Photocatalysis oxidation water purification tank

A photocatalytic oxidation and purification tank technology, which is applied in the direction of oxidized water/sewage treatment, special compound water treatment, light water/sewage treatment, etc., can solve the problems of high treatment cost, small treatment capacity, unsafety, etc., and achieve improvement Effects of removal rate, reduction of treatment cost, and improvement of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

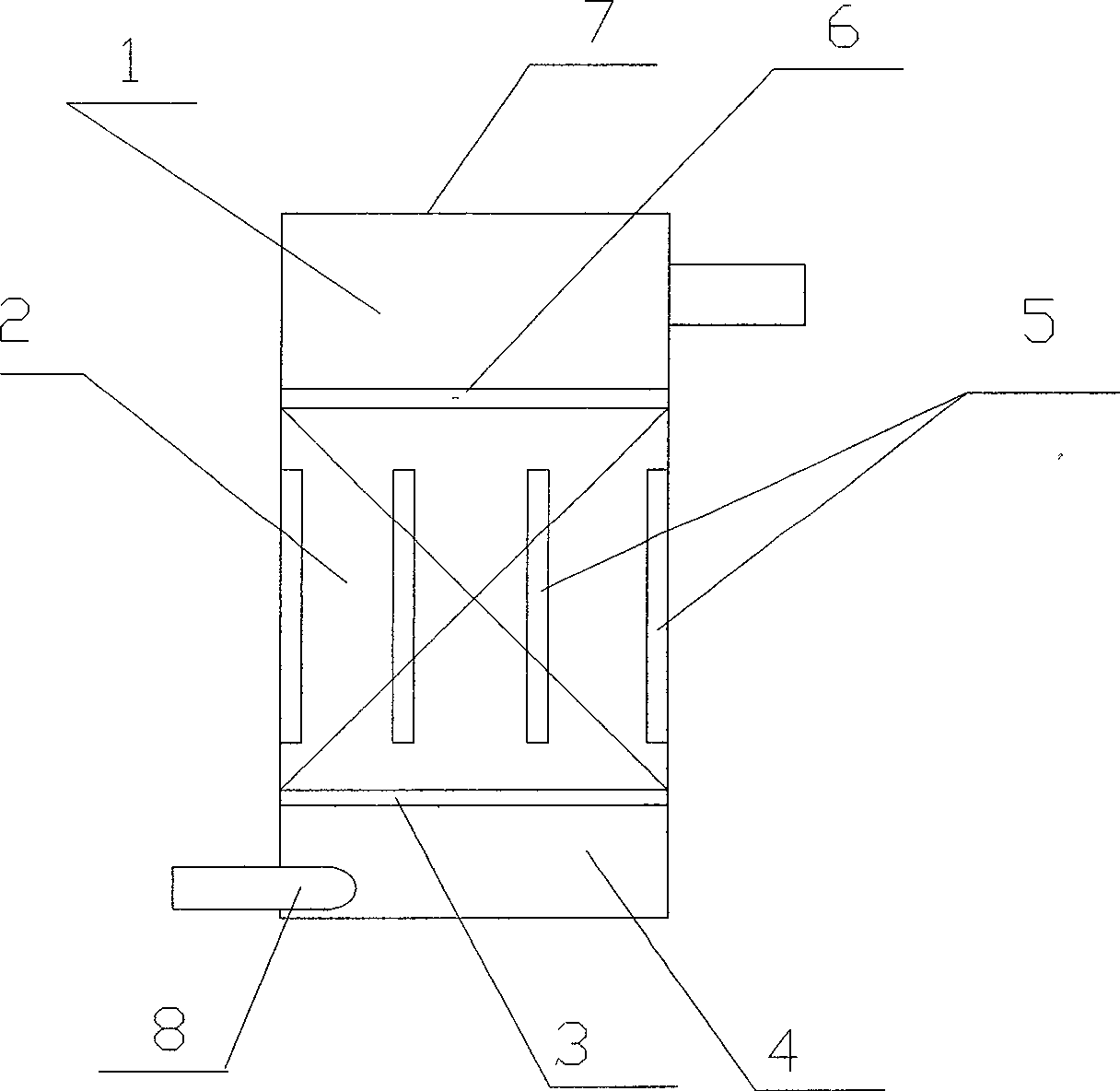

[0010] see figure 1 , the present invention provides a photocatalytic oxidation purification tank, which is provided with two upper and lower horizontal partitions 6, 3 to divide the inner space of the tank into a middle part, an upper part and a lower part, and the upper and lower partitions are all orifice plates, wherein the upper The plate is a small-hole orifice plate, and the lower partition is a large-hole orifice plate. The middle part of the inner space of the tank is a fluidized bed chamber 2, the lower part is a mixing chamber 4, and the upper part is a steady flow chamber 1. The fluidized bed chamber is set There are some ultraviolet light lamps 5 extending vertically, and photocatalyst particles 9 are housed inside. The surface of the photocatalyst particles is covered with photocatalysts. The water inlet pipe 8 of the purification tank is connected with the mixing chamber, and its extension direction is along the Oblique or tangential, the outlet pipe of the puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com