Patents

Literature

91results about How to "Improve peeling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

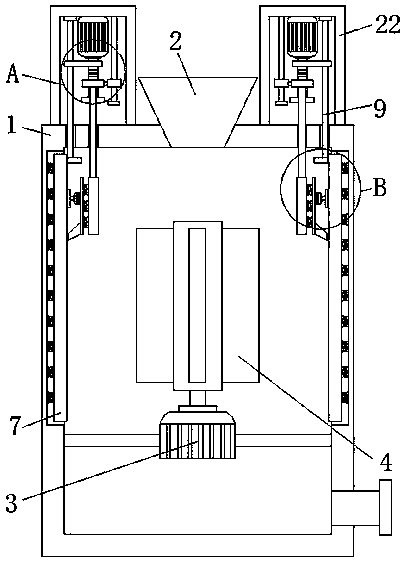

Optical cable and cable sheath peeling device

ActiveCN101587217AImprove peeling qualityImprove efficiencyFibre mechanical structuresApparatus for removing/armouring cablesMilling cutterEngineering

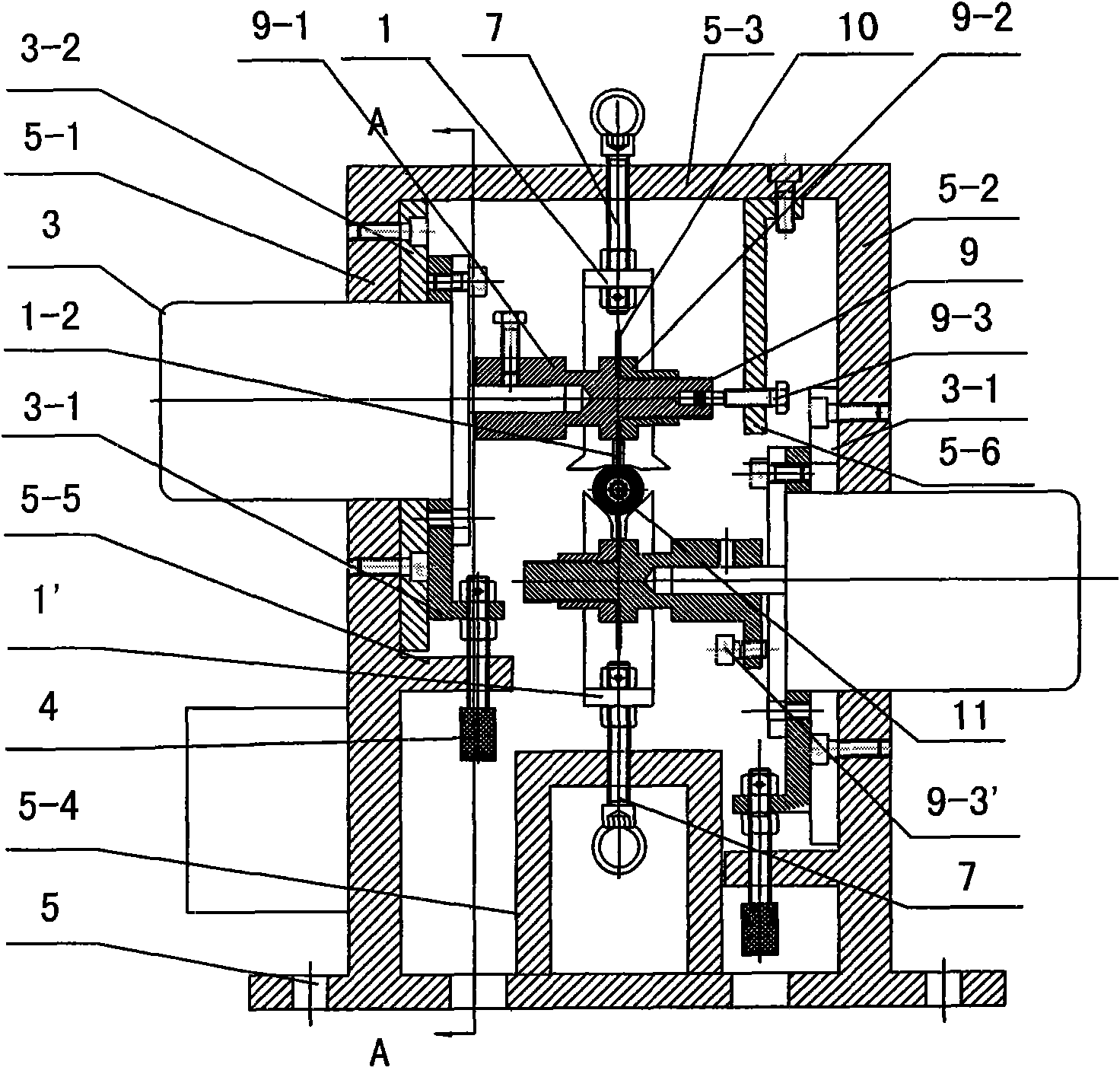

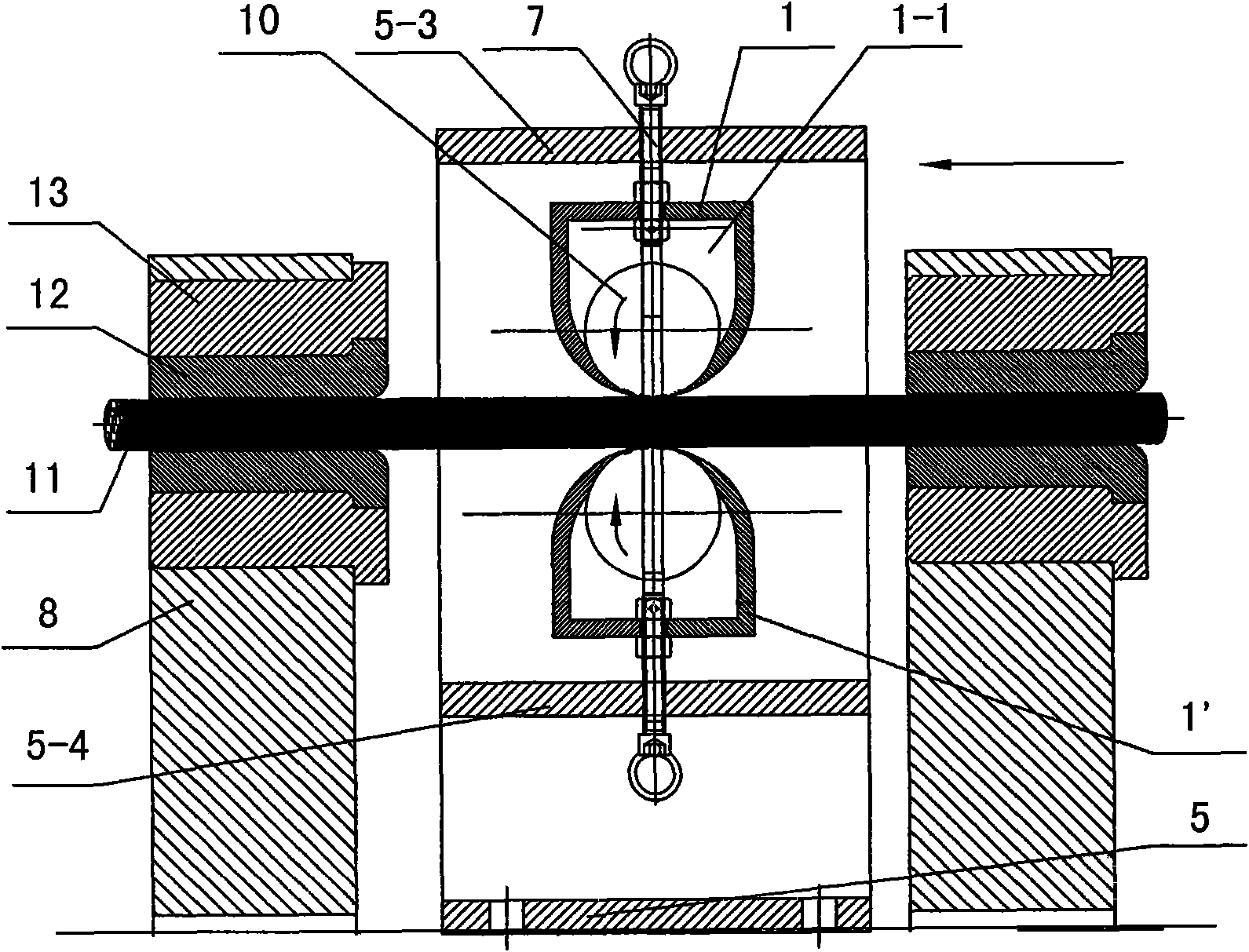

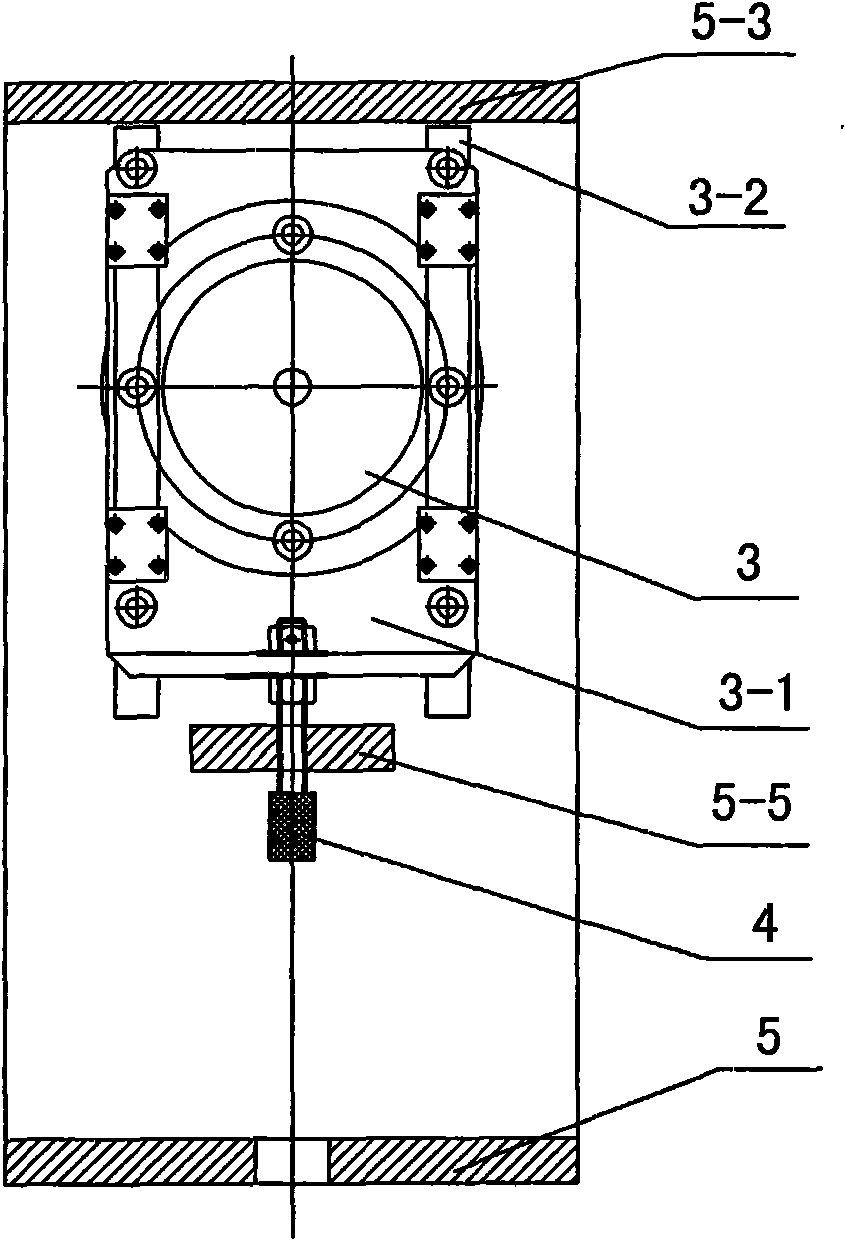

The invention relates to an optical cable and a cable sheath peeling device, belonging to the cable tool technology field. The support frame of the device comprises a door-shaped outer frame and an inner frame. An upper cable clamper and a lower cable clamper are respectively installed in a perpendicular screwed hole in the center of the transverse brace and the inner frame. The middle part of the clamper of the upper cable and the lower cable is provided with a relieving hole and a centering relieving hole along the axial direction of the milling cutter and the opposite ends forming a cross section are respectively provided with a clamping groove and a V-shaped groove with the arc shape. A perpendicular guide rail forming a moving pair with a motor installation seat is respectively at the upper part and the lower part in the inner side of the left vertical support and the right vertical support. A helical pair regulating the lifting of the motor installation seat is arranged at the lower end of the motor installation seat. A lockable milling fixture is sleeved in the main axle of the horizontal motor on the motor installation seat. One end of the milling fixture forms a left-and-right position screw thread fine tuning mechanism by a horizontal regulating screw. The device can effectively peel the optical cable or the cable sheath with easy operation.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD +1

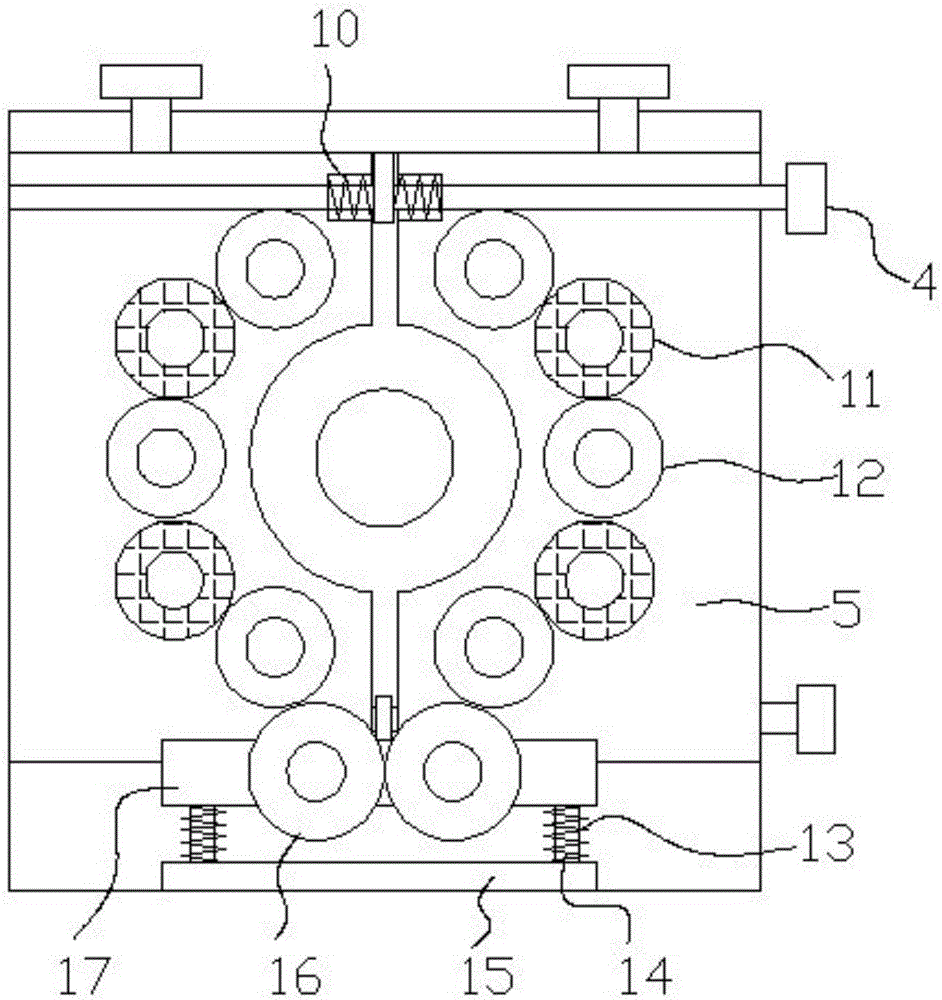

Crushing and shelling device for walnuts

The invention discloses a walnut crushing and peeling device, which comprises a frame, a guide mechanism and a crushing and peeling mechanism; both the guide mechanism and the crushing and peeling mechanism are arranged on the frame; It is transitionally connected with the crushing and peeling mechanism; the guide mechanism includes a guide box and a guide tooth roller, the entrance of the guide box is connected to the feed box, and the outlet of the guide box is provided with a guide tooth roller; the guide tooth roller and The guide boxes are arranged at a certain distance, and the distance is the feeding port; the feeding port is set correspondingly to the feeding port of the crushing and peeling mechanism; by designing the crushing mechanism and the guiding mechanism together, the walnuts can be crushed and peeled. The crushing effect in the shelling mechanism is better, which improves the shelling efficiency and quality of the shelling device, and solves the problems of insufficient walnut shelling in the existing walnut shelling machine, easy damage during the walnut shelling process, and low shelling efficiency , the problem of high cost.

Owner:周鑫

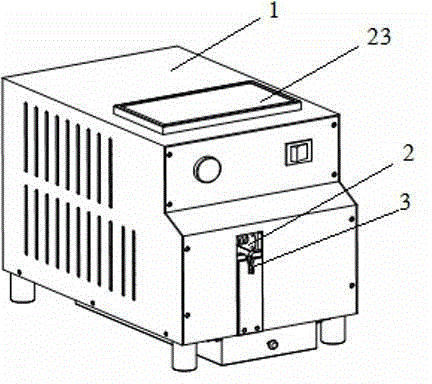

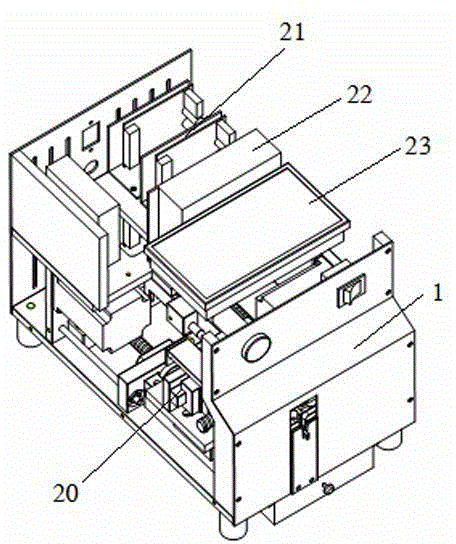

Electric stripping machine

ActiveCN103560441ASo as not to damageReduce demandLine/current collector detailsApparatus for removing/armouring cablesEngineeringReaction speed

The invention discloses an electric stripping machine which comprises a shell. A wire clamping mechanism, a stripping mechanism, a peeling mechanism and an electric control mechanism are arranged inside the shell, and an electric wire containing structure where electric wires stretch to be clamped by the wire clamping mechanism is formed in the side face of the shell. The electric stripping machine has the advantages of being capable of rapidly and accurately striping an insulated layer of the electric wires, good in stripping quality, and free of damage to an inner core; in addition, stripping for the electric wires of different specifications and different sizes is achieved simply by setting different technologies on a touch screen, production efficiency is improved, human cost is saved, and machine requirements are reduced; production cost is further greatly reduced, and due to the fact that electric control is adopted, mute performance is good, and reaction speed is high.

Owner:WELL SHIN ELECTRONICS KUNSHAN

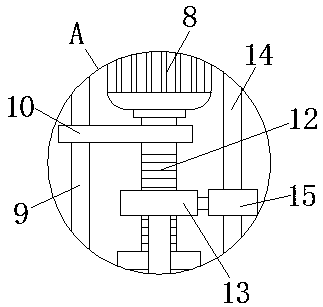

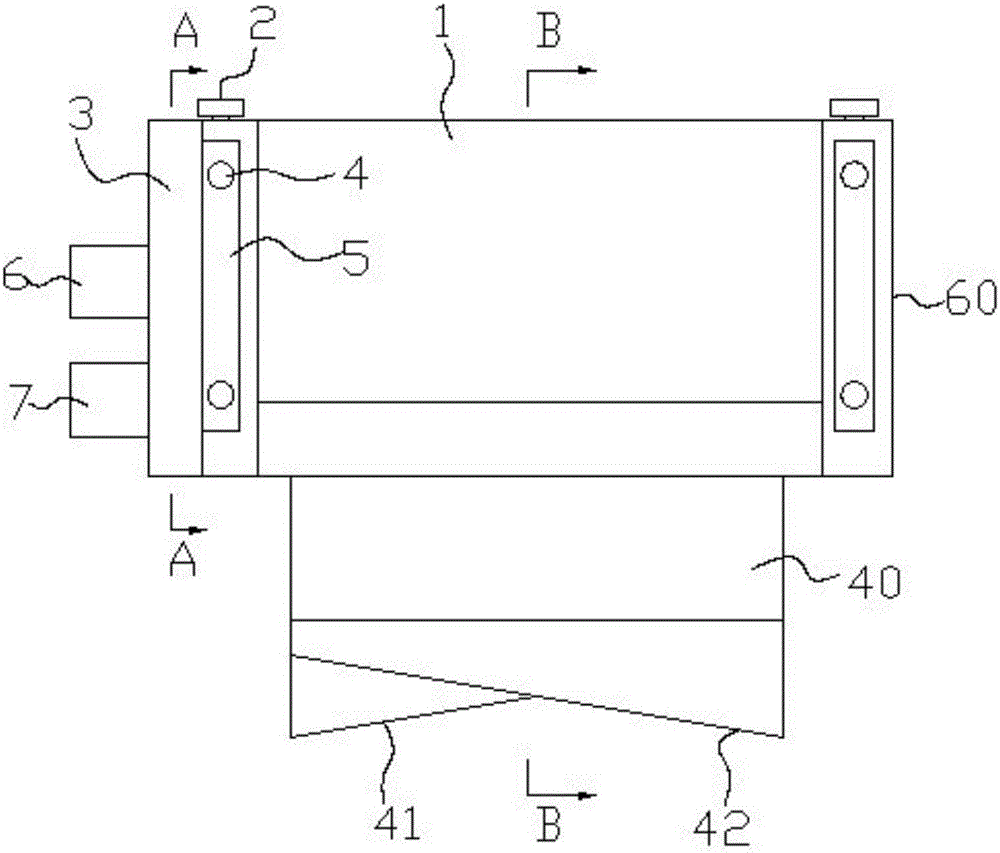

Power cable stripping device for electric power engineering

InactiveCN112165037AImprove peeling effectWide range of applicationsApparatus for removing/armouring cablesPower engineeringEngineering

