Patents

Literature

74results about How to "Gap adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

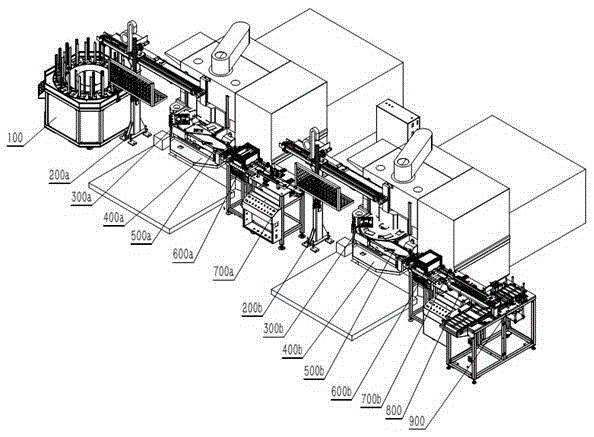

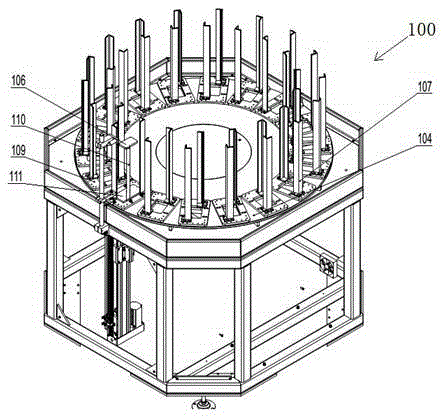

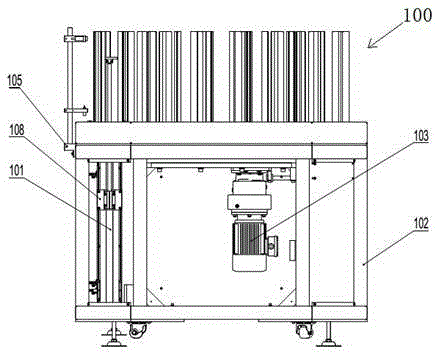

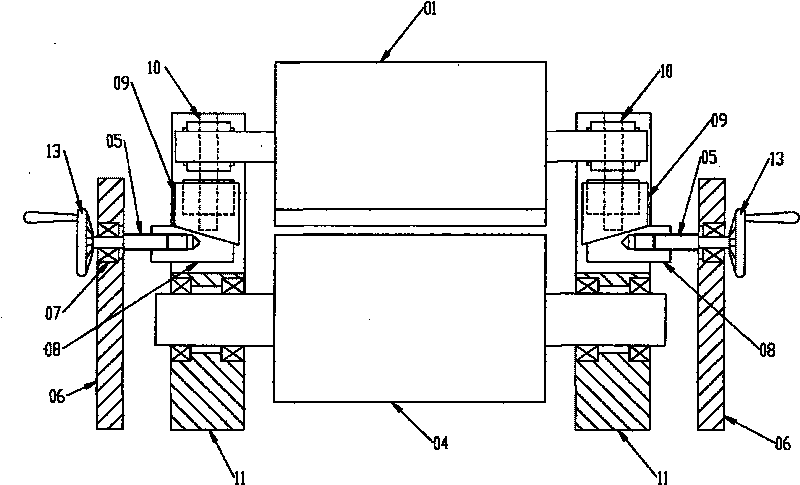

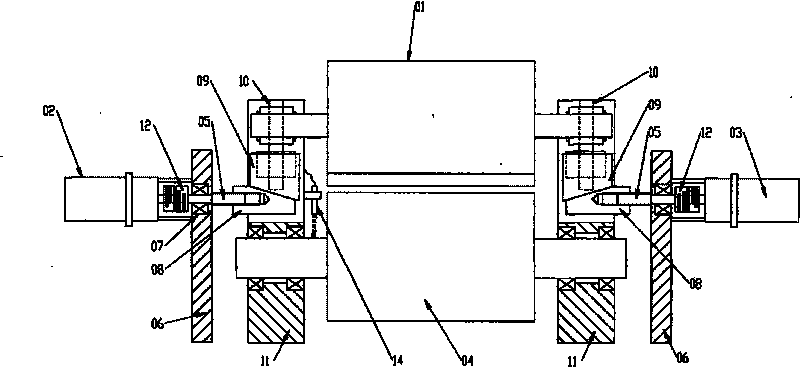

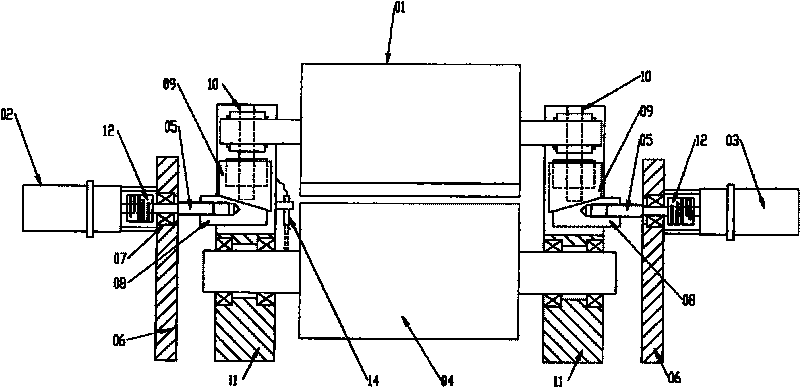

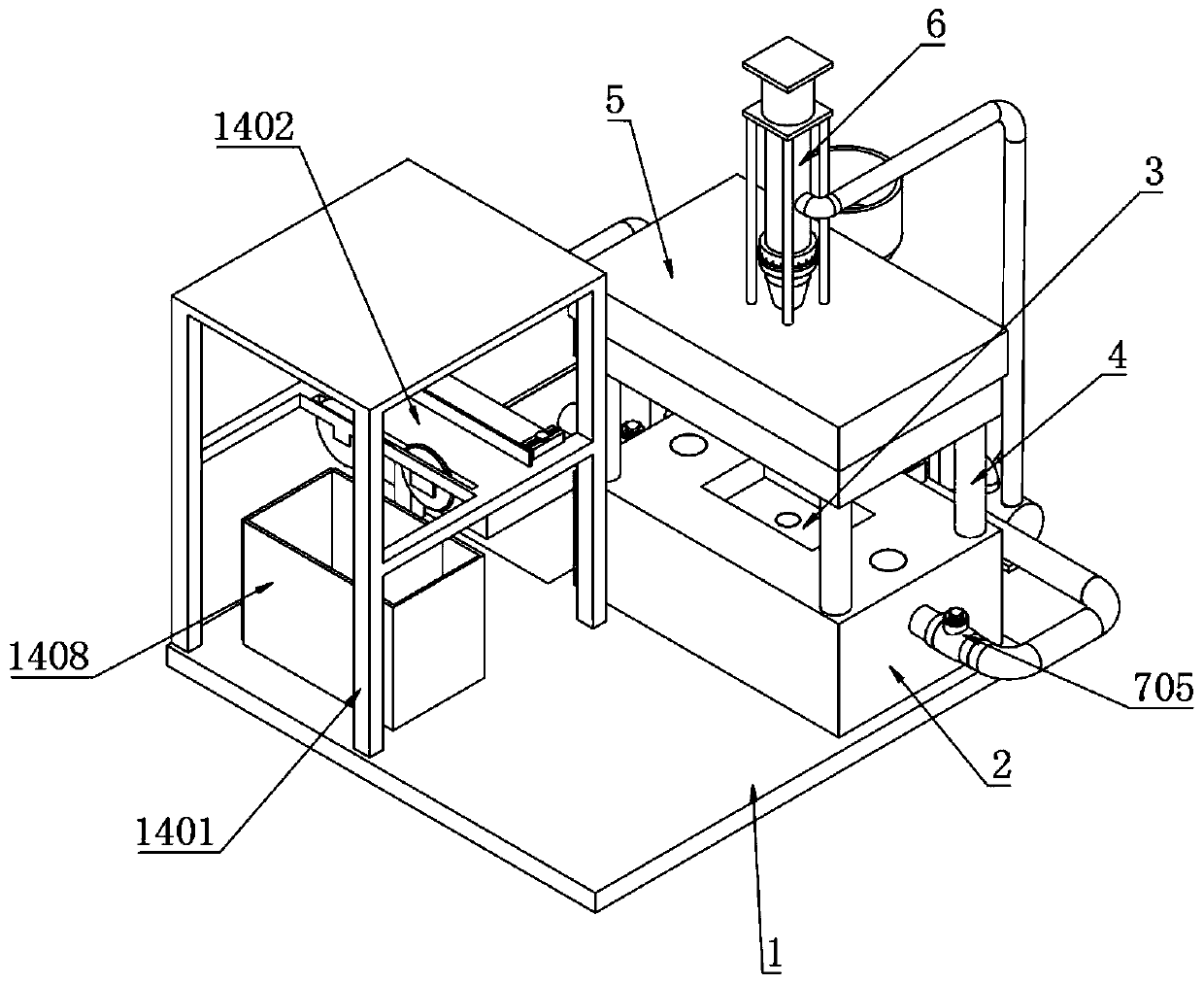

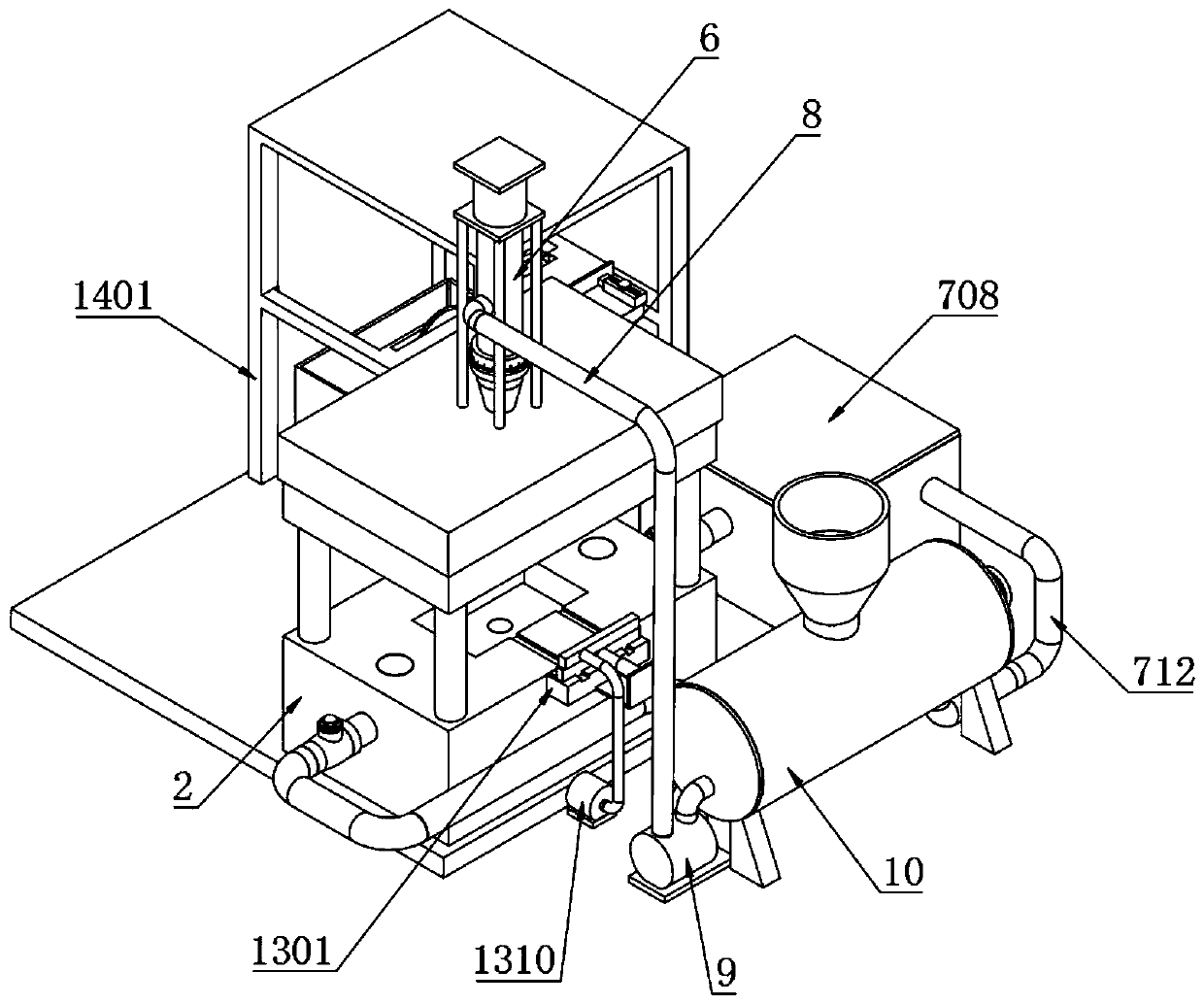

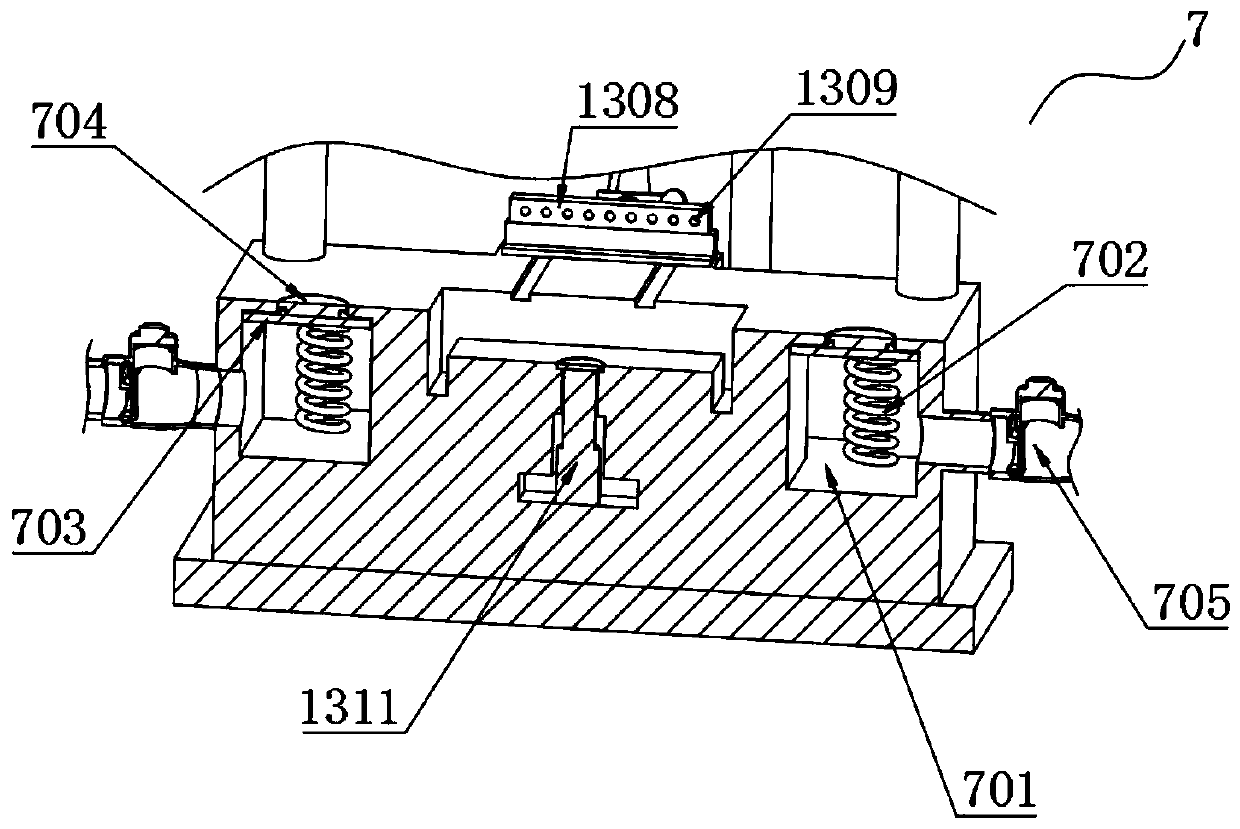

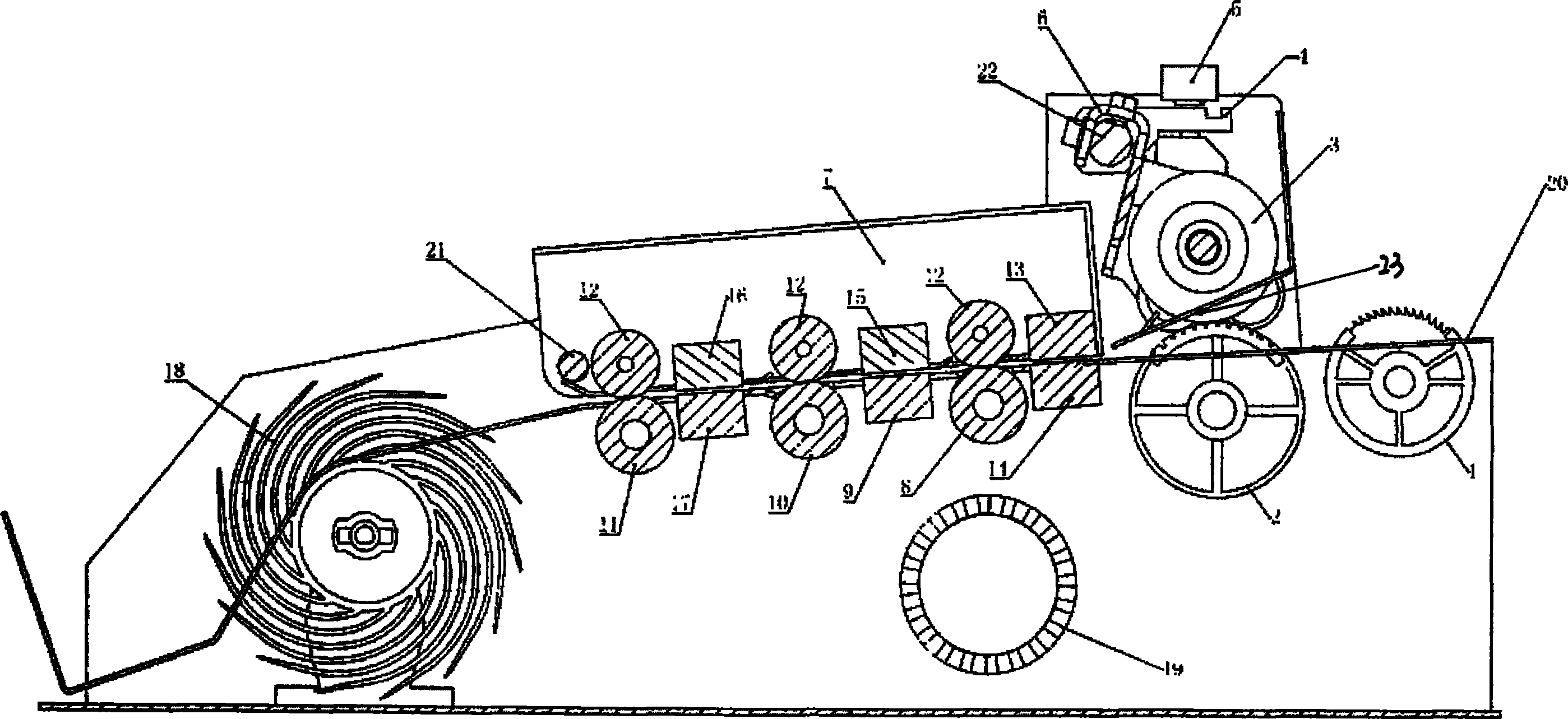

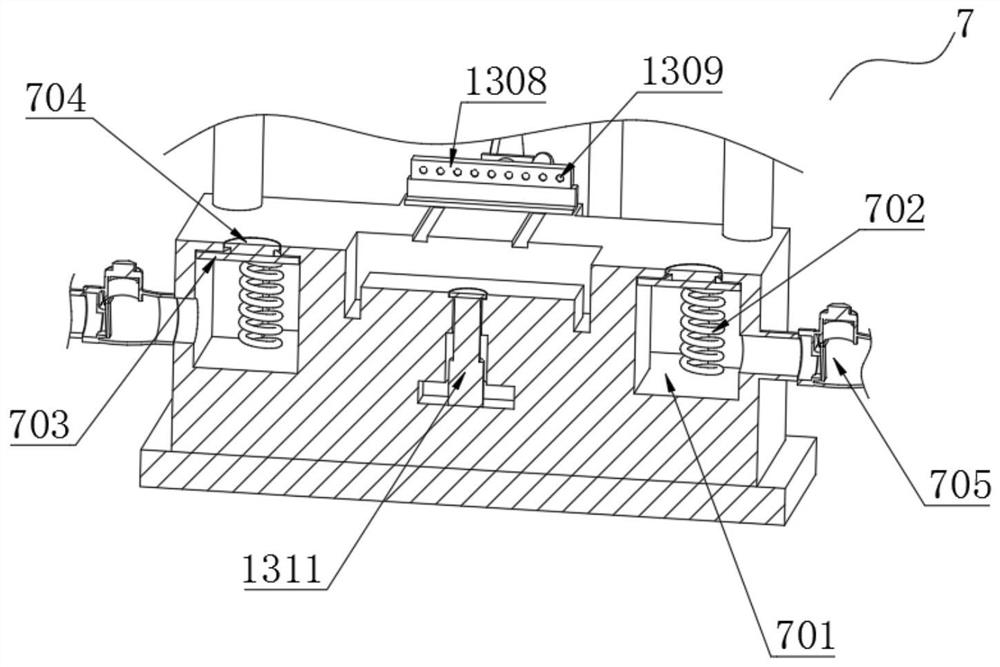

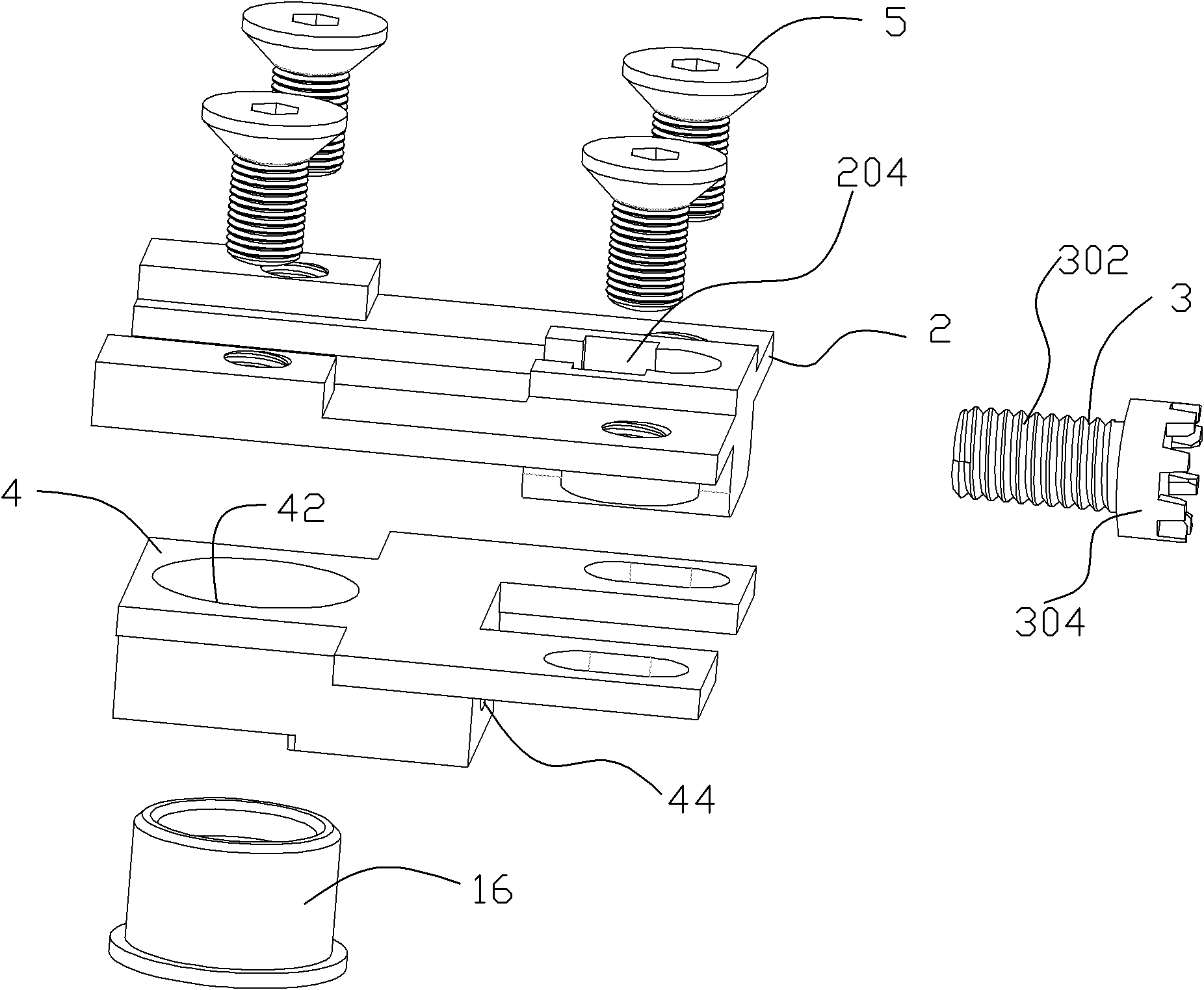

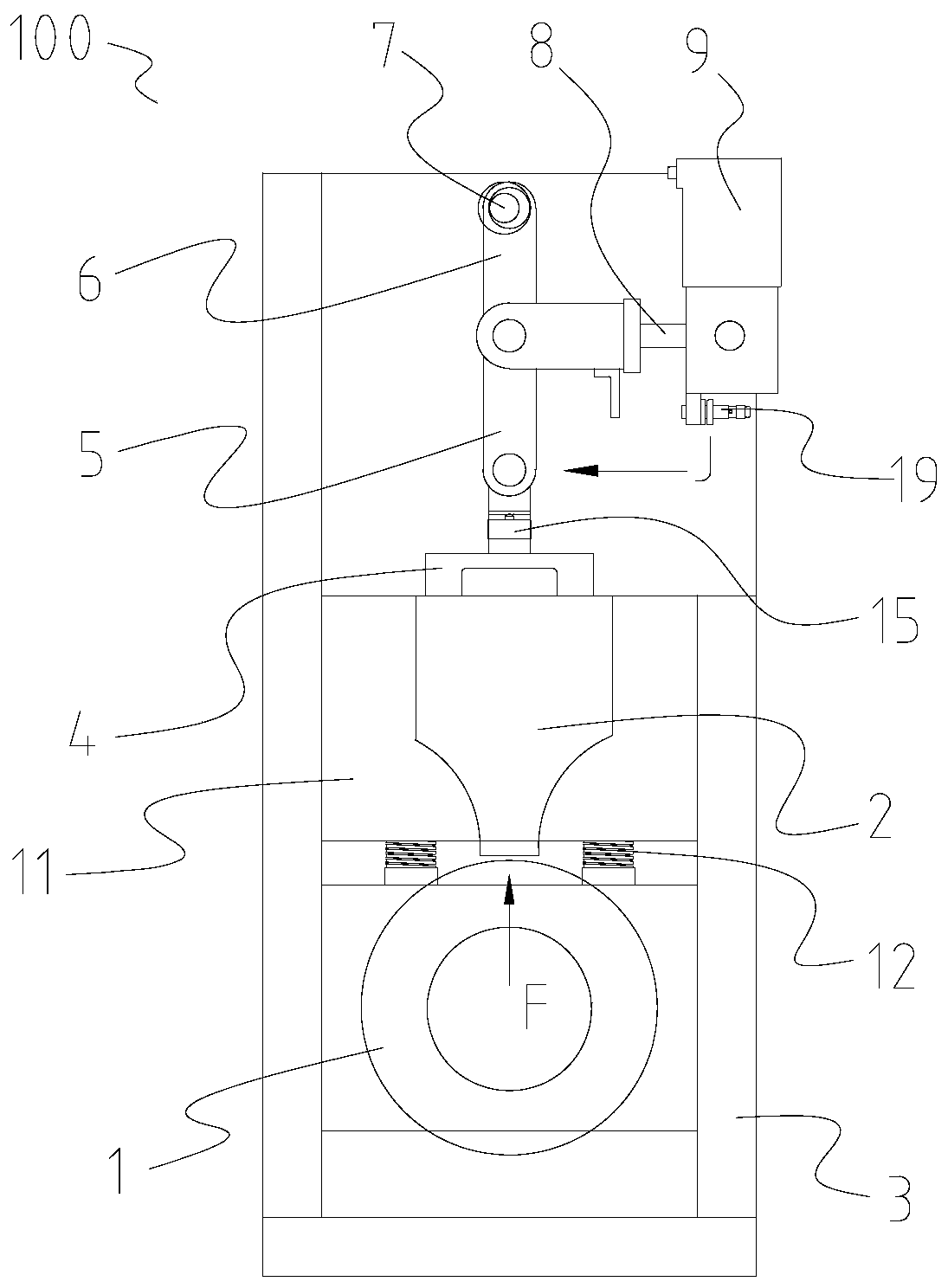

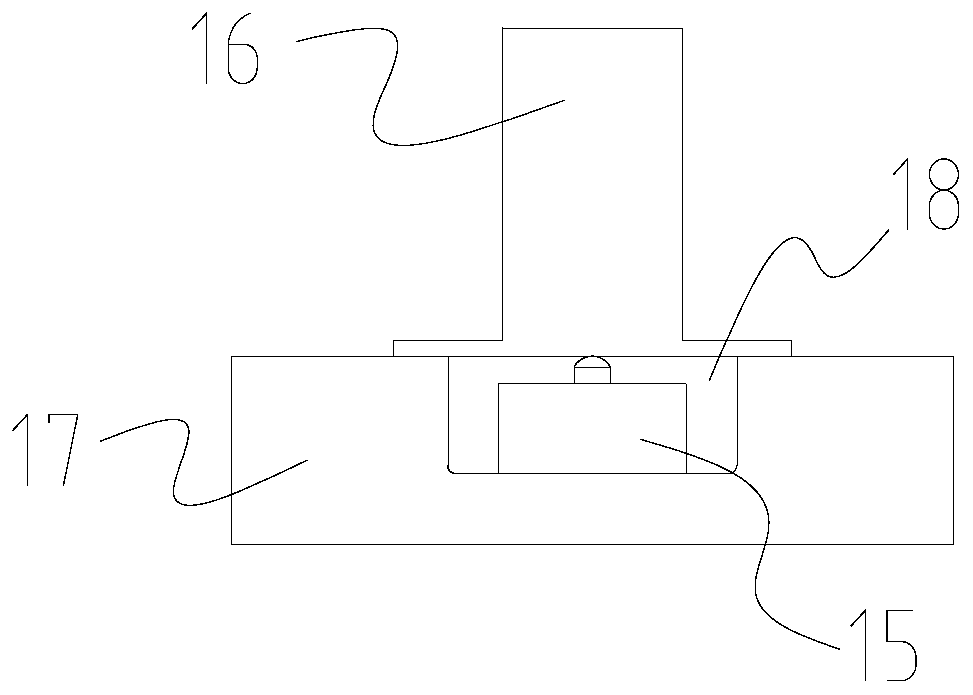

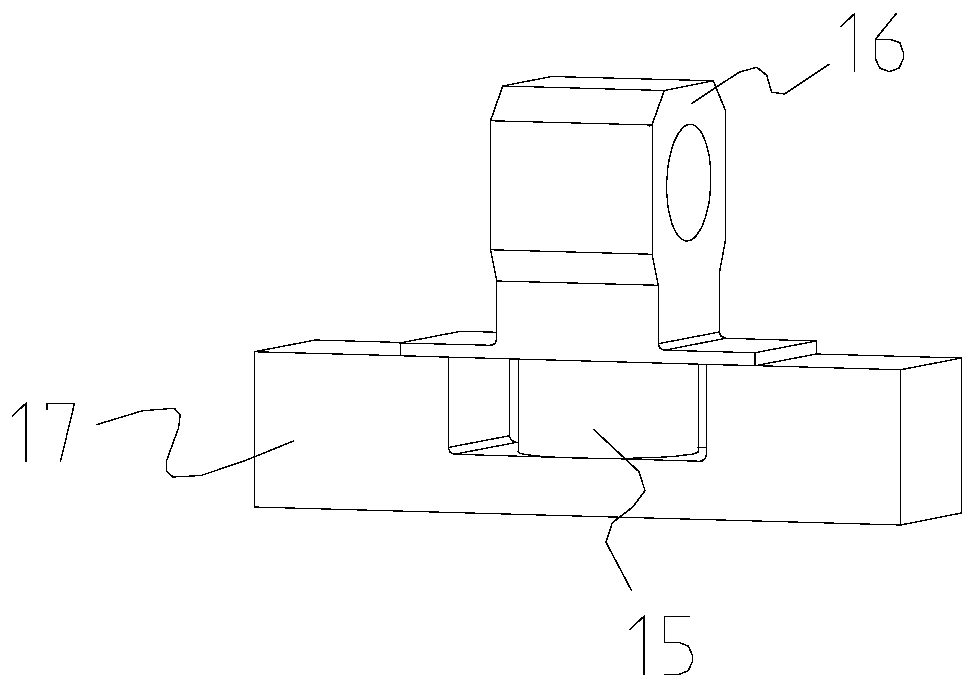

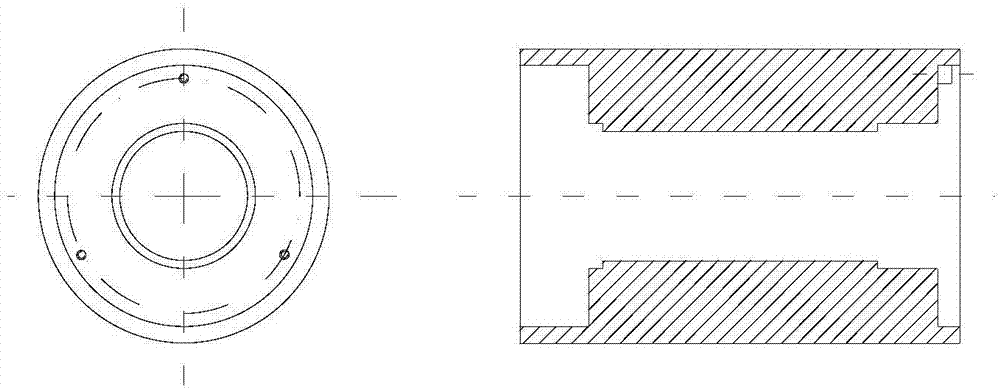

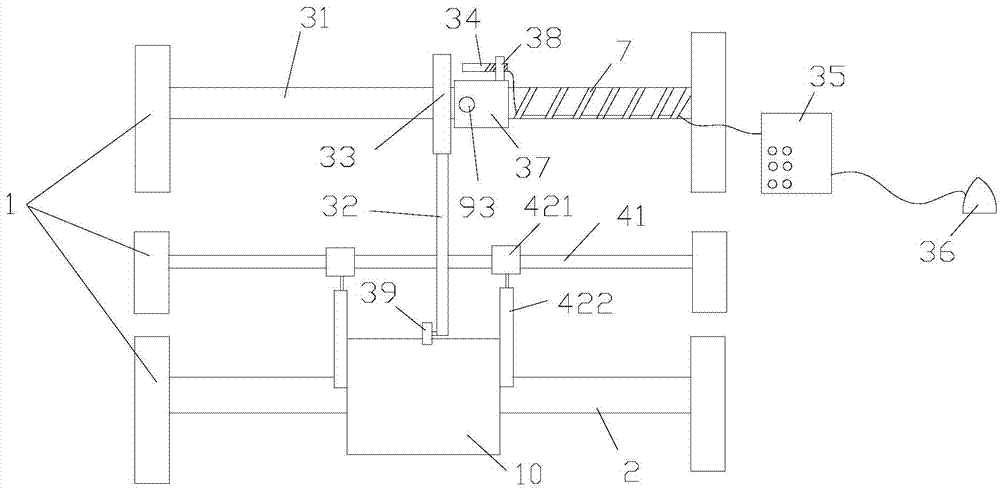

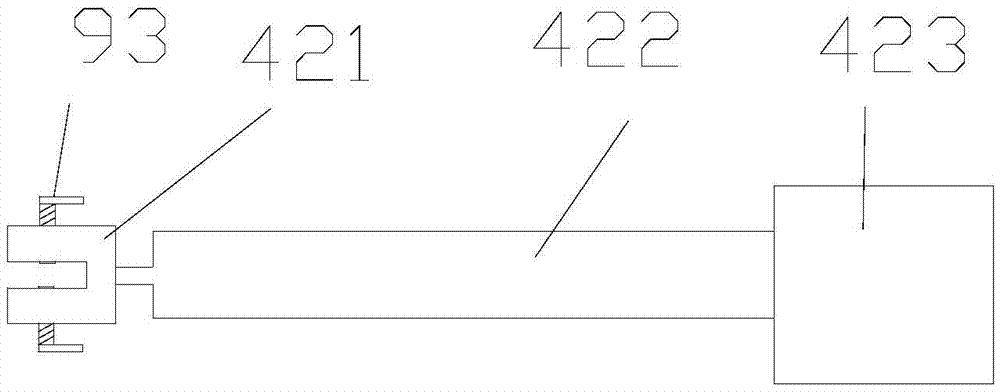

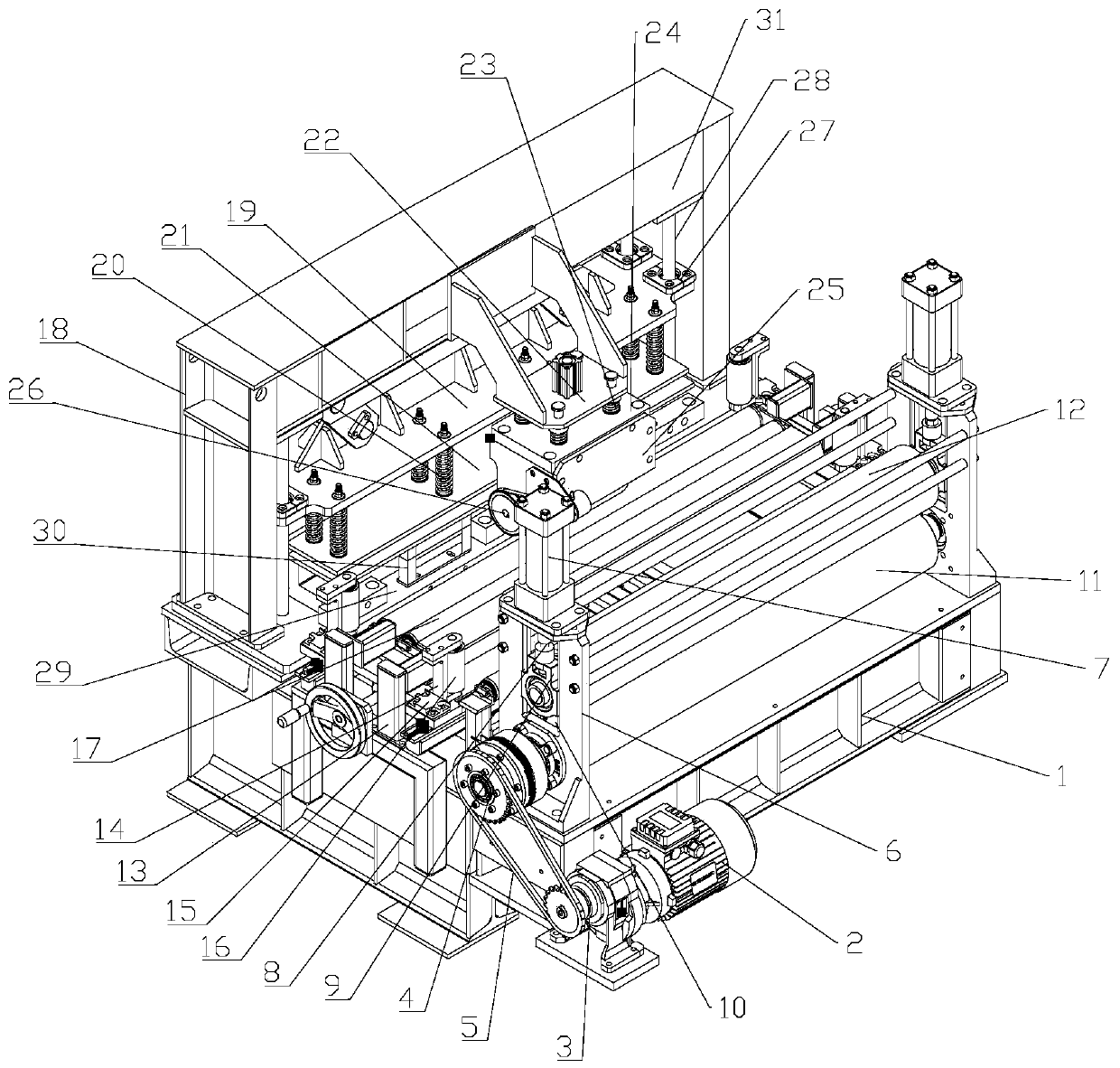

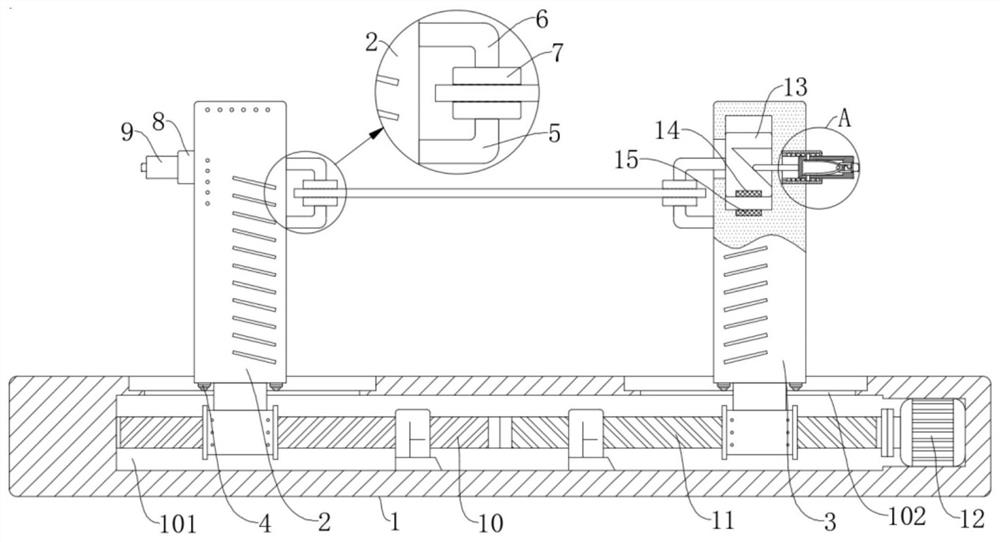

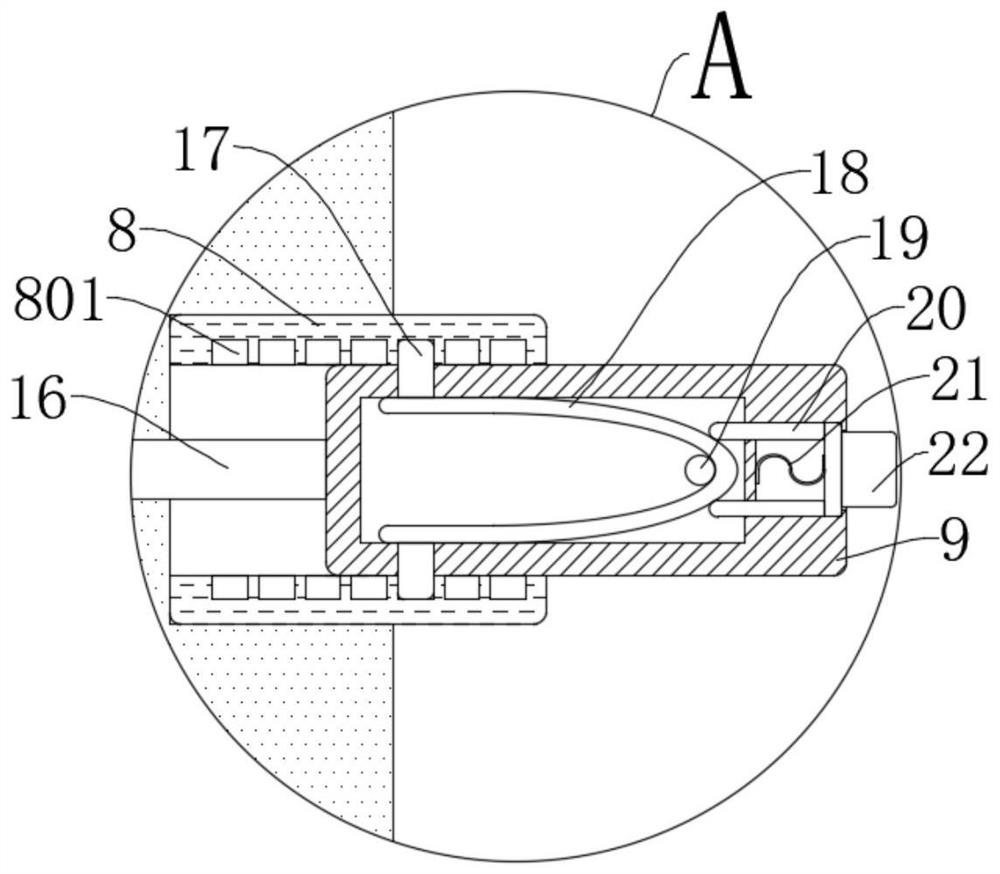

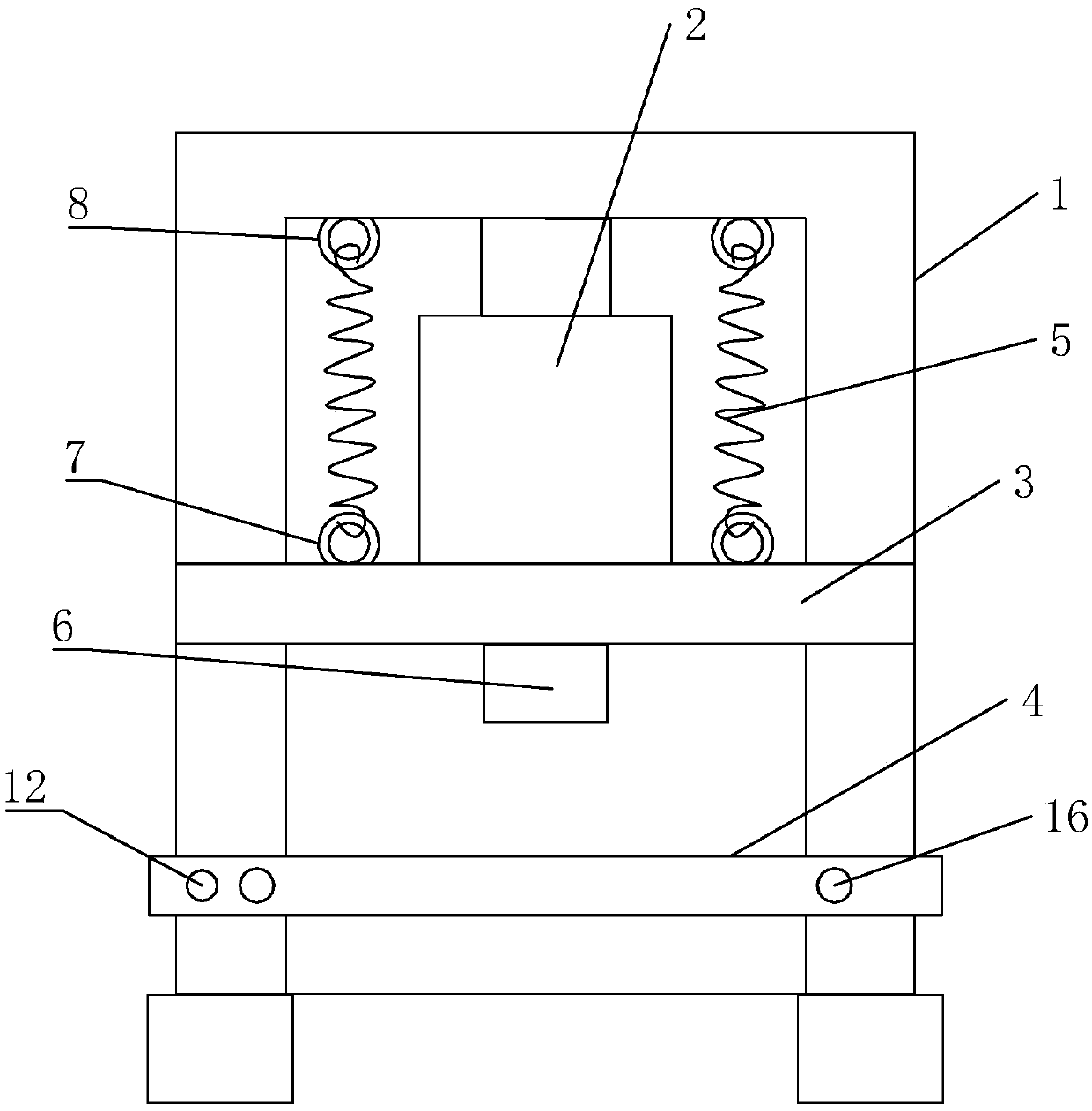

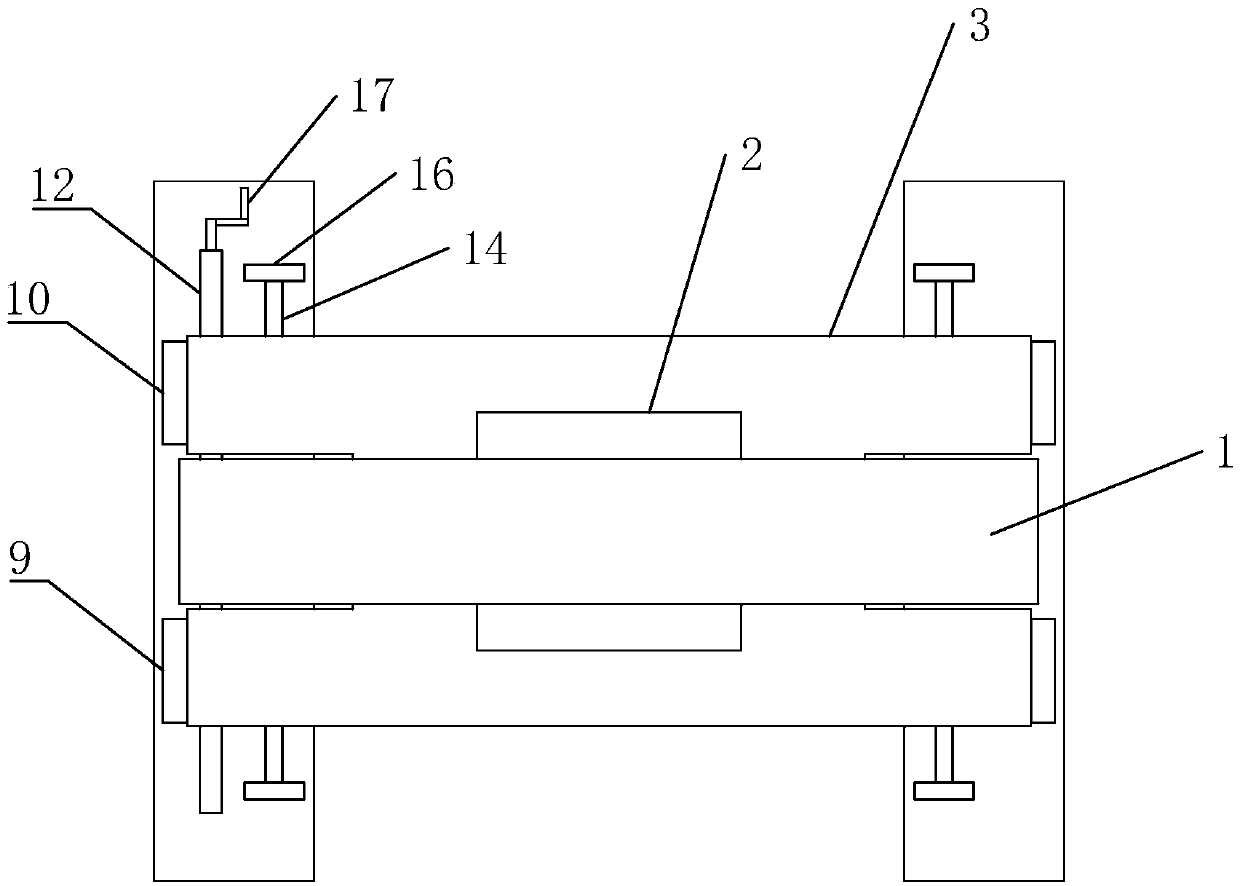

Full-automatic double-end-face grinding production line

ActiveCN105382650AGap adjustmentLow processing and manufacturing costsGrinding feedersPlane surface grinding machinesProduction lineManipulator

The invention discloses a full-automatic double-end-face grinding production line. The production line is arranged in a straight line and sequentially comprises a feeding mechanism, a feeding mechanical arm, a first double-end-face grinding machine, a first transfer conveying belt, a first washing mechanism, a first detecting device, a transfer mechanical arm, a second double-end-face grinding machine, a second transfer conveying belt, a second washing mechanism, a second detecting device, a discharging mechanical arm and a discharging mechanism, wherein the first double-end-face grinding machine is provided with a first grinding machine material drop plate which is engaged with the feeding mechanical arm; the second-end-face grinding machine is provided with a second grinding machine material drop plate which is engaged with the transfer