Power cable stripping device for electric power engineering

A power cable and power engineering technology, which is applied to cable installation devices, cable installation, and equipment for dismantling/armored cables, etc., can solve the problem of low peeling sufficiency, etc. Wide range, improved peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

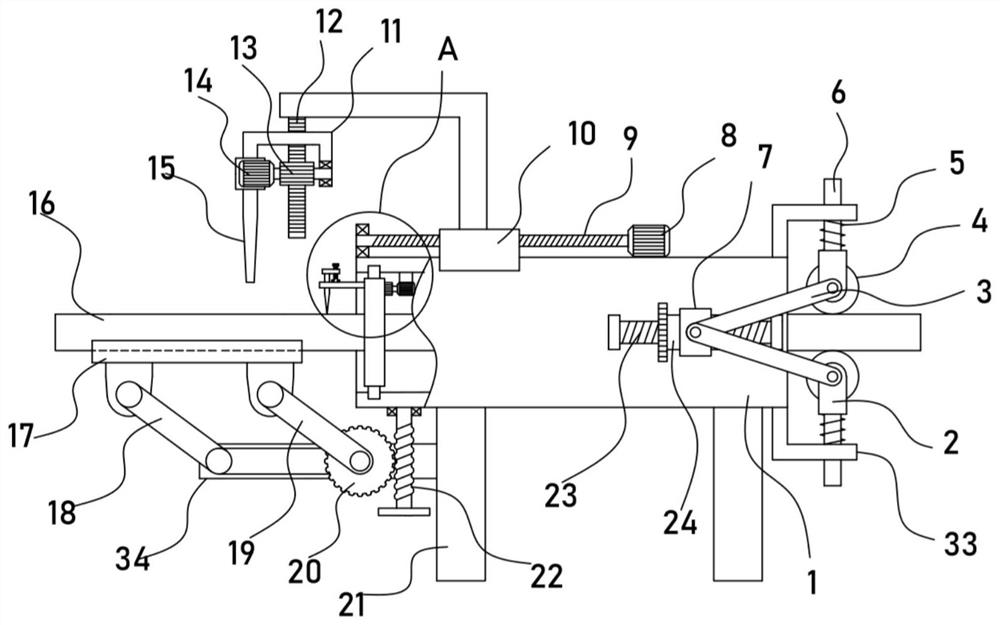

[0022] see Figure 1-3 , a power cable stripping device for electric power engineering, comprising a horizontal pipe 1, a support column 21 is vertically fixed at the bottom of the horizontal pipe 1, a power cable 16 runs through the horizontal pipe 1, and a fixing plate 34 is fixed on the support column 21 , the fixed plate 34 is equipped with an arc-shaped supporting plate 17 for carrying the power cable 16 through a supporting mechanism, and the horizontal tube 1 is driven and connected with a vertically arranged vertical rack 12 through a translation mechanism. 12 is connected with an axial cutting mechanism for axially cutting the power cable 16. The horizontal pipe 1 is driven and rotated by a rotating mechanism to install an inner ring gear 29, which is installed on the inner ring gear 29 for cutting the power cable 16 a circular cutting mechanism for circumferential cutting, the horizontal pipe 1 is provided with a clamping mechanism for clamping the power cable 16 . ...

