Process for hydrothermally preparing zirconium oxychloride with low alkali consumption

A technology of zirconium oxychloride and process method, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve the problems of high purity, large NaOH consumption, environmental pollution, etc., to promote reaction efficiency, promote reaction speed, The effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

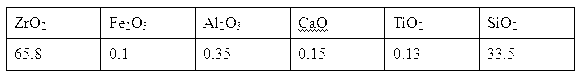

Image

Examples

Embodiment 1

[0042] Sodium hydroxide is formulated into an aqueous solution of 50% by weight, and 3000g of ZrSiO 4 Add 1146g of D50: 1μm ultrafine zircon sand with a molar ratio of 1:6 to NaOH, stir and make slurry, and put it into a 5L high-pressure reactor. The reaction temperature is 300°C, the reaction pressure is adjusted to 7MPa, and the reaction time is 3h. Solid-liquid separation removes excess alkali, then the product of solid-liquid separation is fully dissolved with hydrochloric acid aqueous solution of concentration 20%Wt, and reaction molar ratio is excessive 15%, obtains reactant H 2 SiO 3 , ZrOCl 2 and NaCl aqueous solution, solid-liquid separation to remove impurities such as silicic acid, and the remaining liquid is steamed under negative pressure at 120°C to hydrolyze ZrO(OH) 2 Precipitate, control pH5-6, separate solid-liquid and wash the precipitate, remove sodium ions, and get ZrO(OH) 2 The filter cake is fully dissolved with hydrochloric acid aqueous solution with ...

Embodiment 2

[0044] Sodium hydroxide is formulated into an aqueous solution of 40% by weight, and 3000g is taken according to ZrSiO 4 Add 917g of D50: 1μm ultrafine zircon sand at a molar ratio of 1:6 to NaOH, stir and make slurry, and put it into a 5L high-pressure reactor. The reaction temperature is 250°C, and the reaction pressure is adjusted to 5MPa. Solid-liquid separation removes excess alkali, then the product of solid-liquid separation is fully dissolved with a hydrochloric acid aqueous solution with a concentration of 15%Wt, and the reaction molar ratio is excessive by 10%, to obtain reactant H 2 SiO 3 , ZrOCl 2 and NaCl aqueous solution, solid-liquid separation to remove impurities such as silicic acid, and the remaining liquid is steamed under negative pressure at 100°C to hydrolyze ZrO(OH) 2 Precipitate, control pH5-6, separate solid-liquid and wash the precipitate, remove sodium ions, and get ZrO(OH) 2 The filter cake is fully dissolved with hydrochloric acid aqueous solut...

Embodiment 3

[0046] Sodium hydroxide is formulated into an aqueous solution of 30% by weight, and 3000g of ZrSiO 4 Add 1375g of D50: 5μm superfine zircon sand with a molar ratio of 1:3 to NaOH, stir and make slurry, and put it into a 5L autoclave, the reaction temperature is 200°C, the reaction pressure is adjusted to 3MPa, and the reaction time is 12h. Liquid separation removes excessive alkali, then the product of solid-liquid separation is fully dissolved with the hydrochloric acid aqueous solution of concentration 20%Wt, and reaction molar ratio is excessive 20%, obtains reactant H 2 SiO 3 , ZrOCl 2 and NaCl aqueous solution, solid-liquid separation to remove impurities such as silicic acid, and the remaining liquid is steamed with negative pressure at 110°C to hydrolyze ZrO(OH) 2 Precipitate, control pH5-6, separate solid-liquid and wash the precipitate, remove sodium ions, and get ZrO(OH) 2 The filter cake is fully dissolved with hydrochloric acid aqueous solution with a concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com