mechanical arm. The full-automatic double-end-face grinding production line disclosed by the invention can be used for grinding a wide range of materials, is capable of implementing feeding, grinding, washing, detection and discharging of a work piece material by one time, is high in automation degree and has the effects of guaranteeing the machining quality, reducing the rejection rate, also greatly alleviating the labor strength, reducing the labor and lowering the machining cost and the manufacturing cost for enterprises.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

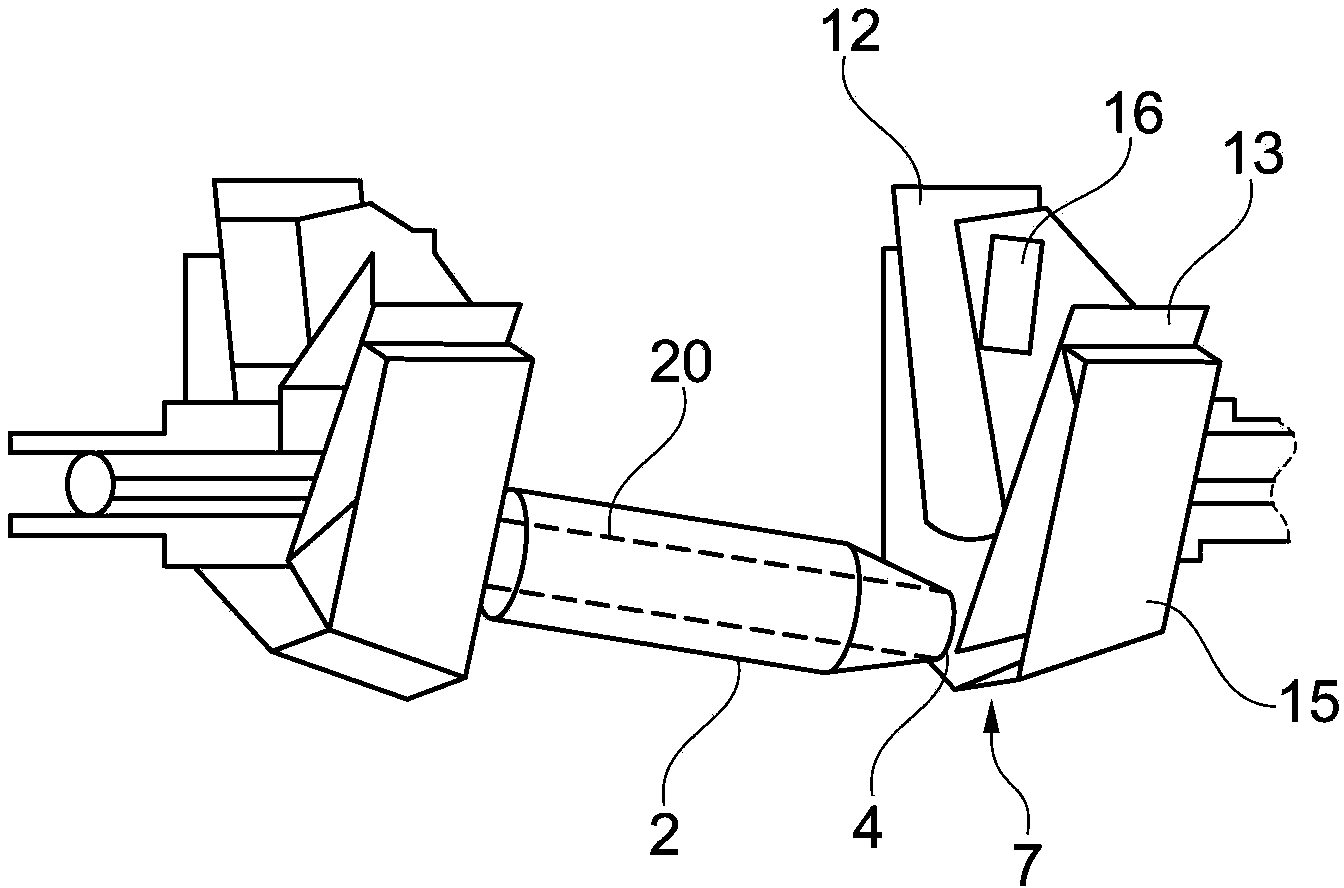

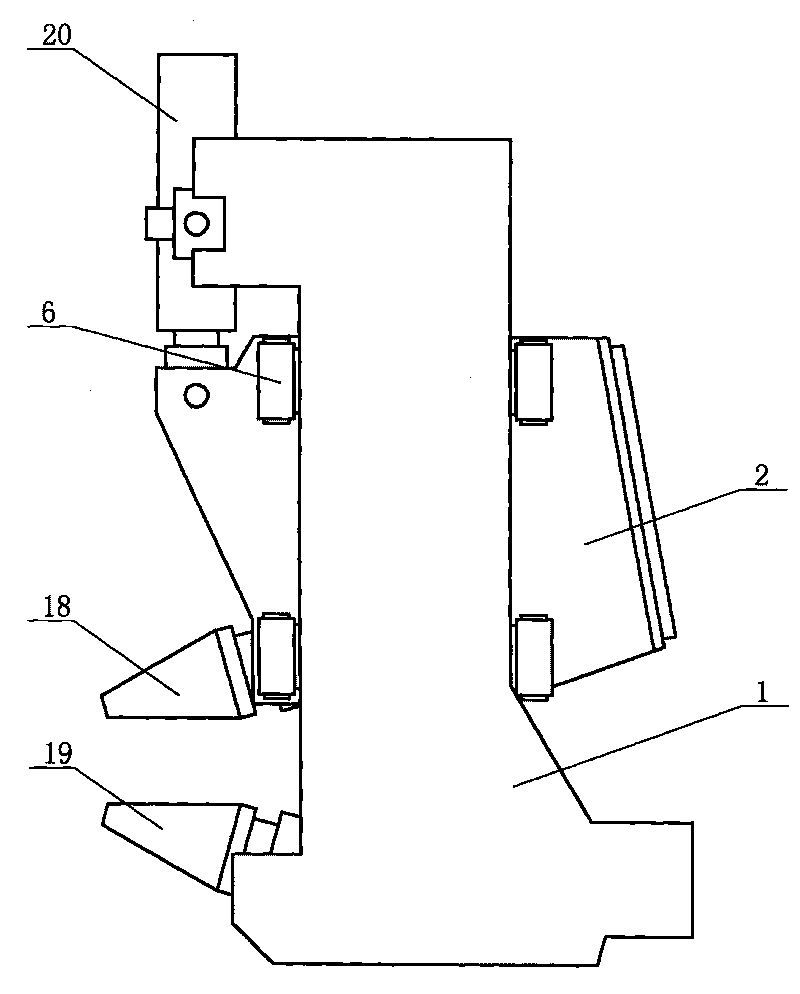

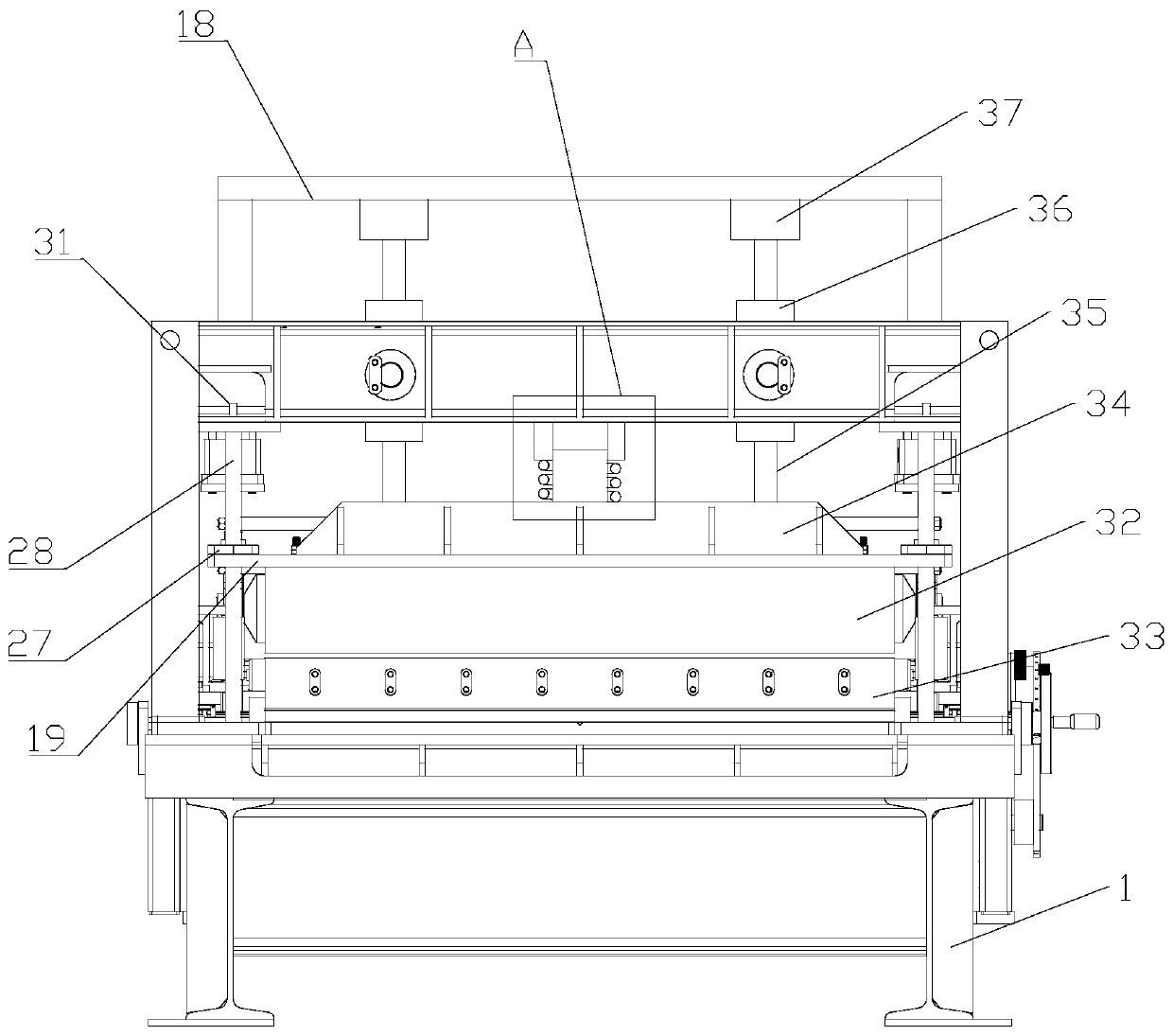

Device capable of automatically adjusting coating machine scraper gap

InactiveCN101712021AEasy to adjustRegulation stabilityLiquid surface applicatorsElectrode manufacturing processesAuto regulationCoupling

The invention discloses a device capable of automatically adjusting coating machine scraper gap, comprising a scraper, a coating roll, a screw, a stationary inclined block, a movable inclined block and a linear guide. The device is characterized in that the device is provided with two servo motors which are respectively connected with the movable inclined blocks at two ends of the scraper by a coupler, a bearing, a screw base and the screw; two servo motors adopt the same PLC to intensively control; the stationary inclined block is also provided with a high-precision displacement transducer and is connected with the PLC; the high-precision displacement transducer collects and adjusts gap feedback information in due time and sends the gap feedback information to the PLC control center to form a closed loop control system. The invention has the beneficial effect that the device adopts the closed loop control system to adjust the height of a scraper; the minimum effective stroke for adjustment is small, so that the gap precision can be accurately controlled; the servo motor operation consistency effectively avoids the problem of inconsistent adjustment height of two ends of the scraper.