Embodiment 2

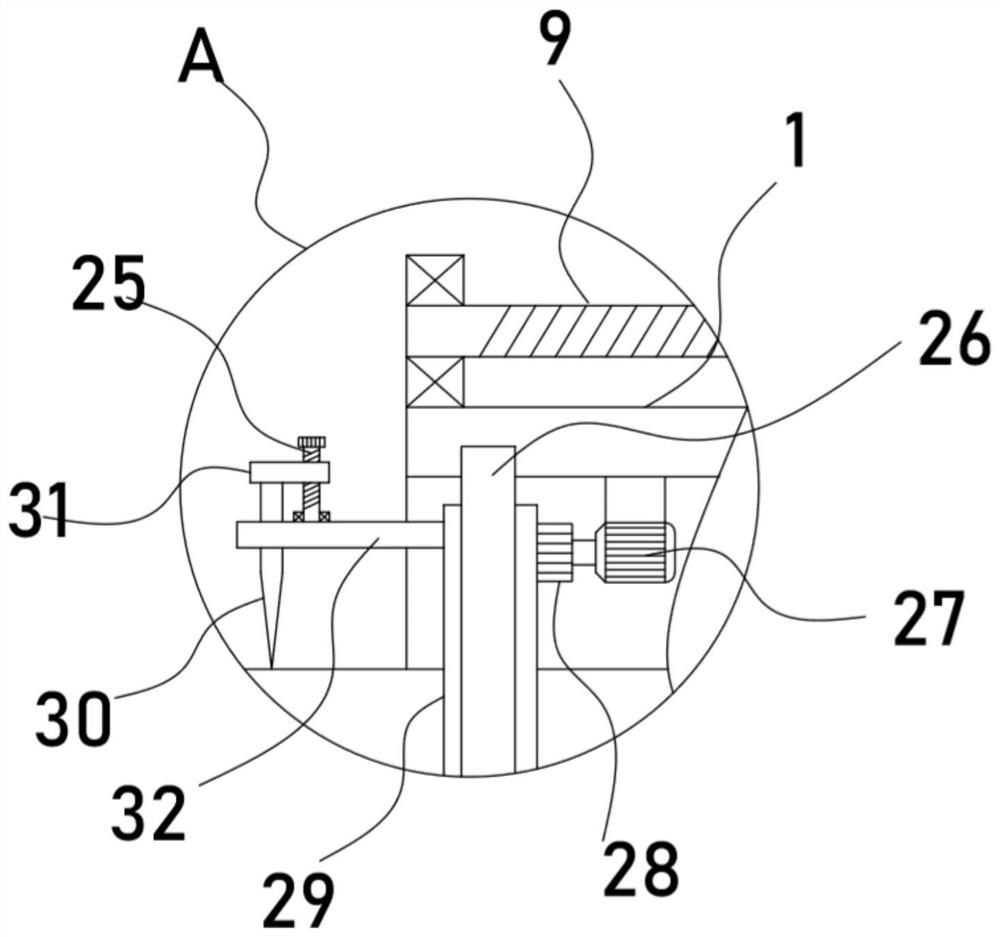

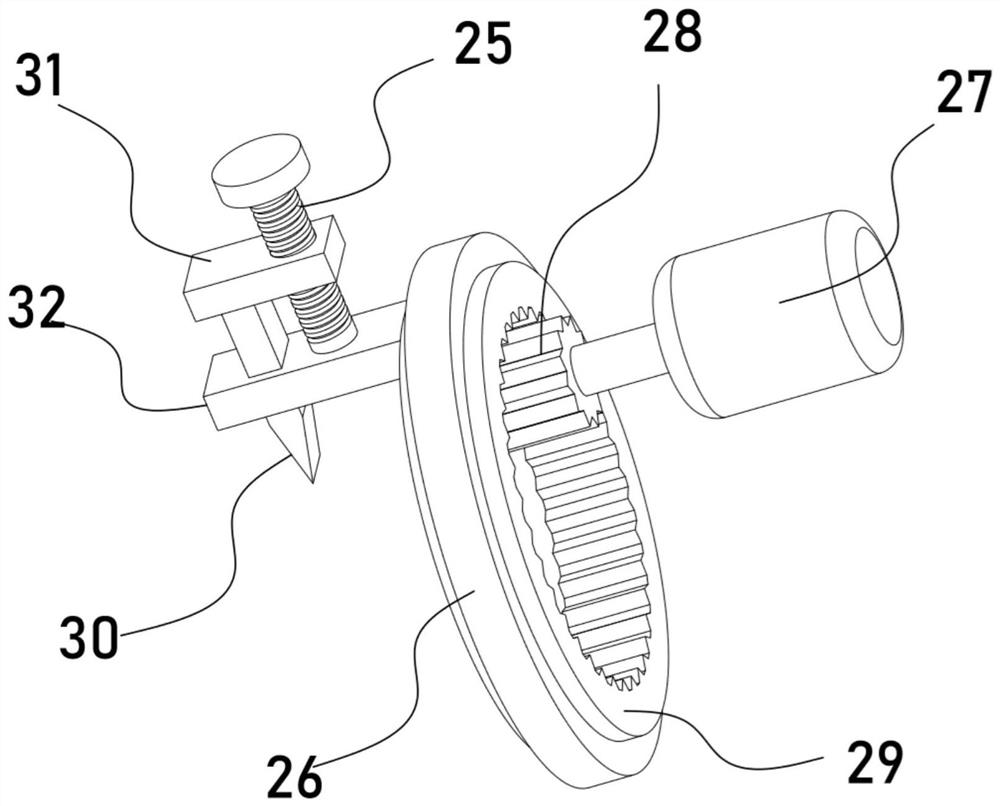

[0029] On the basis of Embodiment 1, in addition, this device is also provided with a circular cutting mechanism, including an inner ring gear 29 rotatably installed in the horizontal tube 1, a support plate 32 is fixed on the inner ring gear 29, and a vertical The circular cutting blade 30 is installed in a straight slide, and the upper end of the circular cutting blade 30 is fixed with a horizontal plate 31. The upper end of the horizontal plate 31 is screwed with a lower end bearing connected to the adjusting stud 25 installed on the support plate 32. The circular cutting mechanism also includes a fixed The driving motor 27 in the horizontal pipe 1 is driven and connected to the driving gear 28, and the driving gear 28 is meshed with the inner ring gear 29. The outer wall of the inner ring gear 29 is fixed with a ring sliding embedded in the inner wall of the horizontal pipe 1 The ring to cover block 26.

[0030] After the sheath of the power cable 16 is cut by the axial cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com