Dividing feeder for long-rod-shaped crop leaf-peeling equipment

A long rod-shaped, feeder technology, applied in the application, agricultural machinery and implements, harvesters and other directions, can solve the problems of uneven leaf stripping, unfavorable stripping quality of long-rod crops, and inability to strip leaves, etc. The effect of peeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

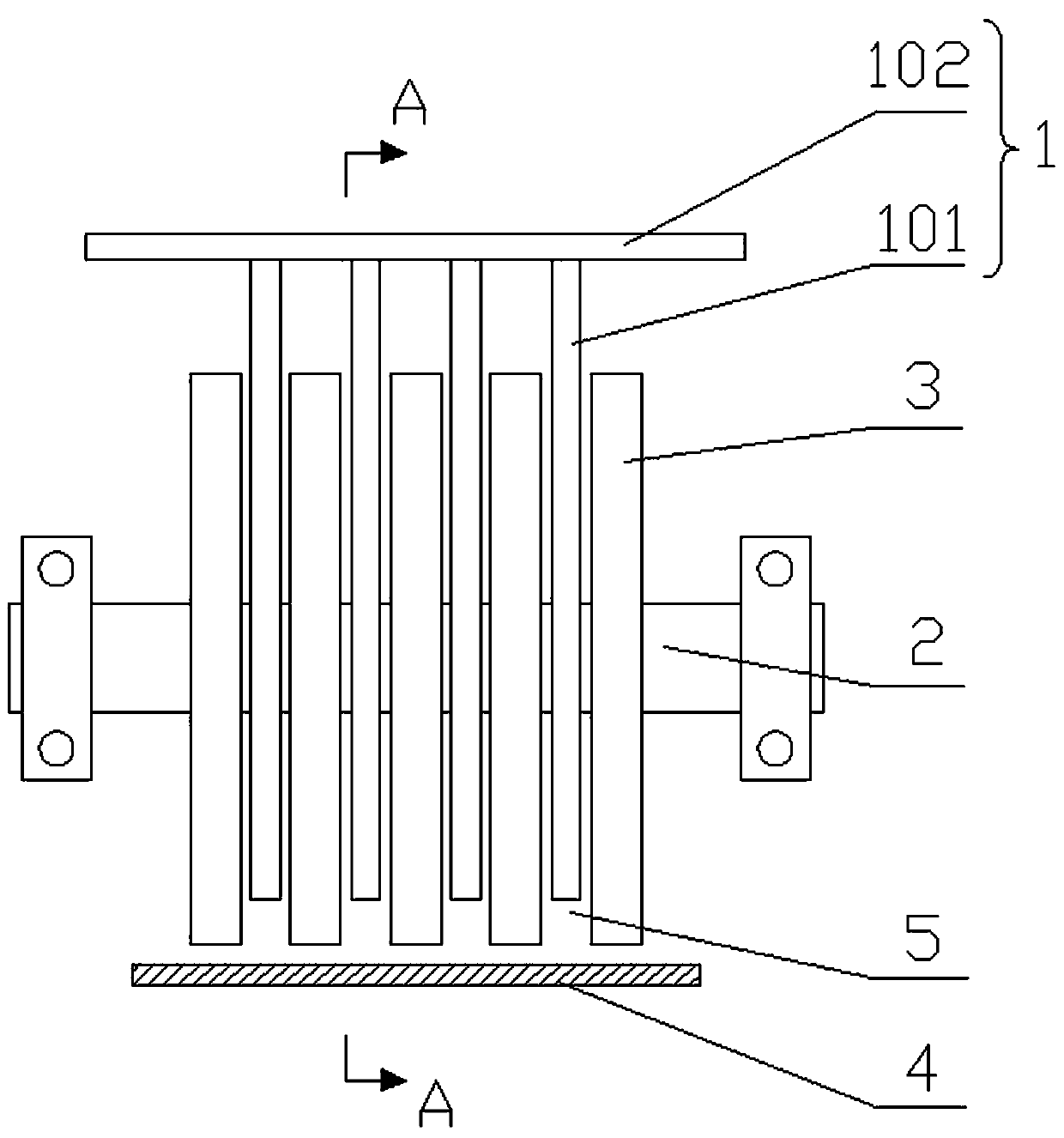

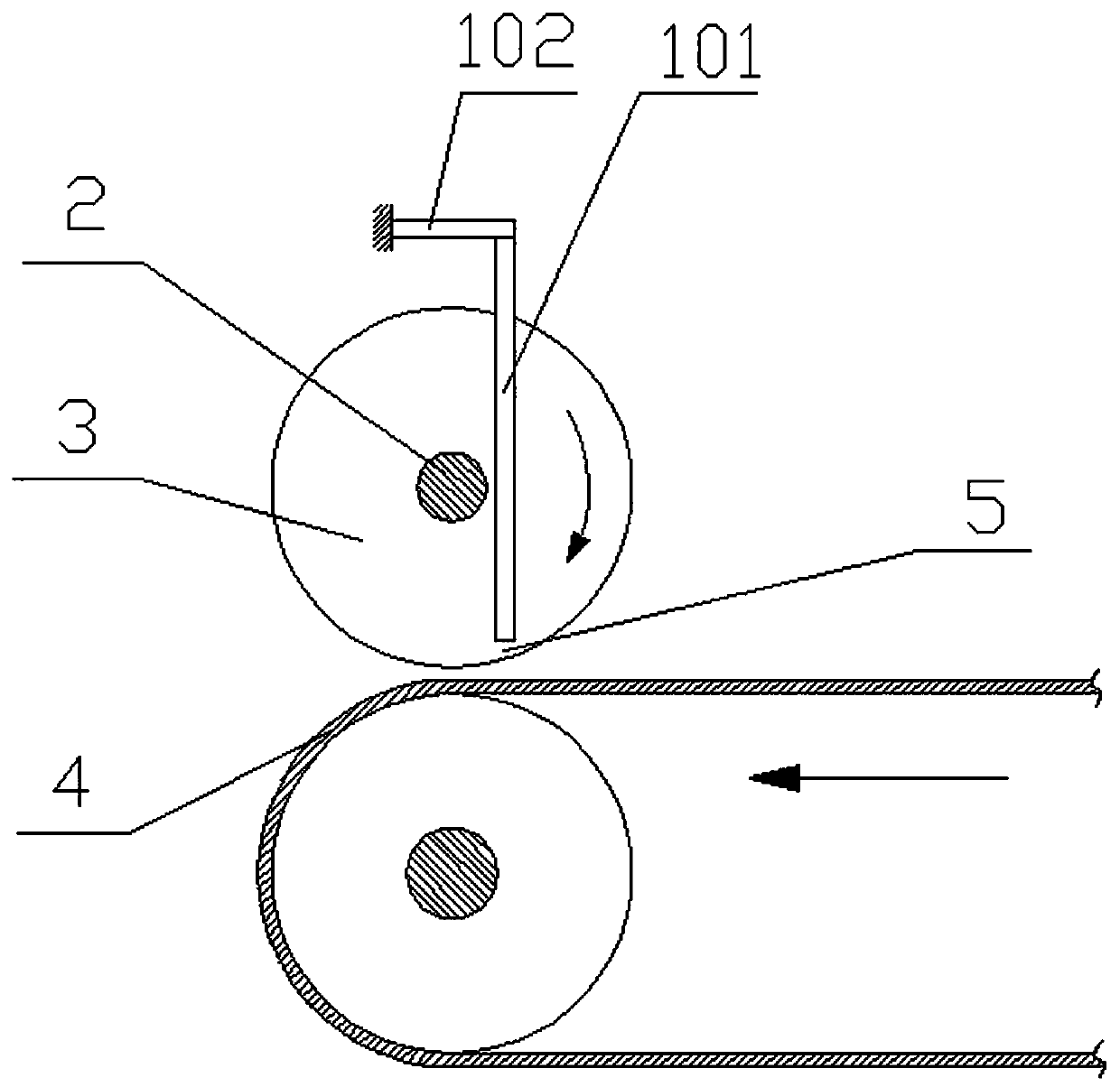

[0012] Such as figure 1 and figure 2 As shown, a shunt feeder for stripping equipment for long rod-shaped crops according to the present invention includes a conveyor belt 4 for conveying long rod-shaped crops and for diverting the long rod-shaped crops on the conveyor belt 4 to A shunt mechanism with discrete intervals.

[0013] Conveyor belt 4 includes an endlessly closed belt body and a driving roller and a driven roller that are cooperating with the belt supply body. The driving roller is connected to a motor provided on the leaf peeling device to drive the belt body to move continuously. The upper edge of the belt body is Always keep level during exercise. The leaf peeling execution unit on the leaf peeling device is arranged at the rear end of the conveying direction of the conveyor belt 4.

[0014] The shunt mechanism includes a rotating shaft 2, a guide plate 3, and a height-limiting grate 1. The rotating shaft 2 is horizontally arranged above the conveyor belt 4 and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com