Owner:东莞市九州浩德新能源设备有限公司

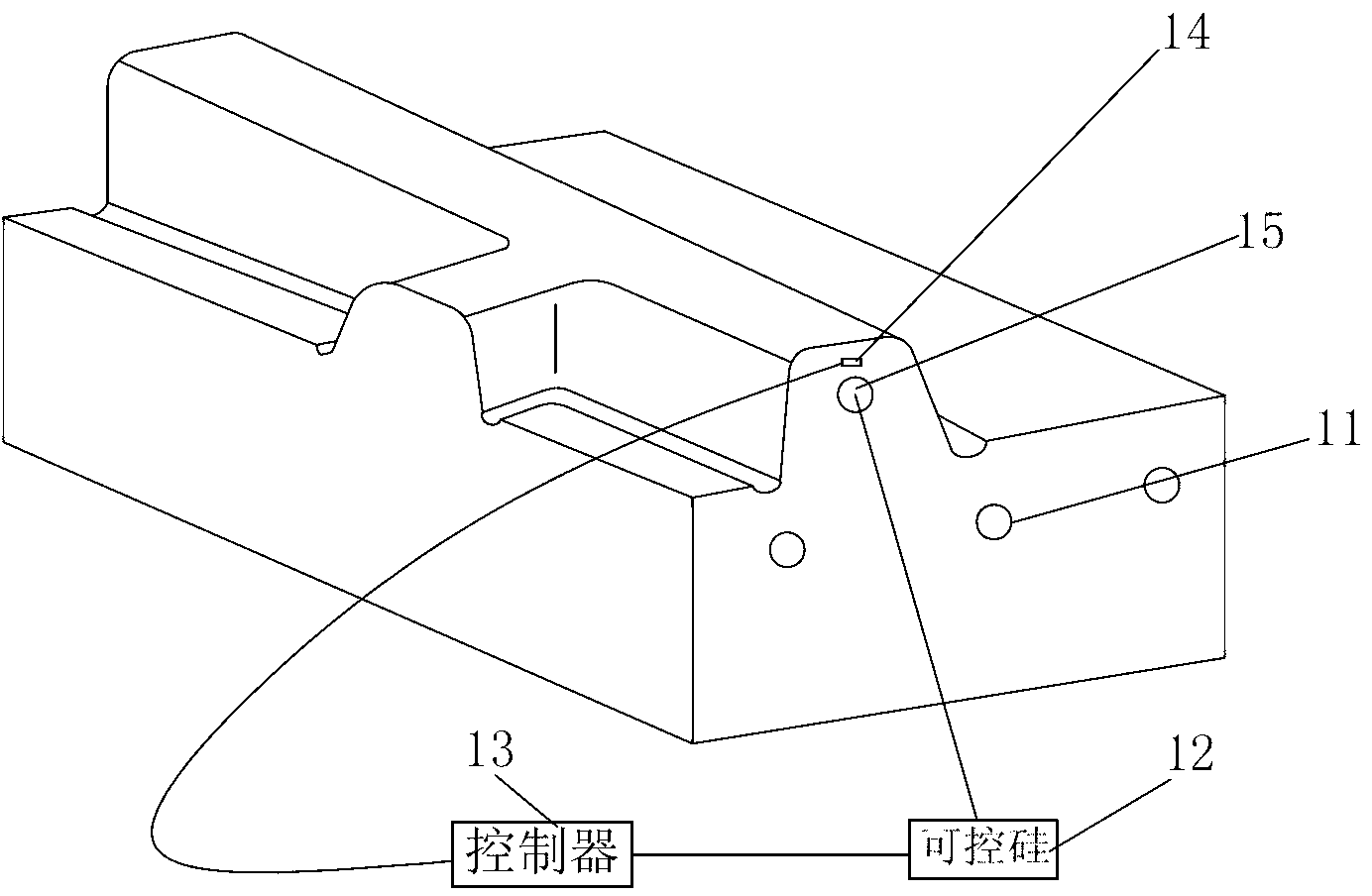

Control method and device for hot-forming plasticity distribution of high-strength steel

InactiveCN103233109AAchieve softeningReduce temperature differenceHeat treatment process controlSilicon-controlled rectifierLow voltage

The invention provides a control method and device for hot-forming plasticity distribution of high-strength steel. The control method comprises the following steps of: step one, heating a heating region of a mold to an appointed temperature; step two, placing and heating a blank in a heating furnace, so that the blank is austenized; step three, taking out the blank from the heating furnace, placing a part of blank in the heating region of the mold according to actual requirements, and placing the another part of blank in a cooling region of the mold; and step four, moving a press machine downwards so as to drive the mold to be closed, so that the blank in the mold is molded. The control device comprises a low mold seat board, a lower voltage withstanding heat insulation plate, a lower mold heating region insert, a lower mold cooling region insert, an upper mold heating region insert, an upper mold cooling region insert, a heating rod hole, a silicon controlled rectifier, a controller, a thermocouple and a heating rod. The control method and device can ensure that a high-strength steel sheet has different strength and plasticity in different regions.

Owner:武汉钢铁有限公司 +1

Externally-arranged type printer scraper device

The invention discloses an externally-arranged type printer scraper device. The externally-arranged type printer scraper device comprises a supporting frame, fixing plates and lead screws; the fixing plates are symmetrically arranged on the two sides of the bottom of the supporting frame, adjusting screw rods are connected to the end faces, close to the supporting frame, of the fixing plates, and penetrate through holes in the supporting frame to extend, adjusting nuts matched with the adjusting screws are arranged on the adjusting screws in a sleeving manner, the adjusting nuts are rotatably fixed to the inner side of the supporting frame, the two lead screws are symmetrically and rotatably arranged on the upper portion of the supporting frame, a dual-shaft motor driving the lead screws to rotate is arranged on the center of the supporting frame, lead screw sleeves matched with the lead screws are arranged on the lead screws in a sleeving manner, connecting rods are hinged to the upper ends of the lead screw sleeves, the other ends of the connecting rods are hinged to the bottom of a connecting plate, and a scraper is connected to the top of the connecting plate through an elastic telescopic part. External arrangement of the scraper is achieved, the manufacturing cost of a printing production line is reduced, and meanwhile the device has the beneficial effects of being easy to adjust and good in ink scraping effect.

Owner:GUANGDONG SHUNCHANG PRINTING

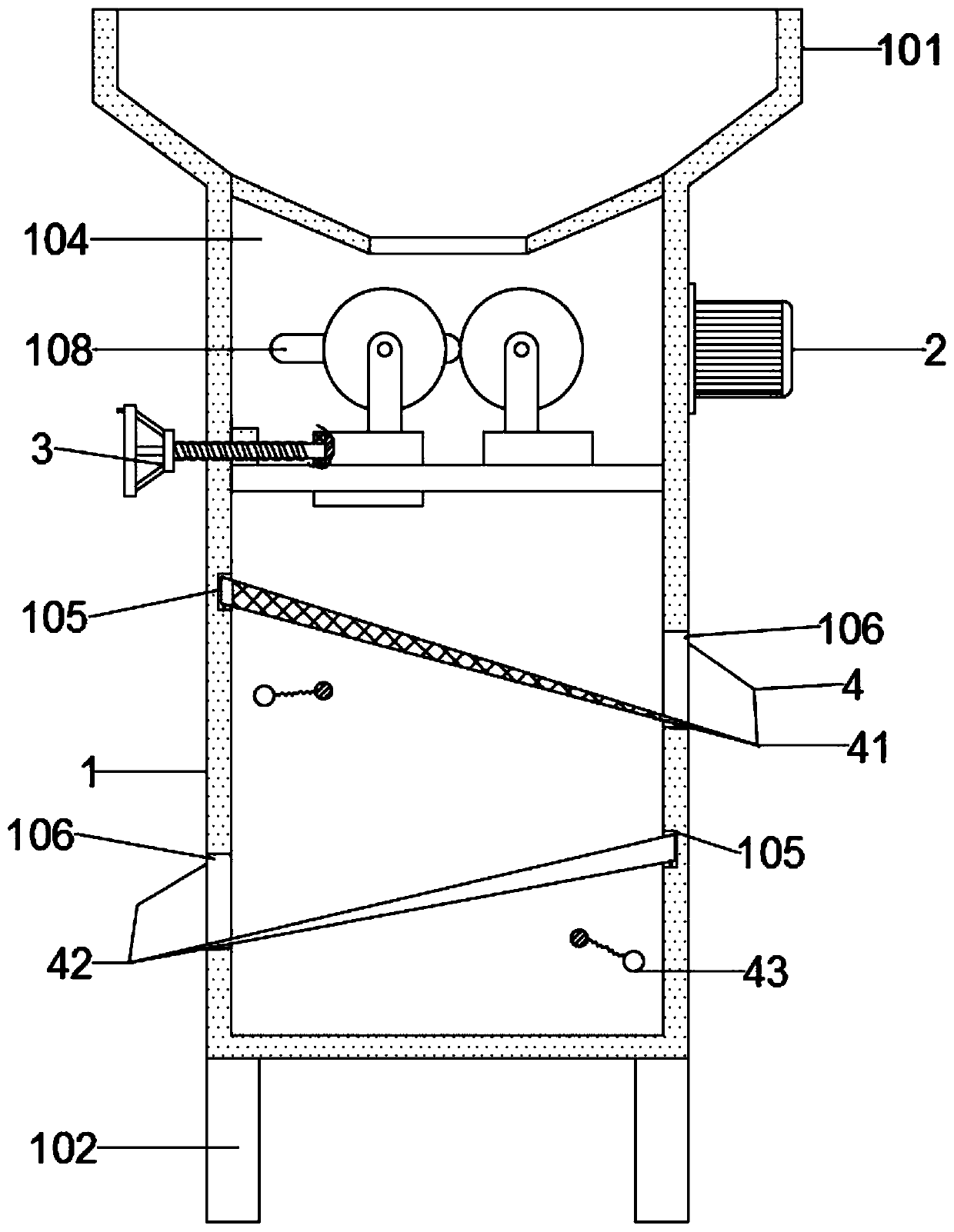

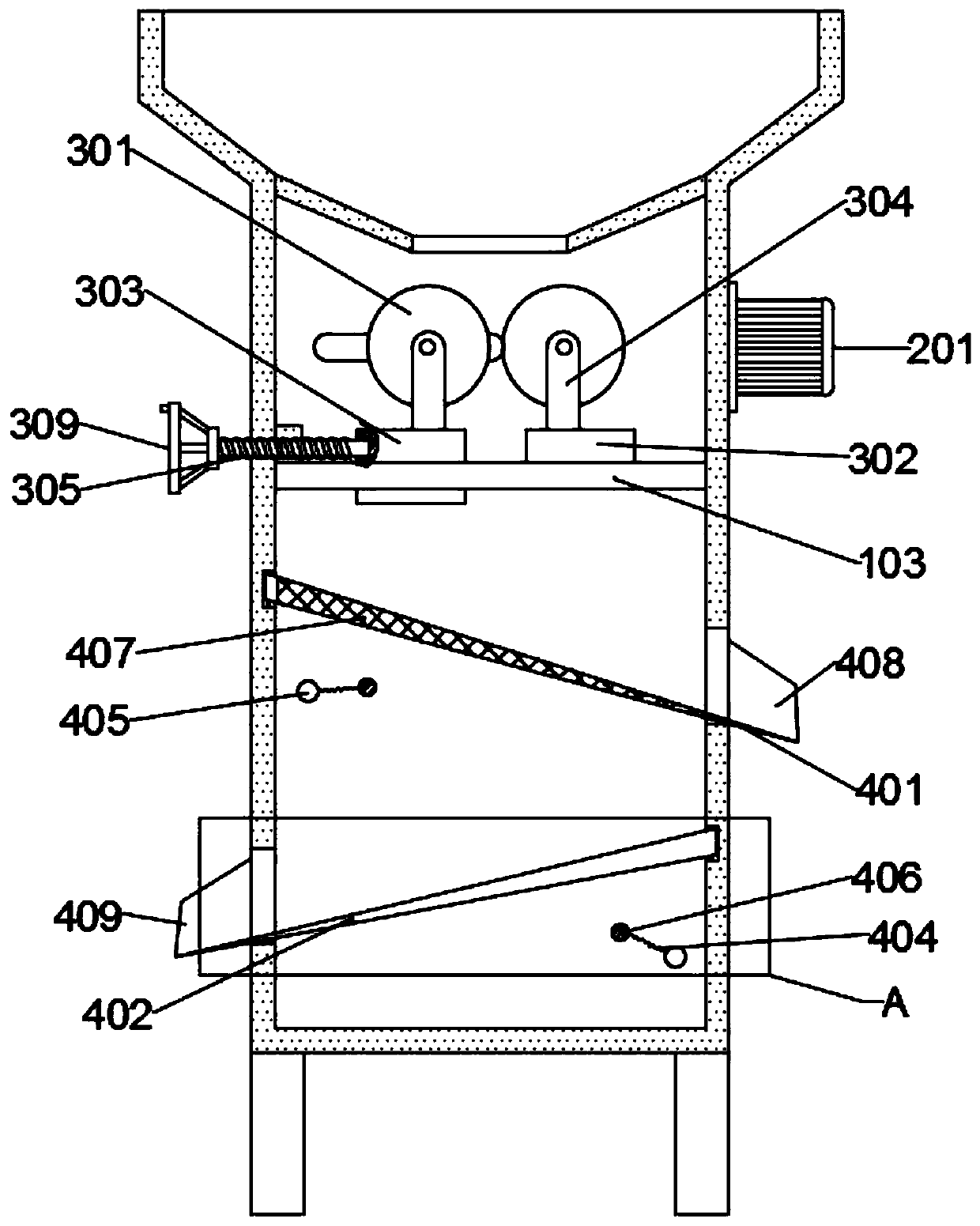

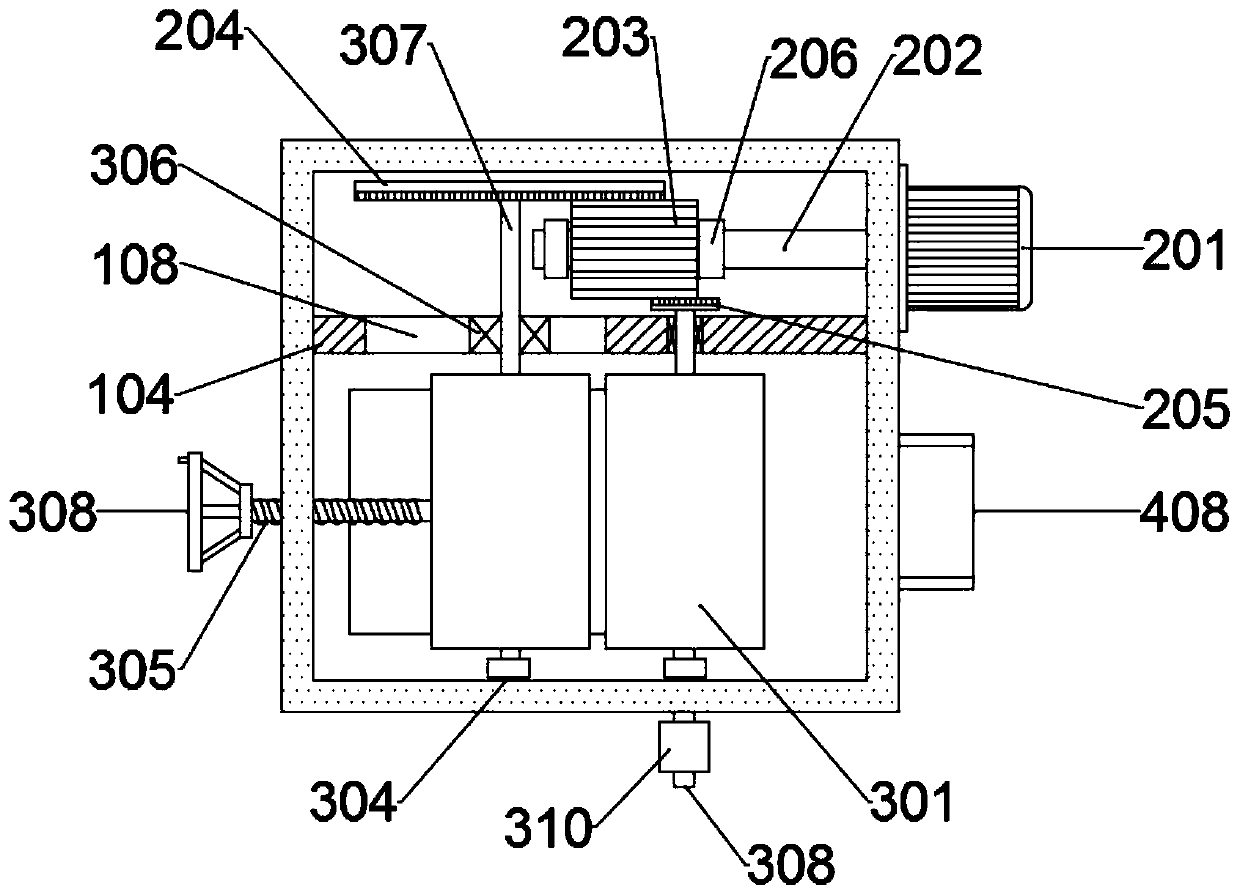

Space-adjustable smashing device for micro powder production

The invention relates to the technical field of smashing devices for micro powder production, in particular to a space-adjustable smashing device for micro powder production. The device is simple in structure, convenient to use, low in production cost and suitable for smashing treatment in the micro powder production process. Through rotation of a motor, rotation of two sets of smashing rollers can be achieved, micro powder smashing is achieved, through manual rotation of a hand rotation disc, adjusting of the gap between the two sets of smashing rollers is achieved, micro powder smashing is achieved, the hand rotating disc is manually rotated by the manual work, adjusting of the gap between the two sets of smashing rollers can be achieved, different powder required in the different needscan be produced, and the application range is wide. The smashed micro powder falls on a screening plate from falling holes, the micro powder smaller than the diameter of screening meshes falls on a guide plate, and slides out of a second discharging hopper connected with the guide plate, and the micro powder larger than the diameter of the screening meshes directly slides out of a first discharging hopper connected with the screen plate for subsequent machining. A gear shaft rotates to drive a vibration ball to continuously beat the screening plate and the guide plate, falling of the micro powder is promoted, and the screening efficiency is improved.

