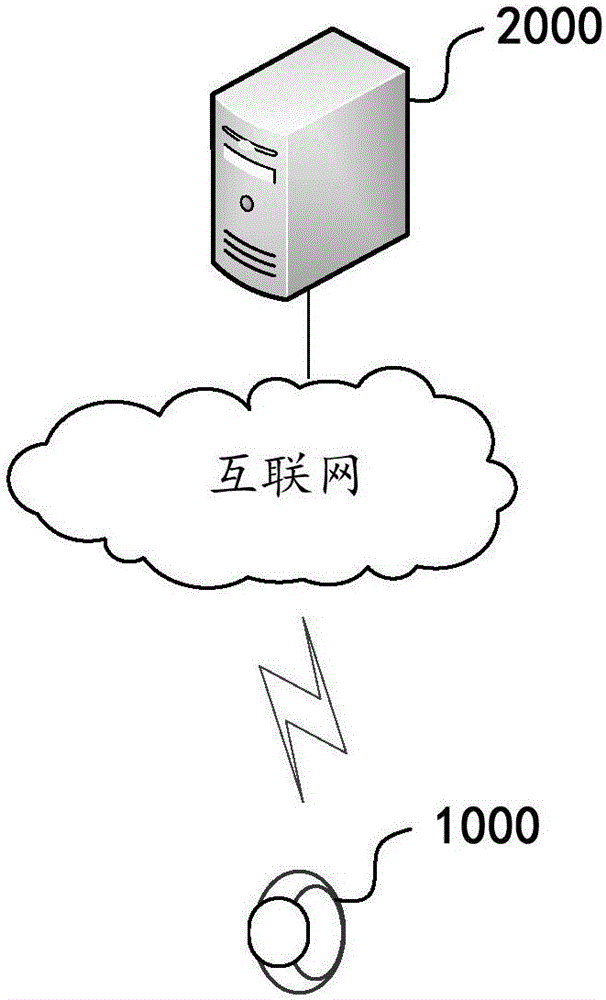

InactiveCN101436181AReduce trafficSpeed up reactionTransmissionSpecial data processing applicationsGeneral purposeNetwork reduction

The invention discloses a method for acquiring and displaying general web media, which comprises the following steps: firstly, acquiring web pages containing the media or media information sources; secondly, extracting given Web media objects and restructuring the given Web media objects on the spot; and thirdly, displaying the given Web media objects to customers. The invention provides a stable, concise and general web media displaying system in the condition that a host or a main domain for displaying the media is not suitable to be changed, and mainly comprises two aspects of media search and media organization. Because the method does not acquire network data for the second time, the network flow can also be obviously reduced and the response speed of the system can be improved.