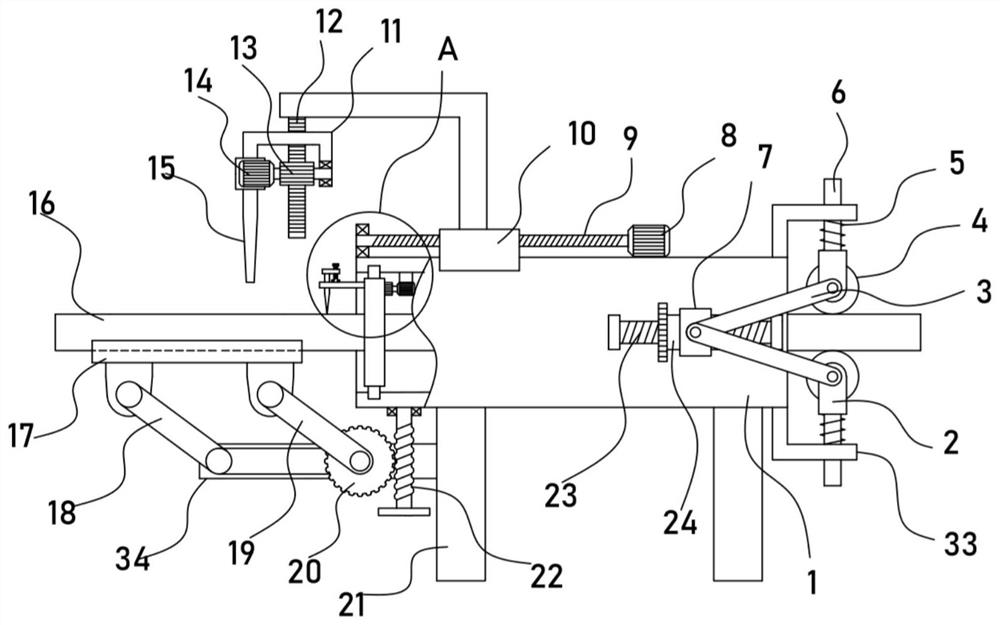

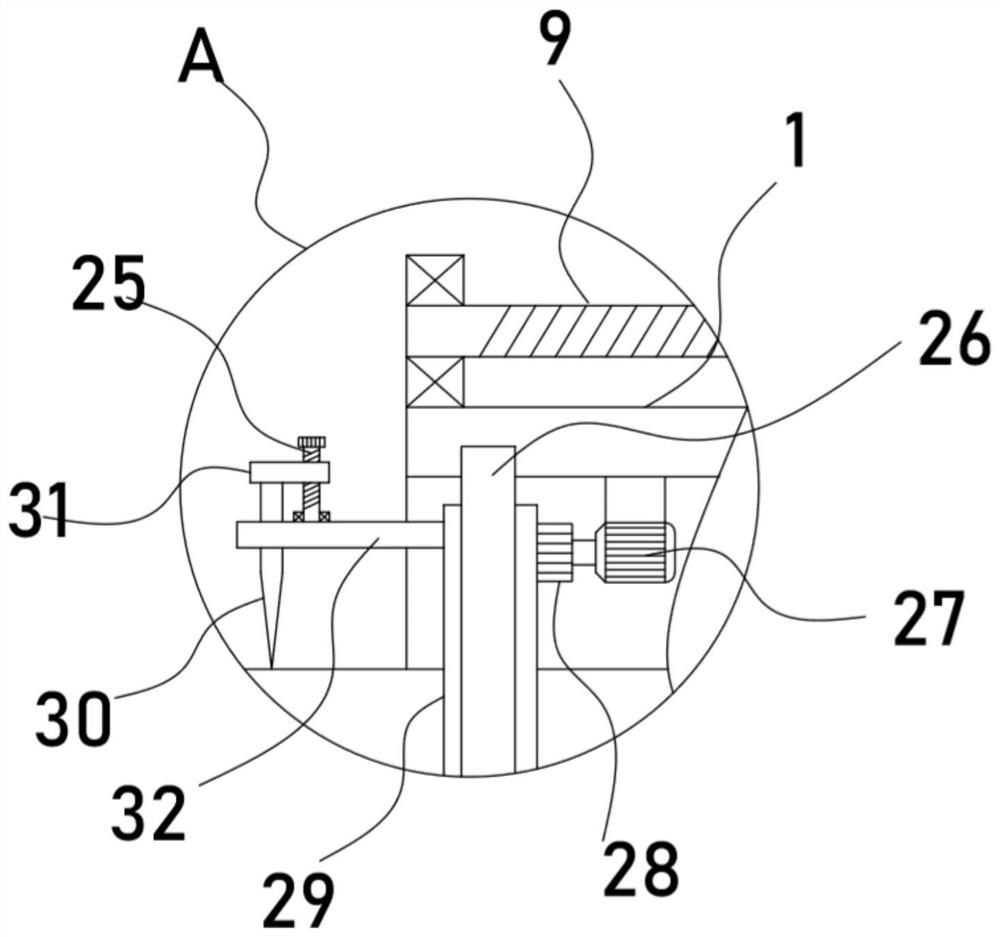

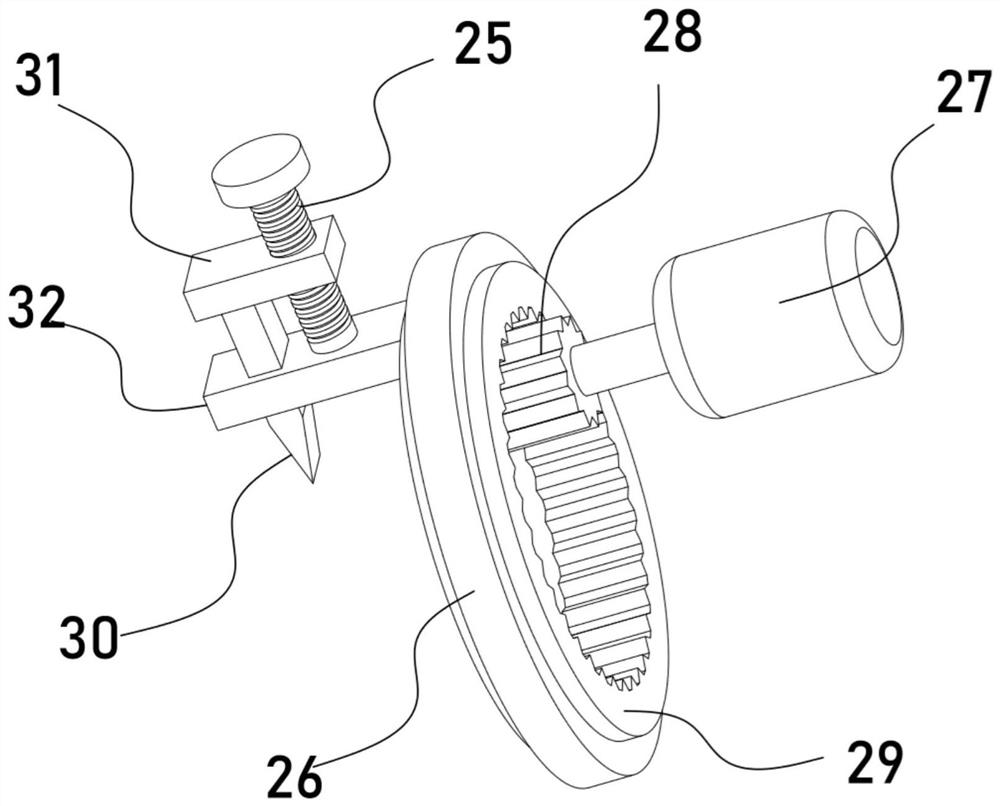

The invention discloses an electric power cable stripping device for electric power engineering, and relates to the technical field of electric power engineering. The electric power cable stripping device comprises a horizontal pipe, a vertical rack is in transmission connection with an axial cutting mechanism used for axially cutting an electric power cable, and an inner gear ring is rotationallyinstalled in the horizontal pipe under the driving of a rotating mechanism; an annular cutting mechanism used for annularly cutting the power cable is installed on the inner gear ring, and a clampingmechanism used for clamping the power cable is arranged on the horizontal pipe; according to the power cable stripping device, the arranged axial cutting mechanism can axially cut the sheath of the power cable, and the arranged circumferential cutting mechanism can circumferentially cut the power cable, so that the sheath of the power cable can be smoothly separated from the main body, and the stripping effect of the sheath of the power cable is remarkably improved; the device can achieve a flexible adjustment effect according to power cables with different diameters and peeling areas of thepower cables, is wide in application range, and is very high in peeling stability and peeling quality.

Owner:杨浩

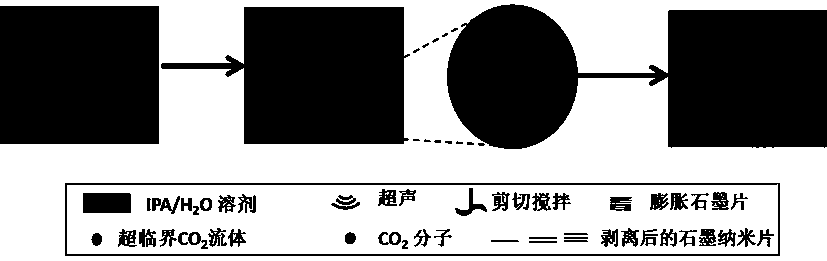

Method for preparing few-layer graphite nanosheets through supersonic supercritical CO2-shear coupled tripping of expanded graphite

PendingCN108439383AImprove diffusivityImprove peeling qualitySingle layer grapheneBulk chemical productionGraphiteSolvent

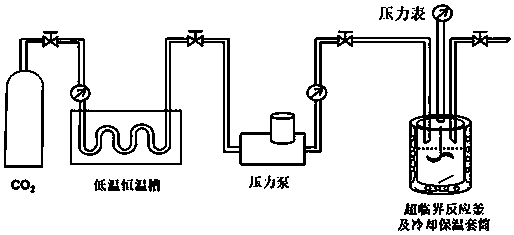

The invention relates to a method for preparing few-layer graphite nanosheets through supersonic supercritical CO2-shear coupled stripping of expanded graphite. The method comprises steps as follows:1) expanded graphite micropowder is dispersed in a stripping solvent to form a suspension; 2) a dispersant and a stripping aid are dissolved in the suspension in the step 1) for ultrasonic dispersion;3) the suspension subjected to ultrasonic dispersion is treated under the high-power ultrasonic action; 4) the suspension stripped in the step 3) is subjected to intercalation stripping for a periodof time under the condition of supercritical CO2 shearing; 5) the suspension is treated under the high-power ultrasonic action, and the few-layer graphite nanosheets are obtained. According to the method, the few-layer graphite nanosheets are prepared on a large scale through stripping of the graphite micropowder, the action force produced under the coupling condition is higher, the yield of stripped graphene can be increased, the solvent is a green solvent and is efficient, environmentally friendly and low in cost, and large-scale production is facilitated.

Owner:ZHENGZHOU UNIV

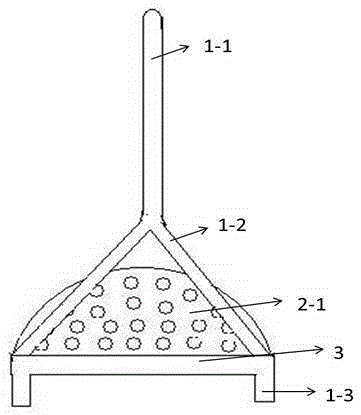

Chinese chestnut shell peeling machine

InactiveCN1596770AIncrease productivityReduce labor intensityHuskingHullingEngineeringMechanical engineering

Owner:印代隆

Abalone shelling machine

ActiveCN105285056AReduce consumptionRealize automatic feeding processShellfish processingConveyor beltEnergy consumption

The invention discloses an abalone shelling machine. The abalone shelling machine comprises a conveyor belt, an abalone arraying shape collating machine, a clamping jaw sliding block, a clamping jaw device, a sliding rail, an abalone shell containing box, a cut-off device, a spring shelling knife device, an abalone meat containing box, a pushing block device, a support gantry and a base. According to the abalone shelling machine disclosed by the invention, the functions of automatically loading, automatically shelling, automatically classifying and collecting shells and meat, and the like can be realized, the shelling quality is improved, processing requirements for shelling rapidly, cleanly and comprehensively are realized, the feeding time is saved, the processing quality is guaranteed, and the energy consumption is reduced.

Owner:大连伟瑞达精密模具制造有限公司

Novel gorgon euryale seed shelling device

ActiveCN111011879AImprove peeling efficiencyReduce the amount of labor and labor intensityHuskingHullingAgricultural engineeringStructural engineering

The invention relates to the field of agricultural machinery, in particular to a novel gorgon euryale seed shelling device which comprises a support, a material chamber fixedly connected with the support, a rotatable material taking mechanism arranged in the material chamber, a shell breaker arranged on the outer side of the material chamber, a transmission half shaft and a ventilation half shaft;the rotatable material taking mechanism is rotationally connected with the support through the transmission half shaft and the ventilation half shaft; the material taking mechanism comprises a seed taking roller; the ventilation half shaft is of a hollow structure and is communicated with a negative pressure device and the interior of the seed taking roller; through holes are uniformly formed inthe seed taking roller along the circumferential direction; an extrusion rod is arranged at the rear end of each through hole; a mounting frame is fixedly connected to the ventilation half shaft; a shell breaking knife comprises two blades which are symmetrically arranged; the center lines of the through holes, the extrusion rods and the shell breaking knife coincide; an air separation plate is attached to the inner wall of the seed taking roller and is fixedly connected to the ventilation half shaft. The gorgon euryale seed husking machine can solve the problems that manual husking efficiencyis low, the consumed labor amount is large, and an existing gorgon euryale seed husking machine is low in husking efficiency, not high in husking quality and high in gorgon euryale seed crushing anddamage rate.

Owner:CHUZHOU UNIV

Internal residue stripping device for asphalt mixing device

PendingCN108905775AQuality improvementImprove efficiencyRotary stirring mixersTransportation and packagingDrive motorEngineering

The invention relates to the technical field of asphalt mixing, and discloses an internal residue stripping device for an asphalt mixing device. The internal residue stripping device comprises a body,the top of the body is fixedly connected with a feeding hopper, the right side of the body is fixedly connected with a discharge pipe, a driving motor is fixedly connected to the inner wall of the left and right sides of the body through a connecting rod, and an output end at the top of the driving motor is fixedly connected with a stirring plate through a rotating shaft. The internal material stripping device of the asphalt stirring device is provided with an asynchronous motor and a threaded rod to rotate a thread block, a guiding slide rod and a guiding bearing seat are arranged to performthe vertical movement of the thread block under the limit position when the threaded rod rotates, a peeling push pedal is subjected to traction to perform the upper and lower movement, a driving belt, a transmission rod and a cam are arranged to vibrate an attachment plate by using the rotation of the threaded rod, the multi-action residue peeling can be achieved by vibration and pushing of the peeling push pedal, and the peeling quality and efficiency can be increased.

Owner:亚建科技有限公司

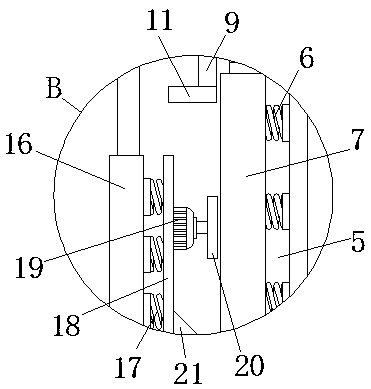

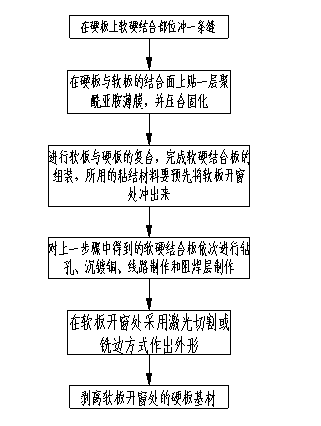

Manufacture method of joint part of hard-and-soft combined plate

ActiveCN103002671AImprove peel qualityImprove productivity and yieldPrinted circuit assemblingSolder maskDeckle

The invention discloses a manufacture method of a joint part of a hard-and-soft combined plate. The manufacture method includes the following steps: a punching a seam on the hard-and-soft joint part on a hard plate; b attaching, pressing and curing a polyimide film on the combined surface of the hard plate and a soft plate; c compositing the hard plate and the soft plate to complete assembling of the hard-and-soft combined plate, wherein the bonding materials are needed to punch a window opening position of the soft plate in advance; d sequentially performing drilling, copper plating, line manufacture and solder mask manufacture on the hard-and-soft combined plate obtained in the step c; e producing the contour at the window opening position of the soft plate in laser cutting or edge milling mode; and f stripping the hard plate base materials at the window opening position of the soft plate. Therefore, the manufacture method can improve the stripping quality of the joint part of the hard-and-soft combined plate, cannot have deckle edge or burrs, cannot damage the soft plate and improves productivity and yield.

Owner:赣州新联兴科技有限公司

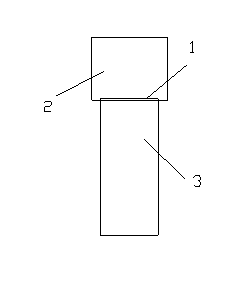

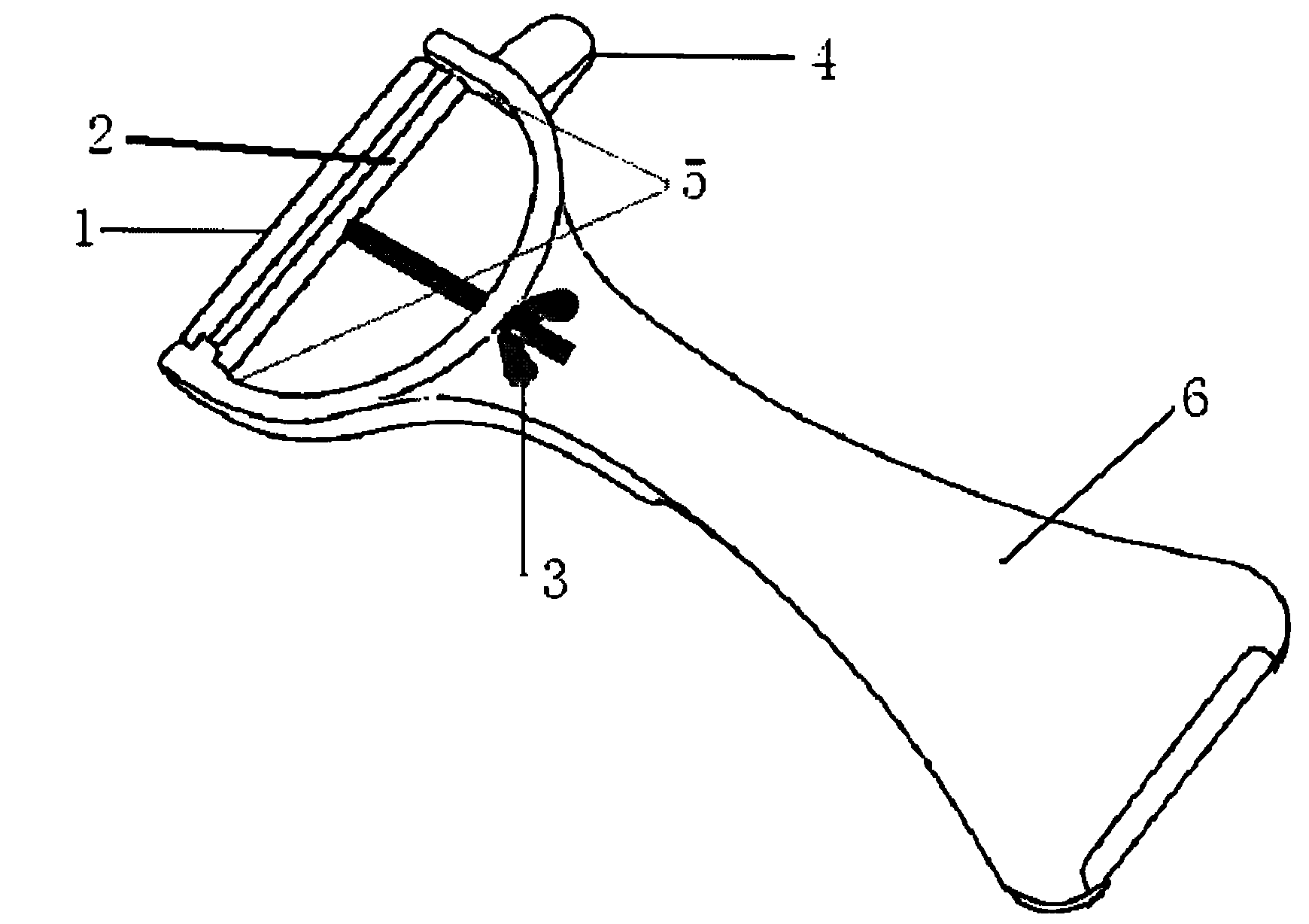

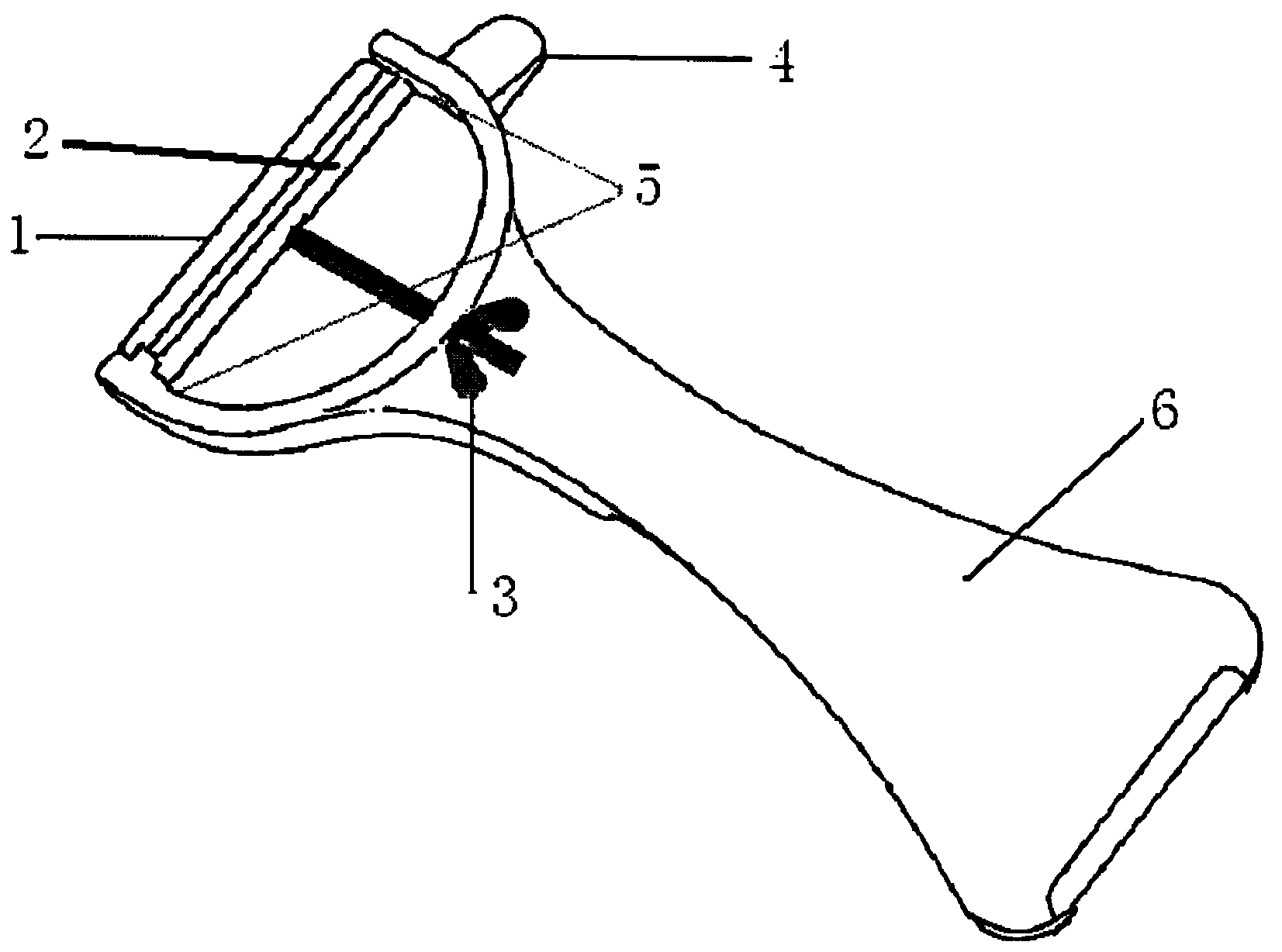

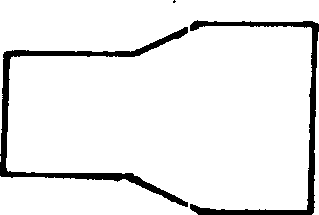

Peeling knife capable of adjusting peeling thickness

The invention discloses a peeling knife capable of adjusting peeling thickness. The peeling knife comprises a knife shank and a fixed knife blade and can also comprises a moving knife blade, wherein the rear part of the knife shank is a hand shank, the front part of the knife shank is a U-shaped knife rest, ribbon sliding slots are arranged at the left inner side and the right inner side of the U-shaped knife rest, and the front end of the U-shaped knife rest is fixedly provided with a fixed knife blade and a moving knife blade; the fixed knife blade is located at the outer side of the moving knife blade, and a gap is arranged between the fixed knife blade and the moving knife blade; the middle part of the moving knife blade is connected with a stud, and the moving knife blade and the stud are integrated; the moving knife blade slides in the sliding slot through the stud; and a flat digging and peeling part is arranged at the outer side of the U-shaped knife rest. The peeling knife provided by the invention is convenient to use, the peeling thickness can be adjusted, so that different melons and fruits can be reasonably peeled, the nutrition is reserved, the taste is enriched, and different demands of different people can be satisfied.

