Method for improving zinc powder activity with ultrasonic, device and application thereof

A technology of ultrasonic wave and zinc powder, which is applied in the field of zinc sulfate solution to remove impurities, can solve the problems of low activity and easy failure of zinc powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

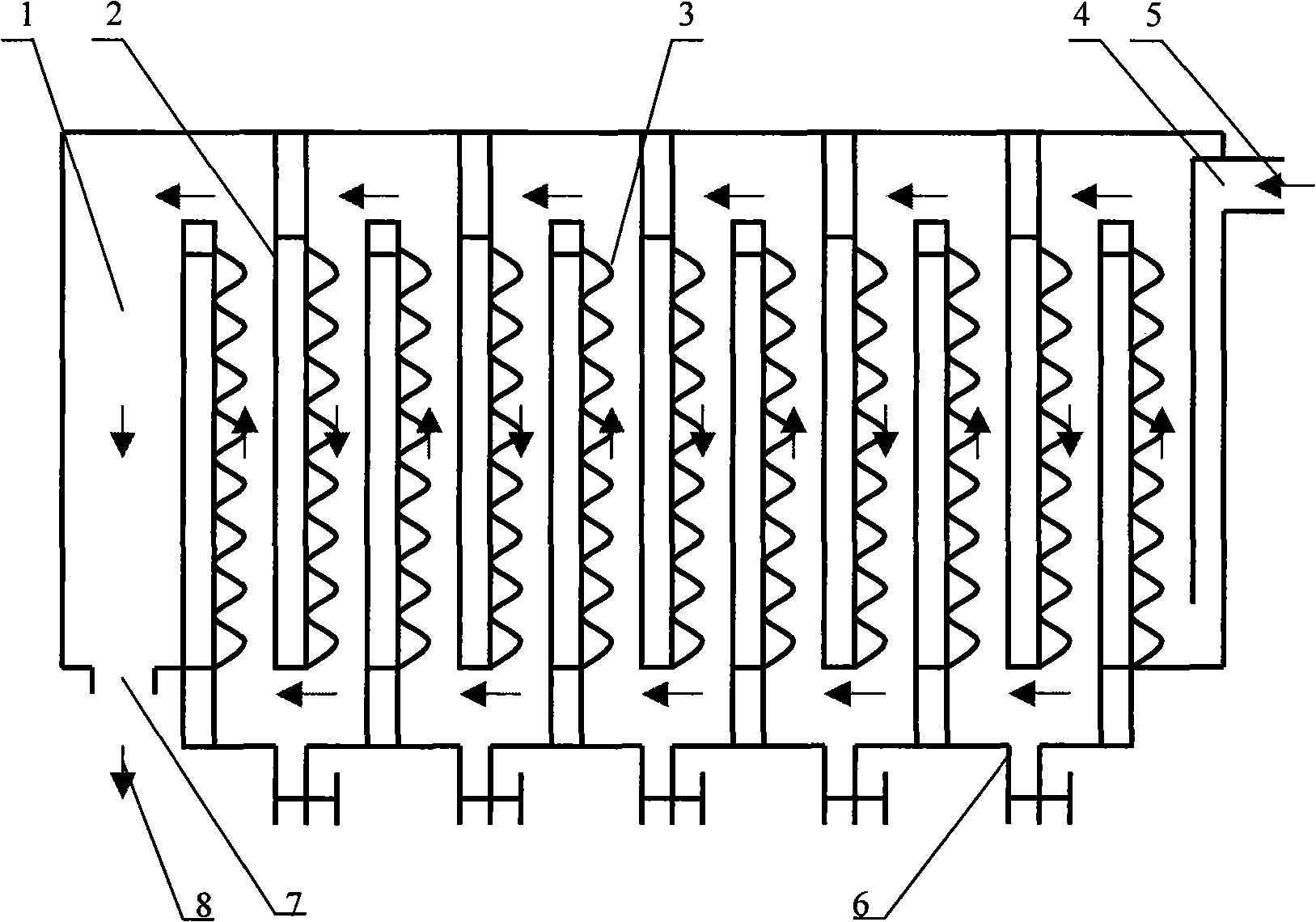

[0026] figure 1 As an embodiment of the present invention, from the attached figure 1 It can be seen that the present invention is a device for improving the activity of zinc powder with ultrasonic waves. The method for improving the activity of zinc powder with ultrasonic waves is to remove the surface of zinc powder with ultrasonic waves under the environment conditions of the solution using zinc powder as a reducing agent. The basic zinc salt passivation film is a method to keep the zinc powder on the fresh and active surface all the time. The ultrasonic wave, frequency 15-60kHz, sound intensity 1-1000w / cm 2 , The ultrasonic cavitation time for zinc powder is 1-45 minutes. The solution environment using zinc powder as the reducing agent at least includes the conventional zinc sulfate solution of the wet zinc smelting process with a cobalt ion concentration below 100mg / L.

