Electromagnetic wire stripping machine

A technology of electromagnetic wire and peeling machine, which is applied to circuits, electrical components, circuit/collector parts, etc., can solve the problems of low peeling efficiency, poor safety, and high labor intensity, and achieve high peeling quality and easy use. , the effect of fast peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

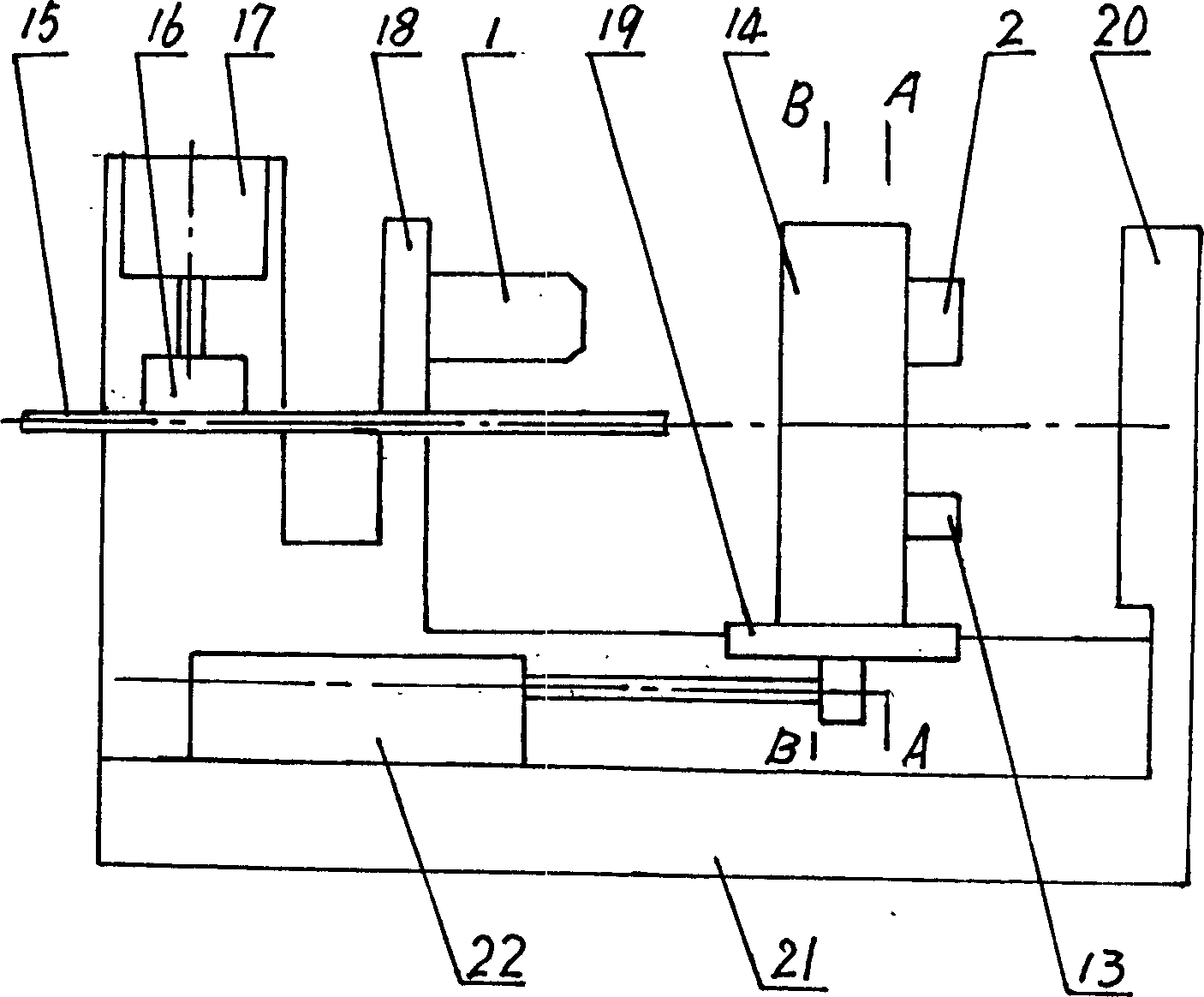

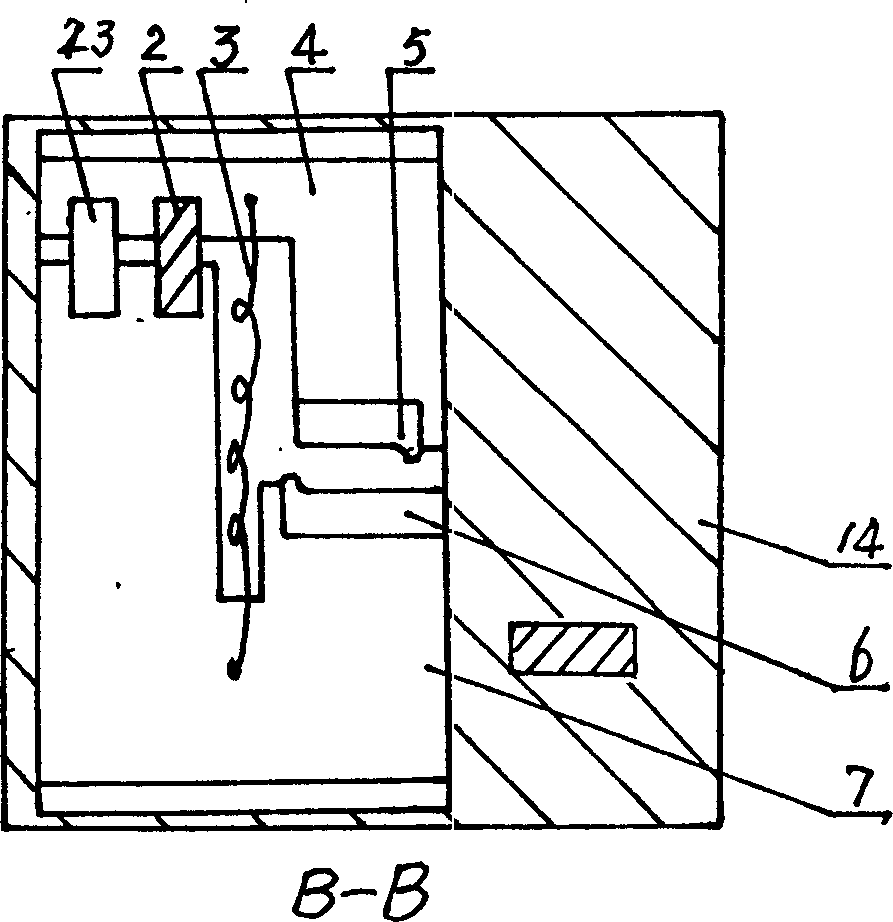

[0012] Further detail below in conjunction with embodiment by accompanying drawing:

[0013] An electromagnetic wire peeling machine, which includes a frame 21, an oil cylinder 22, an oil cylinder 17, a pressing block 16, an electromagnetic wire 15, an oil cylinder 22 is arranged above the frame, an oil cylinder 17 is arranged at the left upper end of the frame, and an oil plug rod end The head is provided with a compression block 16, the left end of the frame 21 is provided with a limit plate 18, the limit plate 18 is provided with a limit pin 1, and the right side of the frame 21 is provided with a limit plate 20, between the limit plate 18,20 In between, the oil plug rod head of the oil cylinder 22 is connected with a sliding tongue 19, and the sliding tongue 19 is provided with a forming knife box 14, and the forming knife box 14 is provided with a peeling device for the upper and lower sides of the electromagnetic wire and a peeling device for the front and rear of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com