Owner:WUXI HENGDA MINE MACHINERY

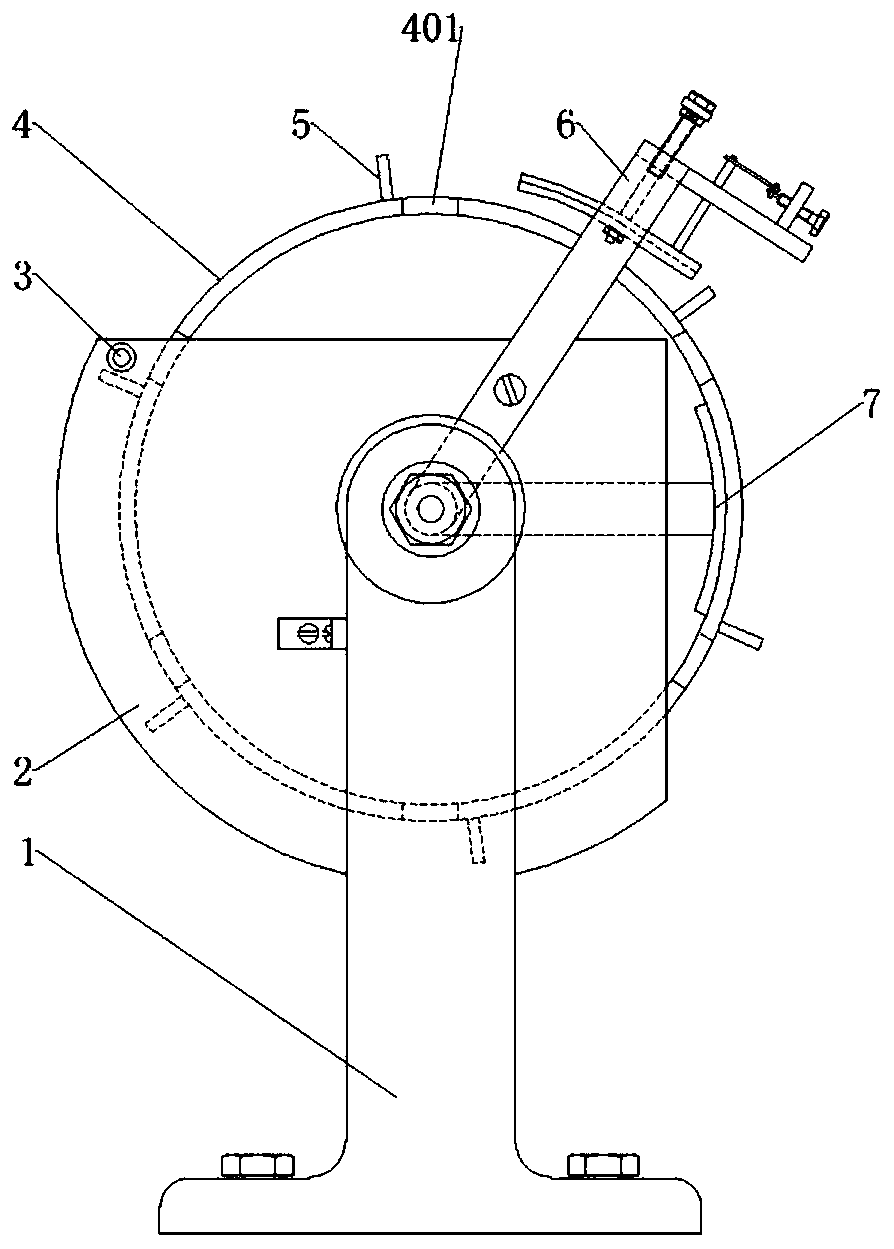

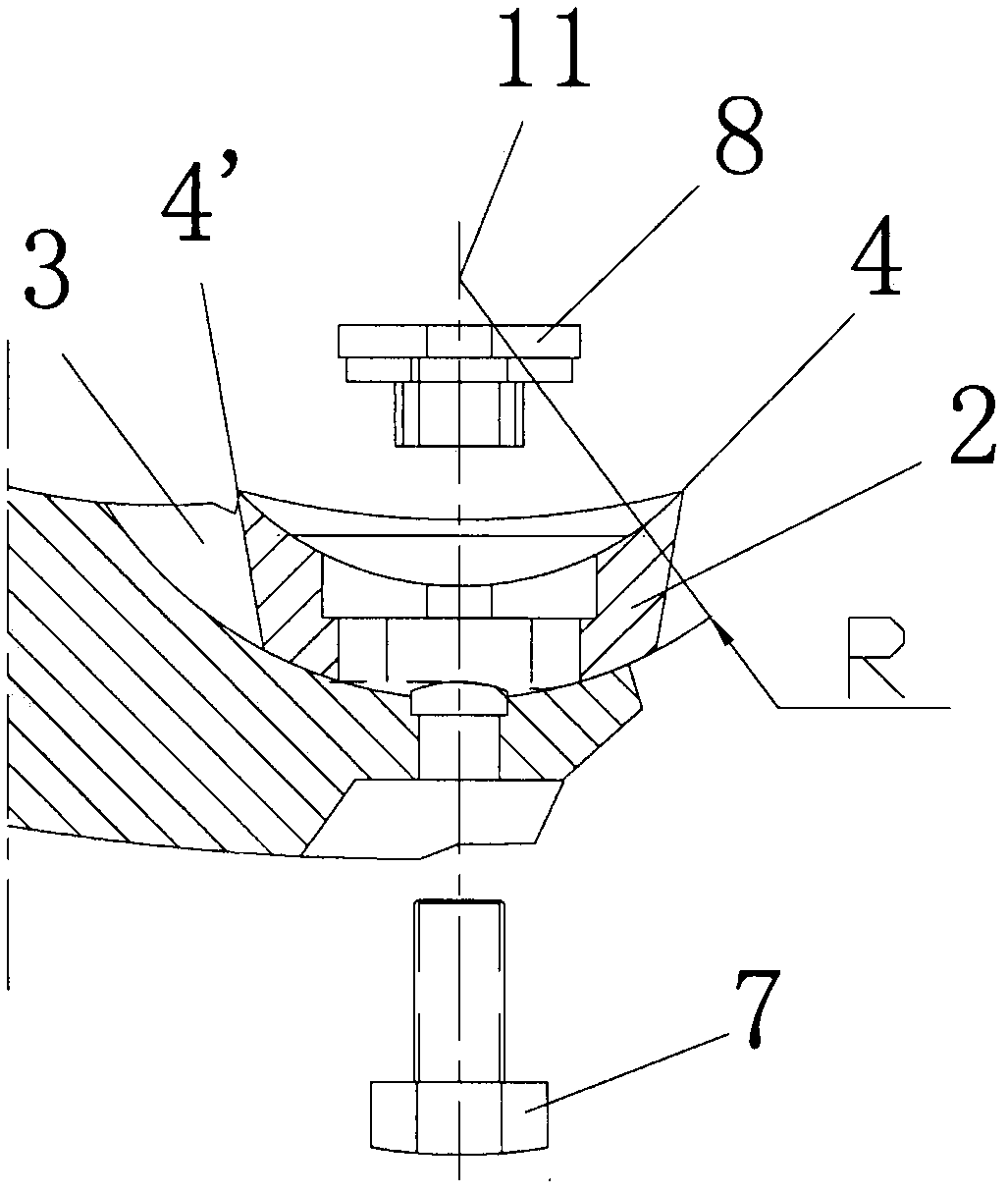

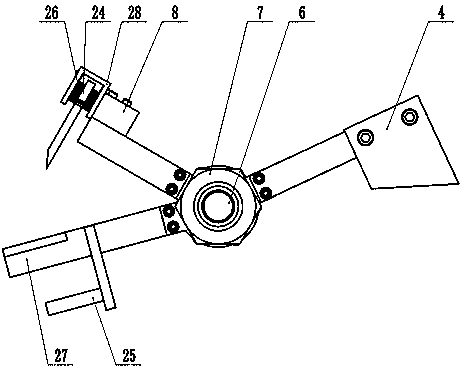

Marrow-bend small dimension wood skinning knife

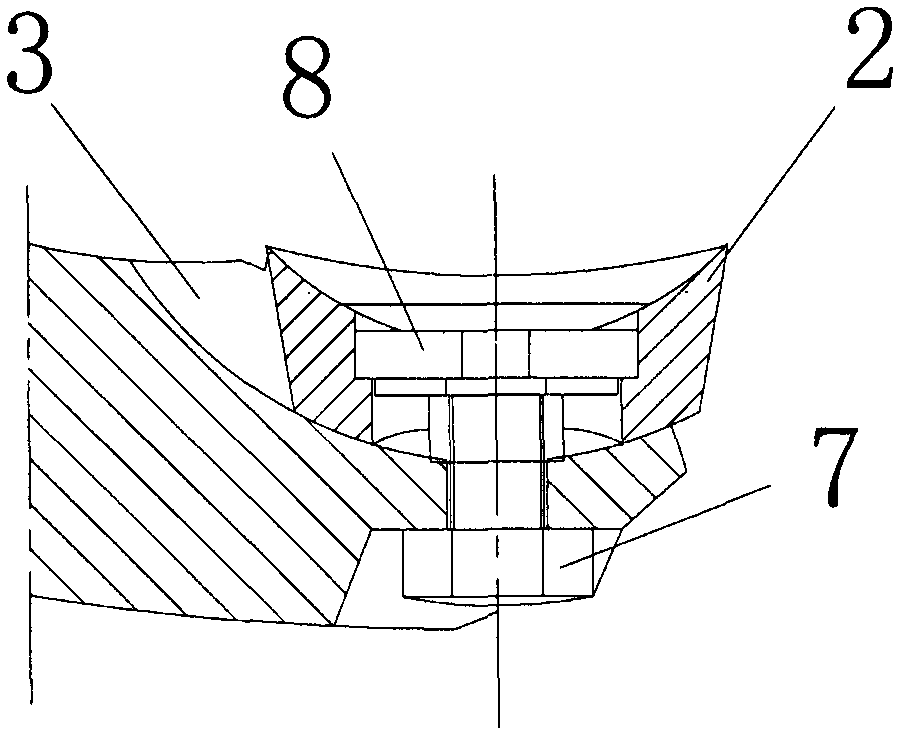

The invention discloses a marrow-bend small dimension wood skinning knife. The marrow-bend small dimension wood skinning knife is used for solving the problems that skinning rate of small dimension wood with large marrow-bend is low, a skinning knife can be fast rusted due to abrasion, the service life of the skinning knife is short and assembly and dismantling and sharpening of the skinning knife are troublesome when skinning is carried out by a raw wood skinning machine. The marrow-bend small dimension wood skinning knife is composed of a knife arm (1) and a blade (2). The marrow-bend small dimension wood skinning knife is characterized in that a gear seat (3) is machined on the floating end of the knife arm (1), the blade (2) is arranged on the gear seat (3) in a fastening mode through a bolt (7) and a nut (8), two cutting edges (4, 4') are machined on the blade (2), the back side of the blade (2) is an installation protrusion surface (5) and an installation groove (9) is machined in the installation protrusion surface (5), the installation protrusion surface (5) is made into an arc around a fixing shaft (11), the radius of the arc is R, the fixing shaft (11) is parallel to the feeding direction of raw wood, an installation concave surface (6) is arranged on the surface of the gear seat (3) and an installation through hole (10) is formed in the gear seat (3), the installation concave surface (6) of the gear seat (3) is made into an arc around the fixing shaft (11), and the radius of the arc is R, and the fixing shaft (11) is parallel to the feeding direction of the raw wood.

Owner:NANJING FORESTRY UNIV

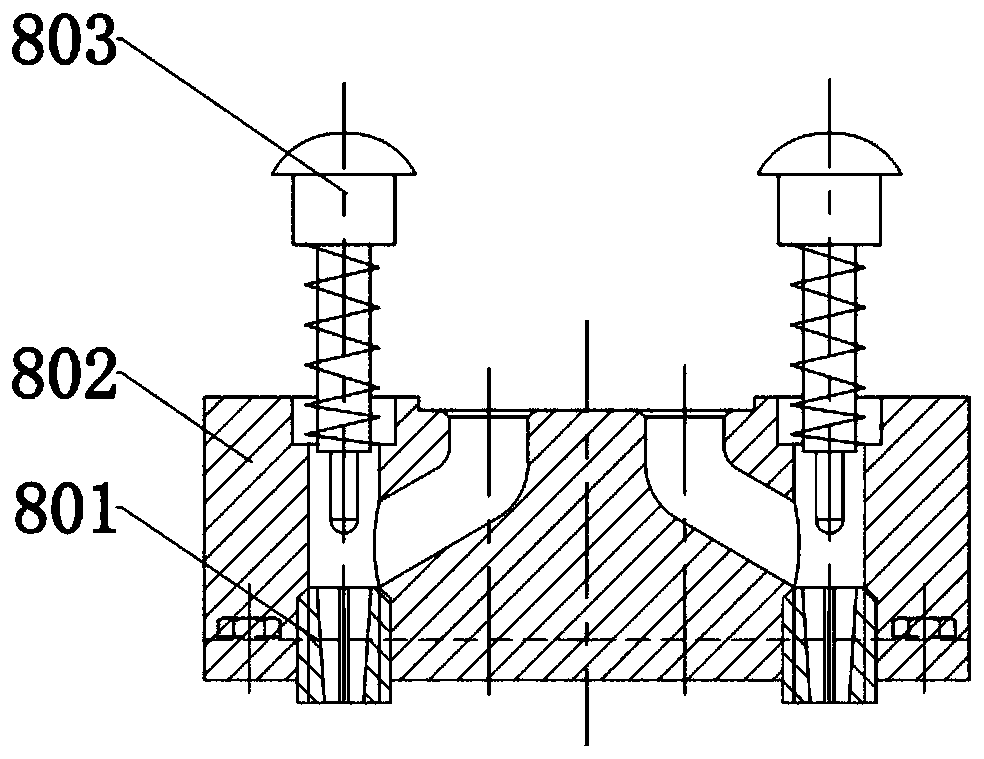

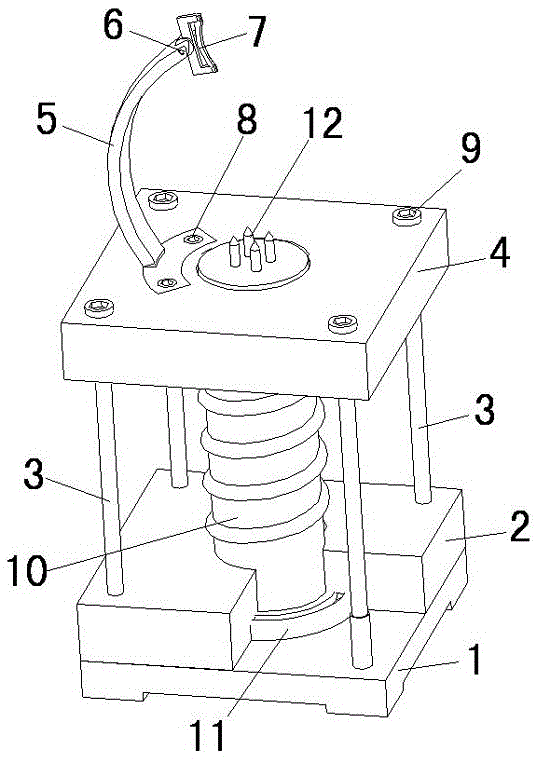

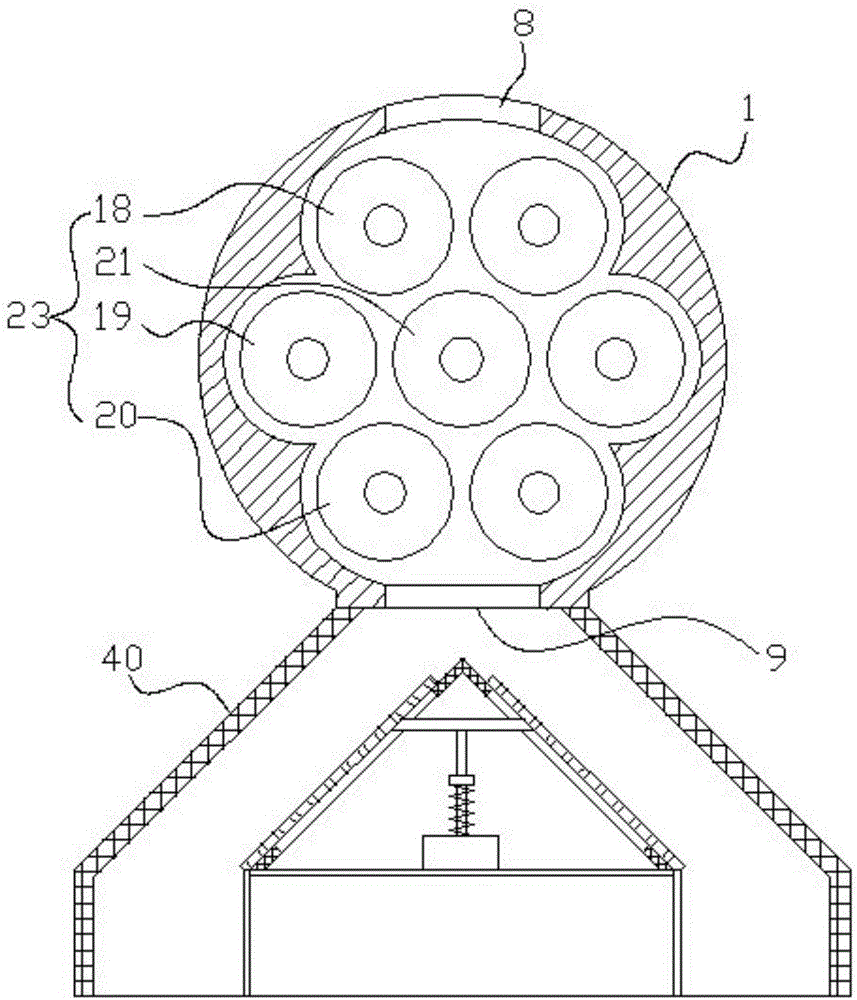

Single-grain cutting type gordon euryale seed shell breaking device

ActiveCN111011878AImprove shelling efficiencyImprove peeling qualityHuskingHullingEngineeringMechanical engineering

The invention discloses a single-grain cutting type gordon euryale seed shell breaking device which comprises a mounting table, a feeding mechanism fixedly connected with the mounting table through asupport, and a shell breaking mechanism fixedly connected with the mounting table and located below the feeding mechanism; the feeding mechanism comprises a roller connected with the support through abearing and provided with a material leaking opening in the side face in the radial direction, and a seed blocking barrel arranged on the outer side of the roller and used for blocking the material leaking opening; the shell breaking mechanism comprises a shell breaking main body; a seed pressing hole and a seed taking hole which are communicated with each other are formed in the shell breaking main body; an extrusion rod is fixed above the seed pressing hole through a spring, and a shell breaking knife is mounted below the seed pressing hole. According to the invention, the feeding mechanismis matched with a shelling mechanism, the hulling work of single grain gordon euryale seed is achieved, seed blocking is not easily caused in the whole hulling process, the smoothness of the whole hulling process is guaranteed, the hulling efficiency is improved, the hulling requirements of gordon euryale seeds of different sizes can be met only by replacing the hulling knife, and the applicationrange is wide.

