Tartary buckwheat shelling device

A tartary buckwheat shelling and tartary buckwheat shelling cavity technology, which is applied to grain shelling, separating solids from solids with airflow, and grain processing, etc. It can solve the problem of poor shelling effect and incomplete shelling of tartary buckwheat grains , low efficiency and other problems, to achieve the effect of avoiding waste, improving the efficiency of shelling, and improving the effect of shelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

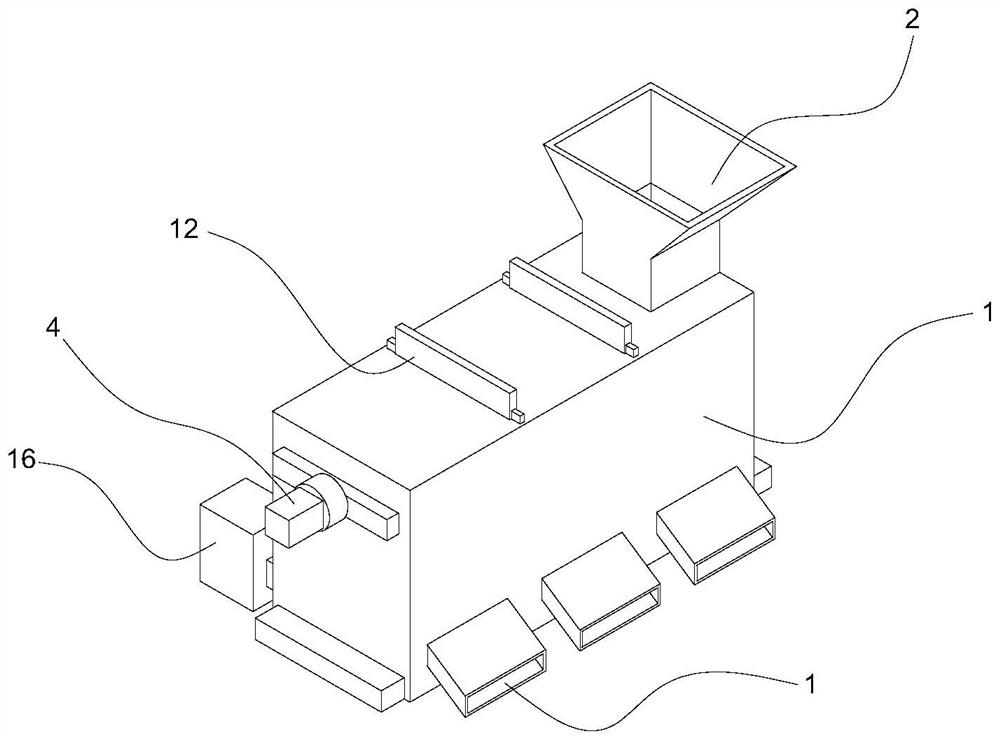

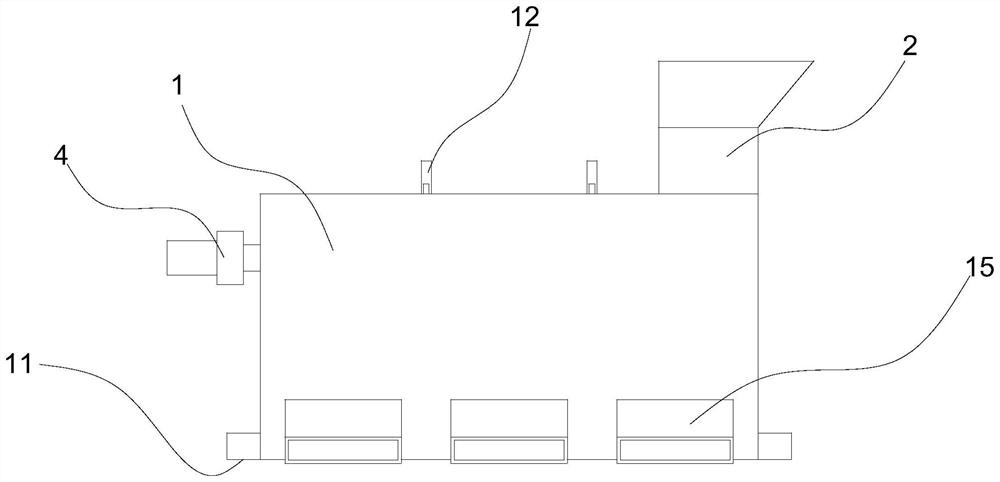

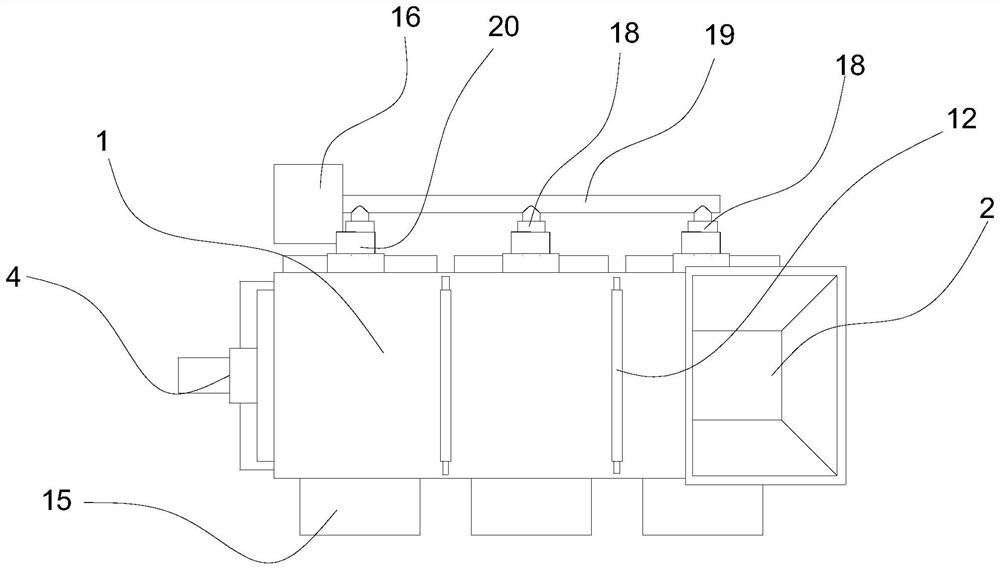

[0027] like figure 1 As shown, the tartary buckwheat shelling device of the present invention includes a body 1; the top of the body 1 is provided with a feeding port 2; the body 1 has an inner cavity, and the top of the inner cavity is provided with a feeding cavity 100 ; The bottom of the feeding cavity 100 is provided with an inclined plate 3;

[0028] One end of the inclined plate 3 is located below the feeding port 2; the other end is inclined downward and extends to the inner wall of the inner cavity of the body 1; the lower end of the inclined plate 3 is provided with an air blowing device 4; The blowing direction of the device 4 is parallel to the inclined plate 3;

[0029] The feeding port 2 communicates with the feeding cavity 100 and is located at one end of the feeding cavity 100; two vertical sieve plates 12 are arranged above the incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com