Electric stripping machine

A peeling machine and electric technology, applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve the problems of large number of machines, waste of resources, high labor costs, etc., achieve fast response, good quiet performance, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

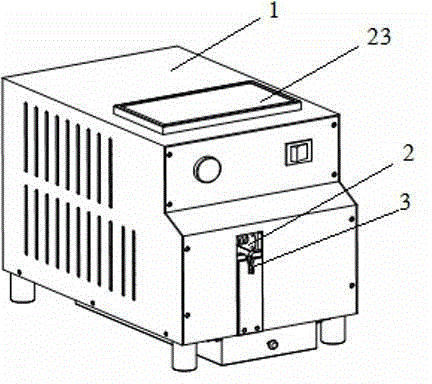

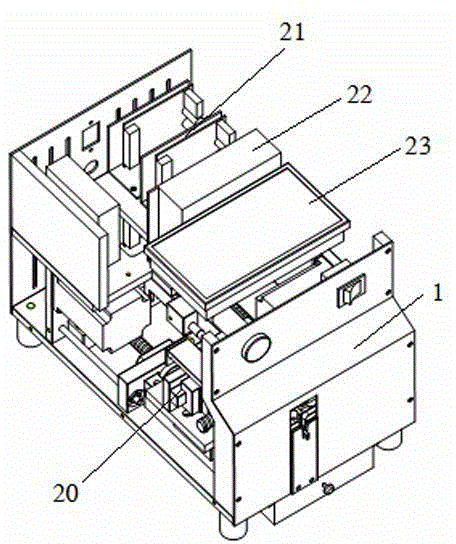

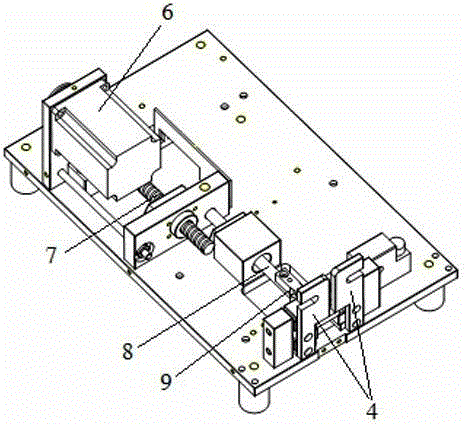

[0018] see Figure 1 to Figure 5 , a kind of electric stripping machine of the present invention, comprises housing 1, and housing 1 is provided with clamping mechanism, peeling mechanism, peeling mechanism and electric control mechanism inside, and each mechanism cooperates to peel off the insulation layer outside electric wire 5. Depend on figure 1 and figure 2 It can be seen that a power supply wire 5 is formed on the side of the housing 1 so that the wire 5 accommodating structure for clamping by the wire clamping mechanism is formed. As a preference, the wire accommodating structure is a through hole 2 formed on the housing 1, and the through hole can be It is square or circular, and has a groove 3 below the through hole 2 , the groove 3 is strip-shaped, and is located between a pair of clamps 4 . In this way, when the peeling ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com