Owner:CHUZHOU UNIV

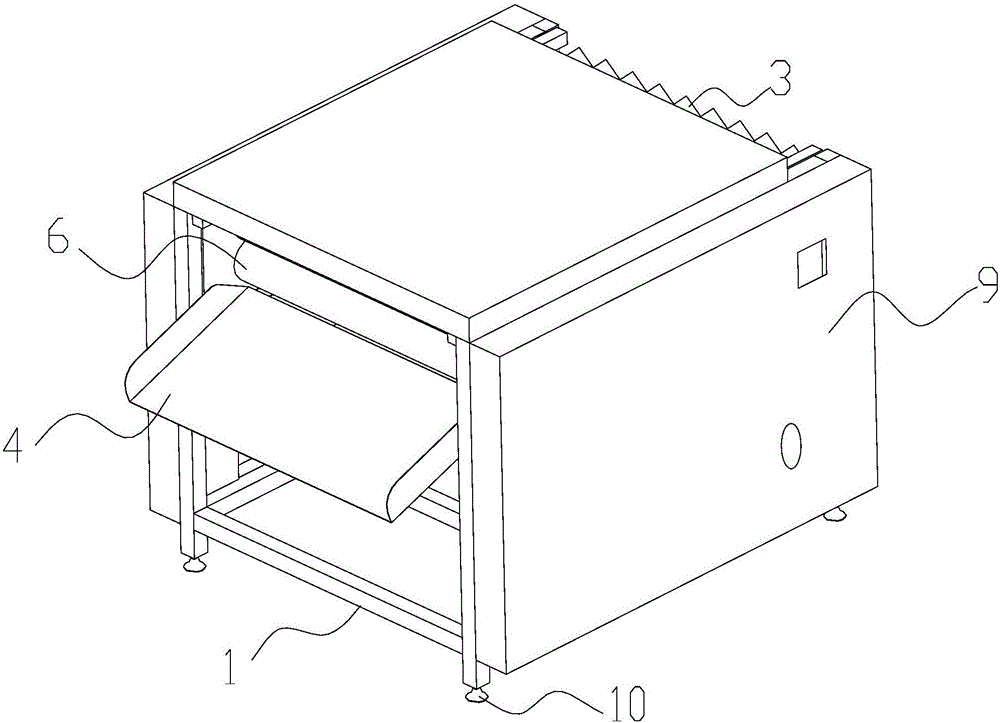

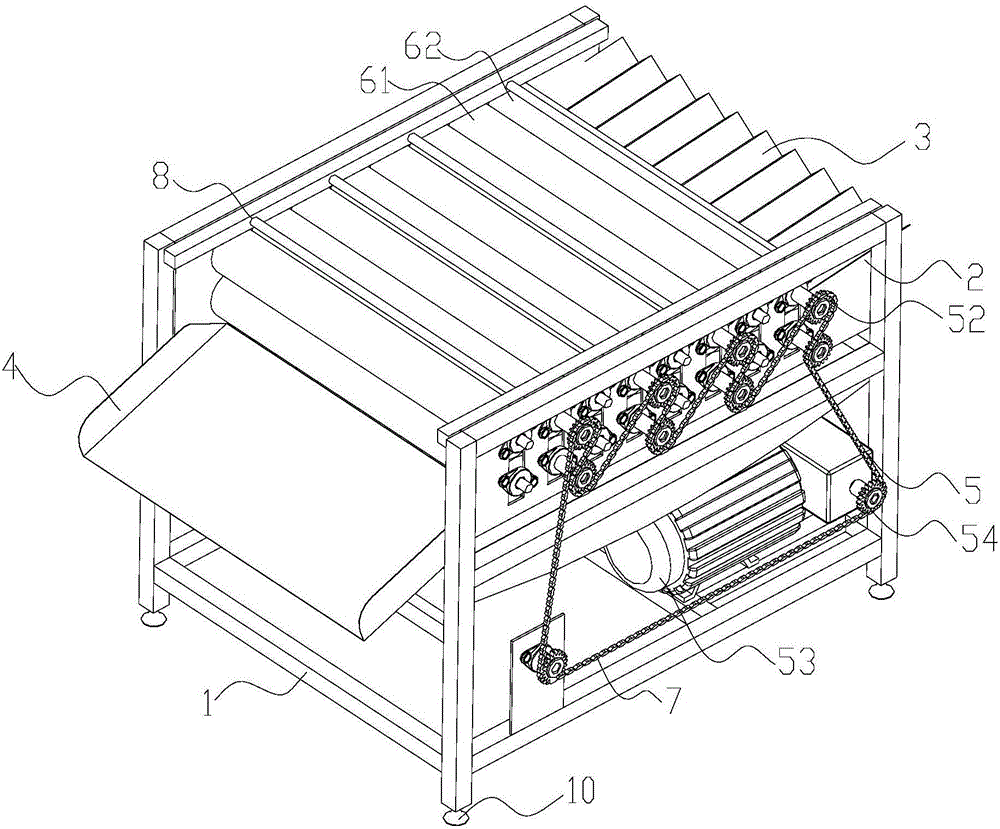

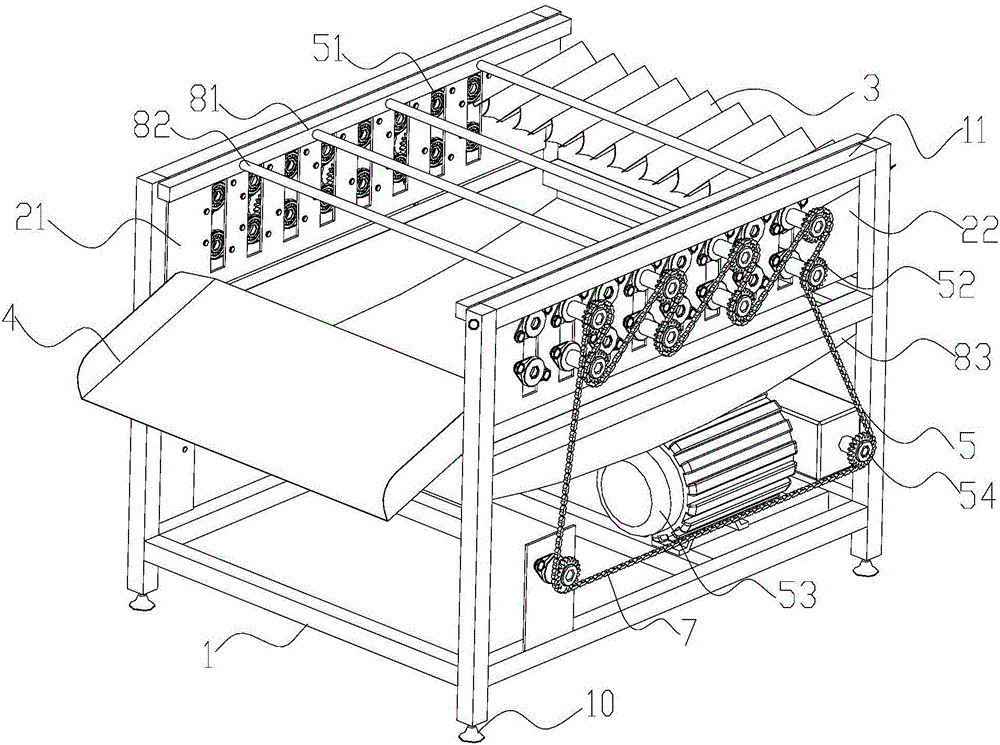

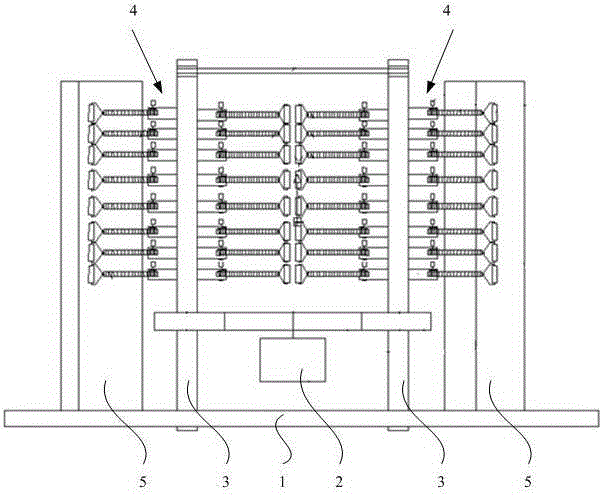

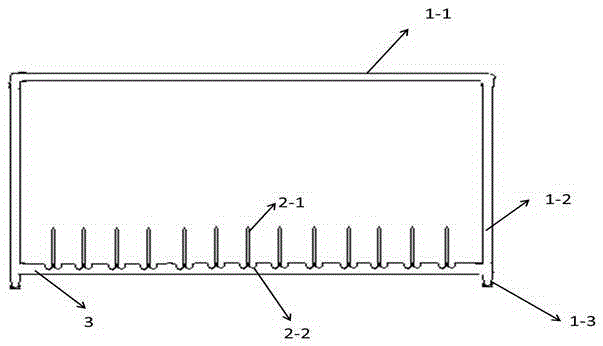

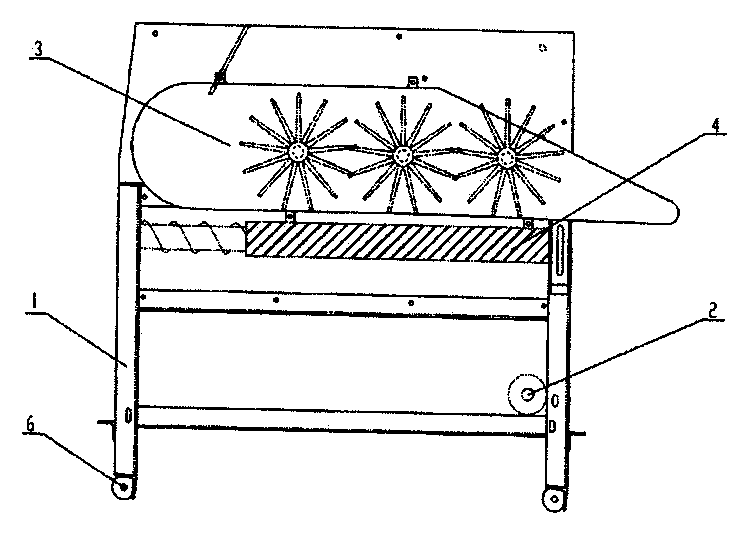

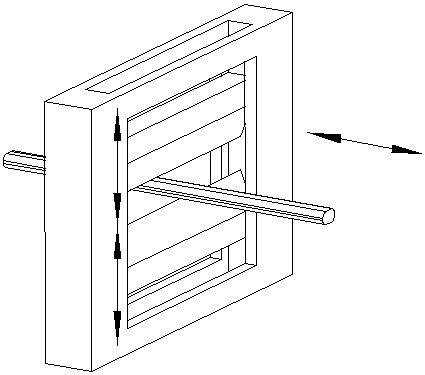

Dendrobium officinale peeling machine

PendingCN106137754ASimple structureImprove peeling qualityPharmaceutical product form changeDendrobium amoenumEngineering

The invention discloses a dendrobium officinale peeling machine and belongs to the technical field of dendrobium officinale processing devices. The dendrobium officinale peeling machine comprises a rack, a feeding plate, a discharging plate, a driving device and upper and lower rows of roller sets, wherein the roller sets are formed by arranging horizontally arranged hairbrush rollers and smooth rollers at intervals, the gap between the upper and lower rows of roller sets forms a dendrobium officinale peeling channel, and the hairbrush rollers and the smooth rollers are respectively and rotatably arranged on the rack. The driving device is arranged on the rack and controls the rotations of the hairbrush rollers and the smooth rollers. The feeding plate is arranged at one end of the rack, one end of the feeding plate extends between the two rows of roller sets, the discharging plate is arranged at the other end of the rack and located below the lower row of roller sets, and dendrobium officinale enters the peeling channel along the feeding plate and then falls onto the discharging plate. The dendrobium officinale peeling machine is simple in structure, high in peeling accuracy and high in speed, does not damage dendrobium officinale, also has a cleaning function and is high in working efficiency.

Owner:GUANGDONG YIFENG ECOLOGICAL IND CO LTD

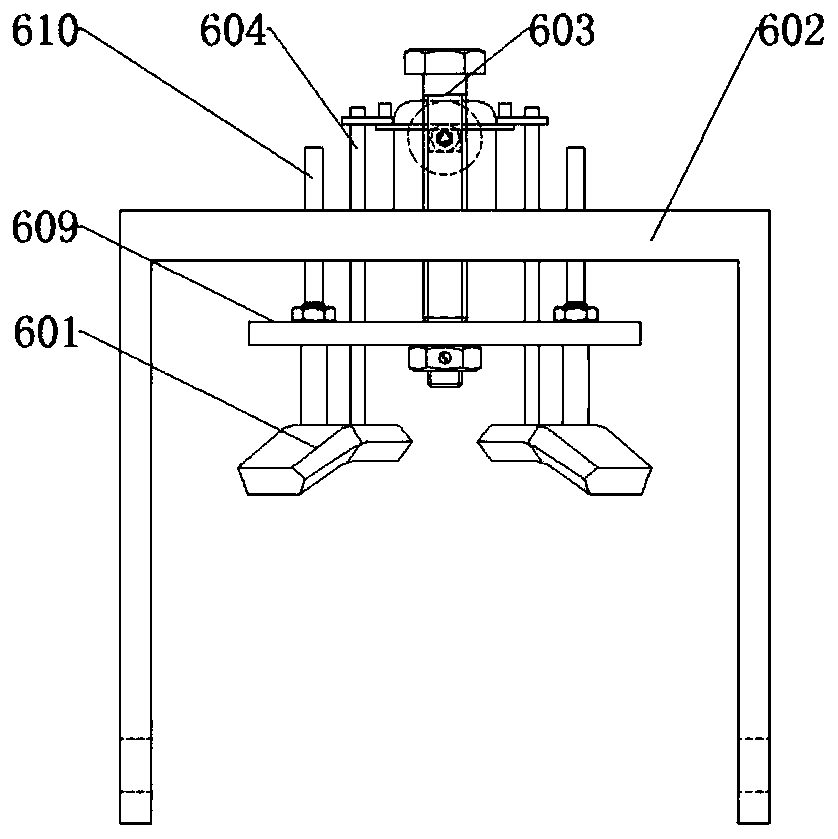

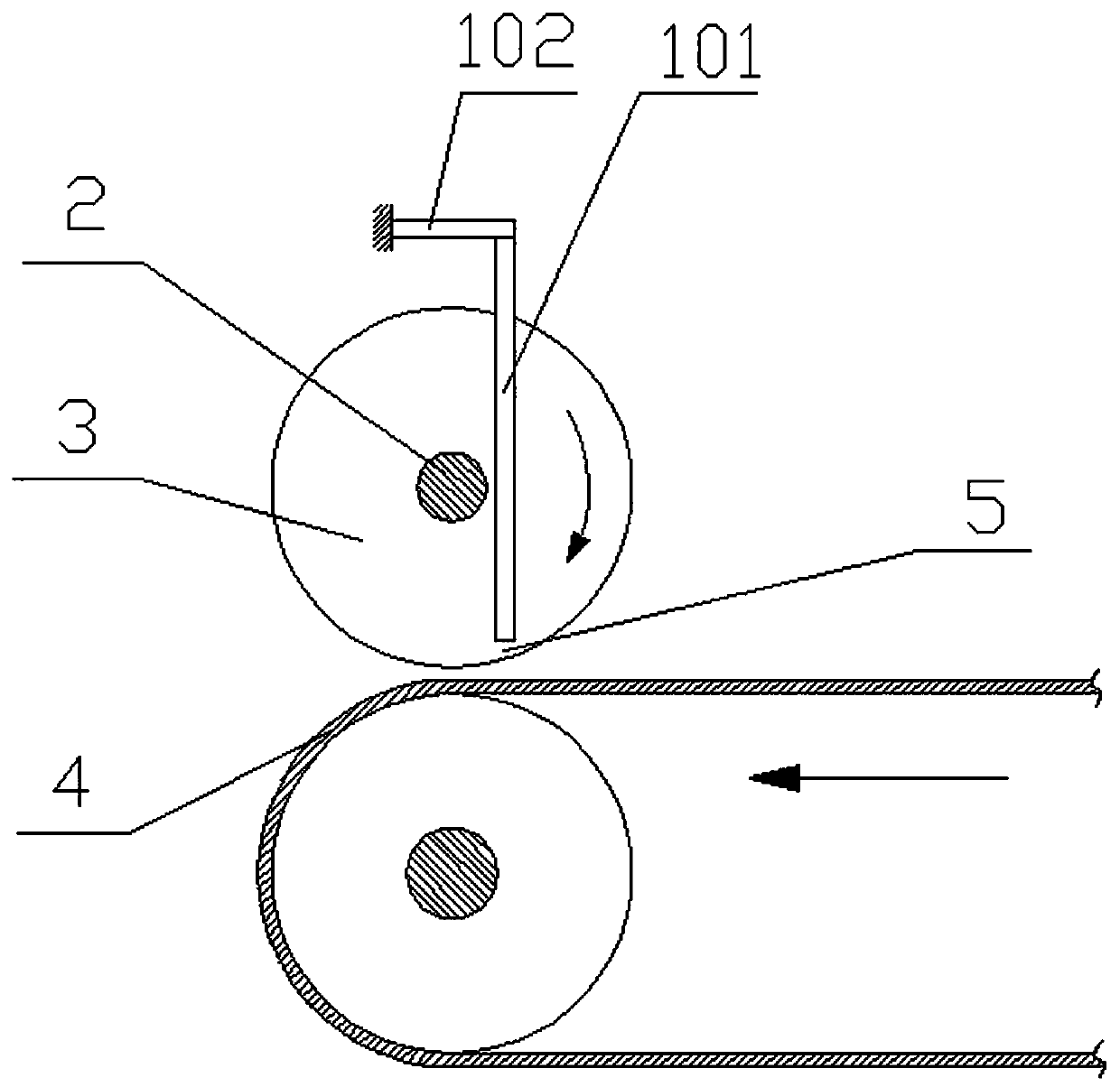

Cooked fish skin removing machine and skin removing method

InactiveCN105325531AImprove peeling efficiencyImprove peeling qualityFish skinningDrive motorBiomedical engineering

The invention discloses a cooked fish skin removing machine and a removing method. The cooked fish skin removing machine comprises a bracket, a drive motor, two rotating shafts and multiple skin sticking modules, wherein the two rotating shafts are arranged side by side and rotationally connected onto the bracket, the drive motor and the rotating shafts are in transmission connection, at least one skin sticking module is arranged on each rotating shaft, each skin sticking module comprises multiple rollers with the sticking function and multiple rotating arms, the multiple rotating arms are distributed around an axis of the corresponding rotating shaft and mounted on the rotating shaft, the rollers are rotationally connected onto the corresponding rotating arms, and each skin sticking module on one rotating shaft is opposite to the corresponding skin sticking module on the other rotating shaft. The cooked fish surface is processed by the skin sticking modules in a sticking mode, the fish skin is not required to be cut by a cutting tool, the cooked fish skin removing efficiency is effectively improved, and meanwhile, the cooked fish skin removing quality is improved.

Owner:QINGDAO AGRI UNIV

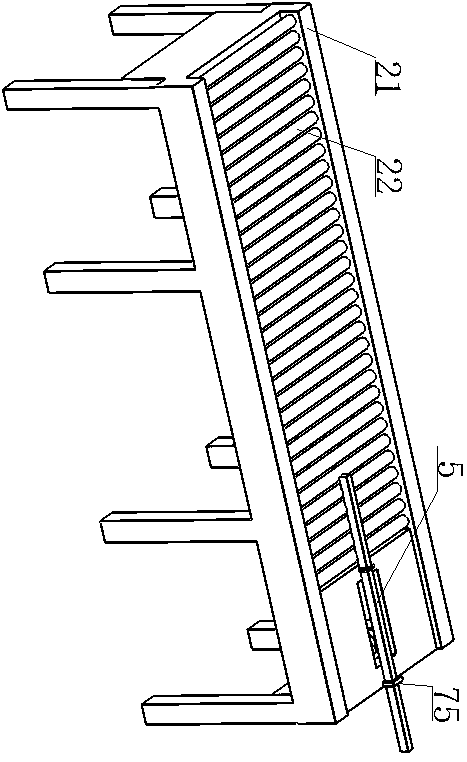

2-inch chip photoresist peeling basket

InactiveCN105304538AAvoid pollutionAvoid debrisSemiconductor/solid-state device manufacturingBiochemical engineeringPhotoresist

Provided is a 2-inch chip photoresist peeling basket which comprises a basket body, clamping groove units, and a support unit. The clamping groove units are arranged on the basket body and each clamping groove unit is provided with two trenches between which a baffle plate for separating the two trenches is disposed. A supporting column is arranged on the bottom of the basket body. The support unit is arranged on the basket body. The peeling faces of two photoresist peeling chips placed in the two trenches are opposite. And the two chips are separated by the baffle plate. The 2-inch chip photoresist peeling basket may effectively enlarge the liquid flowing space of the photoresist peeling faces, prevents a chip interface from being polluted and scratched by winding and wandering of peeled thin films in the reagent solution of the limited space between the chips, prevents a quality problem of uncleaned peeling, effectively improves ultrasonic peeling effect, and improves photoresist peeling quality on the premise that production efficiency is guaranteed.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

A self-rotating fruit peeling machine

The invention discloses a self-rotation type fruit peeling machine. The self-rotation type fruit peeling machine comprises a base, a moving body, a rotating body and a cutting head, wherein four upright columns are uniformly distributed at four corners of the base; a bearing is arranged in the middle of the base; the lower end of the rotating body is arranged in the bearing of the base and is in interference connection with the bearing; a convex rotating guide track is arranged on the outer peripheral surface of the rotating body; the moving body sleeves the upright columns; a concave rotating guide track is arranged in the middle of the moving body; the upper end of the rotating body penetrates in the moving body and is connected with the moving body through a rotating track, so that the moving body moves vertically, and the rotating body rotates; the moving body is provided with an elastic knife rest; the cutting head is fixed at the upper end of the elastic knife rest through a cutting head pin, and can freely rotate around the knife head pin; and a fruit fork is arranged on an end surface of the upper end of the rotating body. By the self-rotation type fruit peeling machine, fruits can be peeled quickly and automatically twice, and the peeling quality is high; the self-rotation type fruit peeling machine is suitable for fruits in various shapes and with various sizes; and the safety performance is high.