[0027] Such as figure 1 The shown device for improving the activity of zinc powder with ultrasonic...

Embodiment 2

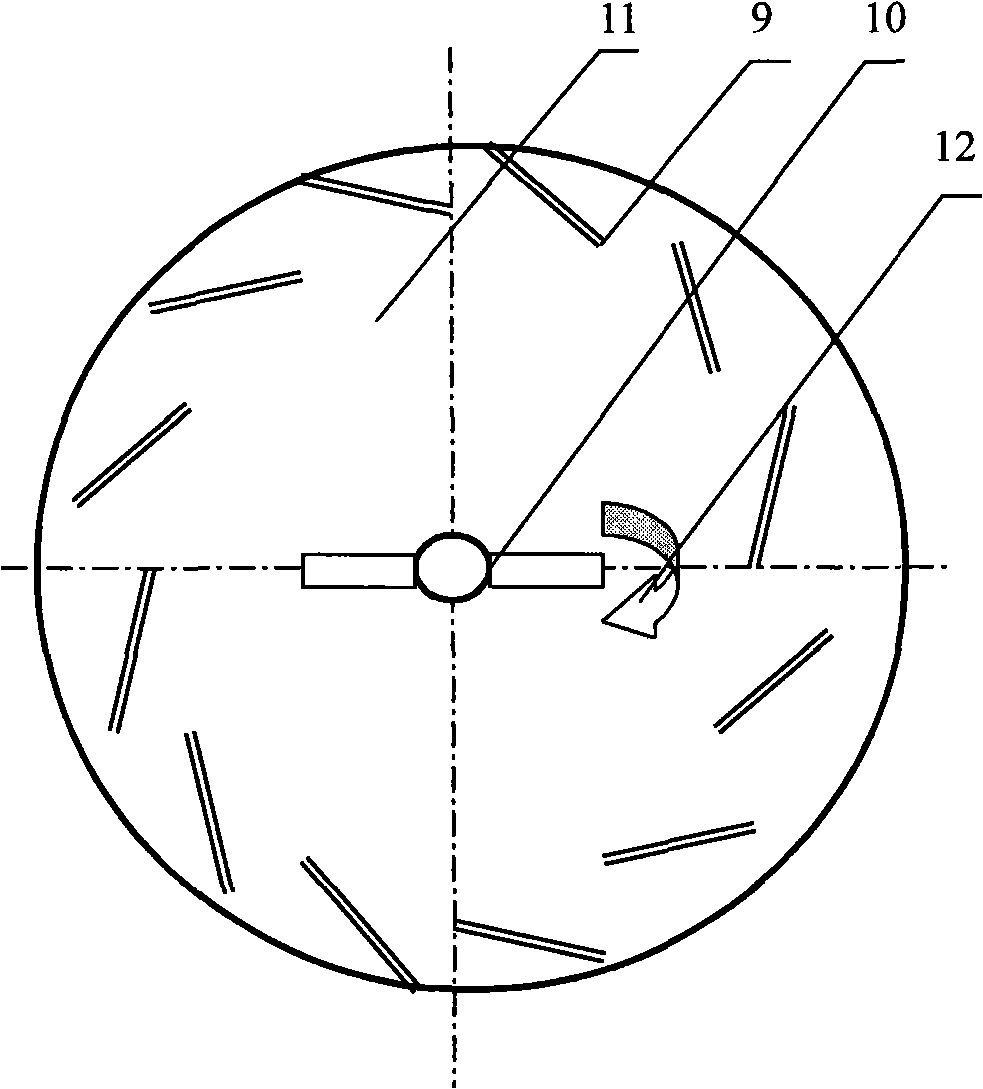

[0030] attached figure 2 is another embodiment of the present invention. Its impurity removal principle is the same as that of Embodiment 1, mainly due to the difference in device structure. Such as figure 2 The shown device for improving the activity of zinc powder with ultrasonic waves includes a cylindrical reaction chamber 11 filled with zinc sulfate solution 5, a mechanical stirring device 10, and more than one plate-type ultrasonic transmitter 9 arranged around the periphery of the cylindrical reaction chamber 11. The ultrasonic transmitter 9 can emit ultrasonic waves against the flow direction 12 of the zinc sulfate solution, or emit ultrasonic waves perpendicular to the flow direction of the zinc sulfate solution.

[0031] The advantage of this implementation device is that the hydrogen film on the surface of the ultrasonic transmitter is impacted by the swirling flow of the solution, the effective distance of the ultrasonic wave is long, and it is convenient for t...