Owner:连云港市沃鑫高新材料有限公司

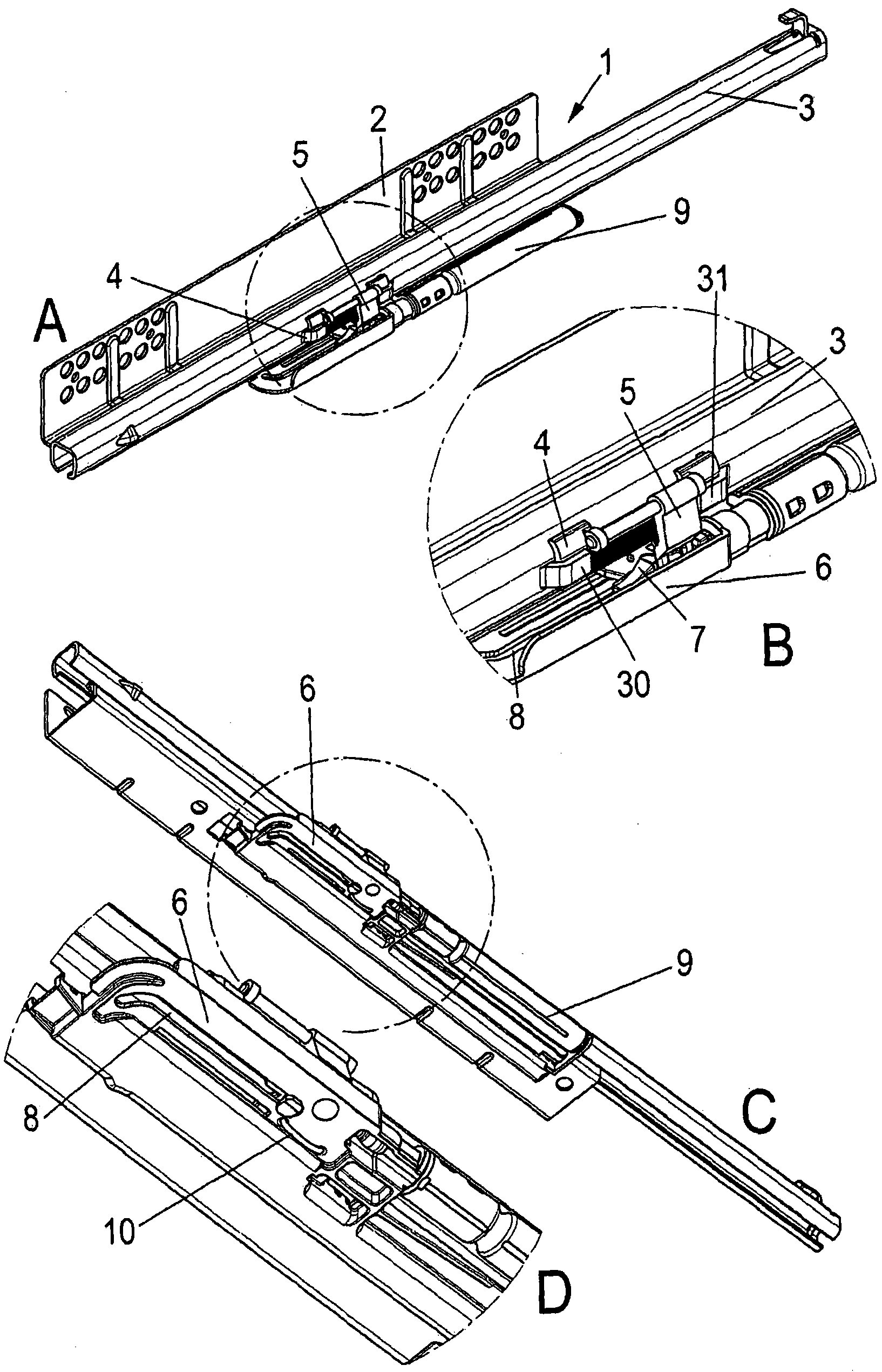

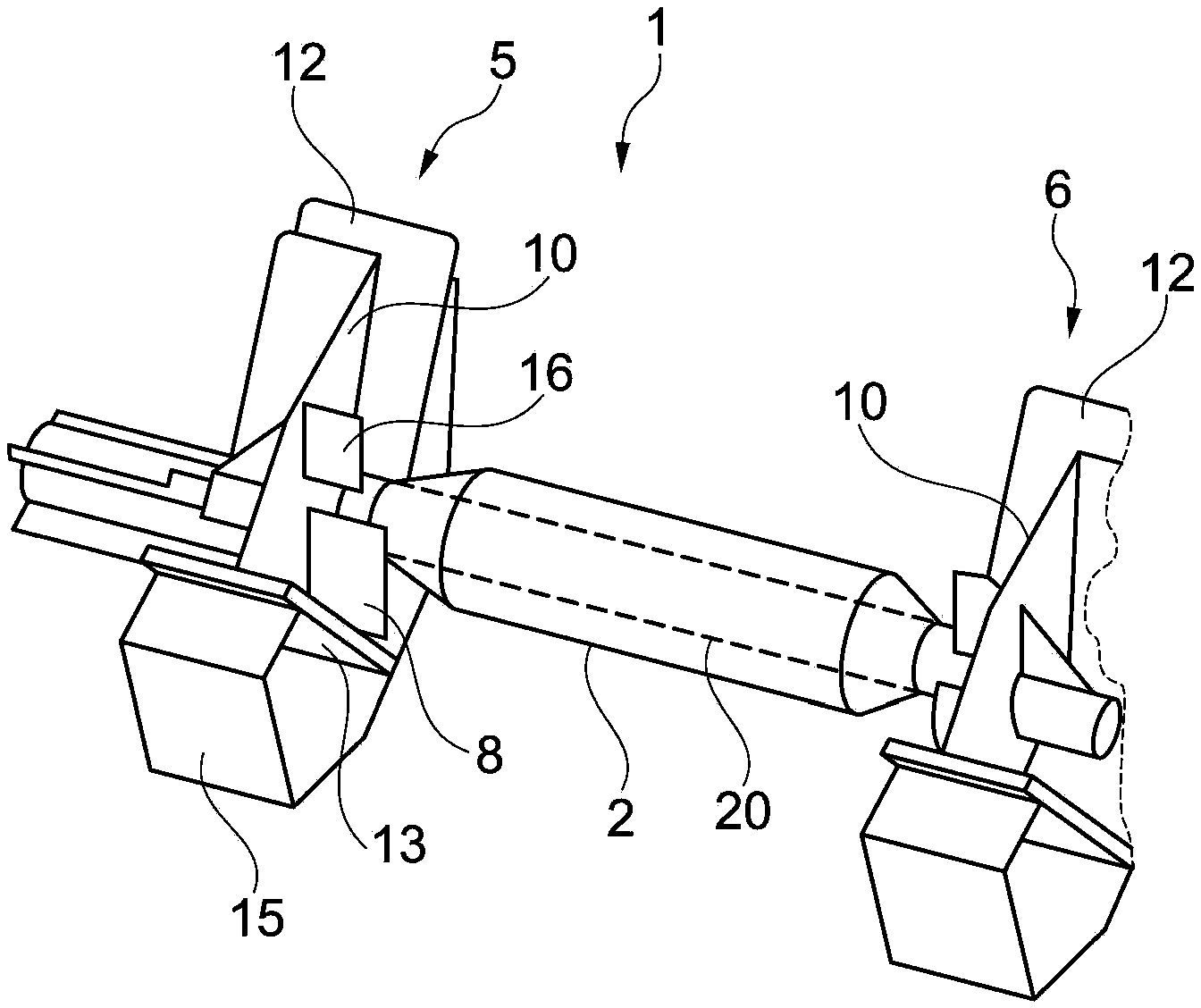

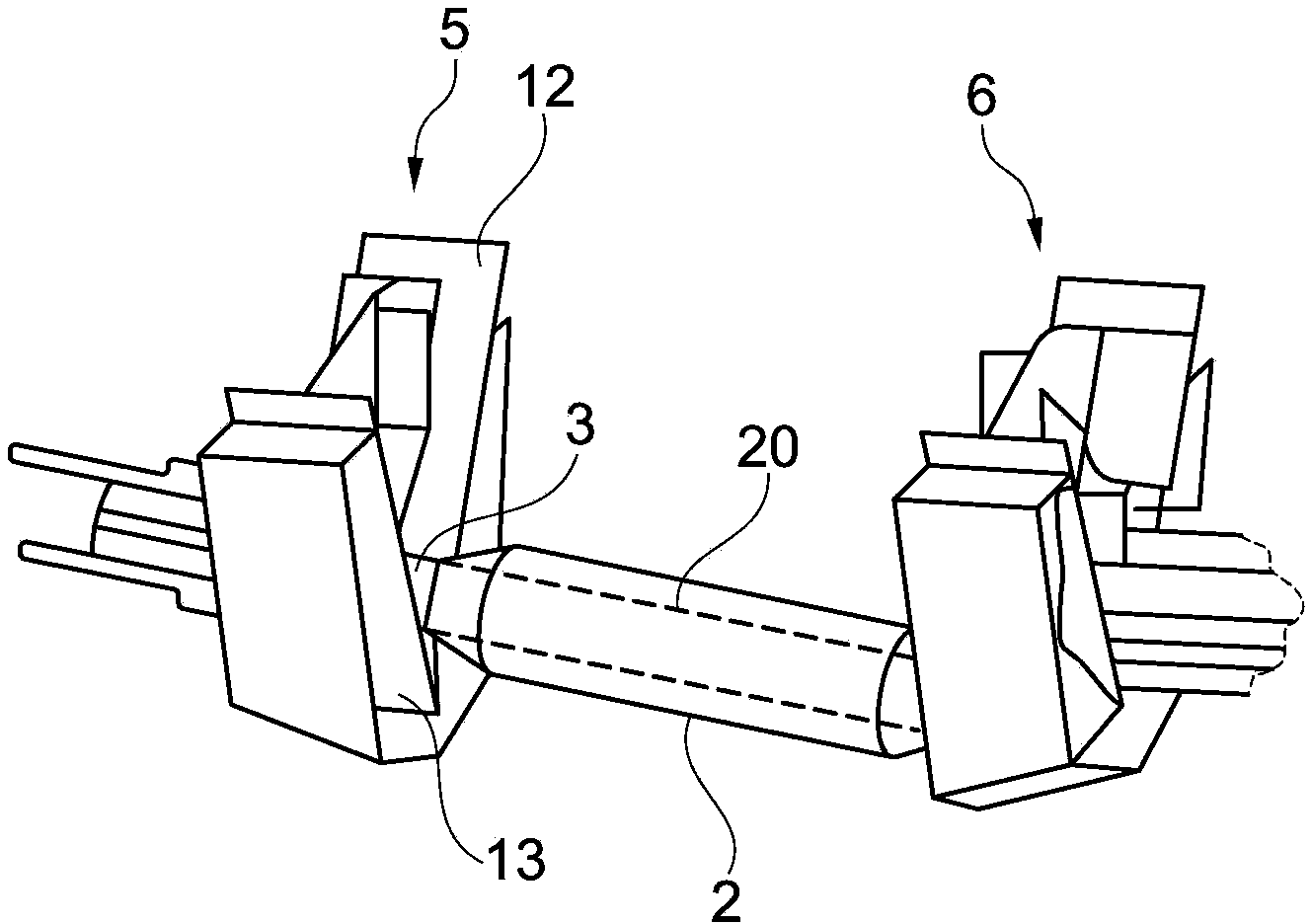

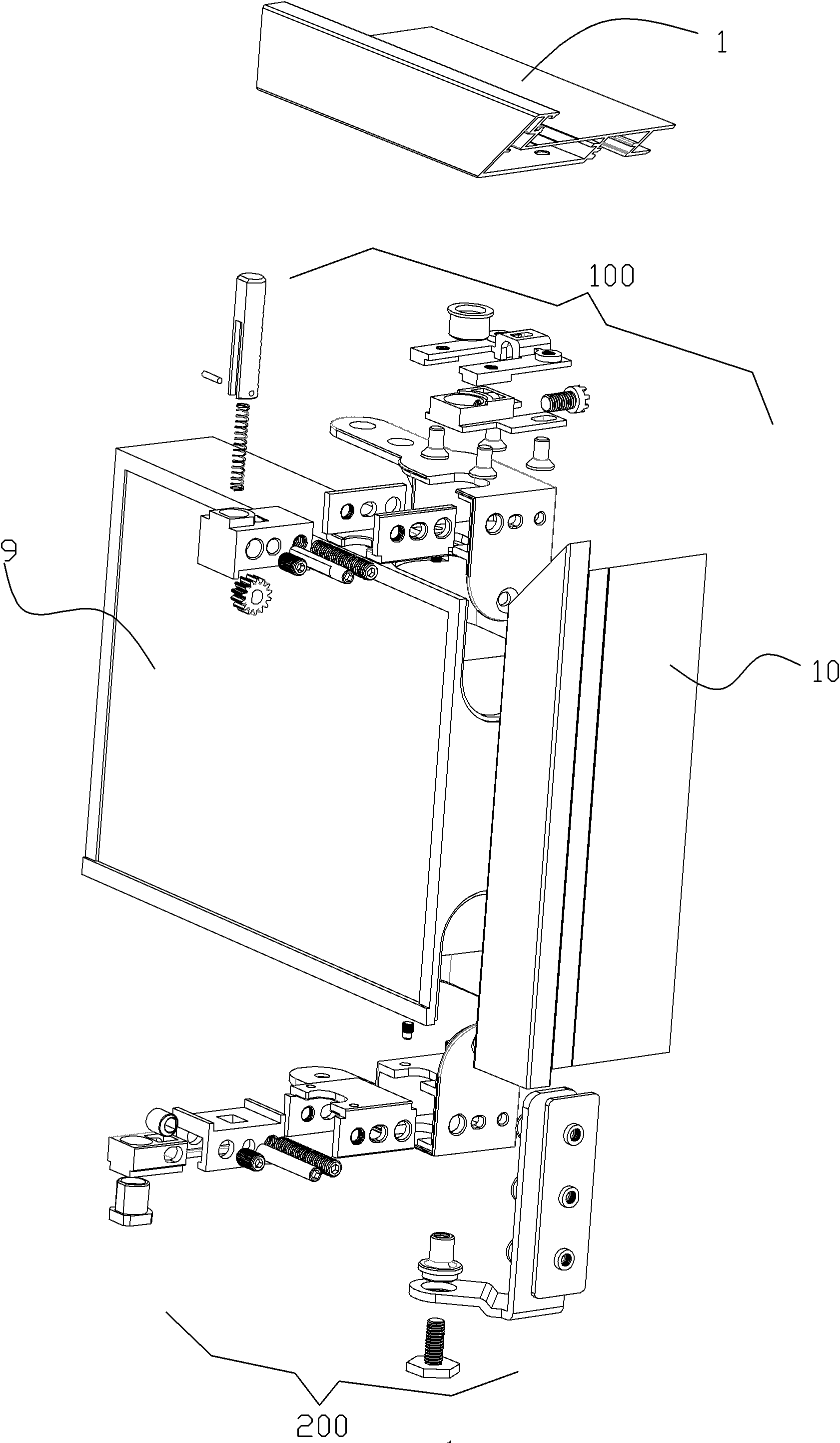

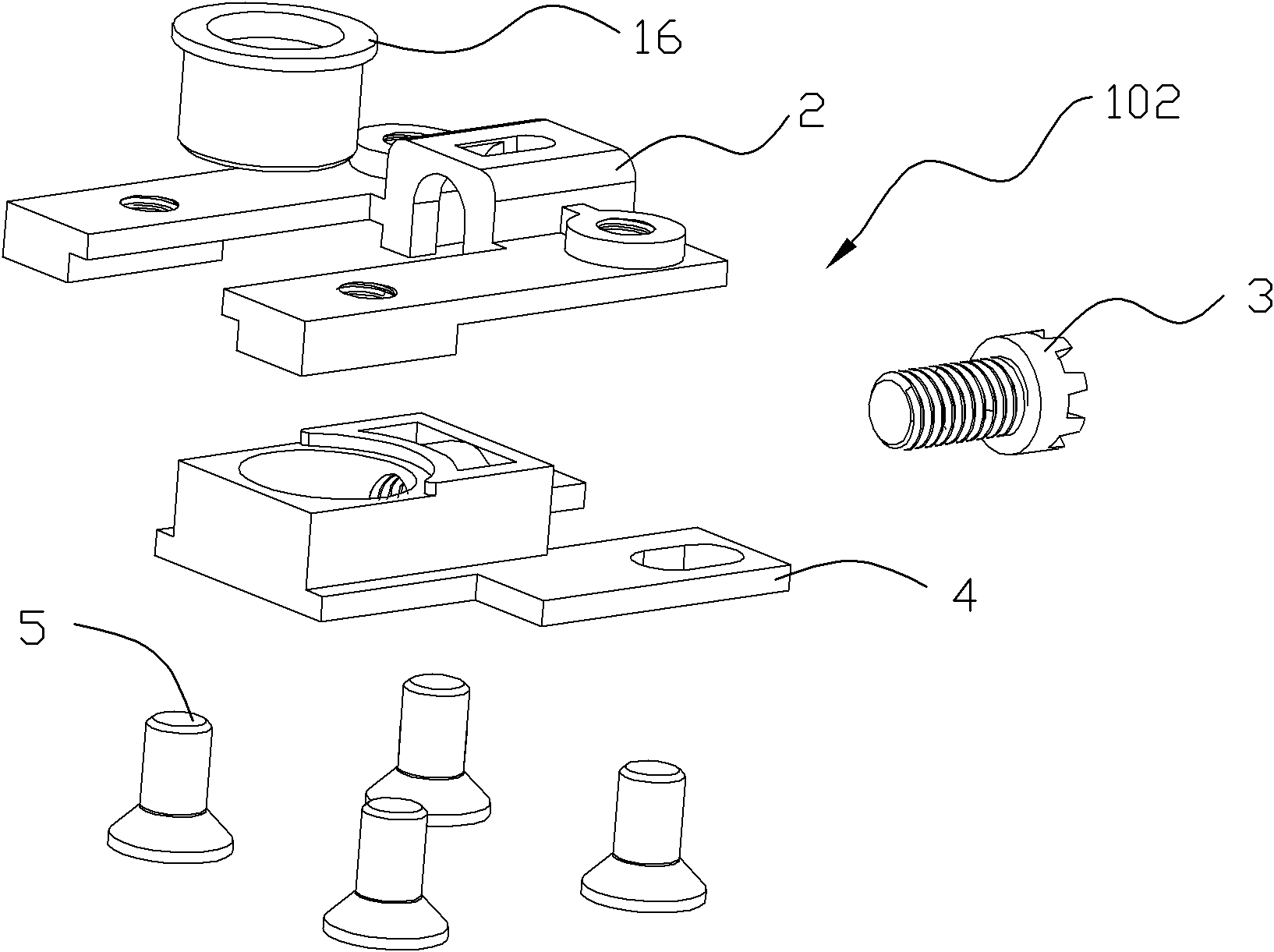

Device for opening and/or closing drawers and method for calibrating the same

The invention relates to a device for opening and / or closing drawers. The device has a pull-out guide (1) including a guide rail (2) fixed at a cabinet body and a displaceably supported sliding rail (3). The sliding rail (3) is fixed with a drawer with a panel and a retaining element (4) with an actuator (5), wherein the actuator (5) is linked with a drawing opening and / or closing mechanism. According to the invention, the actuator (5) is displaceably supported on the retaining element (4) and the retaining element (4) is fixed on different positions in order to adjust the distance between the panel and the cabinet body. In addition, the invention also provides a method for correcting a panel gap by means of such a device so as to adjust the panel gap by a simple method.

Owner:PAUL HETTICH

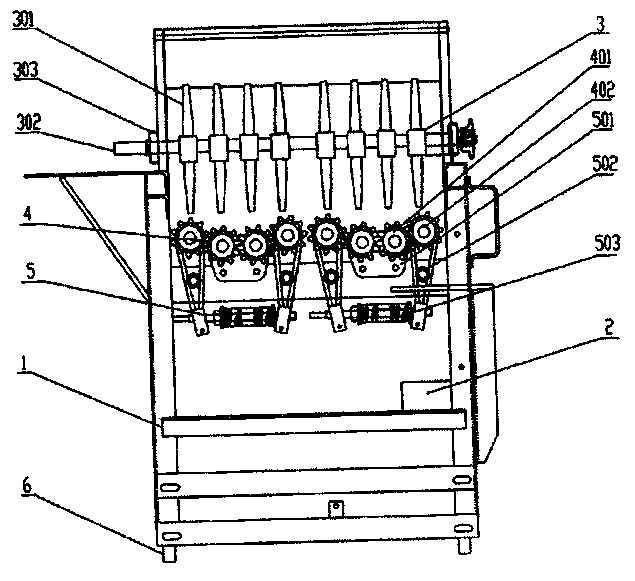

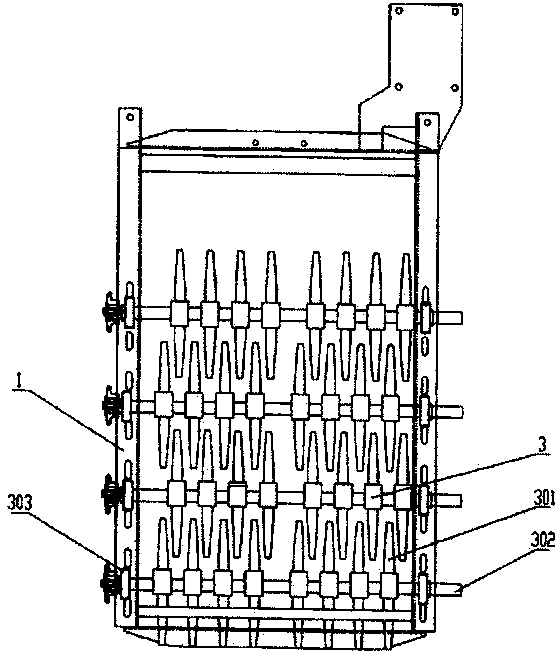

Device for turning over cop and cop bobbin

ActiveCN103572434AIncrease production capacityReduce wearFilament handlingTextiles and paperBobbinEngineering

The invention relates to a device for turning over a cop and a cop bobbin. The device is configured to enable the cop or the cop bobbin with a cop foot ahead to drop downwards. The device comprises brackets used for two cop ends and having a gap which is such configured that a cop head passes through the gap while the cop foot does not; amd holding mechanisms, each of which is arranged under the brackets to be such configured that the holding mechanisms support the cop head. According to the device for turning over the cop and the cop bobbin, the holding mechanisms are such configured that the cop supported by virtue of the cop head or the cop bobbin supported by virtue of the cop head can move along a horizontal direction; and control mechanisms are arranged, which are attached to the brackets respectively and are such configured that the cop head supported by the holding mechanisms is not grasped by the control mechanisms when the control mechanisms are controlled, and the cop foot located in the brackets is grasped by the control mechanisms and moves along the horizontal direction when the control mechanisms are controlled.

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

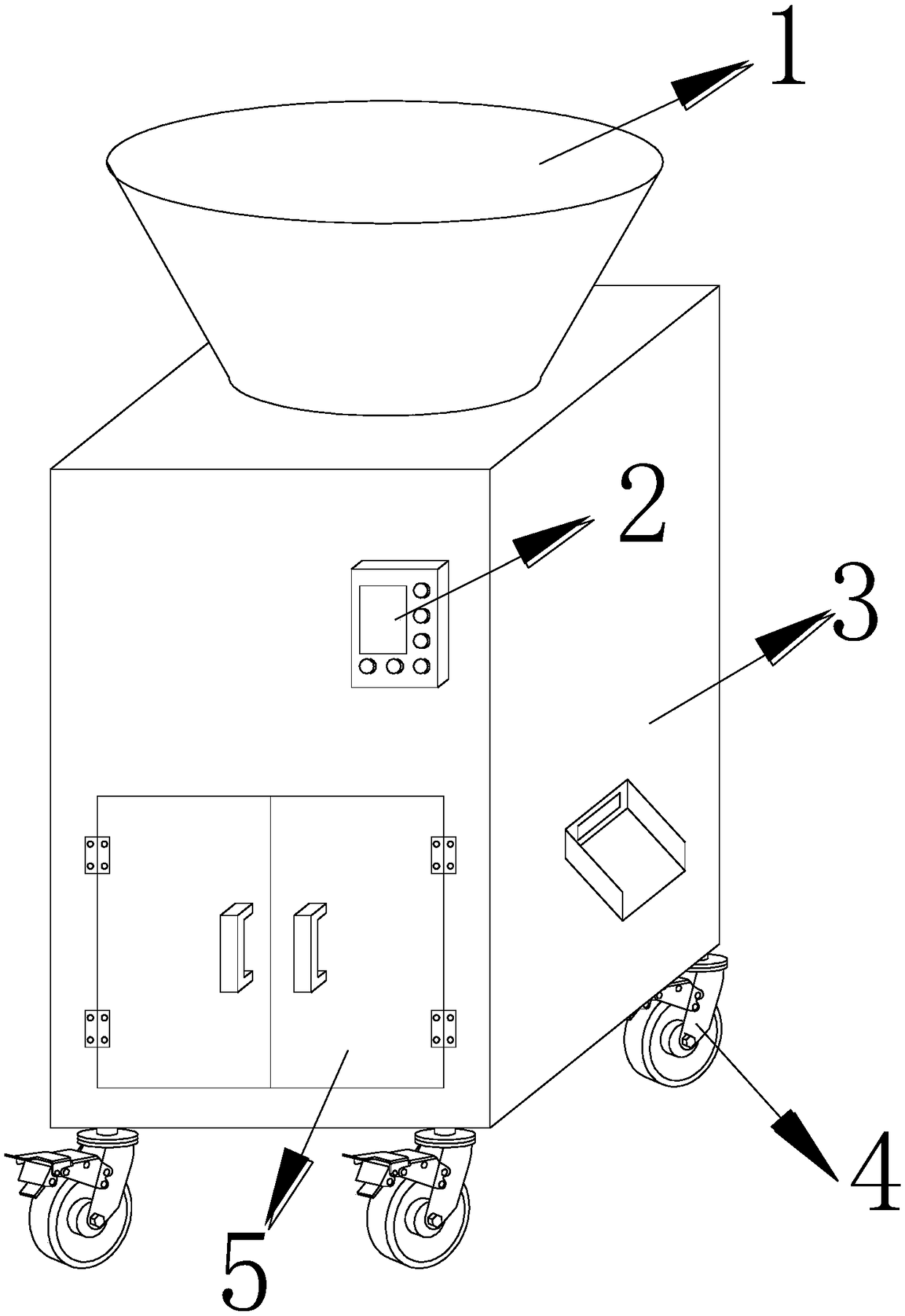

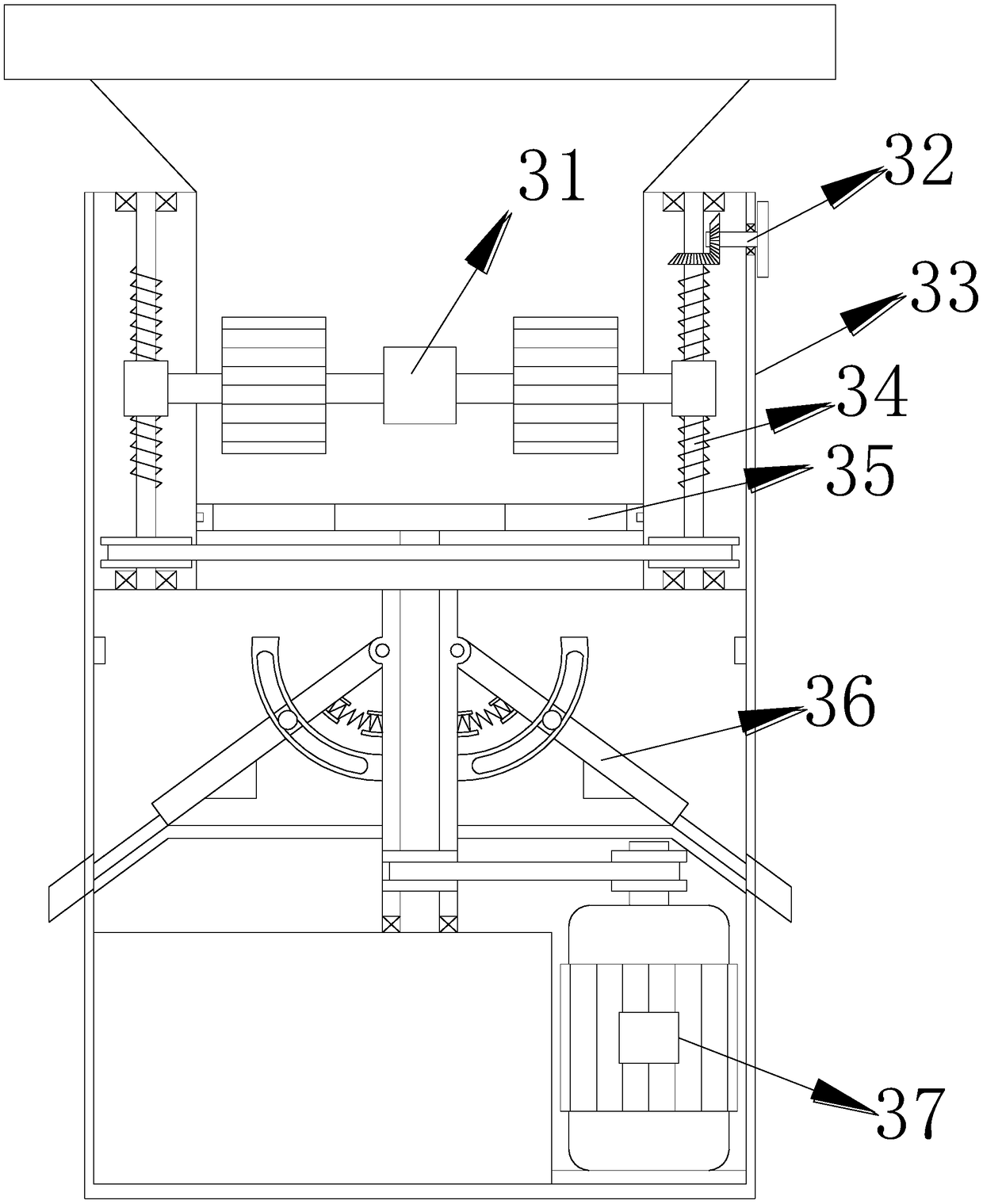

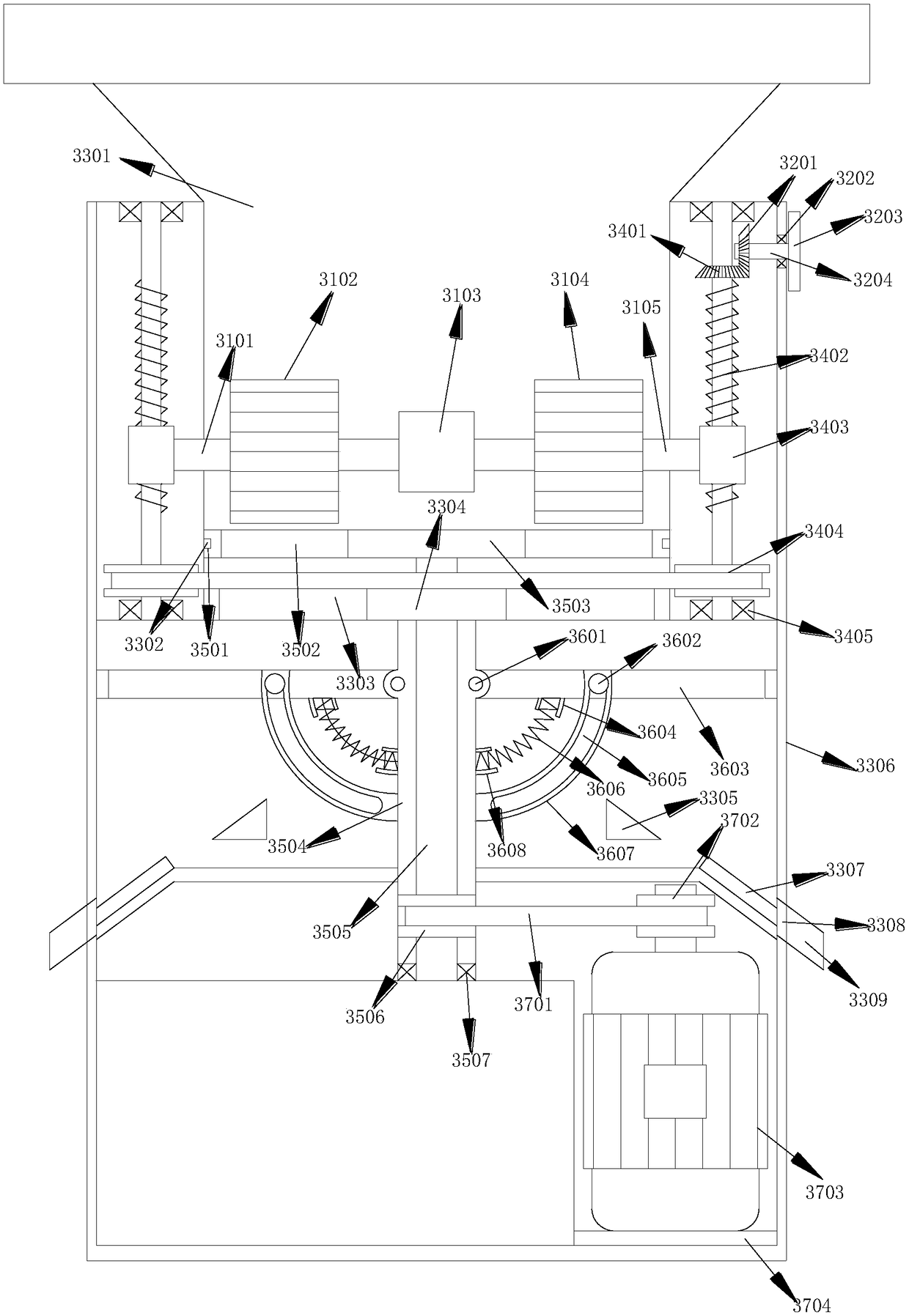

Non-stop die-roller gap adjustable vertical particle forming device

InactiveCN108786657AEasy dischargeWill not cause accumulationSolid fuelsWaste based fuelElectrical and Electronics engineering

The invention discloses a non-stop die-roller gap adjustable vertical particle forming device which structurally comprises a feed hopper, a controller, a particle forming main machine, four universalwheels and a door plate. Four corners of the bottom of the particle forming main machine are mechanically connected with the universal wheels. Compared with the prior art, the vertical particle forming device has the advantages that die-roller gaps can be adjusted without stop by combination of a rotatable die-roller pressing mechanism, a die-roller gap adjusting power mechanism, a body, a die-roller gap adjusting mechanism, a particle forming mechanism and a particle forming main power mechanism, operation is simple and convenient, working efficiency is greatly improved, rapid discharge of materials can be guided by the aid of two discharge ports and a discharge transmission mechanism, materials cannot be stacked, and discharge speed is high.

Owner:安徽万礼食品有限责任公司

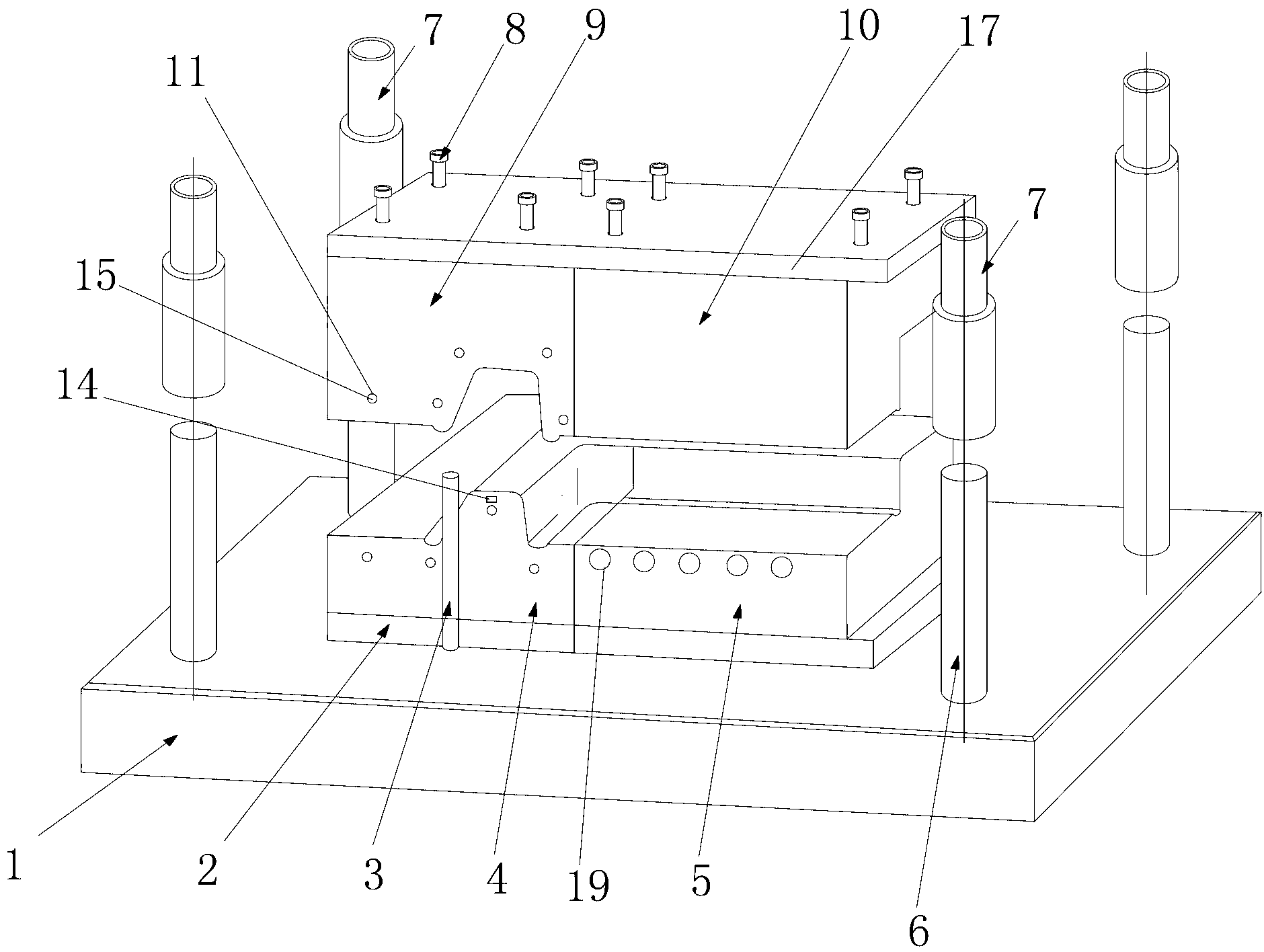

Adjustable type injection mold convenient for formation

The invention discloses an adjustable type injection mold convenient for formation. The middle part of a movable plate is equidistantly provided with tapered holes; one end of the movable plate is fixedly connected with an upper inclined block; the end, far away from the upper inclined block, of the middle part of the movable plate is fixedly connected with a reset spring; a lower inclined block is installed at a position on one side of the upper inclined block and inside a movable groove; the bottom end of the lower inclined block is connected with a top block; an embedded block is fixedly installed at the middle part of the bottom end of an upper mold base; and the middle part of the embedded block is equidistantly provided with second discharging holes. The adjustable type injection mold disclosed by the inventio0n is scientific and reasonable in structure and safe and convenient in use; by cooperative use of first discharging holes and the second discharging holes, raw materials are injected more uniformly; uneven injection easily causes generation of air bubbles in an injection-molded part to affect normal use of the part; the percent of pass of processing of the part is increased; meanwhile by cooperative use of the movable plate and the reset spring, remaining materials for injection molding are cut off by the movable; the length of the remaining materials for the injection-molded part is shortened; and raw materials are saved.

Owner:湖北童话工艺礼品有限公司

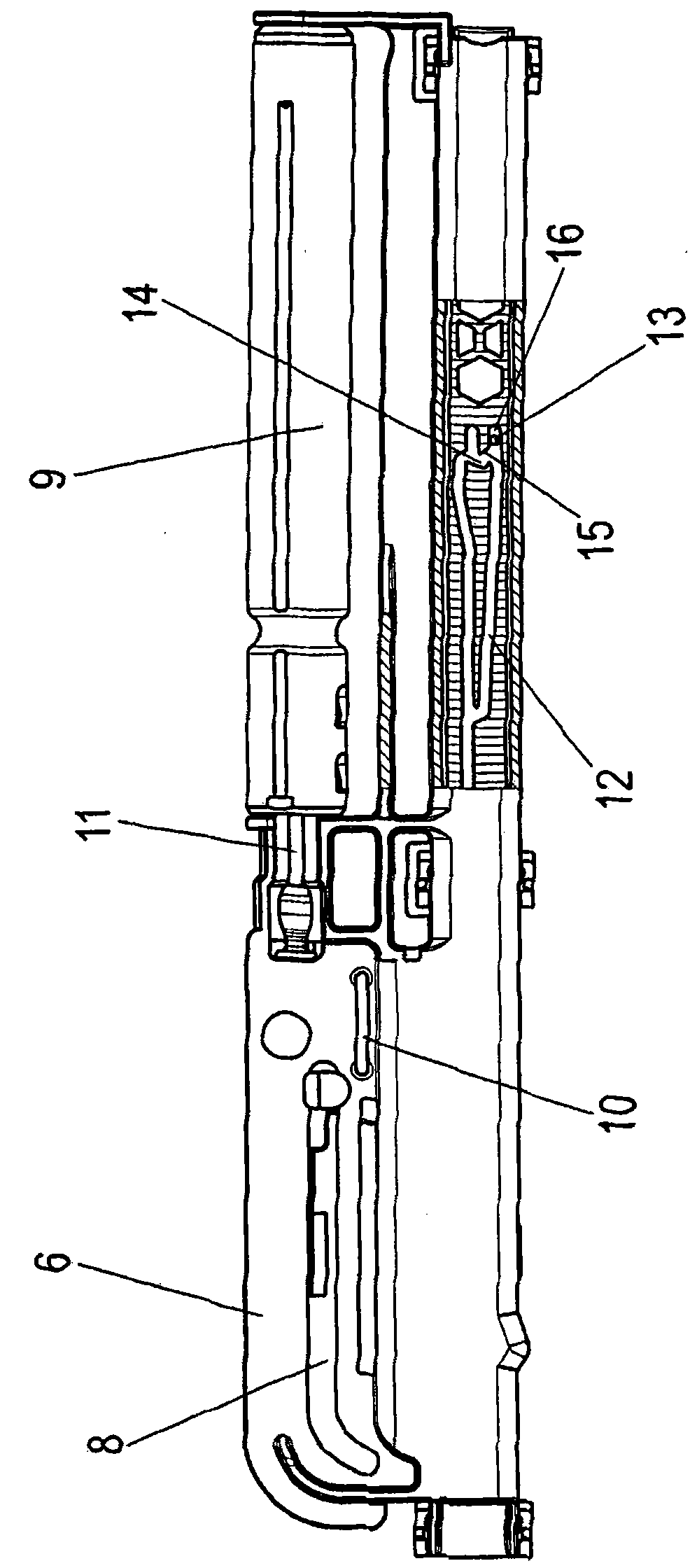

Cash register

InactiveCN102609759AImprove processing efficiencyImprove counterfeit detection efficiencyCounting objects on conveyorsSoft voiceEngineering

The invention provides a cash register. The cash register comprises a cash inlet device, an adjusting device, a transmission device, an identification device and a cash receiving device, wherein the cash inlet device comprises a cash filling plate, a cash conveying wheel and a cash twisting wheel; the cash conveying wheel is arranged at the lower end of a cash inlet; the adjusting device is arranged at the upper end of the cash twisting wheel; the identification device is arranged on one side of the cash twisting wheel and is divided into upper and lower layers to form an identification channel; the cash receiving device is arranged at the outlet of the identification channel of the identification device; and a coding wheel is installed at the lower end of the identification device. The cash register integrates such advantages of the horizontal cash registers as few motion track turns and soft voice and the advantages of the cash separation mechanism of the vertical cash register, and is high in cash separation reliability.