Owner:SUZHOU VOCATIONAL UNIV

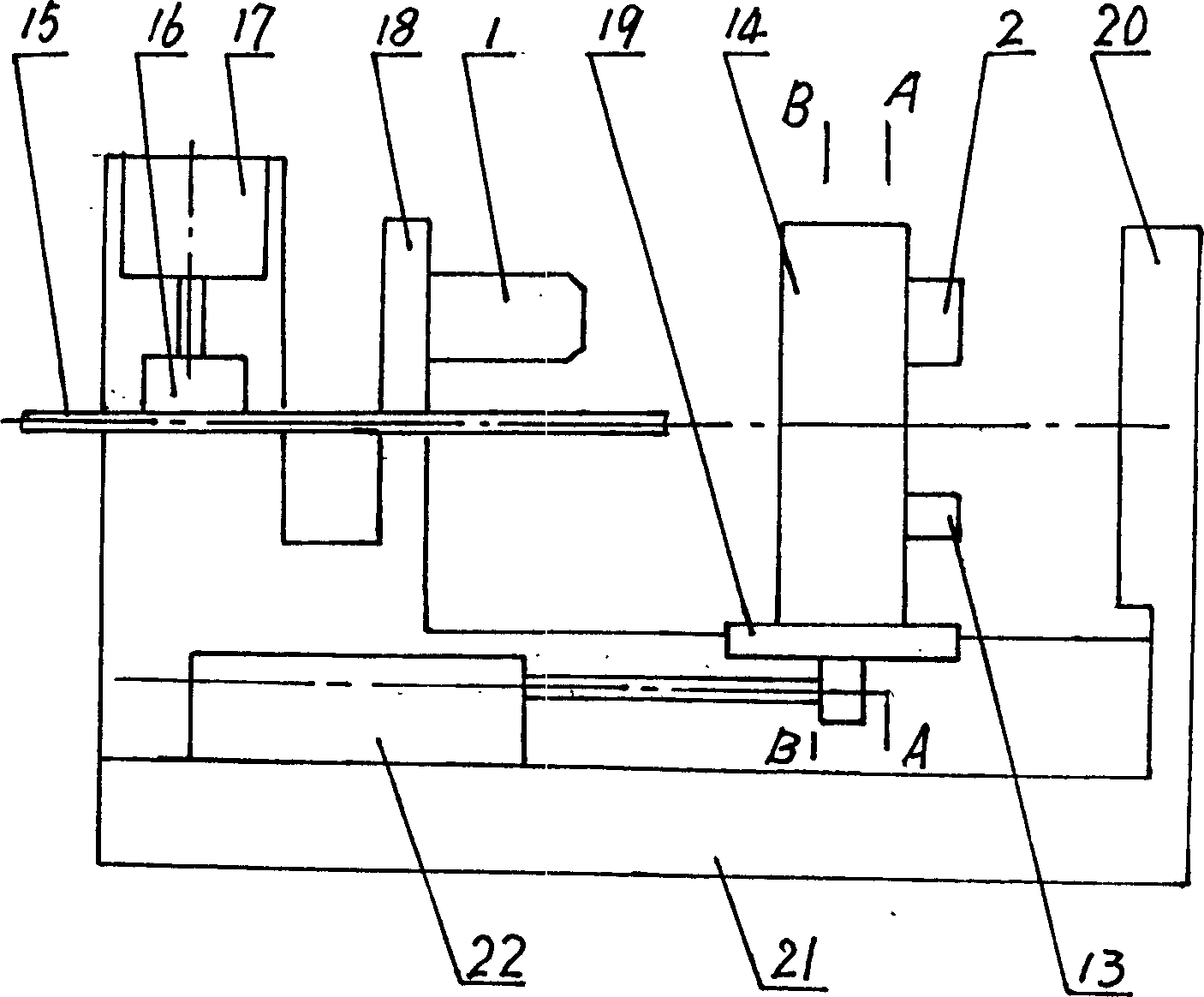

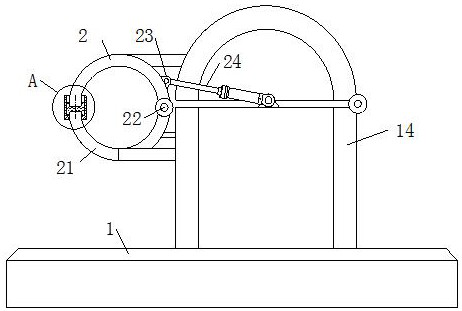

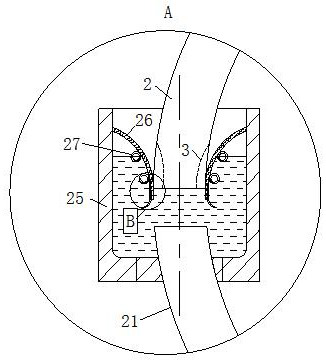

Electromagnetic wire stripping machine

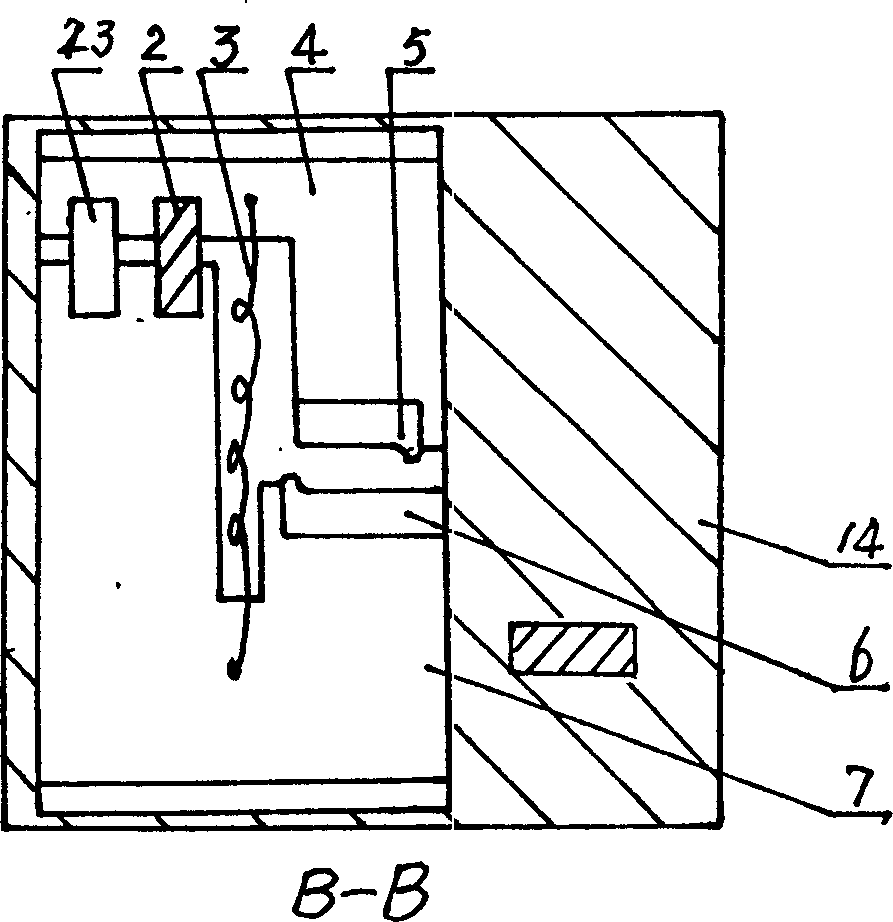

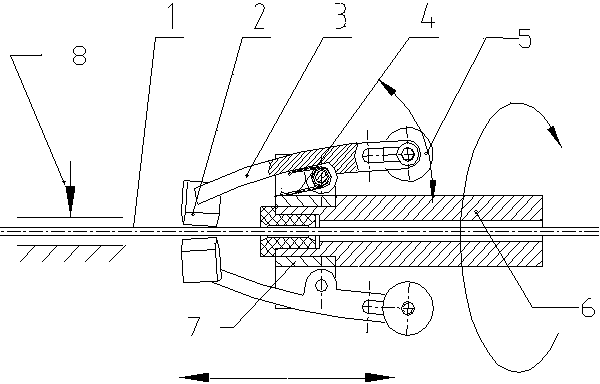

InactiveCN1599154AImprove peeling qualityRealize semi-automatic peeling workLine/current collector detailsSpring forceEngineering

The invention relates to an electromagnetic wire barker machine and includes the machine frame 21, oil cylinder 22, oil cylinder 17, compacting block 16 and electromagnetic wire 15. There are an oil cylinder 22 at the upper part of the frame and an oil cylinder 17 is set at the top left part of the frame. There is a compacting block 16 at the end of the oil plug pole. There are a location limit board 18 at the left end of the frame 21 and a location limit board 20 at the right end of the frame 21. There is a shut-limiting bolt 1 on the location limit board 18. Between the location limit boards 18 and 20, the oil plug pole of the oil cylinder 22 connects with the slippery lingua 19, on which there is molding knife box 14. There are the electromagnetic wire fluctuating barker device and electromagnetic wire fore-and-aft barker device in the molding knife box 14. The invention is featured by high efficiency, safety, convenient use and high quality of peeling, can finish the semiautomatic peeling work of the automatic electromagnetic line, can choose corresponding bit according to the size of section of the electromagnetic wire to be peeled, adapts the spring force and realizes the quick peeling working of many electromagnetic wires.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

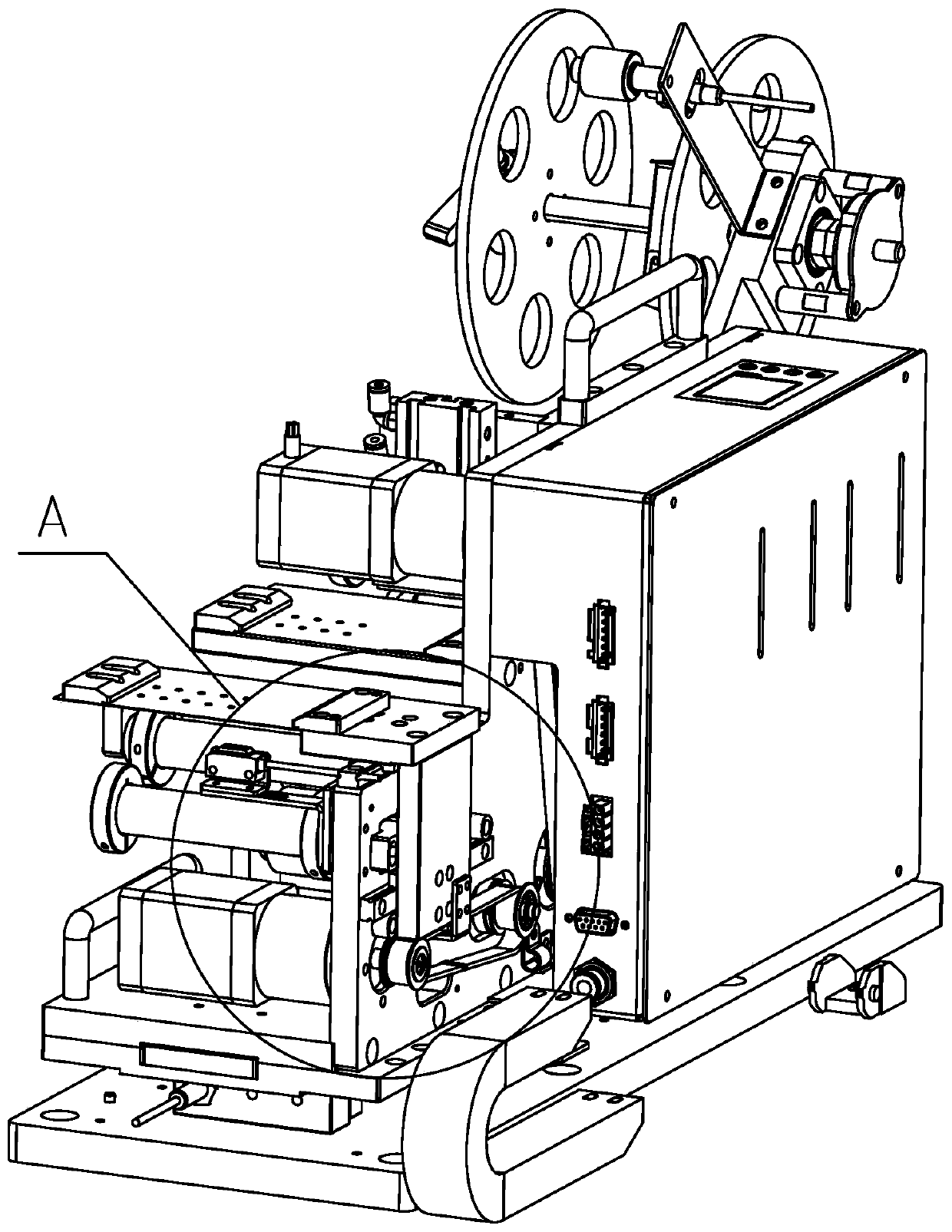

Pulling type automatic mark discharging machine

PendingCN109808977AReasonable structural designImprove stripping efficiencyLabelling machinesRelease linerPhotoelectric sensor

The invention provides a pulling type automatic mark discharging machine. The pulling type automatic mark discharging machine comprises a machine frame. The machine frame is provided with an uncoilingmechanism, a coiling mechanism, a stripping platform and a paper rolling motor. The stripping platform comprises a fixed receiving platform and a stepping receiving platform. A pressing block is arranged on the upper portion, corresponding to the fixed receiving platform, of the machine frame. The stepping receiving platform is connected with the machine frame in a sliding mode and correspondingly fixed on a discharging side of the fixed receiving platform in parallel. A follow-up coiling tension wheel sliding synchronously with the stepping receiving platform is arranged under the stepping receiving platform. A fixed coiling tensioning wheel is rotationally connected with the lower portion, corresponding to the stepping receiving platform, of the machine frame. A photoelectric sensor isfixed to position, corresponding to the final sliding position of a discharging side of the stepping receiving platform, of the machine frame. The pulling type automatic mark discharging machine can effectively realize stepping type stripping of labels on release paper and effectively improve stripping efficiency, the stripping quality is high, label counting is facilitated, the phenomena of incomplete stripping caused by improper machine stopping are reduced, and label waste is reduced.

Owner:快克自动化科技(东莞)有限公司

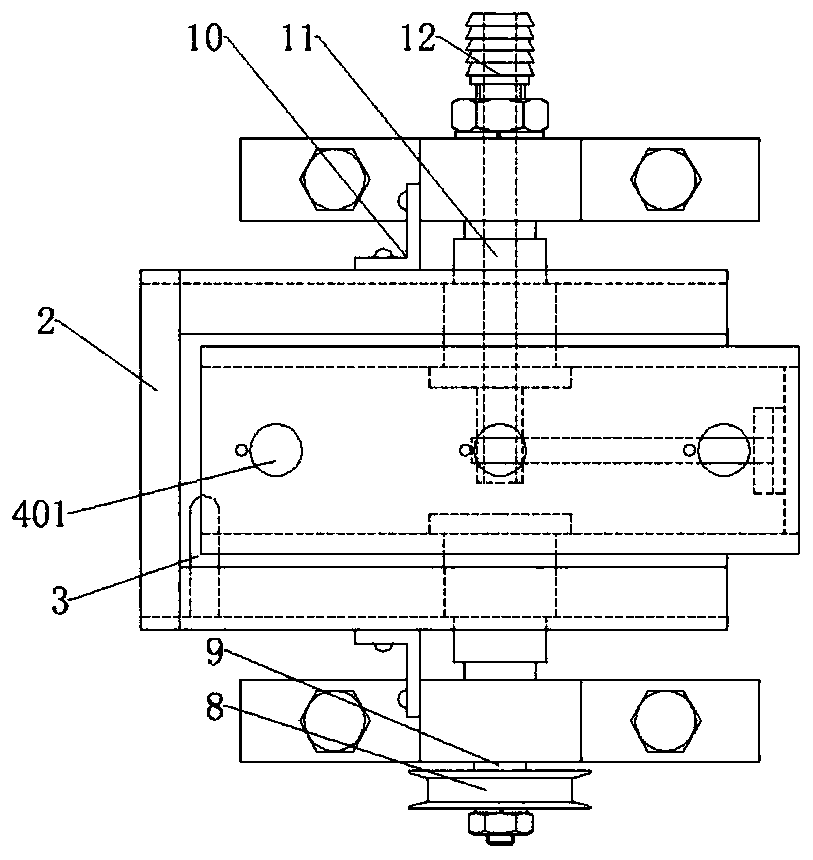

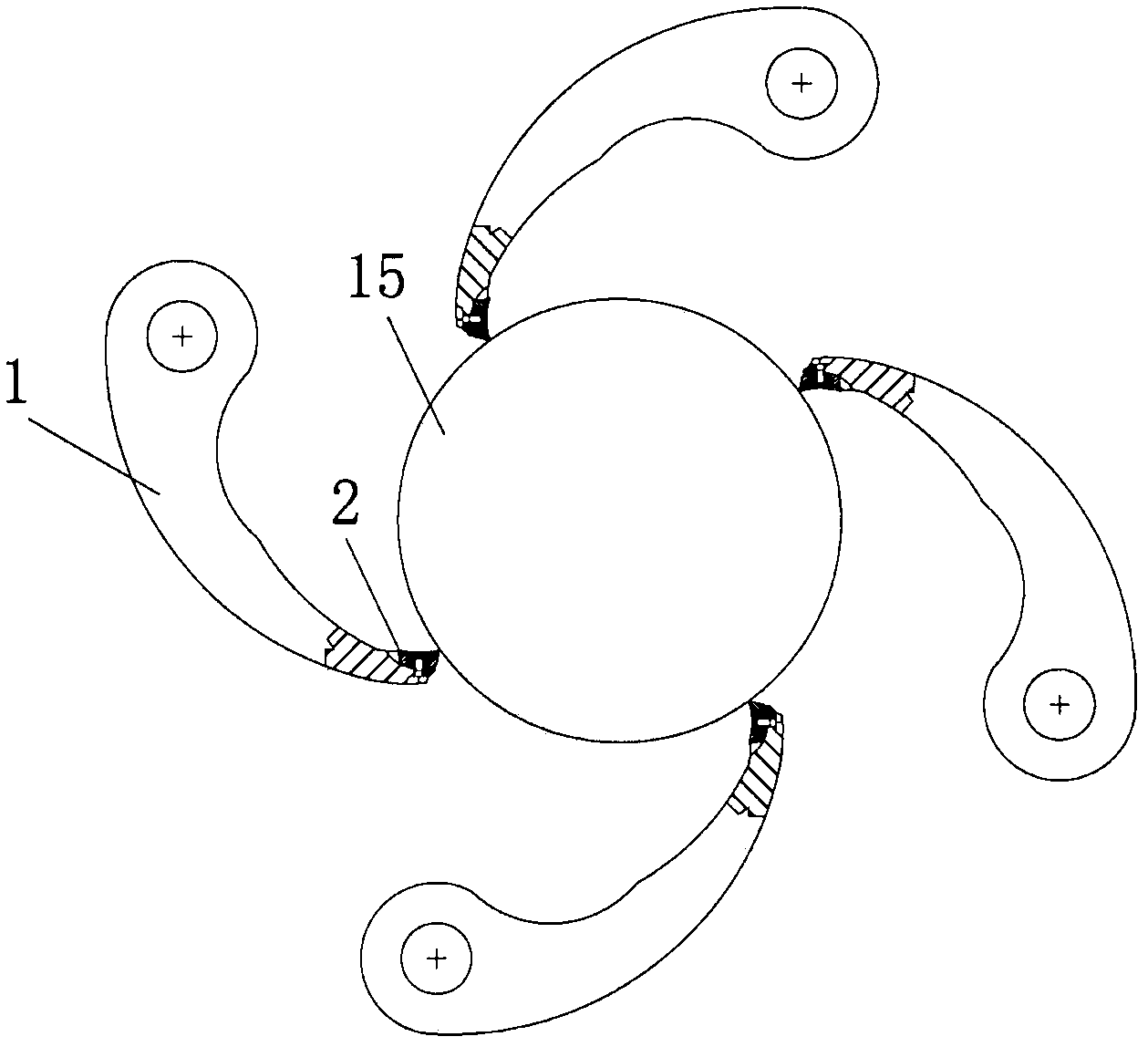

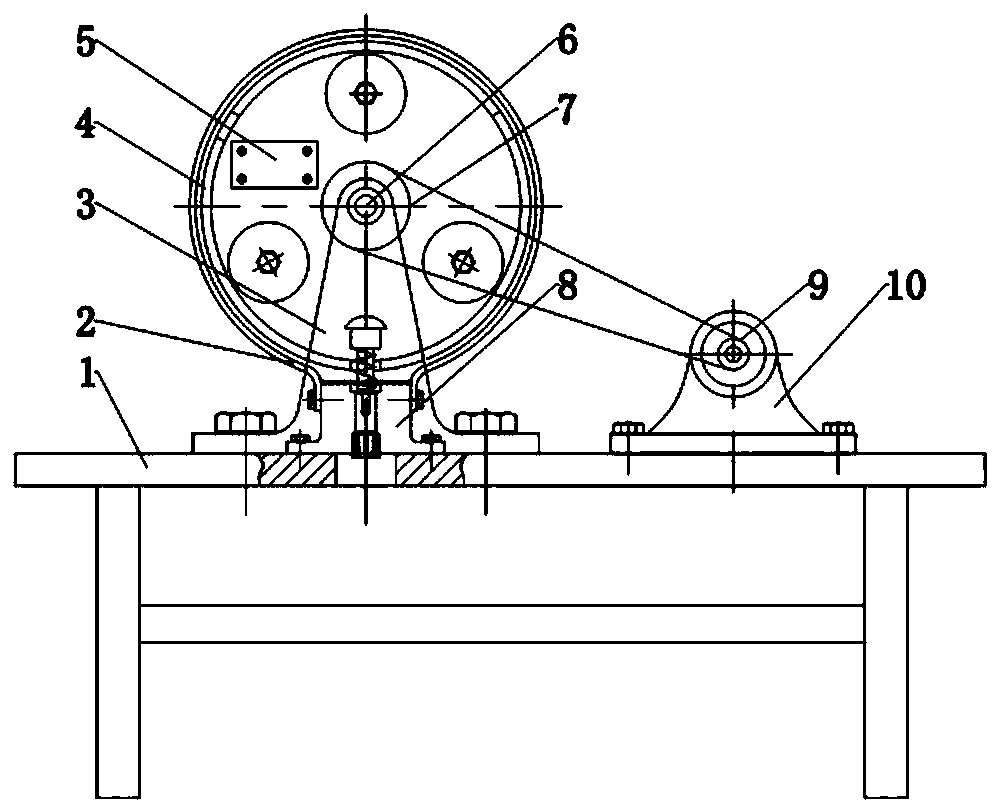

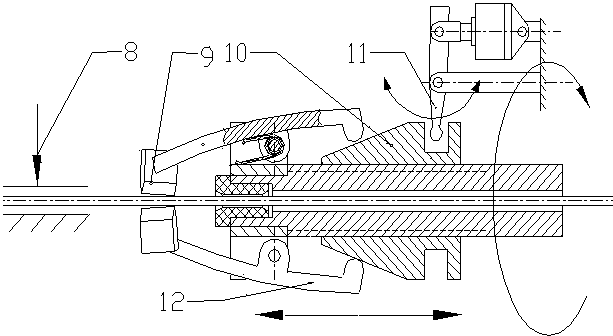

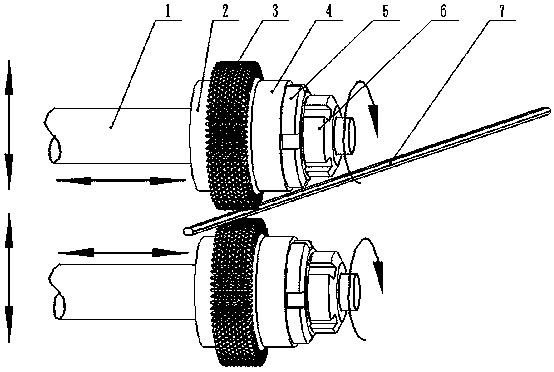

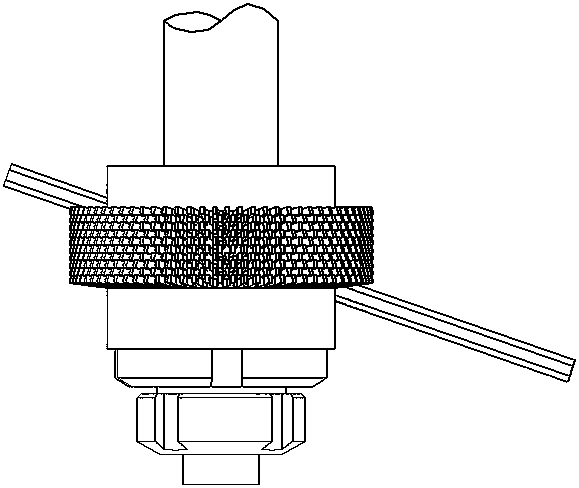

Floating self-centering enameled leather peeling method for wire end of enameled wire

InactiveCN102386548BReduce wear and tearQuality improvementLine/current collector detailsManufacturing technologyEngineering

The invention relates to a floating self-centering enameled leather peeling method for a wire end of an enameled wire, is relative to the manufacturing technique of coils used in an electric motor, a transformer, a current transformer and the like, and mainly aims at the technological updating of the mechanical enameled leather peeling technology that is commonly used during the production process of the electric motor and an electric appliance coil. The floating self-centering enameled leather peeling method is characterized in that a three point centering principle is adopted, three equilong cutter arbors are led to rotate at a high speed, blunt cutters on the cutter arbors are led to be in flexible contact with an enameled leather part to be peeled on the wire under the centrifugal force, and the pressure of the flexible contact is floating and adjustable; and an enameled leather on the enameled wire can be scrubbed, ground and peeled off under flexible squeezing when the blunt cutters move in the axial direction. The floating self-centering enameled leather peeling method overcomes the principle and structural shortages in a conventional mechanical enameled leather peeling process method that enameled leather peeling cutter arbors are pushed through the rigidity of a conical end body so as to force the cutters to cut in the wire forcedly, has the advantages of high enameled leather scraping speed, good quality and high efficiency, is simple and convenient to operate and adjust, can satisfy enameled leather peeling process requirements of different wire diameters and different paint films after being adjusted for one time, and does not need to adjust, grind and replace the cutters, the cutter arbors and the conical end body frequently.