Embodiment 3

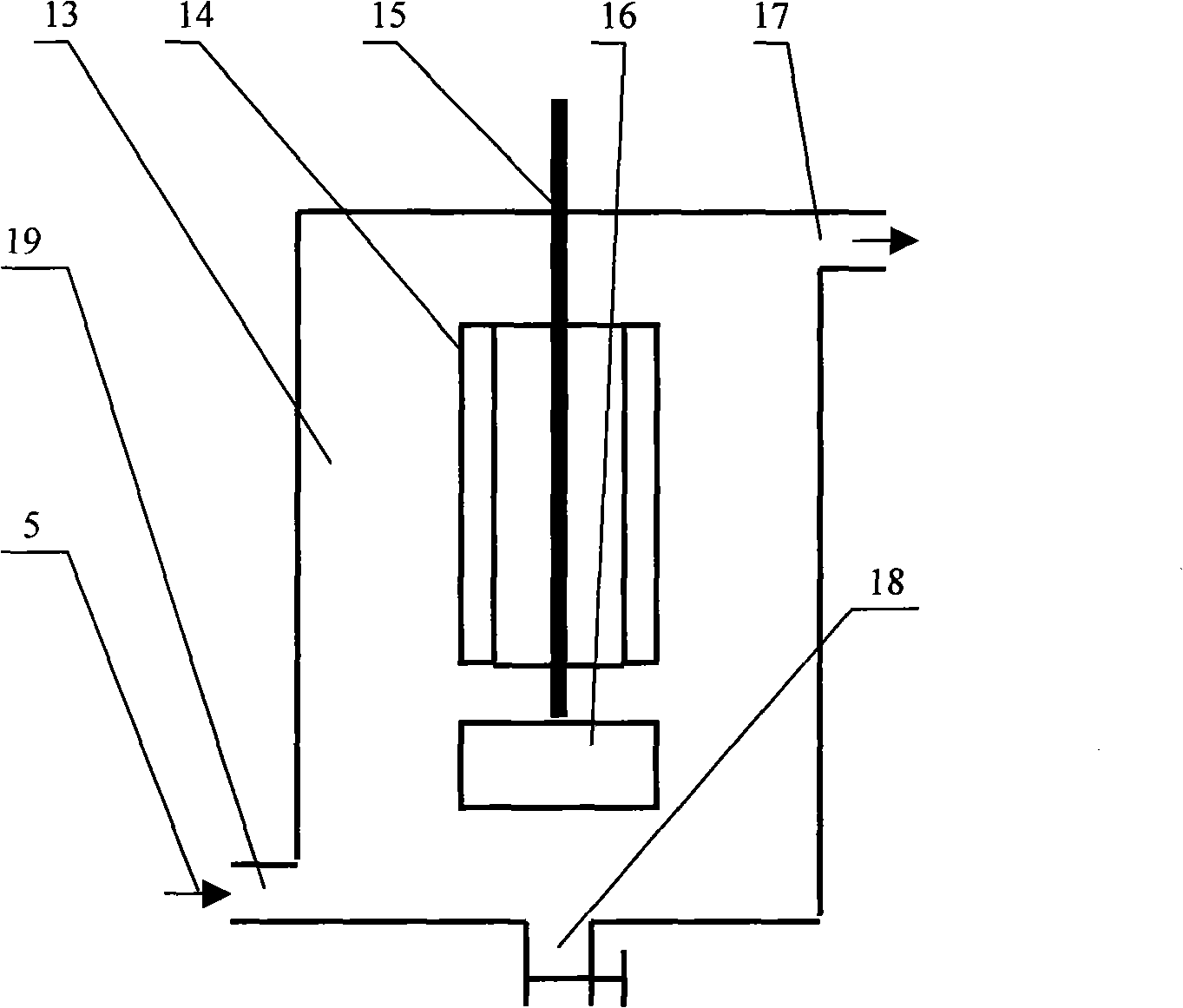

[0033] attached image 3 is another embodiment of the present invention. Its impurity removal principle is the same as that of Embodiment 1, mainly due to the difference in device structure. The cylindrical ultrasonic transmitter has the same vertical axis 15 as the cylindrical reaction chamber, and emits ultrasonic waves toward the circumference of the cylindrical reaction chamber. Such as image 3 The device for replacing and removing cobalt by ultrasonically strengthening zinc powder includes a cylindrical reaction chamber 13 filled with zinc sulfate solution 5, a mechanical stirring device 16 and a cylindrical ultrasonic transmitter 14, and the cylindrical ultrasonic transmitter 14 reacts with the cylindrical The chambers 13 have the same vertical axis, and the cylindrical ultrasonic transmitter 14 emits ultrasonic waves toward the circumference of the cylindrical reaction chamber. The lower side of cylindrical reaction chamber 13 is provided with the inlet 19 of zinc s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com