Injection mold

A technology for injection molds and mold bases, which is used in cleaning methods and utensils, removal of smoke and dust, chemical instruments and methods, etc., can solve the problems of solidification of raw materials at the bottom of the mold cavity, easy generation of air bubbles in parts, and reduction of the qualified rate of parts. The effect of uniformity, improved cleanliness, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

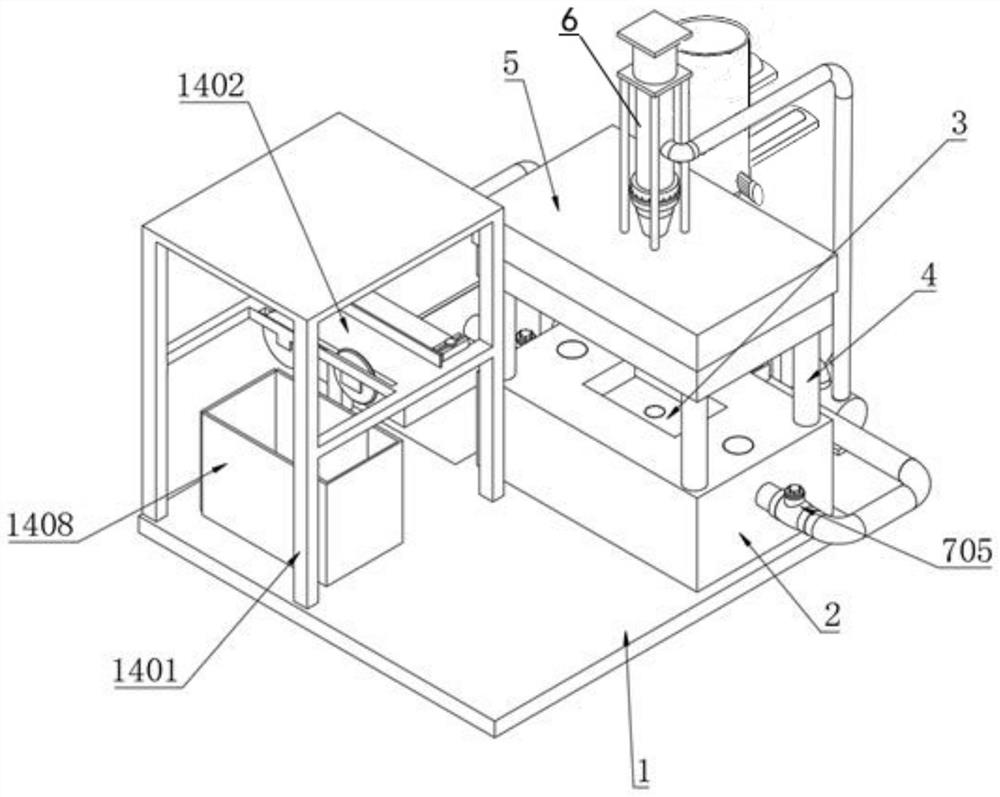

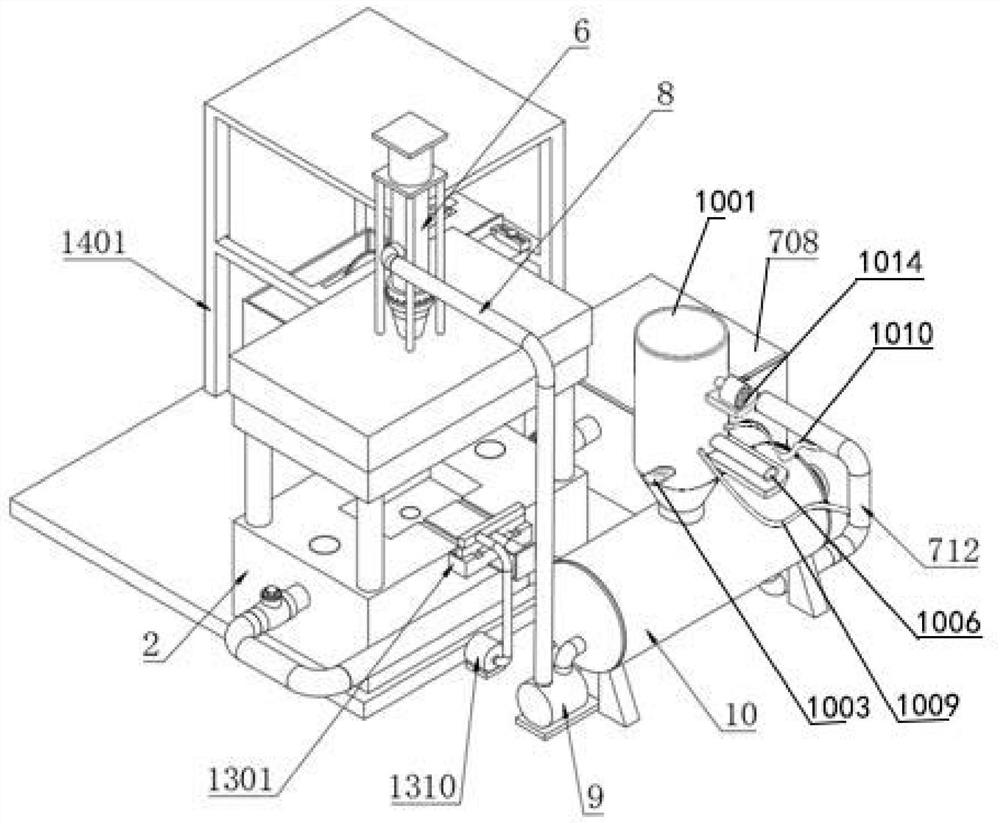

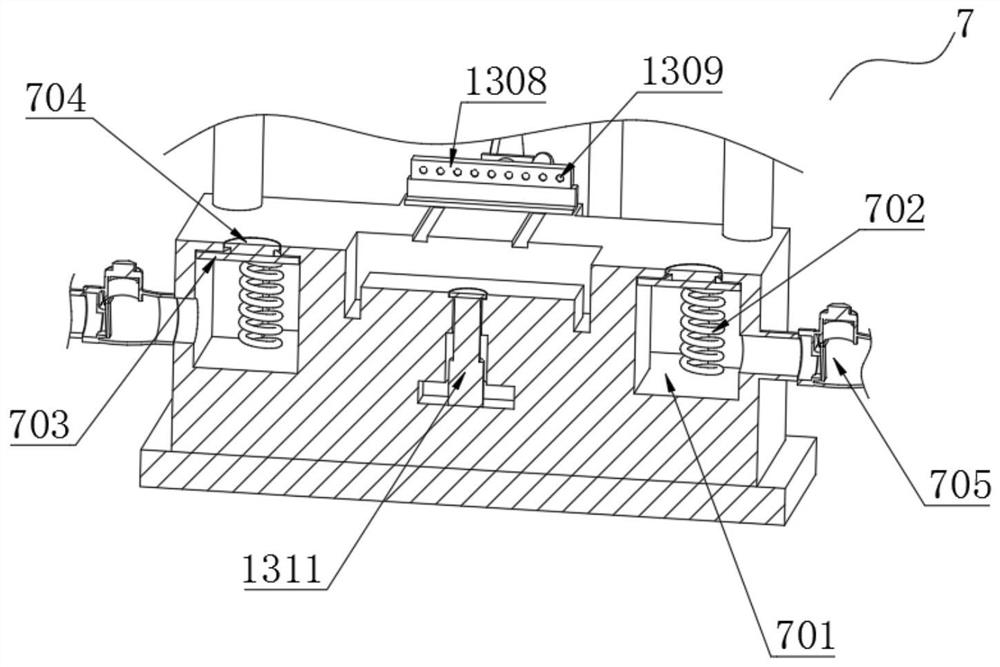

[0038] Example: such as Figure 1-14An injection mold shown includes a base 1, a heat exchange mechanism 7, a raw material tank 10, an adjustment mechanism 11, a discharge mechanism 12, the retrieving mechanism 13 and a trimming mechanism 14, and the feeding hopper 1001 of the raw material tank 10 is built in There is a circular flap 1002, the circular flap 1002 is fixedly connected to the output shaft of the flap motor 1003, the side wall of the feeding hopper 1001 is fixedly connected with a first fixed frame 1004, and the first fixed frame 1004 is fixed with a plurality of legs 1005 with electric telescopic Rod 1006, the rod body of the electric telescopic rod 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com