Owner:ZHEJIANG FOTA ELECTRIC

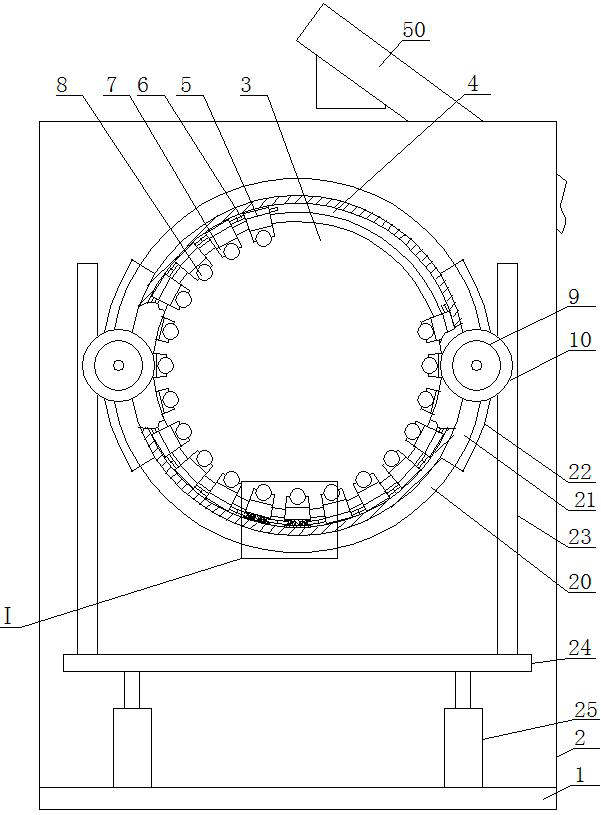

Guiding device of upper tapered roller box body of ring rolling machine

InactiveCN101695734AAvoid side forceImprove work efficiencyMetal rollingEngineeringMechanical engineering

The invention discloses a guiding device of an upper tapered roller box body of a ring rolling machine, which comprises a frame and the upper tapered roller box body. The frame is provided with four track planes. The included angles between the track planes and both lateral surfaces of the upper tapered roller box body are all 45 degrees. Each track plane is provided with two slide blocks. The slide blocks are arranged on regulation blocks respectively. One side of each regulation block is provided with a fixed block. A contact surface between the fixed block and the regulation block is a jagged surface consisting of a plurality of inclined planes. Each fixed block is provided with a regulation hole. An elastic bolt is arranged in each regulation hole. The elastic bolts are all connected with the regulation blocks. Both upper and lower ends of each fixed block are provided with an upper pressing plate and a lower pressing plate. Each upper pressing plate is provided with an upper regulation top thread. Each lower pressing plate is provided with a lower regulation top thread. The guiding device can overcome a side force generated by the upper tapered roller box body when the ring rolling machine works, effectively reduces the wear condition of the guiding device, can improve the work efficiency of the ring rolling machine, and is favorable for saving production cost for enterprises.

Owner:济南沃茨数控机械有限公司

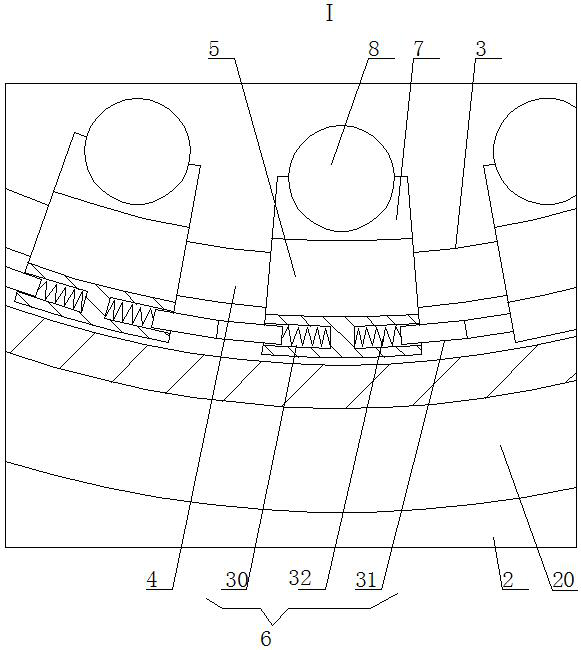

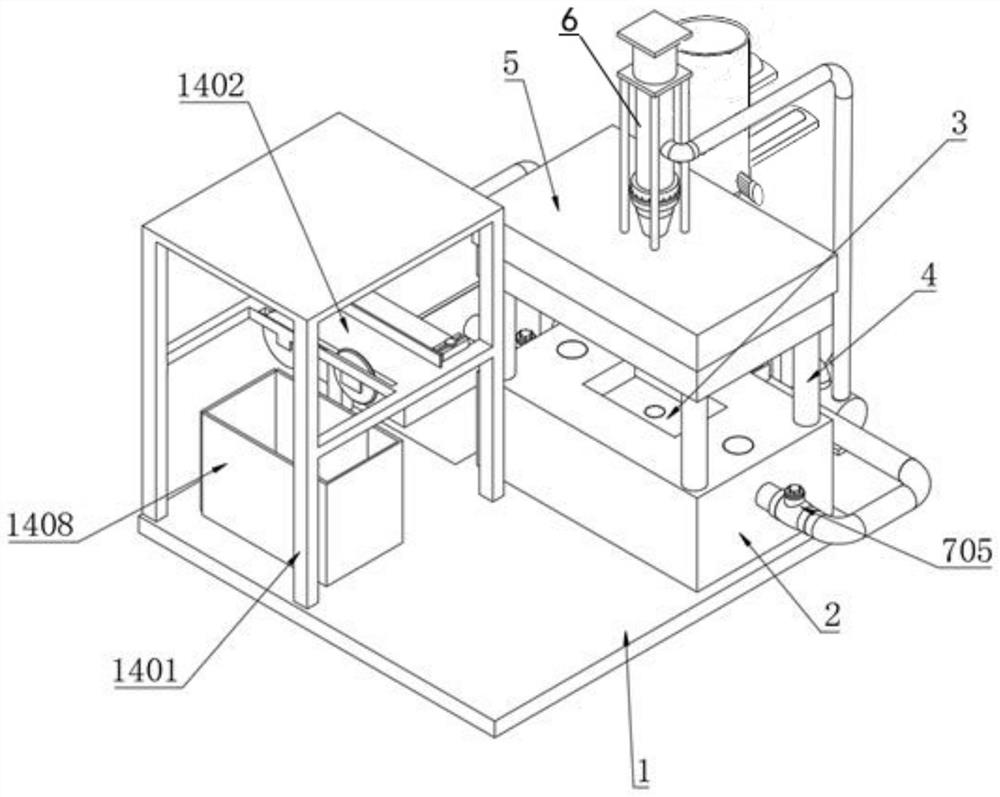

Suction and discharge type material separating and sorting device

The invention belongs to the field of separation devices, and relates to a suction and discharge type material separating and sorting device. The device comprises a base, the top side of the base is fixedly connected with the bottom sides of two supporting plates distributed front and back, circular through grooves are formed in the upper portions of the supporting plates, first annular T-shaped grooves are formed in the inner circumferences of the circular through grooves, multiple first arc-shaped T-shaped sliding blocks are installed in the first annular T-shaped grooves in a sliding fit mode, elastic pieces are fixedly installed on the adjacent sides of the first arc-shaped T-shaped sliding blocks correspondingly, gears are fixedly installed at the outer ends of rotating shafts of motors correspondingly, and the gears can be engaged and matched with corresponding first arc-shaped racks correspondingly. The device is simple in structure and clever in conception, a semi-open drum screen overcomes the defect that feeding can only be conducted from one end, different screening requirements are met, the applicability is improved, meanwhile, the gaps between screen rods are continuously changed, solid particles clamped between the screen rods can be removed, and screening hindrance is reduced.

Owner:山东万达环保科技有限公司

Injection mold

InactiveCN111688105AScientific and reasonable structureEasy to useDirt cleaningElectric machineStructural engineering

The invention discloses an injection mold. The injection mold is characterized in that a feeding hopper of a raw material tank is internally provided with a round turning plate, the round turning plate is fixedly connected with an output shaft of a turning plate motor, a first fixing frame is fixedly connected to the side wall of the feeding hopper, an electric telescopic rod is fixed to the firstfixing frame through a plurality of supporting feet, a rod body of the electric telescopic rod is fixedly connected with a push block, the push block is provided with a hollow cavity, one side of thehollow cavity is in communication with a drainage pipe through a water inlet hose with length allowance, the other side of the hollow cavity is in communication with the drainage pipe through a wateroutlet hose with length allowance, and the communication point of the water inlet hose and the drainage pipe is located in front of the communication point of the water outlet hose and the drainage pipe; the water inlet hose is provided with a first one-way valve pointing to the hollow cavity, the water outlet hose is provided with a second one-way valve pointing to the drainage pipe, a second fixing frame is further fixedly connected to the side wall of the feeding hopper, an exhaust fan is fixedly connected to the second fixing frame, an inlet pipe of the exhaust fan communicates with the upper end of the feeding hopper, a limiting bolt is screwed into the feeding hopper on the opposite side of the push block, and when the round turning plate is located at the horizontal position, the right side of the round turning plate makes contact with the bottom end of the push block and the left side of the round turning plate makes contact with the bottom end of the limiting bolt.

Owner:邓玉欣

Friction lever driving air static pressure guide rail

InactiveCN107042445AIncrease stiffnessLoad largeGrinding carriagesOptical surface grinding machinesBall screwEngineering

The invention relates to a friction lever driving air static pressure guide rail, belongs to the technical field of machine tool equipment units and components, and has the benefits as follows: 1, an upper cross beam and a lower cross beam are adopted for forming a double-cross beam structure, so that the rectangular air static pressure guide rail is high in motion accuracy, frictionless, free from pollution; a back pressure structural design is adopted, an aerostatic guide rail mover is utilized to be arranged on the lower cross beam in a sleeving manner, so that an aerostatic back pressure area is formed between the upper surface of the aerostatic guide rail mover and the upper cross beam, and the load-bearing rigidity of the aerostatic guide rail is improved; besides, with the adoption of the friction lever driving structure, the advantages of high precision, micro-feeding and no transmission clearance are achieved, and the friction lever driving air static pressure guide rail is more economic and practical compared with the driving method adopting a linear motor or ball screw; 2, the aerostatic guide rail mover of the air static pressure guide rail adopts a porous restriction material, thereby being high in rigidity, high in the load-bearing capacity and high in precision, and capable of ensuring a good sliding effect while meeting the back pressure requirements; 3, by adopting a pre-tightening mechanism comprising a puller bolt and a preloaded spring for pre-tightening a pre-tightening friction wheel, the operation is convenient, the pre-tightening effect is good, and the stepless regulation on the pre-tightening force can be realized.

Owner:XI AN JIAOTONG UNIV

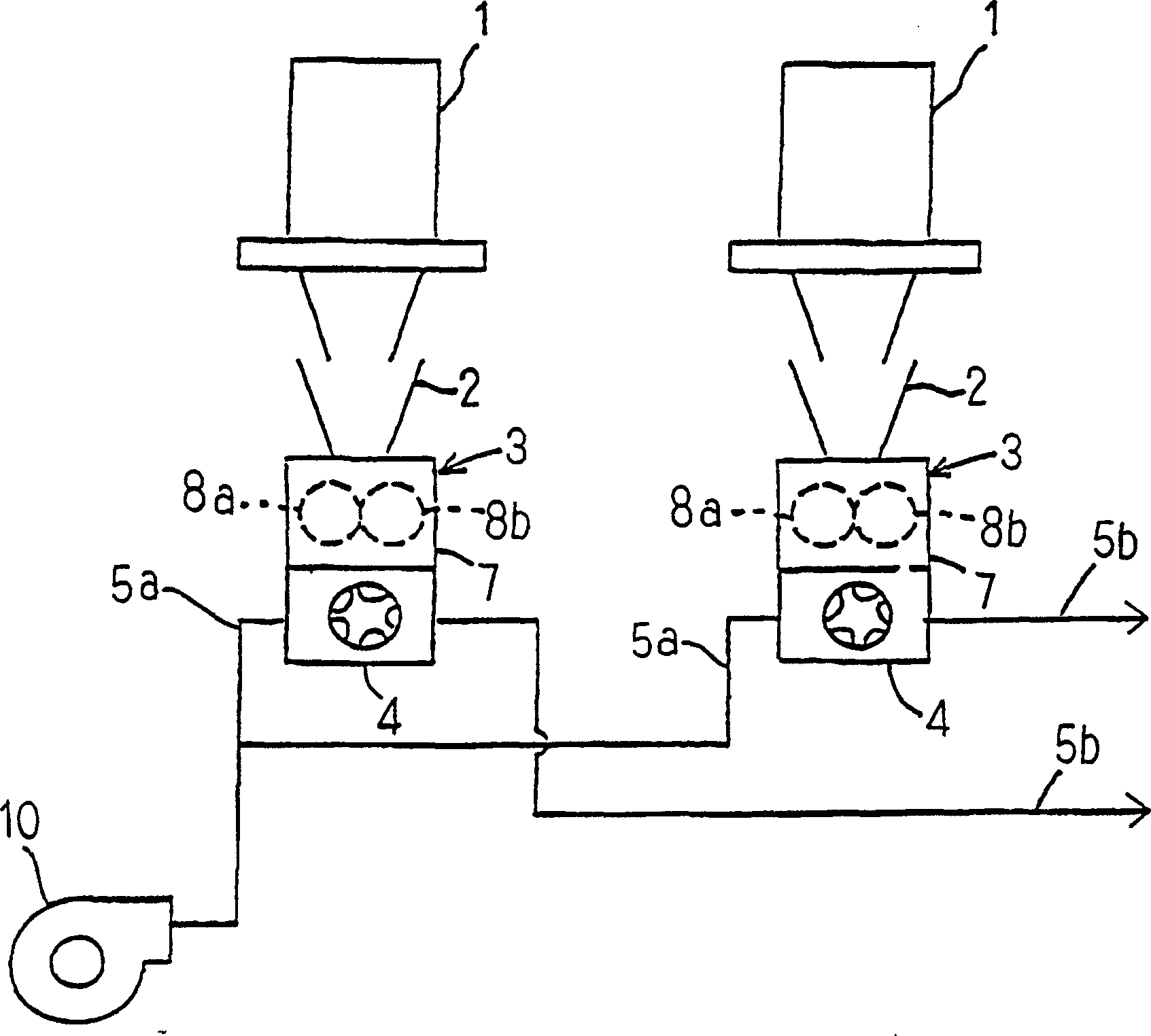

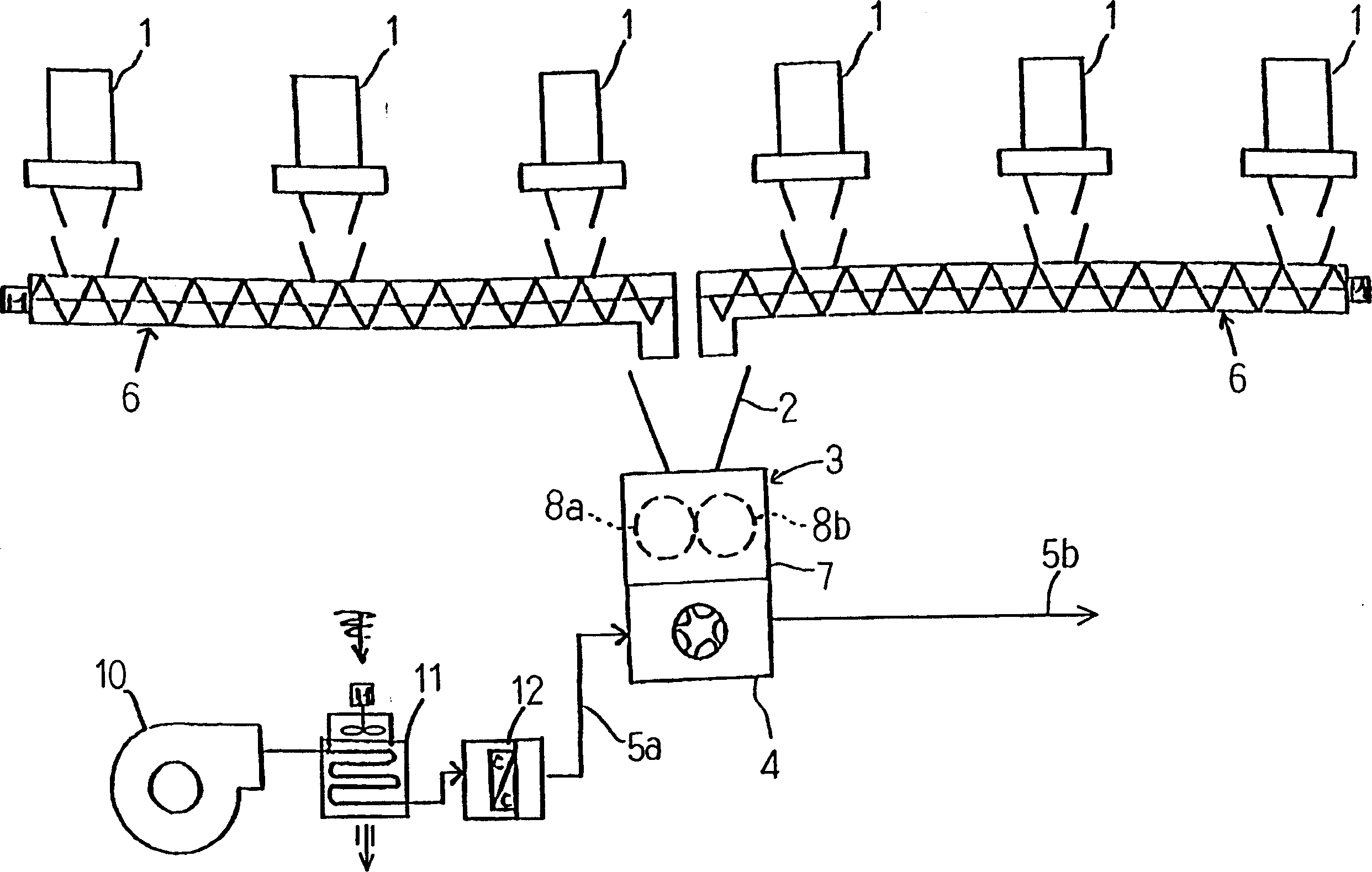

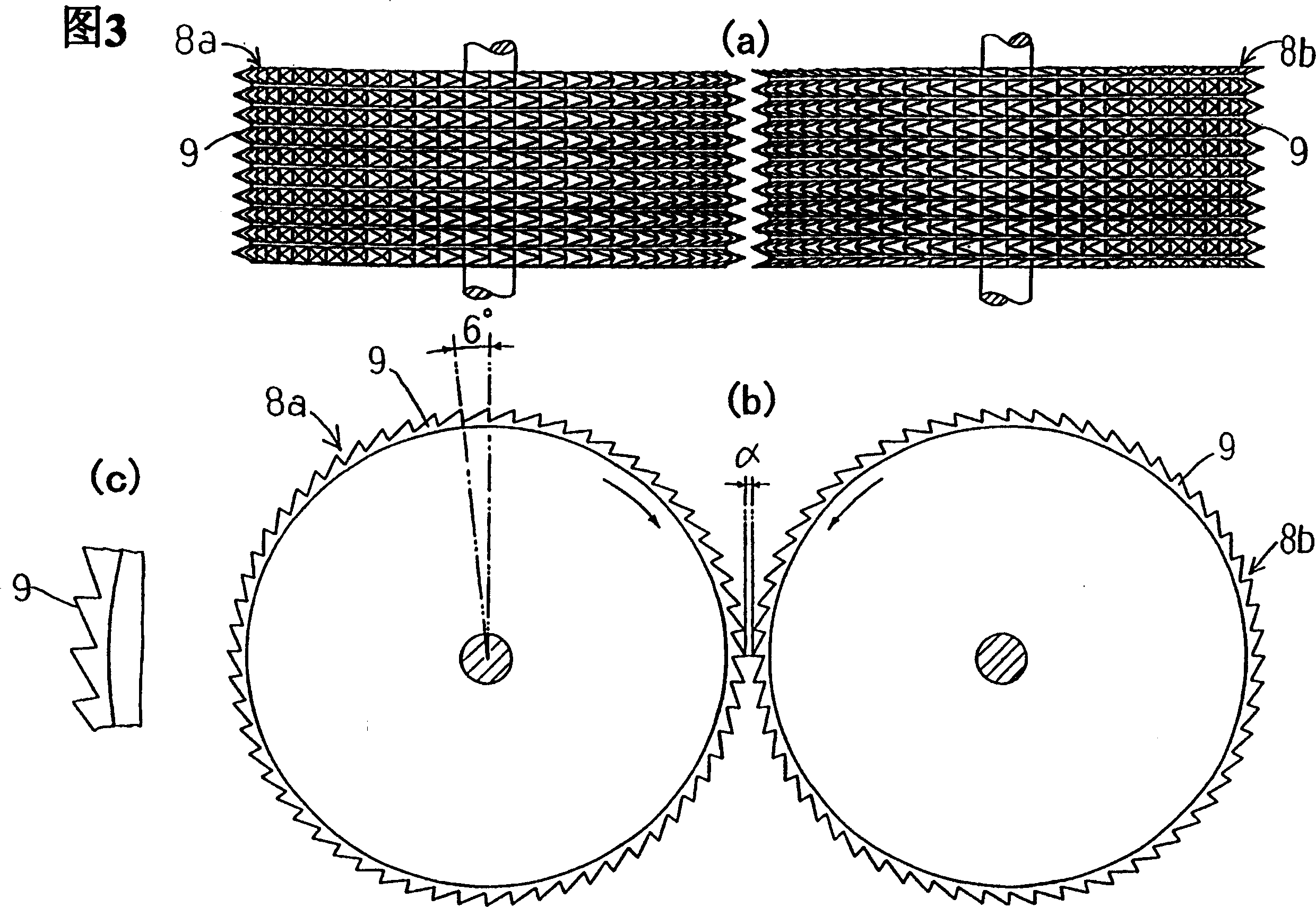

Artificial snow-maker

InactiveCN1255660CGap adjustmentRecreational ice productionLighting and heating apparatusEngineeringCrusher

Provides an artificial snowmaking device with less waste of heat energy, strong snowmaking capability per unit time, simple and compact device, and low cost. A funnel (2) is provided below the thin ice flake outlet of the ice machine (1) for making flaky thin ice flakes, and an ice crusher (3) is arranged below the funnel. A pair of rollers (8a, 8b) are set, tines (9) are formed on the periphery of each roller, and the thin ice flakes provided between the rollers are crushed or crushed with opposite rollers to make artificial snow; 3) is equipped with a pneumatic conveying device (5a, 5b) for conveying the artificial snow generated from the ice crusher to the required place.

