Dual-unit corn husker

A technology of peeling machine and corn, applied in the field of agricultural machinery, can solve the problems of low corn peeling efficiency, inconvenient movement, high cost, etc., and achieve the effects of improving peeling quality and machine reliability, shortening operation time, and avoiding machine congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

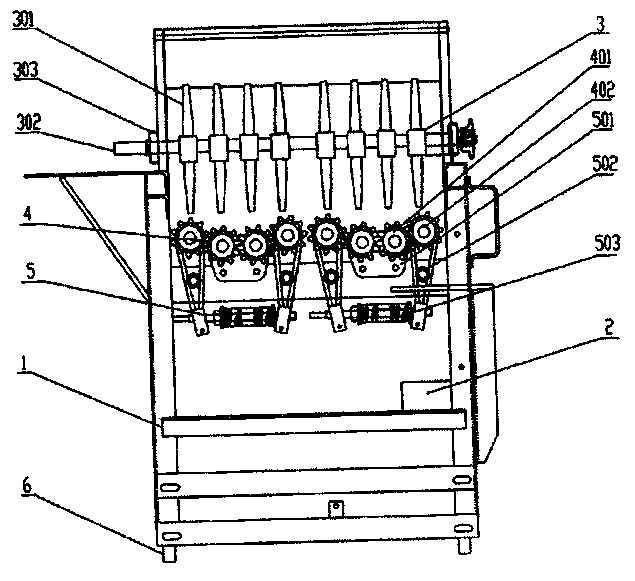

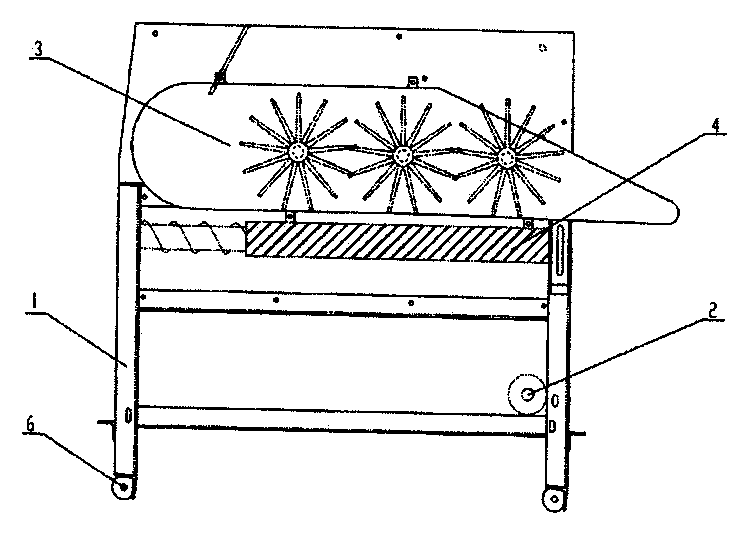

[0020] The two-group corn peeling machine of the present invention comprises a frame 1, a power machine 2 and a transmission mechanism. A pressure-feeding mechanism 3 is provided, and the number of groups of the pressure-feeding mechanism 3 is 3 groups. In the inner cavity of the middle part of the frame 1 below the pressure-feeding mechanism 3, two sets of roller peeling devices 4 are arranged along the length direction of the frame 1. , the roller peeling device 4 is respectively provided with a roller gap adjustment mechanism 5 .

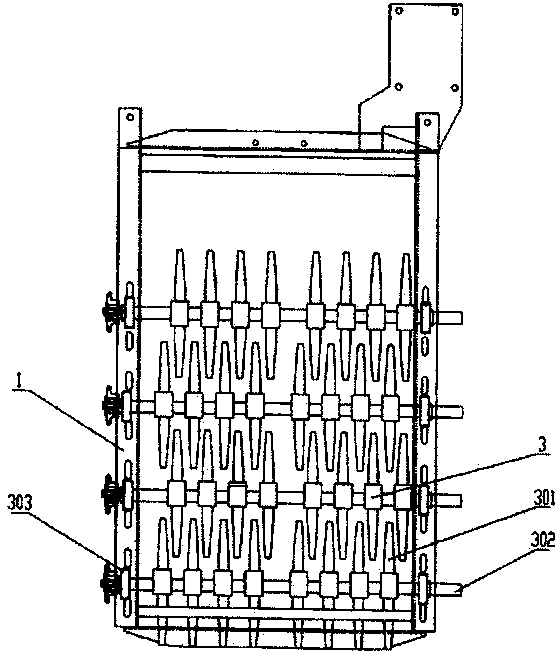

[0021] The pressure feeding mechanism 3 includes a rotating disk 301, a rotating disk support shaft 302 and a rotating disk bearing 303. The rotating disk 301 is a disk-shaped structure composed of radial strips, and the rotating disk supporting shaft 302 is provided with There is a mounting bush with a square cross section, and the rotating discs 301 are evenly distributed at a certain distance in the axial direction of the mounting bush.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com