Owner:XIHUA UNIV

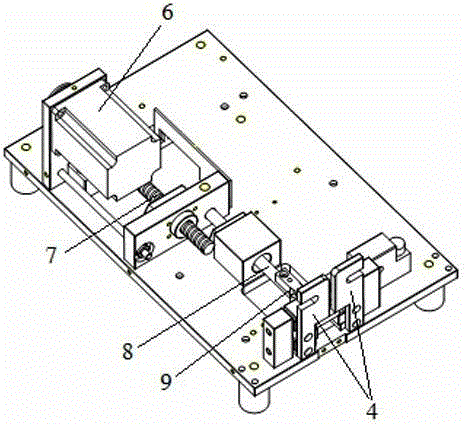

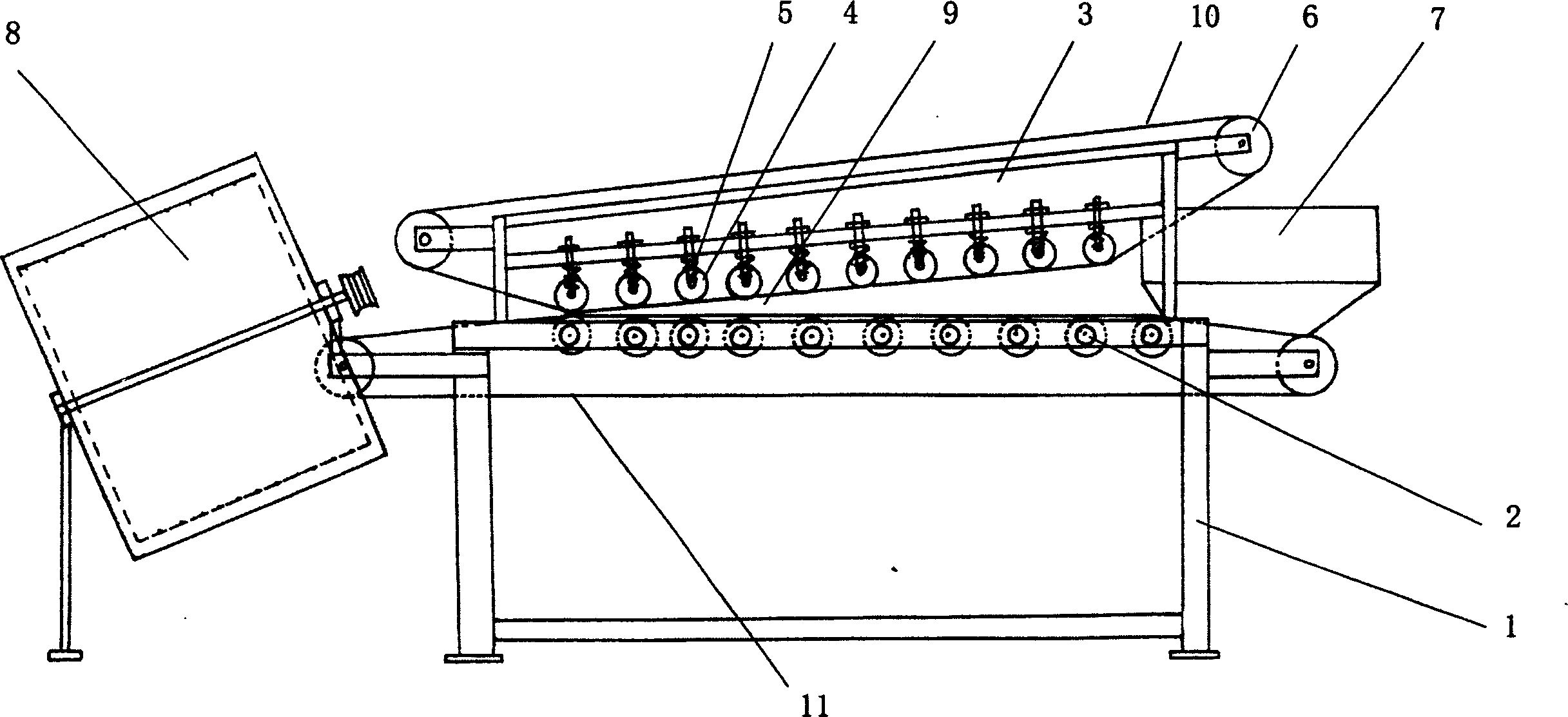

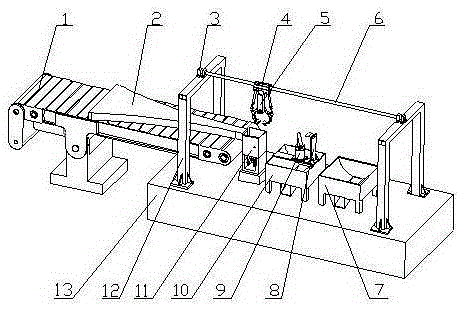

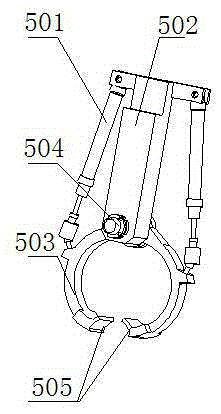

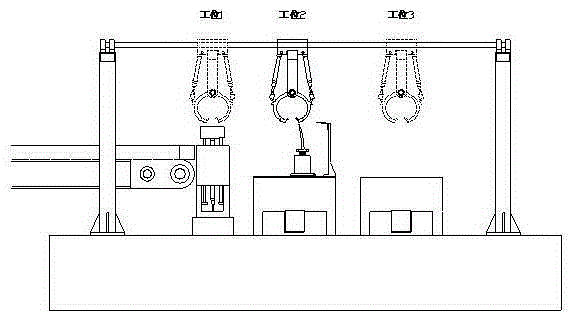

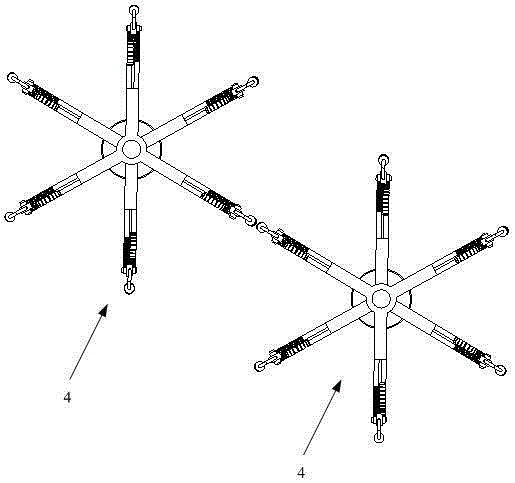

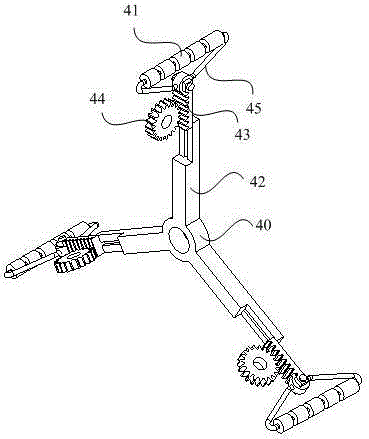

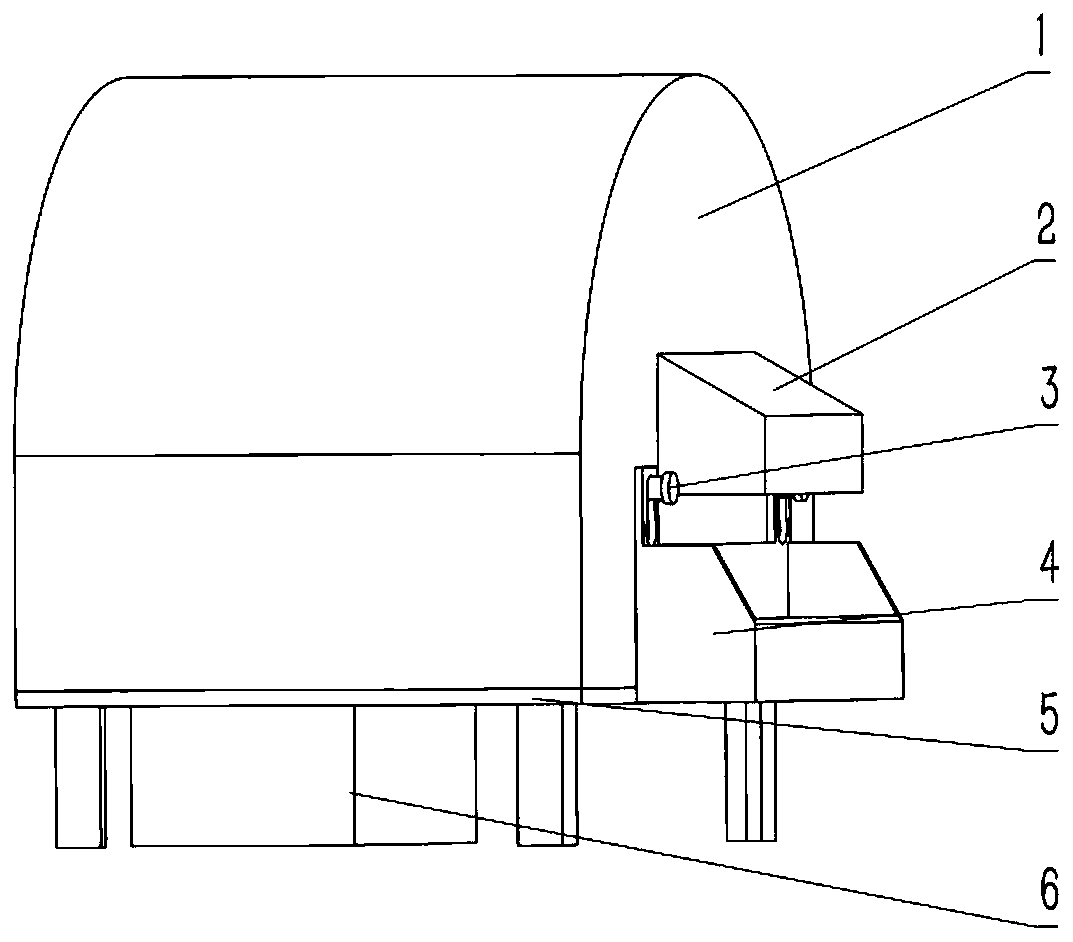

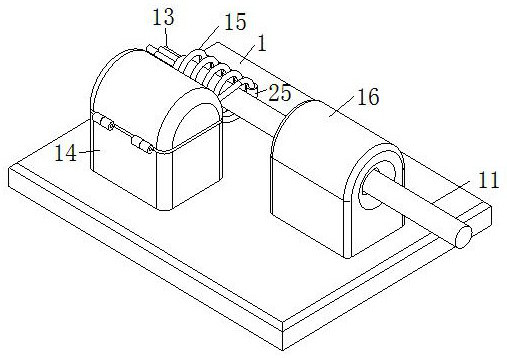

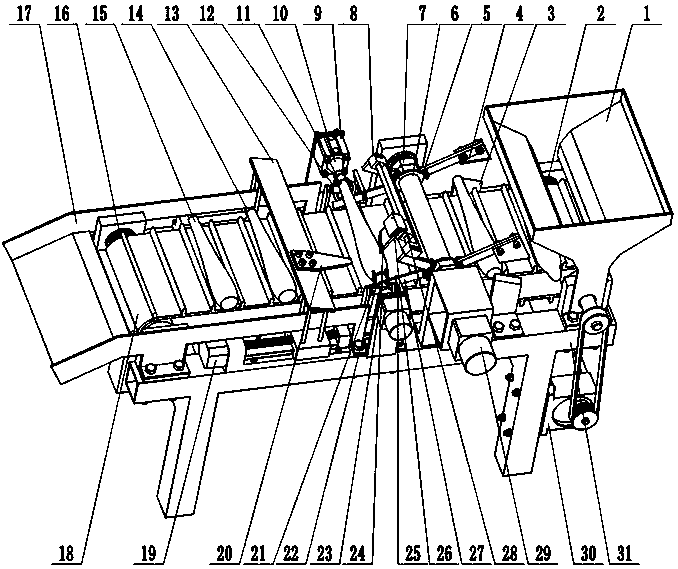

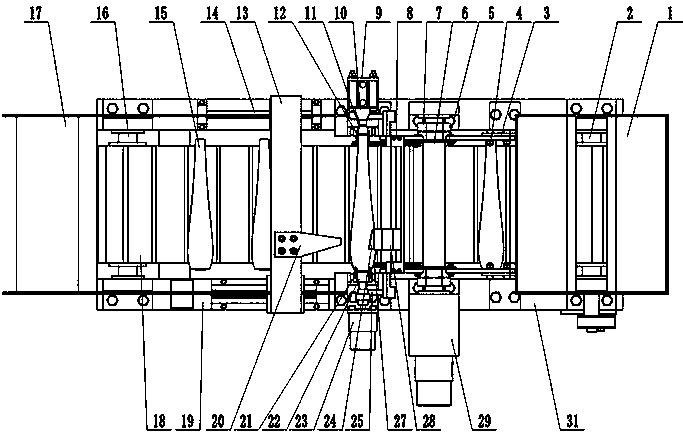

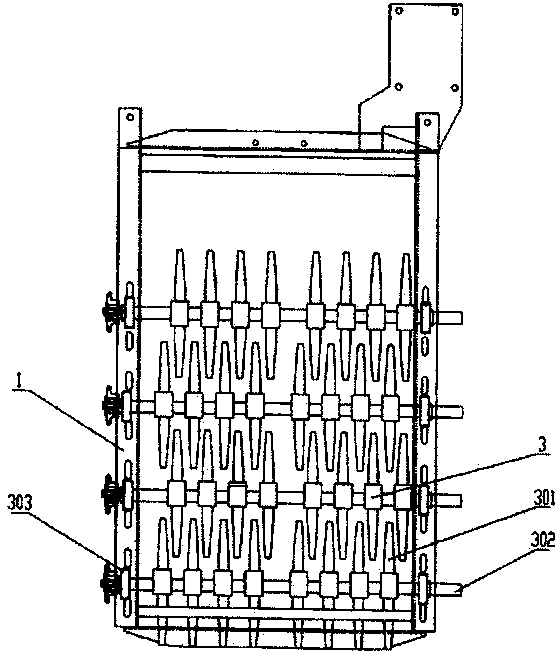

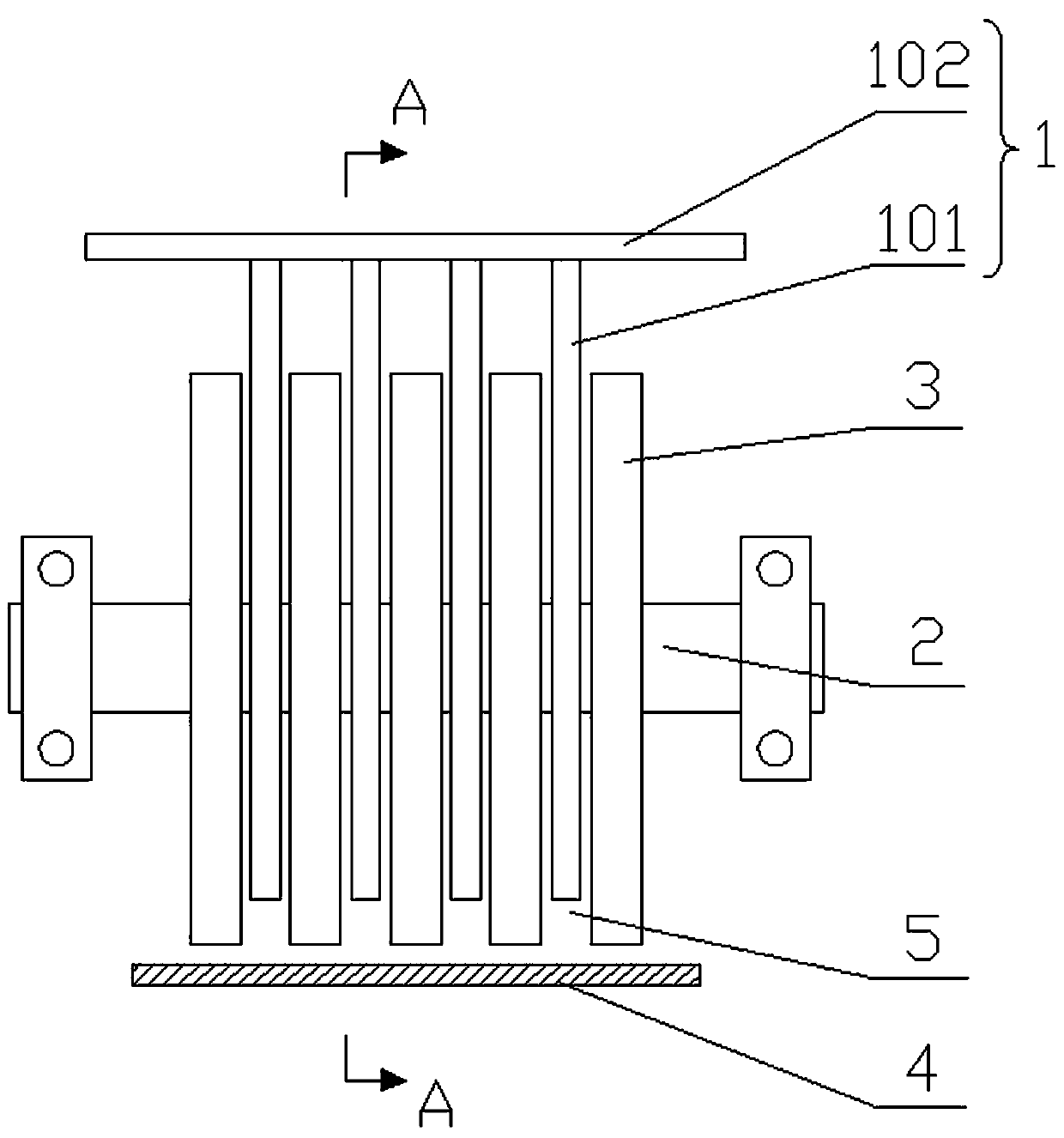

Full-automatic silkworm cocoon stripping production line

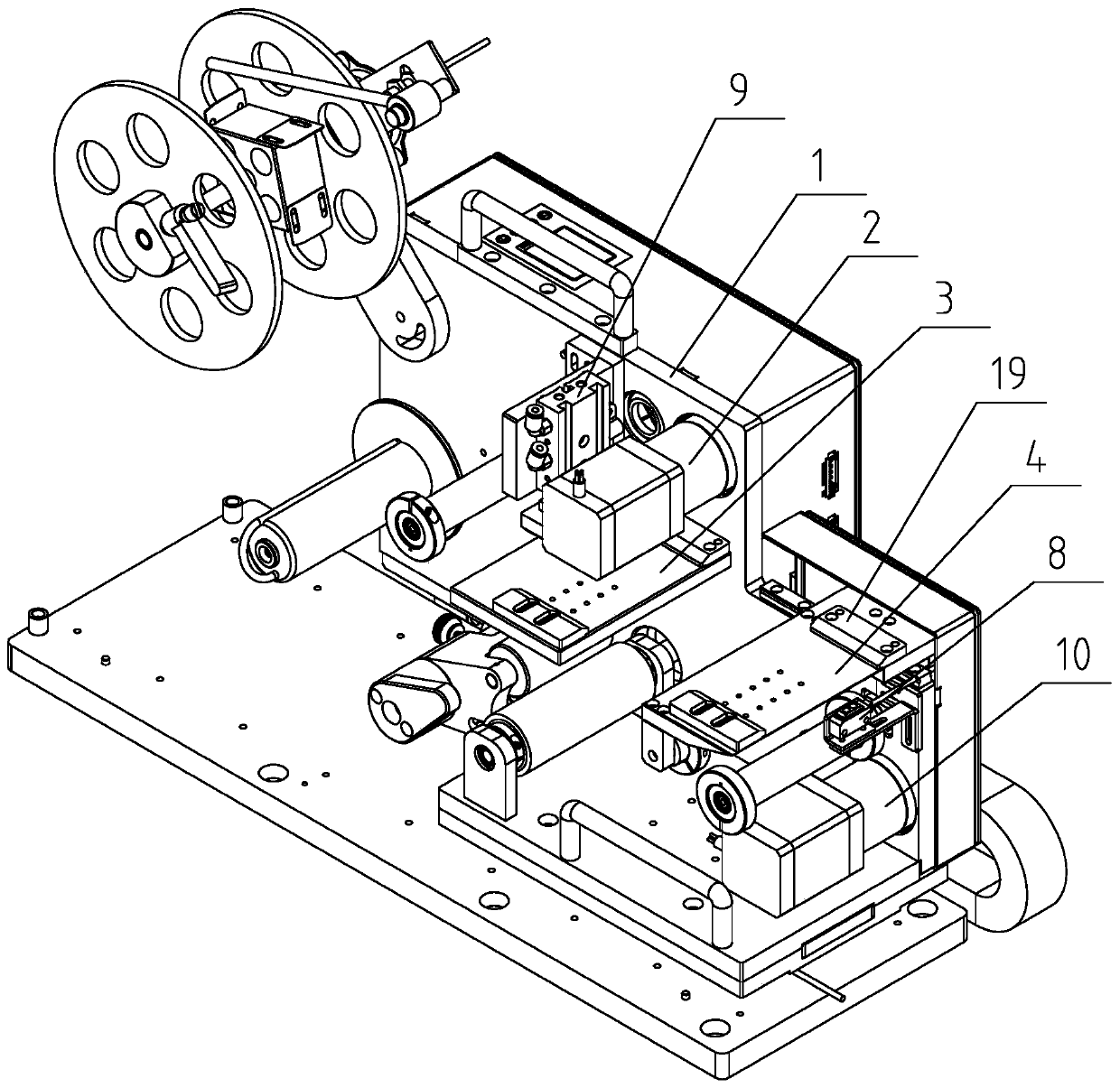

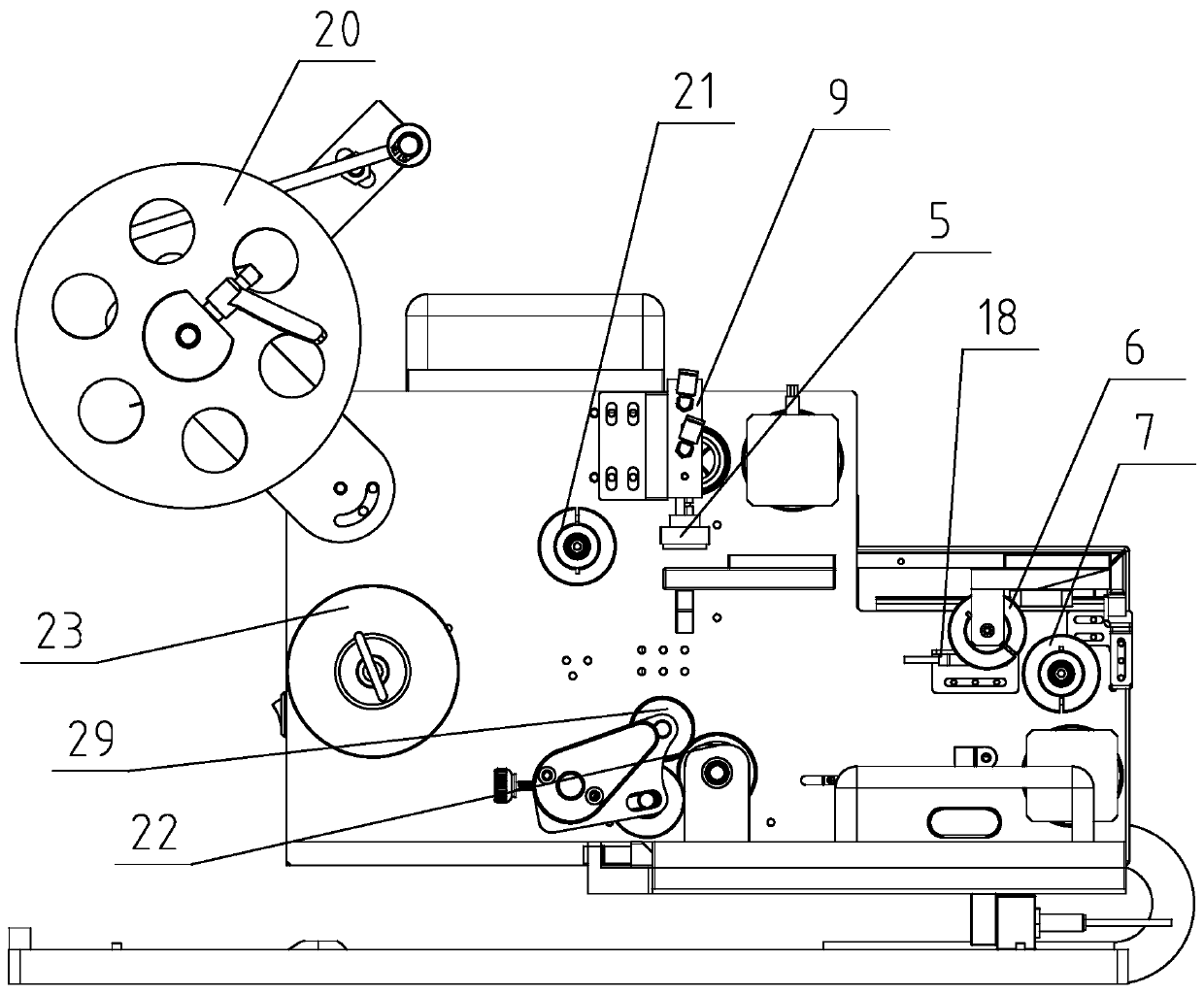

ActiveCN108193287AImprove stripping efficiencyQuality improvementSilk filament obtainingProduction lineEngineering

The invention discloses a full-automatic silkworm cocoon stripping production line. The full-automatic silkworm cocoon stripping production line comprises a silkworm cocoon box conveying device (1). One side of the silkworm cocoon box conveying device (1) is provided with a silkworm cocoon processing platform (2). The silkworm cocoon processing platform (2) is provided with a silkworm cocoon box picking and placing device (3) and a silkworm cocoon stripping device (4) along a length direction. The free end of the silkworm cocoon processing platform (2) is provided with a silkworm cocoon box pushing device (5). The lower part, corresponding to the silkworm cocoon processing platform (2), of the silkworm cocoon stripping device (4) is provided with a silkworm cocoon collecting box (6). The full-automatic silkworm cocoon stripping production line is capable of effectively solving problems of a traditional three-axis transmission stripping device that the equipment volume is large, the stripping quality and the efficiency are low, and effectively solving a problem of a traditional wind power stripping device that the silkworm cocoon cannot be stripped because the silkworm cocoon is tightly winded.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

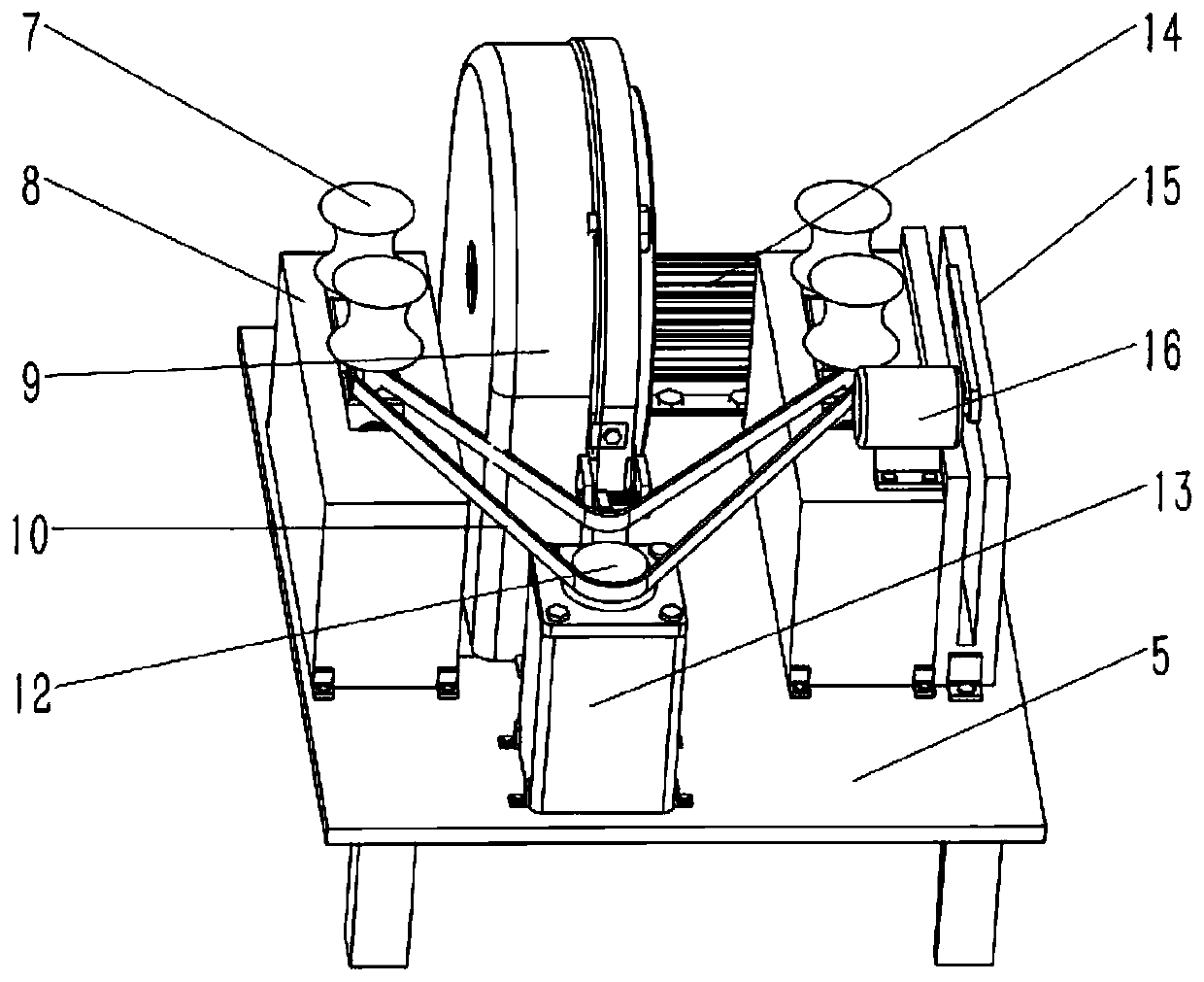

Peeling and cutting machine for sugarcane

ActiveCN109984346ARetain structureThe overall structure is closedVegetable peelingMetal working apparatusFixed frameUltimate tensile strength

The invention discloses a peeling and cutting machine for sugarcane. The machine comprises a gear ring fixing frame perpendicularly fixed to a bottom plate, a step hole is formed in the center of thedisc surface of the gear ring fixing frame, and a gear ring is arranged in the step hole; the gear ring is an inner gear, a peeling mechanism is arranged on the gear ring, and a transmission disc is also in transmission connection with the peeling mechanism; conveying boxes are arranged on the portions, on the two sides of the disc surface of the gear ring fixing frame, of the bottom plate, a pairof transmission wheels are arranged at the top of each conveying box, and the adjacent sides of each pair of transmission wheels form an annular clamping form to clamp the sugarcane; one transmissionmechanism is arranged in each conveying box, the transmission mechanisms are in driving connection with the transmission wheels, a pair of transmission mechanisms and a motor A form a V-shaped layout, and the motor A rotates to drive the two transmission mechanisms to rotate at the same time. The machine solves the problems in the prior art that the labor intensity of sugarcane peeling is high, the peeling efficiency is low, the peeling quality, the safety and the hygiene cannot be ensured, and manual peeling causes waste.

Owner:XIAN UNIV OF TECH

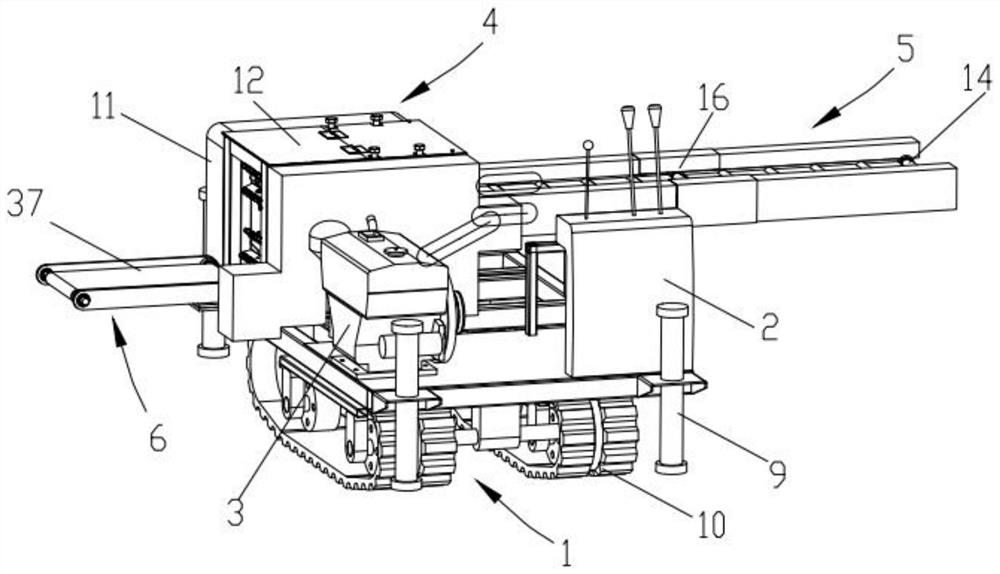

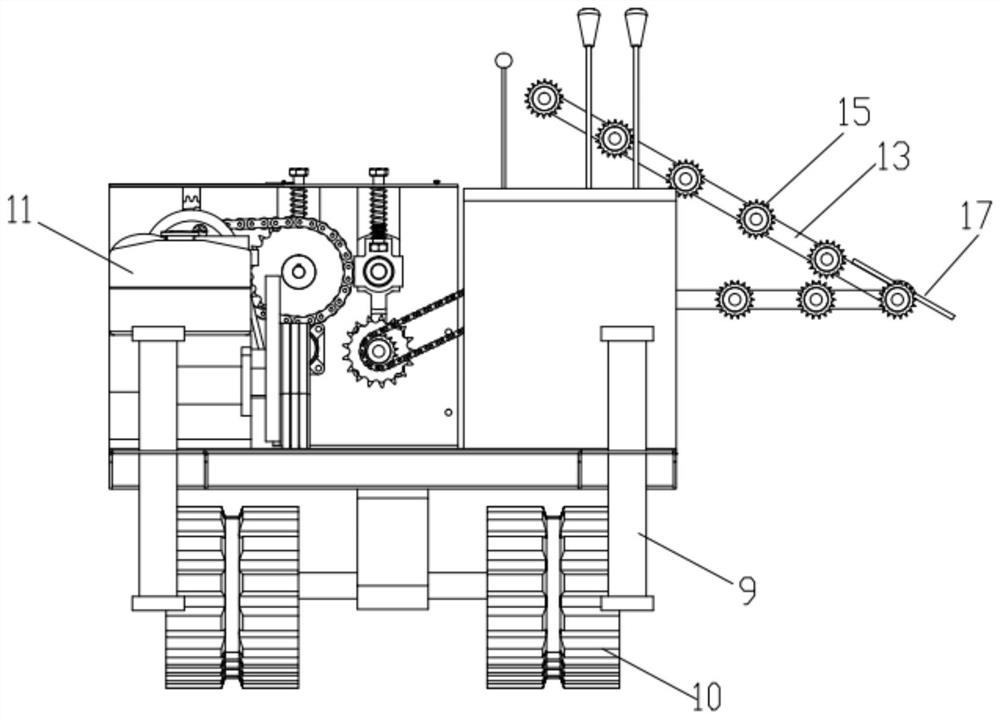

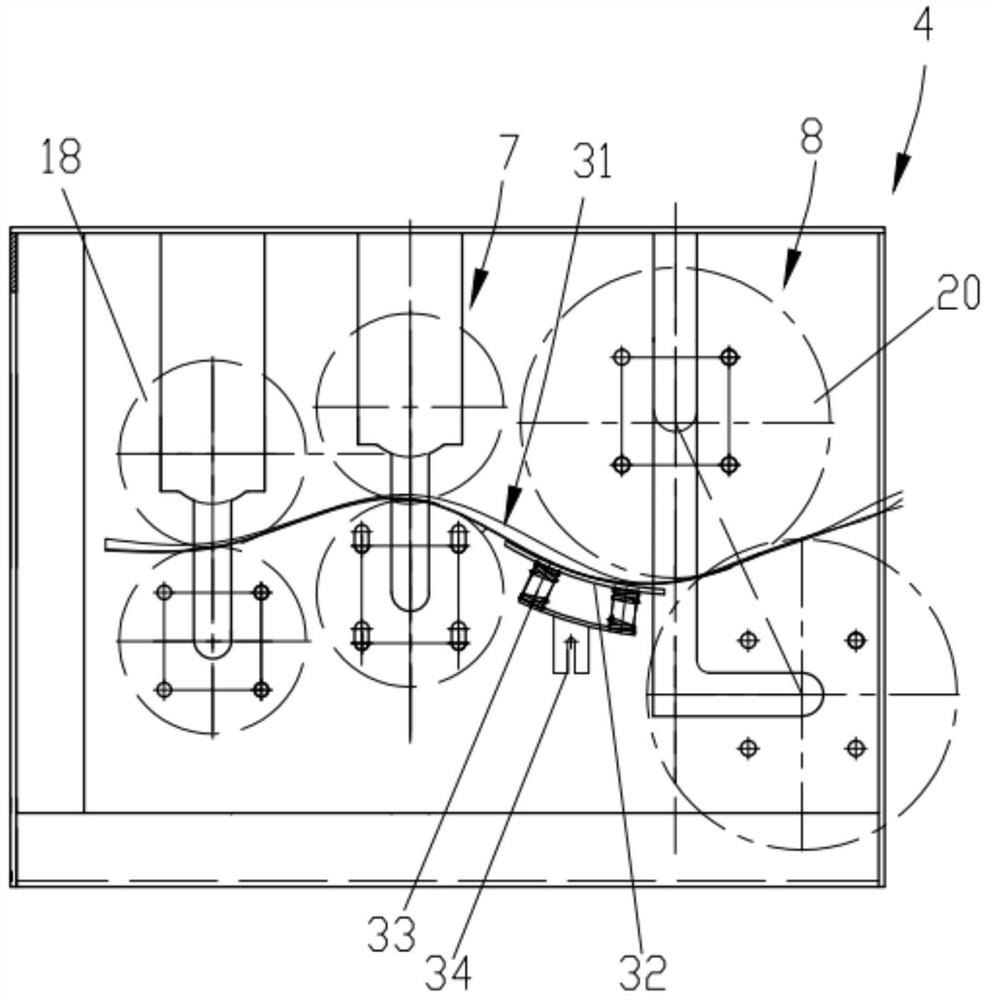

Self-propelled peeling machine for jute and hibiscus cannabinus

ActiveCN112663147AImprove peeling qualityEasy to moveMechanical fibre separationHibiscusAgricultural engineering

The invention discloses a self-propelled peeling machine for jute and hibiscus cannabinus. The self-propelled peeling machine comprises a crawler traveling chassis, an operating room, an engine, a peeling device, a conveying device and an output device, wherein the operating room, the engine, the peeling device, the conveying device and the output device are arranged on the crawler traveling chassis, the output device is connected with the input end of the peeling device, and the conveying device is connected with the input end of the peeling device. The self-propelled peeling machine can adapt to jute / hibiscus cannabinus with different stem diameters, the stem tip peeling quality is good, the moving performance is good, the self-propelled peeling machine can adapt to various different working places, a feeding and clamping mechanism is firmer in clamping and not easy to get stuck, the bone removing effect is remarkably improved, therefore, the income of hemp farmers can be increased, the industrial economic benefit is improved, and the large-scale development of jute / hibiscus cannabinus industry is promoted.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Peeling method of green walnuts