Owner:TOYO SEISAKUSHO KK

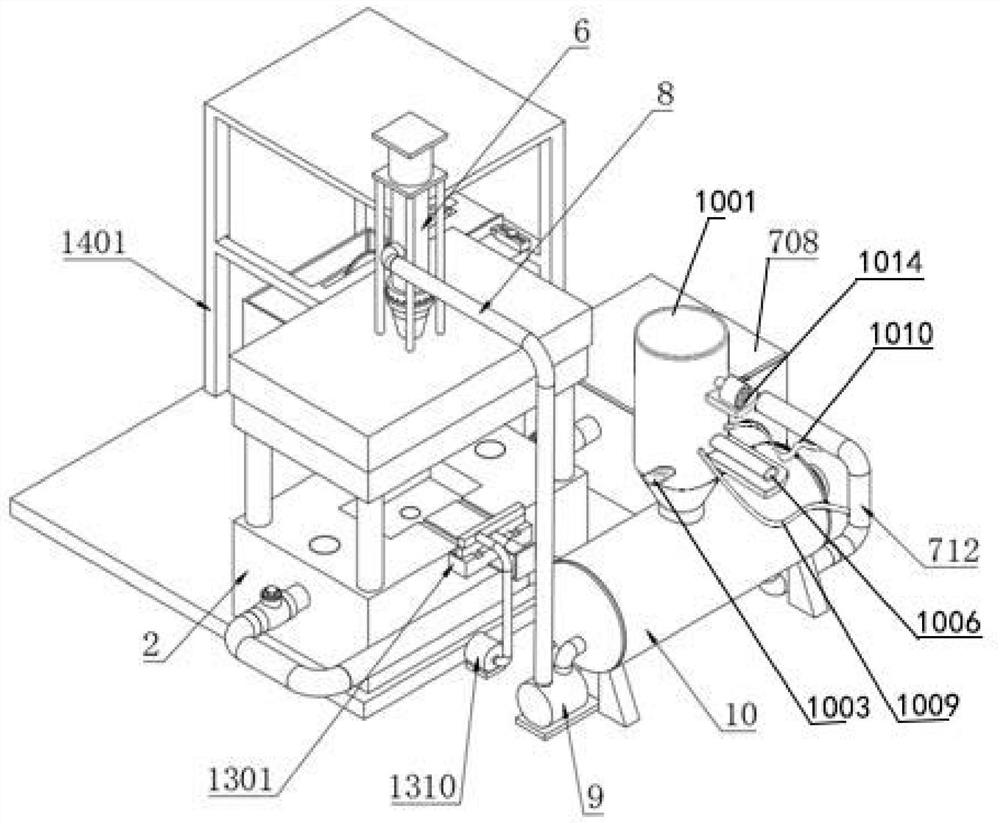

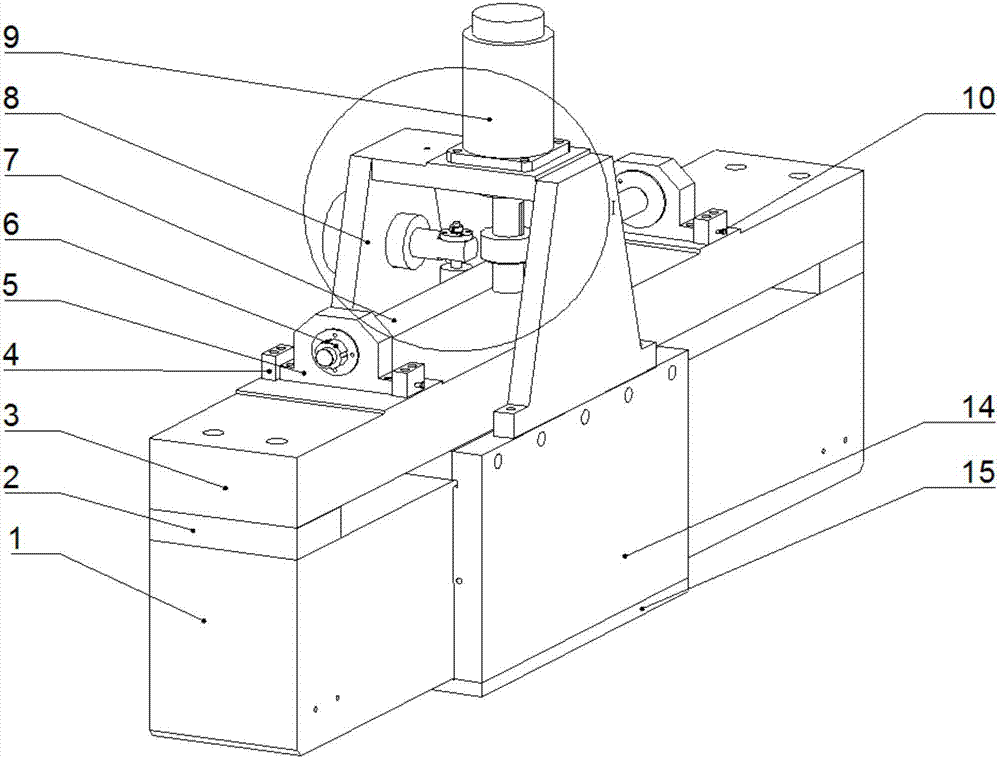

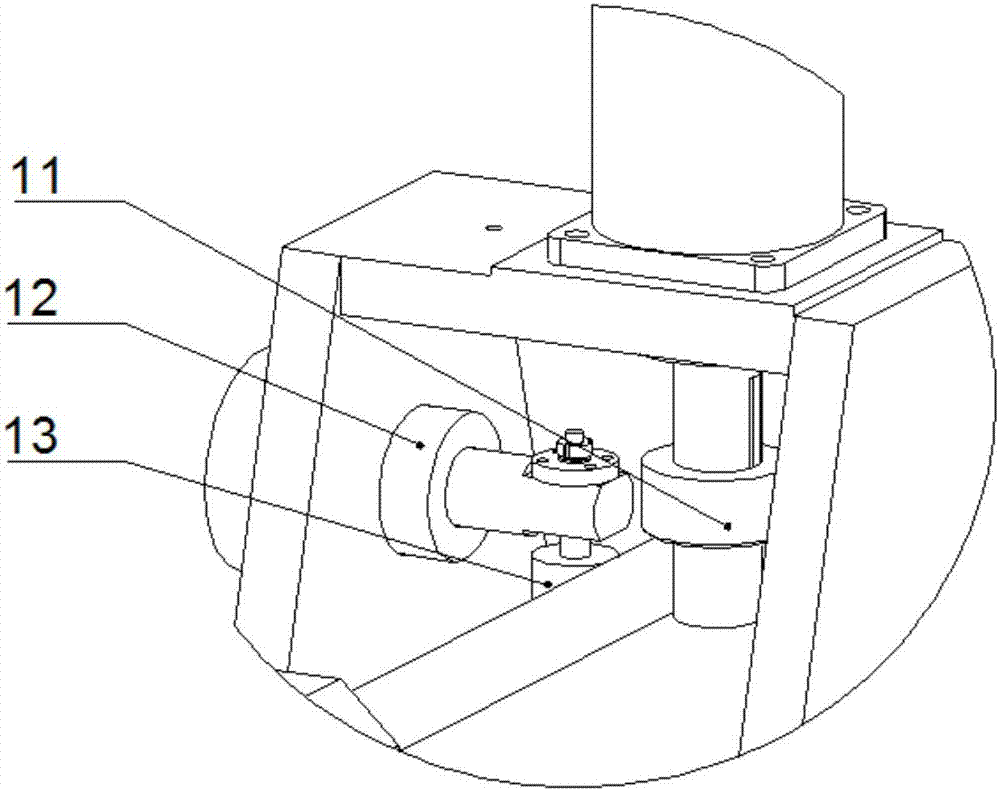

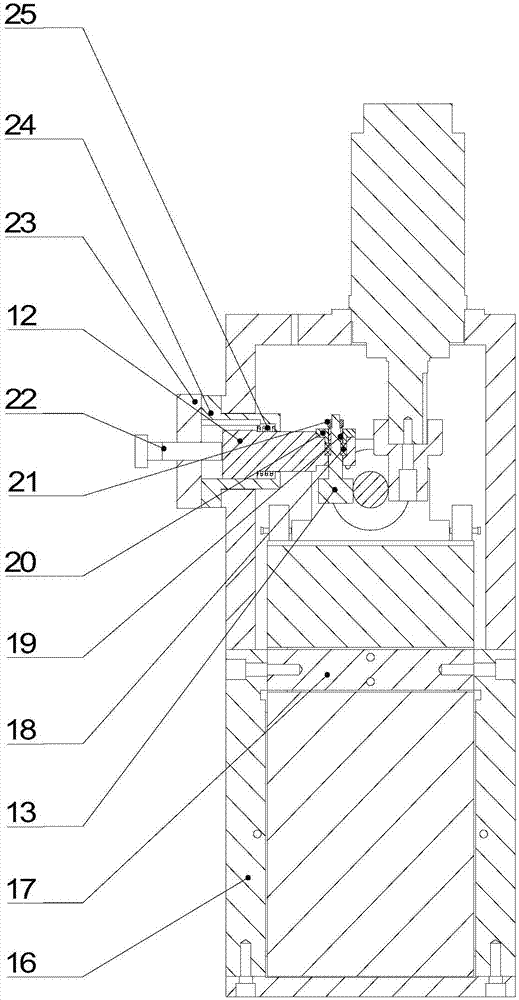

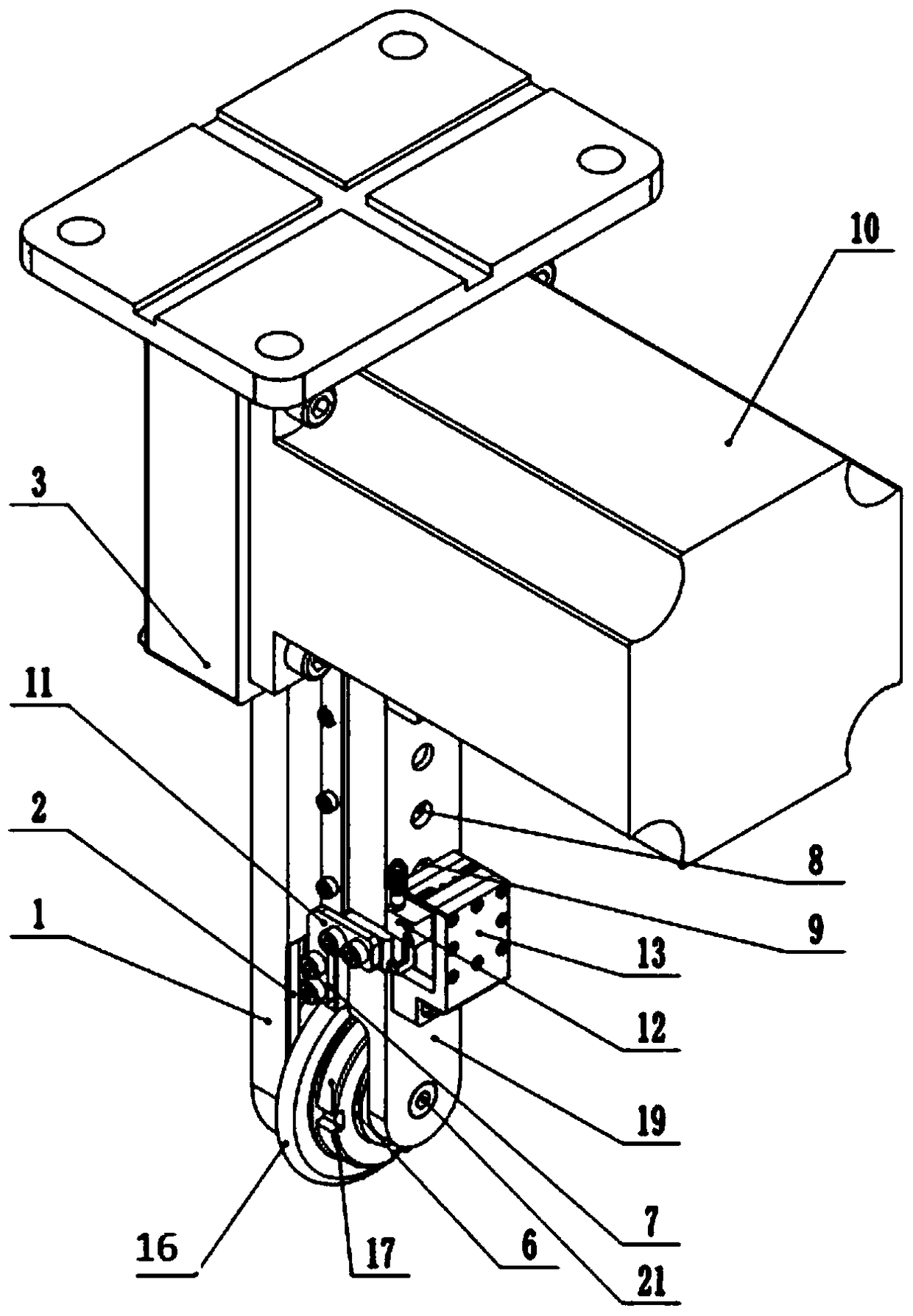

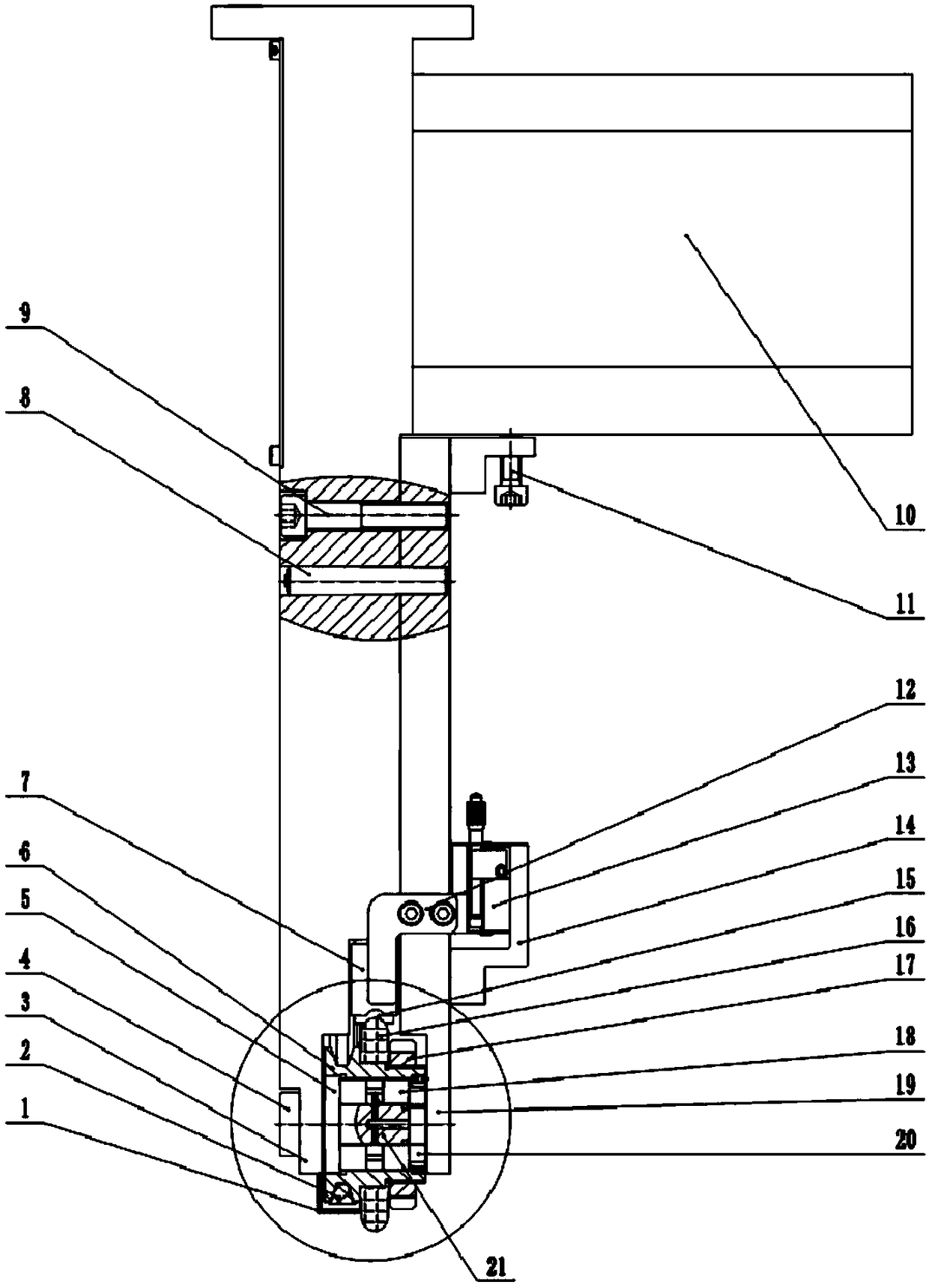

Grinding head with online electrolytic dressing function

ActiveCN109202706ASolve severe blockage problemsMaintain grinding abilityAbrasive surface conditioning devicesGrinding/polishing safety devicesBrushless motorsElectrolysis

The invention discloses a grinding head with an online electrolytic dressing function. The grinding head comprises a motion system, an electrolysis system and a supporting mechanism; the motion systemcomprises a DC brushless motor, a transmission V belt wheel set and a grinding wheel shaft system assembly; the electrolysis system comprises a copper shoe, a copper shoe frame, a fine adjustment mechanism and a fixing frame; and the supporting mechanism comprises a rack support plate, a pressure plate, a connecting screw and a positioning taper pin. According to the grinding head, through the electrolytic action, metal abrasive dust clogging in a grinding wheel is removed, the problem of serious blockage of the grinding wheel when pure metal with large machining plasticity is machined through electrolytic grinding is solved, the grinding condition is improved, the grinding ability of the grinding wheel is kept, the shape and appearance of the grinding wheel cannot be influenced because agrinding wheel material is not removed, and it is further guaranteed that processed products have high processing precision. According to the grinding head, the electrode fine adjustment mechanism isdesigned, a differential ball slide table is adopted for adjusting a gap between the grinding wheel and a copper shoe electrode with high precision, and the best an optimal electrolysis effect is obtained.

Owner:DALIAN UNIV OF TECH

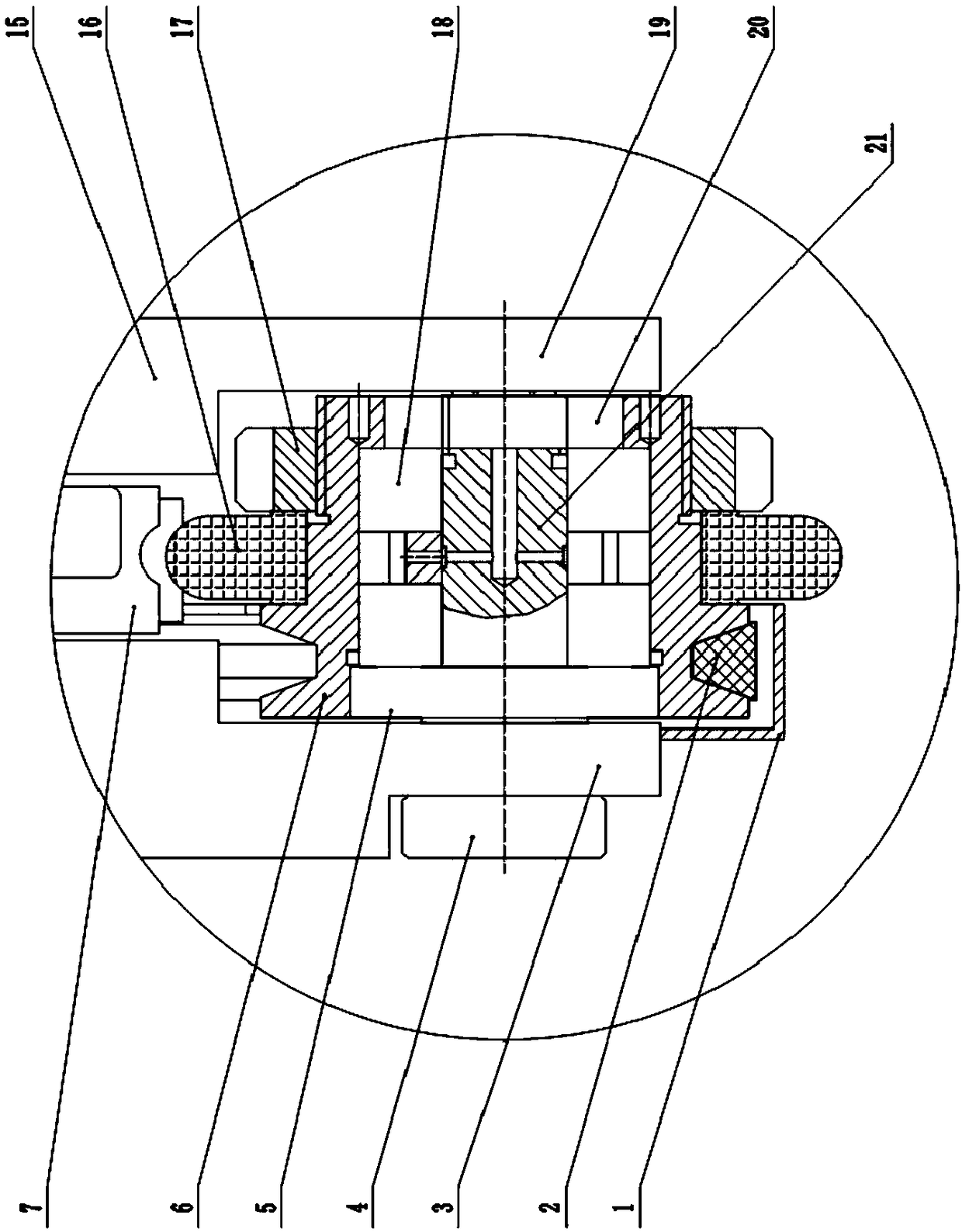

Three-dimensional adjustable hinge device

The invention discloses a three-dimensional adjustable hinge device, which comprises an upper hinge device and a lower hinge device, wherein the upper hinge device comprises a fixing kit of the upper hinge and a movable kit of the upper hinge; the fixing kit of the upper hinge comprises a permanent seat of the upper hinge, a movable seat of the upper hinge and an upper hinge sleeve, wherein the movable seat of the upper hinge is movably buckled on the permanent seat of the upper hinge, and the upper hinge sleeve is longitudinally installed on the movable seat of the upper hinge; the movable kit of the upper hinge comprises an upper hinge base, an upper hinge sliding seat, an upper hinge sliding block and a rotary shaft of the upper hinge, wherein the upper hinge sliding seat is installed on the upper hinge base; the upper hinge sliding block is arranged in the upper hinge sliding seat; the rotary shaft of the upper hinge is installed in the upper hinge sliding block; a longitudinal tooth part is formed on the rotary shaft of the upper hinge; and the rotary shaft of the upper hinge is arranged in the upper hinge sleeve. The lower hinge device comprises a movable kit of a lower hinge and a fixing kit of the lower hinge.

Owner:广东顶固集创家居股份有限公司 +1

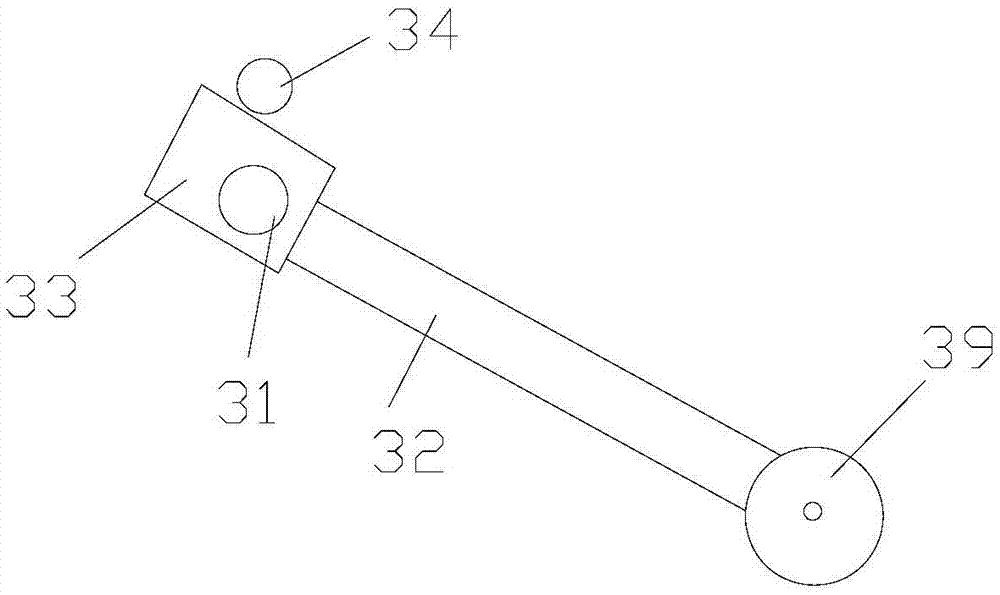

Sheet-shaped object welding device

The invention discloses a sheet-shaped object welding device, which is provided with an ultrasonic welding head, an anvil roller and a gap fine-adjustment connecting rod mechanism, wherein sheet-shaped objects are conveyed to a gap between the ultrasonic welding head and the anvil roller so as to be welded with each other; the ultrasonic welding head is fixed on a moving plate; and the moving plate can move relative to the anvil roller through the gap fine-adjustment connecting rod mechanism so as to enable the ultrasonic welding head to move towards or away from the anvil roller. The sheet-shaped object welding device further comprises a sensing component used for sensing the magnitude of a counter-acting force exerted on the ultrasonic welding head by the sheet-shaped object, the sensingcomponent is provided with a pressure sensor, an upper connecting element and a lower connecting element. According to the invention, the pressure sensor is arranged between the upper connecting element and the lower connecting element, the upper connecting element is connected with the gap fine-adjustment connecting rod mechanism, the lower connecting element is connected with the moving plate,the gap fine-adjustment connecting rod mechanism and the moving plate are connected together through the pressure sensor, and the force borne by the moving plate is further detected. The sheet-shapedobject welding device has the advantages of simple structure, convenient installation and high reliability.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

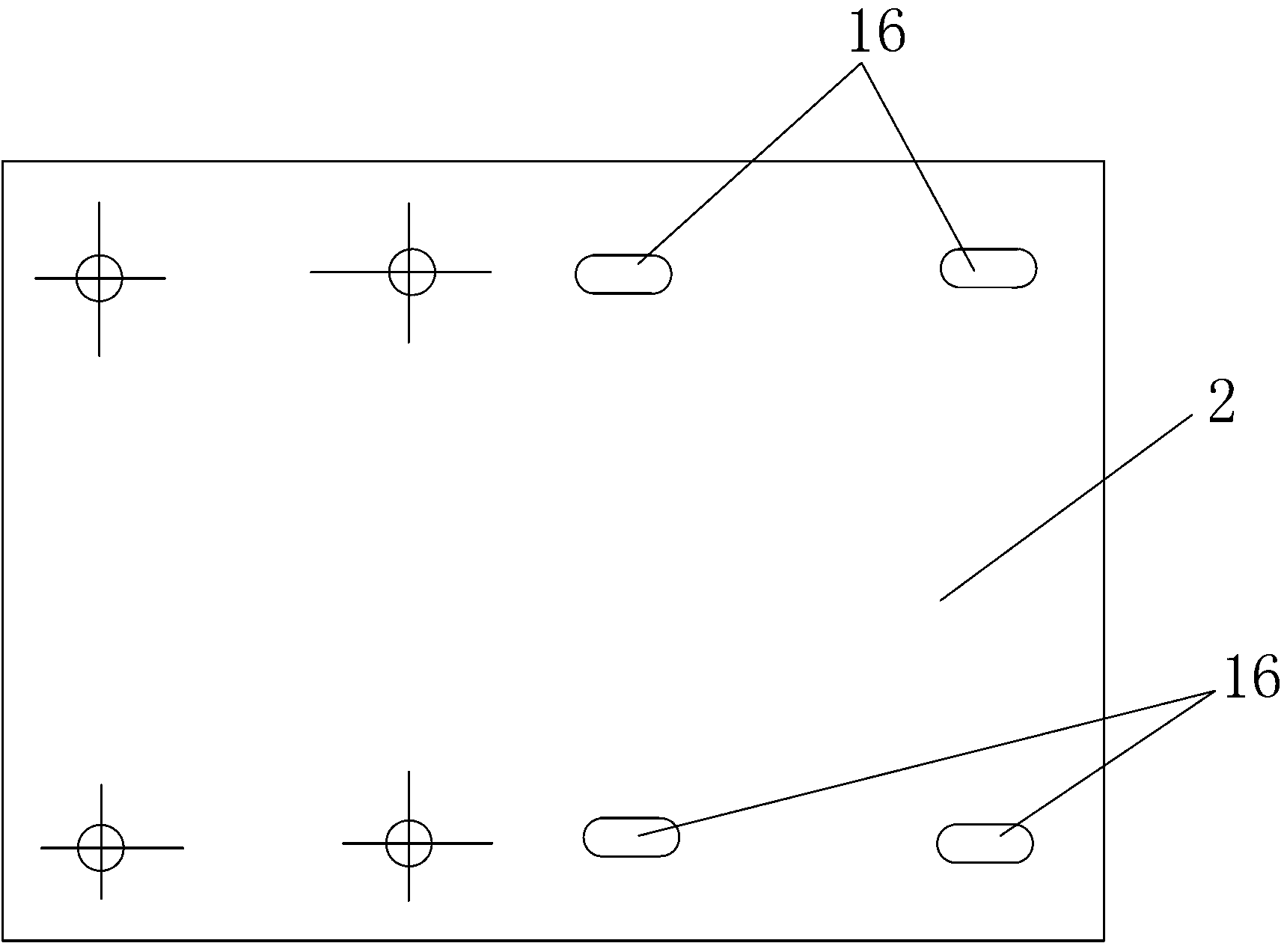

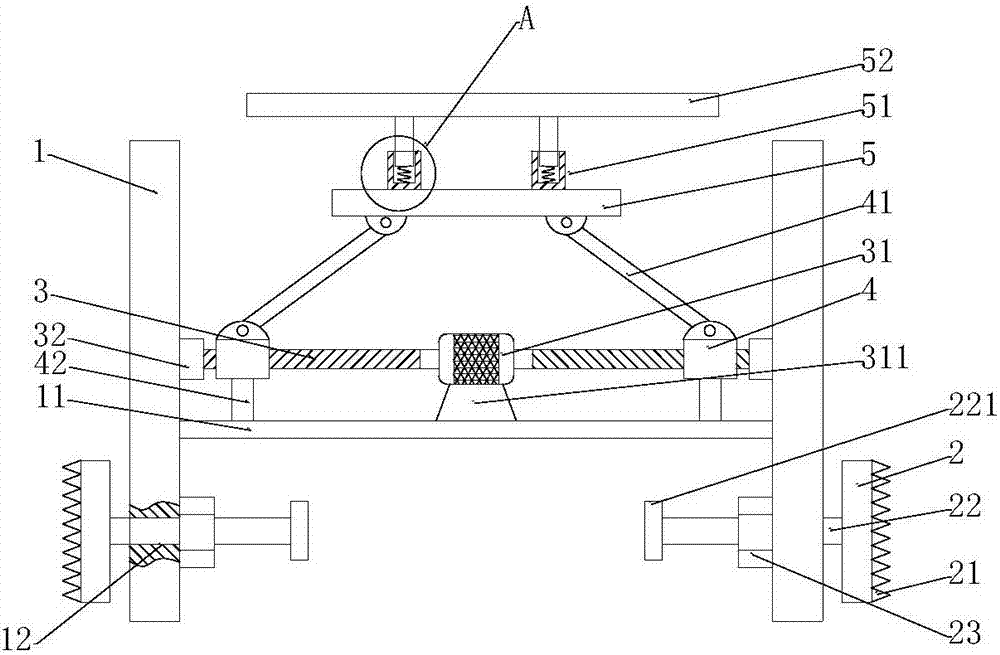

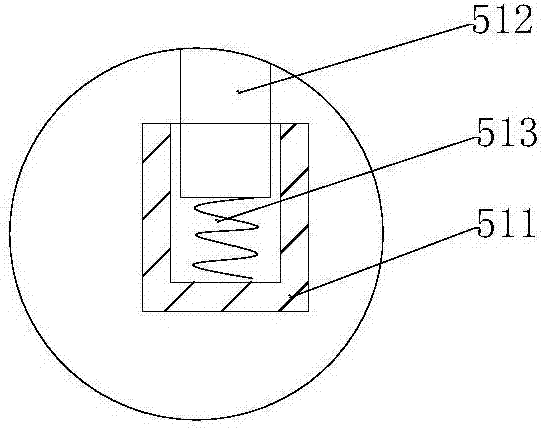

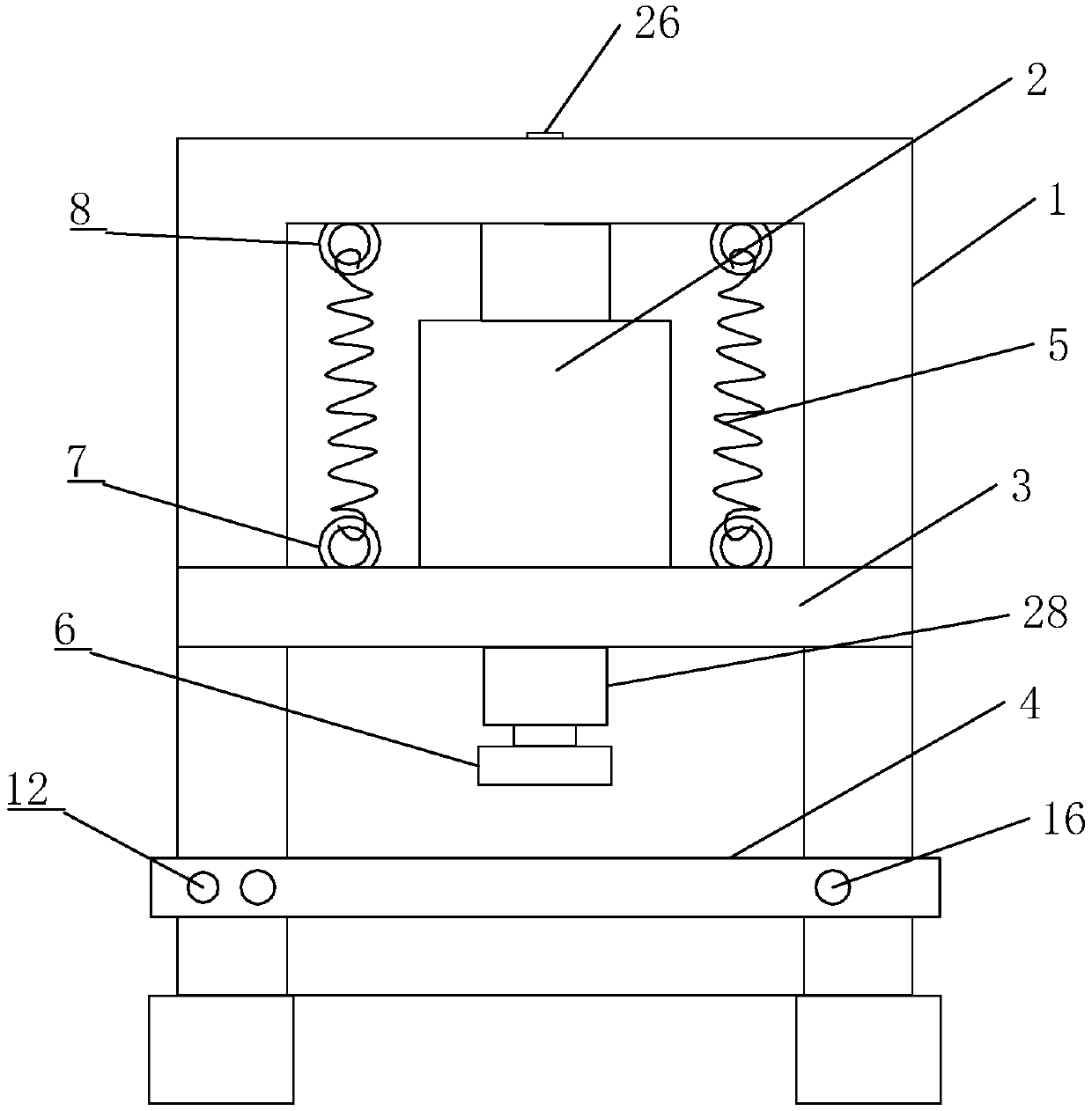

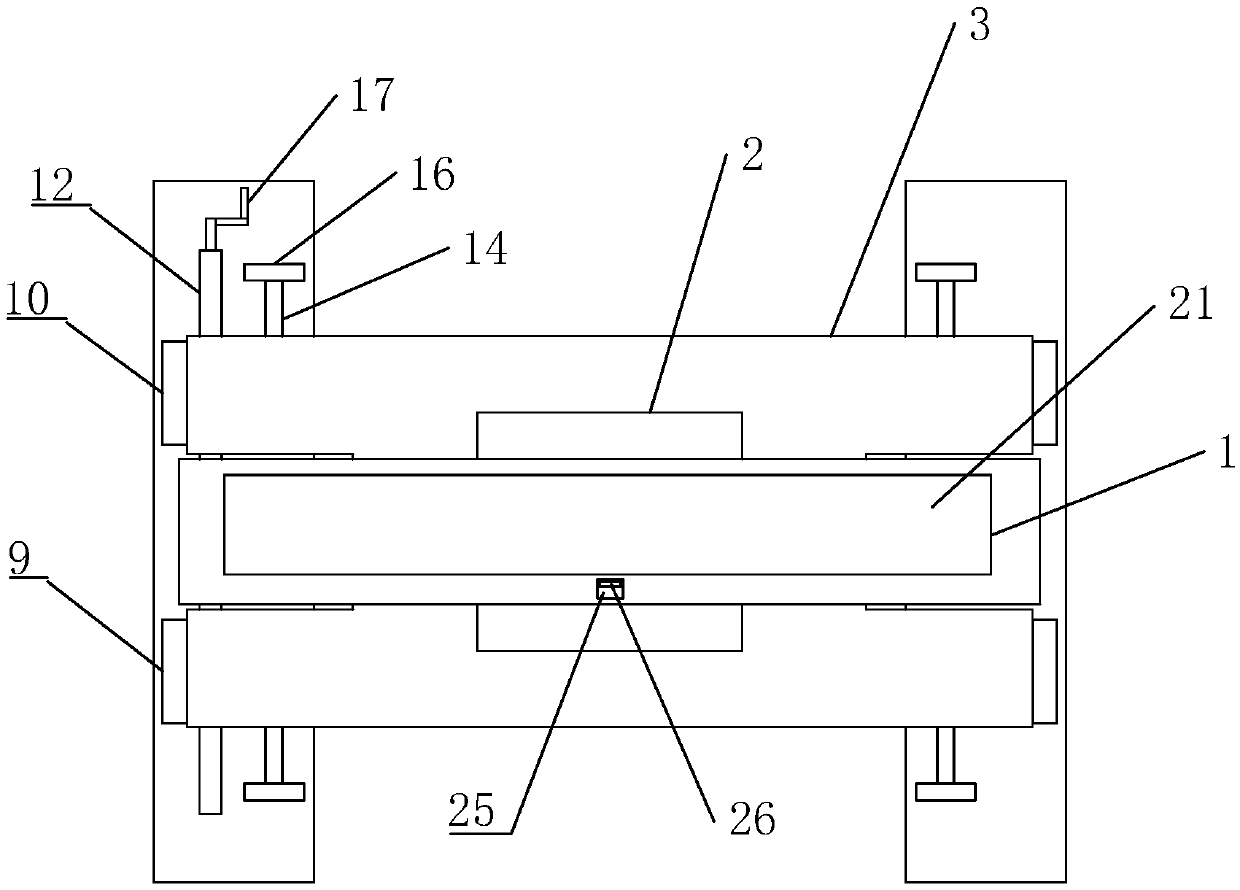

Multifunctional operation platform translation type bearing jacking machine

InactiveCN109570960AImprove up and down movement stabilityEasy to disassembleMetal working apparatusSlide plateComputer engineering

The invention discloses a multifunctional operation platform translation type bearing jacking machine. According to the technical scheme, the multifunctional operation platform translation type bearing jacking machine is characterized in that the multifunctional operation platform translation type bearing jacking machine comprises a frame body, a pushing cylinder, a sliding plate, a fixing plate and tension springs; the frame body is arranged to be in a frame shape; the pushing cylinder is arranged on the top of the frame body; the sliding plate is slidably installed between two vertical supporting rods of the frame body, and the bottom of the pushing cylinder is connected with the sliding plate; the fixing plate is arranged at the bottom of the frame body, and the sliding plate is matchedwith the fixing plate; and the fixing plate comprises a first sliding plate and a second sliding plate which are matched with each other, sliding rods are arranged on the portions, corresponding to the fixing plate, of the two vertical supporting rods of the frame body, the portions, corresponding to the sliding rods, of the first sliding plate and the second sliding plate are provided with sliding holes matched with the corresponding sliding rods, and screw rods on the first sliding plate and the second sliding plate are in screw connection fit with screw holes. According to the multifunctional operation platform translation type bearing jacking machine, operation is easy, the manufacture cost is low, and damage generated in the bearing disassembling process can be avoided.