Owner:SHENGLE INFORMATION TECH SHANGHAI

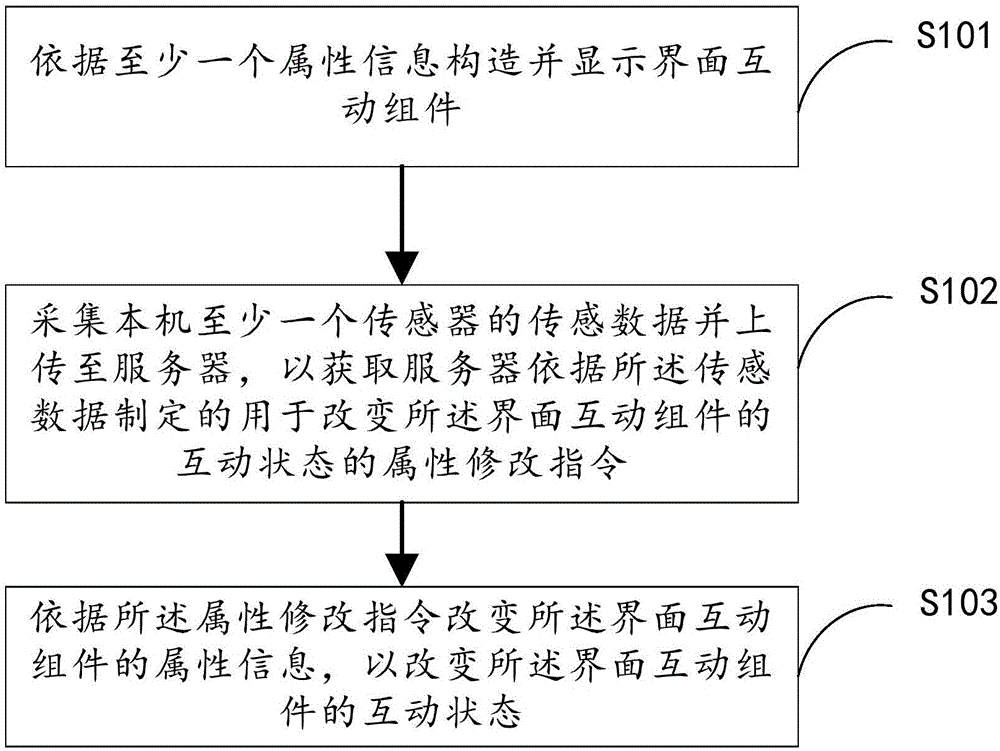

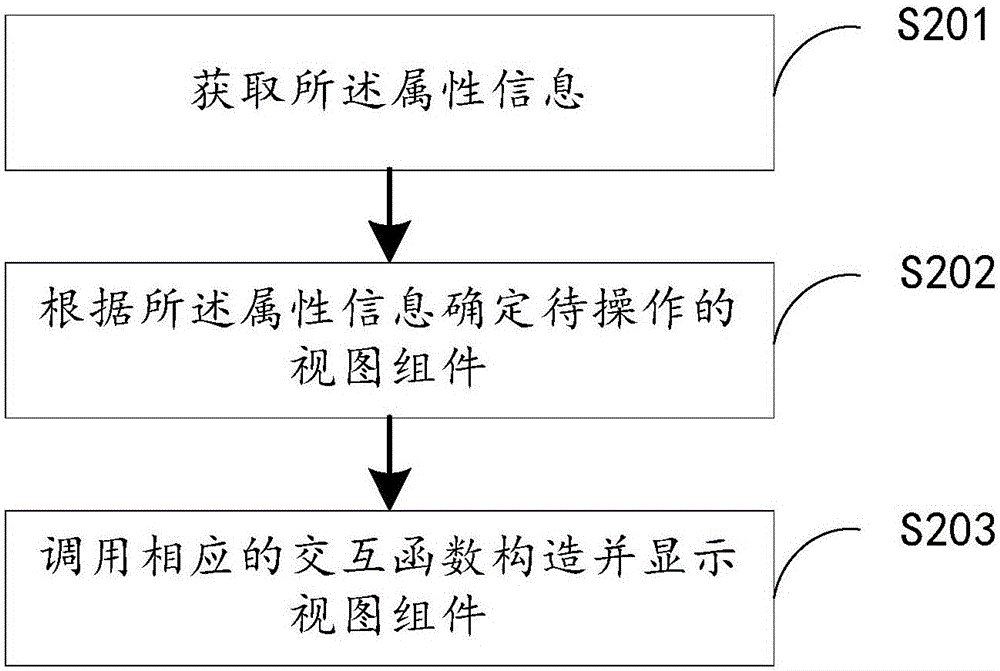

Interface interactive component control method, device and wearable device

InactiveCN106775721AImprove experienceSpeed up reactionDetails for portable computersExecution for user interfacesSensing dataHuman–computer interaction

The invention discloses an interface interactive component control method and an interface interactive component control device; the method includes steps of structuring and displaying an interface interactive component according to at least one property information; collecting the sensing data of at least one sensor of this machine and uploading to the sensor, so as to acquire the proper modifying command of the server formulated according to the sensing data for changing the interactive state of the interface interactive component; changing the property information of the interface interactive component according to the property modifying command, so as to change the interactive state of the interface interactive component. Besides, the invention further provides a wearable device for executing the interface interactive component control method. By fully using the sensing data collected by the sensor carried at the wearable device, the server is applied to analyze the sensing data and generate and change the interactive state of the interface interactive component; through the interactive state of the interface interactive component, a user of the wearable device can be stimulated.

Owner:BEIJING QIHOO TECH CO LTD

Hydrogenation of methylenedianiline

ActiveUS6998507B1Rich in primary amine functionalityHigh yieldOrganic compound preparationAmino compound preparationPretreatment methodFixed bed

The invention is directed to an improvement in a catalytic process for the ring hydrogenation of a methylenedianiline feedstock, including crude methylenedianiline. One component of the improvement is a pretreatment process which resides in passing the crude methylenedianiline feedstock over a ruthenium catalyst carried on a fixed bed support, cooling without venting, and then hydrogenation of the pretreated crude methylenedianiline feedstock over a rhodium catalyst or a mixed Rh / Ru catalyst carried on a monolith support and carrying out the ring hydrogenation in a batch reaction. Another component in the improvement is the employment of a catalyst comprised of rhodium and ruthenium carried on a monolith support.

Owner:EVONIK OPERATIONS GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com