Operating table horizontal-moving type bearing top pressing machine

A translational, console technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of wasting disassembly time, violent damage to bearings, etc., and achieve the effect of convenient disassembly work, improved stability, and convenient rotation operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

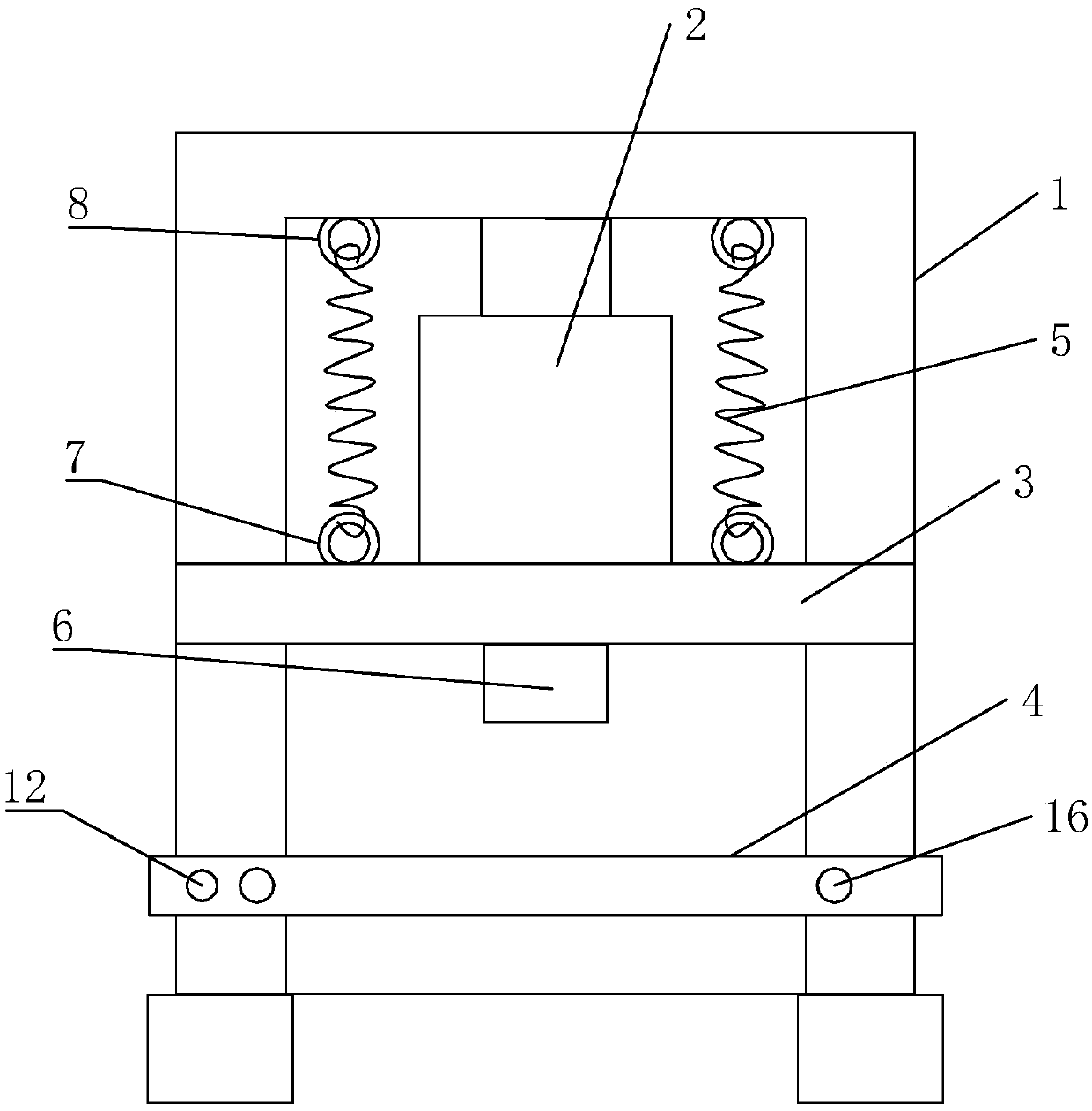

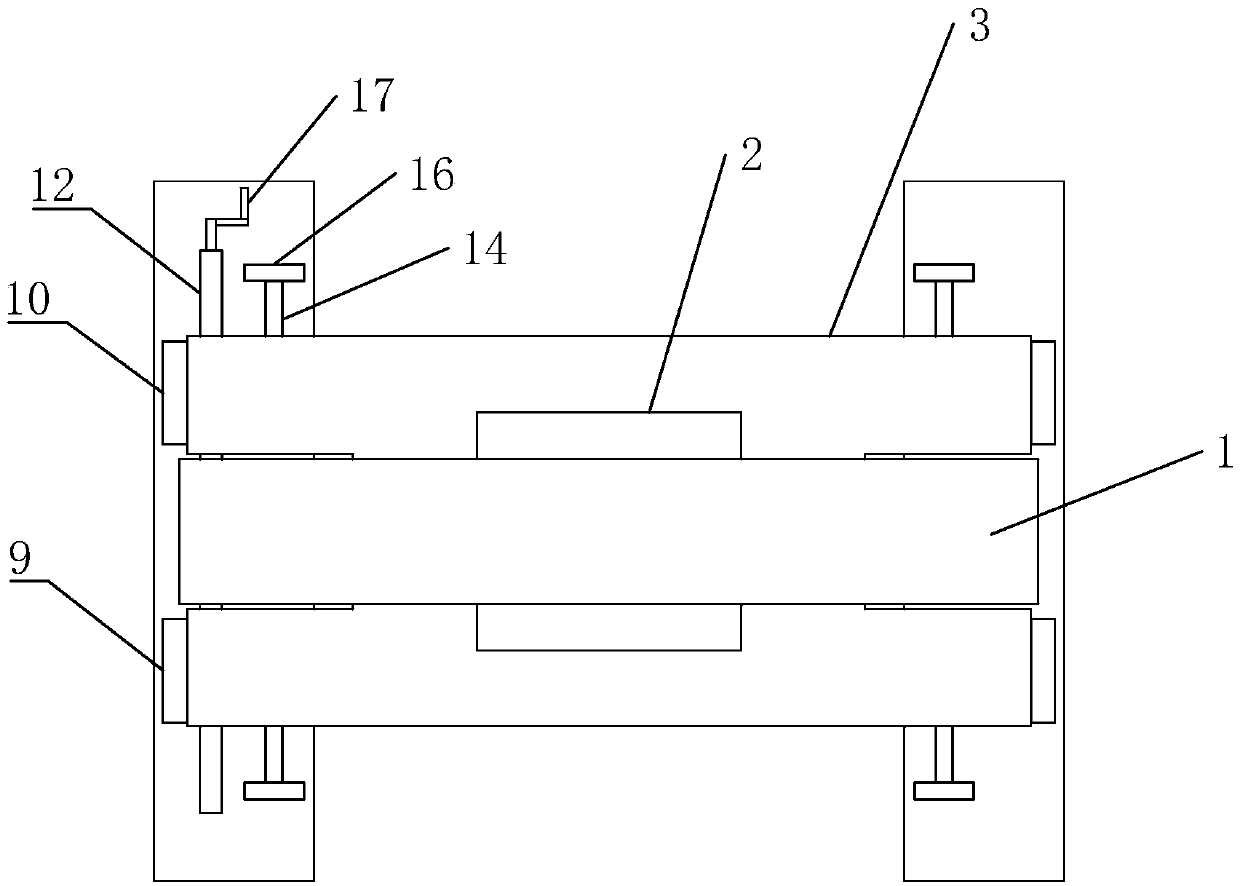

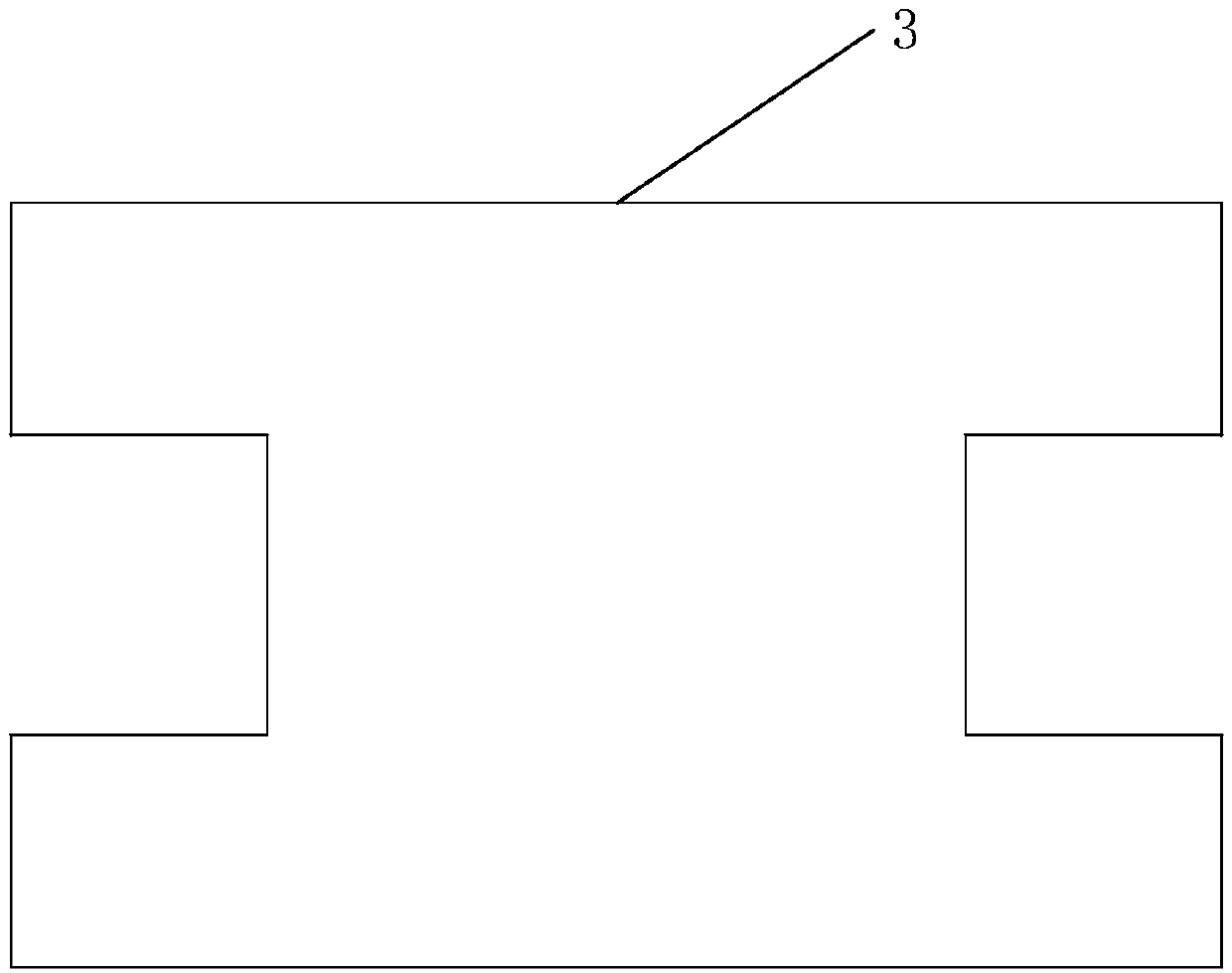

[0020] refer to Figures 1 to 5 As shown, a translational bearing pressing machine for an operation table in this embodiment includes a frame body 1, a push cylinder 2, a sliding plate 3, a fixing plate 4 and a tension spring 5, and the frame body 1 is arranged in a frame shape, and the The push cylinder 2 is arranged on the top of the frame body 1, and the sliding plate 3 is slidably installed between the two vertical support rods of the frame body 1. The bottom of the push cylinder 2 is connected with the slide plate 3 and driven by the push cylinder 2. Sliding plate 3 moves on frame body 1, and described extension spring 5 is provided with two, and two extension springs 5 are symmetrically arranged on sliding plate 3, and extension spring 5 is connected with the top of frame body 1 respectively, and described fixed The plate 4 is arranged on the bottom of the frame body 1, and the sliding plate 3 is arranged in cooperation with the fixed plate 4,

[0021] The fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com