Leaf stripping equipment for long-rod-shaped crops

A long rod-shaped, crop-like technology, applied in cutting equipment, applications, agricultural machinery and tools, etc., can solve the problems of low production efficiency, inability to adapt to large-scale planting production, and high labor intensity, and achieve simple structure and suitable for continuous production. Production operations, the effect of improving the quality of stripped leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

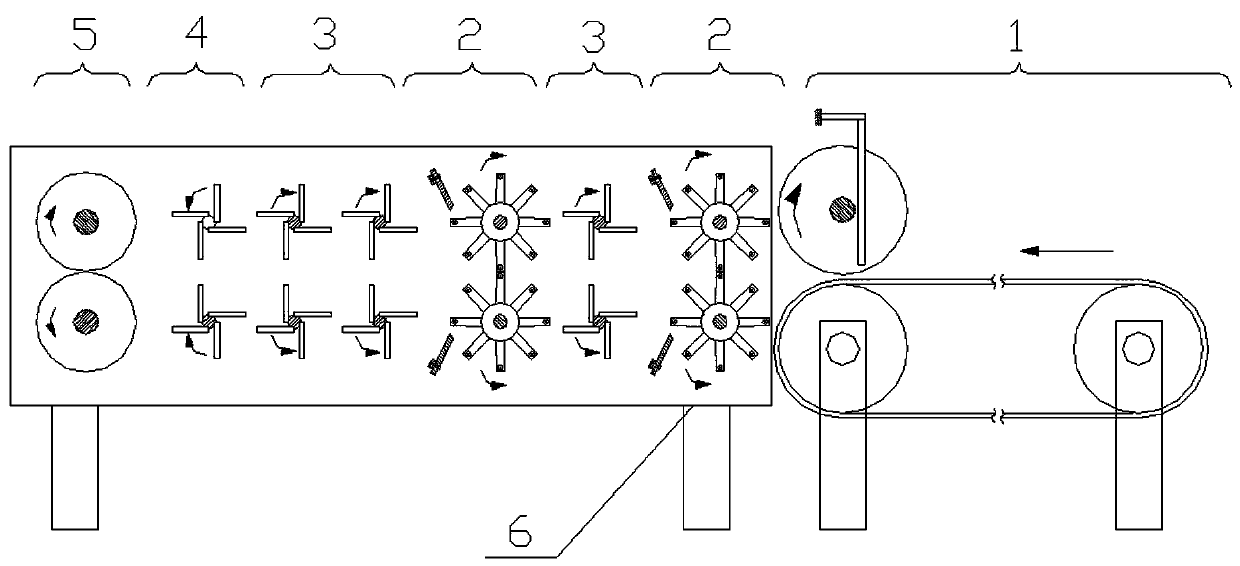

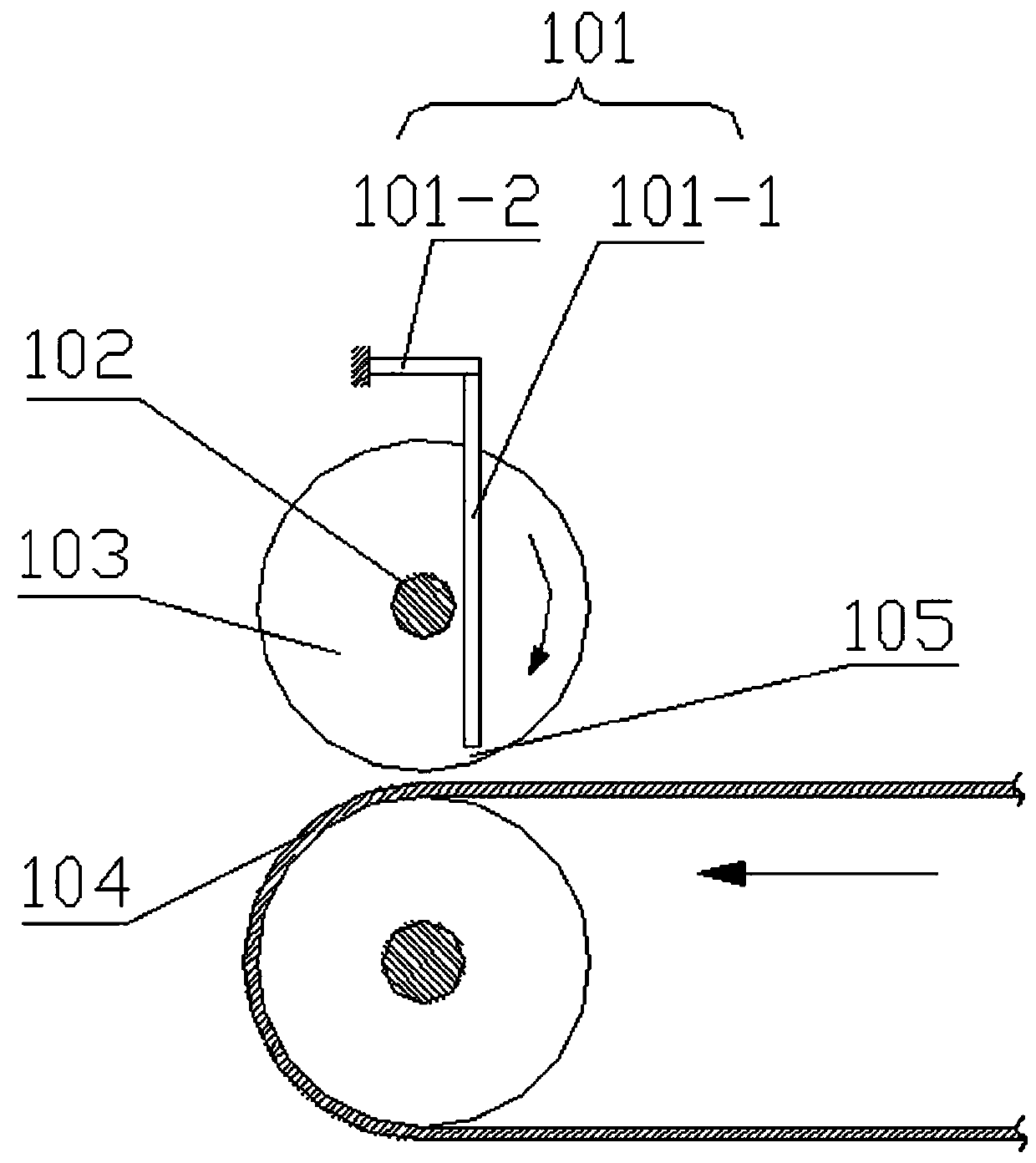

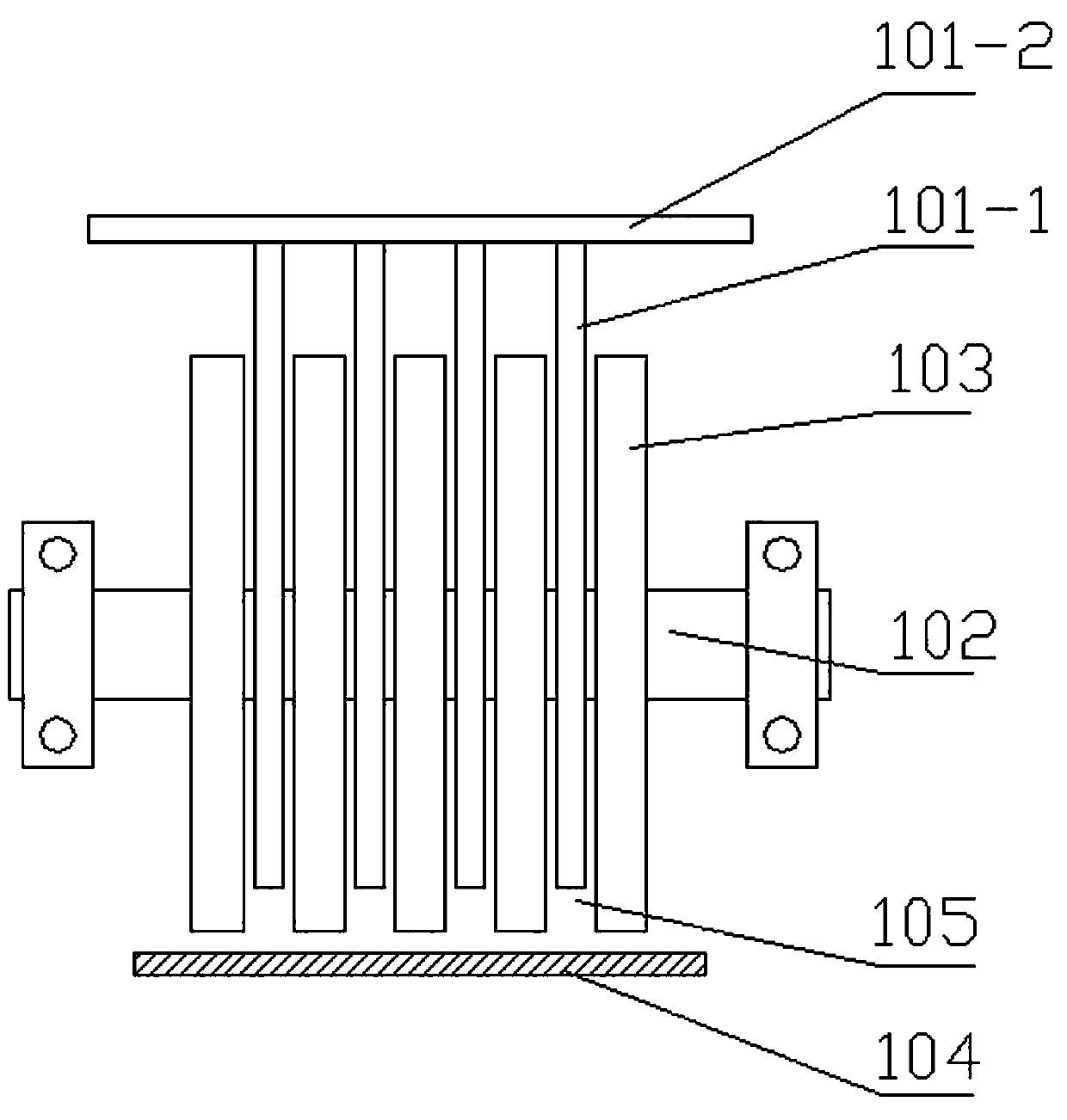

[0027] Such as figure 1 Shown, a kind of stripping equipment for long stalk-shaped crops of the present invention comprises linear frame 6 and a split feeding unit 1, a stripping unit that are arranged on frame 6 successively from right to left 2. A conveying unit 3 , a stripping unit 2 , two conveying units 3 , a backlash unit 4 and an accelerating unit 5 . The position on the frame 6 except for the split feeding unit 1 is provided with a casing with only an open bottom, so as to avoid the pollution caused by stripping and throwing leaves during the leaf stripping or crushing process, and to facilitate the collection and stripping from the bottom of the casing. leaf. After the long rod-shaped crops are transported to the split feeding unit 1, the long rod-shaped crops are transported to the left side of the frame 6 by the conveyor belt 104 in the split feeding unit 1, and the long rod-shaped crops that are close to each other are moved during the conveying process. Stem cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com