Owner:衢州世邦科技有限公司

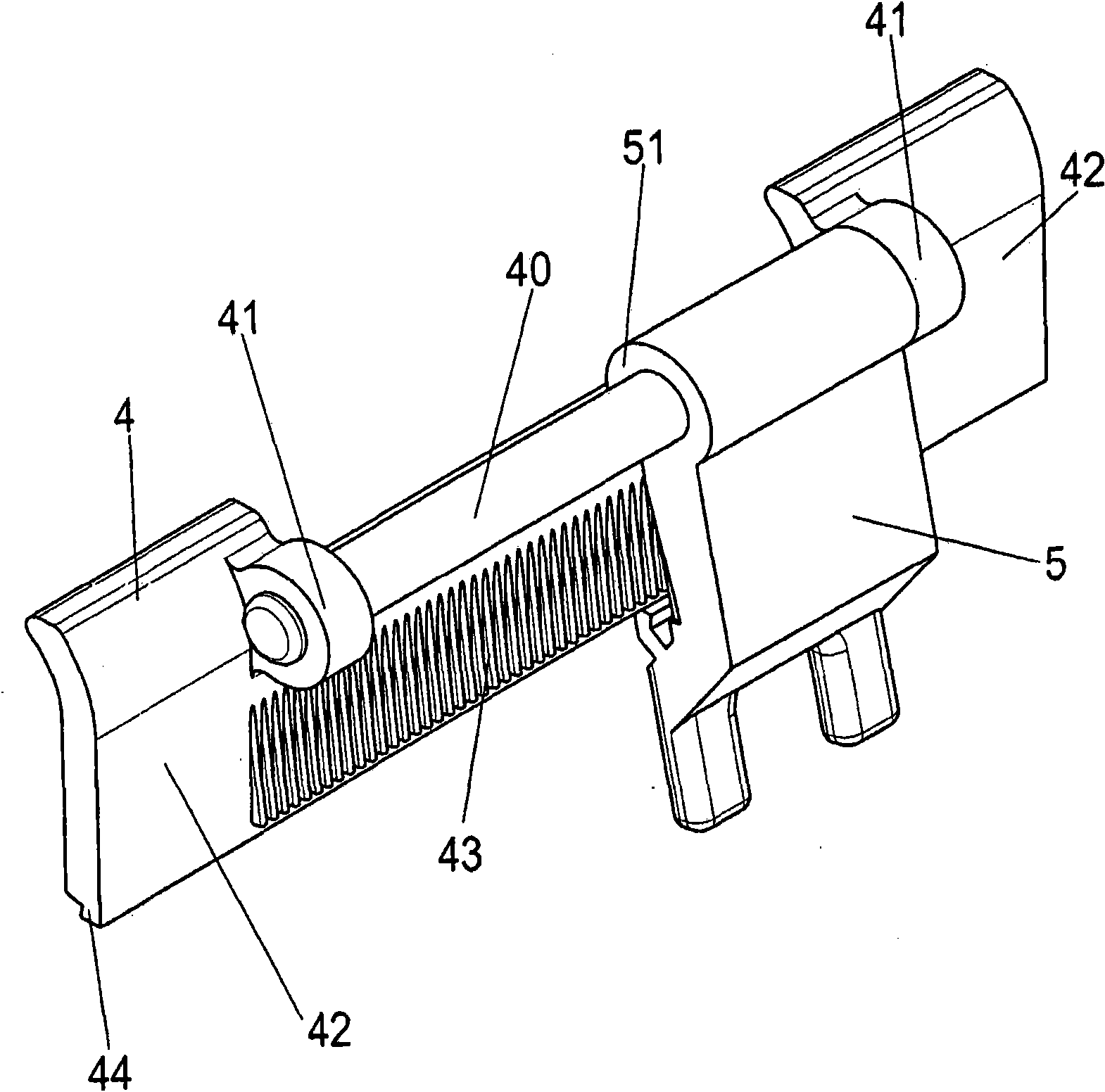

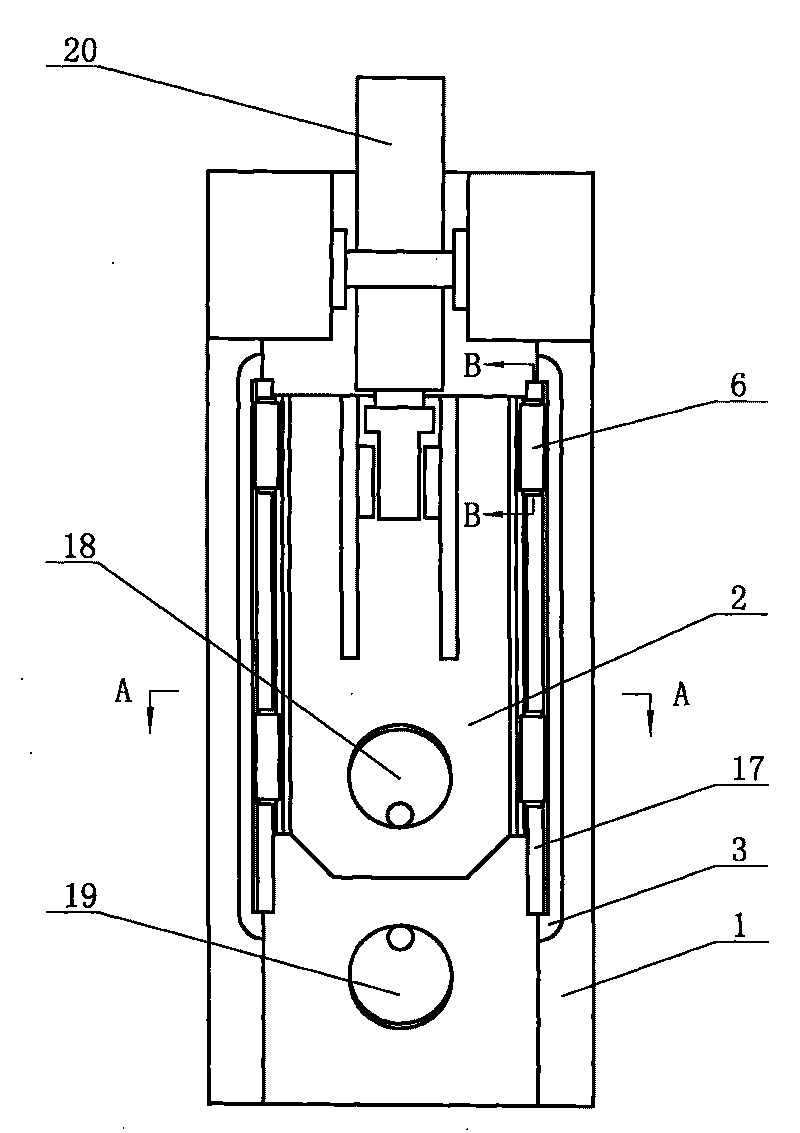

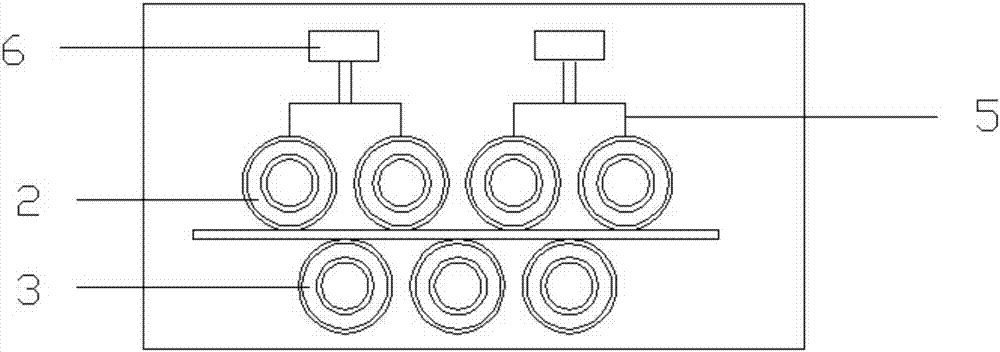

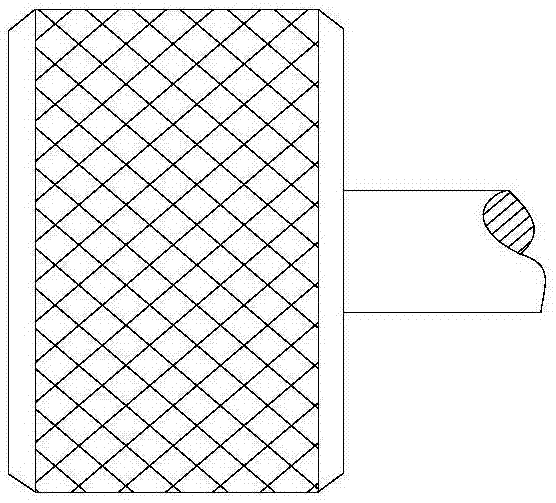

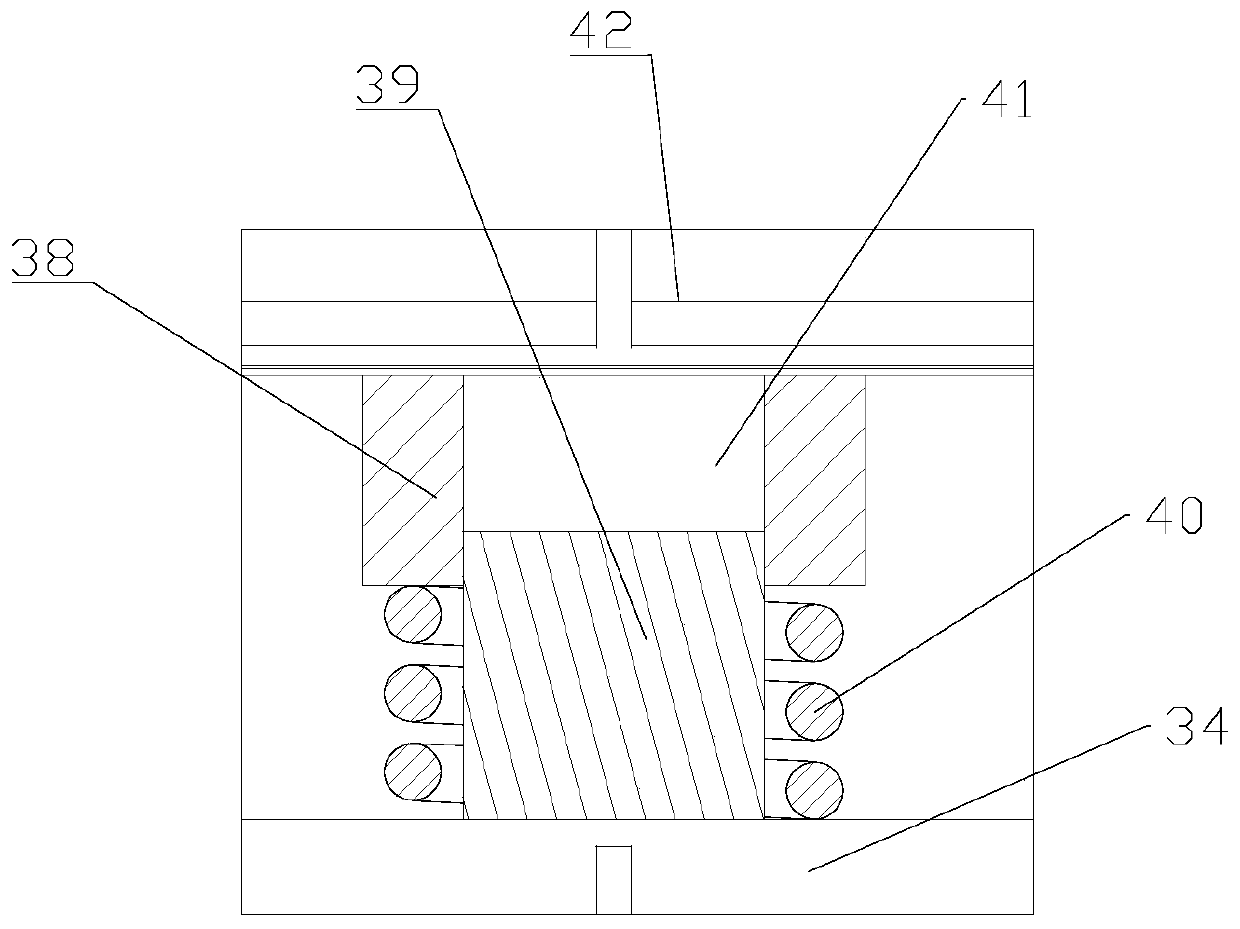

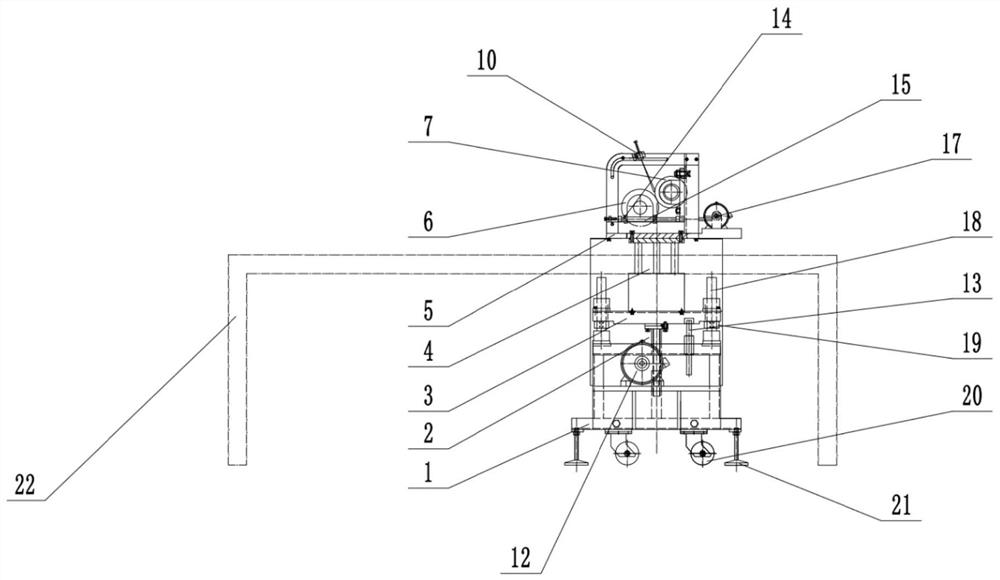

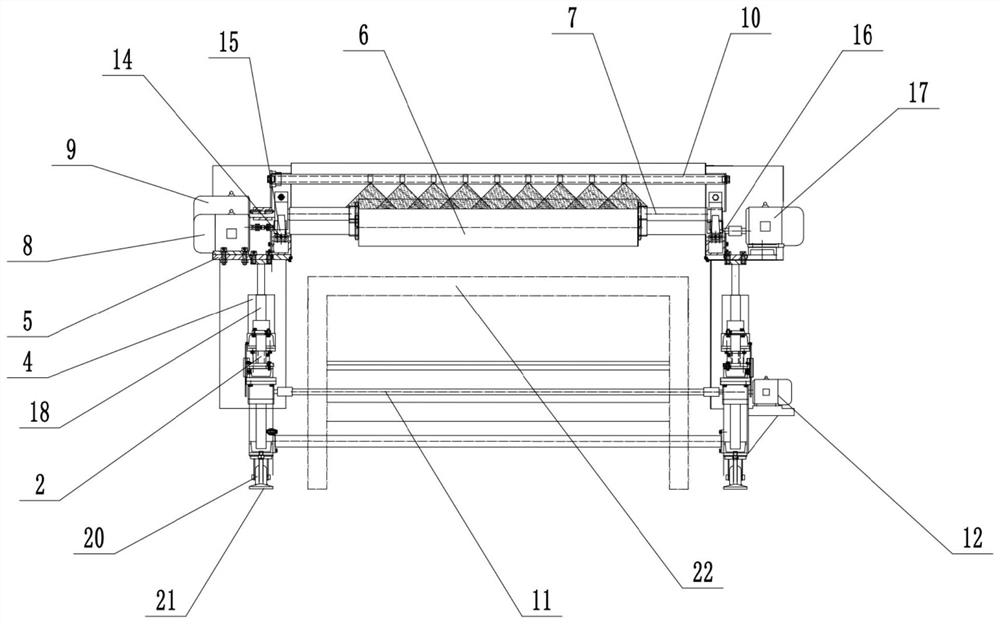

Leveling device for flat steel belt of power station boiler and manufacturing method of leveling wheels

ActiveCN107983853AGap adjustmentAdapt to leveling operationsShaping toolsFurnace typesPower stationFixed frame

The invention provides a leveling device for a flat steel belt of a power station boiler and a manufacturing method of leveling wheels, and aims to solve the problems that the surface of a flat steelstrip machined by an existing leveling device is too smooth and gaps among leveling wheels in the existing leveling device are inconvenient to adjust. The leveling device comprises leveling wheels, fixing frames and hydraulic systems, the leveling wheels comprise upper pressing wheels and lower pressing wheels, the upper pressing wheels are rotationally arranged on the fixing frames, piston rods of the hydraulic systems are connected with the fixing frames, the lower pressing wheels are located below the upper pressing wheels, and rolling pattern roads are arranged on the surfaces of the leveling wheels. The manufacturing method comprises the following steps of a, blanking; b, hardening and tempering; c, machining; d, knurling; and e, carrying out high-frequency quenching on the surface. According to the leveling device for the flat steel belt of the power station boiler and the manufacturing method of leveling wheels, the rolling pattern road are arranged on the surfaces of the leveling wheels, so that the surface of the leveled flat steel strip also has the rolling pattern roads, and the surface of the flat steel strip is prevented from being too smooth; and the upper pressing wheels of the leveling device are driven by the hydraulic systems to move up and down, so that adjustment on gaps among the upper pressing wheels and the lower pressing wheels is achieved, and the device is capable of adapting to leveling operation of flat steel strips with different sizes.

Owner:HARBIN BOILER

Feeding mechanism of bag making machine

The invention discloses a feeding mechanism of a bag making machine. The feeding mechanism comprises a rack and a feeding long shaft; the feeding long shaft is connected with the rack in a rotary manner; a packing film is wound on a roll; the roll sleeves the feeding long shaft; the feeding mechanism further comprises an automatic alarming device and a limiting device; the limiting device is used for limiting the position of the packing film; the automatic alarming device comprises a cross rod, a long rod, a baffle block, a proximity switch, a processor and an alarm; the cross rod is in front of and above the feeding long shaft and is transversely arranged on the rack; the baffle block sleeves the cross rod and is connected with the cross rod in a rotary manner; the higher end of the long rod is connected with the baffle block; the lower end of the long rod is in contact with the packing film on the uppermost layer; the proximity switch is close to the baffle block and is in output connection with the processor; and the processor is in output connection with the alarm. The feeding mechanism has the advantages that the packing film is prevented from off tracking; and when the unwinding of the packing film is finished or is about to be finished, an alarm can be given timely and automatically.

Owner:ANQING BOMEI PLASTIC CO LTD

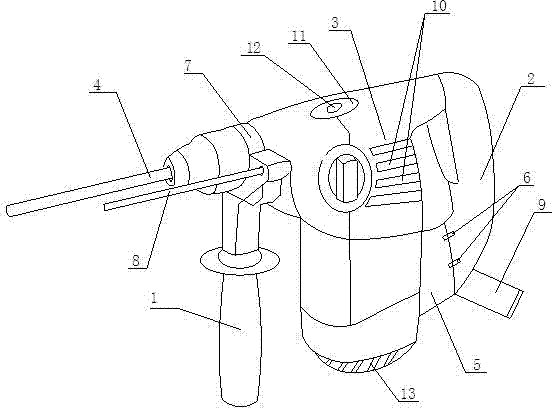

Dual-purpose electric hammer

InactiveCN104117976AGap adjustmentMeet engineering needsPortable power-driven toolsArchitectural engineeringDual purpose

The invention discloses a dual-purpose electric hammer which comprises a front-end handle, a rear-end handle, a gear case and an impact rod. The rear-end handle is connected with the gear case, a connecting column is added between the rear-end handle and the gear case and fixed on the rear-end handle through a locking piece, one end of the impact rod is arranged in a protective cover, a screw is fixed outside the protective cover and is parallel to the impact rod, and a file is installed at the bottom of the rear-end handle. Except a drilling function, the electric hammer further has other functions. A screw hole can be rapidly dilled in an object by means of the screw, and the engineering demand is met. The file is installed at the bottom of the rear-end handle and used for filling machining on the aspect of engineering, so that the electric hammer can be adjusted in the using process in a clearance mode, and dual purposes are achieved.

Owner:NANTONG DONGLIDE TOOLS

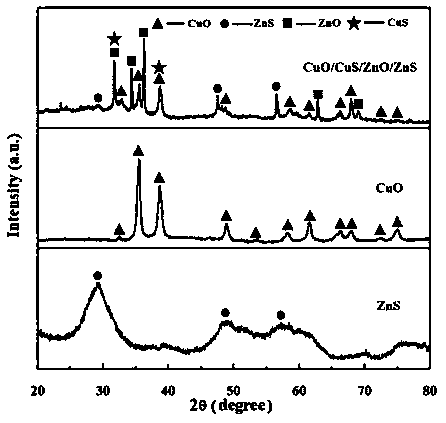

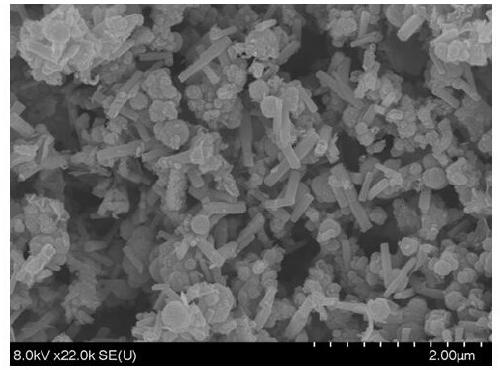

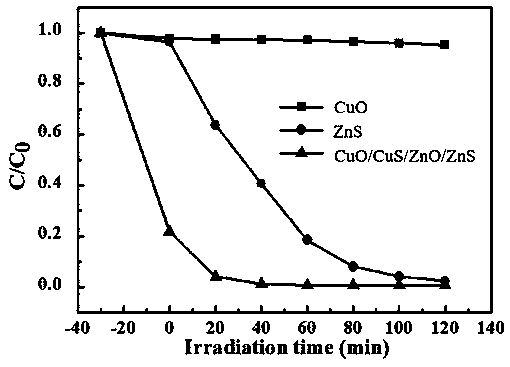

Preparation method of quaternary visible light catalysis nano composite material

ActiveCN111167479AEasy to separateExtend your lifePhysical/chemical process catalystsWater/sewage treatment by irradiationOrganic solventCopper oxide

The invention discloses a preparation method of a quaternary visible light catalysis nano composite material. The preparation method specifically comprises the following steps: (1) uniformly dispersing copper oxide and zinc sulfide in a mass ratio of 1: (1-4) in deionized water to form a mixed solution; and (2) putting the mixed solution obtained in the step (1) into a microwave reactor, carryingout microwave irradiation reaction, cooling to room temperature, and carrying out filtering, washing and drying to obtain the CuO / CuS / ZnO / ZnS quaternary visible light catalysis nano composite material. The obtained CuO / CuS / ZnO / ZnS quaternary visible light catalysis nano composite material has relatively high photocatalytic efficiency under visible light. The preparation method is simple in process, simple and convenient to operate, good in repeatability, clean in process and environment-friendly, and no surfactant or organic solvent is used as a template.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Leather fabric cutting device

PendingCN110735313AGap adjustmentMeet cutting needsLeather clicking/perforating/clickingSevering textilesDrive wheelTransmission belt

The invention discloses a leather fabric cutting device, which relates to the technical field of luggage processing equipment. In order to improve the efficiency and quality of luggage leather cutting, the device specifically comprises a mounting base seat, wherein a fifth guide wheel and a fourth guide wheel are mounted at the upper end of the mounting base seat; a sliding groove and a sliding block are formed in a second mounting frame; the sliding block is connected with the fourth guide wheel; a third hydraulic rod is mounted on the sliding block; a third hydraulic pump is mounted on the second mounting frame; a motor is further mounted on the mounting base seat; a driving wheel is mounted on one side of the motor; a transmission belt is mounted on the driving wheel; a driven wheel ismounted on the transmission belt; the driven wheel is fixedly connected with the fifth guide wheel; a plurality of second guide wheels are mounted at the upper end of the mounting base seat; a first hydraulic pump is mounted on a first mounting frame; a second hydraulic rod is mounted on the first hydraulic pump; a cutter head is mounted on the first hydraulic rod; and a cutter head dislocation plate, which is arranged in dislocation with the cutter head, is mounted at the upper end of the mounting base seat. The device can effectively improve the leather cutting efficiency and quality of luggage leather.