The invention relates to a wet-composting peeling method of green walnuts. The wet-composting peeling method comprises the following steps of (1) stacking green walnuts which are just harvested, and performing wet composting for 3-8h; (2) after wet composting and heating, reversing the heap, controlling the temperature of the green walnut heap to be 26-32 DEG C, enabling the heap reversing number of times not to exceed 3, and then continuing the wet composting for 2-3.5 days; and (3) putting the green walnuts after the wet composting into a peeling machine for peeling. According to the wet-composting peeling method disclosed by the invention, green peel of the green walnuts can be quickly and completely removed, the efficiency is high, the peeling quality is good, the method is simple, and the wet-composting peeling method is widely applied.

Owner:保康县圆佑科技企业孵化器有限公司

A power cable stripping device

ActiveCN113708305BIncreased peeling speedAvoid damageApparatus for removing/armouring cablesPower cableElectric machine

The invention belongs to the technical field of electric power equipment, and specifically relates to a power cable stripping device, which includes a workbench, a cutting unit and a heating unit; a cable body runs through the middle of the cutting unit, and the cable body includes an insulating layer and a conductive core; The heating unit includes a heating table and a high-frequency heating coil, the high-frequency heating coil is connected to a power supply through a high-frequency generator, and the high-frequency heating coil is arranged coaxially with the cable body; the cutting unit includes a cutting table, a driving roller and a driven roller, The driving roller and the driven roller are symmetrically arranged, and the cable body runs through the gap between the driving roller and the driven roller; the driven roller is connected to the cutting table in rotation, and the driving roller is driven by a reduction motor; the middle part of the driving roller is fixedly connected with Disc-shaped cutter; After passing the cable body through the driving roller and the driven roller, the high-frequency heating coil heats the cable body, and then the cutter cuts the insulation layer quickly and stably, reducing the impact of uneven cutting force on the conductor core damage.

Owner:JIANGSU SANQI CABLE & WIRE

Integrated operation device and method for trimming and shelling zizania aquatic

ActiveCN111165837AImprove work efficiencyHigh degree of automationVegetable peelingFood treatmentFisheryEngineering

The invention discloses an integrated operation device and method for trimming and shelling zizania aquatic. The operation device comprises a conveying assembly, a trimming assembly, an opening assembly, a shelling assembly and a cutting assembly, wherein the conveying assembly is used for feeding, conveying and discharging of zizania aquatic; the trimming assembly is used for primarily trimming the head part and the tail part of the zizania aquatic through cooperation of trimming fixed blades and trimming movable blades; the opening assembly cuts the surface of the zizania aquatic to form anopening through straight cutting of an opening knife; the shelling assembly clamps the zizania aquatic through a jacking rotor and a driving rotor and rotates the zizania aquatic, and a shelling knifeis used for stripping the shell of the zizania aquatic; the cutting assembly is used for cutting the head part and the tail part of the zizania aquatic after shelling through cutting knives; and a material removing device at the jacking end and a material removing device at the driving end are used for removing zizania aquatic tailings remained on the integrated operation device. The integrated operation device and method is suitable for trimming and shelling of zizania aquatic, and operations of trimming, opening, shelling, cutting off, material removing and the like of zizania aquatic are completed at one time, so that operation efficiency is greatly improved, shelling quality is improved, and integrated automatic operation is realized.

