Sheet-shaped object welding device

A sheet and welding technology, which is applied in the field of disposable sanitary products, can solve the problems of complicated installation of pressure sensors, lagging force measurement, and inability to adjust the gap in real time, so as to improve welding quality and consistency, strong reliability, and improved Effects of Safety and Continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

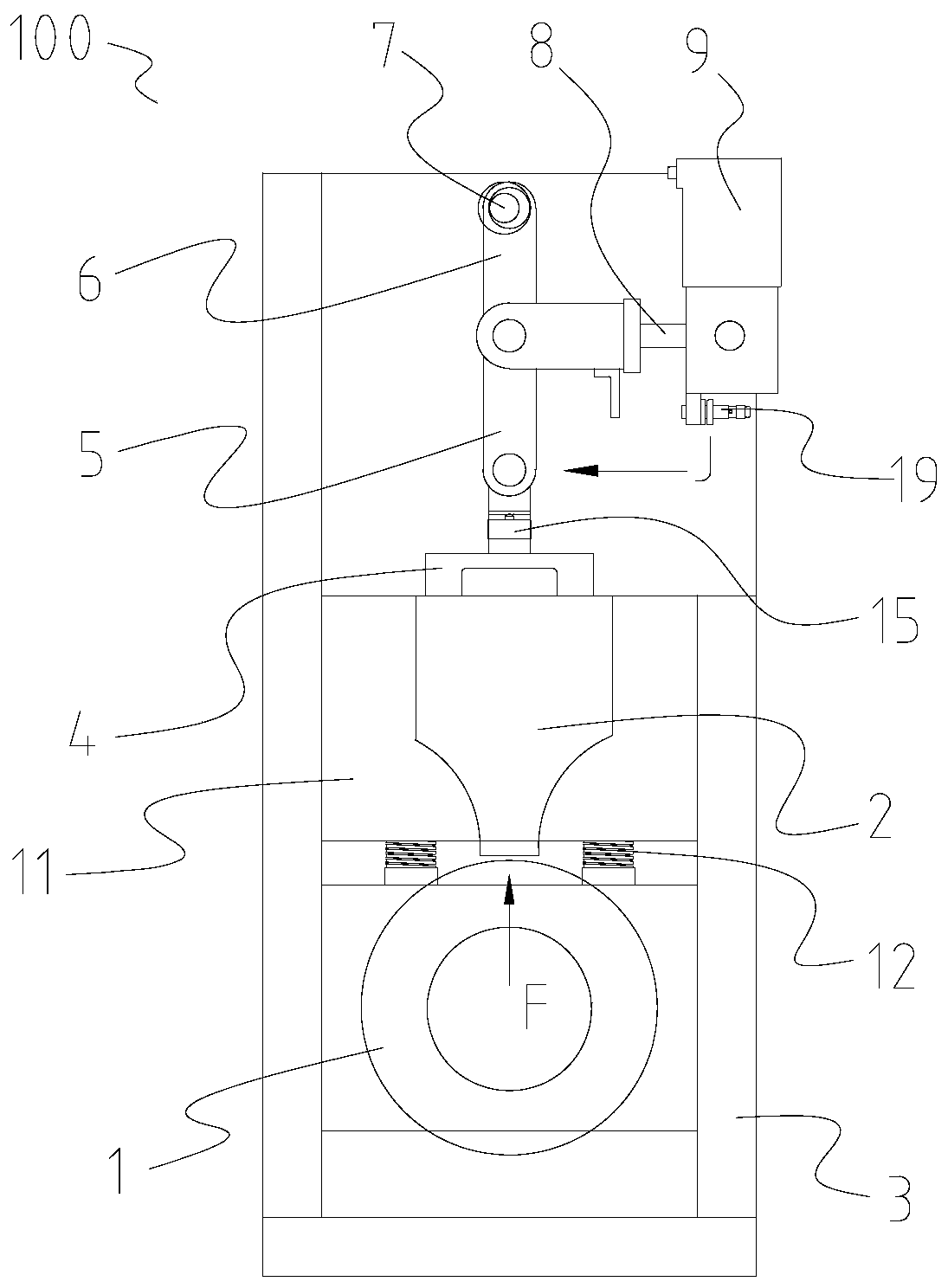

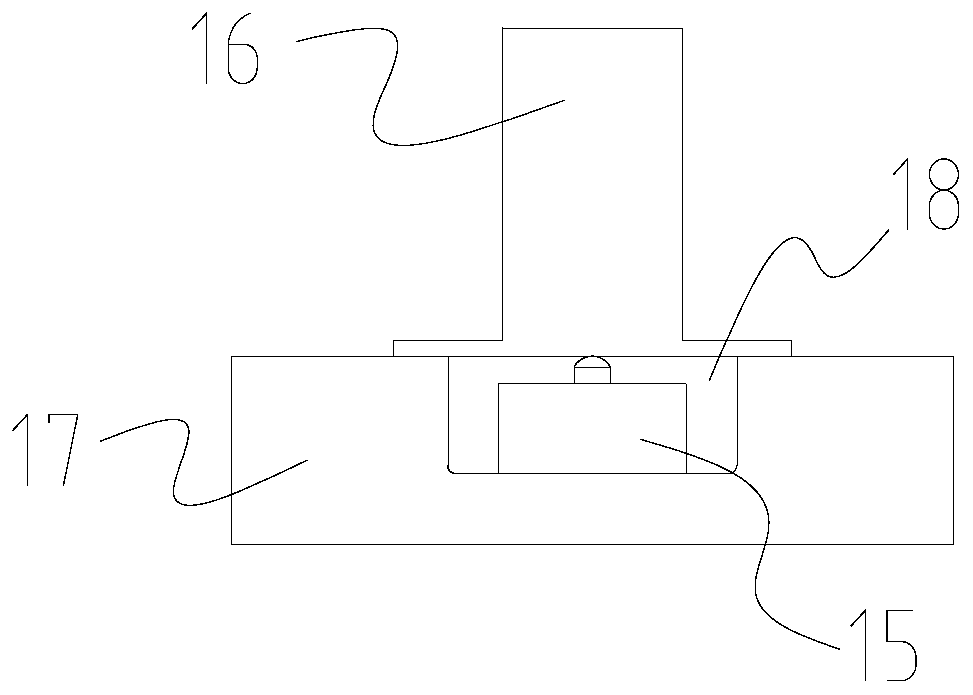

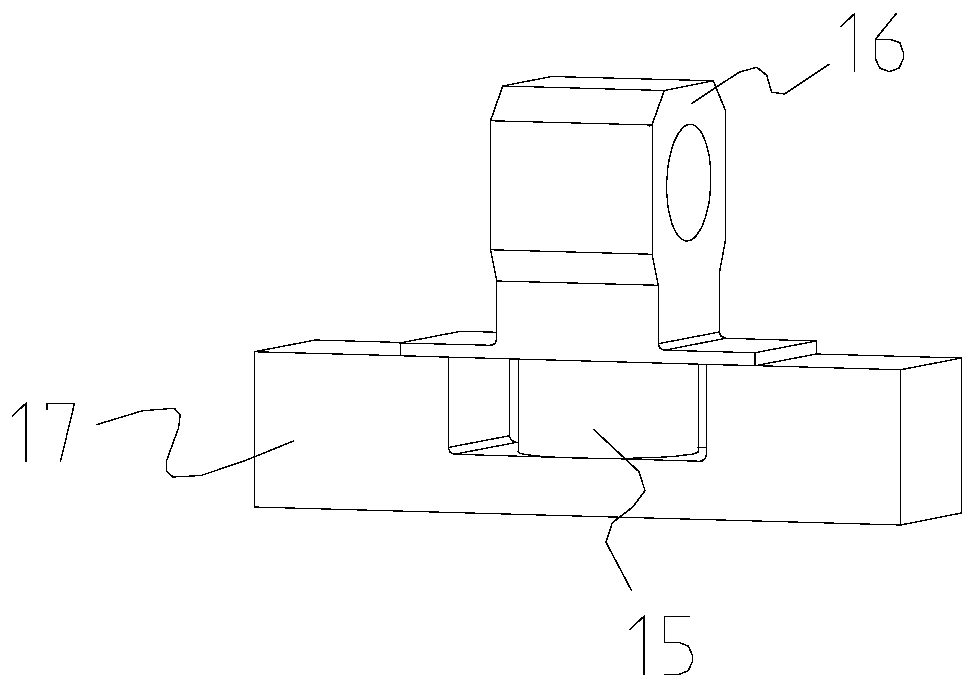

[0022] Such as Figures 1 to 4 As shown, a sheet fusion device 100 has: a frame body 3, an anvil roller 1, an ultrasonic welding head 2 paired with the anvil roller 1, and a moving plate 4 for fixing the ultrasonic welding head, which is used for inducing the ultrasonic welding head to be received by the sheet. The sensing part that exerts the reaction force on the object, the control system that receives the feedback signal of the sensing part and compares the reaction force value with the set value, and the clearance fine-tuning link mechanism. A guide rail is provided on the frame body 1, the ultrasonic welding head 2 is fixed on the flange 11, and the flange 11 can move vertically along the guide rail.

[0023] The sheet is transported to the gap between the ultrasonic welding head and the anvil roller to weld each other, and the moving plate can move relative to the anvil roller through the fine-tuning link mechanism of the gap, so that the ultrasonic welding head can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com