Owner:耒阳市康意电子箱包科技有限公司

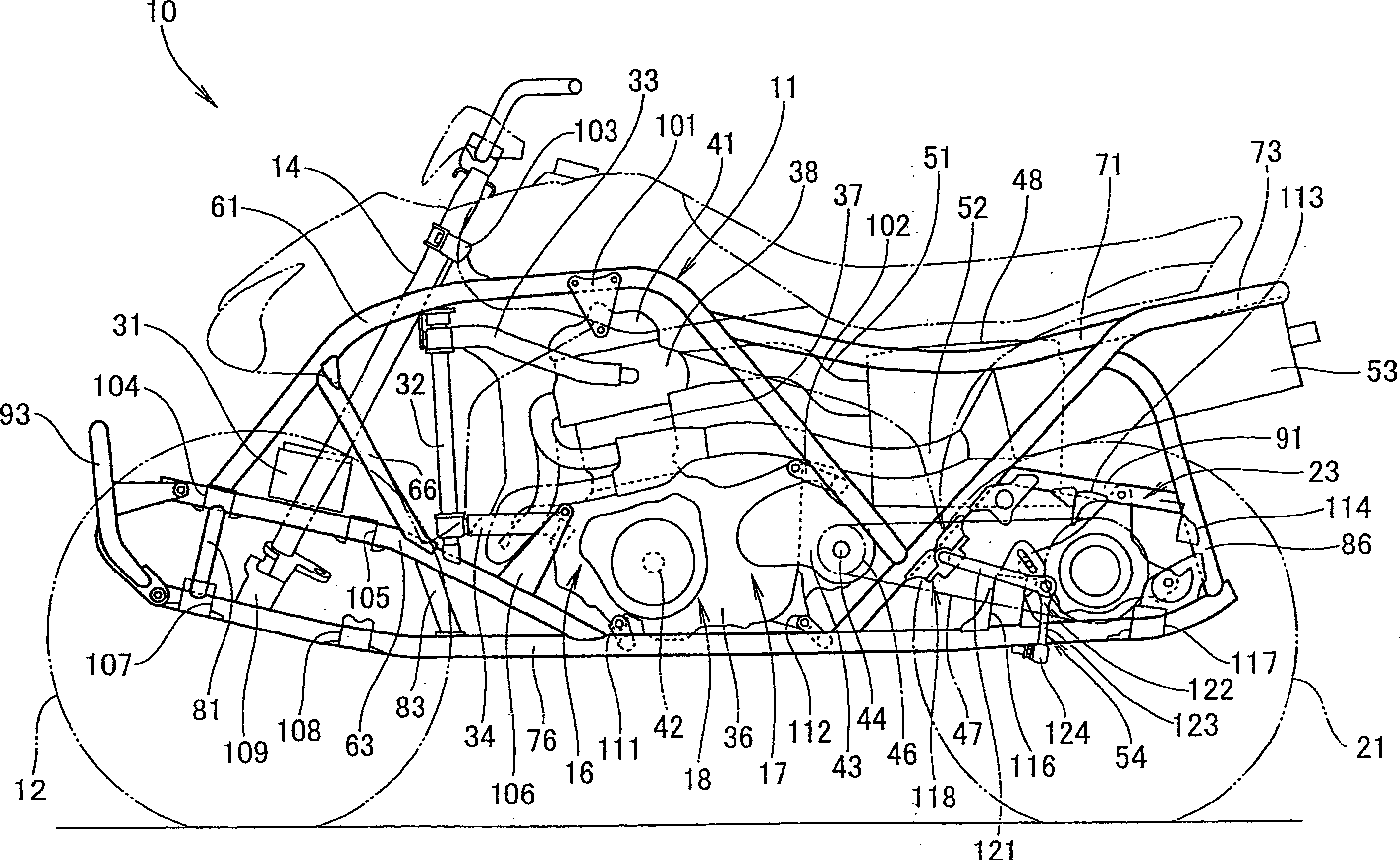

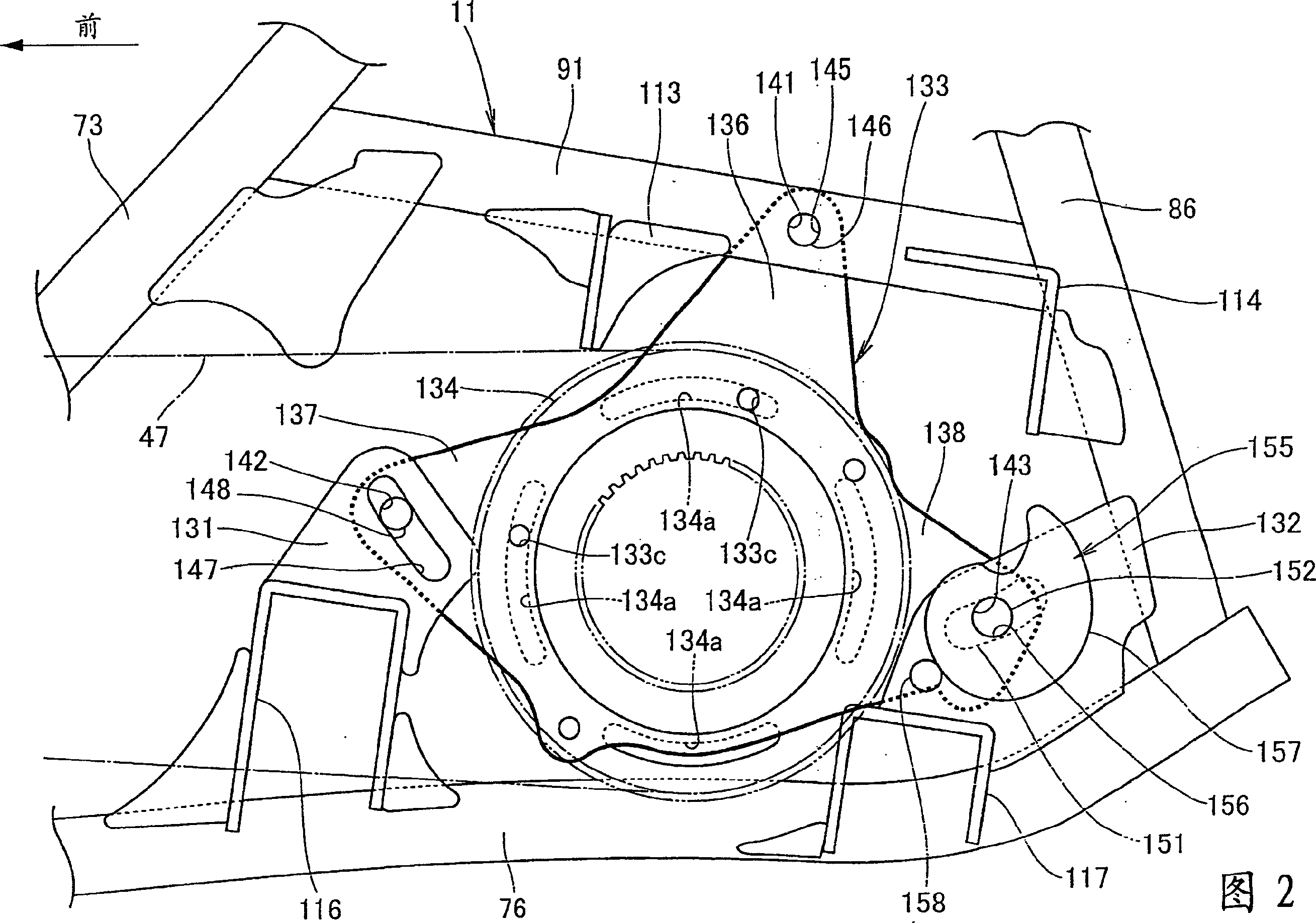

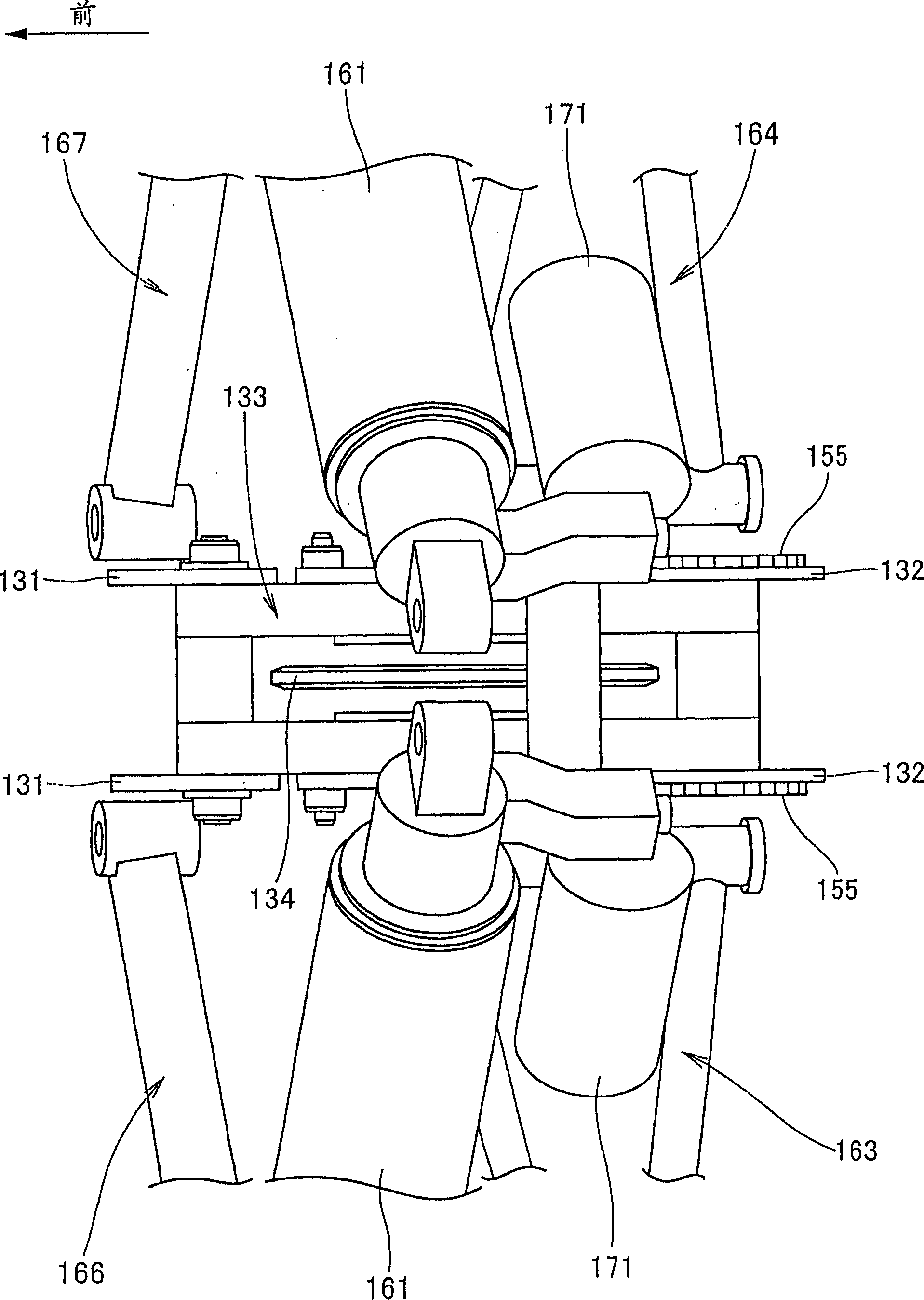

Vehicle and chain play adjusting device thereof

InactiveCN1676405AGood maintainabilityReplaceableGearboxesChain/belt transmissionAutomotive engineeringAnti-roll bar

Owner:HONDA MOTOR CO LTD

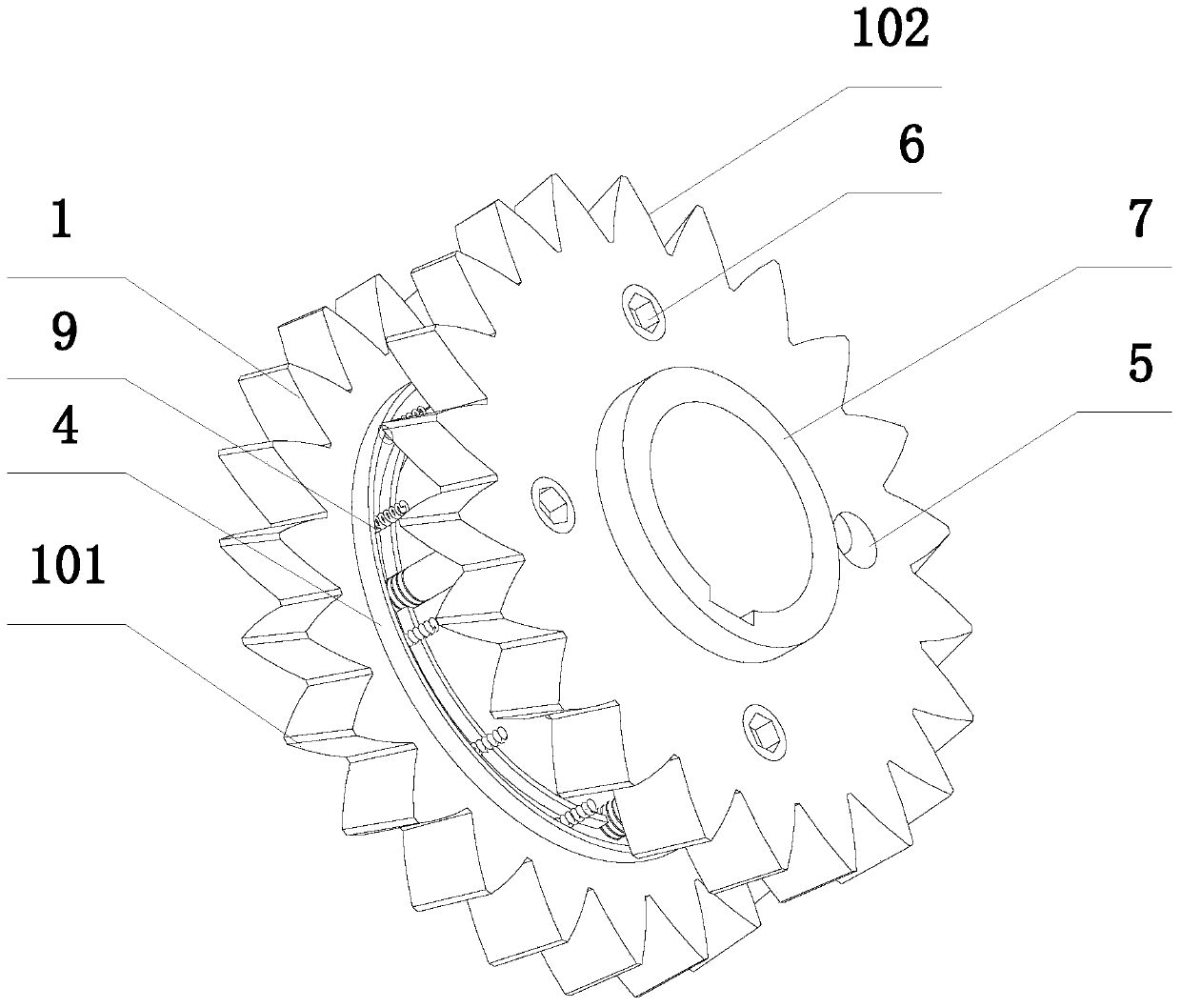

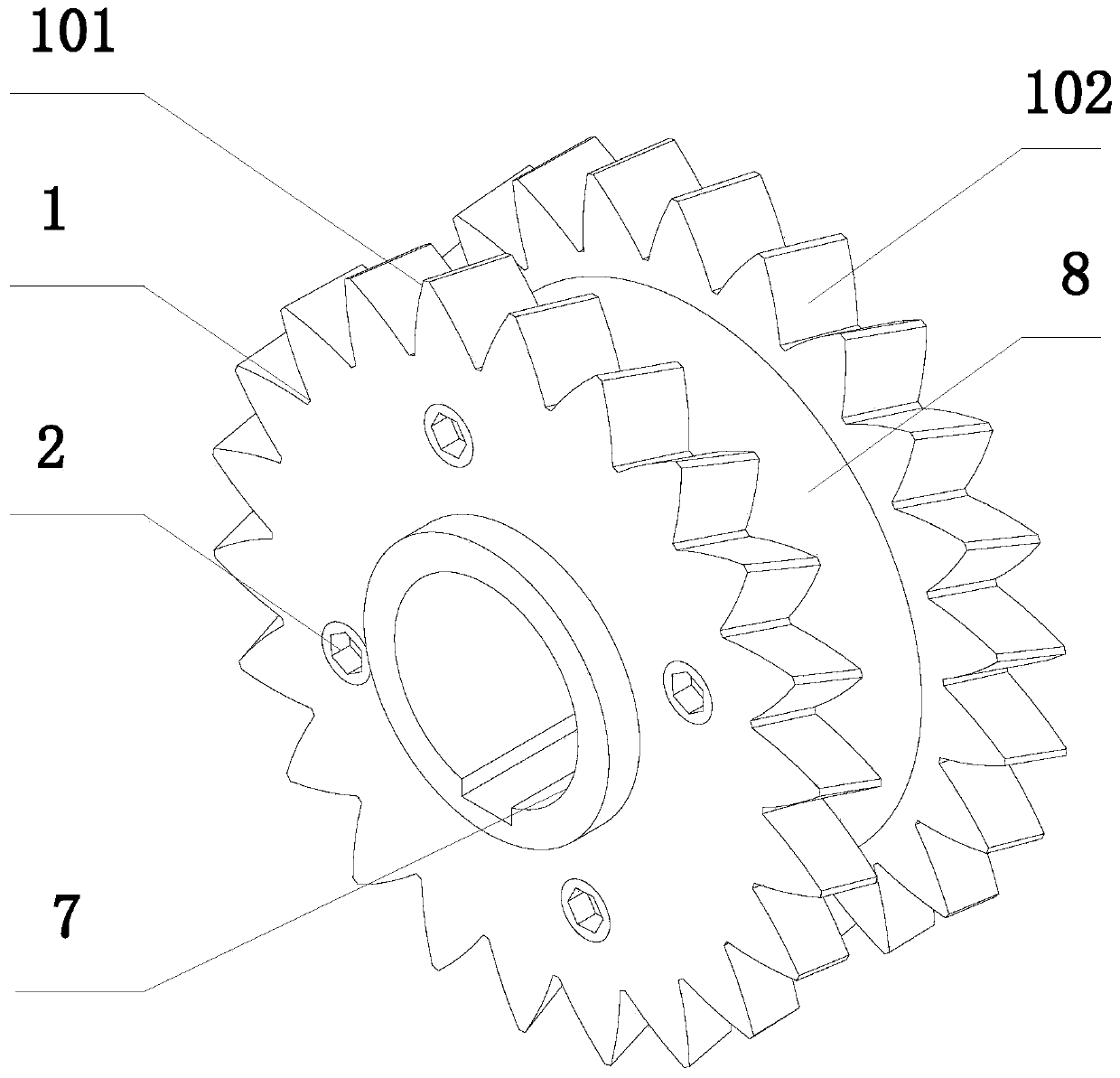

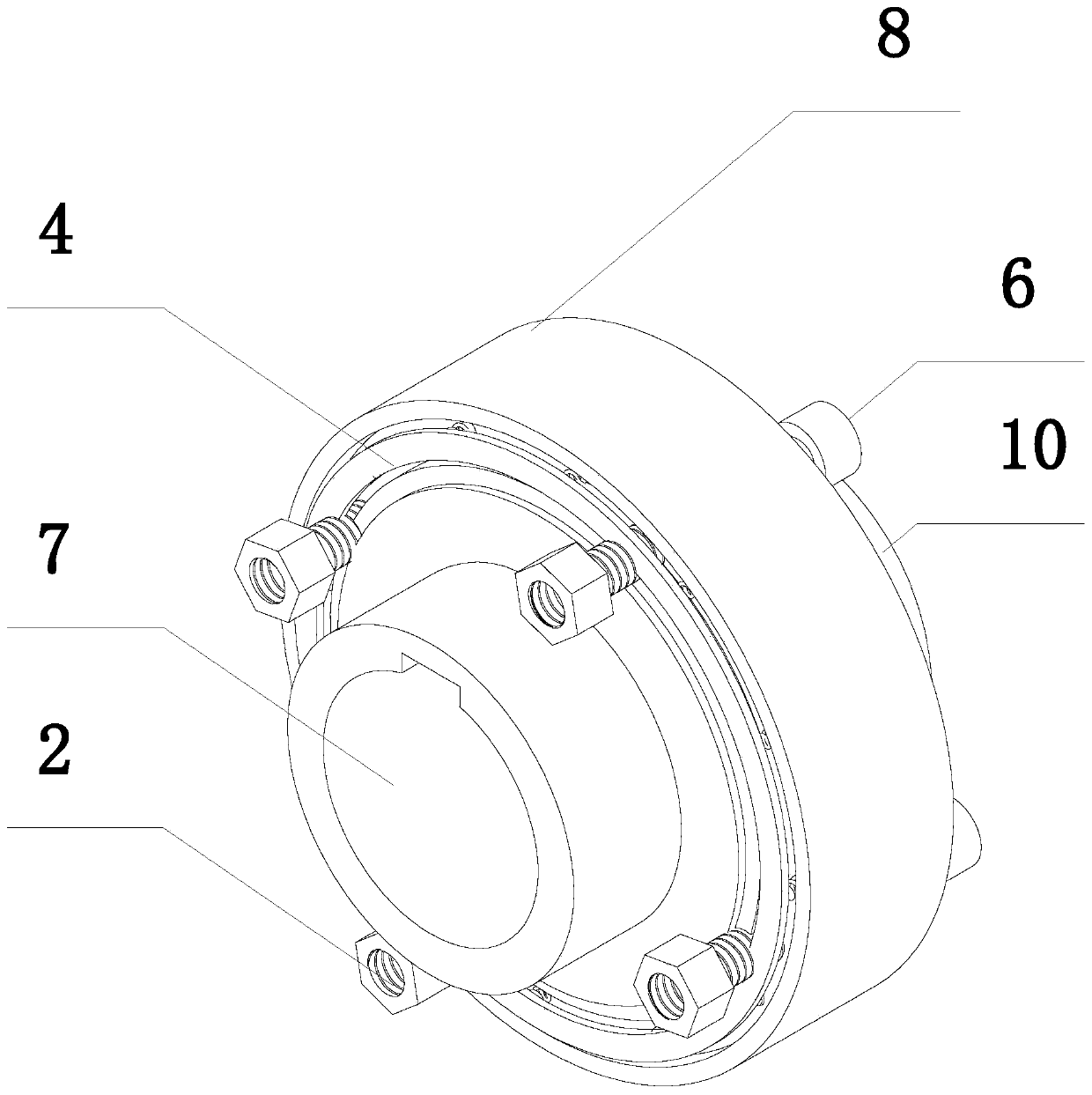

Helical cylindrical gear

ActiveCN110725920AImprove applicabilityImprove the aesthetics of the processPortable liftingGearing elementsGear driveGear wheel

The invention discloses a helical cylindrical gear, and relates to the technical field of gear transmission. The helical cylindrical gear with an anti-backlash device comprises gear pieces; the gear pieces comprise a left gear piece and a right gear piece; nuts are fixedly installed on one side of the left gear piece; a groove is formed in one side, away from the nuts, of the left gear piece; a rubber sleeve is fixedly connected inside the groove; step holes are formed in one side of the right gear piece; and bolts are movably connected inside the stepped holes. According to the helical cylindrical gear with the anti-backlash device, the nuts and the bolts can be effectively embedded in the gear piece through nut holes and the stepped holes on one side of the gear piece, the applicabilityof the anti-backlash helical cylindrical gear is improved, the requirement on a transmission system is reduced, the process attractiveness of the helical cylindrical gear is improved, the bolts adoptinner hexagonal bolt, the gap between the gear pieces is conveniently adjusted, and the stability of gear transmission is guaranteed.

Owner:南通旺鑫新材料有限公司

Viscous slurry grinding machine and using method thereof

PendingCN112692965AGuaranteed surface smoothnessGuaranteed to be smoothPress rollersAuxillary shaping apparatusEngineeringSlurry

The invention discloses a viscous slurry grinding machine and a using method thereof. The viscous slurry grinding machine comprises a rack, the two ends of the rack are each provided with a first height adjusting device, the upper end of each first height adjusting device is connected with a supporting plate, and the first height adjusting devices are used for finely adjusting the height of the supporting plates. The upper end face of each supporting plate is provided with a second height adjusting device, the upper end of each second height adjusting device is connected with a support, and the second height adjusting devices are used for roughly adjusting the height of the supports. A grinding roller and a cleaning roller are mounted between the two supports, one end of the grinding roller and one end of the cleaning roller are connected with a first driving device and a second driving device correspondingly, the grinding roller and the cleaning roller are arranged in parallel, and a gap is formed between the grinding roller and the cleaning roller. A spraying pipe is further mounted between the two supports and is aligned to the gap between the grinding roller and the cleaning roller. According to the viscous slurry grinding machine, the height of the grinding roller can be adjusted, the surface smoothness of a gypsum board is guaranteed, operation is easy, and the production efficiency can be greatly improved.

Owner:SHAANXI UNIV OF SCI & TECH

Cloth aligning structure for cloth sewing

InactiveCN113106637AEffective regulationGap adjustmentWork-feeding meansEngineeringMechanical engineering

The invention relates to the technical field of cloth sewing, in particular to a cloth aligning structure for cloth sewing. The cloth aligning structure comprises a processing platform; a straightening mechanism is slidably mounted on the processing platform; the straightening mechanism comprises a left stand column and a right stand column; the left stand column and the right stand column are driven by a driving device and do linear opposite movement on the processing platform; clamping assemblies are arranged on the sides, close to each other, of the left stand column and the right stand column; each clamping assembly comprises a lower supporting rod and an upper supporting rod; each upper supporting rod is driven by a spacing adjusting mechanism to linearly move up and down on the corresponding stand column; each spacing adjusting mechanism comprises a moving block, a matching cylinder, a telescopic cylinder and a push rod; each upper supporting rod is fixedly connected with the corresponding moving block; and the lower supporting rods and the upper supporting rods are fixedly connected with pressing sheets. Through horizontal opposite movement of the left stand column and the right stand column, the effect of straightening and tightening cloth is achieved, and wrinkles and other situations caused by manual operation are effectively avoided.

Owner:魏彩娥

Operating table horizontal-moving type bearing top pressing machine

InactiveCN109570957AEasy to disassembleImprove stabilityMetal working apparatusSlide plateOperating table

The invention discloses an operating table horizontal-moving type bearing top pressing machine. According to the technical scheme, the operating table horizontal-moving type bearing top pressing machine comprises a frame body, a push cylinder, a sliding plate, a fixing plate and tension springs, wherein the frame body is arranged in a frame shape, the pushing cylinder is arranged at the top of theframe body, the sliding plate is arranged between the two vertical supporting rods of the frame body in a sliding mode, and the bottom of the pushing cylinder is connected with the sliding plate; thefixing plate is arranged at the bottom of the frame body, the sliding plate is arranged in cooperation with the fixing plate, the fixing plate comprises a first sliding plate and a second sliding plate which are matched with each other, sliding rods are respectively arranged at the positions, corresponding to the fixing plates, of the two vertical supporting rods on the frame body, sliding holesmatched with corresponding sliding rods are formed in the positions, corresponding to the sliding rods, of the first sliding plate and the second sliding plate, and the screw rod on the first slidingplate and the second sliding plate are in threaded connection fit with screw holes. The operating table horizontal-moving type bearing top pressing machine is simple to operate, low in manufacturing cost and capable of avoiding damage caused by bearing dismounting.

Owner:衢州世邦科技有限公司

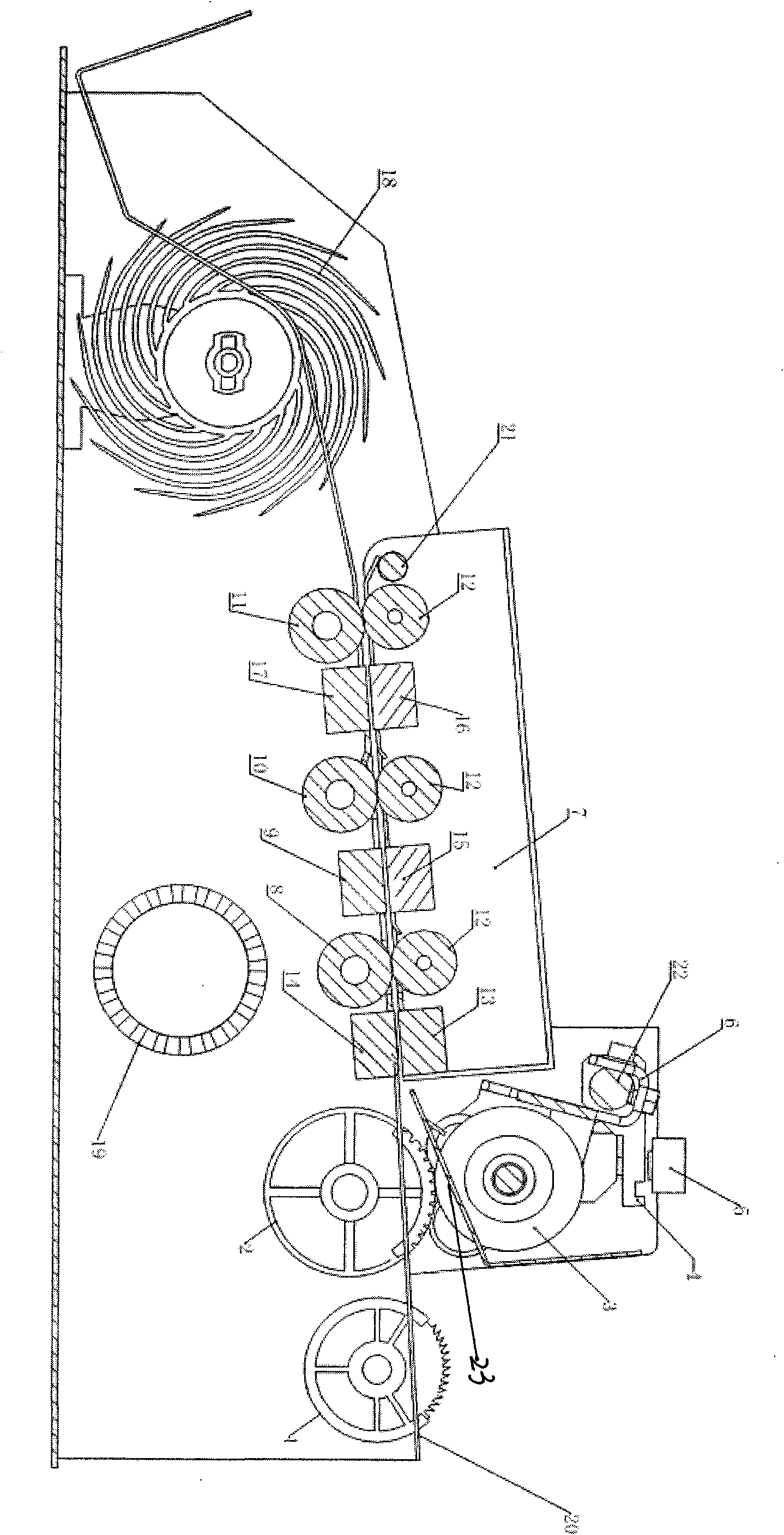

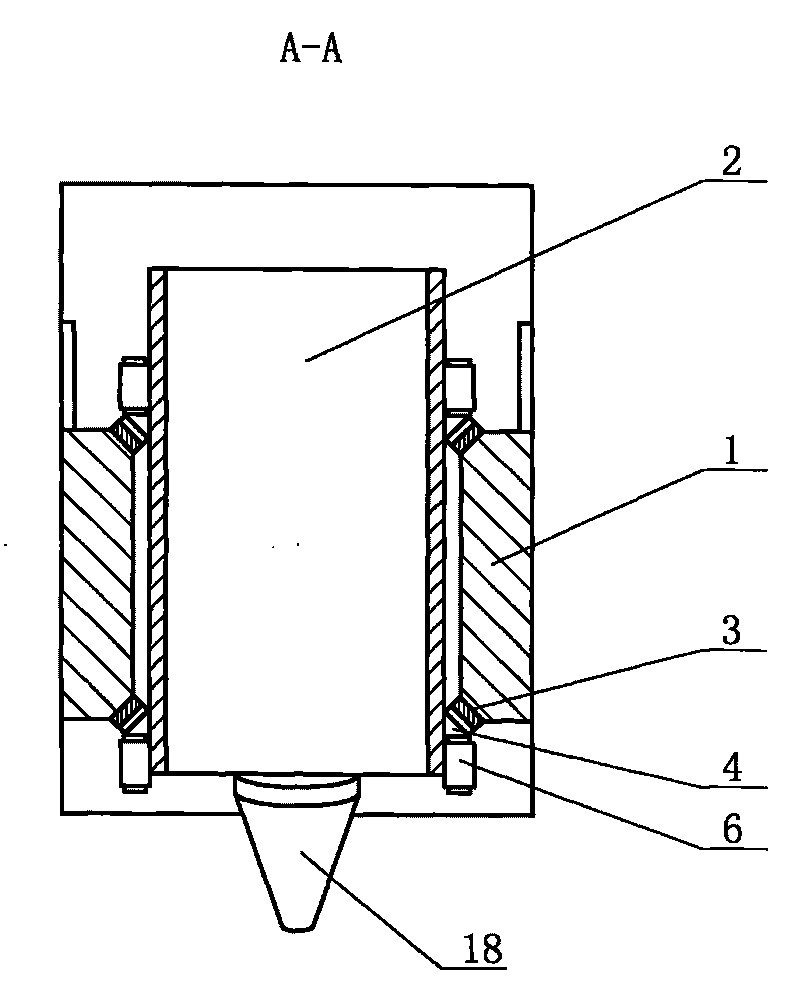

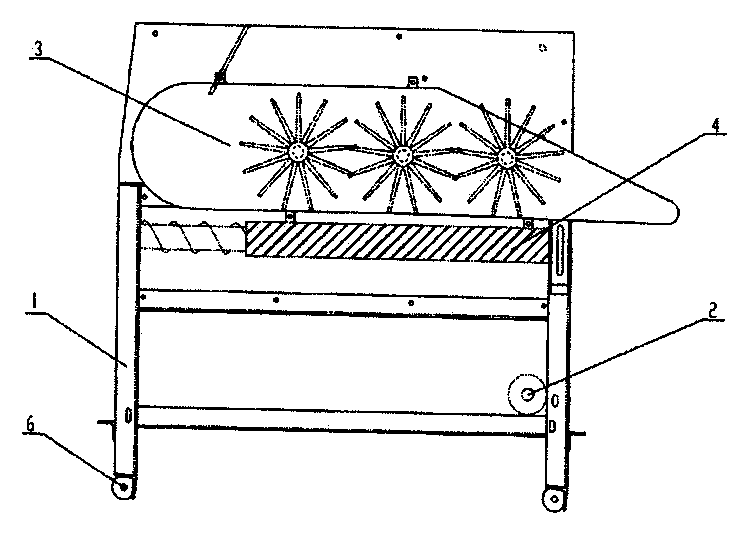

Dual-unit corn husker

InactiveCN104412786ASimple structureImprove peeling efficiencyThreshersAgricultural scienceMechanical reliability

The invention relates to agricultural implements, particularly to a dual-unit corn husker. The dual-unit corn husker comprises a frame, a power mechanism and a transmission mechanism. The frame is of a cuboid frame structure; the power mechanism is mounted at the bottom of the frame; the inside of the inner cavity of the upper portion of the frame is provided with 3-5 sets of pressure feeding mechanisms; the inside of the middle inner cavity of the frame under the pressure feeding mechanisms is provided with two roll-husking units which are respectively provided with a roll gap adjusting mechanism. The dual-unit corn husker is simple in structure and light in weight, greatly improves the corn husking efficiency, meanwhile, avoids crushing of corn cobs caused by overhigh pressure, prevents machine congestion and achieves the aim of improving the husking quality and the mechanical reliability.

Owner:蒋爱成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com