Owner:ZHEJIANG UNIV

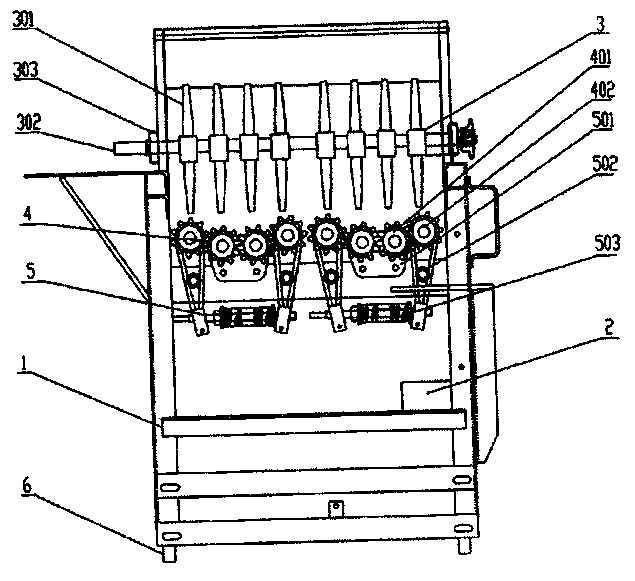

Dual-unit corn husker

InactiveCN104412786ASimple structureImprove peeling efficiencyThreshersAgricultural scienceMechanical reliability

The invention relates to agricultural implements, particularly to a dual-unit corn husker. The dual-unit corn husker comprises a frame, a power mechanism and a transmission mechanism. The frame is of a cuboid frame structure; the power mechanism is mounted at the bottom of the frame; the inside of the inner cavity of the upper portion of the frame is provided with 3-5 sets of pressure feeding mechanisms; the inside of the middle inner cavity of the frame under the pressure feeding mechanisms is provided with two roll-husking units which are respectively provided with a roll gap adjusting mechanism. The dual-unit corn husker is simple in structure and light in weight, greatly improves the corn husking efficiency, meanwhile, avoids crushing of corn cobs caused by overhigh pressure, prevents machine congestion and achieves the aim of improving the husking quality and the mechanical reliability.

Owner:蒋爱成

Equipment for recycling cadmium in soil through mulberry and cadmium recycling method

ActiveCN106625958ARealize gap adjustmentTo achieve the best effect of peelingTree debarkingCultivating equipmentsTherapeutic effectEngineering

The invention discloses equipment for recycling cadmium in soil through a mulberry. The equipment comprises a rod peel stripping device and a separating and screening device at the lower end of the rod peel stripping device. The rod peel stripping device is internally provided with rotary rollers, and the rollers comprise a forward-adverse roller, feeding rollers, stripping rollers and discharging rollers; the outer walls of the rollers are provided with stretchable tender peel knife sets and coarse peel knife sets; each tender peel knife set comprises an interlayer blade and an inner layer blade; tool points of the interlayer blades are uniformly provided with large arc grooves; the inner layer blades are uniformly provided with small arc grooves; tool points of the coarse peel blades are in saw shapes; a shell of the separating and screening device is internally provided with an inner cavity sleeve; the upper end of the inner cavity sleeve is provided with a screening plate; the inner cavity sleeve is internally provided with a telescopic shaft; the telescopic shaft is connected with the screening plate; and the telescopic shaft is provided with a vibrator. A cadmium recycling method includes the following machining steps of land treatment, root pruning of a mulberry seedling, transplanting of the mulberry seedling, mulberry leaf cutting, processing treatment and cadmium recycling. By means of the equipment and the method, the utilization rate of the mulberry land can be raised, the soil repair effect is improved, and the cadmium treatment effect is improved.

Owner:湖南翊天环保科技有限公司

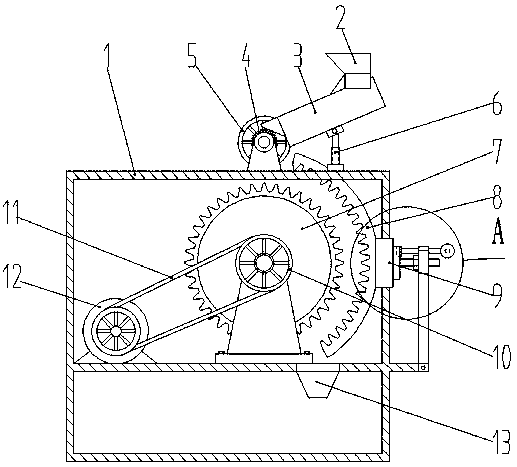

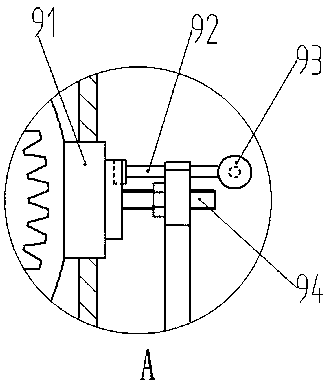

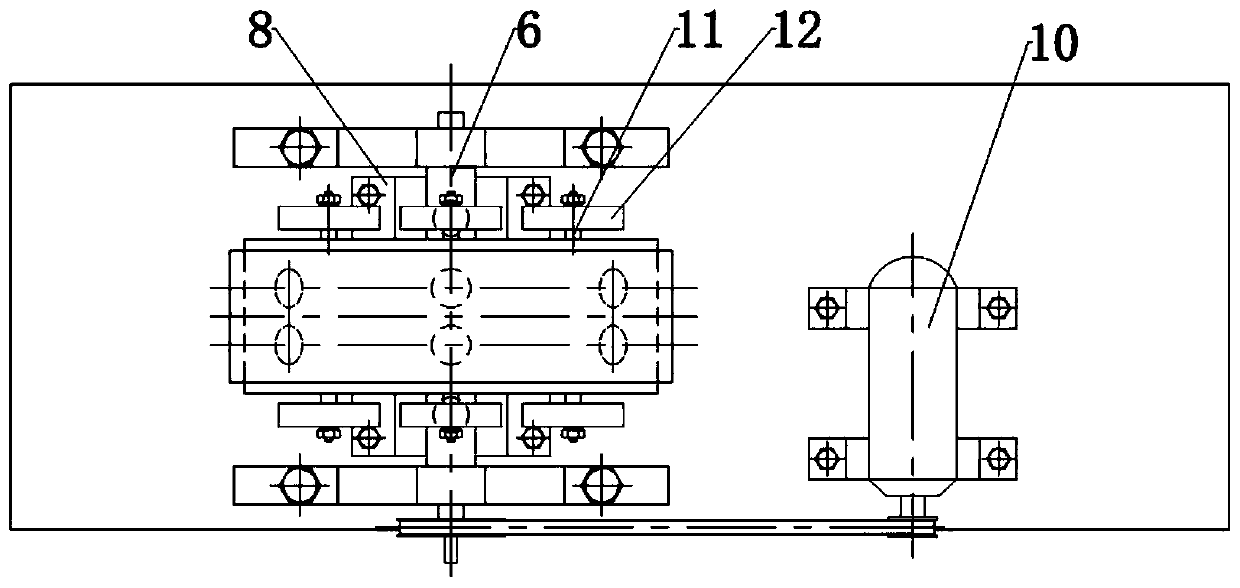

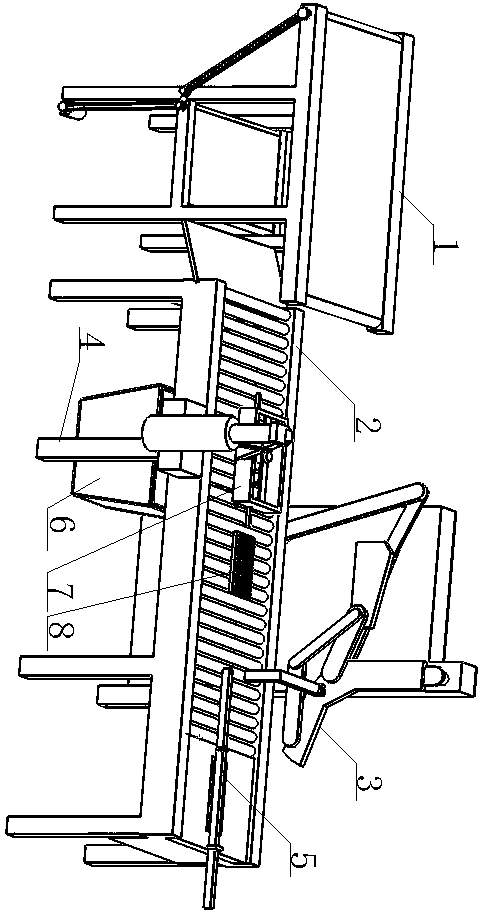

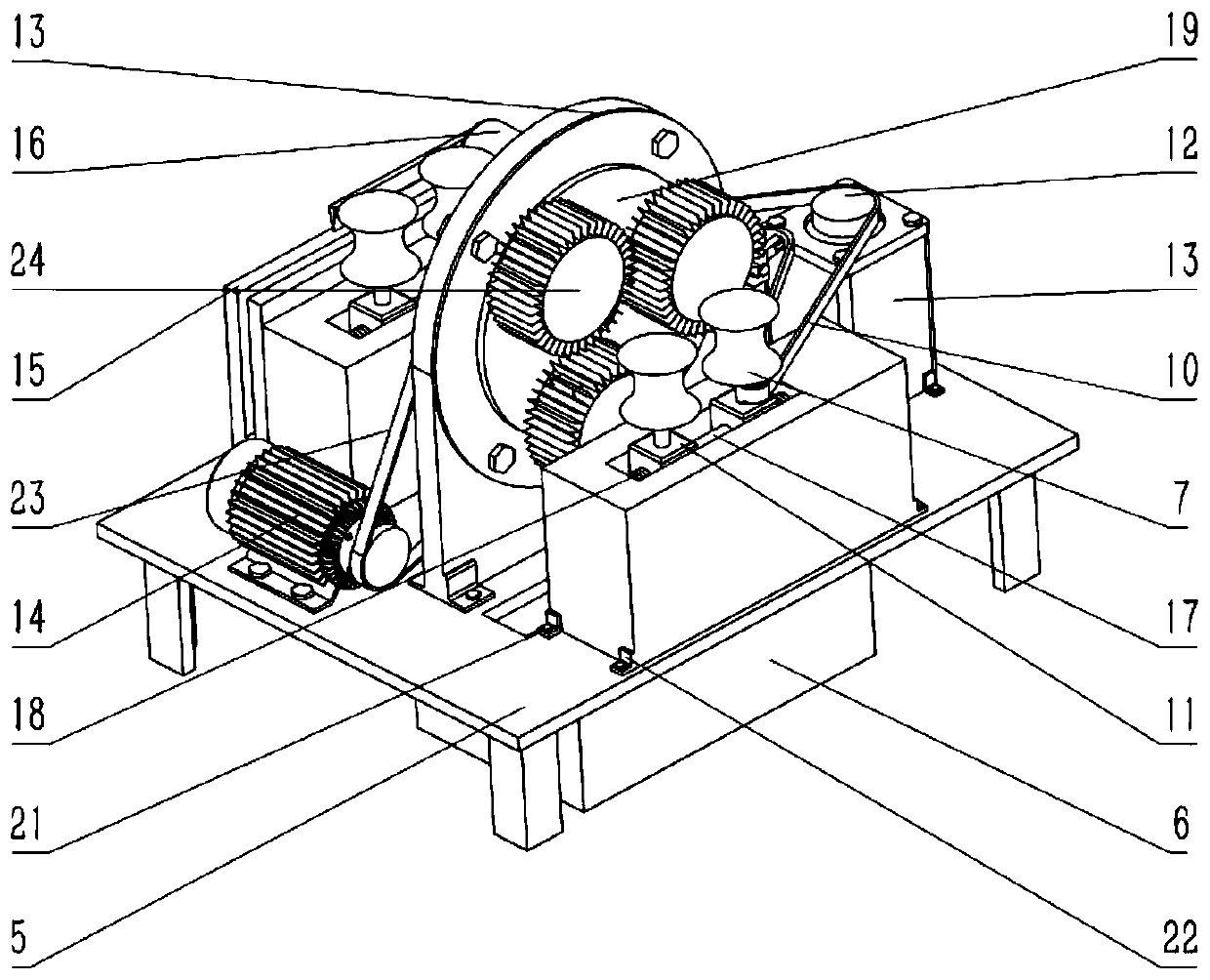

Rectangular enameled wire head flexible brush scraping rotary milling stripping system

InactiveCN105680290BImprove flexibilityReduce wear and tearLine/current collector detailsCoils manufactureManufacturing technologyContact pressure

The invention relates to a flexible brushing and helical milling stripping system for a rectangular enameled wire head, and relates to a manufacturing technology of coils for a motor, a transformer, a converter and the like. Mainly aiming at technological updating of a common mechanical paint stripping technology in the motor and electric appliance coil production process, the system comprises two flexible brushing and helical milling heads and a wire positioning and clamping mechanism, wherein the two flexible brushing and helical milling heads have a rotating function, a playing function, an angle adjusting function, a limiting function and a speed change function; the flexible brushing and helical milling stripping system is characterized in that working tooth parts of the two flexible brushing and helical milling heads carry out flexible free stripping on the surface of the enameled wire head with appropriate hardness, appropriate flexibility, appropriate surface coarseness, appropriate angle and appropriate pressure and rotating speed at the specific position in contact with the enameled wire head; a flexible tool keeps flexible contact with the stripped part of the wire; the flexible contact pressure and helical milling speed are adjustable; when the flexible tool displaces in the direction of the wire, flexible extrusion scraping and stripping can be carried out on the enameled wire.

Owner:XIHUA UNIV

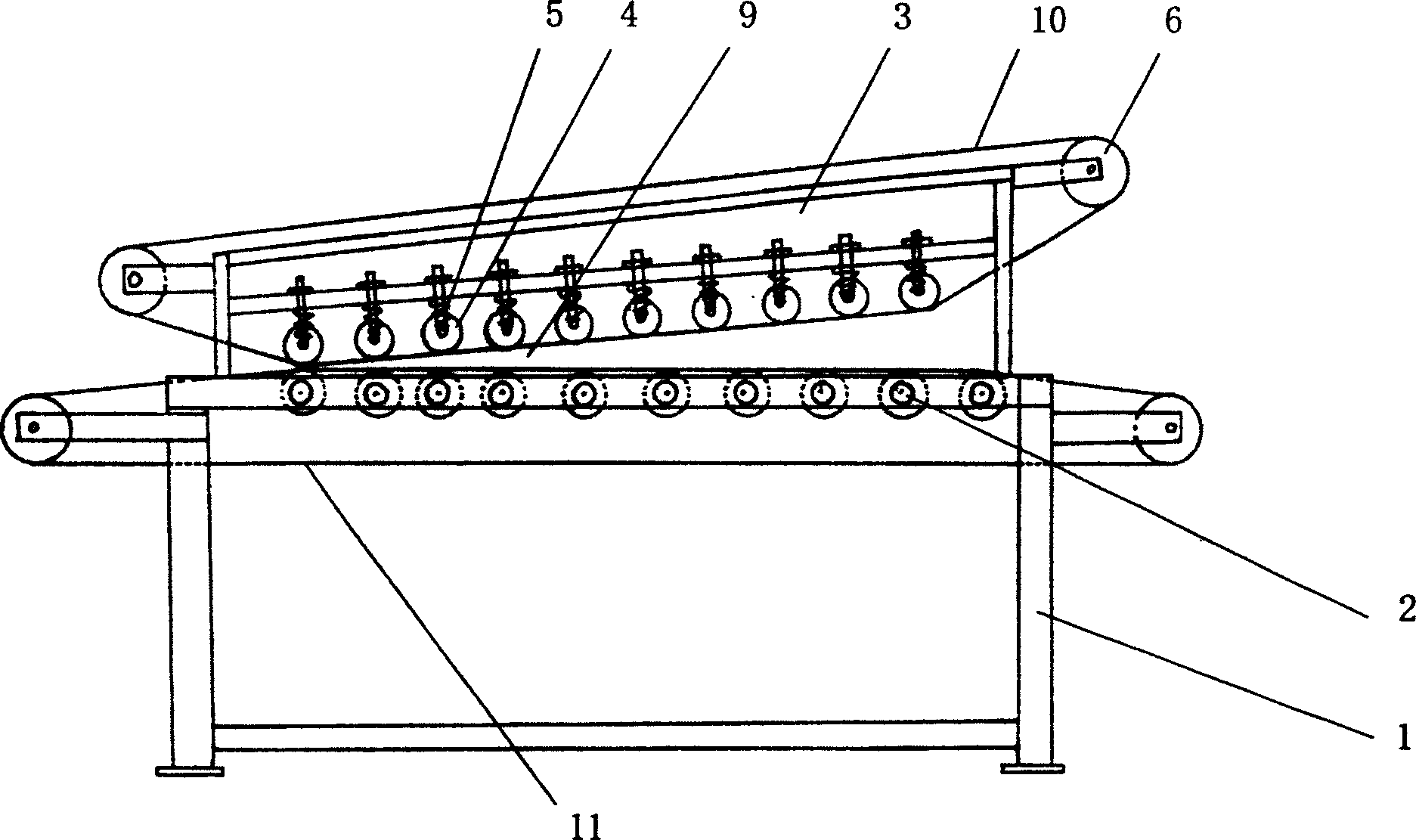

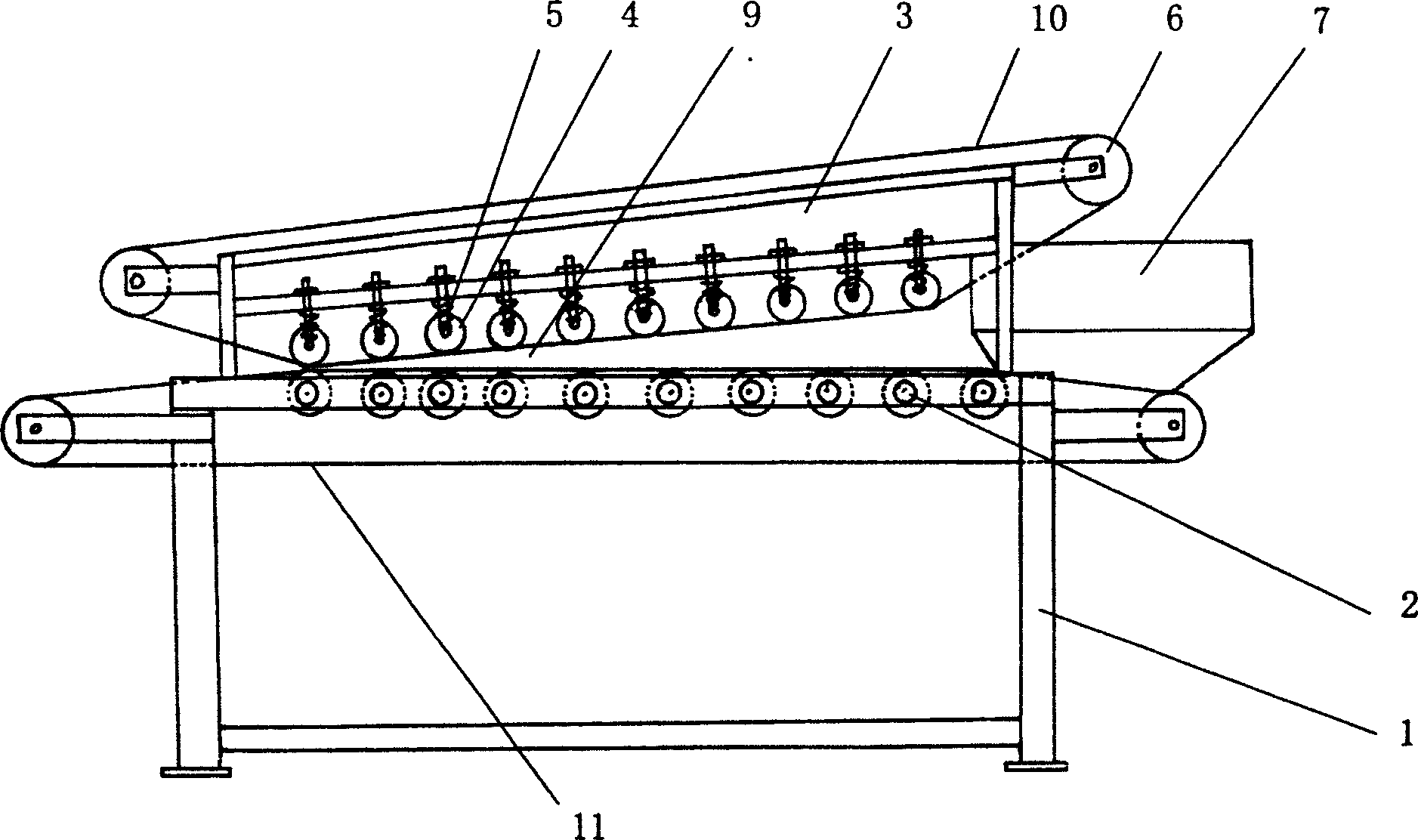

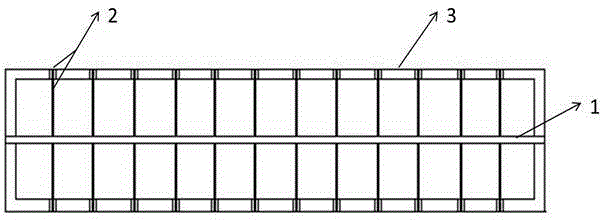

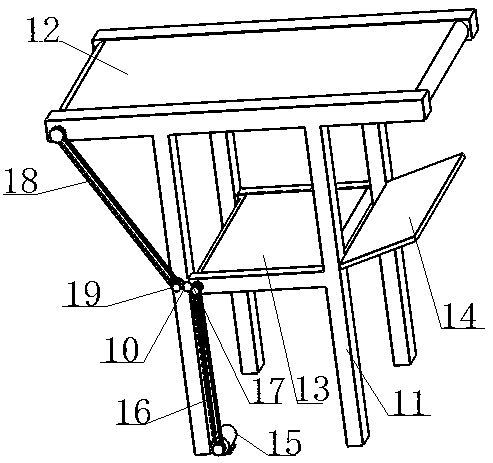

Dividing feeder for long-rod-shaped crop leaf-peeling equipment

PendingCN110651598ATo achieve the effect of root-by-root separationImprove peeling qualityHarvestersAgricultural engineeringFarm machine

The invention relates to the field of agricultural machinery and equipment and particularly discloses a dividing feeder for long-rod-shaped crop leaf-peeling equipment, comprising a conveyer belt anda dividing mechanism; the dividing mechanism comprises a rotating shaft, a plurality of guide discs and a height limiting grate; the rotating shaft is horizontally arranged above the conveyer belt andis perpendicular to the conveying direction of the conveyer belt; all the guide discs are made of a flexible material and are sequentially and concentrically fixed on the rotating shaft at intervals;a gap between any two adjacent guide discs forms a dividing channel which only allows one long rod-shaped crop to pass through in the width direction; the height limiting grate comprises a grate beamand grate teeth which are fixed on the grate beam and are as many as the dividing channels; and the grate teeth are inserted into the dividing channels in a one-to-one correspondence mode, so that only one long rod-shaped crop passes through one dividing channel in the height direction. According to the invention, dense long-rod-shaped crops can be divided in divided and scattered form before entering a peeling execution unit, so that leaf peeling quality is improved.

Owner:严嘉昌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com