Feeding mechanism of bag making machine

A technology of feeding mechanism and bag making machine, which is applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of affecting the normal progress of feeding, reducing processing efficiency, wasting energy, etc., and reducing friction. The effect of resistance, preventing deviation and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

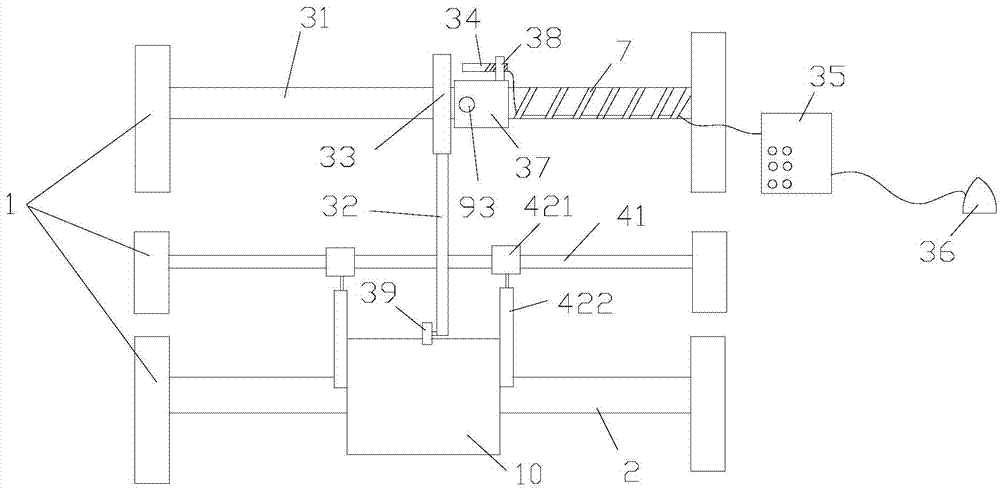

[0029] Such as figure 1 As shown, this embodiment discloses the feeding mechanism of the bag making machine, which includes a frame 1 and a long feeding axis 2 . The long feeding shaft 2 is connected with the frame 1 in rotation, the packaging film 10 is wound on the bobbin (not shown in the figure), and the bobbin is sleeved on the long feeding shaft 2 and passed through the first bolt (not shown in the figure) fixed.

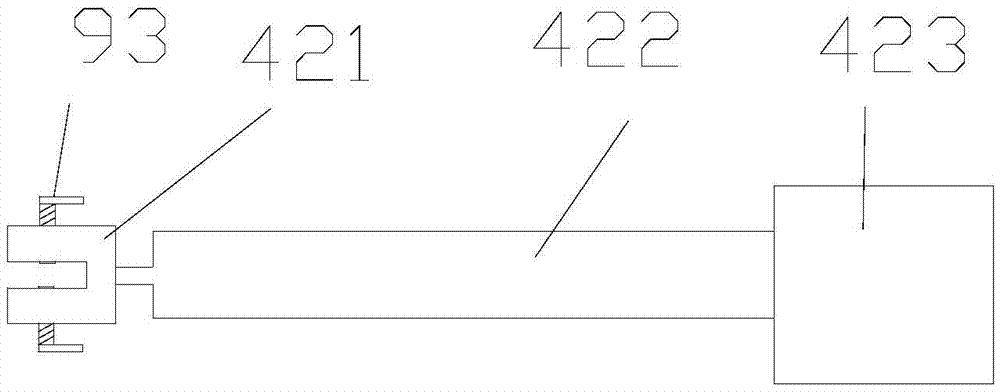

[0030] The feeding mechanism also includes an automatic alarm device and a limit device, and the limit device is used to limit the position of the packaging film 10 .

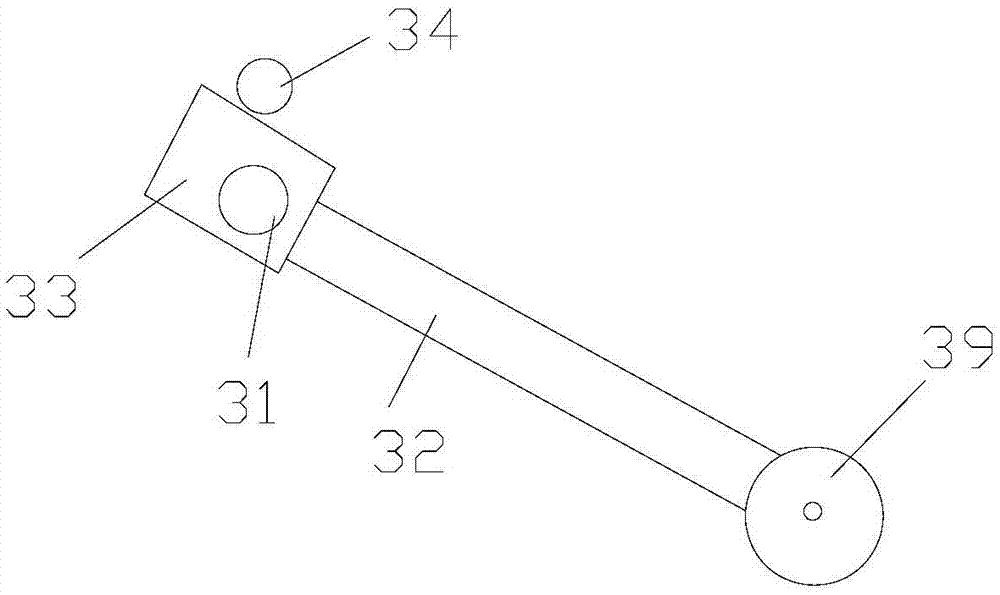

[0031] The automatic alarm device includes a cross bar 31 , a long bar 32 , a block 33 , a proximity switch 34 , a processor 35 and an alarm 36 . The cross bar 31 is positioned at the upper front of the long feeding axis 2 and is placed horizontally on the frame 1 . The stopper 33 is sleeved on the crossbar 31 and is rotatably connected with the crossbar 31. The higher end of the long rod 32...

Embodiment 2

[0043] Such as Figure 5As shown, the difference between this embodiment and Embodiment 1 is that the limiting device includes a limiting frame 6 symmetrically arranged on both sides of the packaging film 10, and the middle part of the limiting frame 6 is sleeved on the long feeding axis 2 and passes through the first Four bolts 94 are fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com